Performance Assessment Model for Petrol Stations Using a Multi-Criteria Condition Rating Index

Abstract

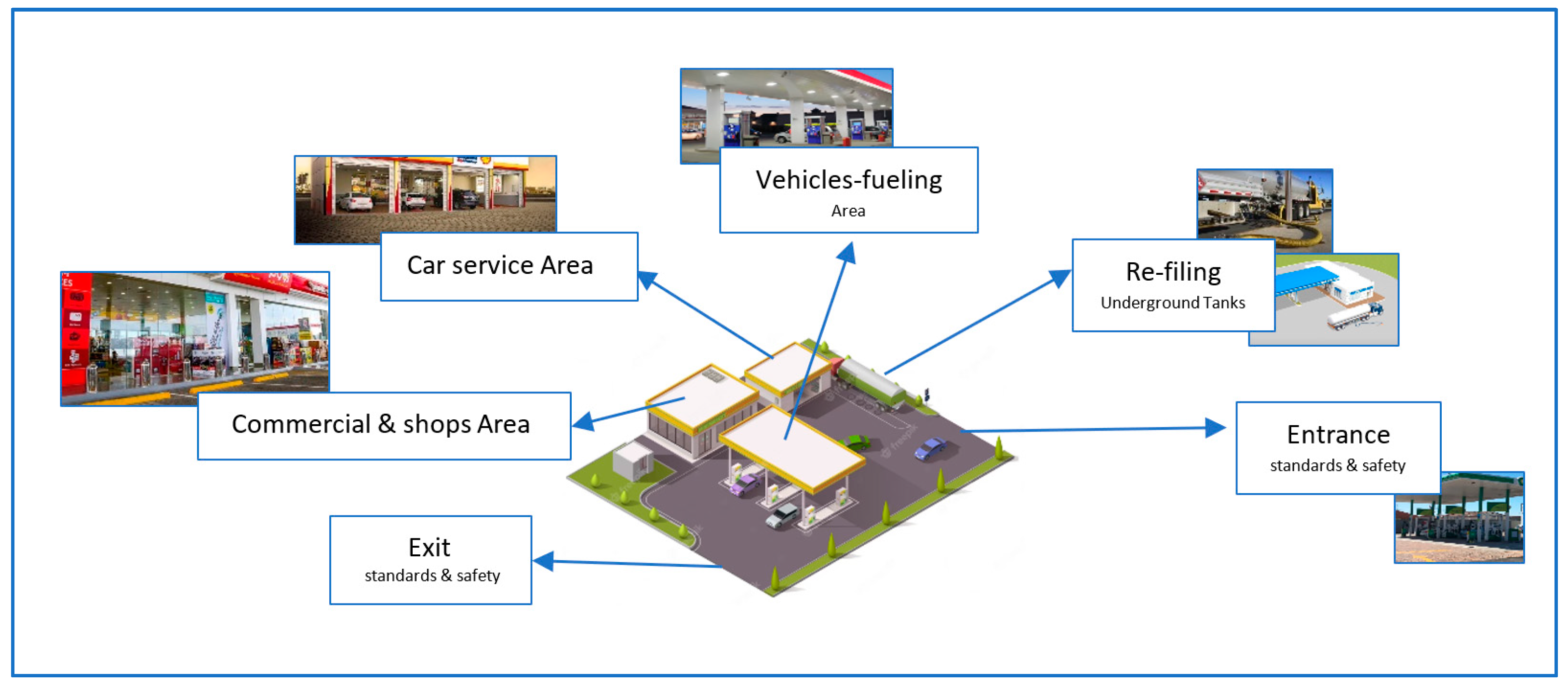

:1. Introduction

2. Background and Motivation

Development and Significance of the CRI

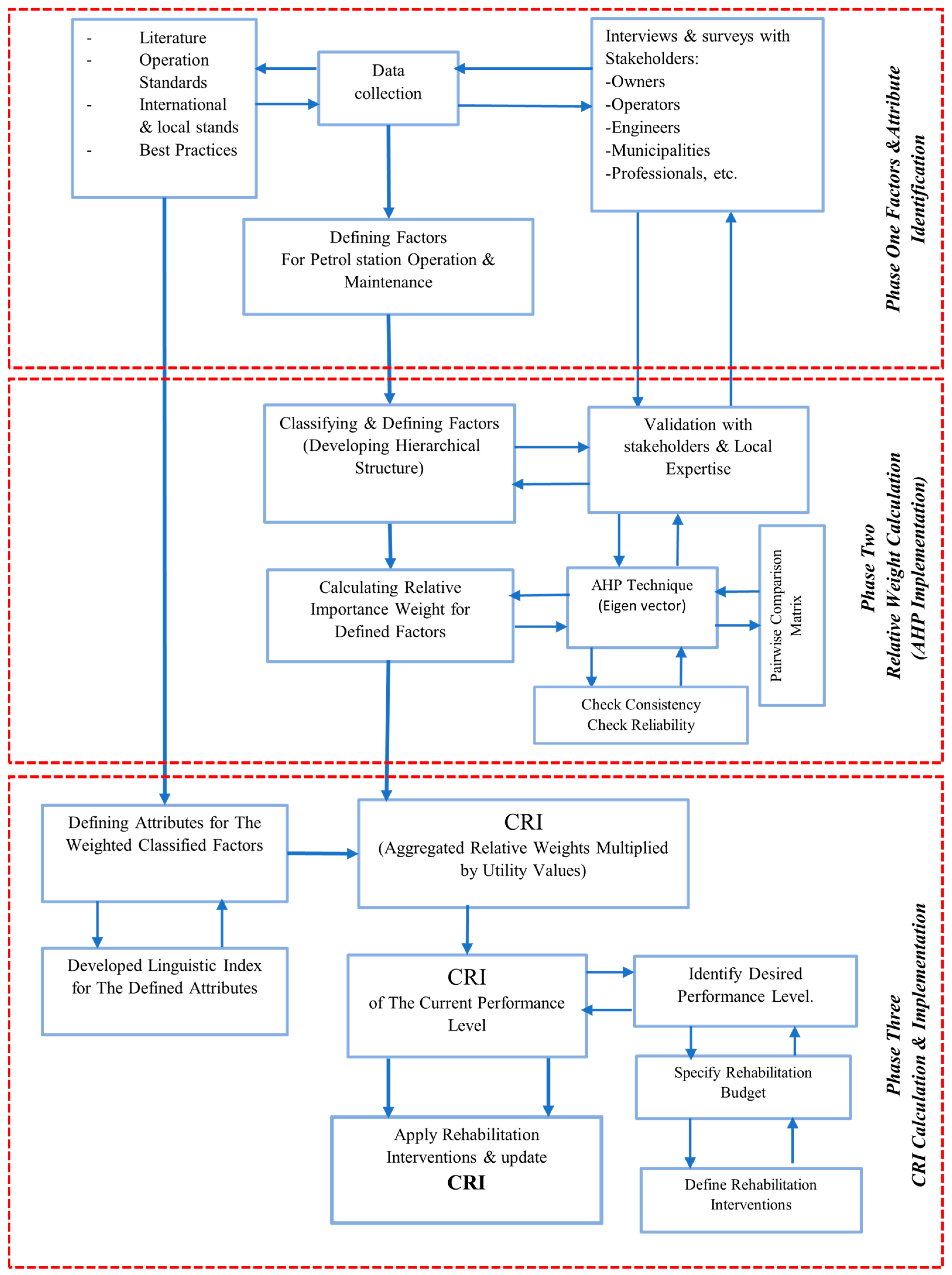

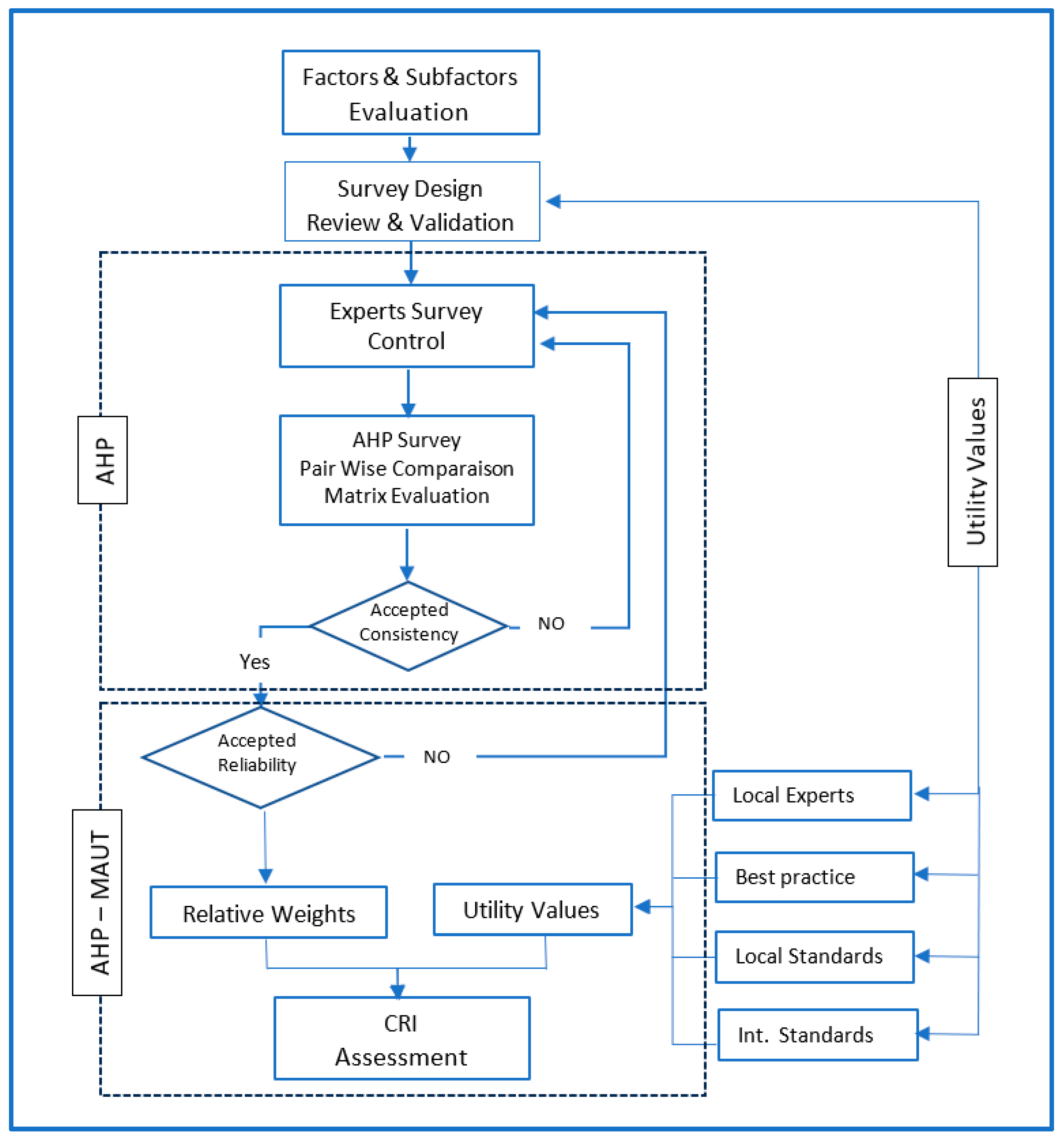

3. Methodology

- Identify factors affecting petrol station operation and maintenance: This phase will involve a comprehensive review of local and international standards and consultation with experts in the field. The goal is to identify all factors that can significantly impact the operation and maintenance of petrol stations.

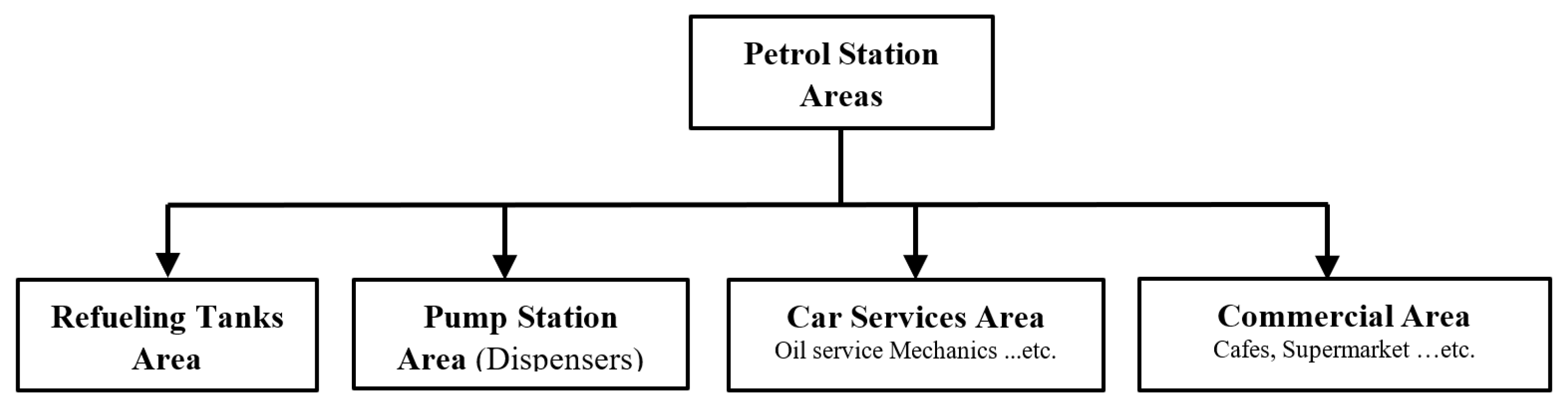

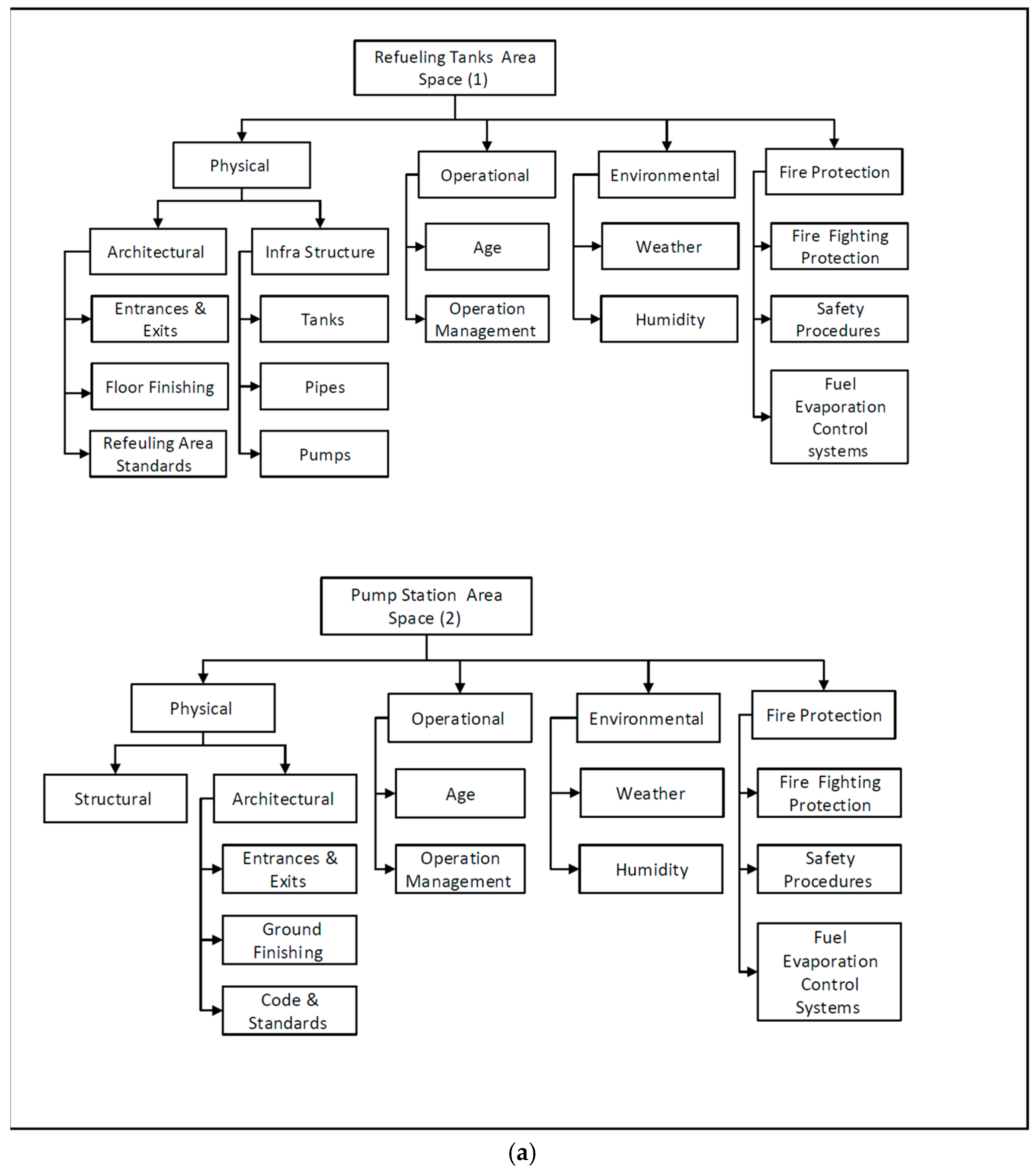

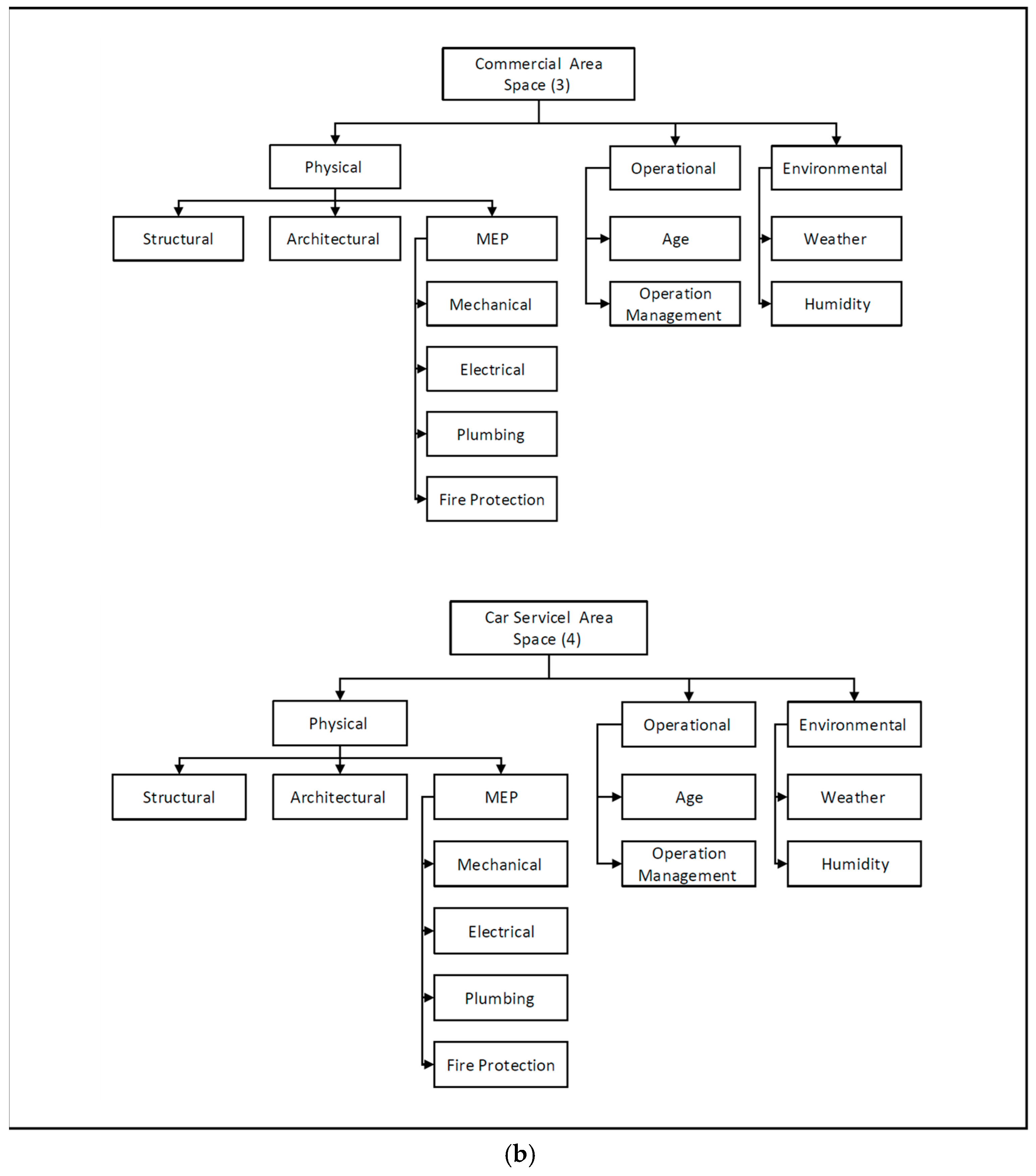

- Organize factors into a hierarchical order: Once all factors have been identified, they will be organized into a hierarchical order. This will involve grouping similar factors and creating a hierarchy of main criteria and sub-factors. This phase aims to develop a structured framework for evaluating the overall performance of petrol stations.

- Extract attributes and calculate CRI: In the final phase, attributes will be extracted for each factor identified in Phase 1. These attributes will be based on petrol station operation standards, best practices, and expert input.The attributes will then be aggregated with their weighted factors to calculate each petrol station’s integrated condition rating index (CRI). The CRI will provide a comprehensive measure of the overall condition of a petrol station.

3.1. Data Collection and Analysis for Phase One

- Cα: Is the Cronbach’s Alpha;

- n: Is the number of points;

- Vi: Is the variance of scores for each point;

- : Is the total variance of overall points.

3.2. Data Collection and Analysis for the Second Two

3.3. Data Collection and Analysis for Phase Three

3.4. Assigning Utility Scores

3.5. The AHP-MAUT CRI Model

- : Relative weight of each main factor (criterion)

- i: Relative weight of each sub-factor

- : Criterion j within factor i, and

- : The sub-factor preference utility value scored out of 10.

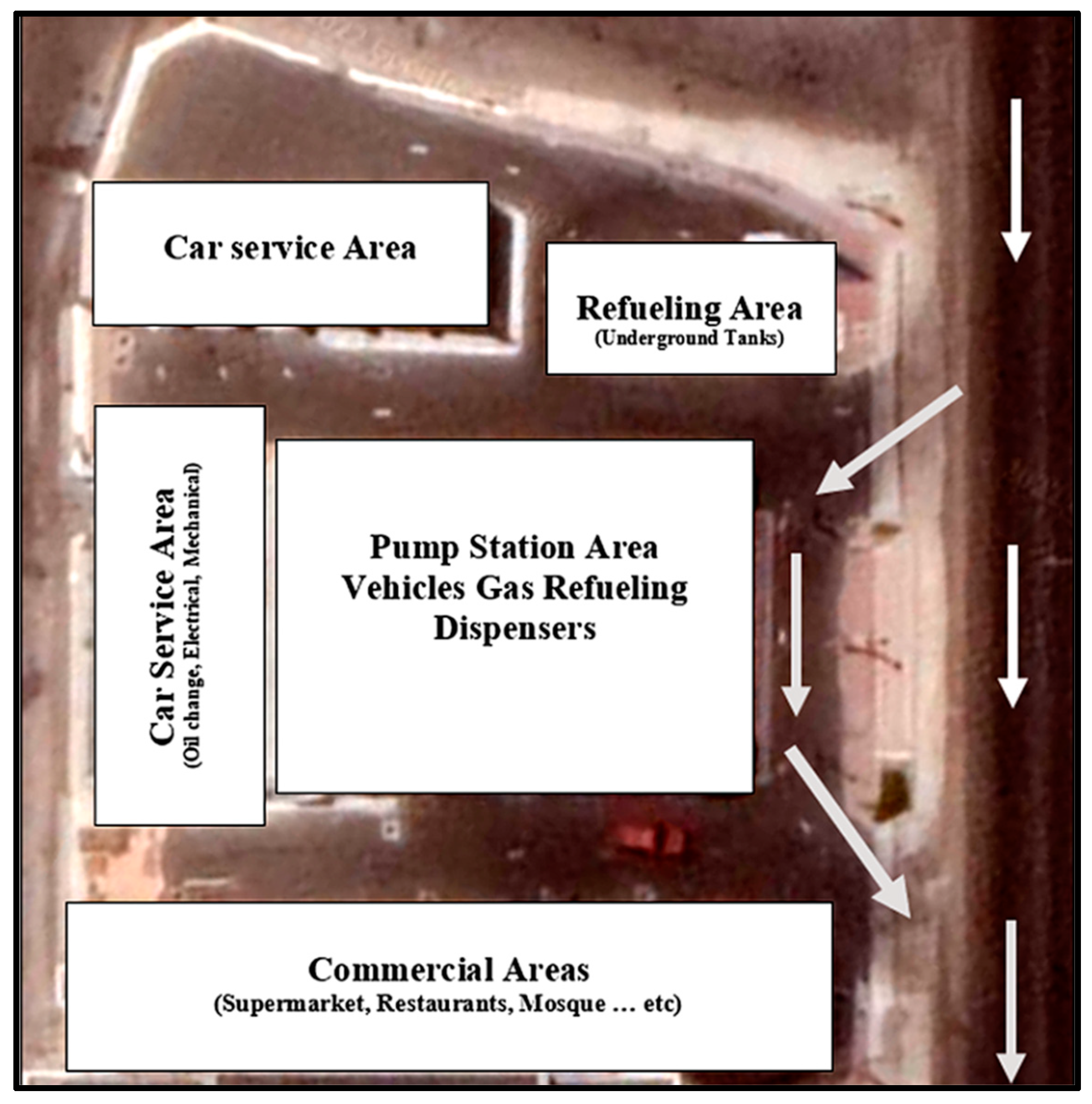

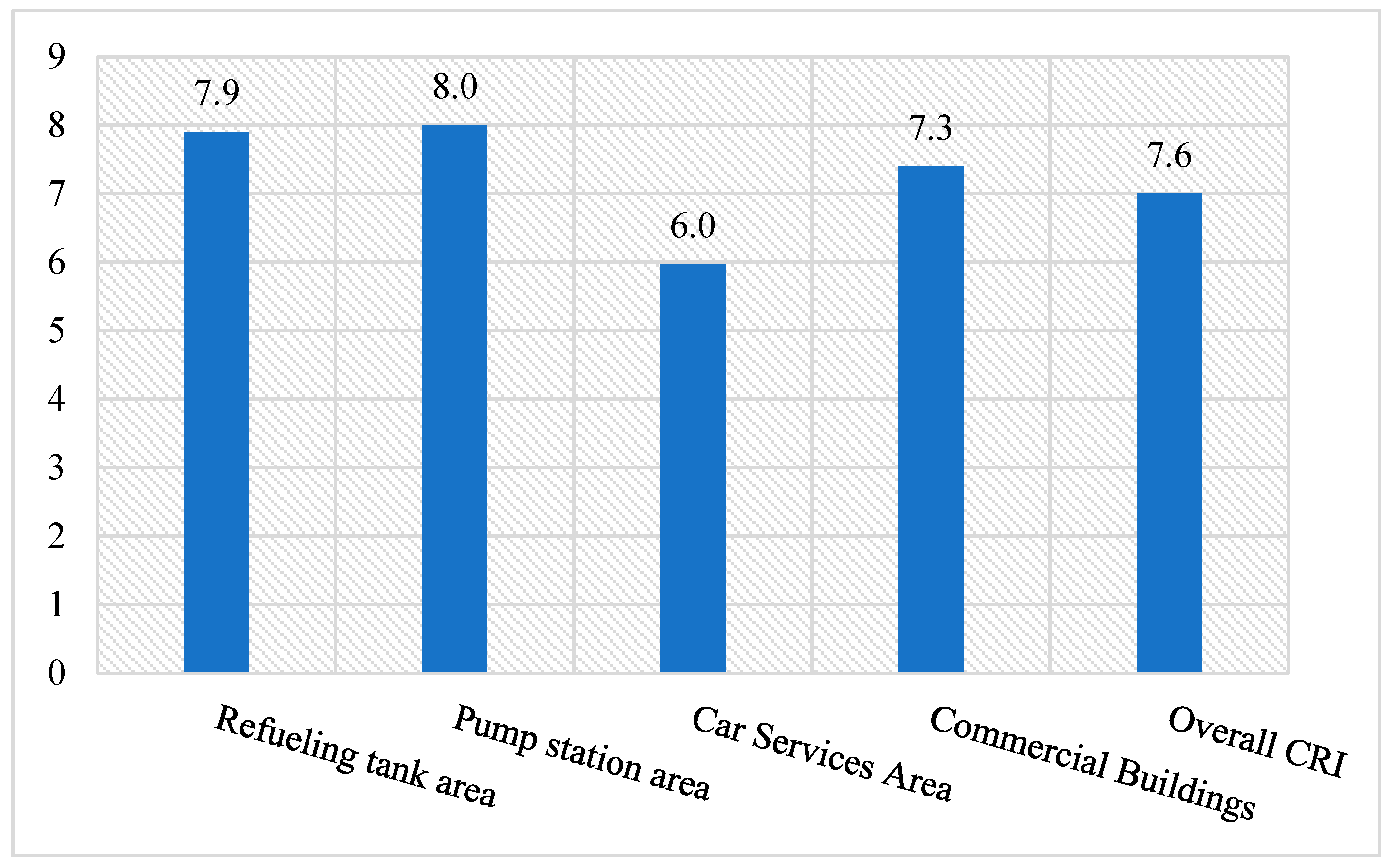

4. CRI Implementation

5. Discussion

6. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- KAPSARC. The Evolution of Gasoline Demand and Prices in Saudi Arabia; KAPSARC: Riyadh, Saudi Arabia, 2021. [Google Scholar]

- Ephraim Ntlaba, M. Strategic Asset Management: A Differentiating Strategy to Enhance a Competitive Advantage of Petrochemical Companies. Int. J. Bus. Econ. Res. 2014, 3, 118. [Google Scholar] [CrossRef]

- Adekunle, E.D.; Alex, O.T.; Adedayo, O.J. Occupational Health Hazards among Petrol Station Workers in Ibadan, Oyo State, Nigeria. Asian J. Chem. Sci. 2023, 13, 248–258. [Google Scholar] [CrossRef]

- Özbakır, O. Occupational Health and Safety in Fuel Stations: Hazard Analysis and Risk Assessment. Gümüşhane Üniversitesi Sağlık Bilim. Derg. 2024, 13, 1158–1173. [Google Scholar] [CrossRef]

- Kebut, C.; Mburu, C.; Kinyua, R. Assessment of Implementation of Fire Risk Reduction Rules at Petroleum Dispensing Stations in Kisumu County, Kenya. Open J. Saf. Sci. Technol. 2021, 11, 55–65. [Google Scholar] [CrossRef]

- Makiti, A.S.; Minga’ate, F. Environmental Health and Safety Practices in Petrol Stations in Nairobi County, Kenya. East Afr. J. Environ. Nat. Resour. 2023, 6, 311–324. [Google Scholar] [CrossRef]

- Aldeeb, O.; Qasem, A. Decision support system (DSS) for facilities rehabilitation and management (part 1): Development of integrated AHP-MAUT performance assessment model (PAM). Facilities 2022, 40, 845–861. [Google Scholar] [CrossRef]

- Savsar, M. Analysis and Scheduling of Maintenance Operations for a Chain of Gas Stations. J. Ind. Eng. 2013, 2013, 278546. [Google Scholar] [CrossRef]

- Atolagbe, B.; McNeil, S. Transportation Asset Management Decision Support Tools: Computational Complexity, Transparency, and Realism. Infrastructures 2023, 8, 143. [Google Scholar] [CrossRef]

- Oruwari, H.O.; Obunwa, Q. Sustainability of the Petroleum Industry. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 5–7 August 2024; SPE: Richardson, TX, USA, 2024. [Google Scholar] [CrossRef]

- Wynn, M.; Jones, P. Industry approaches to the Sustainable Development Goals. Int. J. Environ. Stud. 2022, 79, 134–148. [Google Scholar] [CrossRef]

- Leite Pacheco, J.M.; Neuma de Castro Dantas, T.; Salazar Aramayo, J.L.; dos Santos, A. A new sustainability analysis technique for the design of oil production facilities. Clean. Eng. Technol. 2022, 6, 100370. [Google Scholar] [CrossRef]

- Czaplińska, M.; Rymarzak, M.; Trojanowski, D. Fuel Station Valuation under Polish and RICS Standards. Real Estate Manag. Valuat. 2017, 25, 20–32. [Google Scholar] [CrossRef]

- Kanchwala, I. Designing a Computerized Maintenance Management System for Fuel Dispensing Machines in Petroleum Industry. Ind. Eng. J. 2019, 12. [Google Scholar] [CrossRef]

- Adedeji, O.H.; Olayinka, O.O.; Badejo, A.A.; Osunde, E.O. Spatial Distribution and Environmental Risk Assessment of Petrol Stations in Abeokuta Metropolis, Ogun State, Nigeria. J. Appl. Sci. Environ. Manag. 2022, 26, 1843–1850. [Google Scholar] [CrossRef]

- Kapila, L.; Chinedu, O. Enhancing Operational Efficiency in Oil and Gas Through I4.0-Enabled Condition-Based Maintenance. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Detroit, MI, USA, 10–14 August 2020; IEOM Society International: Southfield, MI, USA, 2024. [Google Scholar] [CrossRef]

- Meihong, Z.; Yun, L. Research on Gas Stations Automation Management System Based on Neural Network. In Proceedings of the 2009 WASE International Conference on Information Engineering, Taiyuan, Chanxi, 10–11 July 2009; IEEE: New York, NY, USA, 2009; pp. 573–575. [Google Scholar] [CrossRef]

- Moretti, N.; Xie, X.; Merino Garcia, J.; Chang, J.; Kumar Parlikad, A. Digital Twin based built environment asset management services development. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 092023. [Google Scholar] [CrossRef]

- Baswaid, A.M.S. Development of an Asset Management Framework for the Oil and Gas Industry. Ph.D. Thesis, Curtin University, Bentley, Australia, 2019. [Google Scholar]

- Chattopadhyay, G. Asset Management: A Holistic Approach to Cost Reduction, Risk Mitigation, and Performance Enhancement. In Advances in Risk-Informed Technologies; Springer: Singapore, 2024; pp. 25–31. [Google Scholar] [CrossRef]

- Abbasi, T.; Lim, K.H.; Ahmed Soomro, T.; Ismail, I.; Ali, A. Condition Based Maintenance of Oil and Gas Equipment: A Review. In Proceedings of the 2020 3rd International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Sukkur, Pakistan, 29–30 January 2020; IEEE: New York, NY, USA, 2020; pp. 1–9. [Google Scholar] [CrossRef]

- Triki, C.; Al-Hinai, N. Optimisation techniques for planning the petrol replenishment to retail stations over a multi-period horizon. Int. J. Oper. Res. 2016, 27, 341. [Google Scholar] [CrossRef]

- Al-Hinai, N.; Triki, C. A two-level evolutionary algorithm for solving the petrol station replenishment problem with periodicity constraints and service choice. Ann. Oper. Res. 2020, 286, 325–350. [Google Scholar] [CrossRef]

- Shulver, M. Total Productive Maintenance. In Wiley Encyclopedia of Management; Wiley: Hoboken, NJ, USA, 2015; pp. 1–2. [Google Scholar] [CrossRef]

- Quatrini, E.; Costantino, F.; Di Gravio, G.; Patriarca, R. Condition-Based Maintenance—An Extensive Literature Review. Machines 2020, 8, 31. [Google Scholar] [CrossRef]

- Li, W.; Lu, X.; Dong, X. Fire system safety risk cognition model and evaluation of major public safety risks. Front. Public Health 2022, 10, 987277. [Google Scholar] [CrossRef]

- Ren, X.; Dong, L.; Ren, J. Multi-criteria Decision Analysis Methods for Sustainability Assessment and Improvement of Energy Systems Under Uncertainties. In Multi-Criteria Decision Analysis; 1000minds: Dunedin, New Zealand, 2021; pp. 161–193. [Google Scholar] [CrossRef]

- Alvarez, C.; Lopez-Campos, M.; Stegmaier, R.; Mancilla-David, F.; Schurch, R.; Angulo, A. A Condition-Based Maintenance Model Including Resource Constraints on the Number of Inspections. IEEE Trans. Reliab. 2020, 69, 1165–1176. [Google Scholar] [CrossRef]

- Zhang, Y.; Ouyang, L.; Meng, X.; Zhu, X. Condition-based maintenance considering imperfect inspection for a multi-state system subject to competing and hidden failures. Comput. Ind. Eng. 2024, 188, 109856. [Google Scholar] [CrossRef]

- Mohad, F.T.; Gomes, L.d.C.; Tortorella, G.d.L.; Lermen, F.H. Operational excellence in total productive maintenance: Statistical reliability as support for planned maintenance pillar. Int. J. Qual. Reliab. Manag. 2024. [Google Scholar] [CrossRef]

- Ikhwan Sifa Bima, R.S. Analisis Total Productive Maintenance (TPM) Menggunakan Overall Equipment Effectiveness (OEE) Pada Unit Thresing Koperasi Kareb Bojonegoro. J. Ind. Eng. Technol. 2024, 4, 24–32. [Google Scholar] [CrossRef]

- Ahmed, M.M.; Kutty, S.R.M.; Shariff, A.M.; Khamidi, M.F. Petrol Fuel Station safety and risk assessment framework. In Proceedings of the 2011 National Postgraduate Conference, Perak, Malaysia, 19–20 September 2011; IEEE: New York, NY, USA, 2011; pp. 1–8. [Google Scholar] [CrossRef]

- Welfle, A.J.; Almena, A.; Arshad, M.N.; Banks, S.W.; Butnar, I.; Chong, K.J.; Cooper, S.J.G.; Daly, H.; Freites, S.G.; Güleç, F.; et al. Sustainability of bioenergy–Mapping the risks & benefits to inform future bioenergy systems. Biomass Bioenergy 2023, 177, 106919. [Google Scholar] [CrossRef]

- Blay-Roger, R.; Saif, M.; Bobadilla, L.F.; Ramirez-Reina, T.; Nawaz, M.A.; Odriozola, J.A. Embracing the sustainable horizons through bioenergy innovations: A path to a sustainable energy future. Front. Chem. 2024, 12, 1416102. [Google Scholar] [CrossRef]

- Susilowati, I.; Wijaya, B.S.; Ramadhani, J.S.; Azizah, M.N.; Yunus, N.R. Implementation of Saudi Aramco’s SDGS to Preserve the Environment in Meeting Global Energy Needs. Int. J. Soc. Sci. Hum. Res. 2023, 6. [Google Scholar] [CrossRef]

- Pison, G.; Van Aelst, S. Diagnostic Plots For Robust Multivariate Methods. J. Comput. Graph. Stat. 2004, 13, 310–329. [Google Scholar] [CrossRef]

- Kang, J.; Wang, Z.; Jin, H.; Dai, H.; Zhang, J.; Wang, L. Dynamic risk assessment of hybrid hydrogen-gasoline fueling stations using complex network analysis and time-series data. Int. J. Hydrogen Energy 2023, 48, 30608–30619. [Google Scholar] [CrossRef]

- Oyeniyi, L.D.; Ugochukwu, C.E.; Mhlongo, N.Z. IoT applications in asset management: A review of accounting and tracking techniques. Int. J. Sci. Res. Arch. 2024, 11, 1510–1525. [Google Scholar] [CrossRef]

- Sayed, M. Impact of Total Productive Maintenance Methodology on the Performance. Int. J. Res. Eng. Technol. 2015, 4, 34–37. [Google Scholar] [CrossRef]

- Bulut, M.S.; Ordu, M.; Der, O.; Basar, G. Sustainable Thermoplastic Material Selection for Hybrid Vehicle Battery Packs in the Automotive Industry: A Comparative Multi-Criteria Decision-Making Approach. Polymers 2024, 16, 2768. [Google Scholar] [CrossRef]

- Der, O.; Ordu, M.; Başar, G. Multi-Objective Optimization of Cutting Parameters for Polyethylene Thermoplastic Material by Integrating Data Envelopment Analysis and SWARA-Based CoCoSo Approach. Osman. Korkut Ata Üniversitesi Fen Bilim. Enstitüsü Derg. 2024, 7, 638–661. [Google Scholar] [CrossRef]

| Cronbach’s Alpha Values | “Interpretation” |

|---|---|

| 0.9 and greater | “High reliability” |

| 0.80–0.89 | “Good reliability” |

| 0.70–0.79 | “Acceptable reliability” |

| 0.65–0.69 | “Marginal reliability” |

| 0.50–0.64 | “Minimal reliability” |

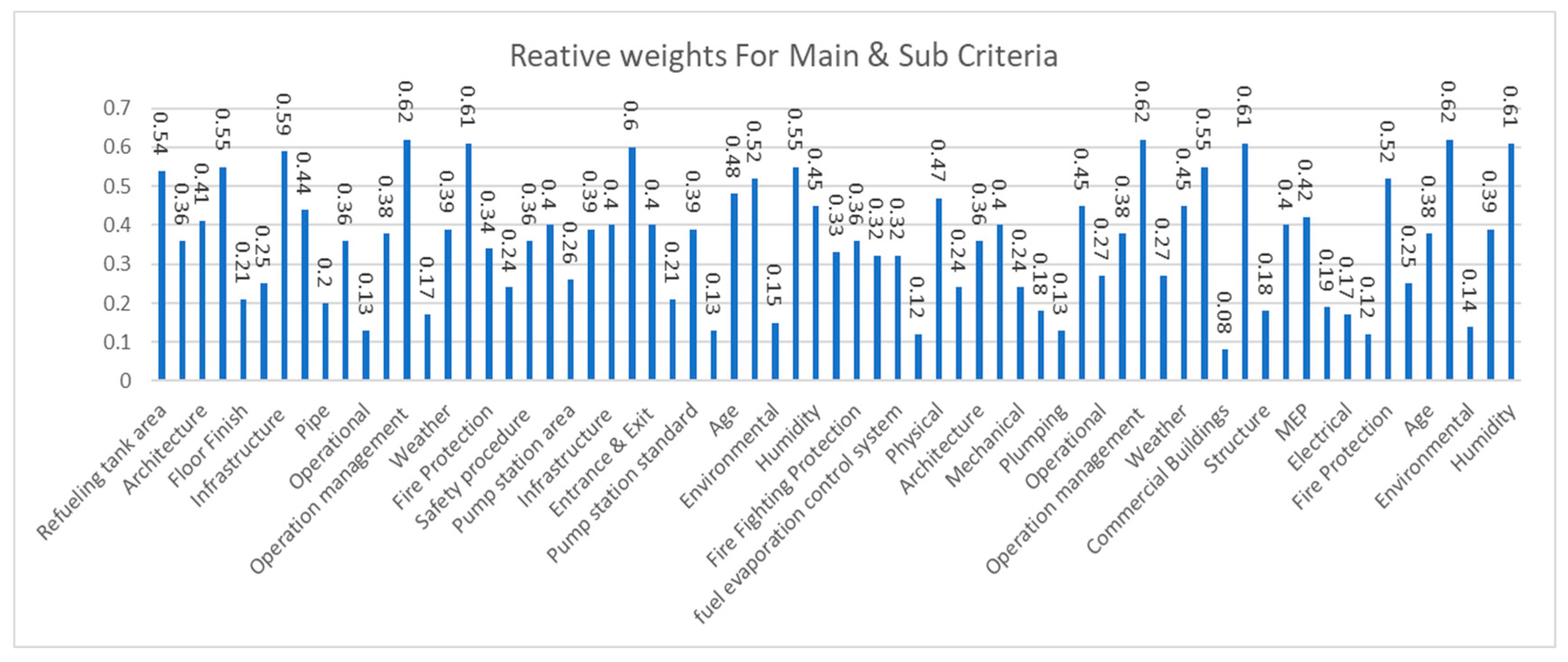

| Petrol Station Spaces | Relative Weight | COV | Cronbach Alpha |

|---|---|---|---|

| Refueling Tanks Area | 0.54 | 0.11 | 0.931 |

| Pump Station Area | 0.26 | 0.13 | |

| Car Service Area | 0.12 | 0.14 | |

| Commercial Building | 0.08 | 0.13 |

| Criteria Level | Functional Space | Final Relative Weights | COV | Cronbach’s Alpha |

|---|---|---|---|---|

| Overall Functional Spaces | ||||

| 1 | Refueling Tanks Area | 0.54 | 0.11 | 0.931 |

| Pump Station Area | 0.26 | 0.13 | ||

| Car Service Area | 0.12 | 0.14 | ||

| Commercial Buildings Area | 0.08 | 0.13 | ||

| Refueling Tank Area | ||||

| 2 | Physical | 0.36 | 0.14 | 0.861 |

| Operational | 0.13 | 0.13 | ||

| Environmental | 0.17 | 0.31 | ||

| Fire Protection | 0.34 | 0.21 | ||

| 3 | Architecture | 0.41 | 0.13 | 0.765 |

| Infra. | 0.59 | 0.16 | ||

| 4 | Entrance and Exit | 0.55 | 0.18 | 0.839 |

| Floor Finish | 0.21 | 0.16 | ||

| Fueling Area Standard | 0.25 | 0.16 | ||

| 5 | Tank | 0.44 | 0.21 | 0.869 |

| Pipe | 0.20 | 0.28 | ||

| Pump | 0.36 | 0.13 | ||

| 6 | Operational Age | 0.38 | 0.16 | 0.910 |

| Operation Management | 0.62 | 0.13 | ||

| 7 | Weather | 0.39 | 0.16 | 0.875 |

| Humidity | 0.61 | 0.16 | ||

| 8 | Fire Fighting Protection | 0.24 | 0.23 | 0.855 |

| Safety Procedure | 0.36 | 0.19 | ||

| Fuel Evaporation Control System | 0.40 | 0.2 | ||

| Pump Station Area | ||||

| 9 | Physical | 0.39 | 0.21 | 0.839 |

| Operational | 0.13 | 0.28 | ||

| Environmental | 0.15 | 0.13 | ||

| Fire Protection | 0.33 | 0.16 | ||

| 10 | Infrastructure | 0.40 | 0.13 | 0.711 |

| Architecture | 0.60 | 0.16 | ||

| 11 | Entrance and Exit | 0.40 | 0.16 | 0.834 |

| Floor Finish | 0.21 | 0.23 | ||

| Fueling Area Standard | 0.39 | 0.19 | ||

| 12 | Operational Age | 0.48 | 0.2 | 0.894 |

| Operation Management | 0.52 | 0.18 | ||

| 13 | Weather | 0.55 | 0.16 | 0.943 |

| Humidity | 0.45 | 0.16 | ||

| 14 | Fire Fighting Protection | 0.36 | 0.23 | 0.895 |

| Safety Procedure | 0.32 | 0.19 | ||

| Fuel Evaporation Control System | 0.32 | 013 | ||

| Car Services Buildings | ||||

| 15 | Physical | 0.47 | 0.11 | 0.785 |

| Operational | 0.27 | 0.25 | ||

| Environmental | 0.27 | 0.2 | ||

| 16 | Structure | 0.24 | 0.18 | 0.751 |

| Architecture | 0.36 | 0.19 | ||

| MEP | 0.40 | 0.26 | ||

| 17 | Mechanical | 0.24 | 0.25 | 0.762 |

| Electrical | 0.18 | 0.19 | ||

| Plumping | 0.13 | 0.26 | ||

| Fire Protection | 0.45 | 0.25 | ||

| 18 | Operational Age | 0.38 | 0.19 | 0.784 |

| Operation Management | 0.62 | 0.23 | ||

| 19 | Weather | 0.45 | 0.18 | 0.859 |

| Humidity | 0.55 | 0.19 | ||

| Commercial Buildings | ||||

| 20 | Physical | 0.61 | 0.25 | 0.811 |

| Operational | 0.25 | 0.17 | ||

| Environmental | 0.14 | 0.19 | ||

| 21 | Structure | 0.18 | 0.2 | 0.851 |

| Architecture | 0.40 | 0.18 | ||

| MEP | 0.42 | 0.16 | ||

| 22 | Mechanical | 0.19 | 0.16 | 0.845 |

| Electrical | 0.17 | 0.23 | ||

| Plumping | 0.12 | 0.19 | ||

| Fire Protection | 0.52 | 0.2 | ||

| 23 | Operational Age | 0.38 | 0.18 | 0.823 |

| Operation Management | 0.62 | 0.13 | ||

| 24 | Weather | 0.39 | 1.15 | 0.743 |

| Humidity | 0.61 | 0.16 | ||

| (a) | ||||

| Factor | Sub-Factor | Utility Score | Utility Description | |

| Architectural Factors | Entrance and exit | 8–10 | Efficient flow, clear signs, safety measures, and vehicle access for all. | |

| 6–8 | Modest efficient flow, clear signs, safety measures, and vehicle access for all. | |||

| 4–6 | Acceptable efficient flow, clear signs, safety measures, and vehicle access for all. | |||

| 2–4 | Inefficient flow, no clear signs, no or inadequate safety measures, and restricted vehicle access. | |||

| Floor Finish | 8–10 | Highly durable, slip-resistant, chemically resistant, and compliant for easy maintenance. | ||

| 6–8 | Moderate durable, slip-resistant, chemically resistant, and compliant for easy maintenance. | |||

| 4–6 | Acceptable: durable, slip-resistant, chemically resistant, and compliant for easy maintenance. | |||

| 2–4 | Non-durable, slip-resistant, chemically resistant, and compliant for easy maintenance. | |||

| Fueling Area Design and Standards | 8–10 | Fully available functioning safety measures, fuel pump integrity, environmental protection, and certified operational requirements. | ||

| 6–8 | Available functioning safety measures, acceptable fuel pump integrity, environmental protection available systems, and certified operational requirements. | |||

| 4–6 | Available functioning safety measures with minor incidence, acceptable fuel pump integrity records, semi-functional environmental protection available systems, and certified operational requirements. | |||

| 2–4 | Available functioning safety measures with many incidents, bad fuel pump integrity, semi-functional environmental protection systems, and operational requirements violations. | |||

| (b) | ||||

| Factor | Sub-factor | Utility score | Utility Description | |

| Infrastructure | Tanks | 8–10 | Available leak detection and prevention systems; excellent structural integrity; available installation records; available corrosion protection measures. | |

| 6–8 | Available leak detection and prevention systems; good structural integrity; available installation records; available corrosion protection measures. | |||

| 4–6 | Available leak detection and prevention systems; acceptable structural integrity; semi-available installation and maintenance records; available corrosion protection measures. | |||

| 2–4 | Available but defective leak detection and prevention systems; inadequate to critical structural integrity; messy or unavailable maintenance records; visible corrosion in the tanks. | |||

| Pipes | 8–10 | Excellent pipe material with no corrosion, full compliance with safety and environment standards, pressure and flow are satisfied, available maintenance records with updates. | ||

| 6–8 | Excellent pipe material with no corrosion, partial compliance with safety and environment standards, pressure and flow are satisfied with minor downtime, partially updated maintenance records with updates. | |||

| 4–6 | Acceptable pipe material with minor corrosion, low compliance with safety and environment standards, pressure, and flow are satisfied with clear downtime and updated maintenance. | |||

| 2–4 | Clearly visible pipe corrosion, low compliance with safety and environment standards, pressure and flow are satisfied with clear downtime and updated maintenance. | |||

| Pumps | 8–10 | Calibrated flow rate, ensured no leaks, compliance with safety and environmental standards, and updated maintenance records. | ||

| 6–8 | Calibrated flow rate with minor errors, ensured no leaks, no downtime, Acceptable compliance with safety and environmental standards, and available maintenance records. | |||

| 4–6 | Calibrated flow rate with clear errors, ensured no leaks or downtime, had acceptable compliance with safety and environmental standards, and had incomplete maintenance records. | |||

| 2–4 | Major flow rate calibration errors, some leaks, non-acceptable downtime, questioned compliance with safety and environmental standards, and incomplete maintenance records. | |||

| (c) | ||||

| Factor | Sub-factor | Utility score | Utility Description | |

| Operational | Operational Age | 8–10 | 0–5 | (New units fully operation conditions) |

| 6–8 | 5–10 | (Good operating condition and proper maintenance) | ||

| 4–6 | 10–15 | (Aging units in acceptable operating conditions) | ||

| 2–4 | 15–20 | (Approaching end of service life with faulty operation) | ||

| 1 | >20 | End of service life (depends on the unit’s useful life) | ||

| Operation Management Standards | 8–10 | Fully trained workers, full compliance with safety regulations, standard customer service and marketing practices, excellent equipment condition and maintenance records, applying fuel quality control and inventory management, continuous employee training, and upgrades programs. | ||

| 6–8 | Good level of trained workers, full compliance with safety regulations, standard customer service and marketing practices, good equipment condition and maintenance records, applying fuel quality control and inventory management, available employee training and upgrades programs. | |||

| 4–6 | Acceptable level of trained workers, good compliance with safety regulations, local customer service and marketing practices, acceptable equipment condition and maintenance records, applying acceptable fuel quality control and inventory management, weak employee training and upgrades programs. | |||

| 2–4 | Unacceptable level of trained workers, barely compliance with safety regulations, local customer service and marketing practices, non-acceptable equipment condition and maintenance records, missing good fuel quality control and inventory management, non-employee training and upgrades programs. | |||

| (d) | ||||

| Factor | Sub-factor | Utility score | Utility Description | |

| Environmental | Weather | 8–10 | Moderate weather all year has mild or no influence on petrol station performance, which depends on demand, footfall, operations, infrastructure, and safety. | |

| 6–8 | Moderate to severe weather yearly cycles have a noticeable impact and need proper maintenance programs to keep good performance and not affect operations, safety, and supply chain. | |||

| 4–6 | Moderate to severe weather almost all year has a noticeable impact on petrol stations’ infrastructure, personnel safety, operation disruption, and failing supply chain operations. | |||

| 2–4 | Extreme weather can influence petrol station performance by affecting fuel demand, footfall, operations, infrastructure, safety, and supply chain management. | |||

| Humidity | 8–10 | Mild to low humidity in weather has minimal impact on fuel quality, low impact on equipment corrosion, and no impact on the safety procedures or operation practices. | ||

| 6–8 | Seasonal humidity cycles in weather remarkably affect fuel quality, accelerate equipment corrosion, raise safety concerns, and impact vapor recovery systems. | |||

| 4–6 | Daily humidity cycles and high temperatures with salty weather severely affect equipment, accelerate equipment corrosion, raise safety concerns, jeopardize vapor recovery systems, and affect fuel quality. | |||

| 2–4 | Sever high humidity in weather, including temperature daily and seasonal cycles, in addition to salty vapors, affects fuel quality, accelerates equipment corrosion, raises safety concerns, and damages vapor recovery systems. | |||

| Fire Protection and Safety | 8–10 | Petrol stations are fully equipped with safety measures like fire extinguishers, automatic fire suppression systems, and emergency shutdown systems to mitigate fire risks. In addition, there are good records for regular inspections, maintenance, and staff training for compliance and preparedness. | ||

| 6–8 | Petrol stations are fully equipped with safety measures like fire extinguishers, automatic fire suppression systems, and emergency shutdown systems to mitigate fire risks. In addition, there are some records for regular inspections, maintenance, and acceptable staff training. | |||

| 4–6 | Petrol stations are partially equipped with some safety measures like fire extinguishers. However, automatic fire suppression systems are missing, and emergency shutdown systems are manually operated only. They lack inspection and maintenance records, in addition to primitive staff training. | |||

| 2–4 | Petrol stations are partially equipped with some safety measures like fire extinguishers. However, automatic fire suppression systems are missing, and there are no emergency shutdown systems, no recodes of inspection maintenance, and no staff training program. | |||

| Condition Score | Condition | Description |

|---|---|---|

| 9–10 | Excellent | The facility is in excellent condition; no rehabilitation is needed. |

| 8–<9 | Good | The facility is in good system condition; minor routine maintenance is needed. |

| 7–<8 | Acceptable | The facility is in acceptable condition, but essential maintenance is needed to keep it functional. |

| 5–<7 | Bad | The facility needs immediate intervention to keep working. Otherwise, the facility must be closed since its performance is below acceptable level. |

| 3–4 | Critical | The facility is non-functional and needs major rehabilitation or replacement. |

| 1–2 | Severe | Unsafe immediate closure is enforced. |

| H. Level | Criteria Main Factor & Subfactors | Relative Weight wt | Utility Score U | Condition Linguistic Description | wt xU | Aggerated Score | Petrol Station Spaces CR | Petrol Station Overall CR |

|---|---|---|---|---|---|---|---|---|

| Space 1 | Refueling tank area | 0.54 | 6.8 | Acceptable | 6.23 | 7.9 | 7.6 | |

| 1.1 | Physical | 0.36 | 8 | Good | 8 | 7.9 | ||

| 1.1.1 | Architecture | 0.41 | 8 | Good | 7.87 | |||

| 1.1.1.1 | Entrance & Exit | 0.55 | 8 | Good | 4.4 | |||

| 1.1.1.2 | Floor Finish | 0.21 | 7 | Acceptable | 1.47 | |||

| 1.1.1.3 | Fueling area standard | 0.25 | 8 | Good | 2 | |||

| 1.1.2 | Infrastructure | 0.59 | 8 | Good | 7.92 | |||

| 1.1.2.1 | Tank | 0.44 | 7 | Acceptable | 3.08 | |||

| 1.1.2.2 | Pipe | 0.2 | 8 | Good | 1.6 | |||

| 1.1.2.3 | Pump | 0.36 | 9 | Excellent | 3.24 | |||

| 1.2 | Operational | 0.13 | 7.5 | Acceptable | 7.62 | 7.62 | ||

| 1.2.1 | Age | 0.38 | 7 | Acceptable | 2.66 | |||

| 1.2.2 | Operation management | 0.62 | 8 | Good | 4.96 | |||

| 1.3 | Environmental | 0.17 | 4 | Critical | 3.56 | 3.52 | ||

| 1.3.1 | Weather | 0.39 | 6 | Bad | 2.34 | |||

| 1.3.2 | Humidity | 0.61 | 2 | Sever | 1.22 | |||

| 1.4 | Fire Protection | 0.34 | 7 | Acceptable | 6.88 | 6.88 | ||

| 1.4.1 | Fire Fighting Protection | 0.24 | 8 | good | 1.92 | |||

| 1.4.2 | Safety procedure | 0.36 | 6 | Bad | 2.16 | |||

| 1.4.3 | Fuel evaporation ctrl. sys | 0.4 | 7 | Acceptable | 2.8 | |||

| Space 2 | Pump station area | 0.26 | 7 | Acceptable | 7 | 8 | ||

| 2.1 | Physical | 0.39 | 8 | Good | 8 | 8 | ||

| 2.1.1 | Infrastructure | 0.4 | 8 | Good | 3.2 | |||

| 2.1.2 | Architecture | 0.6 | 8 | Acceptable | 7.81 | |||

| 2.1.2.1 | Entrance & Exit | 0.4 | 7 | Good | 2.8 | |||

| 2.1.2.2 | Finish | 0.21 | 9 | Excellent | 1.89 | |||

| 2.1.2.3 | Pump station standard | 0.39 | 8 | Good | 3.12 | |||

| 2.2 | Operational | 0.13 | 8 | Acceptable | 7.52 | 7.52 | ||

| 2.2.1 | Age | 0.48 | 7 | Acceptable | 3.36 | |||

| 2.2.2 | Operation management | 0.52 | 8 | Good | 4.16 | |||

| 2.3 | Environmental | 0.15 | 7 | Bad | 4.2 | 4.2 | ||

| 2.3.1 | Weather | 0.55 | 6 | Bad | 3.3 | |||

| 2.3.2 | Humidity | 0.45 | 2 | Sever | 0.9 | |||

| 2.4 | Fire Protection | 0.33 | 7 | Acceptable | 7.04 | 7.04 | ||

| 2.4.1 | Fire Fighting Protection | 0.36 | 8 | good | 2.88 | |||

| 2.4.2 | Safety procedure | 0.32 | 6 | Bad | 1.92 | |||

| 2.4.3 | Fuel evaporation ctrl. Sys | 0.32 | 7 | Acceptable | 2.24 | |||

| Space 3 | Car Services Area | 0.12 | 5 | Bad | 5.22 | 6.0 | ||

| 3.1 | Physical | 0.47 | 6 | Bad | 2.82 | 5.97 | ||

| 3.1.1 | Structure | 0.24 | 7 | Acceptable | 7 | |||

| 3.1.2 | Architecture | 0.36 | 6 | Bad | 6 | |||

| 3.1.3 | MEP | 0.4 | 6 | Bad | 5.33 | |||

| 3.1.3.1 | Mechanical | 0.24 | 6 | Bad | 1.44 | |||

| 3.1.3.2 | Electrical | 0.18 | 8 | Good | 1.44 | |||

| 3.1.3.3 | Plumping | 0.13 | 5 | Bad | 0.65 | |||

| 3.1.3.4 | Fire Protection | 0.45 | 4 | Critical | 1.8 | |||

| 3.2 | Operational | 0.27 | 6 | Bad | 5.14 | 5.14 | ||

| 3.2.1 | Age | 0.38 | 7 | Acceptable | 2.66 | |||

| 3.2.2 | Operation management | 0.62 | 4 | Critical | 2.48 | |||

| 3.3 | Environmental | 0.27 | 5 | Bad | 3.8 | 3.8 | ||

| 3.3.1 | Weather | 0.45 | 6 | Bad | 2.7 | |||

| 3.3.2 | Humidity | 0.55 | 2 | Sever | 1.1 | |||

| Space 4 | Commercial Buildings | 0.08 | 6 | Bad | 6 | 7.3 | ||

| 4.1 | Physical | 0.61 | 7 | Acceptable | 7 | 7.4 | ||

| 4.1.1 | Structure | 0.18 | 7 | Acceptable | 7 | |||

| 4.1.2 | Architecture | 0.4 | 6 | Bad | 7 | |||

| 4.1.3 | MEP | 0.42 | 8 | Acceptable | 7.95 | |||

| 4.1.3.1 | Mechanical | 0.19 | 9 | Excellent | 1.71 | |||

| 4.1.3.2 | Electrical | 0.17 | 8 | Good | 1.36 | |||

| 4.1.3.3 | Plumping | 0.12 | 6 | Bad | 0.72 | |||

| 4.1.3.4 | Fire Protection | 0.52 | 8 | Good | 4.16 | |||

| 4.2 | Operational | 0.25 | 6 | Bad | 6 | 5.14 | ||

| 4.2.1 | Age | 0.38 | 7 | Acceptable | 2.66 | |||

| 4.2.2 | Operation management | 0.62 | 4 | Critical | 2.48 | |||

| 4.3 | Environmental | 0.14 | 8 | Acceptable | 8 | 3.56 | ||

| 4.3.1 | Weather | 0.39 | 6 | Bad | 2.34 | |||

| 4.3.2 | Humidity | 0.61 | 2 | Sever | 1.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qasem, A. Performance Assessment Model for Petrol Stations Using a Multi-Criteria Condition Rating Index. Sustainability 2025, 17, 2355. https://doi.org/10.3390/su17062355

Qasem A. Performance Assessment Model for Petrol Stations Using a Multi-Criteria Condition Rating Index. Sustainability. 2025; 17(6):2355. https://doi.org/10.3390/su17062355

Chicago/Turabian StyleQasem, Altayeb. 2025. "Performance Assessment Model for Petrol Stations Using a Multi-Criteria Condition Rating Index" Sustainability 17, no. 6: 2355. https://doi.org/10.3390/su17062355

APA StyleQasem, A. (2025). Performance Assessment Model for Petrol Stations Using a Multi-Criteria Condition Rating Index. Sustainability, 17(6), 2355. https://doi.org/10.3390/su17062355