Optimisation Strategies and Technological Advancements for Sustainable Direct Reduction Iron Production—A Systematic Review

Abstract

1. Introduction

2. Review Methodology

- Categorise the different optimisation strategies capable of enhancing the sustainability of the DRI process.

- Establish new technologies used to enhance the sustainability of DRI.

- Establish economic implications of sustaining the DRI process.

Sustainability Indicators for the DRI Process

3. Qualitative Findings

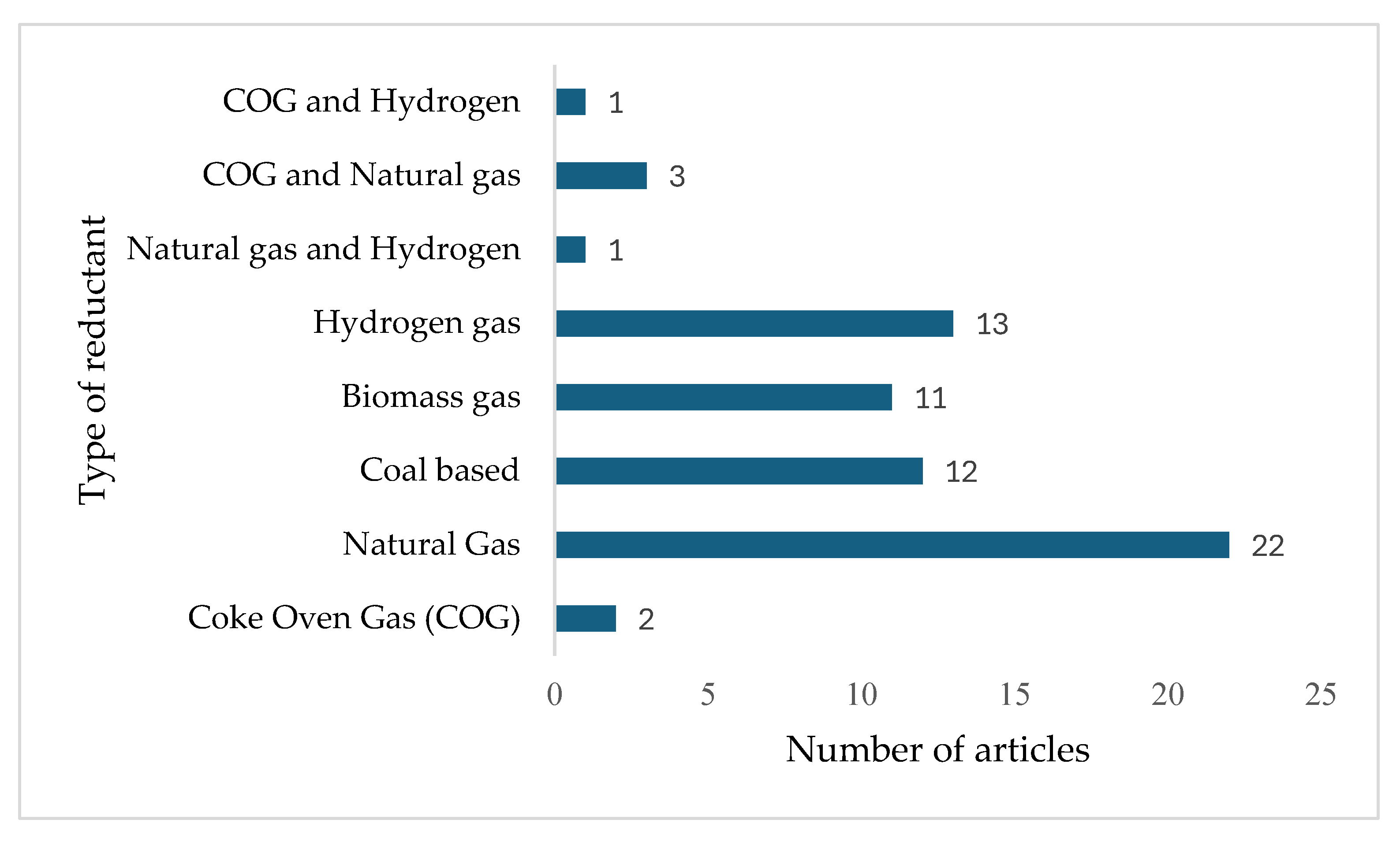

3.1. Comparison of Various Reductants Used in Various Optimisation Strategies

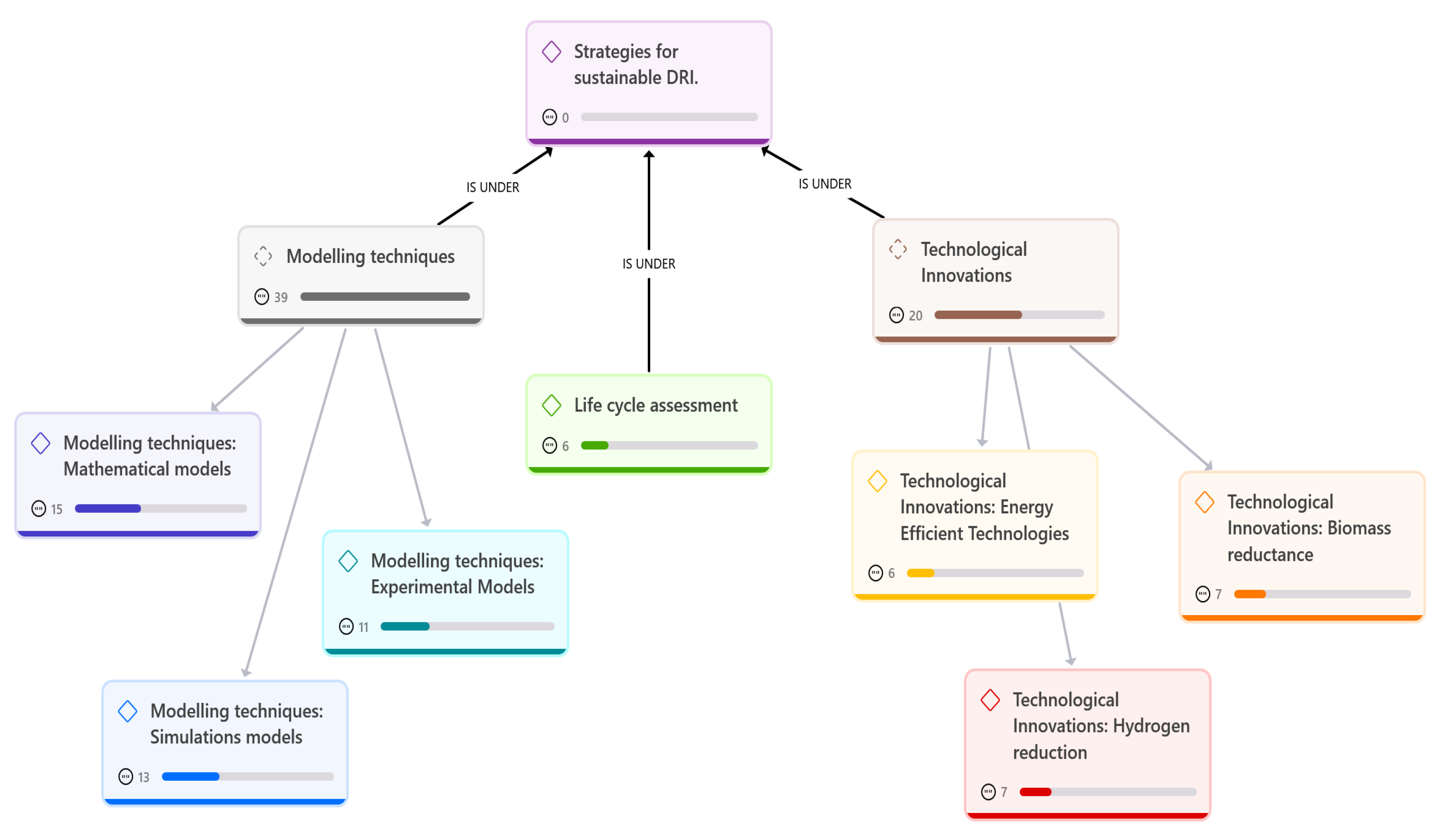

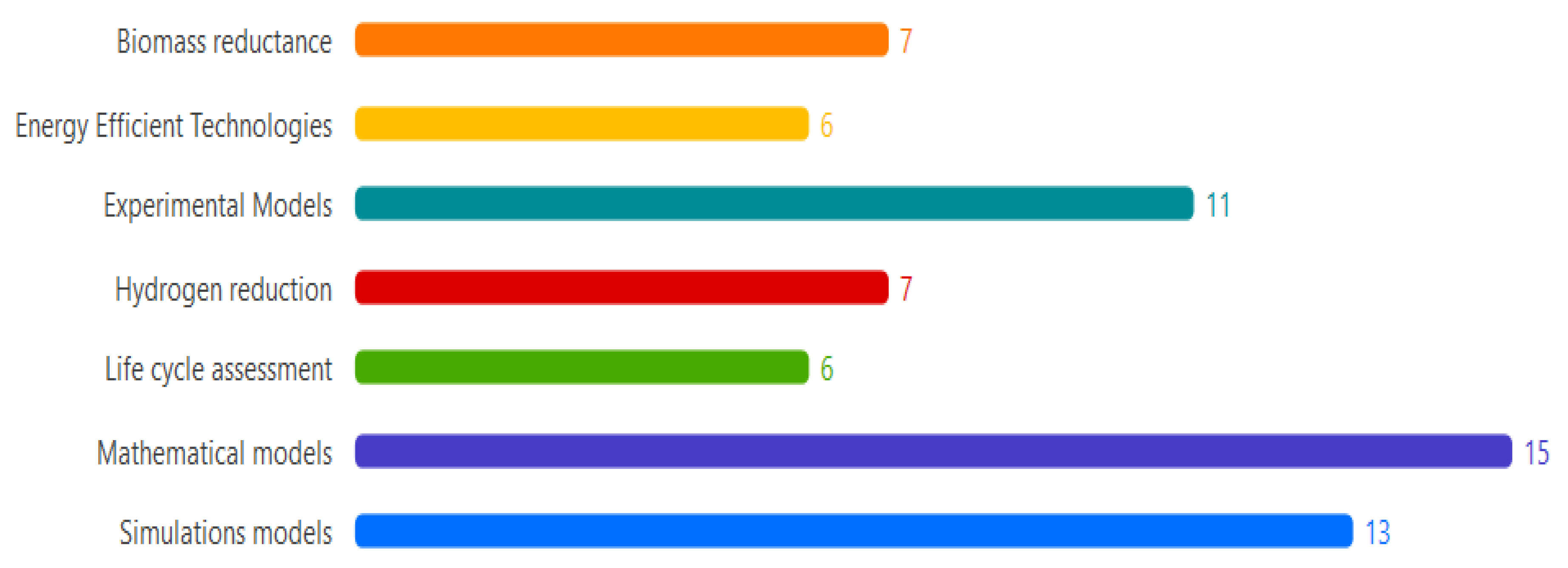

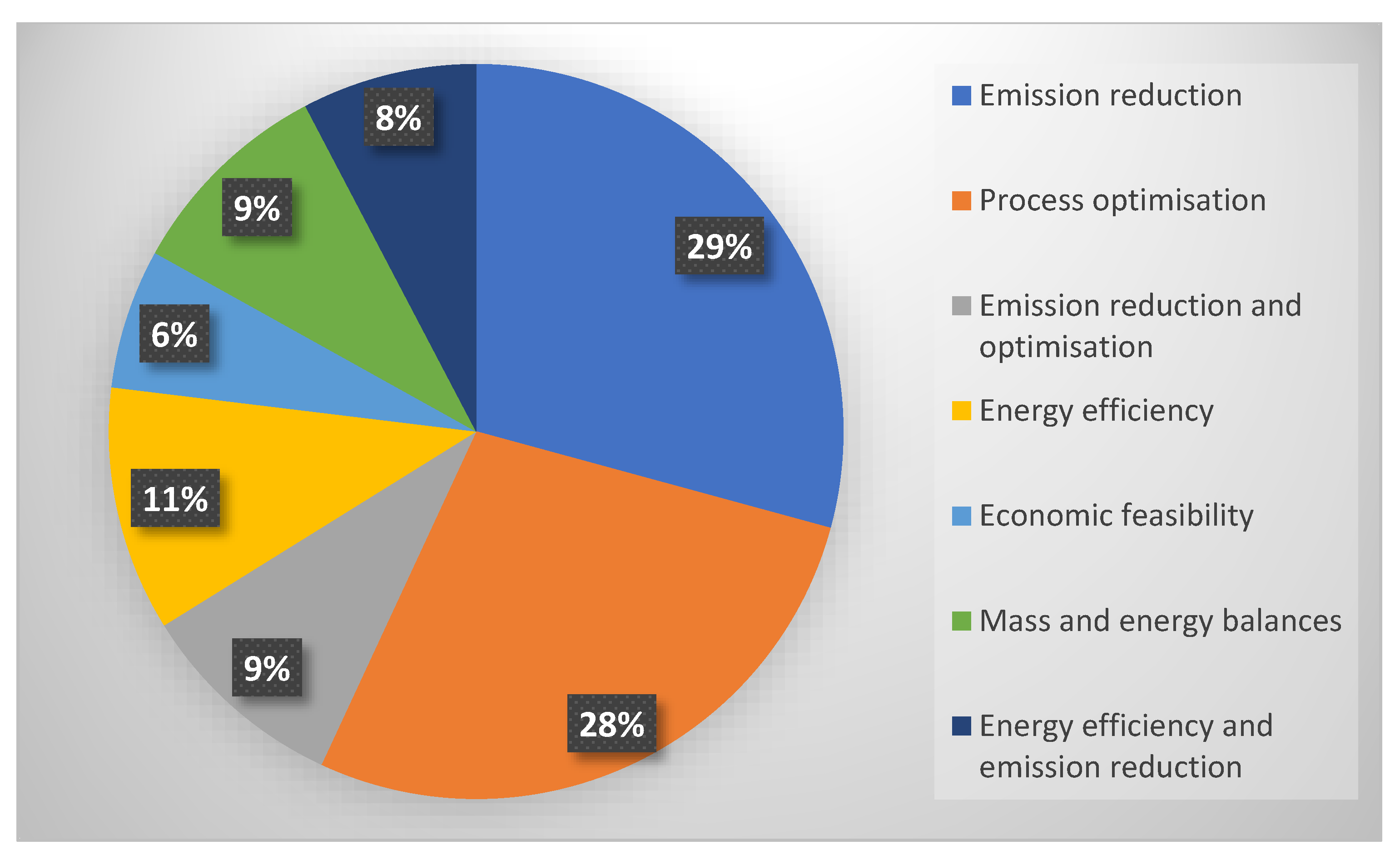

3.2. Thematic Analysis of the Strategies

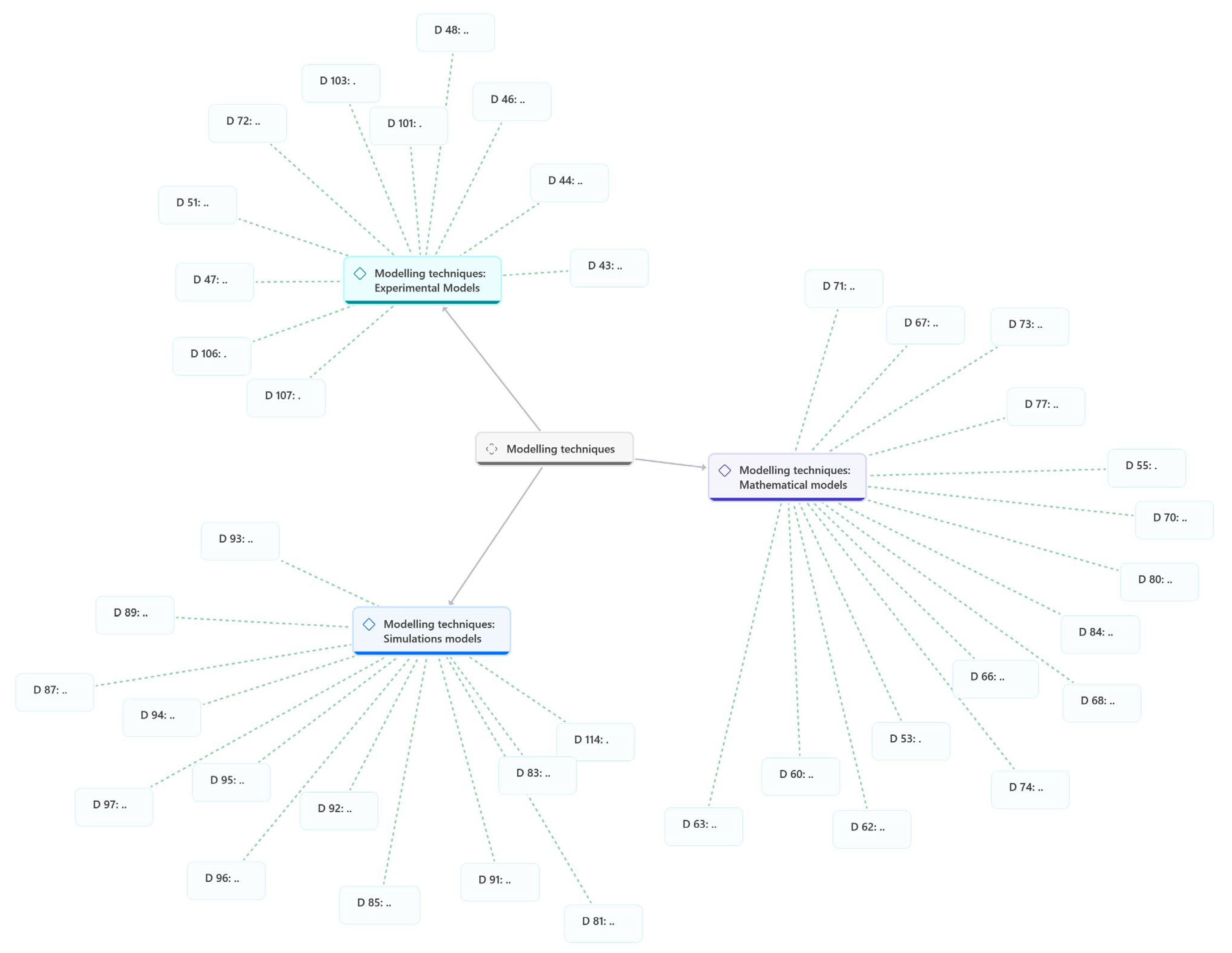

3.2.1. Modelling Techniques as a Strategy

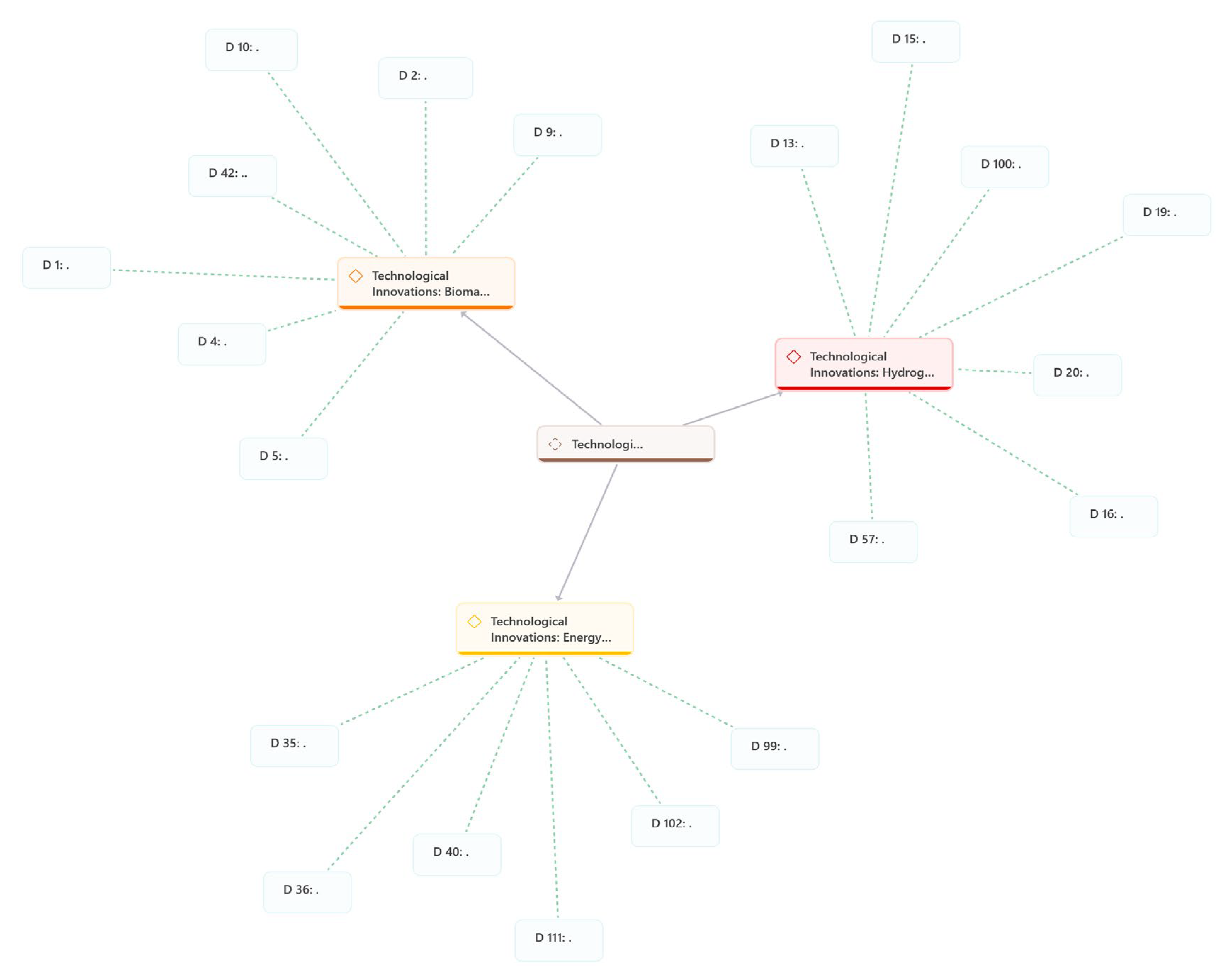

3.2.2. Technological Innovations for Sustainability Enhancement of DRI

3.2.3. Life Cycle Assessment

3.3. The Economic Impact of Adopting Sustainable Approaches for DRI Production

Challenges with Adopting Hydrogen DRI

4. Proposed Approach to Enhance the Sustainability of DRI

- Reduce

- Reuse

- Recycling

- Recover

- Reclaim

Contribution of the Research

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| C | Carbon |

| CE | Circular Economy |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| DRI | Direct reduction iron |

| Fe | Iron |

| FIT | Flash iron technology |

| GHG | Greenhouse gas |

| H2 | Hydrogen |

| H-DR | Hydrogen direct reduction |

| Kg | Kilogram |

| LCA | Life cycle assessment |

| MWH | Megawatts hour |

| PRISMA | Preferred Reporting Items for Systematic Reviews |

| SDG | Sustainable Development Goals |

| USA | United States of America |

| UK | United Kingdom |

References

- Hasanbeigi, A.; Arens, M.; Price, L. Alternative emerging ironmaking technologies for energy-efficiency and carbon dioxide emissions reduction: A technical review. Renew. Sustain. Energy Rev. 2014, 33, 645–658. [Google Scholar] [CrossRef]

- Dattagupta, N. Environmental Sustainability Assessment of Sponge Iron Industries in West Bengal using DEA. Int. J. Res. Anal. Rev. 2018, 5, 171–174. [Google Scholar]

- Kritzinger, H.P.; Kingsely, T.C. Modelling and optimization of a rotary kiln direct reduction process. J. S. Afr. Inst. Min. Metall. 2009, 115, 51–60. [Google Scholar] [CrossRef]

- Edwell, M.T. Valuation of % metallization and % accretion formation in a rotary kiln of sponge iron process based on Fuzzy Logic Inference System. J. Sustain. Res. Eng. 2022, 7, 46–57. [Google Scholar]

- Poonia, A.K.; Soni, A.B.; Khanam, S. Optimization of Operating Parameters for Sponge Iron Production Process using Neural Network. Int. J. ChemTech Res. 2016, 9, 20–34. [Google Scholar]

- Harini, T.A. Review on mitigation of air pollution in sponge iron industries. Int. J. Civ. Eng. Technol. 2017, 8, 1353–1356. [Google Scholar]

- Dutta, S.K.; Sah, R. Direct Reduced Iron: Production. In Encyclopedia of Iron, Steel, and Their Alloys; CRC Press: Boca Raton, FL, USA, 2016; pp. 1082–1108. [Google Scholar]

- Bhaskar, A.; Assadi, M.; Somehsaraei, H.N. Decarbonization of the iron and steel industry with direct reduction of iron ore with green hydrogen. Energies 2020, 13, 758. [Google Scholar] [CrossRef]

- Kumar, S.; Toppo, S.; Kumar, A.; Tewari, G.; Beck, A.; Bachan, V.; Singh, T. Assessment of heavy metal pollution in groundwater of an industrial area: A case study from Ramgarh, Jharkhand, India. Int. J. Environ. Anal. Chem. 2022, 102, 7290–7312. [Google Scholar] [CrossRef]

- Kibira, D.; Jain, S.; Mclean, C.R. A System Dynamics Modeling Framework for Sustainable Manufacturing. In Proceedings of the 27th Annual System Dynamics Society Conference, Albuquerque, NM, USA, 26–30 July 2009; pp. 1–22. [Google Scholar]

- World Direct Reduction Statistics 2022. 2023. Available online: https://www.midrex.com/wp-content/uploads/MidrexSTATSBook2022.pdf (accessed on 28 September 2022).

- Strezov, V.; Evans, A.; Evans, T. Defining sustainability indicators of iron and steel production. J. Clean. Prod. 2013, 51, 66–70. [Google Scholar] [CrossRef]

- Aromataris, E.; Fernandez, R.; Godfrey, C.M.; Holly, C.; Khalil, H.; Tungpunkom, P. Summarizing systematic reviews: Methodological development, conduct and reporting of an umbrella review approach. Int. J. Evid. Based Healthc. 2015, 13, 132–140. [Google Scholar] [CrossRef]

- Li, S.; Zhang, H.; Nie, J.; Dewil, R.; Baeyens, J.; Deng, Y. The direct reduction of iron ore with hydrogen. Sustainability 2021, 13, 8866. [Google Scholar] [CrossRef]

- Nurdiawati, A.; Zaini, I.N.; Wei, W.; Gyllenram, R.; Yang, W.; Samuelsson, P. Towards fossil-free steel: Life cycle assessment of biosyngas-based direct reduced iron (DRI) production process. J. Clean. Prod. 2023, 393, 136262. [Google Scholar] [CrossRef]

- Moziraji, M.R.; Tehrani, A.A.; Reshadi, M.A.M.; Bazargan, A. Natural gas as a relatively clean substitute for coal in the MIDREX process for producing direct reduced iron. Energy Sustain. Dev. 2024, 78, 101356. [Google Scholar] [CrossRef]

- Chukwuleke, O.P.; Cai, J.J.; Chukwujekwu, S.; Xiao, S. Shift from Coke to Coal Using Direct Reduction Method and Challenges. J. Iron Steel Res. Int. 2009, 16, 1–5. [Google Scholar] [CrossRef]

- Lisienko, V.G.; Lapteva, A.V.; Chesnokov, Y.N.; Lugovkin, V.V. Greenhouse-gas (CO2) emissions in the steel industry. Steel Transl. 2015, 45, 623–626. [Google Scholar] [CrossRef]

- Dattagupta, N.; Mitra, S.; Agrawal, K.M. Development of an Environmentally Sustainable Model with Optimum Utilization of Resources- A case study of India. Int. J. Energy Environ. Econ. 2020, 26, 159–182. [Google Scholar]

- Dhara, S.; Kumar, S.; Roy, B.C. Management of Solid Waste for Sustainability of Steel Industry. HCTL Open Int. J. Technol. Innov. Res. 2015, 16, 1–6. [Google Scholar]

- Fruehan, R.J. Research on sustainable steelmaking. Iron Steel Technol. 2005, 2, 108–117. [Google Scholar] [CrossRef]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. Development of composite sustainability performance index for steel industry. Ecol. Indic. 2007, 7, 565–588. [Google Scholar] [CrossRef]

- Rambaree, K. Three Methods of Qualitative Data Analysis Using ATLAS. Ti: ‘A Posse Ad Esse’. In Proceedings of the Atlas Ti User Conference, Fostering Dialog on Qualitative Methods, Berlin, Germany, 12–14 September 2014. [Google Scholar]

- Hosseinzadeh, M.; Mashhadimoslem, H.; Maleki, F.; Elkamel, A. Prediction of Solid Conversion Process in Direct Reduction Iron Oxide Using Machine Learning. Energies 2022, 15, 9276. [Google Scholar] [CrossRef]

- Guo, D.; Zhu, L.; Guo, S.; Cui, B.; Luo, S.; Laghari, M.; Chen, Z.; Ma, C.; Zhou, Y.; Chen, J.; et al. Direct reduction of oxidized iron ore pellets using biomass syngas as the reducer. Fuel Process. Technol. 2016, 148, 276–281. [Google Scholar] [CrossRef]

- Metolina, P.; Ribeiro, T.R.; Guardani, R. Hydrogen-based direct reduction of industrial iron ore pellets: Statistically designed experiments and computational simulation. Int. J. Miner. Metall. Mater. 2022, 29, 1908–1921. [Google Scholar] [CrossRef]

- Mousa, E.; Ghali, S. Mathematical Analysis of the Parameters Affecting the Direct Reduction of Iron Ore Pellets. J. Metall. Eng. 2015, 4, 78. [Google Scholar] [CrossRef]

- Ponugoti, P.V.; Garg, P.; Geddam, S.N.; Nag, S.; Janardhanan, V.M. Kinetics of iron oxide reduction using CO: Experiments and Modeling. Chem. Eng. J. 2022, 434, 134384. [Google Scholar] [CrossRef]

- Runkana, V.; Natekar, P.; Bandla, V.; Pothal, G.; Chatterjee, A. Modelling and optimisation of directreduction of iron ore by coal in a rotary kiln. In Proceedings of the International Mineral Processing Congress, Brisbane, Australia, 6–10 September 2010; pp. 3383–3393. Available online: https://www.researchgate.net/publication/289000075 (accessed on 2 January 2025).

- Zugliano, A.; Primavera, A.; Pignattone, D.; Martinis, A. Online modelling of ENERGIRON direct reduction shaft furnaces. IFAC Proc. Vol. 2013, 46, 346–351. [Google Scholar] [CrossRef]

- Parisi, D.R.; Laborde, M.A. Modeling of counter current moving bed gas-solid reactor used in direct reduction of iron ore. Chem. Eng. J. 2004, 104, 35–43. [Google Scholar] [CrossRef]

- Shams, A.; Moazeni, F. Modeling and Simulation of the MIDREX Shaft Furnace: Reduction, Transition and Cooling Zones. JOM 2015, 67, 2681–2689. [Google Scholar] [CrossRef]

- Mirzajani, A.; Ebrahim, H.A.; Nouri, S.M.M. Simulation of a direct reduction moving bed reactor using a three interface model. Braz. J. Chem. Eng. 2018, 35, 1019–1028. [Google Scholar] [CrossRef]

- Kumari, V.; Roy, G.G.; Sen, P.K. Mathematical Model to Estimate the Rate Parameters and Thermal Efficiency for the Reduction of Iron Ore–Coal Composite Pellets in Multi-layer Bed at Rotary Hearth Furnace. Trans. Indian Inst. Met. 2015, 68, 109–116. [Google Scholar] [CrossRef]

- Zuo, H.B.; Hu, Z.W.; Zhang, J.L.; Li, J.; Liu, Z.J. Direct reduction of iron ore by biomass char. J. Miner. Metall. Mater. 2013, 20, 514–521. [Google Scholar] [CrossRef]

- Dey, N.R.; Prasad, A.K.; Singh, S.K. Energy survey of the coal based sponge iron industry. Case Stud. Therm. Eng. 2015, 6, 1–15. [Google Scholar] [CrossRef][Green Version]

- Ramezani-Mooziraji, M.; Dezvareh, G. Life Cycle Assessment of the Sponge Iron Production Process Using OpenLCA Software: A Case Study of Khuzestan Steel Plant, Iran. J. Health Syst. Res. 2023, 19, 200–208. [Google Scholar] [CrossRef]

- Trinca, A.; Patrizi, D.; Verdone, N.; Bassano, C.; Vilardi, G. Toward green steel: Modeling and environmental economic analysis of iron direct reduction with different reducing gases. J. Clean. Prod. 2023, 427, 139081. [Google Scholar] [CrossRef]

- Nyankson, E.; Kolbeinsen, L. Investigating the Effect of Water Gas Shift Reaction and Other Parameters on the Direct Reduction of Iron Ore Pellets. Int. J. Eng. Res. Technol. 2015, 4, 260e7. [Google Scholar]

- Han, H.; Duan, D.; Yuan, P.; Li, D. Biomass reducing agent utilisation in rotary hearth furnace process for DRI production. Ironmak. Steelmak. 2015, 42, 579–584. [Google Scholar] [CrossRef]

- Filho, I.R.S.; Springer, H.; Ma, Y.; Mahajan, A.; da Silva, C.C.; Kulse, M.; Raabe, D. Green steel at its crossroads: Hybrid hydrogen-based reduction of iron ores. J. Clean. Prod. 2022, 340, 130805. [Google Scholar] [CrossRef]

- Zang, G.; Sun, P.; Elgowainy, A.; Bobba, P.; McMillan, C.; Ma, O.; Podkaminer, K.; Rustagi, N.; Melaina, M.; Koleva, M. Cost and Life Cycle Analysis for Deep CO2 Emissions Reduction for Steel Making: Direct Reduced Iron Technologies. Steel. Res. Int. 2023, 94, 2200297. [Google Scholar] [CrossRef]

- Nduagu, E.I.; Yadav, D.; Bhardwaj, N.; Elango, S.; Biswas, T.; Banerjee, R.; Rajagopalan, S. Comparative life cycle assessment of natural gas and coal-based directly reduced iron (DRI) production: A case study for India. J. Clean. Prod. 2022, 347, 131196. [Google Scholar] [CrossRef]

- Béchara, R.; Hamadeh, H.; Mirgaux, O.; Patisson, F. Carbon impact mitigation of the iron ore direct reduction process through computer-aided optimization and design changes. Metals 2020, 10, 367. [Google Scholar] [CrossRef]

- Ghadi, A.Z.; Valipour, M.S.; Biglari, M. CFD simulation of two-phase gas-particle flow in the Midrex shaft furnace: The effect of twin gas injection system on the performance of the reactor. Int. J. Hydrogen Energy 2017, 42, 103–118. [Google Scholar] [CrossRef]

- Liu, Y.; Su, F.; Wen, Z.; Li, Z.; Yong, H.; Feng, X. Numerical simulation and parameters optimisation of direct reduction process of iron ore-carbon composite pellet. Trans. Inst. Min. Metall. Sect. C Miner. Process. Extr. Metall. 2015, 124, 27–34. [Google Scholar] [CrossRef]

- Mharakurwa, E.T.; Nyakoe, G.N.; Ikua, B.W. Accretion Control in Sponge Iron Production Kiln using Fuzzy Logic. J. Sustain. Res. Eng. 2014, 1, 27–33. [Google Scholar]

- Petit, H.A.; Boechat, F.O.; de Carvalho, R.M.; Tavares, L.M. Analysis of impact of mechanical degradation of iron ore pellets on gas flow in a direct reduction furnace using simulation. J. Mater. Res. Technol. 2024, 28, 4540–4550. [Google Scholar] [CrossRef]

- Nouri, S.M.M.; Ebrahim, H.A.; Jamshidi, E. Simulation of direct reduction reactor by the grain model. Chem. Eng. J. 2011, 166, 704–709. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, S.; Wang, Y.; Zhang, J.; Cheng, Q.; Ma, Y. Study on optimization of reduction temperature of hydrogen-based Shaft Furnace—Numerical simulation and multi-criteria evaluation. Int. J. Hydrogen Energy 2023, 48, 16132–16142. [Google Scholar] [CrossRef]

- Fan, X.H.; Wang, Y.; Chen, X.L. Mathematical models and expert system for grate-kiln process of iron ore oxide pellet production. Part II: Rotary kiln process control. J. Cent. South Univ. Technol. 2012, 19, 1724–1727. [Google Scholar] [CrossRef]

- Gaurav, G.K.; Khanam, S. Computational fluid dynamics analysis of sponge iron rotary kiln. Case Stud. Therm. Eng. 2017, 9, 14–27. [Google Scholar] [CrossRef]

- Hamadeh, H.; Mirgaux, O.; Patisson, F. Detailed modeling of the direct reduction of iron ore in a shaft furnace. Materials 2018, 11, 1865. [Google Scholar] [CrossRef]

- Gaurav, G.K.; Khanam, S. Analysis of temperature profile and % metallization in rotary kiln of sponge iron process through CFD. J. Taiwan Inst. Chem. Eng. 2016, 63, 473–481. [Google Scholar] [CrossRef]

- Da Costa, A.R.; Wagner, D.; Patisson, F. Modelling a new, low CO2 emissions, hydrogen steelmaking process. J. Clean. Prod. 2013, 46, 27–35. [Google Scholar] [CrossRef]

- Alhumaizi, K.; Ajbar, A.; Soliman, M. Modelling the complex interactions between reformer and reduction furnace in a midrex-based iron plant. Can. J. Chem. Eng. 2012, 90, 1120–1141. [Google Scholar] [CrossRef]

- Béchara, R.; Hamadeh, H.; Mirgaux, O.; Patisson, F. Optimization of the iron ore direct reduction process through multiscale process modeling. Materials 2018, 11, 1094. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Liu, S.-H.; Huang, T.-Y.; Zhang, G.; Guo, H.; Shiau, G.-H.; Shen, F. Effects of reducing time on metallization degree of carbothermic reduction of tall pellets bed. ISIJ Int. 2016, 56, 88–93. [Google Scholar] [CrossRef]

- Zulkania, A.; Rochmadi, R.; Hidayat, M.; Cahyono, R.B. Reduction Reactivity of Low Grade Iron Ore-Biomass Pellets for a Sustainable Ironmaking Process. Energies 2022, 15, 137. [Google Scholar] [CrossRef]

- Luo, S.; Zhou, Y.; Yi, C. Two-step direct reduction of iron ore pellets by utilization of biomass: Effects of preheating temperature, pellet size and composition. J. Renew. Sustain. Energy 2013, 5, 063114. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Rahbari, A.; Sabah, S.; Brooks, G.; Pye, J.; Rhamdhani, M.A. Process modelling for the production of hydrogen-based direct reduced iron in shaft furnaces using different ore grades. Ironmak. Steelmak. 2024. [Google Scholar] [CrossRef]

- Zhou, Y.; Jiang, X.; Wang, X.; Zheng, H.; Gao, Q.; Shen, F. Effects of Metallization Degree of DRI on the Yield and CO2 Emission in Reduction Shaft Furnace Process. J. Sustain. Metall. 2024, 10, 1112–1126. [Google Scholar] [CrossRef]

- Abanades, S.; Rodat, S. Solar-aided direct reduction of iron ore with hydrogen targeting carbon-free steel metallurgy. Renew. Energy 2024, 235, 121297. [Google Scholar] [CrossRef]

- Scaccabarozzi, R.; Artini, C.; Campanari, S.; Spinelli, M. Techno-Economic and CO2 Emissions Analysis of the Molten Carbonate Fuel Cell Integration in a DRI Production Plant for the Decarbonization of the Steel Industry. Appl. Energy 2024, 376, 124264. [Google Scholar] [CrossRef]

- Das, D.; Anand, A.; Gautam, S.; Rajak, V.K. Assessment of utilization potential of biomass volatiles and biochar as a reducing agent for iron ore pellets. Environ. Technol. 2024, 45, 158–169. [Google Scholar] [CrossRef]

- Singh, A.K.; Mishra, B.; Kumar, S.; Sinha, O.P.; Singh, R. Reduction behaviour of iron ore pellets using hardwood biomasses as a reductant for sustainable ironmaking. Biomass Convers. Biorefin. 2022, 14, 27943–27954. [Google Scholar] [CrossRef]

- Yuan, P.; Shen, B.; Duan, D.; Adwek, G.; Mei, X.; Lu, F. Study on the formation of direct reduced iron by using biomass as reductants of carbon containing pellets in RHF process. Energy 2017, 141, 472–482. [Google Scholar] [CrossRef]

- Yi, L.; Zhang, N.; Hao, H.; Wang, L.; Xiao, H.; Li, G.; Liang, Z.; Huang, Z.; Jiang, T. Synergetic conversion laws of biomass and iron ore for syngas and direct reduced iron co-production. J. Clean. Prod. 2022, 363, 132387. [Google Scholar] [CrossRef]

- Rosner, F.; Papadias, D.; Brooks, K.; Yoro, K.; Ahluwalia, R.; Autrey, T.; Breunig, H. Green steel: Design and cost analysis of hydrogen-based direct iron reduction. Energy Environ. Sci. 2023, 16, 4121–4134. [Google Scholar] [CrossRef]

- Wang, R.R.; Zhao, Y.Q.; Babich, A.; Senk, D.; Fan, X.Y. Hydrogen direct reduction (H-DR) in steel industry—An overview of challenges and opportunities. J. Clean. Prod. 2021, 20, 129797. [Google Scholar] [CrossRef]

- Boretti, A. The perspective of hydrogen direct reduction of iron. J. Clean. Prod. 2023, 429, 139585. [Google Scholar] [CrossRef]

- Sahu, S.; Tirumalaraju, D.; Khanam, S.; Sahoo, A. Energy Conservation in Sponge Iron Production Process through Proper Utilization of Waste Heat. Int. J. Eng. Sci. Innov. Technol. 2013, 2, 359–366. [Google Scholar]

- Cavaliere, P. Direct Reduced Iron: Most Efficient Technologies for Greenhouse Emissions Abatement. In Clean Ironmaking and Steelmaking Processes; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 419–484. [Google Scholar] [CrossRef]

- Vu, T.T.; Seo, J.; Kim, E.; Ryoo, S.G.; Park, B.C.; Song, D. Techno-economic analysis of integrated MIDREX process with CO2 capture and storage: Evaluating sustainability and viability for iron production. Process Saf. Environ. Prot. 2024, 189, 1314–1322. [Google Scholar] [CrossRef]

- Bond, N.K.; Symonds, R.T.; Hughes, R.W. Pressurized Chemical Looping for Direct Reduced Iron Production: Economics of Carbon Neutral Process Configurations. Energies 2024, 17, 545. [Google Scholar] [CrossRef]

- Chen, X.; Sun, Z.; Kuo, P.C.; Aziz, M. Thermodynamics analysis of innovative carbon-negative systems for direct reduction of iron ore via chemical looping technology. Energy 2024, 309, 133019. [Google Scholar] [CrossRef]

- Wan, F.; Li, J. Exploring hydrogen metallurgy to CO2 emissions reduction in China’s iron and steel production: An analysis based on the life cycle CO2 emissions—LEAP model. Energy Rep. 2024, 11, 4552–4563. [Google Scholar] [CrossRef]

- Azimi, A.; van der Spek, M. Prospective Life Cycle Assessment Suggests Direct Reduced Iron Is the Most Sustainable Pathway to Net-Zero Steelmaking. Ind. Eng. Chem. Res. 2025, 64, 3871–3885. [Google Scholar] [CrossRef] [PubMed]

- Yarahmadi, M.; Javanbakht, V. Sponge Iron Production by Calcium Carbonate, Sodium Carbonate, and Barium Carbonate Catalysts Using Tunnel Kiln Method. Annals of Organic and Inorganic Chemistry. 2023. Available online: http://meddocsonline.org/ (accessed on 2 January 2025).

- Garikayi, T.; Nyanga, L.; Mushiri, T.; Mhlanga, S.; Kuipa, P.K. 523-1 Designing of an Intelligent Fuzzy Logic System for Accretion Prevention in Sponge Iron SL/RN Rotary Kiln Based 100TPD DRI Process. In Proceedings of the SAIIE25 Proceedings, Stellenbosch, South Africa, 9–11 July 2013. [Google Scholar]

- Man, Y.; Feng, J.X. Effect of iron ore-coal pellets during reduction with hydrogen and carbon monoxide. Powder Technol. 2016, 301, 1213–1217. [Google Scholar] [CrossRef]

- Jiang, X.; Wang, L.; Shen, F.M. Shaft furnace direct reduction technology—Midrex and Energiron. Adv. Mater. Res. 2013, 805–806, 654–659. [Google Scholar] [CrossRef]

- Guo, D.; Li, Y.; Cui, B.; Chen, Z.; Luo, S.; Xiao, B.; Zhu, H.; Hu, M. Direct reduction of iron ore/biomass composite pellets using simulated biomass-derived syngas: Experimental analysis and kinetic modelling. Chem. Eng. J. 2017, 327, 822–830. [Google Scholar] [CrossRef]

- Loder, A.; Siebenhofer, M.; Böhm, A.; Lux, S. Clean iron production through direct reduction of mineral iron carbonate with low-grade hydrogen sources; the effect of reduction feed gas composition on product and exit gas composition. Clean Eng. Technol. 2021, 5, 100345. [Google Scholar] [CrossRef]

- Öhman, A.; Karakaya, E.; Urban, F. Enabling the transition to a fossil-free steel sector: The conditions for technology transfer for hydrogen-based steelmaking in Europe. Energy Res. Soc. Sci. 2022, 84, 102384. [Google Scholar] [CrossRef]

- Ahmad, J.K. Using Water Hydrogen Instead of Reducing Gas in the Production of Direct Reduced Iron (DRI). J. Adv. Oxid. Technol. 2010, 13, 124–129. [Google Scholar] [CrossRef]

- Patisson, F.; Mirgaux, O. Hydrogen ironmaking: How it works. Metals 2020, 10, 922. [Google Scholar] [CrossRef]

- Midilli, A.; Kucuk, H.; Topal, M.E.; Akbulut, U.; Dincer, I. A comprehensive review on hydrogen production from coal gasification: Challenges and Opportunities. Int. J. Hydrogen Energy 2021, 46, 25385–25412. [Google Scholar] [CrossRef]

- Kumar, S.S.; Himabindu, V. Hydrogen production by PEM water electrolysis—A review. 2019. Mater. Sci. Energy Technol. 2019, 2, 442–454. [Google Scholar] [CrossRef]

- Quader, M.A.; Ahmed, S.; Ghazilla, R.A.R.; Ahmed, S.; Dahari, M. A comprehensive review on energy efficient CO2 breakthrough technologies for sustainable green iron and steel manufacturing. Renew. Sustain. Energy Rev. 2015, 50, 594–614. [Google Scholar] [CrossRef]

- Salemi, S.; Torabi, M.; Haghparast, A.K. Technoeconomical investigation of energy harvesting from MIDREX® process waste heat using Kalina cycle in direct reduction iron process. Energy 2022, 239, 122322. [Google Scholar] [CrossRef]

- Sohn, H.Y. Energy consumption and CO2 emissions in ironmaking and development of a novel flash technology. Metals 2020, 10, 54. [Google Scholar] [CrossRef]

- Nikolaou, I.E.; Tsagarakis, K.P. An introduction to circular economy and sustainability: Some existing lessons and future directions. Sustain. Prod. Consum. 2021, 28, 600–609. [Google Scholar] [CrossRef]

- Calzadilla, A.; Winning, M.; Domenech, T. Synergies And Trade-Offs Between Climate And Circular Economy Policies in the Steel Industry. In Proceedings of the 25th Annual Conference on Global Economic Analysis, Online, 8–10 June 2020. [Google Scholar]

- Lee, S.; Manfredi, L.R. Promoting recycling, reducing and reusing in the School of Design: A step toward improving sustainability literacy. Int. J. Sustain. High. Educ. 2021, 22, 1038–1054. [Google Scholar] [CrossRef]

- Pandey, S.; Pandey, M.; Sinha, S.K. Utilization of Kiln Accretion as a Raw Material in Rural Road Laying. Civ. Environ. Res. 2014, 6, 110–114. [Google Scholar]

- Vilakazi, A.Q.; Ndlovu, S.; Chipise, L.; Shemi, A. The Recycling of Coal Fly Ash: A Review on Sustainable Developments and Economic Considerations. Sustainability 2022, 14, 1958. [Google Scholar] [CrossRef]

- Velumani, S.K.; Venkatraman, S. Assessing the Impact of Fly Ash and Recycled Concrete Aggregates on Fibre-Reinforced Self-Compacting Concrete Strength and Durability. Processes 2024, 12, 1602. [Google Scholar] [CrossRef]

- Kumar, V.; Khanam, S. Recovery and utilization of waste heat in a coal-based sponge iron process. Chem. Eng. Process. Process Intensif. 2012, 56, 19–28. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. MetaArXiv 2020. [Google Scholar] [CrossRef]

| Approach | Problem Addressed | Reductant Type | Country/Region | Year Published |

|---|---|---|---|---|

| Simulation models | ||||

| Simulation of direct reduction moving-bed reactor [33] | Mass and energy balance within the reactor | Natural gas | Iran | 2018 |

| Computer-aided optimisation to reduce carbon footprint [44] | Emission reduction | Natural gas | France | 2020 |

| Fuzzy Logic System for accretion prevention [45] | Waste reduction | Coal-based | South Africa | 2013 |

| CFD simulation of two-phase gas-particle flow [46] | Optimisation of process parameters | Natural gas | Iran | 2017 |

| Numerical simulation and parameter optimisation [47] | Mass and energy balance on the reduction rate | Coke oven gas | China | 2015 |

| Accretion control in sponge iron production using Fuzzy Logic [5] | Process optimisation | Coal-based | Kenya | 2014 |

| Neural network to optimise sponge iron production [48] | Optimisation of process parameters | Coal-based | India | 2016 |

| Simulation of impacts of mechanical pellets on iron reduction [36] | Process optimisation | Natural gas | Brazil | 2023 |

| Artificial Neural Network to predict solid conversion process of DRI [25] | Process optimisation | Natural gas | Iran | 2022 |

| Productivity increment of coal-based sponge iron using simulation [49] | Waste reduction | Coal-based | India | 2016 |

| Modelling and simulation of the Midrex shaft furnace [33] | Mass and energy balance within the shaft furnace | Natural gas | Canada | 2015 |

| Simulation of direct reduction reactor [50] | Process optimisation | Natural gas | Iran | 2011 |

| Numerical simulation to optimise reduction temperature of HR [51] | Mass and energy balances in the shaft furnace | Hydrogen gas | China | 2023 |

| Mathematical models | ||||

| Mathematical model and expert system to optimise reduction [52] | Control and optimisation of process parameters | Coal-based | China | 2012 |

| Computational fluid dynamic analysis of sponge iron rotary kiln [53] | Optimisation of process parameters | Coal-based | India | 2017 |

| Modelling 2D model for direct reduction shaft furnace [3] | Emission reduction | Natural gas | France | 2018 |

| Modelling and optimisation of rotary kiln DRI using the FORTRAN model [54] | Process optimisation | Coal-based | South Africa | 2015 |

| Analysis of temperature profile and % metallization in rotary kin [55] | Optimisation of process parameters | Coal-based | India | 2017 |

| Mathematical model to estimate parameters and efficiency of RHF [35] | Thermal efficiency | Coal-based | India | 2014 |

| Mathematical analysis of parameters affecting the reduction of iron ore [28] | Efficiency of the reduction process | Natural gas | Egypt | 2015 |

| Modelling of counter-current moving-bed reactor for DRI [32] | Mass energy balance within the shaft furnace | Natural gas | Argentina | 2004 |

| Modelling kinetics of iron oxide reduction using CO [29] | Effect of residence time on the reduction rate | Natural gas | India | 2022 |

| Modelling a new low-emission hydrogen DRI process using a 2D model [38] | CO2 emission reduction | Hydrogen gas | France | 2012 |

| Mathematical modelling of sponge iron DRI [30] | Energy efficiency, CO2 emission reduction | Coal-based | India | 2010 |

| Modelling and environmental economic analysis of DRI with different gases [56] | Emission reduction by using different reducing gases | Coke oven gas and hydrogen | Italy | 2023 |

| Online modelling of the Energiron Direct Reduction Shaft furnace [31] | Process optimisation | Natural gas | Italy | 2013 |

| Modelling the complex iterations of the Midrex shaft furnace [57] | Mass and energy interactions. | Natural gas | Saudi Arabia | 2012 |

| Multiscale process modelling of iron ore DRI using Aspen [58] | Process optimisation Emission reduction | Natural gas | France | 2018 |

| Experimental models | ||||

| Effect of iron ore coal pellets during reduction with hydrogen and CO [59] | Optimisation of process parameters | Hydrogen gas | China | 2016 |

| Statistically designed experiments for hydrogen-based direct reduction iron [27] | CO2 emission reduction | Hydrogen gas | Brazil | 2022 |

| The effect of water gas shift reaction and other parameters on DRI [40] | Reducing the production cost | Natural gas | USA | 2015 |

| Kinetics of iron oxide reduction using CO, experiments, and modelling [29] | Optimisation of process parameters | Natural gas | India | 2022 |

| Prediction of solid conversion process in DRI using machine learning [25] | Optimisation of process parameters | Natural gas | Iran | 2022 |

| Reaction reactivity of low-grade iron ore biomass for sustainable process [60] | CO2 emission reduction | Biomass gas | Indonesia | 2022 |

| Effects of preheating temperature and pellet size on reduction in DRI with biomass [61] | Improving the degree of metallization | Biomass gas | China | 2013 |

| Process modelling of hydrogen DRI, varying process parameters [62] | Variability in energy consumption | Hydrogen gas | Australia | 2024 |

| Effects of metallization degree on CO2 emission yield [63] | Productivity and emission reduction | Coke oven gas | China | 2024 |

| Solar-aided DRI using hydrogen as a reductant [64] | Low-CO2 alternatives | Hydrogen gas | France | 2024 |

| Using molten carbonate fuel cells to reduce energy consumption [65] | Energy efficiency and emission reduction | Natural gas | Italy | 2024 |

| Biomass Reductant | ||||

| Utilisation potential of biomass volatiles and biochar as reducing agents for DRI [66] | Emission reduction | Biomass gas | India | 2024 |

| Biomass reducing agent utilisation in the RHF process in DRI [41] | Emission reduction | Biomass gas | China | 2015 |

| Direct reduction of iron ore by biomass char [36] | Productivity and process optimisation | Biomass gas | China | 2013 |

| Direct reduction of oxidized iron ore pellets using biomass syngas as a reducer [26] | CO2 emission reduction | Biomass gas | China | 2016 |

| Reduction behaviour of iron ore pellets using hardwood biomasses as reductants [67] | Process optimisation with alternative reductants | Biomass gas | Germany | 2022 |

| Using biomass as a reductant of DRI in the RHF [68] | Emission reduction, optimisation of process parameters | Biomass gas | China | 2017 |

| Synergetic conversion laws of biomass and iron ore for DRI and syngas coproduction [69] | Productivity, emission reduction | Biomass gas | China | 2022 |

| Hydrogen Reductants | ||||

| Decarbonisation of the DRI process using green hydrogen [8] | Emission reduction | Hydrogen gas | Norway | 2020 |

| Hybrid hydrogen-based reduction of iron ore processes [42] | Emission reduction | Hydrogen gas | Germany | 2022 |

| Design and cost analysis of hydrogen-based DRI [70] | Optimising the operational cost of hydrogen reduction | Hydrogen gas | USA | 2023 |

| Hydrogen direct reduction; an overview of challenges and opportunities [14] | Feasibility of the hydrogen DRI process | Hydrogen gas | Germany | 2021 |

| Direct reduction of iron ore with hydrogen [14] | Emission reduction, reducing energy consumption | Hydrogen gas | China | 2021 |

| The perspective of hydrogen direct reduction of iron [71] | Emission reduction, process optimisation | Hydrogen gas | Australia | 2023 |

| Transitioning to hydrogen-based reduction technologies | Emission reduction Challenges associated with hydrogen DRI | Hydrogen gas | Canada | 2023 |

| Energy-Efficient Technologies | ||||

| Energy conservation in sponge iron process through proper utilisation of waste heat [72] | Waste heat recovery | Coal-based | India | 2013 |

| Energy survey for coal-based sponge iron industry [36] | Energy losses, increase in energy efficiency | Coal-based | India | 2015 |

| Most efficient technologies for greenhouse emission Abatement [73] | Emission reduction, energy efficiency | Coke oven gas and natural gas | Switzerland | 2019 |

| Techno-economic analysis of DRI through the integration of carbon capture and Storage technology [74] | Emission reduction | Natural gas | Korea | 2024 |

| Economic analysis of the pressurised chemical looping system integrated with the Midrex process [75] | Energy efficiency and emission reduction | Natural gas | Canada | 2024 |

| Decarbonization using chemical looping technology and biomass [76] | The need for low-cost syngas | Biomass gas | Japan | 2024 |

| Life Cycle Assessments | ||||

| Comparative life cycle assessment of natural gas and coal-based DRI [43] | Emission reduction throughout the life cycle | Coke oven gas and natural gas | India | 2022 |

| Cost and life cycle analysis for CO2 reduction in DRI technologies [42] | Emission reduction throughout the life cycle | Natural gas and hydrogen | USA | 2023 |

| Life cycle assessment of biosyngas-based DRI production process [15] | Emission reduction | Biomass gas | Sweden | 2023 |

| Life cycle assessment for sponge iron production process [37] | Reducing energy consumption | Natural gas | Iran | 2023 |

| Life cycle assessment of hydrogen DRI to reduce CO2 emissions [77] | Emission reduction | Hydrogen gas | China | 2024 |

| Prospective LCA approach for decarbonization options in the UK [78] | Emission reduction | Natural gas | UK | 2025 |

| Problems Addressed | Total | |||||||

| Emission reduction | 1 | 3 | 3 | 3 | 3 | 1 | 5 | 19 |

| Process optimisation | 6 | 7 | 4 | 1 | 18 | |||

| Emission reduction and optimisation | 1 | 1 | 3 | 1 | 6 | |||

| Energy efficiency | 2 | 1 | 1 | 2 | 1 | 7 | ||

| Economic feasibility | 1 | 2 | 1 | 4 | ||||

| Mass and energy balances | 4 | 2 | 6 | |||||

| Energy efficiency and emission reduction | 1 | 1 | 1 | 2 | 5 | |||

| Total | 13 | 15 | 11 | 7 | 7 | 6 | 6 | 65 |

| Strategy | Simulation models | Mathematical models | Experimental models | Biomass technology | Hydrogen technology | Energy-efficient tech | Life cycle assessment |

| for | Methane Steam Reforming | Coal Gasification | Membrane Electrolysis | Biomass Gasification | Methanol Steam Reforming |

|---|---|---|---|---|---|

| Cost (USD/kg H2) | 1.25 | 1.5 | 7.7 | 3 | 1.8–2.2 |

| GHG emission (kg CO2/kg H2) | 8.1–11 | 13–17 | 0 | +/−0 | <7 |

| H2 yield % | 70–85 | 50–60 | 70 | 20–40 | <90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nyakudya Ncube, R.Y.; Ayomoh, M. Optimisation Strategies and Technological Advancements for Sustainable Direct Reduction Iron Production—A Systematic Review. Sustainability 2025, 17, 2266. https://doi.org/10.3390/su17052266

Nyakudya Ncube RY, Ayomoh M. Optimisation Strategies and Technological Advancements for Sustainable Direct Reduction Iron Production—A Systematic Review. Sustainability. 2025; 17(5):2266. https://doi.org/10.3390/su17052266

Chicago/Turabian StyleNyakudya Ncube, Ratidzo Yvonne, and Michael Ayomoh. 2025. "Optimisation Strategies and Technological Advancements for Sustainable Direct Reduction Iron Production—A Systematic Review" Sustainability 17, no. 5: 2266. https://doi.org/10.3390/su17052266

APA StyleNyakudya Ncube, R. Y., & Ayomoh, M. (2025). Optimisation Strategies and Technological Advancements for Sustainable Direct Reduction Iron Production—A Systematic Review. Sustainability, 17(5), 2266. https://doi.org/10.3390/su17052266