Numerical Simulation Study on Through-Anchor Cable Reinforcement Control of Inter-Roadway Coal Pillars in Double-Roadway Layouts

Abstract

1. Introduction

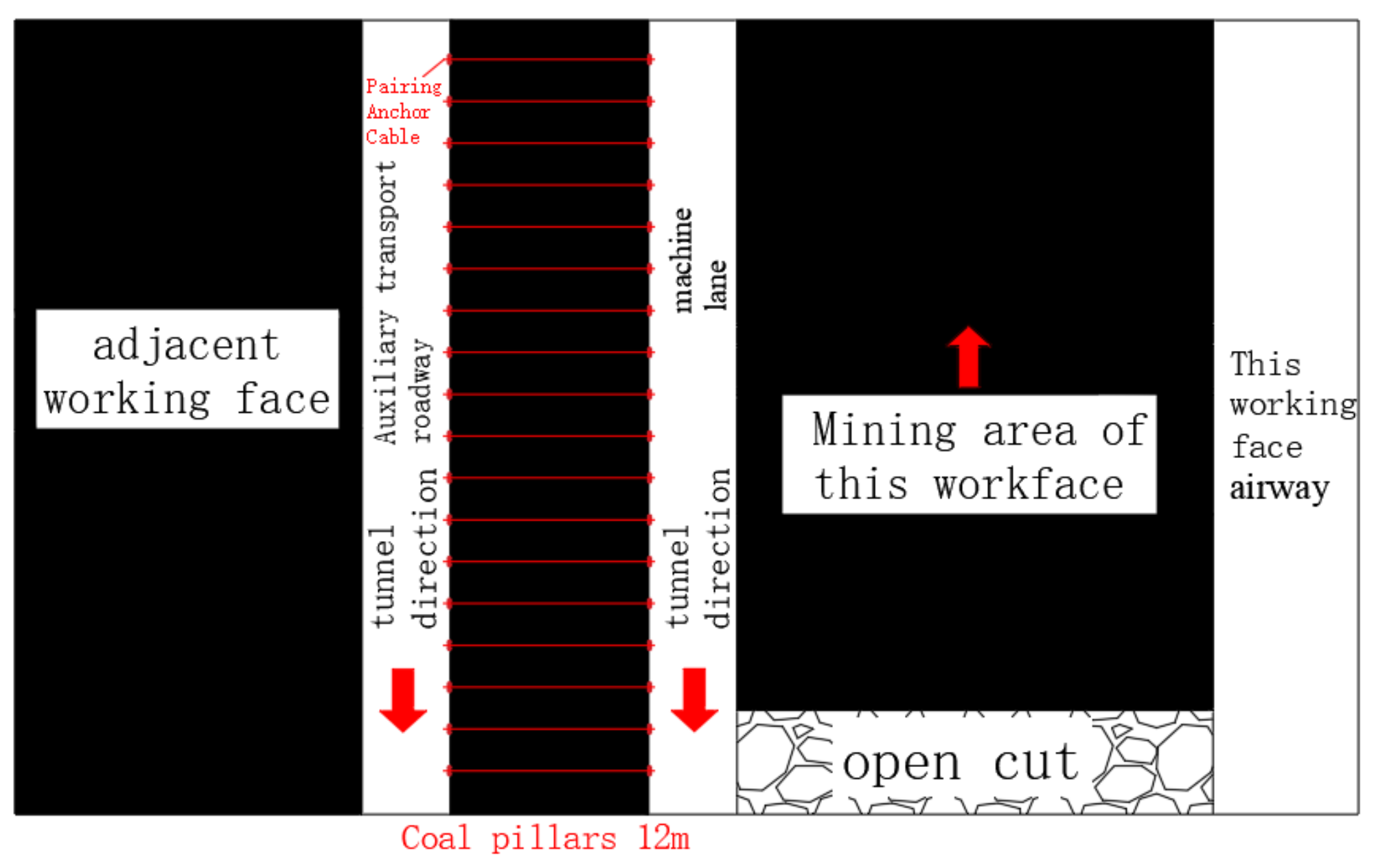

2. Project Introduction

3. Determination of the Width of the Inter-Roadway Coal Pillar

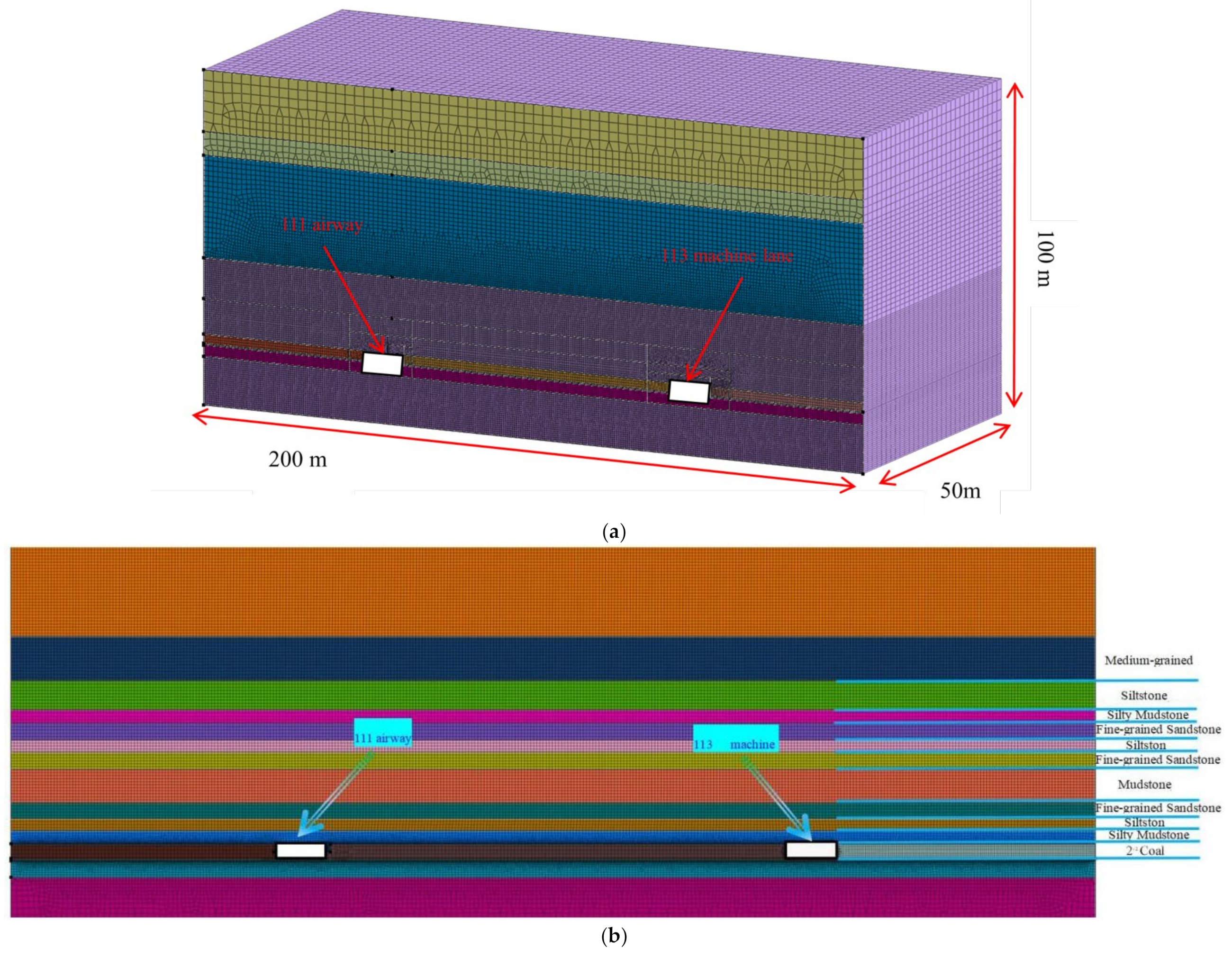

3.1. Numerical Calculation

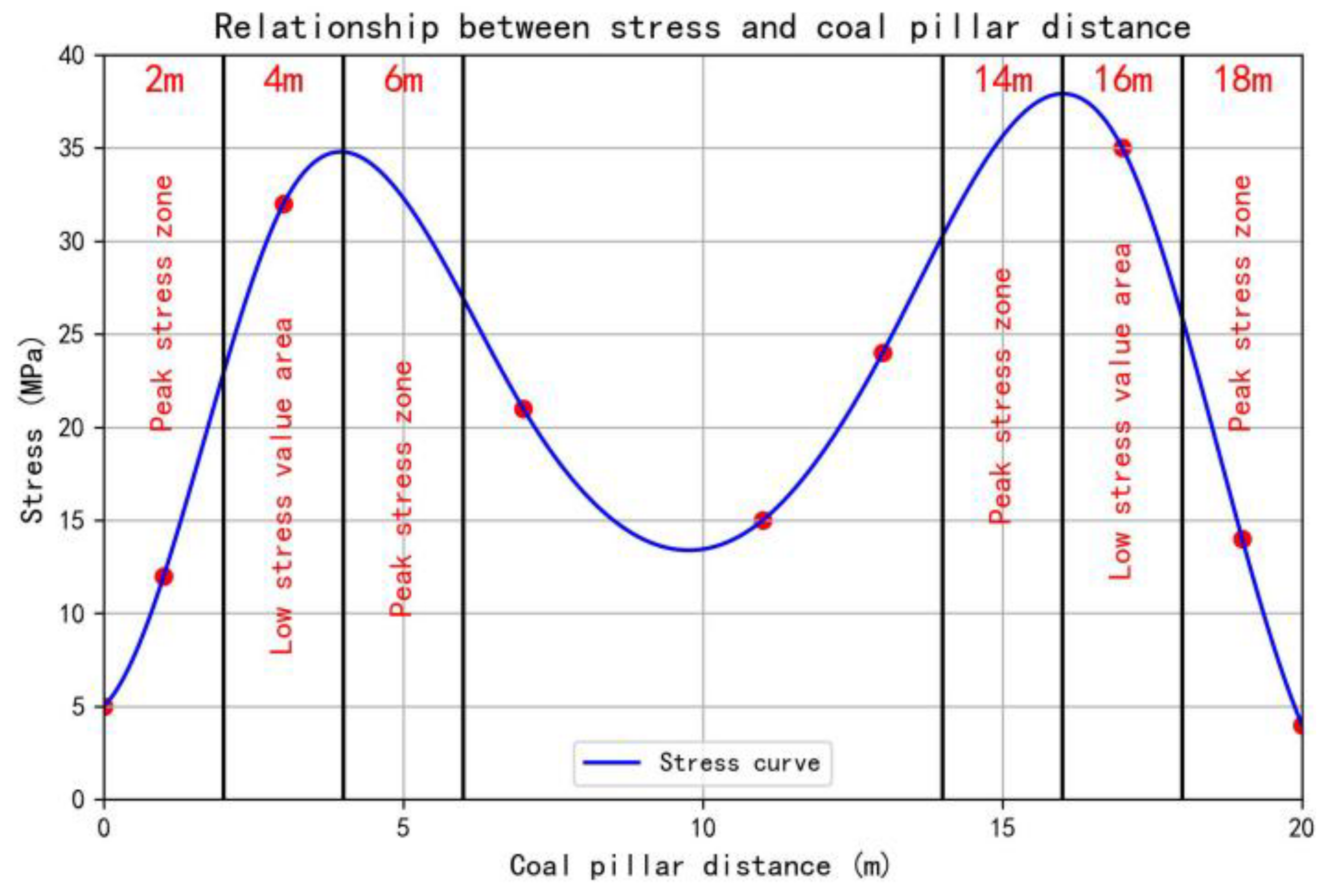

Distribution Law of Lateral Support Pressure During Mining Recovery on Both Sides of the 20 m Inter-Roadway Coal Pillar

- The 0–2 m and 18–20 m sections are low-stress zones and plastic zones, where the stress values mainly range from 4.5 to 22.5 MPa. A noticeable increase in stress is observed towards the interior of the coal pillar.

- The 2–4 m and 16–18 m sections are stress peak zones and elastic zones, with a peak stress of 34.9 MPa. The overall stress level is relatively high, but due to the three-dimensional stress state, the zone remains in the elastic range without failure.

- The 4–6 m and 14–16 m sections are stress-reduction zones and elastic zones, where the stress levels gradually decrease, and the coal pillar progressively enters a more stable mechanical state. The formation of the stress-relief zone and the elastic zone significantly impacts the overall stability of the coal pillar: the stress-relief zone reduces the risk of localized failure by releasing stress at the edges of the coal pillar, while the elastic zone ensures overall stability by maintaining the high load-bearing capacity of the core region. As the stress level gradually decreases, the coal pillar transitions into a more stable mechanical state, further enhancing its resistance to deformation and failure. These mechanical characteristics directly influence reinforcement strategies: for the stress-relief zone; techniques such as bolting and cable anchoring are required to enhance its residual strength. For the elastic zone, the focus should be on monitoring stress concentration to prevent it from entering a plastic failure stage. Overall, reinforcement strategies should dynamically adjust support methods based on the elastic stress distribution and deformation characteristics of the coal pillar, ensuring its long-term stability and safe mining operations.

- The 6–14 m section is a low-stress zone and elastic zone, with stress values ranging from 15 to 25 MPa. All areas remain in an elastic state, exhibiting good stability.

3.2. Simulation of Coal Pillars with Different Dimensions

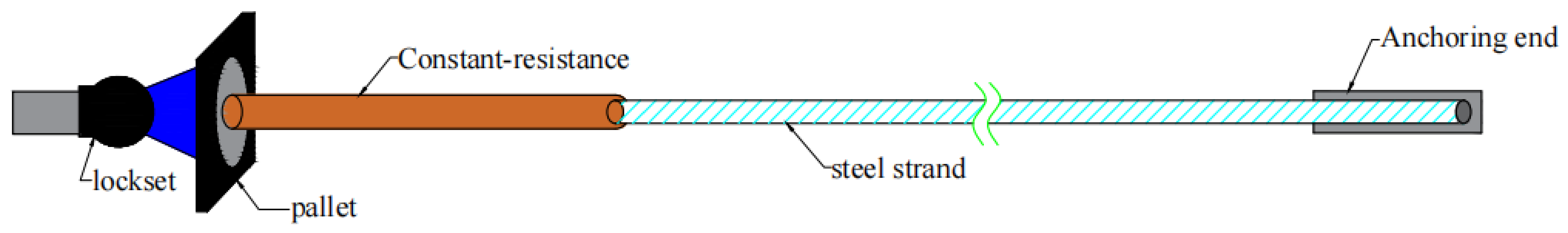

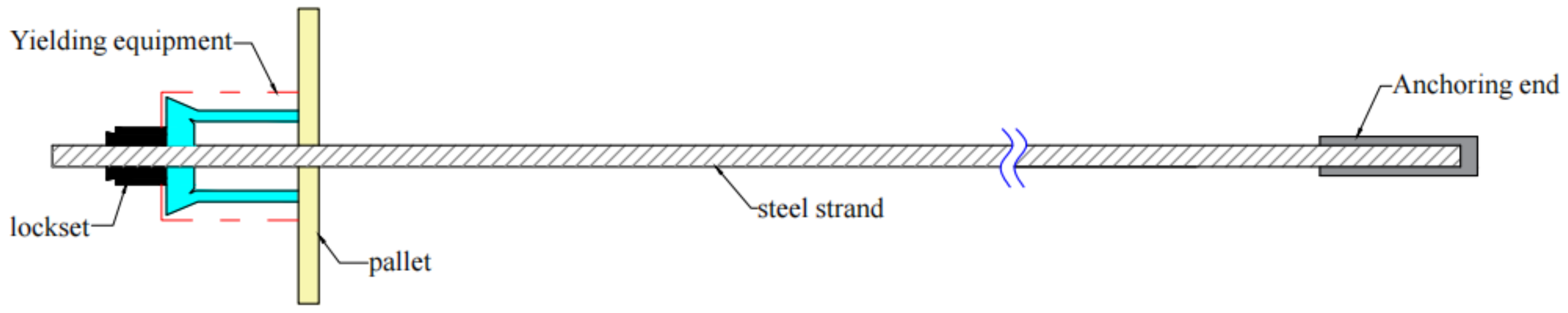

4. Negative Poisson’s Ratio (NPR) Anchor Cables and Pressurizer Pressure Characteristics

5. Reinforcement and Numerical Analysis of the 12 m Coal Pillar Section

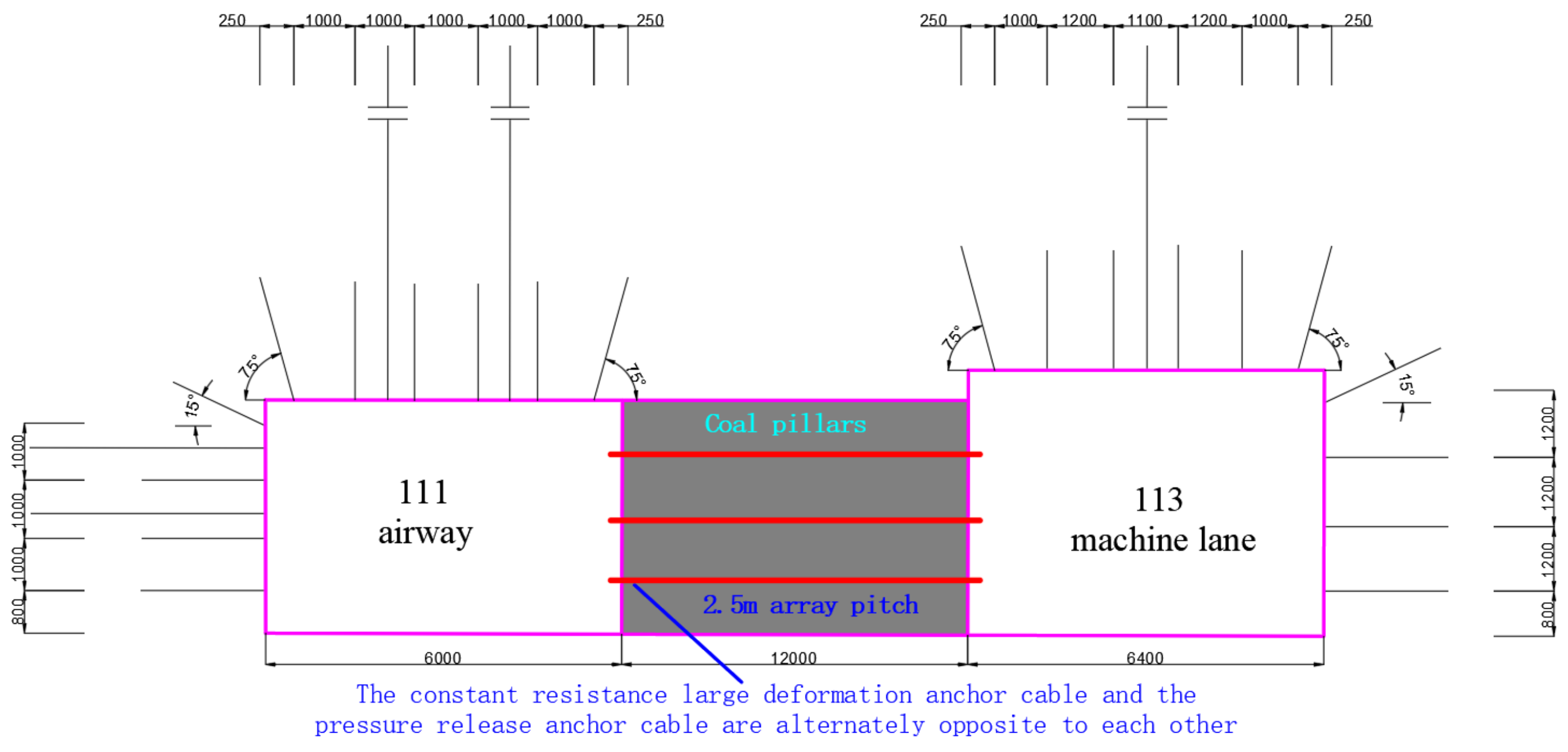

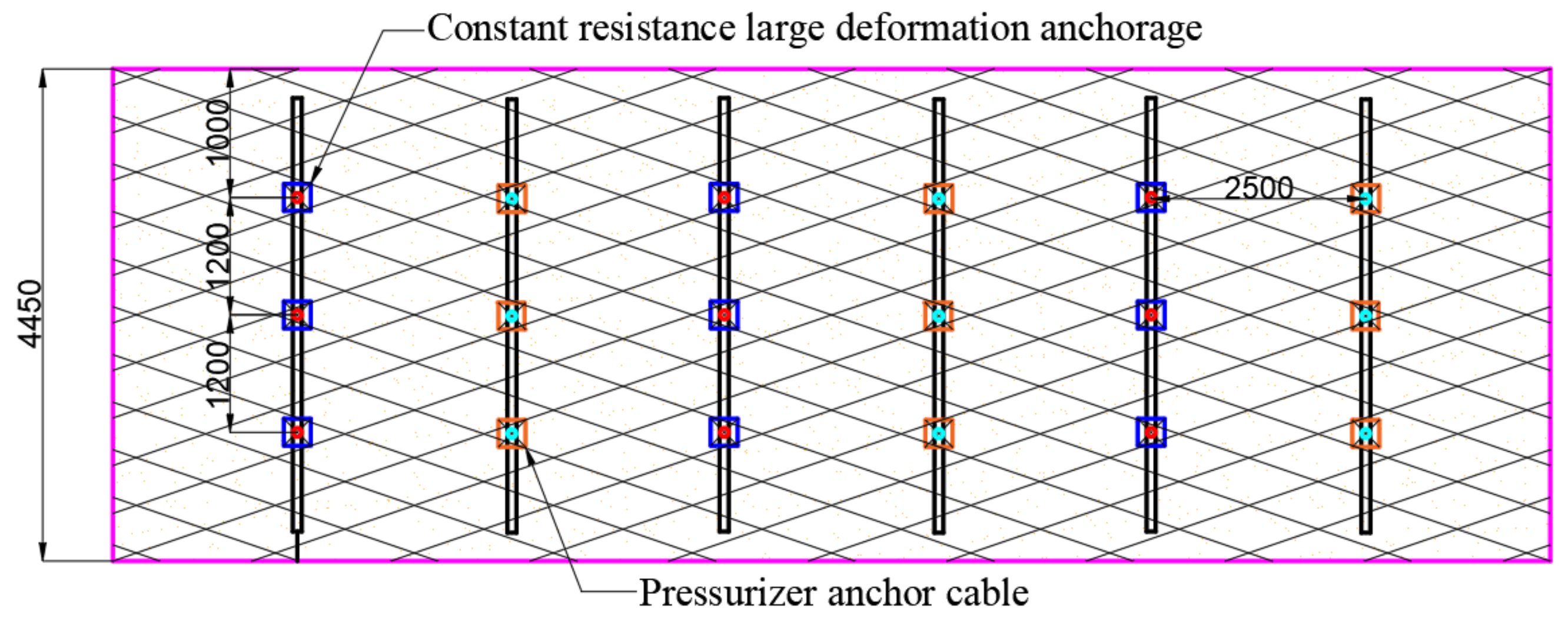

5.1. Design Parameters for Double-Roadway Coal Pillar Support

5.2. Numerical Analysis of Cross-Through Reinforcement Using Pressure-Relief Anchor Cables and NPR Anchor Cables

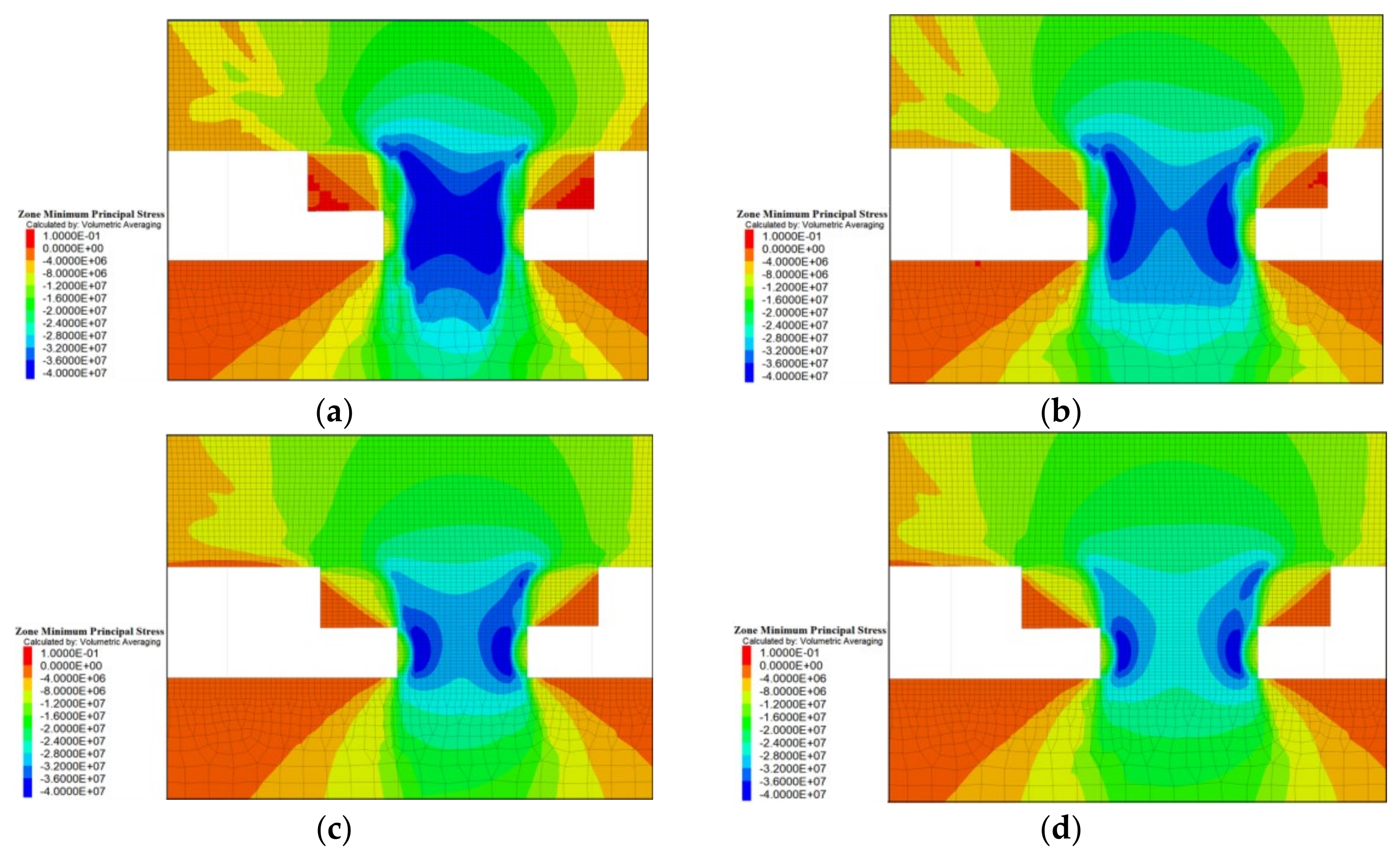

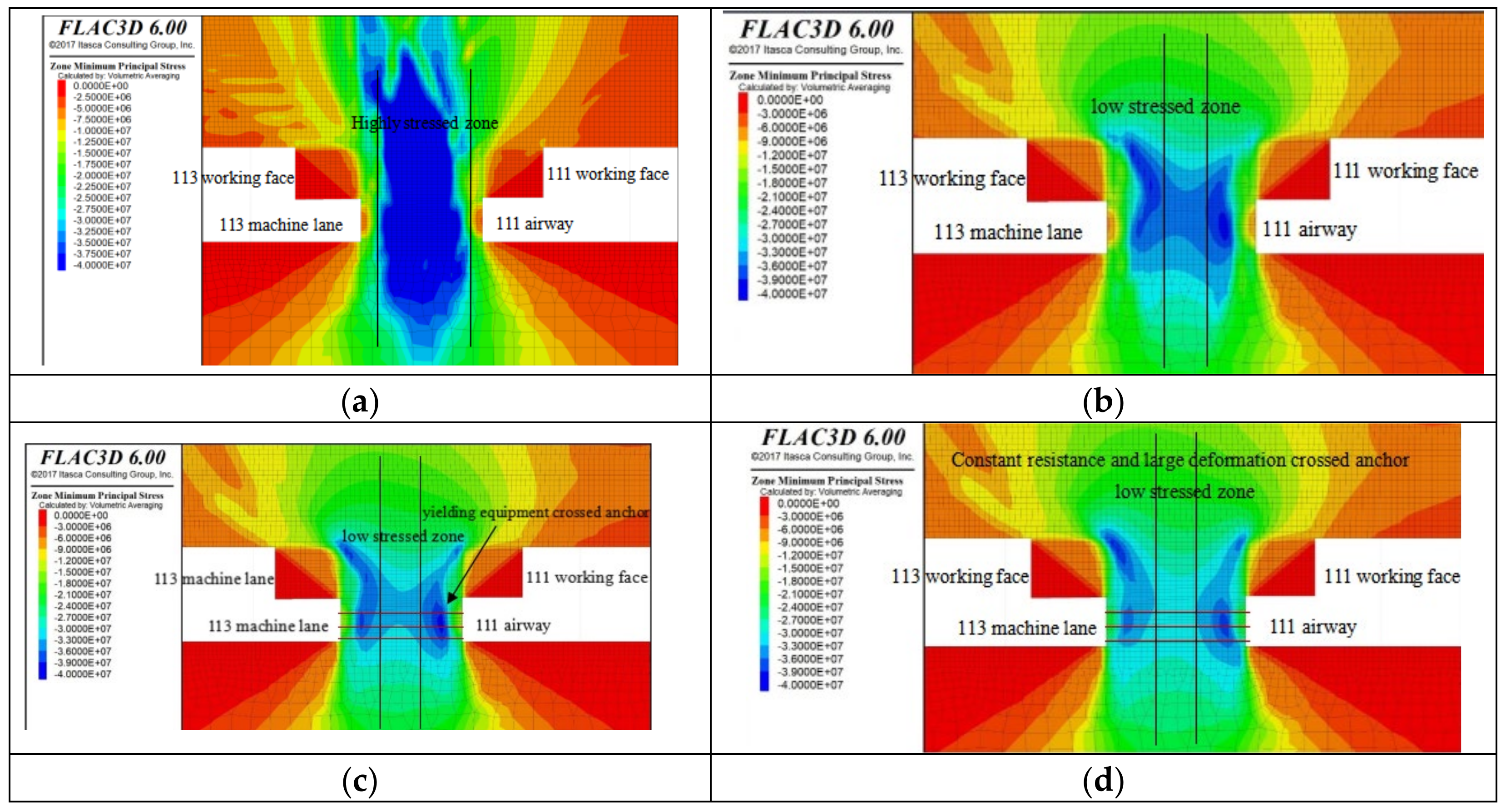

5.2.1. Stress Distribution

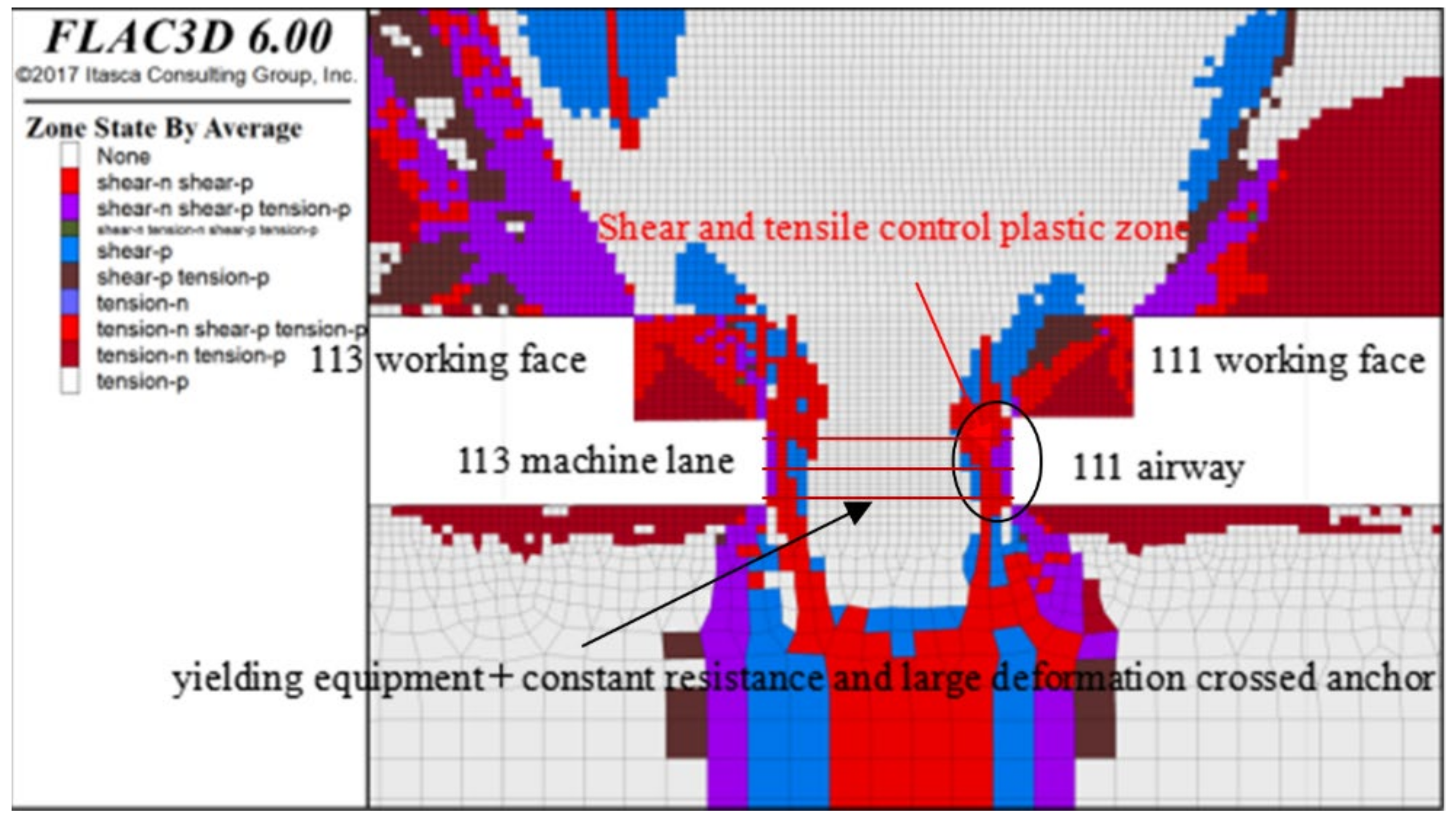

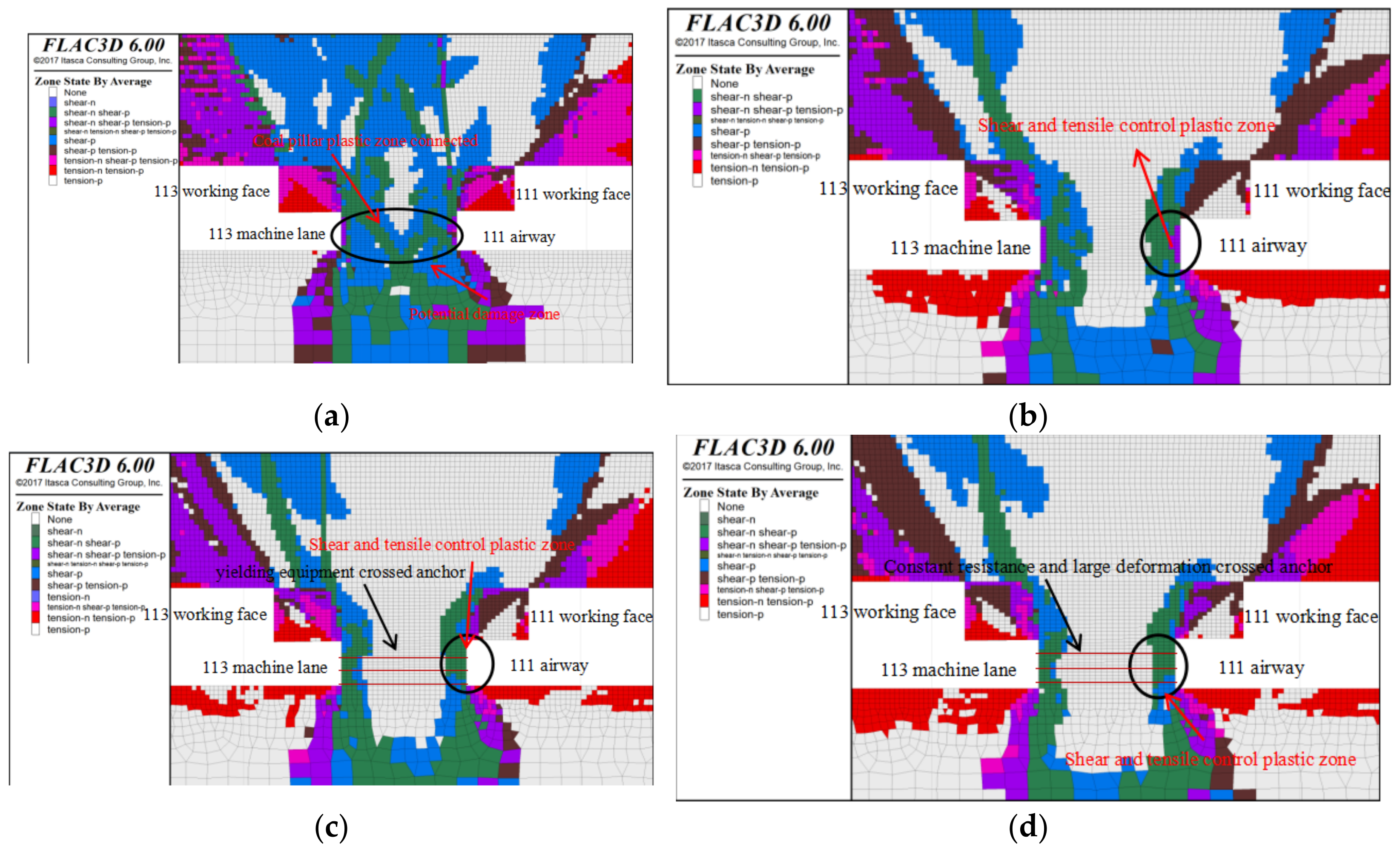

5.2.2. Distribution of the Plastic Zone in the Surrounding Rock

5.2.3. Distribution of the Plastic Zone in the Surrounding Rock, as Shown in Figure 14

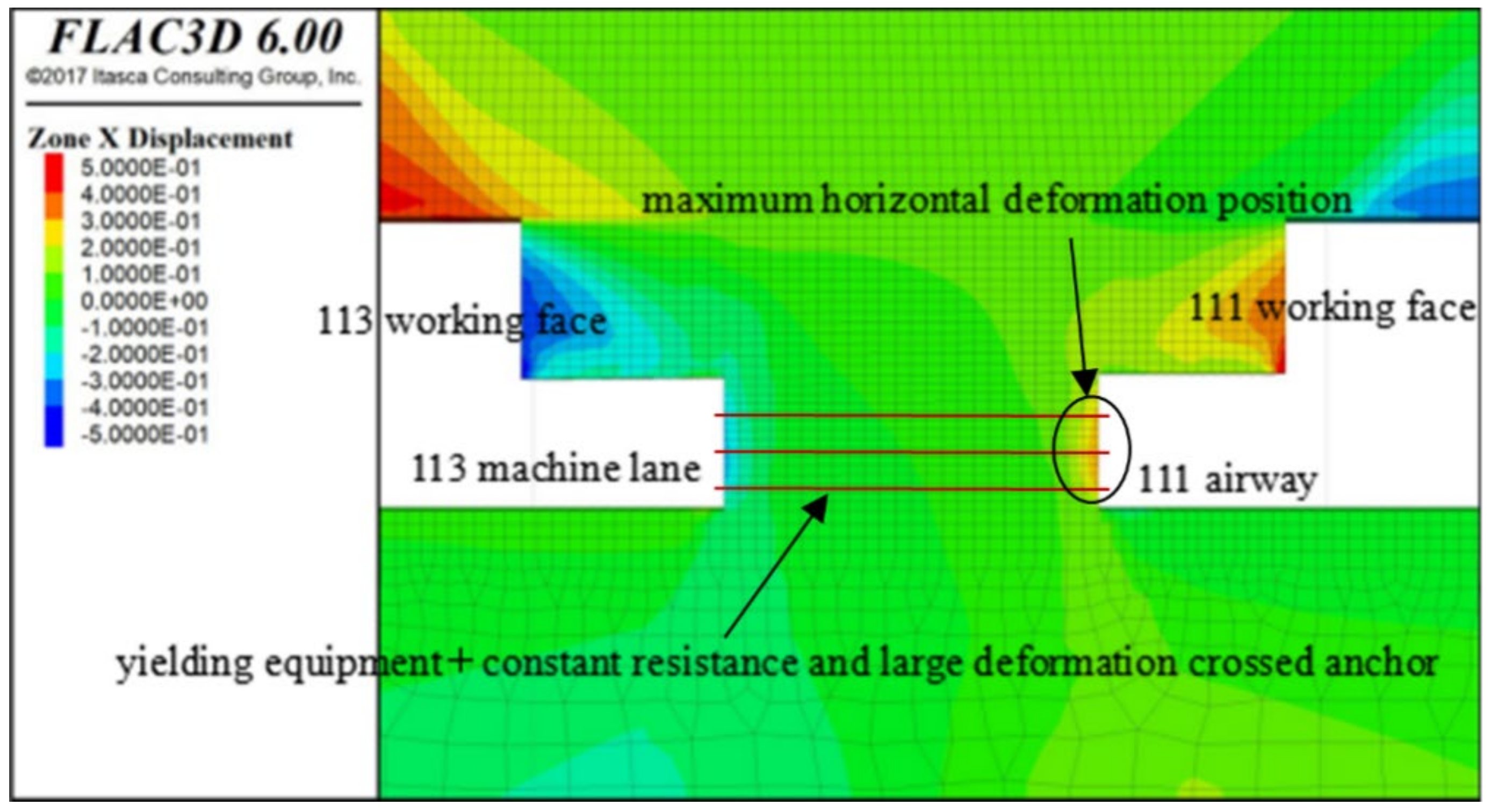

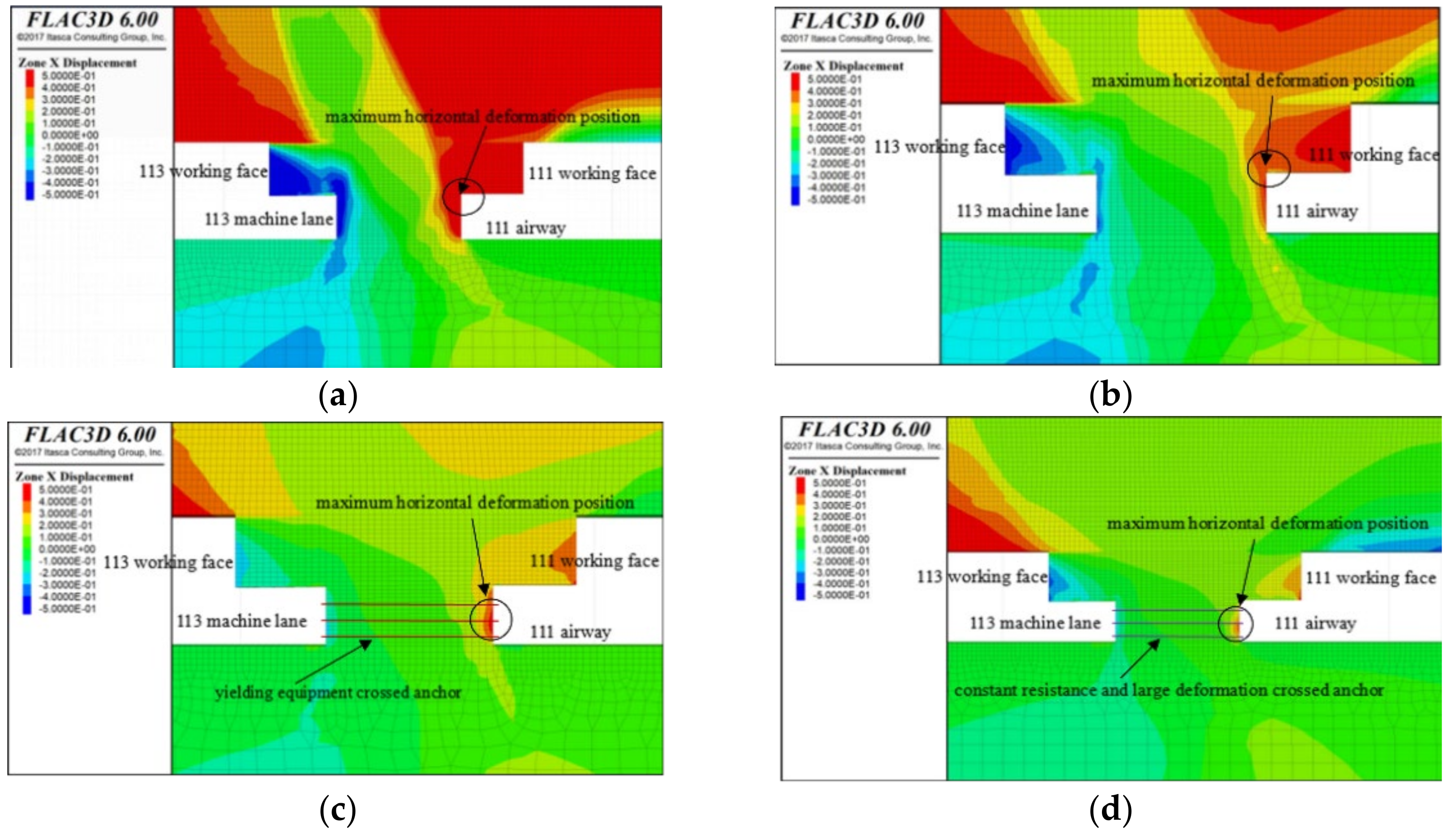

- (1)

- Location of maximum deformation: The maximum horizontal deformation of the 12 m coal pillar occurs in the lower section of the roadway.

- (2)

- Maximum horizontal deformation: The unilateral deformation reaches 33.7 cm. Due to the reinforcing effect of the cross-through anchor cables and the constraints of the triaxial stress state, the horizontal deformation of the coal pillar is significantly reduced, enhancing its stability against horizontal deformation.

- (3)

- Anchor cable extension in the cross-through scheme: At the maximum deformation of the coal pillar, the pressure-relief anchor exceeds its pressure-relief capacity, preventing the NPR anchor cables from fully extending. This effectively restricts the pillar’s deformation, maintaining its stability.Figure 14. Cross-through reinforcement using pressure-relief anchor cables and NPR anchor cables.

6. Discussion

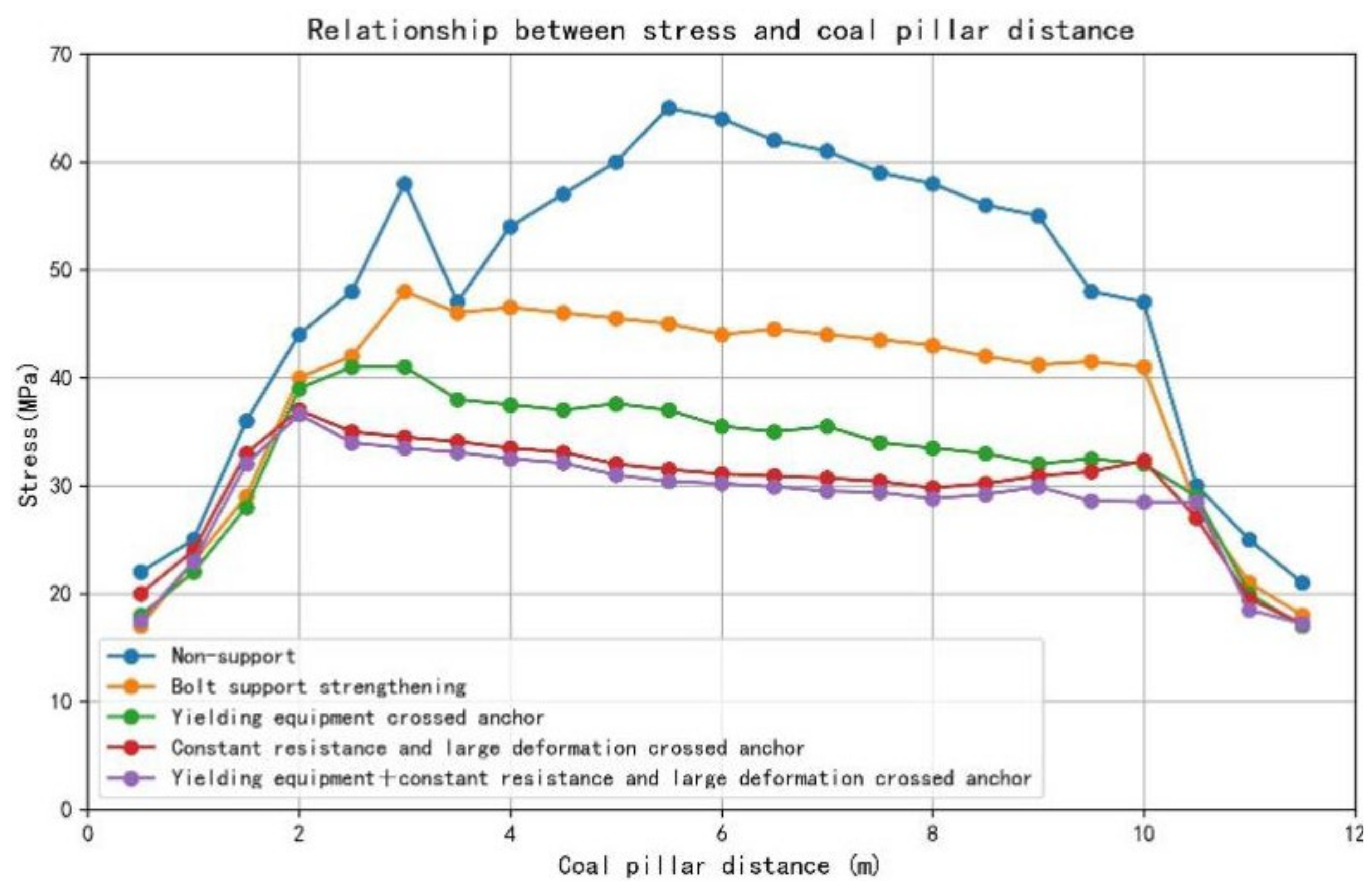

6.1. Comparison and Analysis of Stress Distribution in the 12 m Coal Pillar

6.2. Comparison and Analysis of the Distribution of Plastic Zones in Surrounding Rock

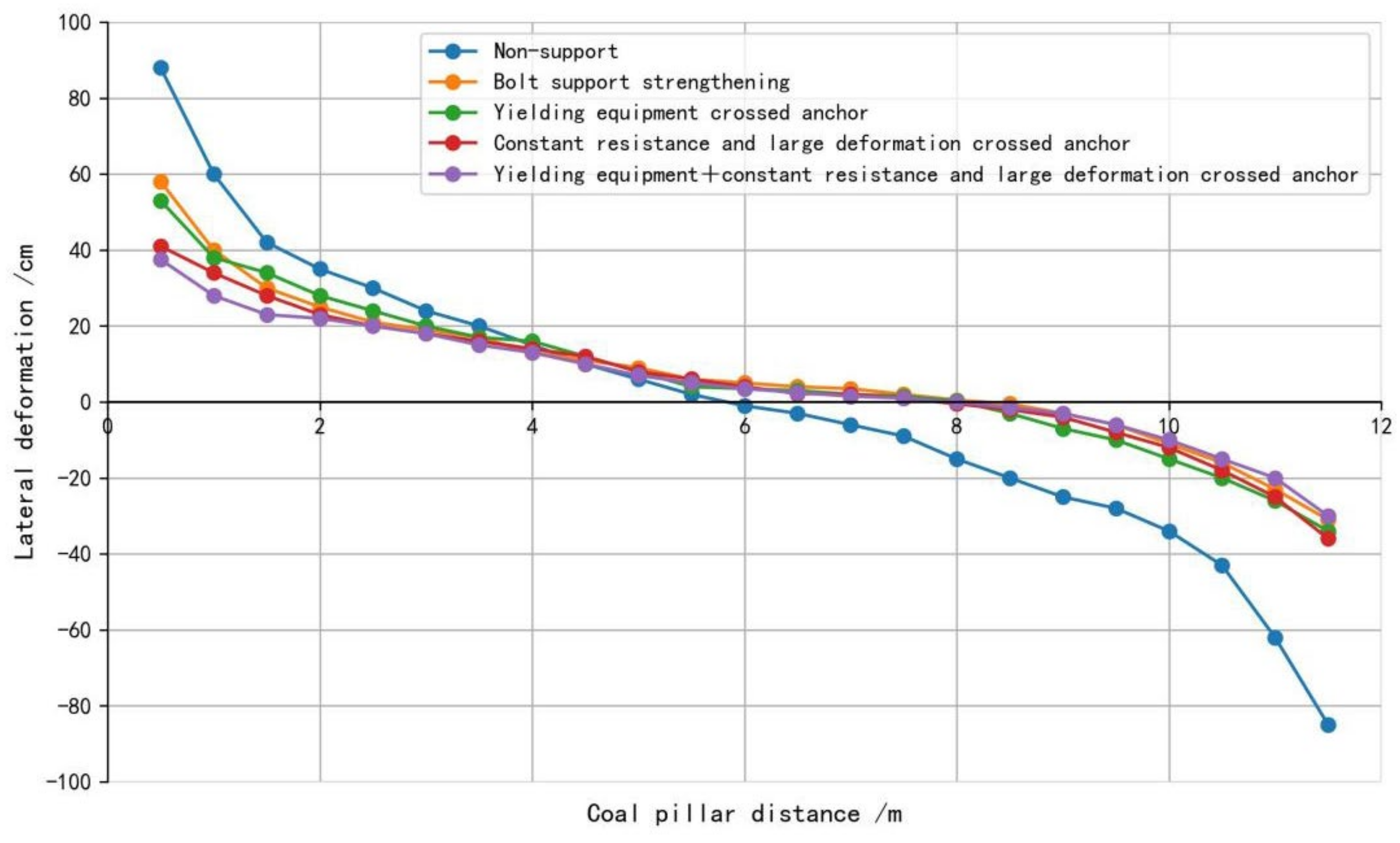

6.3. Comparison of Strata Deformation

- (1)

- Maximum deformation location: In the no-support scheme, the deformation of the coal pillar is very large, making it difficult to maintain stability. In the conventional anchor rod reinforcement scheme, the maximum horizontal deformation of the 12 m coal pillar occurs near the top of the roadway and 1.5 m downward. In the schemes using pressure-relief anchor cables and bidirectional large-deformation constant-resistance anchor cables, the maximum horizontal deformation occurs in the middle and lower parts of the coal pillar.

- (2)

- Maximum horizontal deformation: The maximum horizontal deformations (on one side) for the five schemes are 89.2 cm, 52.3 cm, 46.1 cm, and 38.5 cm, respectively. The bidirectional anchor cable reinforcement significantly reduces the horizontal deformation of the coal pillar under a three-dimensional stress state, thus improving its stability.

- (3)

- Anchor cable extension in bidirectional scheme: As shown in Figure 19, in the pressure-relief anchor cable scheme, the maximum horizontal deformation of the coal pillar is 46.1 cm, which does not exceed the pressure-relief limit of the anchor cable. In the bidirectional constant-resistance large-deformation anchor cable scheme, the maximum horizontal deformation reaches 38.5 cm, exceeding the extension limit of the constant-resistance anchor cable. Therefore, both pressure-relief and constant-resistance large-deformation anchor cables can be used together for reinforcement in the design.

6.4. Field Monitoring

7. Conclusions

- (1)

- The feasibility of optimizing the coal pillar from 20 m to 12 m was exploited to enhance the pressure-relief performance of the through-going reinforcement zone coal pillar. After reinforcement, the two free surfaces of the reinforced coal body were compressed under a certain preload, which enhanced the bearing capacity of the coal body in the reinforcement area and significantly improved the mechanical properties of the reinforced coal body, thereby considerably enhancing the peak strength and residual strength of the narrow coal pillar between the roadways.

- (2)

- By employing Flac3D numerical simulation software, the situation of the coal pillar in the section under five distinct states was simulated. The characteristics of vertical stress, plastic zone distribution, and ground deformation were compared and analyzed through numerical simulation. It was ascertained that the 12 m coal pillar could be stably maintained for a prolonged period by adopting negative Poisson’s ratio (NPR) constant-resistance large-deformation anchor rods and pressure-relief anchor rods interlaced and drilled through.

- (3)

- The interlacing and intersection of the negative Poisson’s ratio (NPR) constant-resistance large-deformation anchor rope and the pressure-relief anchor rope through the coal pillar gave rise to a reduction in the peak stress value of the coal pillar from 68.5 MPa to 35.3 MPa. This conspicuously enhanced the peak strength and residual strength of the coal pillar, furnishing guidance for the optimization of the dynamic pressure coal pillar in Jinjitan Coal Mine.

- (4)

- The innovative cross-penetration reinforcement system utilizing negative Poisson’s ratio (NPR) constant-resistance large-deformation anchor cables combined with yield-absorbing anchor cables demonstrates significant advantages: it effectively constrains the instability deformation of narrow coal pillars and enhances their overall load-bearing capacity, particularly showing remarkable performance in high-stress environments. However, this advanced technique presents certain implementation challenges, primarily the requirement for simultaneous reinforcement installation during roadway excavation, which necessitates precise coordination between excavation and support operations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zha, W.; Shi, H.; Liu, S.; Kang, C. Surrounding rock control of gob-side entry driving with narrow coal pillar and roadway side sealing technology in Yangliu Coal Mine. Int. J. Min. Sci. Technol. 2017, 27, 819–823. [Google Scholar] [CrossRef]

- Feng, J.C.; Ma, N.J.; Zhao, Z.Q.; Zhang, H.; Yu, Z.M. Width of narrow coal pillar of roadway driving along goaf at large height mining face in deep mine. J. Min. Saf. Eng. 2014, 31, 580–586. [Google Scholar]

- Zhang, K.X.; Zhang, Y.J.; Ma, Z.Q.; Bi, W.G.; Yang, Y.M.; Li, Y. Determination of the narrow pillar width of gob-side entry driving. J. Min. Saf. Eng. 2015, 32, 446–452. [Google Scholar]

- Singh, R.; Singh, S.-K.; Kushwaha, A.; Sinha, A. Stability of the Parting between coal pillar workings in level contiguous seams during depillaring. Int. J. Rock Mech. Min. Sci. 2012, 55, 1–14. [Google Scholar] [CrossRef]

- Su, H.; Bai, J.; Yan, S.; Chen, Y.; Zhang, Z. Study on gob-side entry retaining in fully-mechanized longwall with top-coal caving and its application. Int. J. Min. Sci. Technol. 2015, 25, 503–510. [Google Scholar] [CrossRef]

- Kushwaha, A.; Singh, S.K.; Tewari, S.; Sinha, A. Empirical approach for designing of support system in mechanized coal pillar mining. Int. J. Rock Mech. Min. Sci. 2010, 47, 1063–1078. [Google Scholar] [CrossRef]

- Ghasemi, E.; Shahriar, K. A new coal pillars design method in order to enhance safety of the retreat mining in room and pillar mines. Saf. Sci. 2012, 50, 579–585. [Google Scholar] [CrossRef]

- Xie, H.; Zhou, H.; Liu, J.; Gao, F.; Zhang, R.; Xue, D.; Zhang, Y. Mining-induced mechanical behavior in coal seams under different mining layouts. J. China Coal Soc. 2011, 36, 1067–1074. [Google Scholar]

- Li, L.; Zhang, A.; Zhang, C. Study on the Abutment Pressure and Advanced Support of Driving Roadway along Goaf of Isolated Mining Face. Adv. Mater. Res. 2014, 3226, 2533–2538. [Google Scholar] [CrossRef]

- Wang, T.; Wei, Y. Evolution law of stress-deformation-permeability of coal pillar along gob and its effect on stability of coal pillar. IOP Conf. Ser. Earth Environ. Sci. 2021, 859, 012050. [Google Scholar] [CrossRef]

- Ren, J.; Zhao, Y.; Wang, W.; Guo, J.; Sun, Z.; Liu, S. Optimal Design of a Protective Coal Pillar with a Buried Pipeline in a Thick Loose Layer in Western China: Methodology and Case Study. Rock Mech. Rock Eng. 2023, 56, 2879–2896. [Google Scholar] [CrossRef]

- Liu, S.; Bai, J.; Wang, X.; Wang, G.; Wu, B.; Li, Y.; Zhao, J. Study on the Stability of Coal Pillars Under the Disturbance of Repeated Mining in a Double-Roadway Layout System. Front. Earth Sci. 2021, 9, 754747. [Google Scholar] [CrossRef]

- Khanal, M.; Adhikary, D.; Jayasundara, C.; Balusu, R. Numerical Study of Mine Site Specific Multiseam Mining and Its Impact on Surface Subsidence and Chain Pillar Stress. Geotech. Geol. Eng. 2016, 34, 217–235. [Google Scholar] [CrossRef]

- Zhu, Z.; Wu, Y.; Liang, Z. Mining-Induced Stress and Ground Pressure Behavior Characteristics in Mining a Thick Coal Seam with Hard Roofs. Front. Earth Sci. 2022, 10, 843191. [Google Scholar] [CrossRef]

- Zhang, C.; Jin, Z.; Feng, G.; Song, X.; Rui, G.; Yujiang, Z. Double peaked stress–strain behavior and progressive failure mechanism of encased coal pillars under uniaxial compression. Rock Mech. Rock Eng. 2020, 53, 3253–3266. [Google Scholar] [CrossRef]

- Huang, W.; Zhao, T.; Zhang, C.; Liu, Y.; Sui, L.; Hou, T.; Jiang, D. Assessment of pillar stability and its control in a double roadway layout. Energy Sci. Eng. 2024, 12, 4192–4209. [Google Scholar] [CrossRef]

- Kang, H.; Yan, L.; Guo, X.; Zhang, Z.; Gao, F. Characteristics of deformation and support technology of perimeter rock in multi-lane arrangement of retrenchment face. In Proceedings of the 12th National Rock Mechanics and Engineering Conference, Nanjin, China, 19–23 October 2012; Chinese Society of Rock Mechanics and Engineering; Mining Design and Research Branch, General Research Institute of Coal Science: Beijing, China; Mining Design Division, Tiandi Technology Corporation: Beijing, China, 2012; Volume 31. [Google Scholar]

- Zang, C.; Chen, M.; Zhang, G.; Wang, K.; Gu, D. Research on the failure process and stability control technology in a deep roadway: Numerical simulation and field test. Energy Sci. Eng. 2020, 8, 2297–2310. [Google Scholar] [CrossRef]

- Li, G.; Ma, F.; Guo, J.; Zhao, H.; Liu, G. Study on deformation failure mechanism and support technology of deep soft rock roadway. Eng. Geol. 2020, 264, 105262. [Google Scholar] [CrossRef]

- He, M.C.; Gong, W.; Wang, J.; Qi, P.; Tao, Z.; Du, S.; Peng, Y. Development of a novel energy-absorbing bolt with extraordinarily large elongation and constant resistance. Int. J. Rock Mech. Min. Sci. 2014, 67, 29–42. [Google Scholar] [CrossRef]

- Kang, H.; Lv, H.; Zhang, X.; Gao, F.; Wu, Z.; Wang, Z. Evaluation of the ground response of a pre-driven longwall recovery room supported by concrete cribs. Rock Mech. Rock Eng. 2015, 49, 1025–1040. [Google Scholar] [CrossRef]

- Tan, X.J.; Chen, W.Z.; Liu, H.Y.; Chan, A.H.C.; Tian, H.; Meng, X.; Wang, F.; Deng, X. A combined supporting system based on foamed concrete and U-shaped steel for underground coal mine roadways undergoing large deformations. Tunn. Undergr. Space Technol. 2017, 68, 196–210. [Google Scholar] [CrossRef]

- He, M.; Ren, S.; Guo, L.; Lin, W.; Zhang, T.; Tao, Z. Experimental study on influence of host rock strength on shear performance of MicroNPR steel bolted rock joints. Int. J. Rock Mech. Min. Sci. 2022, 159, 105236. [Google Scholar] [CrossRef]

- Sun, X.; Li, G.; Zhao, C.; Liu, Y.; Miao, C. Investigation of Deep Mine Shaft Stability in Alternating Hard and Soft Rock Strata Using Three-Dimensional Numerical Modeling. Processes 2019, 7, 2. [Google Scholar] [CrossRef]

- Sun, X.; Zhao, C.; Tao, Z.; Kang, H.; He, M. Failure mechanism and control technology of large deformation for Muzhailing Tunnel in stratified rock masses. Bull. Eng. Geol. Environ. 2021, 80, 4731–4750. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, B.; Li, G.; Tao, Z.; Zhao, C. Application of Constant Resistance and Large Deformation Anchor Cable in Soft Rock Highway Tunnel. Adv. Civ. Eng. 2019, 2019, 1–19. [Google Scholar] [CrossRef]

- Sun, X.; Wang, J.; Zhao, W.; Ming, J.; Zhang, Y.; Li, Z.; Miao, C.; Guo, Z. Instability mechanism of mining roadway passing through fault at different angles in kilometre-deep mine and control measures of roof cutting and NPR cables. J. Mt. Sci. 2024, 21, 236–251. [Google Scholar] [CrossRef]

- Wu, Y. Research on the performance of a new type of anchor cable letting compressor letting pressure. Coal Mine Saf. 2020, 51, 130–133. [Google Scholar] [CrossRef]

- Li, J.; Chen, S.; Yu, F.; Jiang, L. Reinforcement Mechanism and Optimisation of Reinforcement Approach of a High and Steep Slope Using Prestressed Anchor Cables. Appl. Sci. 2020, 10, 266. [Google Scholar] [CrossRef]

- Li, L.; Qian, D.; Yang, X.; Jiao, H. Pressure Relief and Bolt Grouting Reinforcement and Width Optimization of Narrow Coal Pillar for Goaf-Side Entry Driving in Deep Thick Coal Seam: A Case Study. Minerals 2022, 12, 1292. [Google Scholar] [CrossRef]

- Yang, S.; Wang, J.; Ning, J.; Qiu, P. Experimental Study on Mechanical Properties, Failure Behavior and Energy Evolution of Different Coal-Rock Combined Specimens. Appl. Sci. 2019, 9, 4427. [Google Scholar] [CrossRef]

| Number | Name of Rock | Depth of Burial | Compressive Strength (MPa) | Modulus of Elasticity (GPa) | Poisson’s Ratio | Capacity (kN/m3) | Angle of Internal Friction/° |

|---|---|---|---|---|---|---|---|

| M9 | Medium-grained sandstone | 146.25 | 59.20 | 25..5 | 0.24 | 2.35 | 37 |

| M8 | Siltstone | 164.95 | 39.15 | 22.0 | 0.23 | 2.50 | 39 |

| M7 | Silty mudstone | 173.61 | 33.56 | 21.0 | 0.20 | 2.25 | 33 |

| M6 | Fine-grained sandstone | 184.43 | 43.15 | 22.0 | 0.20 | 2.35 | 32 |

| M5 | Siltstone | 192.23 | 35.09 | 23.0 | 0.24 | 2.35 | 40 |

| M4 | Fine-grained sandstone | 203.52 | 45.34 | 23.0 | 0.21 | 2.25 | 32 |

| M3 | Mudstone | 225.01 | 40.07 | 21.0 | 0.23 | 2.35 | 33 |

| M2 | Fine-grained sandstone | 235.12 | 45.29 | 22.0 | 0.20 | 2.50 | 34 |

| M1 | Siltstone | 242.89 | 42.02 | 25.0 | 0.24 | 2.35 | 40 |

| Main roof | Silty mudstone | 251.93 | 65.15 | 21.0 | 0.20 | 2.15 | 39 |

| Coal | 2−2 coal | 263.00 | 18.55 | 19.6 | 0.24 | 1.50 | 37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, L.; Xu, S.; He, M. Numerical Simulation Study on Through-Anchor Cable Reinforcement Control of Inter-Roadway Coal Pillars in Double-Roadway Layouts. Sustainability 2025, 17, 2416. https://doi.org/10.3390/su17062416

Peng L, Xu S, He M. Numerical Simulation Study on Through-Anchor Cable Reinforcement Control of Inter-Roadway Coal Pillars in Double-Roadway Layouts. Sustainability. 2025; 17(6):2416. https://doi.org/10.3390/su17062416

Chicago/Turabian StylePeng, Linjun, Shunyu Xu, and Manchao He. 2025. "Numerical Simulation Study on Through-Anchor Cable Reinforcement Control of Inter-Roadway Coal Pillars in Double-Roadway Layouts" Sustainability 17, no. 6: 2416. https://doi.org/10.3390/su17062416

APA StylePeng, L., Xu, S., & He, M. (2025). Numerical Simulation Study on Through-Anchor Cable Reinforcement Control of Inter-Roadway Coal Pillars in Double-Roadway Layouts. Sustainability, 17(6), 2416. https://doi.org/10.3390/su17062416