Holistic Sustainable Design: Incorporating Change Propagation and Triple Bottom Line Sustainability

Abstract

1. Introduction

2. Background

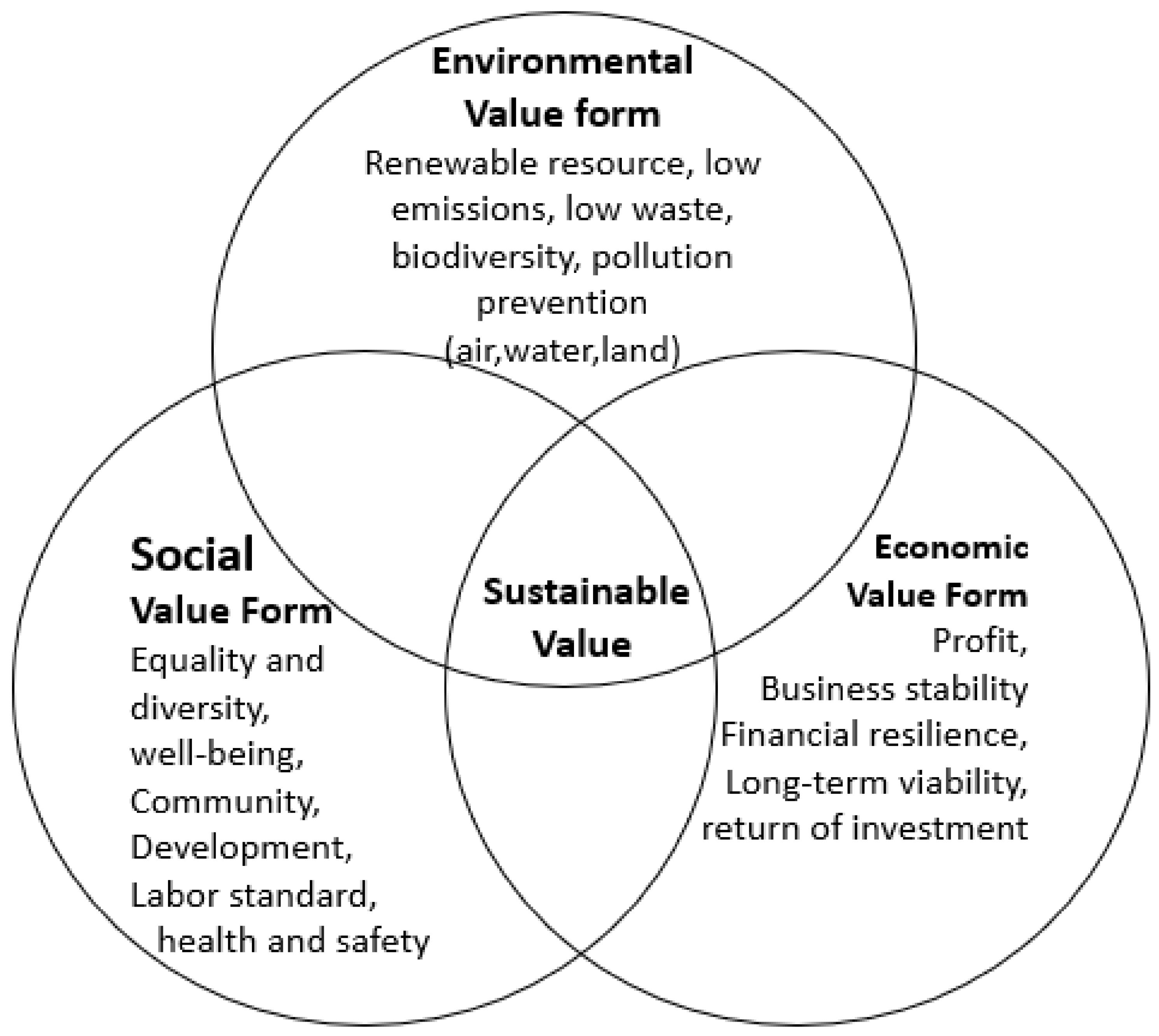

2.1. Sustainable Product Design

- Navigating a complex landscape of tools: The quantity of sustainable design methodologies available makes it difficult for practitioners to identify the most effective approach for a given product or industry.

- Lack of universal applicability: Many sustainability tools are designed to address specific industries or design challenges, making them unsuitable for broader implementation across diverse engineering fields.

- Overemphasis on environmental factors: Most available tools prioritize environmental impact assessment, often overlooking critical economic and social dimensions of sustainability.

- Weak links between design decisions and sustainability outcomes: Many existing tools fail to translate sustainability assessments into actionable design recommendations, limiting their practical application.

2.2. Change Propagation

2.3. Life Cycle Assessment

- Goal and Scope: The first step of LCA is to define the goal and scope of the analysis, which includes identifying the system boundaries and specifying the life cycle stages that should be included in the analysis. The product and product system should be described, including the product’s upstream and downstream processes. The product’s components, manufacturing, distribution, use, and disposal are considered in these streams. In addition, the product’s intended function and the functional unit should be defined in this stage. A functional unit is a measure used to quantify a product’s function and provide a standard basis for comparisons. Another parameter defined in this phase of LCA is the reference flow, which includes the product required to fulfill the defined function. Using the parameters in the previous steps, the system boundaries can be defined by selecting which unit processes need to be included in the analysis. The selection process is done based on the environmental significance of the processes. Then, the selected unit processes and boundaries are combined to create a process tree to demonstrate the inputs and outputs of the unit processes within the production system.

- Inventory Analysis: The life cycle inventory (LCI) analysis includes data collection, validation, and calculation of the inputs and outputs of the product system defined. These data include inputs (e.g., energy, materials, water) and outputs (e.g., emissions, waste) associated with each life cycle phase of the product. The sources of LCI are categorized into primary and secondary data. The primary data are collected by direct measurements and observations with the highest accuracy, but they are time-consuming and costly. Secondary data refers to data collected from existing sources that provide access to a wide range of information collected by various entities, making it easier to gather data efficiently. The activities and processes within the system boundary defined earlier are analyzed concerning a reference flow (functional unit) to determine the overall inputs and outputs of the product system.

- Impact Assessment: The inventory data collected in the LCI analysis step is implemented in the life cycle impact assessment (LCIA) to quantify the product’s environmental impacts. LCIA includes classification, characterization, and two optional steps of normalization and weighting. The inventory data collected are classified into different impact categories. The LCIA method selected for LCA is an essential part of the framework to represent the environmental impacts in a meaningful format. One of the most popular LCIA methods is ReCiPe, which transforms the LCI results into 18 midpoint categories and then aggregates those midpoints into three endpoint categories. These endpoints are also known as areas of protection, which are damage to human health, damage to ecosystems, and damage to resource availability [42]. Each endpoint is measured in terms of its specific unit representing the value of environmental impacts. The damage to human health is measured as disability-adjusted life years (DALYs), the unit for damage to ecosystems is the local species loss integrated over time (species.year), and the damage to resource availability has a unit of U.S. dollars (USD), which represents the extra costs involved for future mineral and fossil resource extraction. ReCiPe offers three cultural perspective factors: I, H, and E. The individualist (I) perspective is a short-term, optimistic view that technology can avoid many problems in the future. The hierarchist (H) is based on scientific consensus concerning the time frame, and the egalitarian (E) perspective takes a long-term view based on precautionary thinking.

- Interpretation: The last step of LCA is interpreting the results, which includes three key elements: identification of key issues, evaluation of the results, conclusions, and recommendations.

3. Methodology

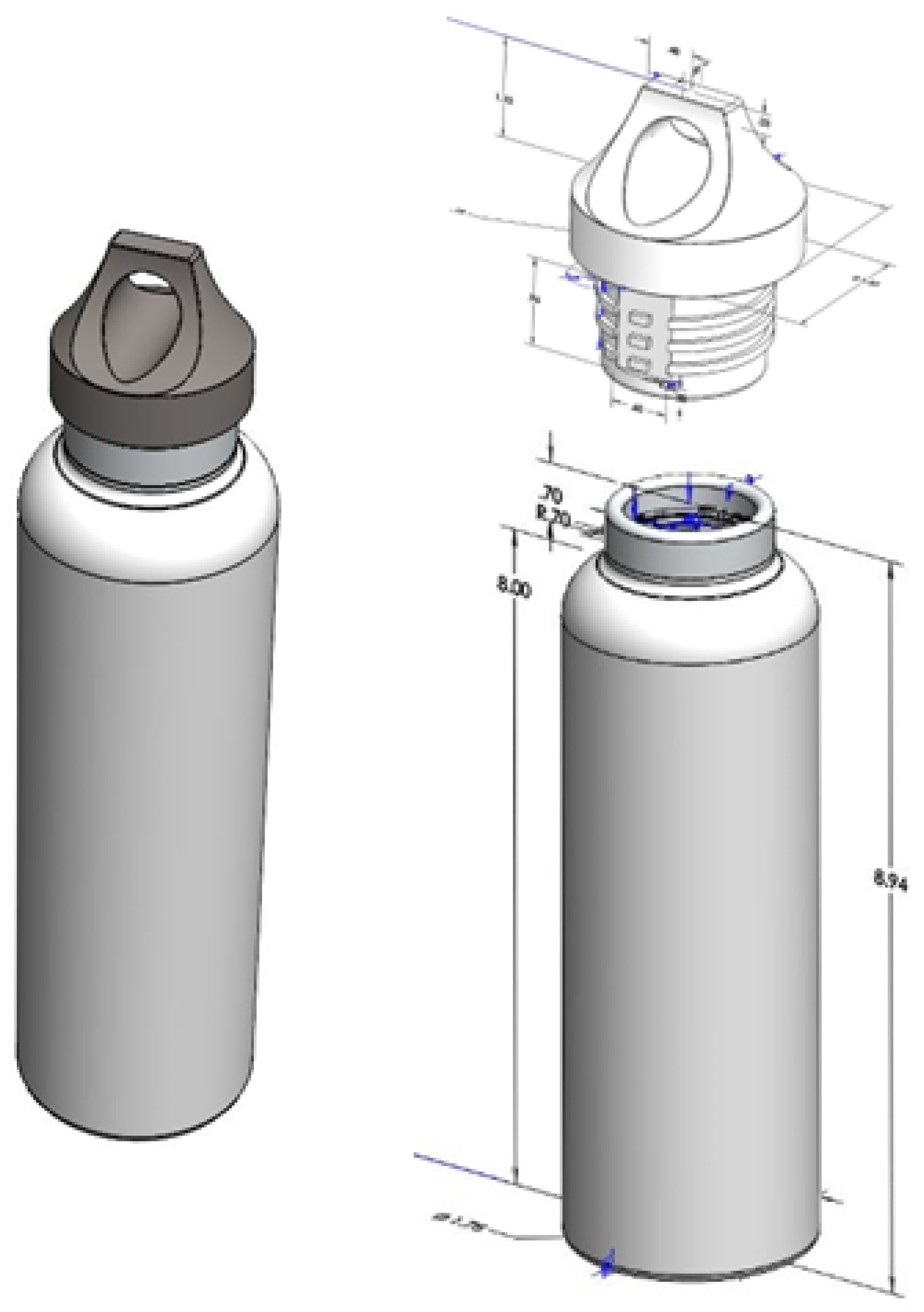

3.1. Reusable Water Bottle Case Study

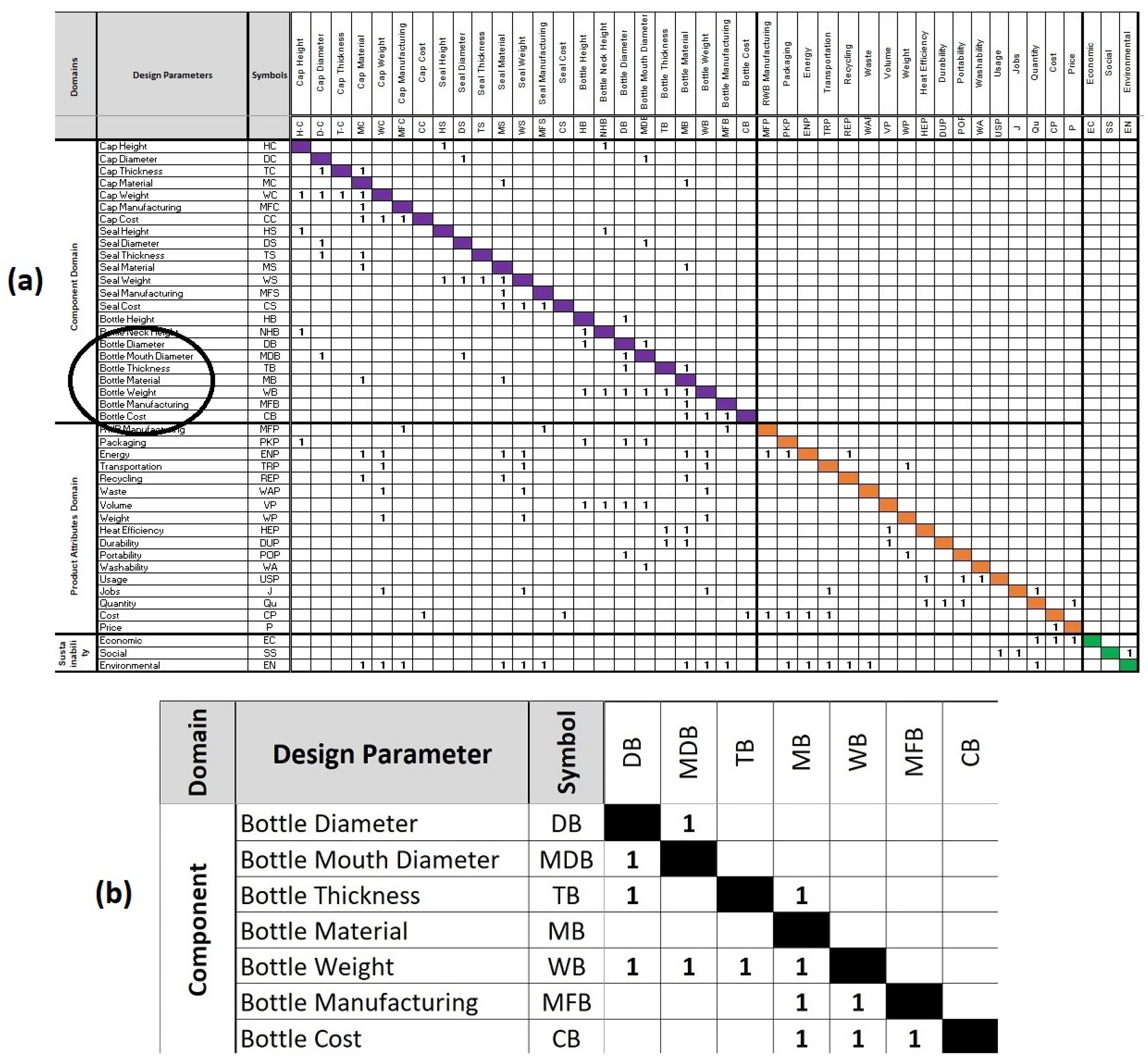

3.2. System Definition

3.3. Change Propagation

3.3.1. Economic Sustainability

3.3.2. Social Sustainability

3.3.3. Environmental Sustainability

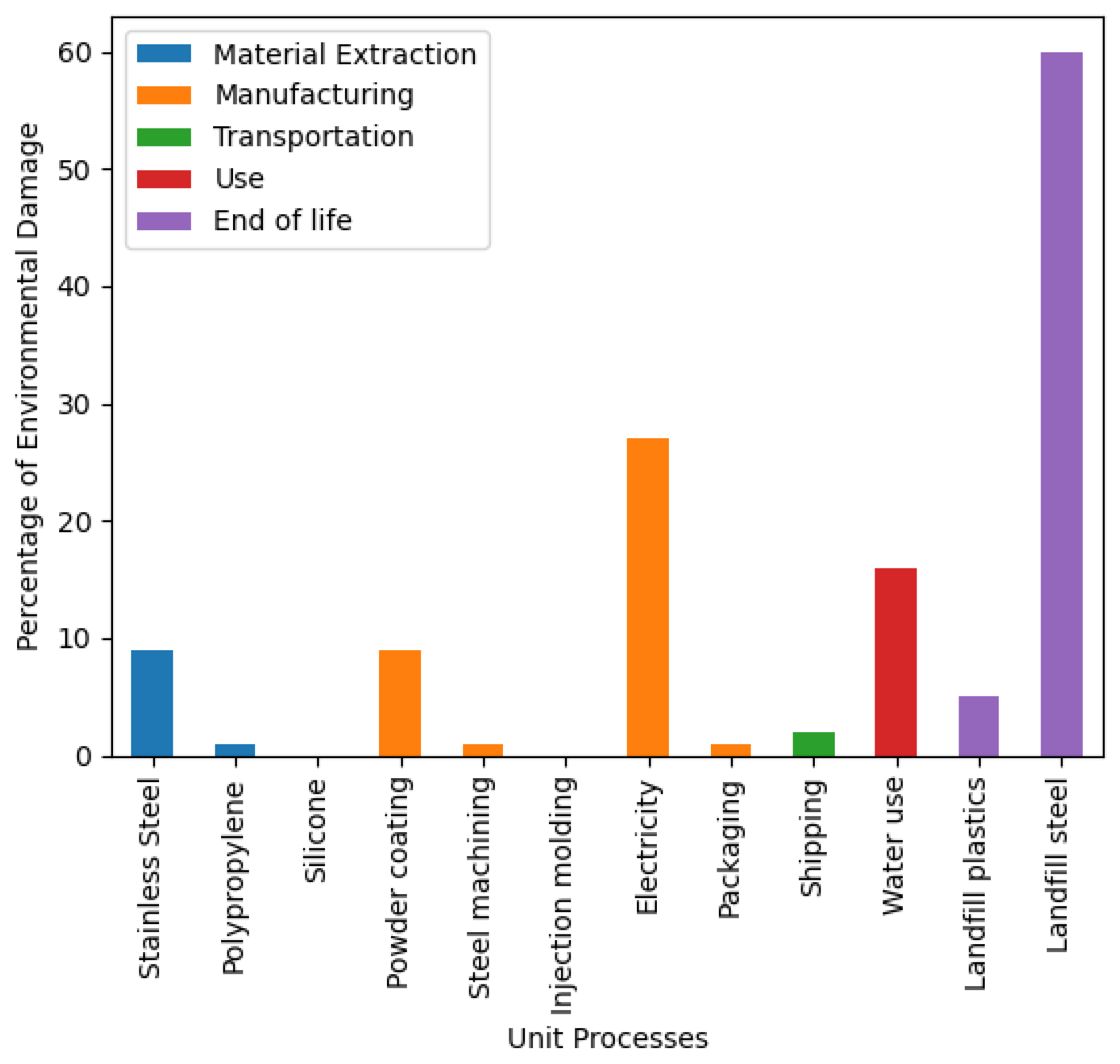

Goal and Scope

Life Cycle Inventory

Life Cycle Impact Assessment

4. Results

4.1. Sustainability Assessment

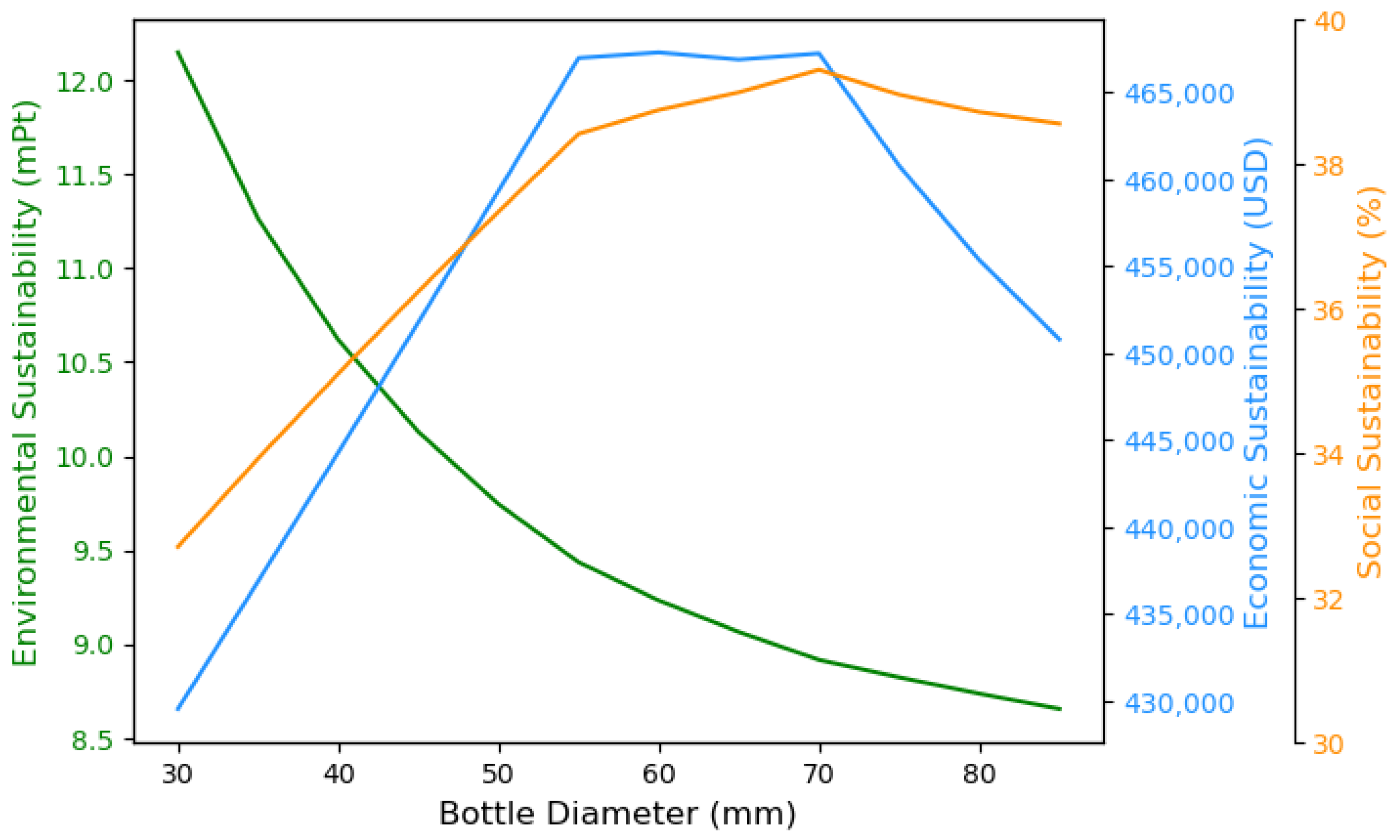

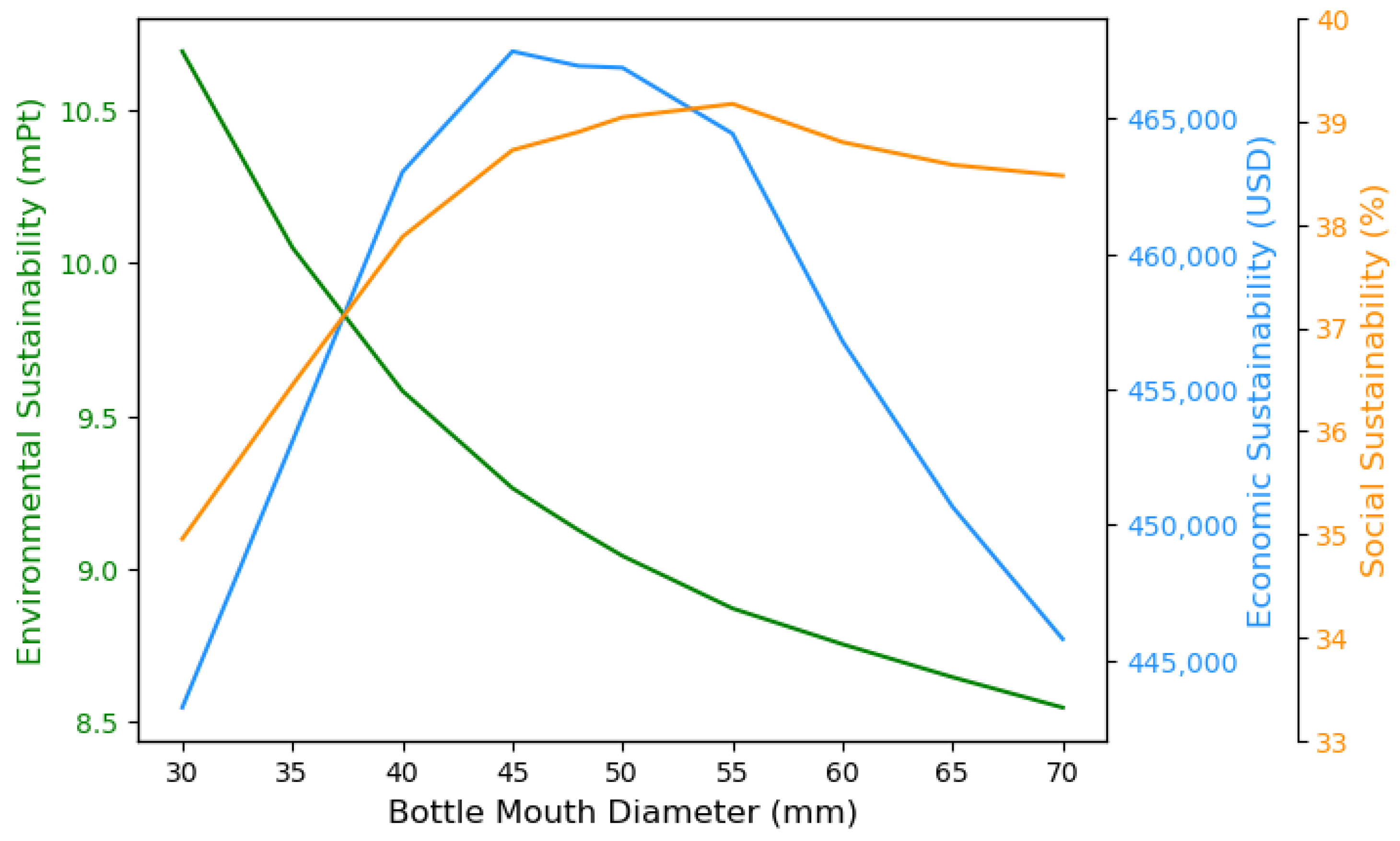

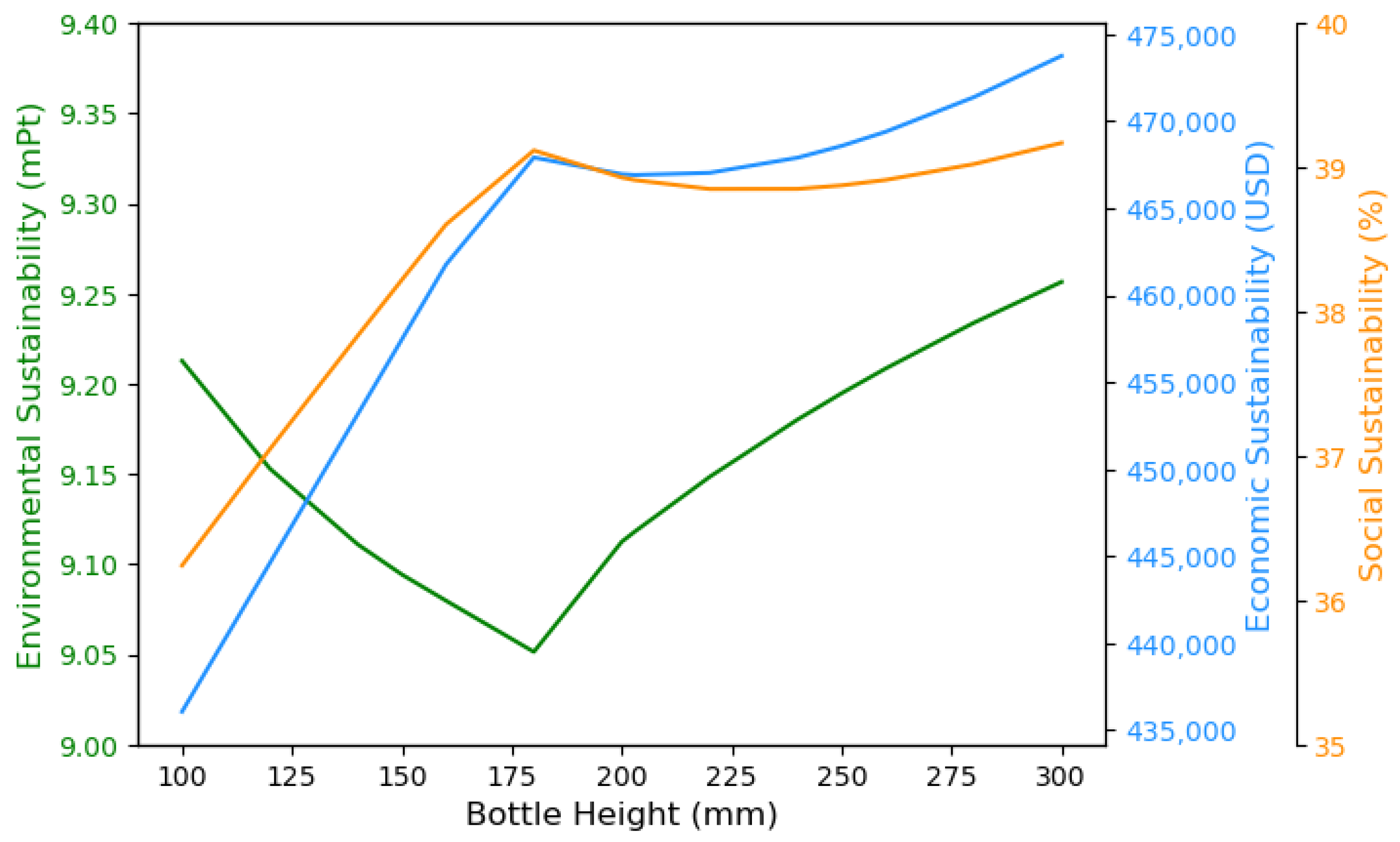

4.2. Sustainability Improvement

5. Discussion

5.1. Case Study Results

5.2. Case Study Implications on Design

5.3. Holistic Sustainable Design Framework

5.4. Limitations and Future Research Opportunities

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business; Capstone: Oxford, UK, 1997. [Google Scholar]

- UN General Assembly. Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://www.refworld.org/docid/57b6e3e44.html (accessed on 21 January 2022).

- Lewis, H.; Gertsakis, J.; Grant, T.; Morelli, N.; Sweatman, A. Design+ Environment: A Global Guide to Designing Greener Goods; Routledge: London, UK, 2017. [Google Scholar]

- Kulatunga, A.; Karunatilake, N.; Weerasinghe, N.; Ihalawatta, R. Sustainable manufacturing based decision support model for product design and development process. Procedia CIRP 2015, 26, 87–92. [Google Scholar] [CrossRef]

- Kalita, H.; Kumar, K.; Davim, J.P. Chapter One—Current tools and methodology for a sustainable product life cycle and design. In Sustainable Manufacturing and Design; Kumar, K., Zindani, D., Davim, J.P., Eds.; Woodhead Publishing Reviews: Mechanical Engineering Series; Woodhead Publishing: Cambridge, UK, 2021; pp. 3–17. [Google Scholar] [CrossRef]

- Ahmad, S.; Wong, K.Y.; Tseng, M.L.; Wong, W.P. Sustainable product design and development: A review of tools, applications and research prospects. Resour. Conserv. Recycl. 2018, 132, 49–61. [Google Scholar] [CrossRef]

- Evans, S.; Vladimirova, D.; Holgado, M.; Van Fossen, K.; Yang, M.; Silva, E.A.; Barlow, C.Y. Business model innovation for sustainability: Towards a unified perspective for creation of sustainable business models. Bus. Strategy Environ. 2017, 26, 597–608. [Google Scholar] [CrossRef]

- Kuo, T.C.; Huang, S.H.; Zhang, H.C. Design for manufacture and design for ‘X’: Concepts, applications, and perspectives. Comput. Ind. Eng. 2001, 41, 241–260. [Google Scholar] [CrossRef]

- Spangenberg, J.H.; Fuad-Luke, A.; Blincoe, K. Design for Sustainability (DfS): The interface of sustainable production and consumption. J. Clean. Prod. 2010, 18, 1485–1493. [Google Scholar] [CrossRef]

- Holt, R.; Barnes, C. Towards an integrated approach to “Design for X”: An agenda for decision-based DFX research. Res. Eng. Des. 2010, 21, 123–136. [Google Scholar] [CrossRef]

- Costa, D.; Quinteiro, P.; Dias, A. A systematic review of life cycle sustainability assessment: Current state, methodological challenges, and implementation issues. Sci. Total Environ. 2019, 686, 774–787. [Google Scholar] [CrossRef]

- Rousseaux, P.; Gremy-Gros, C.; Bonnin, M.; Henriel-Ricordel, C.; Bernard, P.; Floury, L.; Staigre, G.; Vincent, P. “Eco-tool-seeker”: A new and unique business guide for choosing ecodesign tools. J. Clean. Prod. 2017, 151, 546–577. [Google Scholar] [CrossRef]

- International Organization for Standardization. Environmental Management: Life Cycle Assessment; Requirements and Guidelines; ISO: Geneva, Switzerland, 2006; Volume 14044. [Google Scholar]

- Kota, S.; Chakrabarti, A. A method for estimating the degree of uncertainty with respect to life cycle assessment during design. J. Mech. Des. 2010, 132, 091007. [Google Scholar] [CrossRef]

- Fauzi, R.T.; Lavoie, P.; Sorelli, L.; Heidari, M.D.; Amor, B. Exploring the current challenges and opportunities of life cycle sustainability assessment. Sustainability 2019, 11, 636. [Google Scholar] [CrossRef]

- Basereh Taramsari, H.; Mudhar, S.; Hoffenson, S. An Integrated Holistic Approach Toward Sustainable Product Design Using Life Cycle Assessment. In Proceedings of the ASME 2023 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 20–23 August 2023; American Society of Mechanical Engineers: New York, NY, USA, 2023; Volume 87332, p. V005T05A001. [Google Scholar]

- Budynas, R.G.; Nisbett, J.K. Shigley’s Mechanical Engineering Design; McGraw-Hill: New York, NY, USA, 2011; Volume 9. [Google Scholar]

- Gagnon, B.; Leduc, R.; Savard, L. From a conventional to a sustainable engineering design process: Different shades of sustainability. J. Eng. Des. 2012, 23, 49–74. [Google Scholar] [CrossRef]

- Wrisberg, N.; de Haes, H.A.U.; Triebswetter, U.; Eder, P.; Clift, R. Analytical Tools for Environmental Design and Management in a Systems Perspective: The Combined Use of Analytical Tools; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2002; Volume 10. [Google Scholar]

- Baumann, H.; Boons, F.; Bragd, A. Mapping the green product development field: Engineering, policy and business perspectives. J. Clean. Prod. 2002, 10, 409–425. [Google Scholar] [CrossRef]

- Suppipat, S.; Teachavorasinskun, K.; Hu, A.H. Challenges of Applying Simplified LCA Tools in Sustainable Design Pedagogy. Sustainability 2021, 13, 2406. [Google Scholar] [CrossRef]

- Rodriguez, L.J.; Peças, P.; Carvalho, H.; Orrego, C.E. A literature review on life cycle tools fostering holistic sustainability assessment: An application in biocomposite materials. J. Environ. Manag. 2020, 262, 110308. [Google Scholar] [CrossRef]

- Telenko, C.; O’Rourke, J.M.; Conner Seepersad, C.; Webber, M.E. A compilation of design for environment guidelines. J. Mech. Des. 2016, 138, 031102. [Google Scholar] [CrossRef]

- Faludi, J. Recommending sustainable design practices by characterising activities and mindsets. Int. J. Sustain. Des. 2017, 3, 100–136. [Google Scholar] [CrossRef]

- Koh, E.C.; Caldwell, N.H.; Clarkson, P.J. A method to assess the effects of engineering change propagation. Res. Eng. Des. 2012, 23, 329–351. [Google Scholar] [CrossRef]

- Ahmad, N.; Wynn, D.C.; Clarkson, P.J. Change impact on a product and its redesign process: A tool for knowledge capture and reuse. Res. Eng. Des. 2013, 24, 219–244. [Google Scholar] [CrossRef]

- Eckert, C.; Clarkson, P.J.; Zanker, W. Change and customisation in complex engineering domains. Res. Eng. Des. 2004, 15, 1–21. [Google Scholar] [CrossRef]

- Brahma, A.; Wynn, D.C. Concepts of change propagation analysis in engineering design. Res. Eng. Des. 2023, 34, 117–151. [Google Scholar] [CrossRef]

- Sharman, D.M.; Yassine, A.A. Characterizing complex product architectures. Syst. Eng. 2004, 7, 35–60. [Google Scholar] [CrossRef]

- Eppinger, S.D.; Browning, T.R. Design Structure Matrix Methods and Applications; MIT Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Gopsill, J.A.; Snider, C.; McMahon, C.; Hicks, B. Automatic generation of design structure matrices through the evolution of product models. AI EDAM 2016, 30, 424–445. [Google Scholar] [CrossRef]

- Tang, D.; Xu, R.; Tang, J.; He, R. Design structure matrix-based engineering change management for product development. Int. J. Internet Manuf. Serv. 2008, 1, 231–245. [Google Scholar] [CrossRef]

- De Napoli, L.; Rizzuti, S.; Rocco, C. An integrated model for the environmental assessment of industrial products during the design process. Concurr. Eng. 2017, 25, 360–380. [Google Scholar] [CrossRef]

- Wang, C.S.; Lin, P.Y.; Chang, T.R. Green quality function development and modular design structure matrix in product development. In Proceedings of the 2010 14th International Conference on Computer Supported Cooperative Work in Design, Shanghai, China, 14–16 April 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 94–99. [Google Scholar]

- Shoval, S. Dynamic modularization throughout system lifecycle using multilayer design structure matrices. Procedia Cirp 2016, 40, 85–90. [Google Scholar] [CrossRef][Green Version]

- Maurer, M.; Lindemann, U. The application of the Multiple-Domain Matrix: Considering multiple domains and dependency types in complex product design. In Proceedings of the 2008 IEEE International Conference on Systems, Man and Cybernetics, Singapore, 12–15 October 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 2487–2493. [Google Scholar]

- Maurer, M.; Lindemann, U. Structural awareness in complex product design–The Multiple-Domain Matrix. In Proceedings of the 9th International DSM Conference—DSM 2007, Munich, Germany, 16–18 October 2007. [Google Scholar]

- Lindemann, U.; Maurer, M. Facing multi-domain complexity in product development. In Proceedings of the Future of Product Development: Proceedings of the 17th CIRP Design Conference; Springer: Berlin/Heidelberg, Germany, 2007; pp. 351–361. [Google Scholar]

- Bartolomei, J.E.; Hastings, D.E.; De Neufville, R.; Rhodes, D.H. Engineering Systems Multiple-Domain Matrix: An organizing framework for modeling large-scale complex systems. Syst. Eng. 2012, 15, 41–61. [Google Scholar] [CrossRef]

- Giffin, M.; De Weck, O.; Bounova, G.; Keller, R.; Eckert, C.; Clarkson, P.J. Change propagation analysis in complex technical systems. J. Mech. Des. 2009, 131, 081001. [Google Scholar] [CrossRef]

- Barahmand, Z.; Eikeland, M.S. Life Cycle Assessment under Uncertainty: A Scoping Review. World 2022, 3, 692–717. [Google Scholar] [CrossRef]

- Huijbregts, M.A.; Steinmann, Z.J.; Elshout, P.M.; Stam, G.; Verones, F.; Vieira, M.; Hollander, A.; Zijp, M.; van Zelm, R. ReCiPe 2016: A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level Report I: Characterization; Technical report; National Institute for Public Health and the Environment: Bilthoven, The Netherlands, 2016. [Google Scholar]

- Whitefoot, K.S.; Fowlie, M.L.; Skerlos, S.J. Compliance by design: Influence of acceleration trade-offs on co2 emissions and costs of fuel economy and greenhouse gas regulations. Environ. Sci. Technol. 2017, 51, 10307–10315. [Google Scholar] [CrossRef]

- Millet, D.; Bistagnino, L.; Lanzavecchia, C.; Camous, R.; Poldma, T. Does the potential of the use of LCA match the design team needs? J. Clean. Prod. 2007, 15, 335–346. [Google Scholar] [CrossRef]

- Morbidoni, A.; Favi, C.; Germani, M. CAD-Integrated LCA Tool: Comparison with dedicated LCA Software and Guidelines for the improvement. In Glocalized Solutions for Sustainability in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 569–574. [Google Scholar]

- Lenzen, M.; Crawford, R. The path exchange method for hybrid LCA. Environ. Sci. Technol. 2009, 43, 8251–8256. [Google Scholar] [CrossRef] [PubMed]

- Pomponi, F.; Lenzen, M. Hybrid life cycle assessment (LCA) will likely yield more accurate results than process-based LCA. J. Clean. Prod. 2018, 176, 210–215. [Google Scholar] [CrossRef]

- Yang, Y.; Heijungs, R.; Brandão, M. Hybrid life cycle assessment (LCA) does not necessarily yield more accurate results than process-based LCA. J. Clean. Prod. 2017, 150, 237–242. [Google Scholar] [CrossRef]

- Gluch, P.; Baumann, H. The life cycle costing (LCC) approach: A conceptual discussion of its usefulness for environmental decision-making. Build. Environ. 2004, 39, 571–580. [Google Scholar] [CrossRef]

- Neugebauer, S.; Forin, S.; Finkbeiner, M. From life cycle costing to economic life cycle assessment—Introducing an economic impact pathway. Sustainability 2016, 8, 428. [Google Scholar] [CrossRef]

- Benoît Norris, C.; Traverzo, M.; Neugebauer, S.; Ekener, E.; Schaubroeck, T.; Russo Garrido, S. Guidelines for Social Life Cycle Assessment of Products and Organizations 2020; United Nations Environment Programme: Nairobi, Kenya, 2020. [Google Scholar]

- Kloepffer, W. Life cycle sustainability assessment of products. Int. J. Life Cycle Assess. 2008, 13, 89–95. [Google Scholar] [CrossRef]

- Ciroth, A.; Finkbeiner, M.; Traverso, M.; Hildenbrand, J.; Kloepffer, W.; Mazijn, B.; Prakash, S.; Sonnemann, G.; Valdivia, S.; Ugaya, C.M.L.; et al. Towards a Life Cycle Sustainability Assessment: Making Informed Choices on Products; Technical report; United Nations Environment Programme: Nairobi, Kenya, 2011. [Google Scholar]

- Finkbeiner, M.; Schau, E.M.; Lehmann, A.; Traverso, M. Towards life cycle sustainability assessment. Sustainability 2010, 2, 3309–3322. [Google Scholar] [CrossRef]

- Deng, C.; Li, Z.; Shao, X.; Zhang, C. Integration and optimization of LCA and LCC to eco-balance for mechanical product design. In Proceedings of the 2008 7th World Congress on Intelligent Control and Automation, Chongqing, China, 25–27 June 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 1085–1090. [Google Scholar]

- Seo, K.K.; Min, S.H.; Yoo, H.W. Artificial neural network based life cycle assessment model for product concepts using product classification method. In Proceedings of the International Conference on Computational Science and Its Applications—ICCSA 2005, Singapore, 9–12 May 2005; Springer: Berlin/Heidelberg, Germany, 2005; pp. 458–466. [Google Scholar]

- Poole, S.; Simon, M. Technological trends, product design and the environment. Des. Stud. 1997, 18, 237–248. [Google Scholar] [CrossRef]

- Ramanujan, D.; Bernstein, W.Z.; Chandrasegaran, S.K.; Ramani, K. Visual analytics tools for sustainable lifecycle design: Current status, challenges, and future opportunities. J. Mech. Des. 2017, 139, 111415. [Google Scholar] [CrossRef]

- Brundage, M.P.; Bernstein, W.Z.; Hoffenson, S.; Chang, Q.; Nishi, H.; Kliks, T.; Morris, K. Analyzing environmental sustainability methods for use earlier in the product lifecycle. J. Clean. Prod. 2018, 187, 877–892. [Google Scholar] [CrossRef]

- Wu, M. Hydroflask 21oz Water Bottle (White). 2017. Available online: https://grabcad.com/library/hydroflask-21oz-water-bottle-white-1 (accessed on 20 March 2022).

- Heijungs, R.; Suh, S. The Computational Structure of Life Cycle Assessment; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2002; Volume 11. [Google Scholar]

- Ecoinvent. Ecoinvent Database. 2023. Available online: https://ecoinvent.org (accessed on 22 January 2023).

- National Institute for Public Health and the Environment Ministry of Health, Welfare and Sport. Normalization Scores ReCiPe 2016. 2023. Available online: https://www.rivm.nl/en/life-cycle-assessment-lca/downloads (accessed on 22 January 2023).

- Azapagic, A.; Clift, R. Life cycle assessment and multiobjective optimisation. J. Clean. Prod. 1999, 7, 135–143. [Google Scholar] [CrossRef]

| Sustainability Dimension | Metric | Value |

|---|---|---|

| Environmental | Single Score (mPt) | 9.06 |

| Social | Social Metric (%) | 38 |

| Economic | Profit (USD) | 466,881 |

| Endpoint | Total Value | Most Significant Midpoint |

|---|---|---|

| Damage to Resource availability | USD2013 | Mineral resource scarcity |

| Damage to Human health | DALY | Global warming |

| Damage to Ecosystems | species.yr | Global warming |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taramsari, H.B.; Hoffenson, S.; Nilchiani, R. Holistic Sustainable Design: Incorporating Change Propagation and Triple Bottom Line Sustainability. Sustainability 2025, 17, 2274. https://doi.org/10.3390/su17052274

Taramsari HB, Hoffenson S, Nilchiani R. Holistic Sustainable Design: Incorporating Change Propagation and Triple Bottom Line Sustainability. Sustainability. 2025; 17(5):2274. https://doi.org/10.3390/su17052274

Chicago/Turabian StyleTaramsari, Hossein Basereh, Steven Hoffenson, and Roshanak Nilchiani. 2025. "Holistic Sustainable Design: Incorporating Change Propagation and Triple Bottom Line Sustainability" Sustainability 17, no. 5: 2274. https://doi.org/10.3390/su17052274

APA StyleTaramsari, H. B., Hoffenson, S., & Nilchiani, R. (2025). Holistic Sustainable Design: Incorporating Change Propagation and Triple Bottom Line Sustainability. Sustainability, 17(5), 2274. https://doi.org/10.3390/su17052274