Abstract

The purpose of the current research study was to evaluate the effect of innovation on sustainability along with the mediating role of top management support and the moderating role of Industry 4.0 between innovation and sustainability. The data were collected through a questionnaire-based survey of manufacturing firms in Oman. PLS-SEM was applied to the data collected from 294 top-level and middle-level managers of manufacturing firms in Oman. The study results revealed that innovation is a positive determinant of the sustainability of manufacturing firms in Oman. Innovation was also found to favourably shape top management support in Oman’s manufacturing firms, which, in turn, impacted sustainability positively. The results suggest that top management support acts as a positive mediator between innovation and the sustainability of Omani manufacturing firms. The findings, however, did not support the moderating effects of Industry 4.0 on the association between innovation and sustainability. The present study is expected to support the literature through its rare findings and empirical evidence, especially regarding the mediating role of top management support between innovation and sustainability. It will also help managers of firms in Oman find ways of building their sustainability performance and develop better strategies to cope with sustainability challenges.

1. Introduction

In 2015, the establishment of 17 Sustainable Development Goals (SDGs) created by the United Nations (UN) pointed out the need for businesses to transcend from purely financial performance to a triple bottom line (TBL) perspective containing economic, social, and environmental facets. The SDGs act as a guiding framework for organisations towards ethical and sustainable business practices [1,2]. As a result, companies worldwide continue to feel the heat to gear their corporate strategies toward SDGs, which tackle social inequalities, environmental degradation, and climate change whilst remaining economically viable [1,3,4].

However, a paradox emerges when firms attempt to balance innovation and sustainability. While innovation is widely regarded as a driver of sustainable development, it can also create unintended negative consequences. Financial performance alone can no longer guarantee long-term prosperity. This perspective is essential because sustainability-oriented innovation is a widely researched area among many developed economies. Omani firms operate in an emerging economy, where contextualised barriers lead to the under-adoption of innovative and sustainable practices [5,6,7]. Industrial shifting, digitalisation hurdles, and the demand for active top management support (TMS) can expose these adverse impacts of sustainability initiatives. Additionally, the studies conducted to explore sustainability and innovation phenomena were conducted separately, and an integrative framework guiding the relationship among Industry 4.0, TMS, and sustainability has yet to be studied, especially in the context of Oman’s manufacturing sector.

Along with the pressures of industrial competition and economic sustainability, external disruptions, like the COVID-19 pandemic, have increased the need for Omani firms to build resilience via innovation and technological advancements. Despite these critical aspects, there is little empirical research on how Omani manufacturing firms can strategically use innovation to maintain sustainability. So far, scholars have focused on the effect of innovation on financial performance while neglecting its influence on the other dimensions of sustainability: societal and environmental factors [7].

Innovation has been advocated as one of the most important factors improving sustainability by many previous researchers, e.g., refs. [5,7,8,9]. However, this claim about the role of innovation in providing sustainability remains vague to Omani manufacturing firms due to the lack of sufficient empirical evidence. Researchers have measured the effect of innovation by considering only financial parameters [10]. Some researchers argue that TMS is also associated with organisational innovation [11,12,13]. Nevertheless, the role of TMS in driving sustainability performance has rarely been empirically tested in prior studies, especially in Oman. No proper study in the past literature has examined the path from innovation to the sustainability of Omani manufacturing firms considering the mediating role of TMS. To fill these gaps, this study empirically examines the relationship between innovation (regarding both products and processes) and sustainability performance (economic, social, and environmental) with the mediating effect of TMS and the moderating effect of Industry 4.0. Insights provided by previous studies have been limited by investigating these variables in isolation, and none have thoroughly investigated the interrelationships of these factors in Omani manufacturing firms. This study supplements the previously established innovation-driven paths of firms seizing and navigating the way toward sustainability.

The present research study aims to fill this gap by finding and assessing different factors that can predict or affect the sustainability of Omani firms (e.g., innovation, TMS, and Industry 4.0). This study aims to assess the effect of innovation on sustainability with the mediating effect of TMS and the moderating impact of Industry 4.0. To achieve these objectives, the following research questions were formulated: How does innovation influence Omani manufacturing firms’ sustainability performance (economic, social, and environmental)? What is the mediating role of TMS in the relationship between innovation and sustainability? Furthermore, how does Industry 4.0 moderate the relationship between innovation and sustainability performance?

This study makes the following key contributions:

This study differs from previously conducted ones that focused mainly on financial performance; it evaluates sustainability from economic, social, and environmental dimensions. It examines Industry 4.0 as a moderating factor, providing evidence of the new pathway that technology is taking in the context of sustainability-based innovation.

This study emphasises the importance of leadership since TMS mediates the relationship between innovation and sustainability. By focusing on Oman, we bridge an important gap in the literature on sustainability in the manufacturing sector for the Gulf region through region-specific empirical evidence. By developing a theoretical framework and providing empirical evidence about how firms may translate their innovation and digital transformation (Industry 4.0) goals into sustained sustainability performance, this work adds to both the academic literature and managerial practice.

This paper is structured as follows: we give a critical review of the literature and the development of our hypotheses in Section 2. Section 3 describes the methodology employed to gather and analyse our data. Section 4 explains the study’s results and provides a discussion. Lastly, Section 5 presents some key implications, contributions, and limitations.

2. Theoretical Background and Framework Development

Researchers define sustainability as the ability to meet the needs of the present without compromising the resources needed by future generations [8,14]. Sustainable development goals (SDGs) are key to sustainability, which refer to 17 goals established by the UN in 2015 to end poverty, secure the planet, and safeguard goodwill and opulence for all. SDGs, also recognised as ‘Global Goals’, seek to create an equitable world with more sustainability for the current and coming generations [15,16]. SDGs aim to resolve many environmental, social, and ethical issues by providing a universal target to UN member states that they can use to guide their long-term goals and strategies to secure human well-being [14,17,18]. SDGs raised the need for businesses to monitor and assess their performance in light of the TBL perspective, an accounting framework incorporating three performance measurements, i.e., financial/economic, social, and environmental [1,2,17]. Ref. [2] suggests that the TBL acts as the key to sustainable development by gauging the firm’s performance in terms of profit, people, and planet to achieve sustainability. The literature provides several predictors of sustainability that can directly or indirectly influence sustainability, e.g., innovation, management practices, Industry 4.0, knowledge management, and total quality management [1,8,19,20].

2.1. Innovation and Sustainability

Researchers have considered many factors to analyse the sustainability performance of firms. Generally, researchers use performance measurements to analyse the firm’s abilities [8,10,21]. The literature suggests that firms assess their performances using financial and non-financial variables such as return on investment (ROI), net profit, return on assets (ROA), market share, competitive position, stakeholder satisfaction, and productivity [5,7,10,21,22]. Researchers argue that non-financial variables are as important as financial factors when assessing a firm’s performance because relying on financial factors only and making decisions based on the firm’s financial performance is insufficient to determine the sustainable development and performance of a firm [10,23]. Therefore, sustainability performance is garnering a lot of attention from modern researchers as it depicts the performance and ability of the firm in both financial and non-financial aspects.

Although most studies used financial performance as the key performance measurement indicator in the past while evaluating different predictors of firm performance in recent years, the trend has changed. Now, many researchers evaluate the firm’s performance in terms of sustainability, and all three (financial, social, and environmental) aspects of the performance are evaluated [5,7,10,12,24]. Among different factors predicting performance, innovation has been advocated as one of the most important determinants by researchers because it helps a firm find new ways of conducting business and perform operations that can address financial, social, and environmental concerns [5,7,10,21,25,26]. Previous researchers have signified innovation as the antecedent of financial and environmental performance [21,22]. However, it has been noticed that most researchers have focused on the financial approach while evaluating the effect of innovation practices on firm performance and neglected essential non-financial variables [21,27]. This means there is an obvious need for further empirical studies to assess the effect of innovation on a firm’s sustainability performance.

Another pitfall found in the previous literature is that many researchers have focused on one or two types of innovation while checking the influence of innovation on performance and have neglected other innovation types, such as process innovation, market innovation, and management innovation [28,29]. The impact on the sustainability performance of SMEs in Malaysia caused by innovation while focusing on market innovation has also been investigated. The initial idea of innovation suggests that innovation refers to the innovative processes, elements of individuality, new products, research development, and the progression of terminologies [30]. This means that innovation is not only about the product or process but must be incorporated within the firm’s systems, management, and other practices. Therefore, innovation needs to be studied from different aspects, such as product, process, market, and organisational aspects, to examine the firm’s innovativeness in all manners.

Given the importance of innovation and its different types, researchers in recent years have focused on different innovation types while checking the influence of innovation on performance [31]. Some have examined the influence of different innovation types on the performance of SMEs and found a significant association between innovation and performance [27]. Others suggest that innovation positively affects the financial performance of manufacturing firms in Turkey [26]. The role of innovation in improving the sustainability performance of SMEs in the UK has also been evaluated, revealing that sustainably oriented innovation is a strong predictor of sustainability performance [32]. Again, the positive role of green innovation in shaping sustainability performance in the context of the Malaysian hotel industry was advocated for.

Similarly, several prior researchers have emphasised innovation’s positive effect on sustainability [33,34,35,36]. However, the combined effect of all four types of innovation on sustainability performance has been rarely analysed in past studies. Therefore, using the combined effect of four types of innovation, the current study hypothesises the following:

H1.

Innovation has a significant positive effect on a firm’s sustainability performance.

2.2. Role of Top Management Support in Innovation and Sustainability

Researchers have suggested that innovation promotes a firm’s sustainability performance and results in various positive outcomes, e.g., continuous improvement practices, process management, and competitive advantage [27,37,38]. An important factor that has been largely ignored in previous studies while assessing innovation–sustainability models is top management support (TMS). TMS is essential for improving innovation-oriented sustainability performance [21,27]. When an organisation adopts any strategic approach, it has to mobilise its top management, which can, in turn, help the firm achieve the end outcomes of that approach. Ref. [21] suggests that when a firm adopts a customer-oriented strategy, it needs to mobilise its resources, such as management and people, in such a way that they support the customer-oriented approach to address the core needs of their customers and enhance the firm’s financial performance. This is similar to innovation strategies, which also strongly require TMS.

Ref. [27] suggests that TMS needs to be developed in an organisation in order to promote a culture of innovation throughout the organisation. When employees feel that their top management and leadership support innovation, they are more likely to develop creative and innovative ideas to improve the firm’s financial and non-financial performance [27]. It also argued that innovation requires taking risks, so the willingness of top management to take risks is needed to convert innovations into financial or non-financial contributions for the firm. Hence, the current study argues that when an organisation adopts an innovation approach, it needs to mobilise its top management and increase TMS to promote innovation and performance. This means that innovation tends to influence TMS. This seems to be a two-way process, but no past study has considered and examined this process in such a manner. Many past studies have determined and proven the positive association between TMS and innovation [11,39,40]. They have suggested the importance of TMS for enhancing the innovation culture in an organisation and achieving innovation goals. When a firm applies new systems and innovative management procedures, it encourages people to show a high degree of willingness and support towards the system to strive for innovation and sustainability smoothly. However, this claim of the current study does not receive any further support from the literature, so it needs to be tested through empirical data.

H2.

Innovation has a significant positive effect on the TMS of the firm.

Once top management becomes willing and supportive of innovation practices, they will provide all the necessary resources to achieve the innovation goals [27]. This suggests that top management should support innovation activities throughout the management and organisation. Researchers emphasise that when a firm’s top management shows support and willingness towards innovative ideas and procedures, the firm is likely to grow and perform better. The resource-based view (RBV) also supports the viewpoint that a firm can build and enhance its ability and performance by using its resources (e.g., management and people) in the best and most efficient way [21,41,42]. Ref. [42] suggests that TMS positively influences a firm’s performance.

Similarly, many prior researchers have advocated for the role of top management and the support they provide for innovation [21,43]. It can be said that innovation derives from TMS, which in turn supports the sustainability performance of a firm. However, very few studies directly evaluate how TMS supports sustainability performance. Furthermore, no past study has explained the possible mediating role of TMS in innovation and sustainability performance. To overcome this gap, the present study wants to test the following hypotheses:

H3.

TMS has a significant positive effect on a firm’s sustainability performance.

H4.

TMS significantly positively mediates the association between innovation and the sustainability performance of firms.

2.3. Role of Industry 4.0 Between Innovation and Sustainability

Industry 4.0 refers to incorporating modern intelligent digital technologies and innovation into industrial and business processes. It comprises a set of technologies integrated into manufacturing and other industrial processes, such as industrial IoT networks, big data, automated technology, artificial intelligence (AI), and robotics [2,44,45]. In recent years, many researchers have attempted to examine the influence of Industry 4.0 on organisational performance and sustainability, given the great Industrial Revolution. According to scholars, modern technologies incorporated into businesses derived from the Industrial Revolution help implement automated operations in more efficient and environmentally friendly ways [44,46,47]. This means that the Industrial Revolution positively impacted the TBL performance of firms.

Some researchers have advocated for the direct influence of Industry 4.0 on sustainability performance [2,44,45,47,48]. Some claim that the Industrial Revolution caused a positive moderating effect on firm performance [49,50]. Based on these studies, the current study claims that Industry 4.0 moderates the impact of innovation on sustainability performance. However, this claim does not receive enough support from the existing literature as the moderating effect of Industry 4.0 between innovation and sustainability has been very rarely investigated, especially in the context of Omani manufacturing firms. Given the above discussion and the prevailing gap in the literature, the following hypothesis is formulated:

H5.

Industry 4.0 significantly moderates innovation’s effect on sustainability performance.

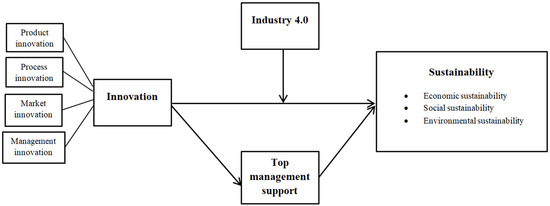

The Framework Development of this research is presented in Figure 1.

Figure 1.

Framework of study.

3. Methodology

3.1. Population, Sampling, and Data Collection

The present study was conducted as a survey of manufacturing firms in Oman to assess the effect of innovation on their sustainability, along with the mediating role of TMS between innovation and sustainability and the moderating influence of Industry 4.0 on the innovation–sustainability relationship. Therefore, Oman’s manufacturing firms made up the target population of this study to meet the research purpose. The sample was selected using a non-probability purposive sampling technique to ensure that participants had relevant knowledge of the study variables. Since innovation, sustainability practices, and Industry 4.0 integration are strategic-level decisions, top-level and middle-level managers were chosen as respondents as they possess the expertise to provide informed insights.

The sample size was determined following the procedure of [51], which recommends a minimum of ten times the number of items in the measurement model for structural equation modelling (SEM) analysis. Since the current study’s measurement model comprised 27 items, the minimum required sample size was 270 responses. To account for potential invalid, missing, or incomplete responses, this study targeted 300 participants. The data were collected via an online questionnaire, sent to managers through email and other digital platforms, followed by telephonic and email reminders to improve the response rate. However, since this study relies entirely on self-reported responses, response bias is possible. Managers may unintentionally overestimate their firms’ innovation efforts and sustainability achievements due to company interests or social desirability bias. This is a known challenge in survey-based research, where respondents may feel compelled to provide socially acceptable or strategically favourable answers.

To mitigate this limitation and improve data validity, future research could incorporate additional verification methods, such as cross-referencing survey responses with publicly available financial or sustainability reports of manufacturing firms, using third-party industry benchmarks or government reports to validate firm-level innovation and sustainability claims. A limitation of this study is that the extent to which firms have implemented Industry 4.0 was not specifically assessed. While its moderating effect was analysed, differences in adoption levels might have influenced the findings. Future research could categorise firms based on their Industry 4.0 adoption stages to gain deeper insights into their role in sustainability performance.

Future research would also benefit from conducting follow-up qualitative interviews with selected managers to gain deeper insights and validate the survey findings. Triangulating the results with secondary data sources, such as case studies or independent industry evaluations, would also help.

3.2. Study Instrument

The primary research instrument was a structured questionnaire consisting of 27 items designed to measure key study variables. All measurement scales were adapted from validated prior research to ensure reliability.

Innovation was assessed as a multidimensional construct, including product, process, market, and management innovation.

- Product innovation: 3 items from [52].

- Process innovation: 3 items from [52].

- Market innovation: 3 items from [52], also used in [27].

- Management innovation: 3 items from [53].

Sustainability was measured across three dimensions (economic, social, and environmental) using scales from [54], with three items per dimension. TMS was measured using a three-item scale previously validated by [27,52]. Industry 4.0 adoption was measured using a three-item scale from [54]. All items were rated using a five-point Likert scale (1 = Strongly Disagree, 5 = Strongly Agree). Appendix A includes the complete survey questionnaire and instructions provided to respondents for transparency and reproducibility.

4. Analysis and Results

The data collected through the methods mentioned above and procedures came in the form of quantifiable responses, which were put into Smart PLS to run structural equation modelling (SEM). Before running PLS-SEM, the data were analysed in terms of their reliability, validity, and adequacy through different statistical tests in the following ways:

4.1. Demographic Characteristics of Respondents

The analysis was performed with 294 valid responses after eliminating missing, invalid, and blank responses. Most of the responses (i.e., 88.1%) came from male respondents, while only 11.9% of responses belonged to female respondents. This indicates that the proportion of male managers in Omani manufacturing firms is far higher than that of female managers. Therefore, it can be said that the findings of this research tend to be more pertinent to male managers of Omani manufacturing firms. Furthermore, the present study showed that most of the managers associated with this study as respondents were young (i.e., 25–35 years or less than 25 years).

The proportion of master’s degree holders among the respondents of this study was the highest (i.e., 40.1%), followed by graduation (i.e., 27.2%) and professional qualifications (i.e., 25.9%). This indicates that most managers of Omani manufacturing firms are well educated and qualified. Furthermore, estimates about the experience of responding managers in the current study show that almost half of the respondents had work experience of 5–10 years, while some (i.e., 31.6%) respondents had experience of 10–15 years. Hence, it can be said that the current study’s data came from expert managing bodies of Omani manufacturing firms. Furthermore, it is evident from Table 1 that the current data come from managers of different sizes of companies, i.e., small, medium, and large companies, so it can be said that this is a good mix of all-sized firms, and the current findings could be pertinent to Omani manufacturing firms of all sizes.

Table 1.

Demographic profile of respondents.

4.2. Reliability, Validity, and Model Fit

Before assessing the hypotheses of the present research, the data needed to be evaluated regarding its reliability, multicollinearity, and validity. Therefore, relevant statistical tests were applied to ensure the appropriateness of the data and measurement model in these matters. The factor loadings of all items of the currently studied variables are illustrated in Table 2.

Table 2.

Factor loading and multicollinearity.

Table 2 indicates that the factor loadings of all currently studied items are definitely >0.7, which implies that an observed variable is intensely connected to the respective items/factors. The multicollinearity issue was assessed by computing the variance inflation factors (VIFs) of all items (as indicated in Table 2). The VIF of all items was <5, which indicated that the current data had no multicollinearity, as per the guidelines [55].

The decision about the reliability of the data used by the present research was made using the indicator of composite reliability (CR) because it is considered an enhanced and unbiased sign of reliability compared to Cronbach’s alpha [56]. It is indicated in Table 3 that the CR of all studied variables exceeds 0.7, depicting that the specific item used for measuring the respective variable perfectly measures that particular variable. Hence, the reliability of the current data was confirmed. For assessing the convergent validity, the AVE of all the variables was assessed (as indicated in Table 3), which was >0.5 for all the studied variables, so it was proved that the current data on the studied variables showed good constructs and convergent validity, as per guidelines of [55].

Table 3.

Reliability and convergent validity.

The current data were also found to show excellent discriminant validity because the HTMT for all distinct variables of this study was <0.85 (see Table 4), as per the guidelines given by the authors of [55]. According to them, the HTMT of two theoretically distinct variables should not exceed 0.85. Hence, it was proven that each studied variable of this study showed the highest correlation with itself in comparison to all correlations with other variables. This means that all theoretically distinct variables in this study were discriminating from each other. Table 5 indicates the model fitness in the current data through model fit indicators.

Table 4.

Discriminant validity (HTMT).

Table 5.

LV predict summary and model fit.

Table 5 depicts that the observed model shows an SRMR less than 0.1 and an NFI near 1, which depicts the model’s good fitness.

4.3. Hypothesis Testing

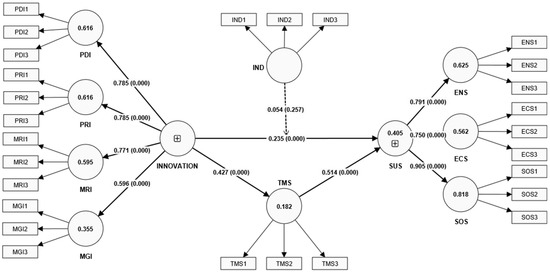

The results of PLS-SEM revealed that innovation showed a significant positive impact on sustainability (p-value < 0.05). They indicate that innovation caused a significant positive effect on sustainability, with a 95% confidence interval (see Table 6). This means there was a 23.5% increase followed by a unitary increase in innovation and sustainability. The impact of innovation on TMS was also found to be significant and positive at the 95% confidence interval (p-value < 0.05). This finding showed that the increase in innovation caused TMS to increase by 42.7%, which is a powerful positive effect (see Table 6). The impact of TMS on sustainability was also found to be significant and positive (p-value < 0.05), which showed that the increase in TMS was followed by an increase of 51.4% in sustainability, which is also a strong positive effect. These findings proved that all direct hypothetical paths of the present study were true.

Table 6.

Hypotheses testing (PLS-SEM).

The mediated path from innovation to sustainability was also analysed, which showed that TMS acts as a significant and positive mediator between innovation and sustainability because the p-value of this mediated path was <0.05 (see Table 6). This indicates that an improvement in innovation leads to increased TMS, which significantly enhances the firm’s sustainability. The hypotheses test results further indicated that Industry 4.0 did not significantly moderate the effect of innovation on sustainability (p-value > 0.05). The results did not support the moderating effect of Industry 4.0 on the relationship between innovation and sustainability. Figure 2 shows the summary of the structural model of this research.

Figure 2.

Structural model. Note: ECS = economic sustainability, ENS = environmental sustainability, SOS = social sustainability, IND = Industry 4.0, PDI = product innovation, PRI = process innovation, MGI = management innovation, MRI = market innovation, TMS = top management support, SUS = sustainability.

5. Discussion of Results

This study evaluated the influence of innovation on the firm’s sustainability performance by collecting data from people managing Omani manufacturing firms. The findings of this study show that innovation is a significant positive predictor of the sustainability performance of manufacturing firms in Oman. They confirmed H1 of this study and suggested that when Oman manufacturing firms adopt and improve innovation practices, they will likely enhance their sustainability performance. These results support various prior findings such as those of [22,26,27,28,29,31,32,33] that declare innovation and its different types as predictors of different types of firm performances.

The present study also declared innovation as the positive predictor of TMS, which confirmed H2 of this study. It was found that Oman manufacturing firms improving their innovation practices are likely to mobilise and enhance their TMS. These results were consistent with the guidelines of the previous literature, such as those of the study of [27], which discussed a close linkage between TMS and innovation. However, being a rarely studied phenomenon, the relationship between innovation and TMS receives little theoretical support from the literature. The current study further revealed that TMS was a positive predictor of sustainability, which confirmed H3 of this study. It was found that Oman manufacturing firms with high TMS are very likely to enhance their sustainability performance. The results of the present study were again in line with the previous literature (e.g., RBV) and existing findings such as those of [21,27,42,43], which advocate for the importance of management support in enhancing a firm’s performance.

Another finding of the present research suggested that TMS acts as a significant and positive mediator between innovation and sustainability. It confirmed H4 of this study and suggested that if Oman manufacturing firms enhance their product, management, process, and market innovation, they are likely to enhance their TMS, which improves their sustainability. These findings, though new, were found to have reasonable theoretical grounds because the linkage existing between innovation and TMS and between TMS and firm performance has been discussed in different past studies such as [21,27,42,43].

The last hypothesis of this study, i.e., H5, was rejected because no significant moderating impact of Industry 4.0 was found on the relationship between innovation and sustainability. These findings contradicted the findings of several prior studies that supported and advocated for the direct or moderating connection of Industry 4.0 with firm performance [45,47,49,50]. The contradiction of the current findings with past ones may be attributed to the variance of contexts between these studies. This means that Industry 4.0 might not significantly impact the sustainability performance of manufacturing firms in Oman because past studies have never assessed the moderating effect of Industry 4.0 on innovation and sustainability in this particular context.

6. Conclusions and Implications

This study examined the impact of innovation on sustainability performance, the mediating role of TMS, and the moderating role of Industry 4.0 in Omani manufacturing firms. The data were collected from managerial-level respondents and analysed using PLS-SEM to derive empirical insights. The findings confirm that innovation significantly enhances sustainability performance, encompassing economic, social, and environmental dimensions. Moreover, this study establishes that TMS plays a crucial mediating role in this relationship, reinforcing that strong managerial support amplifies the benefits of innovation on sustainability. However, Industry 4.0 was found to have no significant moderating impact on the sustainability outcomes driven by innovation. Beyond these findings, this study contributes theoretically and practically to the ongoing discourse on sustainability in manufacturing. The following sections delineate the specific contributions of this research to academic knowledge and practical applications.

7. Theoretical Implications

This study makes several key theoretical contributions to the literature on innovation, sustainability, and strategic management:

First, this research study is one of the first empirical investigations into the mediating role of TMS in the innovation–sustainability relationship, particularly in the context of Omani manufacturing firms. While prior studies have explored the direct impact of innovation on sustainability, this study extends existing knowledge by revealing how managerial support acts as a crucial mechanism driving sustainability outcomes.

Second, this study enriches the resource-based view (RBV) theory by providing empirical evidence on how manufacturing firms in Oman leverage their resources (such as innovation and managerial capabilities) to enhance sustainability performance. This aligns with the RBV perspective, emphasising that a firm’s internal capabilities determine its competitive advantage.

Third, this study addresses a critical research gap by providing an empirical validation of innovation’s effect on sustainability performance across three dimensions—economic, social, and environmental. Unlike previous studies focusing on financial outcomes, this study offers a more holistic sustainability assessment.

Finally, the unexpected finding that Industry 4.0 did not significantly moderate the innovation–sustainability relationship raises important questions for future research. This suggests that the effectiveness of Industry 4.0 technologies may be contingent on sector-specific factors or organisational readiness, which future studies should further explore through comparative analyses.

8. Practical Implications

The findings of this study also offer valuable insights for industry leaders, policymakers, and corporate strategists aiming to enhance sustainability in manufacturing firms.

This study highlights that innovation alone is not enough to ensure sustainability; firms must also mobilise strong TMS to realise the benefits of innovation fully. Managers should focus on cultivating a culture of leadership that actively promotes and integrates innovation into sustainability strategies to maximise long-term success. Developing structured innovation strategies that align with sustainability goals can enhance firm performance across economic, social, and environmental dimensions.

This study’s findings underscore the need for policies encouraging leadership-driven innovation adoption in manufacturing firms. Government agencies and industry regulators can be pivotal in designing support programmes, incentives, or training initiatives that strengthen managerial capabilities in sustainability-driven innovation. Since Industry 4.0 did not significantly moderate the innovation–sustainability relationship, policymakers should conduct further sector-specific assessments before heavily investing in digital transformation strategies for sustainability improvement. The results can also guide Omani economic policymakers in shaping regulations and industrial policies that incentivise innovation while ensuring sustainable growth in the manufacturing sector

Author Contributions

Conceptualization, S.J. and U.A.-M.; Software, S.J.; Formal analysis, S.J.; Resources, U.A.-M.; Data curation, S.J.; Writing—original draft, S.J.; Writing—review & editing, U.A.-M.; Visualization, U.A.-M.; Supervision, U.A.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Higher Education, Research and Innovation (MoHERI) of the Sultanate of Oman under: MoHERI/BFP/SU/2022. SU Ref: SU/BFP/RG/2022.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Questionnaire

Dear Sir/Madam,

I am researcher from Department of Accounting and finance, Sohar University, Oman conducting a study titled “Navigating the Innovation-Sustainability Paradox: The Strategic Role of Leadership and Industry 4.0 in Oman’s Manufacturing Sector”. The purpose of this questionnaire is to collect valuable feedback from participants like you to support this research and enhance its findings.

Your participation in this study is entirely voluntary, and you are free to withdraw at any stage without any obligation. I assure you that all information provided will remain strictly confidential, and the data will only be used for academic purposes in an anonymous form. This ensures that individual responses cannot be identified. By completing this questionnaire, you are indicating your willingness to participate in the study. I deeply appreciate your time, effort, and honest feedback, as it will play a significant role in advancing our understanding of this important subject.

Sincerely,

--------------------------------------------------------------------------------------------------------------------

Section A: Respondents Profile

Gender

- ○

- Male

- ○

- Female

Age

- ○

- Less than 25 Years

- ○

- 26 to 30 Years

- ○

- 31 to 35 years

- ○

- More than 35 Years

Experience

- ○

- Less than 2 Years

- ○

- 2 to 5 Years

- ○

- 5 to 8 years

- ○

- More than 8 Years

Marital Status

- ○

- Single

- ○

- Married

Education

- ○

- Intermediate

- ○

- Graduation

- ○

- Master

- ○

- Other

---------------------------------------------------------------------------------------------------------------------

Detail of Rating Scale

| 1 | 2 | 3 | 4 | 5 |

| Strongly Disagree | Disagree | Natural | Agree | Strongly Agree |

| Please indicate the extent of your agreement with the following statement on a 5-point scale about Product Innovation | |||||

| Increasing manufacturing quality in components and materials of current products. | 1 | 2 | 3 | 4 | 5 |

| Decreasing manufacturing cost in components and materials of current products | 1 | 2 | 3 | 4 | 5 |

| Developing newness for current products leading to improved ease of use for customers and to improved customer satisfaction. | 1 | 2 | 3 | 4 | 5 |

| Please indicate the extent of your agreement with the following statement on a 5-point scale about Process Innovation | |||||

| Decreasing variable cost components in manufacturing processes, techniques, machinery and software. | 1 | 2 | 3 | 4 | 5 |

| Determining and eliminating non-value adding activities in delivery related processes. | 1 | 2 | 3 | 4 | 5 |

| Cost innovations in all type of processes | 1 | 2 | 3 | 4 | 5 |

| Please indicate the extent of your agreement with the following statement on a 5-point scale about Marketing Innovation | |||||

| Renewing the design of the current and/or new products through changes such as in appearance, packaging, shape and volume without changing their basic technical and functional features. | 1 | 2 | 3 | 4 | 5 |

| Renewing the distribution channels without changing the logistics processes related to the delivery of the product. | 1 | 2 | 3 | 4 | 5 |

| Renewing the product promotion techniques employed for the promotion of the current and/or new products. | 1 | 2 | 3 | 4 | 5 |

| Please indicate the extent of your agreement with the following statement on a 5-point scale about Management Innovation | |||||

| We regularly make changes to our employees’. tasks and functions. | 1 | 2 | 3 | 4 | 5 |

| Our organization regularly implements new management systems. | 1 | 2 | 3 | 4 | 5 |

| The policy with regard to compensation has been changed with a certain time period. | 1 | 2 | 3 | 4 | 5 |

| Please indicate the extent of your agreement with the following statement on a 5-point scale about Top Management Support | |||||

| In our company the development of new andinnovative ideas are encouraged | 1 | 2 | 3 | 4 | 5 |

| Upper management is aware and very receptive to ideas and suggestions. | 1 | 2 | 3 | 4 | 5 |

| Developing one’s own ideas is encouraged for the improvement of the corporation. | 1 | 2 | 3 | 4 | 5 |

| Please indicate the extent of your agreement with the following statement on a 5-point scale about Economic Sustainability | |||||

| Our company has improved Profits | 1 | 2 | 3 | 4 | 5 |

| Our company has improved turnover | 1 | 2 | 3 | 4 | 5 |

| Our company has improved Market share | 1 | 2 | 3 | 4 | 5 |

| Please indicate the extent of your agreement with the following statement on a 5-point scale about Environmental Sustainability | |||||

| Our company has improved Energy consumption | 1 | 2 | 3 | 4 | 5 |

| Our company has improved Circular economy | 1 | 2 | 3 | 4 | 5 |

| Our company has improved practices with partners | 1 | 2 | 3 | 4 | 5 |

| Please indicate the extent of your agreement with the following statement on a 5-point scale about Social Performance | |||||

| Our company has improved or enhanced Salary remuneration | 1 | 2 | 3 | 4 | 5 |

| Our company has improved the Work conditions | 1 | 2 | 3 | 4 | 5 |

| Our company has improved Surrounding society | 1 | 2 | 3 | 4 | 5 |

Thank You

References

- Khan, I.S.; Ahmad, M.O.; Majava, J. Industry 4.0 and sustainable development: A systematic mapping of triple bottom line, circular economy and sustainable business models perspectives. J. Clean. Prod. 2021, 297, 126655. [Google Scholar] [CrossRef]

- Nogueira, E.; Gomes, S.; Lopes, J.M. The key to sustainable economic development: A triple bottom line approach. Resources 2022, 11, 46. [Google Scholar] [CrossRef]

- Ahmed, N.; Li, C.; Khan, A.; Qalati, S.A.; Naz, S.; Rana, F. Purchase intention toward organic food among young consumers using theory of planned behavior: Role of environmental concerns and environmental awareness. J. Environ. Plan. Manag. 2021, 64, 796–822. [Google Scholar] [CrossRef]

- Garg, A.; Goel, P.; Sharma, A.; Rana, N.P. As you sow, so shall you reap: Assessing drivers of socially responsible investment attitude and intention. Technol. Forecast. Soc. Change 2022, 184, 122030. [Google Scholar] [CrossRef]

- Imran, R.; Alraja, M.N.; Khashab, B. Sustainability Performance and green innovation: Green human resources management and big data as antecedents. IEEE Trans. Eng. Manag. 2021, 70, 4191–4206. [Google Scholar] [CrossRef]

- Janik, B.; Maruszewska, K. Sustainable investments in Western European countries: A multidimensional approach. Fluxos E Riscos Rev. Estud. Sociais 2019, 5, 35–46. [Google Scholar]

- Alraja, M.N.; Imran, R.; Khashab, B.M.; Shah, M. Technological innovation, sustainable green practices and SMEs’ Sustainability Performance in times of crisis (COVID-19 pandemic). Inf. Syst. Front. 2022, 24, 1081–1105. [Google Scholar] [CrossRef]

- Hanaysha, J.R.; Al-Shaikh, M.E.; Joghee, S.; Alzoubi, H.M. Impact of innovation capabilities on business sustainability in small and medium enterprises. FIIB Bus. Rev. 2022, 11, 67–78. [Google Scholar] [CrossRef]

- Omri, A. Technological innovation and sustainable development: Does the stage of development matter? Environ. Impact Assess. Rev. 2020, 83, 106398. [Google Scholar] [CrossRef]

- Asad, M.; Rizwan, A.; Shah, M.; Munir, A. Impact of innovation practices on Sustainability Performance SMEs. Her. Natl. Acad. Manag. Staff Cult. Arts 2018, 3, 537–546. [Google Scholar]

- Hsu, H.-Y.; Liu, F.-H.; Tsou, H.-T.; Chen, L.-J. Openness of technology adoption, top management support and service innovation: A social innovation perspective. J. Bus. Ind. Mark. 2019, 34, 575–590. [Google Scholar] [CrossRef]

- Shahab, Y.; Ntim, C.G.; Chen, Y.; Ullah, F.; Li, H.X.; Ye, Z. Chief executive officer attributes, Sustainability Performance, environmental performance, and environmental reporting: New insights from the upper echelons perspective. Bus. Strategy Environ. 2020, 29, 1–16. [Google Scholar] [CrossRef]

- Swink, M. Technological innovativeness as a moderator of new product design integration and top management support. J. Prod. Innov. Manag. 2000, 17, 208–220. [Google Scholar] [CrossRef]

- Sachs, J.D.; Schmidt-Traub, G.; Mazzucato, M.; Messner, D.; Nakicenovic, N.; Rockström, J. Six transformations to achieve the sustainable development goals. Nat. Sustain. 2019, 2, 805–814. [Google Scholar] [CrossRef]

- Bali Swain, R.; Yang-Wallentin, F. Achieving sustainable development goals: Predicaments and strategies. Int. J. Sustain. Dev. World Ecol. 2020, 27, 96–106. [Google Scholar] [CrossRef]

- Thanki, H.; Shah, S.; Rathod, H.S.; Oza, A.D.; Burduhos-Nergis, D.D. I am ready to invest in socially responsible investments (SRI) options only if the returns are not compromised: Individual investors’ intentions toward SRI. Sustainability 2022, 14, 11377. [Google Scholar] [CrossRef]

- Gu, W.; Wang, J.; Hua, X.; Liu, Z. Entrepreneurship and high-quality economic development: Based on the triple bottom line of sustainable development. Int. Entrep. Manag. J. 2021, 17, 1–27. [Google Scholar] [CrossRef]

- Wanadjaja, T.L.; Samputra, P.L. Examining tri hita karana as the critic to the triple bottom line of sustainable development. IOP Conf. Ser. Earth Environ. Sci. 2021, 716, 012121. [Google Scholar] [CrossRef]

- Govindan, K.; Azevedo, S.G.; Carvalho, H.; Cruz-Machado, V. Impact of supply chain management practices on sustainability. J. Clean. Prod. 2014, 85, 212–225. [Google Scholar] [CrossRef]

- Ramus, C.A. Organisational support for employees: Encouraging creative ideas for environmental sustainability. Calif. Manag. Rev. 2001, 43, 85–105. [Google Scholar] [CrossRef]

- Chaudhry, N.I.; Aftab, I.; Arif, Z.; Tariq, U.; Roomi, M.A. Impact of customer-oriented strategy on financial performance with mediating role of HRM and innovation capability. Pers. Rev. 2019, 48, 631–643. [Google Scholar] [CrossRef]

- Zhou, Y.; Agyemang, A.O.; Adam, I.O.; Twum, A.K. Assessing the impact of technological innovation on environmental and financial performance of Chinese textile manufacturing companies. Int. J. Technol. Policy Manag. 2022, 22, 369–393. [Google Scholar] [CrossRef]

- Fauzi, H.; Svensson, G.; Rahman, A.A. “Triple bottom line” as “Sustainable corporate performance”: A proposition for the future. Sustainability 2010, 2, 1345–1360. [Google Scholar] [CrossRef]

- Marzouk, J.; El Ebrashi, R. The interplay among green absorptive capacity, green entrepreneurial, and learning orientations and their effect on triple bottom line performance. Bus. Strategy Environ. 2024, 33, 1962–1976. [Google Scholar] [CrossRef]

- De, D.; Chowdhury, S.; Dey, P.K.; Ghosh, S.K. Impact of lean and sustainability-oriented innovation on sustainability performance of small and medium-sized enterprises: A data envelopment analysis-based framework. Int. J. Prod. Econ. 2020, 219, 416–430. [Google Scholar] [CrossRef]

- Dey, P.K.; Malesios, C.; De, D.; Chowdhury, S.; Abdelaziz, F.B. The impact of lean management practices and sustainably-oriented innovation on sustainability performance of small and medium-sized enterprises: Empirical evidence from the UK. Br. J. Manag. 2020, 31, 141–161. [Google Scholar] [CrossRef]

- Beyhan Yasar, N.; Sezen, B.; Karakadilar, I.S. Mediating effect of continuous improvement on the relationship between innovation and financial performance. Total Qual. Manag. Bus. Excell. 2019, 30, 893–907. [Google Scholar] [CrossRef]

- Bakar LJ, A.; Ahmad, H. Assessing the relationship between firm resources and product innovation performance: A resource-based view. Bus. Process Manag. J. 2010, 16, 420–435. [Google Scholar] [CrossRef]

- Rosli, M.M.; Sidek, S. The impact of innovation on the performance of small and medium manufacturing enterprises: Evidence from Malaysia. J. Innov. Manag. Small Medium Enterp. 2013, 2013, 885666. [Google Scholar] [CrossRef]

- Lumpkin, G.T.; Dess, G.G. Linking two dimensions of entrepreneurial orientation to firm performance: The moderating role of environment and industry life cycle. J. Bus. Ventur. 2001, 16, 429–451. [Google Scholar] [CrossRef]

- Boachie-Mensah, F.; Acquah, I.S. The effect of innovation types on the performance of small and medium-sized enterprises in the Sekondi-Takoradi Metropolis. Arch. Bus. Res. 2015, 3, 77–98. [Google Scholar] [CrossRef]

- Asadi, S.; Pourhashemi, S.O.; Nilashi, M.; Abdullah, R.; Samad, S.; Yadegaridehkordi, E.; Razali, N.S. Investigating influence of green innovation on sustainability performance: A case on Malaysian hotel industry. J. Clean. Prod. 2020, 258, 120860. [Google Scholar] [CrossRef]

- Jum’a, L.; Zimon, D.; Madzik, P. Impact of big data technological and personal capabilities on Sustainability Performance on Jordanian manufacturing companies: The mediating role of innovation. J. Enterp. Inf. Manag. 2024, 37, 329–354. [Google Scholar] [CrossRef]

- Kuzma, E.; Padilha, L.S.; Sehnem, S.; Julkovski, D.J.; Roman, D.J. The relationship between innovation and sustainability: A meta-analytic study. J. Clean. Prod. 2020, 259, 120745. [Google Scholar] [CrossRef]

- Shahzad, M.; Qu, Y.; Zafar, A.U.; Rehman, S.U.; Islam, T. Exploring the influence of knowledge management process on corporate Sustainability Performance through green innovation. J. Knowl. Manag. 2020, 24, 2079–2106. [Google Scholar] [CrossRef]

- Xu, J.; Yu, Y.; Zhang, M.; Zhang, J.Z. Impacts of digital transformation on eco-innovation and Sustainability Performance: Evidence from Chinese manufacturing companies. J. Clean. Prod. 2023, 393, 136278. [Google Scholar] [CrossRef]

- Distanont, A. The role of innovation in creating a competitive advantage. Kasetsart J. Soc. Sci. 2020, 41, 15–21. [Google Scholar] [CrossRef]

- Obeidat, U.; Obeidat, B.; Alrowwad, A.; Alshurideh, M.; Masadeh, R.; Abuhashesh, M. The effect of intellectual capital on competitive advantage: The mediating role of innovation. Manag. Sci. Lett. 2021, 11, 1331–1344. [Google Scholar] [CrossRef]

- Al Shaar, E.M.; Khattab, S.A.; Alkaied, R.N.; Manna, A.Q. The effect of top management support on innovation: The mediating role of synergy between organisational structure and information technology. Int. Rev. Manag. Bus. Res. 2015, 4, 499. [Google Scholar]

- Yu, C.; Wang, Y.; Li, T.; Lin, C. Do top management teams’ expectations and support drive management innovation in small and medium-sized enterprises? J. Bus. Res. 2022, 142, 88–99. [Google Scholar] [CrossRef]

- Varadarajan, R. Customer information resources advantage, marketing strategy and business performance: A market resources-based view. Ind. Mark. Manag. 2020, 89, 89–97. [Google Scholar] [CrossRef]

- Sheikh, A.A.; Shahzad, A.; Ku Ishak, A. The impact of market orientation, top management support, use of e-marketing and technological opportunism on the firm performance: A mediated-moderation and moderated-mediation analysis. Abasyn J. Soc. Sci. 2017, 10, 212–234. [Google Scholar]

- Mousa, S.K.; Othman, M. The impact of green human resource management practices on Sustainability Performance in healthcare organisations: A conceptual framework. J. Clean. Prod. 2020, 243, 118595. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int. J. Prod. Res. 2020, 58, 1319–1337. [Google Scholar] [CrossRef]

- Yavuz, O.; Uner, M.M.; Okumus, F.; Karatepe, O.M. Industry 4.0 technologies, sustainable operations practices and their impacts on Sustainability Performance. J. Clean. Prod. 2023, 387, 135951. [Google Scholar] [CrossRef]

- Gupta, S.; Meissonier, R.; Drave, V.A.; Roubaud, D. Examining the impact of Cloud ERP on Sustainability Performance: A dynamic capability view. Int. J. Inf. Manag. 2020, 51, 102028. [Google Scholar] [CrossRef]

- Haseeb, M.; Hussain, H.I.; Ślusarczyk, B.; Jermsittiparsert, K. Industry 4.0: A solution towards technology challenges of sustainable business performance. Soc. Sci. 2019, 8, 154. [Google Scholar] [CrossRef]

- Li, L. Digital transformation and Sustainability Performance: The moderating role of market turbulence. Ind. Mark. Manag. 2022, 104, 28–37. [Google Scholar] [CrossRef]

- Ijaz Baig, M.; Yadegaridehkordi, E. Exploring moderating effects of industry 4.0 adoption on Sustainability Performance of Malaysian manufacturing organisations. J. Ind. Prod. Eng. 2023, 40, 271–286. [Google Scholar]

- Li, Y.; Dai, J.; Cui, L. The impact of digital technologies on economic and environmental performance in the context of industry 4.0: A moderated mediation model. Int. J. Prod. Econ. 2020, 229, 107777. [Google Scholar] [CrossRef]

- Kline, R.B. Principles and Practice of Structural Equation Modeling, 4th ed.; Guilford Publications: New York, NY, USA, 2015. [Google Scholar]

- Gunday, G.; Ulusoy, G.; Kilic, K.; Alpkan, L. Effects of innovation types on firm performance. Int. J. Prod. Econ. 2011, 133, 662–676. [Google Scholar] [CrossRef]

- Vaccaro, I.G.; Jansen, J.J.; Van Den Bosch, F.A.; Volberda, H.W. Management innovation and leadership: The moderating role of organisational size. J. Manag. Stud. 2012, 49, 28–51. [Google Scholar] [CrossRef]

- Varela, L.; Araújo, A.; Ávila, P.; Castro, H.; Putnik, G. Evaluation of the relation between lean manufacturing, industry 4.0, and sustainability. Sustainability 2019, 11, 1439. [Google Scholar] [CrossRef]

- Hair, J.; Hollingsworth, C.L.; Randolph, A.B.; Chong AY, L. An updated and expanded assessment of PLS-SEM in information systems research. Ind. Manag. Data Syst. 2017, 117, 442–458. [Google Scholar] [CrossRef]

- Peterson, R.A.; Kim, Y. On the relationship between coefficient alpha and composite reliability. J. Appl. Psychol. 2013, 98, 194–198. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).