Sustainability Transformation Through Green Supply Chain Management Practices and Green Innovations in Pakistan’s Manufacturing and Service Industries

Abstract

1. Introduction

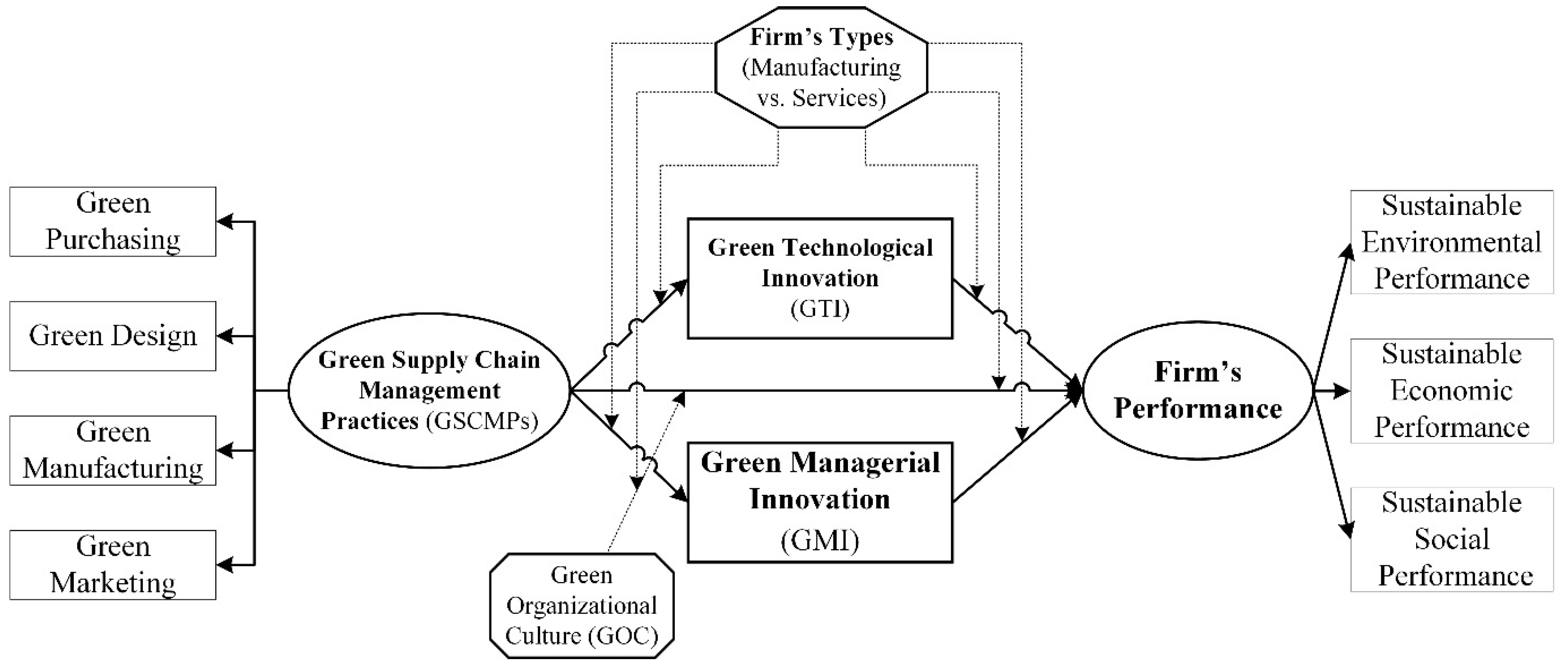

2. Literature Review and Framework Development

2.1. Theoretical Base of the Study

2.2. Literature Review

2.2.1. Green Supply Chain Management Practices (GSCMPs)

2.2.2. Green Technological Innovation (GTI)

2.2.3. Green Managerial Innovation (GMI)

2.2.4. Green Organizational Culture (GOC)

2.2.5. Firm Sustainable Performance

2.3. Hypothesis Development

2.3.1. Green Supply Chain Management Practices and Green Technological Innovation

2.3.2. Green Supply Chain Management Practices and Green Managerial Innovation

2.3.3. Green Supply Chain Management Practices and Firm Sustainable Performance

2.3.4. Green Innovations and Firm Sustainable Performance

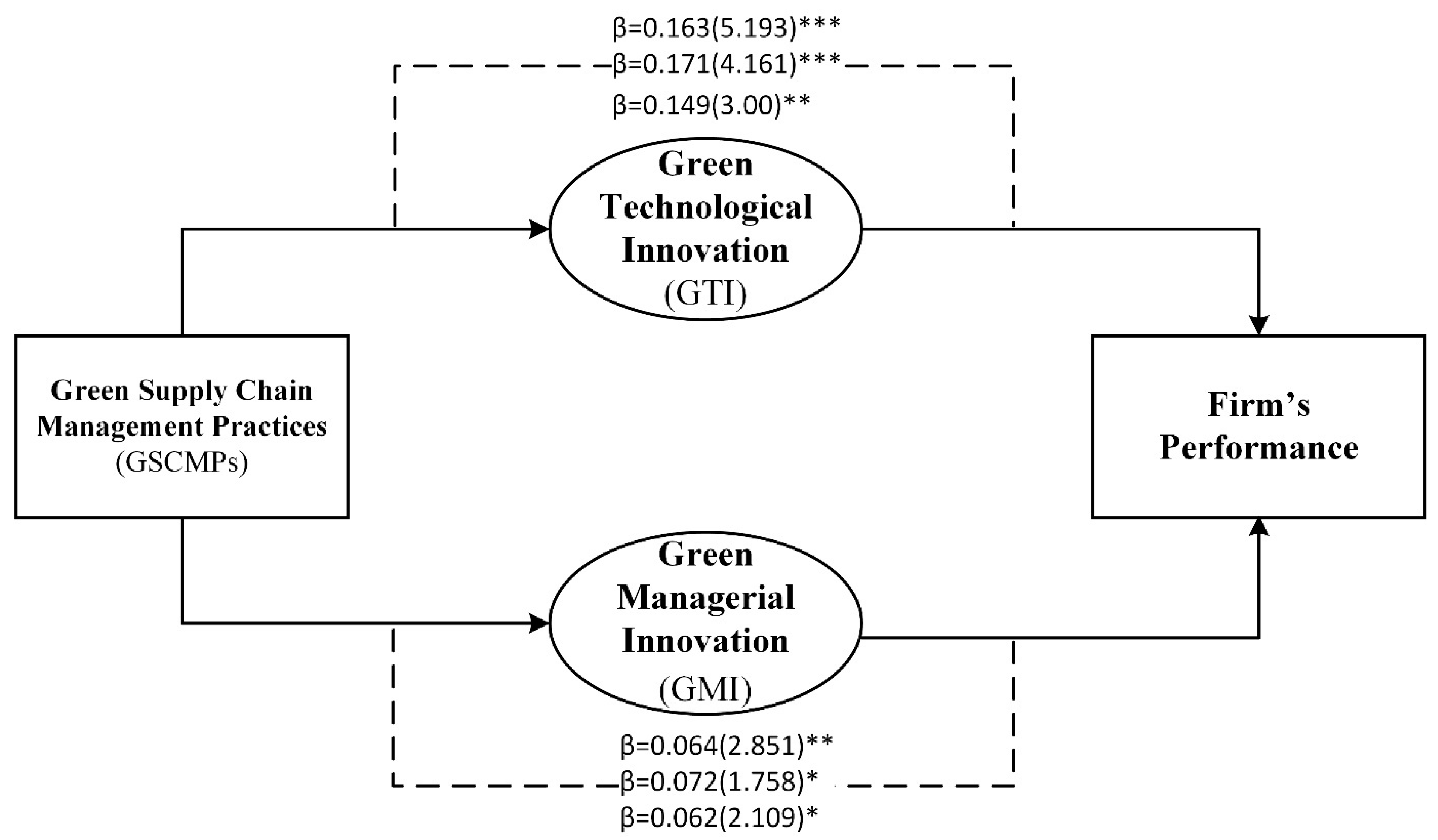

2.3.5. Mediating Effects of Green Innovations

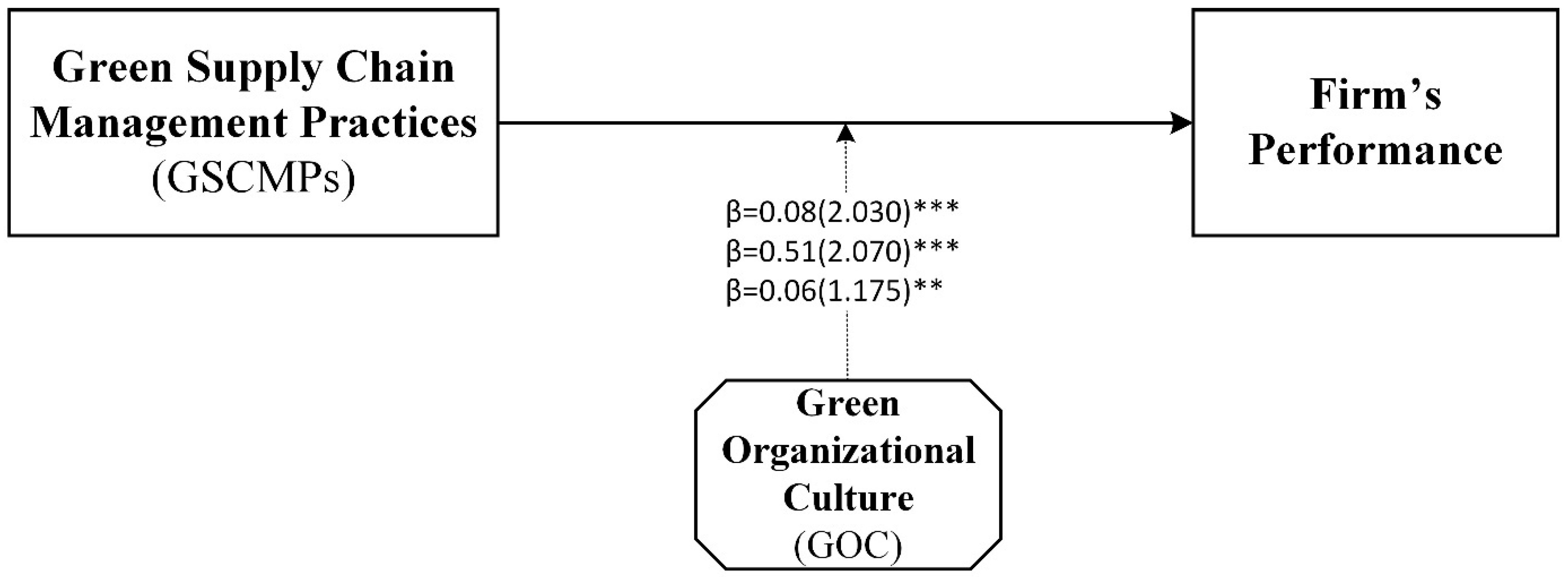

2.3.6. Moderating Role of Green Organizational Culture

3. Research Methodology

3.1. Sampling and Data Collection

3.2. Assumptions

3.3. Measurement Instrument Development

3.4. Data Analysis Approach

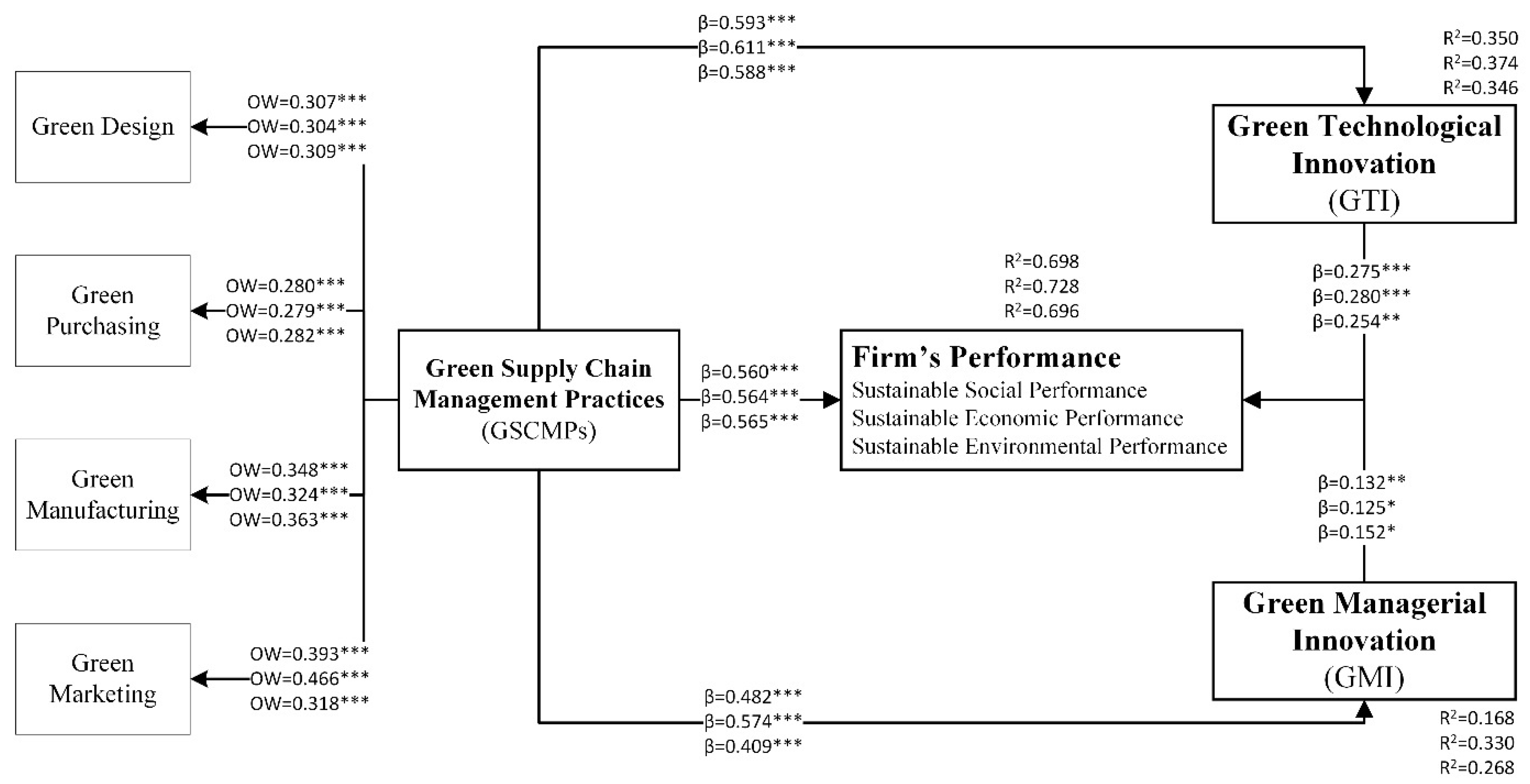

4. Data Analysis Results

5. Discussion

6. Theoretical Contributions

7. Practical and Managerial Implications

8. Conclusions

9. Limitations and Future Work Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rapdecho, C.; Aunyawong, W. The relationship among operational efficiency, esg implementation, green supply chain management, and sustainable supply chain performance. In Proceedings of the International Academic Multidisciplinary Research Conference in Fukuoka 2024, Fukuoka, Japan, 22–25 March 2024; pp. 186–193. [Google Scholar]

- Alkaraan, F.; Elmarzouky, M.; de Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Gulko, N. Maximising Sustainable Performance: Integrating Servitisation Innovation into Green Sustainable Supply Chain Management under the Influence of Governance and Industry 4.0. J. Bus. Res. 2025, 186, 115029. [Google Scholar] [CrossRef]

- Alkhatib, A.W. Fostering Green Innovation: The Roles of Big Data Analytics Capabilities and Green Supply Chain Integration. Eur. J. Innov. Manag. 2024, 27, 2818–2840. [Google Scholar] [CrossRef]

- Iqbal, M.; Ma, J.; Ahmad, N.; Ullah, Z.; Hassan, A. Energy-Efficient Supply Chains in Construction Industry: An Analysis of Critical Success Factors Using ISM-MICMAC Approach. Int. J. Green Energy 2023, 20, 265–283. [Google Scholar] [CrossRef]

- Wiredu, J.; Yang, Q.; Sampene, A.K.; Gyamfi, B.A.; Asongu, S.A. The Effect of Green Supply Chain Management Practices on Corporate Environmental Performance: Does Supply Chain Competitive Advantage Matter? Bus. Strategy Environ. 2024, 33, 2578–2599. [Google Scholar] [CrossRef]

- Khan, M.; Hamza, F. Impression of Internal and External Green Supply Chain Management Practices on Consumer Purchasing Behavior. J. Future Sustain. 2025, 5, 81–90. [Google Scholar] [CrossRef]

- Tian, H.; Pertheban, T.R.; Han, X. Navigating Industrial Performance: Impact of Corporate Social Responsibility on Sustainable Development with Moderation of Reverse Supply Chain Management. Corp. Soc. Responsib. Environ. Manag. 2025, 32, 1346–1357. [Google Scholar] [CrossRef]

- García Alcaraz, J.L.; Díaz Reza, J.R.; Arredondo Soto, K.C.; Hernández Escobedo, G.; Happonen, A.; Puig, I.; Vidal, R.; Jiménez Macías, E. Effect of Green Supply Chain Management Practices on Environmental Performance: Case of Mexican Manufacturing Companies. Mathematics 2022, 10, 1877. [Google Scholar] [CrossRef]

- Roh, T.; Noh, J.; Oh, Y.; Park, K.-S. Structural Relationships of a Firm’s Green Strategies for Environmental Performance: The Roles of Green Supply Chain Management and Green Marketing Innovation. J. Clean. Prod. 2022, 356, 131877. [Google Scholar] [CrossRef]

- Wu, D.; Ding, H.; Wang, W.; Cheng, Y. Green Technology Investment and Supply Chain Coordination Strategies Considering Marketing Efforts and Risk Aversion under Carbon Tax Policy. J. Ind. Manag. Optim. 2025, 21, 418–453. [Google Scholar] [CrossRef]

- Taamneh, M.M.; Al-Okaily, M.; Abudoleh, J.D.; Albdareen, R.; Taamneh, A.M. Nexus between Green Human Resource Management Practices and Corporate Social Responsibility: Does Transformational Leadership Make Difference? Int. J. Organ. Anal. 2025, 33, 1–24. [Google Scholar] [CrossRef]

- Pham, T.; Luong, T.; Huynh, N. The Impact of Sustainable Supply Chain Management Practices on Environmental Performance of Viet-Namese Agricultural Enterprises. Manag. Sci. Lett. 2025, 15, 71–80. [Google Scholar] [CrossRef]

- Wu, G.; Xu, Q.; Niu, X.; Tao, L. How Does Government Policy Improve Green Technology Innovation: An Empirical Study in China. Front. Environ. Sci. 2022, 9, 799794. [Google Scholar] [CrossRef]

- Iqbal, M.; Ismail, M.; Ibrahim, M.; Khalil, C.H.; Ahmad, I. Evaluation of International Logistics and Supply Chain Disruption During the COVID-19 Pandemic Through Scientometric Techniques. In Emerging Trends in Sustainable Supply Chain Management and Green Logistics; IGI Global: Hershey, PA, USA, 2023; pp. 15–40. [Google Scholar]

- Farrukh Shahzad, M.; Liu, H.; Zahid, H. Industry 4.0 Technologies and Sustainable Performance: Do Green Supply Chain Collaboration, Circular Economy Practices, Technological Readiness and Environmental Dynamism Matter? J. Manuf. Technol. Manag. 2025, 36, 1–22. [Google Scholar] [CrossRef]

- Bekele, A.A.; Mahesh, G.; Ingle, P.V. Enhancing SMCs’ Competitiveness through Improving Material Supply Chain Management Practice. Int. J. Constr. Manag. 2025, 25, 77–88. [Google Scholar] [CrossRef]

- Sarjana, S.; Najib, M.A.A.; Hanun, J. Digitalization of Supply Chain Technology to Encourage Green Supply Chain. In Proceedings of the E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2024; Volume 577, p. 03005. [Google Scholar]

- Bhadoriya, A.; Jani, M.Y.; Chaudhari, U. Combined Effect of Carbon Emission, Exchange Scheme, Trade Credit, and Advertisement Efforts in a Buyer’s Inventory Decision. Process Integr. Optim. Sustain. 2022, 6, 1043–1061. [Google Scholar] [CrossRef]

- Ali, S.R.; Hossain, M.A.; Islam, K.M.Z.; Alam, S.M.S. Weaving a Greener Future: The Impact of Green Human Resources Management and Green Supply Chain Management on Sustainable Performance in Bangladesh’s Textile Industry. Clean. Logist. Supply Chain 2024, 10, 100143. [Google Scholar] [CrossRef]

- Barney, J.B.; Arikan, A.M. The Resource-based View: Origins and Implications. In The Blackwell Handbook of Strategic Management; Wiley: Hobkon, NJ, USA, 2005; pp. 123–182. [Google Scholar]

- Munizu, M.; Alam, S.; Pono, M.; Riyadi, S. Do Digital Marketing, Integrated Supply Chain, and Innovation Capability Affect Competitiveness, and Creative Industry Performance? Int. J. Data Netw. Sci. 2024, 8, 1025–1034. [Google Scholar] [CrossRef]

- Correia, R.J.; Teixeira, M.S.; Dias, J.G. Dynamic Capabilities: Antecedents and Implications for Firms’ Performance. Int. J. Product. Perform. Manag. 2022, 71, 3270–3292. [Google Scholar] [CrossRef]

- Yuan, B.; Cao, X. Do Corporate Social Responsibility Practices Contribute to Green Innovation? The Mediating Role of Green Dynamic Capability. Technol. Soc. 2022, 68, 101868. [Google Scholar] [CrossRef]

- Amenta, E.; Ramsey, K.M. Institutional Theory. In Handbook of Politics: State and Society in Global Perspective; Springer: New York, NY, USA, 2010; pp. 15–39. [Google Scholar]

- Rashid, A.; Baloch, N.; Rasheed, R.; Ngah, A.H. Big Data Analytics-Artificial Intelligence and Sustainable Performance through Green Supply Chain Practices in Manufacturing Firms of a Developing Country. J. Sci. Technol. Policy Manag. 2025, 16, 42–67. [Google Scholar] [CrossRef]

- Mahapatra, A.S.; Sengupta, S.; Dasgupta, A.; Sarkar, B.; Goswami, R.T. What Is the Impact of Demand Patterns on Integrated Online-Offline and Buy-Online-Pickup in-Store (BOPS) Retail in a Smart Supply Chain Management? J. Retail. Consum. Serv. 2025, 82, 104093. [Google Scholar] [CrossRef]

- Fayyaz, A.; Liu, C.; Xu, Y.; Ramzan, S. Effects of Green Human Resource Management, Internal Environmental Management and Developmental Culture between Lean Six Sigma and Operational Performance. Int. J. Lean Six Sigma 2025, 16, 109–140. [Google Scholar] [CrossRef]

- Iqbal, M.; Waqas, M.; Ahmad, N.; Hussain, K.; Hussain, J. Green Supply Chain Management as a Pathway to Sustainable Operations in the Post-COVID-19 Era: Investigating Challenges in the Chinese Scenario. Bus. Process Manag. J. 2024, 30, 1065–1087. [Google Scholar] [CrossRef]

- Singh, R.K.; Mathiyazhagan, K.; Gunasekaran, A. Advancing towards Sustainable and Net-Zero Supply Chains: A Comprehensive Analysis of Knowledge Capabilities and Industry Dynamism. J. Knowl. Manag. 2025, 29, 148–170. [Google Scholar] [CrossRef]

- Gao, J.Q.; Li, D.; Qiao, G.H.; Jia, Q.R.; Li, S.R.; Gao, H.L. Circular Economy Strategies in Supply Chains, Enhancing Resource Efficiency and Sustainable Development Goals. Environ. Sci. Pollut. Res. 2024, 31, 8751–8767. [Google Scholar] [CrossRef] [PubMed]

- Kareem, S.; Fehrer, J.A.; Shalpegin, T.; Stringer, C. Navigating Tensions of Sustainable Supply Chains in Times of Multiple Crises: A Systematic Literature Review. Bus Strategy Environ. 2025, 34, 316–337. [Google Scholar] [CrossRef]

- Shah, N.H.; Jani, M.Y.; Chaudhari, U. Study of Imperfect Manufacturing System with Preservation Technology Investment under Inflationary Environment for Quadratic Demand: A Reverse Logistic Approach. J. Adv. Manuf. Syst. 2017, 16, 17–34. [Google Scholar] [CrossRef]

- Miswanto, M.; Tarigan, S.; Wardhani, S.; Khuan, H.; Rahmadyanti, E.; Jumintono, J.; Ranatarisza, M.; Machmud, M. Investigating the Influence of Financial Literacy and Supply Chain Management on the Financial Performance and Sustainability of SMEs. Uncertain Supply Chain Manag. 2024, 12, 407–416. [Google Scholar] [CrossRef]

- Pellegrino, R.; Gaudenzi, B.; Qazi, A. Capturing Key Interdependences among Supply Chain Disruptions and Mitigation Strategies to Enhance Firm Performance. Int. J. Qual. Reliab. Manag. 2025, 42, 254–284. [Google Scholar] [CrossRef]

- Jani, M.Y.; Chaudhari, U.; Sarkar, B. How Does an Industry Control a Decision Support System for a Long Time? RAIRO-Oper. Res. 2021, 55, 3141–3152. [Google Scholar] [CrossRef]

- Jia, F.; Xu, Y.; Chen, L.; Fernandes, K. Does Supply Chain Concentration Improve Sustainability Performance: The Role of Operational Slack and Information Transparency. Int. J. Oper. Prod. Manag. 2025, 45, 269–300. [Google Scholar] [CrossRef]

- Arianpoor, A.; Lamloom, I.T.; Moghaddampoor, B.; Khayoon, H.M.; Zaidan, A.S. The Impact of Managerial Psychological Characteristics on the Supply Chain Management Efficiency. TQM J. 2025, 37, 150–170. [Google Scholar] [CrossRef]

- Sahu, A.K.; Sharma, M.; Raut, R.; Gedam, V.V.; Agrawal, N.; Priyadarshinee, P. Effect of Lean-Green Practice and Green Human Resource on Supply Chain Performance: A Resource-Based View. Benchmarking Int. J. 2024, 32, 636–665. [Google Scholar] [CrossRef]

- El-Garaihy, W.H.; Farag, T.; Al Shehri, K.; Centobelli, P.; Cerchione, R. Driving Sustainability in Supply Chain Management for a More Inclusive and Responsible Future. Int. J. Product. Perform. Manag. 2024, 73, 43–84. [Google Scholar] [CrossRef]

- Mulyani, S.; Basrowi, B. The Effect of Environmentally Oriented Leadership and Public Sector Management Quality on Supply Chain Performance: The Moderating Role of Public Sector Environmental Policy. Uncertain Supply Chain Manag. 2024, 12, 471–480. [Google Scholar] [CrossRef]

- Chiang, C.; Chuang, M.-C. Effect of Sustainable Supply Chain Management on Procurement Environmental Performance: A Perspective on Resource Dependence Theory. Sustainability 2024, 16, 586. [Google Scholar] [CrossRef]

- Zaman, S.I.; Ali, M.R.; Khan, S.A. Exploring Interrelationships among Barriers and Enablers of Green Procurement for a Sustainable Supply Chain. Int. J. Procure Manag. 2024, 19, 226–252. [Google Scholar] [CrossRef]

- Chaudhari, U.; Bhadoriya, A.; Jani, M.Y.; Sarkar, B. A Generalized Payment Policy for Deteriorating Items When Demand Depends on Price, Stock, and Advertisement under Carbon Tax Regulations. Math Comput. Simul. 2023, 207, 556–574. [Google Scholar] [CrossRef]

- Al Karim, R.; Kabir, M.R.; Rabiul, M.K.; Kawser, S.; Salam, A. Linking Green Supply Chain Management Practices and Environmental Performance in the Manufacturing Industry: A Hybrid SEM-ANN Approach. Environ. Sci. Pollut. Res. 2024, 31, 13925–13940. [Google Scholar] [CrossRef] [PubMed]

- Liao, F.; Hu, Y.; Ye, S. Corporate Social Responsibility and Green Supply Chain Efficiency: Conditioning Effects Based on CEO Narcissism. Humanit Soc. Sci. Commun. 2024, 11, 1. [Google Scholar] [CrossRef]

- Lu, H.T.; Li, X.; Yuen, K.F. Digital Transformation as an Enabler of Sustainability Innovation and Performance–Information Processing and Innovation Ambidexterity Perspectives. Technol. Forecast Soc. Chang. 2023, 196, 122860. [Google Scholar] [CrossRef]

- Kong, L.; Akbar, M.; Poulova, P. The Role of Environment, Social, and Governance Performance in Shaping Corporate Current and Future Value: The Case of Global Tech Leaders. Sustainability 2023, 15, 13114. [Google Scholar] [CrossRef]

- Chavez, R.; Yu, W.; Jajja, M.S.S.; Song, Y.; Nakara, W. The Relationship between Internal Lean Practices and Sustainable Performance: Exploring the Mediating Role of Social Performance. Prod. Plan. Control 2022, 33, 1025–1042. [Google Scholar] [CrossRef]

- Sun, X.; El Askary, A.; Meo, M.S.; Hussain, B. Green Transformational Leadership and Environmental Performance in Small and Medium Enterprises. Econ. Res.-Ekon. Istraživanja 2022, 35, 5273–5291. [Google Scholar] [CrossRef]

- Kiet, H.V.T.T.; Sang, M.V.; Truc, T.B.; Lan, T.K.N.; Dinh, H.Q.; Dao, P.T.B. Impact of Green Supply Chain Management on Social Performance through Economic Undergraduate’s View. J. Infrastruct. Policy Dev. 2024, 8, 3075. [Google Scholar] [CrossRef]

- Feng, Y.; Akram, R.; Hieu, V.M.; Tien, N.H. The Impact of Corporate Social Responsibility on the Sustainable Financial Performance of Italian Firms: Mediating Role of Firm Reputation. Econ. Res.-Ekon. Istraživanja 2022, 35, 4740–4758. [Google Scholar] [CrossRef]

- Jan, A.; Salameh, A.A.; Rahman, H.U.; Alasiri, M.M. Can Blockchain Technologies Enhance Environmental Sustainable Development Goals Performance in Manufacturing Firms? Potential Mediation of Green Supply Chain Management Practices. Bus. Strategy Environ. 2024, 33, 2004–2019. [Google Scholar] [CrossRef]

- Baah, C.; Agyabeng-Mensah, Y.; Afum, E.; Lascano Armas, J.A. Exploring Corporate Environmental Ethics and Green Creativity as Antecedents of Green Competitive Advantage, Sustainable Production and Financial Performance: Empirical Evidence from Manufacturing Firms. Benchmarking Int. J. 2024, 31, 990–1008. [Google Scholar] [CrossRef]

- Noja, G.G.; Cristea, M.; Panait, M.; Trif, S.M.; Ponea, C. Ștefan The Impact of Energy Innovations and Environmental Performance on the Sustainable Development of the EU Countries in a Globalized Digital Economy. Front. Environ. Sci. 2022, 10, 934404. [Google Scholar] [CrossRef]

- Zhang, D.; Shi, L.; Liu, G. Supply Chain in Transition Navigating Economic Growth and Environmental Sustainability through Education. Environ. Sci. Pollut. Res. 2024, 31, 12321–12339. [Google Scholar] [CrossRef]

- Liao, F.; Hu, Y.; Chen, M.; Xu, S. Digital Transformation and Corporate Green Supply Chain Efficiency: Evidence from China. Econ. Anal. Policy 2024, 81, 195–207. [Google Scholar] [CrossRef]

- Jum’a, L.; Alkalha, Z.; Alaraj, M. Towards Environmental Sustainability: The Nexus between Green Supply Chain Management, Total Quality Management, and Environmental Management Practices. Int. J. Qual. Reliab. Manag. 2024, 41, 1209–1234. [Google Scholar] [CrossRef]

- Ardini, L.; Fahlevi, M. Circular Economy from an Environmental Accounting Perspective: Strengthening Firm Performance through Green Supply Chain Management and Import Regulation in Indonesia’s Plastic Recycling Industry. Uncertain Supply Chain Manag. 2024, 12, 1633–1646. [Google Scholar] [CrossRef]

- Nazir, S.; Zhaolei, L.; Mehmood, S.; Nazir, Z. Impact of Green Supply Chain Management Practices on the Environmental Performance of Manufacturing Firms Considering Institutional Pressure as a Moderator. Sustainability 2024, 16, 2278. [Google Scholar] [CrossRef]

- Galdos-Urbizu, L.; Zubeltzu-Jaka, E.; Erauskin-Tolosa, A.; Etxeberria, I.A. The Impact of Green Supply Chain Management on Corporate Environmental Performance and the Moderating Roles: A Meta-analysis. Bus. Strategy Dev. 2024, 7, e351. [Google Scholar] [CrossRef]

- Manigandan, P.; Alam, M.S.; Murshed, M.; Ozturk, I.; Altuntas, S.; Alam, M.M. Promoting Sustainable Economic Growth through Natural Resources Management, Green Innovations, Environmental Policy Deployment, and Financial Development: Fresh Evidence from India. Resour. Policy 2024, 90, 104681. [Google Scholar] [CrossRef]

- Li, X.; He, J. Mechanism of the Green Supply Chain Profit of Building Materials Considering the Duopoly Competition Model and Consumer Green Preference. Int. J. Syst. Sci. Oper. Logist. 2024, 11, 2311283. [Google Scholar] [CrossRef]

- Aunyawong, W.; Waiyawuththanapoom, P.; Thitart, P.; Kerdpitak, C.; Vaiyavuth, R.; Sritapanya, K.; Shaharudin, M. The Effect of Green Supply Chain Management Practices on Performances of Herb Manufacturers in Thailand. Uncertain Supply Chain Manag. 2024, 12, 417–424. [Google Scholar] [CrossRef]

- Visamitanan, K.; Assarut, N. Impact of Green Supply Chain Management Practices on Employee Engagement and Organizational Commitment: Mediating Role of Firm Performance. Glob. Bus. Rev. 2024, 25, 1336–1355. [Google Scholar] [CrossRef]

- Miar, M.; Rizani, A.; Pardede, R.; Basrowi, B. Analysis of the Effects of Capital Expenditure and Supply Chain on Economic Growth and Their Implications on the Community Welfare of Districts and Cities in Central Kalimantan Province. Uncertain Supply Chain Manag. 2024, 12, 489–504. [Google Scholar] [CrossRef]

- Alexandro, R.; Basrowi, B. The Influence of Macroeconomic Infrastructure on Supply Chain Smoothness and National Competitiveness and Its Implications on a Country’s Economic Growth: Evidence from BRICS Countries. Uncertain Supply Chain Manag. 2024, 12, 167–180. [Google Scholar] [CrossRef]

- Hebaz, A.; Oulfarsi, S.; Eddine, A.S. Prioritizing Institutional Pressures, Green Supply Chain Management Practices for Corporate Sustainable Performance Using Best Worst Method. Clean. Logist. Supply Chain 2024, 10, 100146. [Google Scholar] [CrossRef]

- Khan, T.; Emon, M.M.H.; Siam, S.A.J. Impact of Green Supply Chain Practices on Sustainable Development in Bangladesh. Malays. Bus. Manag. J. 2024, 3, 73–83. [Google Scholar] [CrossRef]

- Vargas-Hernández, J.G.; Maillard, C.A.R.; Vargas-González, O.C. Green Organizational Culture, Green Innovation, and Green Performance for Achieving Environmental Sustainability. In Research Anthology on Business Law, Policy, and Social Responsibility; IGI Global: Hershey, PA, USA, 2024; pp. 932–953. [Google Scholar]

- Radakovich, P.S. The Relationship Between Organizational Culture, Intrinsic Motivation, and Employee Performance: A Systematic Review and Meta-Analysis; Wayne State University: Detroit, MI, USA, 2016; ISBN 1369434855. [Google Scholar]

- Manigandan, R.; Raghuram, J.N.V. Examining the Pathways to Success: Investigating the Mediating Role of Green Innovation in the Relationship between Green Entrepreneurial Orientation, Green Organisational Culture, and Competitive Advantage in the Hotel Industry. Int. J. Work Innov. 2024, 5, 99–121. [Google Scholar] [CrossRef]

- Epoh, L.R.; Mafini, C. Green Supply Chain Management in Small and Medium Enterprises: Further Empirical Thoughts from South Africa. J. Transp. Supply Chain Manag. 2018, 12, 495. [Google Scholar] [CrossRef]

- Sahoo, S.; Kumar, A.; Upadhyay, A. How Do Green Knowledge Management and Green Technology Innovation Impact Corporate Environmental Performance? Understanding the Role of Green Knowledge Acquisition. Bus. Strategy Environ. 2023, 32, 551–569. [Google Scholar] [CrossRef]

- Ma, Y.; Hou, G.; Yin, Q.; Xin, B.; Pan, Y. The Sources of Green Management Innovation: Does Internal Efficiency Demand Pull or External Knowledge Supply Push? J. Clean Prod. 2018, 202, 582–590. [Google Scholar] [CrossRef]

- Silva, G.M.; Gomes, P.J.; Sarkis, J. The Role of Innovation in the Implementation of Green Supply Chain Management Practices. Bus. Strategy Environ. 2019, 28, 819–832. [Google Scholar] [CrossRef]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to Use and How to Report the Results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Sarstedt, M.; Ringle, C.M.; Hair, J.F. Partial Least Squares Structural Equation Modeling. In Handbook of Market Research; Springer: Berlin/Heidelberg, Germany, 2021; pp. 587–632. [Google Scholar]

- Ab Hamid, M.R.; Sami, W.; Sidek, M.H.M. Discriminant Validity Assessment: Use of Fornell & Larcker Criterion versus HTMT Criterion. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2017; Volume 890, p. 012163. [Google Scholar]

- Rasoolimanesh, S.M. Discriminant Validity Assessment in PLS-SEM: A Comprehensive Composite-Based Approach. Data Anal. Perspect. J. 2022, 3, 1–8. [Google Scholar]

- Chicco, D.; Warrens, M.J.; Jurman, G. The Coefficient of Determination R-Squared Is More Informative than SMAPE, MAE, MAPE, MSE and RMSE in Regression Analysis Evaluation. PeerJ Comput. Sci. 2021, 7, e623. [Google Scholar] [CrossRef] [PubMed]

- Karim, R.A.; Kawser, S.; Rabiul, M.K.; Chowdhury, T.; Murtaza, F.N.Y. Green Supply Chain Management Practices and Environmental Performance in the Healthcare Sector: The Mediating Role of Green Innovation. Glob. Knowl. Mem. Commun. 2024; ahead of print. [Google Scholar] [CrossRef]

- Islam, H. Nexus of Economic, Social, and Environmental Factors on Sustainable Development Goals: The Moderating Role of Technological Advancement and Green Innovation. Innov. Green Dev. 2025, 4, 100183. [Google Scholar] [CrossRef]

- Harfouche, A.; Merhi, M.I.; Albizri, A.; Dennehy, D.; Thatcher, J.B. Sustainable Development through Technological Innovations and Data Analytics. Inf. Syst. Front. 2025, 26, 1989–1996. [Google Scholar] [CrossRef]

- Zada, M.; Khan, S.; Zada, S.; Dhar, B.K. Driving Sustainable Development Through CSR Leadership: Insights Into Organizational Learning and Technological Innovation. Sustain. Dev. 2025, 33, 1–15. [Google Scholar] [CrossRef]

- Şengüllendi, M.F.; Bilgetürk, M.; Afacan Fındıklı, M. Ethical Leadership and Green Innovation: The Mediating Role of Green Organizational Culture. J. Environ. Plan. Manag. 2024, 67, 1702–1723. [Google Scholar] [CrossRef]

| Total Variance Explained | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Component | Initial Eigenvalues | Extraction Sums of Squared Loadings | Rotation Sums of Squared Loadings | ||||||

| Total | % of Variance | Cumulative % | Total | % of Variance | Cumulative % | Total | % of Variance | Cumulative % | |

| 1 | 12.326 | 31.604 | 31.604 | 12.326 | 31.604 | 31.604 | 4.423 | 11.340 | 11.340 |

| 2 | 3.120 | 8.000 | 39.605 | 3.120 | 8.000 | 39.605 | 3.431 | 8.797 | 20.137 |

| 3 | 2.515 | 6.449 | 46.054 | 2.515 | 6.449 | 46.054 | 3.193 | 8.187 | 28.324 |

| 4 | 2.322 | 5.955 | 52.009 | 2.322 | 5.955 | 52.009 | 2.961 | 7.591 | 35.915 |

| 5 | 2.000 | 5.129 | 57.138 | 2.000 | 5.129 | 57.138 | 2.916 | 7.478 | 43.393 |

| 6 | 1.500 | 3.845 | 60.984 | 1.500 | 3.845 | 60.984 | 2.904 | 7.445 | 50.838 |

| Variables | Items | Frequency | Percentage |

|---|---|---|---|

| Gender | Male | 268 | 55.83% |

| Female | 212 | 44.16% | |

| Age | 30–35 years | 217 | 45.20% |

| 36–40 years | 159 | 33.12% | |

| >40 years | 104 | 21.66% | |

| Education | Graduates | 96 | 20.00% |

| Post-Graduate | 193 | 40.20% | |

| Doctorate | 113 | 23.54% | |

| Others | 78 | 16.25% | |

| Experience | 5–7 years | 215 | 44.79% |

| 8–10 years | 172 | 35.83% | |

| >10 years | 93 | 19.37% | |

| Industry Type | Manufacturing | Textiles | 92 (19.16%) |

| Pharmaceuticals | 78 (16.25%) | ||

| Cements | 56 (11.66%) | ||

| Services | Logistics | 95 (19.79%) | |

| IT | 83 (17.29%) | ||

| Healthcare | 76 (15.83%) | ||

| Total | 480 |

| Variables | Description | Variable Type | Items | Source |

|---|---|---|---|---|

| Green Supply Chain Management Practices | Integration of environmental considerations into supply chain operations, from procurement to delivery. | |||

| Green Designing | Developing products and processes that prioritize environmental sustainability throughout their lifecycle. | Ordinal | “4 items using Five-point Likert Scale” | [72] |

| Green Purchasing | Procuring eco-friendly raw materials and products from environmentally responsible suppliers. | Ordinal | “4 items using Five-point Likert Scale” | [73] |

| Green Manufacturing | Implementing energy-efficient, waste-minimizing, and eco-friendly production processes. | Ordinal | “5 items using Five-point Likert Scale” | [73] |

| Green Marketing | Promoting sustainability-oriented products and practices to enhance brand reputation and meet consumer expectations. | Ordinal | “3 items using Five-point Likert Scale” | [73] |

| Green Technological Innovation | Adoption of advanced technologies to reduce environmental impact and improve operational efficiency. | Ordinal | “4 items using Five-point Likert Scale” | [74] |

| Green Managerial Innovation | Adoption of innovative managerial practices and systems to integrate sustainability into organizational strategies. | Ordinal | “3 items using Five-point Likert Scale” | [74] |

| Green Organizational Culture | Shared values and practices within a firm that emphasize sustainability and environmental stewardship. | Ordinal | “4 items using Five-point Likert Scale” | [69] |

| Firm Sustainable Performance | A firm’s ability to achieve long-term environmental, social, and economic goals. | |||

| Environmental Sustainable Performance | The reduction in ecological footprints through emissions control, resource conservation, and waste management. | Ordinal | “4 items using Five-point Likert Scale” | [75] |

| Social Sustainable Performance | Enhancing stakeholder well-being, including fair labor practices, community development, and ethical engagement. | Ordinal | “4 items using Five-point Likert Scale” | [75] |

| Economic Sustainable Performance | Achieving financial gains while adopting cost-effective and sustainable business practices. | Ordinal | “4 items using Five-point Likert Scale” | [75] |

| Constructs | Items | Complete | Manufacturing | Services | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| λ | Cα | CR | AVE | VIF | λ | Cα | CR | AVE | VIF | λ | Cα | CR | AVE | VIF | ||

| Green Designing | GD1 | 0.799 | 0.838 | 0.891 | 0.672 | 1.705 | 0.819 | 0.869 | 0.91 | 0.718 | 1.799 | 0.775 | 0.8 | 0.867 | 0.621 | 1.699 |

| GD2 | 0.805 | 1.791 | 0.857 | 2.312 | 0.758 | 1.52 | ||||||||||

| GD3 | 0.848 | 2.59 | 0.877 | 2.778 | 0.805 | 2.494 | ||||||||||

| GD4 | 0.825 | 2.443 | 0.834 | 2.333 | 0.812 | 2.673 | ||||||||||

| Green Purchasing | GP1 | 0.784 | 0.843 | 0.894 | 0.68 | 1.888 | 0.819 | 0.864 | 0.907 | 0.709 | 2.145 | 0.734 | 0.82 | 0.881 | 0.65 | 1.69 |

| GP2 | 0.846 | 2.341 | 0.835 | 2.335 | 0.854 | 2.373 | ||||||||||

| GP3 | 0.863 | 2.248 | 0.862 | 2.366 | 0.87 | 2.234 | ||||||||||

| GP4 | 0.803 | 1.754 | 0.851 | 2.154 | 0.759 | 1.516 | ||||||||||

| Green Manufacturing | GM1 | 0.756 | 0.856 | 0.897 | 0.635 | 1.701 | 0.731 | 0.843 | 0.888 | 0.613 | 1.573 | 0.799 | 0.854 | 0.906 | 0.658 | 2.036 |

| GM2 | 0.849 | 2.647 | 0.842 | 2.151 | 0.848 | 2.577 | ||||||||||

| GM3 | 0.791 | 2.151 | 0.796 | 2.678 | 0.787 | 1.892 | ||||||||||

| GM4 | 0.81 | 1.798 | 0.772 | 1.613 | 0.842 | 2.141 | ||||||||||

| GM5 | 0.775 | 1.689 | 0.77 | 1.726 | 0.778 | 1.697 | ||||||||||

| Green Marketing | GMKT1 | 0.872 | 0.814 | 0.89 | 0.729 | 1.963 | 0.866 | 0.802 | 0.884 | 0.718 | 1.962 | 0.877 | 0.827 | 0.897 | 0.743 | 2.001 |

| GMKT2 | 0.879 | 2.045 | 0.881 | 2.116 | 0.88 | 1.983 | ||||||||||

| GMKT3 | 0.809 | 1.577 | 0.791 | 1.479 | 0.828 | 1.731 | ||||||||||

| Green Technological Innovation | GTI1 | 0.798 | 0.86 | 0.905 | 0.705 | 1.743 | 0.791 | 0.849 | 0.898 | 0.688 | 1.808 | 0.805 | 0.873 | 0.913 | 0.725 | 1.853 |

| GTI2 | 0.827 | 1.988 | 0.849 | 2.105 | 0.81 | 2.031 | ||||||||||

| GTI3 | 0.861 | 2.224 | 0.824 | 1.882 | 0.897 | 2.936 | ||||||||||

| GTI4 | 0.871 | 2.395 | 0.852 | 2.086 | 0.89 | 2.979 | ||||||||||

| Green Managerial Innovation | GMI1 | 0.886 | 0.863 | 0.916 | 0.785 | 1.414 | 0.897 | 0.868 | 0.919 | 0.792 | 2.511 | 0.876 | 0.854 | 0.911 | 0.774 | 2.123 |

| GMI2 | 0.908 | 1.344 | 0.908 | 2.626 | 0.907 | 2.744 | ||||||||||

| GMI3 | 0.863 | 1.496 | 0.864 | 1.969 | 0.856 | 1.958 | ||||||||||

| Green Organizational Cultural | GOC1 | 0.85 | 0.872 | 0.91 | 0.716 | 1.842 | 0.756 | 0.828 | 0.883 | 0.654 | 1.712 | 0.91 | 0.909 | 0.912 | 0.722 | 2.017 |

| GOC2 | 0.837 | 2.175 | 0.837 | 1.715 | 0.822 | 2.838 | ||||||||||

| GOC3 | 0.824 | 2.613 | 0.841 | 2.535 | 0.765 | 2.91 | ||||||||||

| GOC4 | 0.874 | 2.556 | 0.798 | 2.458 | 0.894 | 2.238 | ||||||||||

| Sustainable Environmental Performance | SENP1 | 0.85 | 0.884 | 0.92 | 0.742 | 2.193 | 0.852 | 0.873 | 0.912 | 0.723 | 2.161 | 0.848 | 0.89 | 0.924 | 0.752 | 2.215 |

| SENP2 | 0.842 | 2.118 | 0.839 | 1.89 | 0.849 | 2.302 | ||||||||||

| SENP3 | 0.899 | 2.043 | 0.881 | 2.853 | 0.906 | 2.186 | ||||||||||

| SENP4 | 0.855 | 2.475 | 0.828 | 2.233 | 0.864 | 2.645 | ||||||||||

| Sustainable Social Performance | SSCP1 | 0.787 | 0.796 | 0.867 | 0.621 | 1.51 | 0.819 | 0.81 | 0.877 | 0.642 | 1.799 | 0.763 | 0.782 | 0.858 | 0.602 | 1.395 |

| SSCP2 | 0.828 | 2.086 | 0.877 | 2.51 | 0.771 | 1.853 | ||||||||||

| SSCP3 | 0.8 | 2.021 | 0.823 | 2.1 | 0.779 | 2.007 | ||||||||||

| SSCP4 | 0.733 | 1.394 | 0.72 | 1.276 | 0.791 | 1.566 | ||||||||||

| Sustainable Economic Performance | SECP1 | 0.895 | 0.884 | 0.92 | 0.742 | 2.621 | 0.896 | 0.871 | 0.913 | 0.725 | 2.7 | 0.893 | 0.85 | 0.896 | 0.684 | 2.604 |

| SECP2 | 0.798 | 1.88 | 0.819 | 1.963 | 0.763 | 1.815 | ||||||||||

| SECP3 | 0.845 | 2.2 | 0.883 | 2.694 | 0.795 | 1.95 | ||||||||||

| SECP4 | 0.819 | 1.779 | 0.803 | 1.898 | 0.85 | 1.789 | ||||||||||

| Discriminant Validity (HTMT Ratios) | Discriminant Validity (Fornell–Lacker Criteria) | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Complete Sample | |||||||||||||||||||||

| GD | GM | GMI | GMKT | GOC | GP | GTI | SECP | SENP | SSCP | GD | GM | GMI | GMKT | GOC | GP | GTI | SECP | SENP | SSCP | ||

| GD | GD | 0.82 | |||||||||||||||||||

| GM | 0.428 | GM | 0.362 | 0.797 | |||||||||||||||||

| GMI | 0.391 | 0.389 | GMI | 0.341 | 0.342 | 0.886 | |||||||||||||||

| GMKT | 0.502 | 0.544 | 0.536 | GMKT | 0.42 | 0.463 | 0.447 | 0.854 | |||||||||||||

| GOC | 0.096 | 0.074 | 0.067 | 0.089 | GOC | 0.081 | 0.022 | 0.019 | 0.064 | 0.846 | |||||||||||

| GP | 0.295 | 0.677 | 0.344 | 0.503 | 0.067 | GP | 0.25 | 0.579 | 0.296 | 0.415 | 0.019 | 0.824 | |||||||||

| GTI | 0.499 | 0.553 | 0.598 | 0.586 | 0.079 | 0.425 | GTI | 0.43 | 0.477 | 0.518 | 0.492 | 0.054 | 0.363 | 0.84 | |||||||

| SECP | 0.456 | 0.609 | 0.421 | 0.789 | 0.06 | 0.442 | 0.635 | SECP | 0.398 | 0.536 | 0.365 | 0.668 | 0.029 | 0.381 | 0.552 | 0.84 | |||||

| SENP | 0.526 | 0.551 | 0.487 | 0.484 | 0.1 | 0.47 | 0.605 | 0.373 | SENP | 0.455 | 0.482 | 0.426 | 0.413 | 0.09 | 0.407 | 0.53 | 0.331 | 0.862 | |||

| SSCP | 0.456 | 0.538 | 0.62 | 0.712 | 0.101 | 0.492 | 0.605 | 0.571 | 0.674 | SSCP | 0.381 | 0.459 | 0.516 | 0.577 | 0.078 | 0.413 | 0.513 | 0.478 | 0.575 | 0.788 | |

| Manufacturing Industry | |||||||||||||||||||||

| GD | GM | GMI | GMKT | GOC | GP | GTI | SECP | SENP | SSCP | GD | GM | GMI | GMKT | GOC | GP | GTI | SECP | SENP | SSCP | ||

| GD | GD | 0.847 | |||||||||||||||||||

| GM | 0.292 | GM | 0.251 | 0.783 | |||||||||||||||||

| GMI | 0.402 | 0.385 | GMI | 0.356 | 0.343 | 0.89 | |||||||||||||||

| GMKT | 0.482 | 0.514 | 0.667 | GMKT | 0.411 | 0.434 | 0.554 | 0.847 | |||||||||||||

| GOC | 0.146 | 0.1 | 0.128 | 0.112 | GOC | 0.11 | 0.031 | 0.068 | 0.063 | 0.809 | |||||||||||

| GP | 0.164 | 0.595 | 0.397 | 0.423 | 0.064 | GP | 0.147 | 0.511 | 0.348 | 0.354 | 0.021 | 0.842 | |||||||||

| GTI | 0.527 | 0.473 | 0.612 | 0.673 | 0.08 | 0.329 | GTI | 0.456 | 0.408 | 0.529 | 0.56 | 0.05 | 0.284 | 0.829 | |||||||

| SECP | 0.442 | 0.469 | 0.53 | 0.795 | 0.107 | 0.356 | 0.762 | SECP | 0.389 | 0.419 | 0.463 | 0.671 | 0.008 | 0.315 | 0.659 | 0.851 | |||||

| SENP | 0.423 | 0.487 | 0.48 | 0.572 | 0.167 | 0.491 | 0.487 | 0.312 | SENP | 0.373 | 0.423 | 0.425 | 0.487 | 0.158 | 0.433 | 0.423 | 0.28 | 0.85 | |||

| SSCP | 0.301 | 0.518 | 0.634 | 0.757 | 0.126 | 0.467 | 0.599 | 0.471 | 0.685 | SSCP | 0.255 | 0.443 | 0.533 | 0.614 | 0.1 | 0.401 | 0.5 | 0.406 | 0.582 | 0.801 | |

| Services Industry | |||||||||||||||||||||

| GD | GM | GMI | GMKT | GOC | GP | GTI | SECP | SENP | SSCP | GD | GM | GMI | GMKT | GOC | GP | GTI | SECP | SENP | SSCP | ||

| GD | GD | 0.788 | |||||||||||||||||||

| GM | 0.581 | GM | 0.484 | 0.811 | |||||||||||||||||

| GMI | 0.387 | 0.411 | GMI | 0.338 | 0.363 | 0.88 | |||||||||||||||

| GMKT | 0.526 | 0.576 | 0.385 | GMKT | 0.429 | 0.496 | 0.324 | 0.862 | |||||||||||||

| GOC | 0.085 | 0.061 | 0.082 | 0.093 | GOC | 0.062 | 0.009 | 0.061 | 0.046 | 0.85 | |||||||||||

| GP | 0.457 | 0.762 | 0.297 | 0.598 | 0.112 | GP | 0.37 | 0.648 | 0.251 | 0.489 | 0.021 | 0.806 | |||||||||

| GTI | 0.471 | 0.629 | 0.587 | 0.496 | 0.106 | 0.533 | GTI | 0.414 | 0.551 | 0.51 | 0.424 | 0.055 | 0.455 | 0.852 | |||||||

| SECP | 0.471 | 0.75 | 0.293 | 0.78 | 0.058 | 0.537 | 0.5 | SECP | 0.409 | 0.655 | 0.265 | 0.662 | 0.048 | 0.466 | 0.457 | 0.827 | |||||

| SENP | 0.639 | 0.594 | 0.533 | 0.421 | 0.074 | 0.452 | 0.712 | 0.427 | SENP | 0.548 | 0.527 | 0.468 | 0.363 | 0.086 | 0.384 | 0.632 | 0.392 | 0.867 | |||

| SSCP | 0.65 | 0.56 | 0.607 | 0.664 | 0.127 | 0.533 | 0.609 | 0.678 | 0.687 | SSCP | 0.532 | 0.49 | 0.5 | 0.539 | 0.081 | 0.437 | 0.53 | 0.559 | 0.591 | 0.776 | |

| Second-Order Constructs | Overall Sample | Manufacturing Industry Group | Services Industry Group | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Outer-Weights | STDEV | t-Value | p-Value | VIF | Outer-Weights | STDEV | t-Value | p-Value | VIF | Outer-Weights | STDEV | t-Value | p-Value | VIF | ||

| Green Supply Chain Management Practices | Green Designing | 0.307 | 0.029 | 10.479 | *** | 1.269 | 0.304 | 0.048 | 6.369 | *** | 1.215 | 0.309 | 0.034 | 9.098 | *** | 1.393 |

| Green Purchasing | 0.28 | 0.021 | 13.145 | *** | 1.569 | 0.279 | 0.034 | 8.157 | *** | 1.395 | 0.282 | 0.027 | 10.56 | *** | 1.842 | |

| Green Manufacturing | 0.348 | 0.02 | 17.367 | *** | 1.715 | 0.324 | 0.029 | 11.328 | *** | 1.516 | 0.363 | 0.028 | 12.975 | *** | 2.025 | |

| Green Marketing | 0.393 | 0.024 | 16.273 | *** | 1.46 | 0.466 | 0.039 | 11.892 | *** | 1.445 | 0.318 | 0.026 | 12.108 | *** | 1.5 | |

| Firm’s Sustainable Performance | Sustainable Environmental Performance | 0.398 | 0.021 | 19.37 | *** | 1.504 | 0.391 | 0.027 | 14.247 | *** | 1.517 | 0.405 | 0.028 | 14.255 | *** | 1.549 |

| Sustainable Social Performance | 0.418 | 0.017 | 24.949 | *** | 1.736 | 0.425 | 0.026 | 16.426 | *** | 1.673 | 0.411 | 0.021 | 19.784 | *** | 1.907 | |

| Sustainable Economic Performance | 0.433 | 0.022 | 19.834 | *** | 1.304 | 0.462 | 0.034 | 13.599 | *** | 1.201 | 0.399 | 0.028 | 14.422 | *** | 1.467 | |

| Complete | Manufacturing Industry Group | Services Industry Group | |||||||

|---|---|---|---|---|---|---|---|---|---|

| R-Square | R-Square Adjusted | Q-Square | R-Square | R-Square Adjusted | Q-Square | R-Square | R-Square Adjusted | Q-Square | |

| Firm Sustainable Performance | 0.698 | 0.688 | 0.585 | 0.728 | 0.718 | 0.53 | 0.698 | 0.688 | 0.585 |

| Green Managerial Innovation | 0.168 | 0.163 | 0.153 | 0.33 | 0.326 | 0.602 | 0.168 | 0.163 | 0.153 |

| Green Technological Innovation | 0.35 | 0.345 | 0.332 | 0.374 | 0.37 | 0.393 | 0.35 | 0.345 | 0.332 |

| Hypothesis | Complete | Manufacturing Industry Group | Services Industry Group | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| β | STDEV | t-Value | p-Value | F-Square | β | STDEV | t-Value | p-Value | F-Square | β | STDEV | t-Value | p-Value | F-Square | ||

| H1: | Green Supply Chain Management Practices → Green Technological Innovation | 0.593 | 0.041 | 14.515 | 0.000 | 0.543 | 0.611 | 0.056 | 10.885 | 0 | 0.596 | 0.588 | 0.055 | 10.618 | 0.000 | 0.530 |

| H2: | Green Supply Chain Management Practices → Green Managerial Innovation | 0.482 | 0.051 | 9.518 | 0.000 | 0.303 | 0.574 | 0.064 | 8.937 | 0 | 0.490 | 0.409 | 0.075 | 5.439 | 0.000 | 0.201 |

| H3: | Green Supply Chain Management Practices → Firm Sustainable Performance | 0.56 | 0.045 | 12.458 | 0.000 | 0.631 | 0.564 | 0.061 | 9.303 | 0 | 0.622 | 0.565 | 0.072 | 7.869 | 0.000 | 0650 |

| H4: | Green Technological Innovation → Firm Sustainable Performance | 0.275 | 0.05 | 5.485 | 0.000 | 0.144 | 0.28 | 0.061 | 4.572 | 0 | 0.166 | 0.254 | 0.083 | 3.062 | 0.002 | 0.116 |

| H5: | Green Managerial Innovation → Firm Sustainable Performance | 0.132 | 0.043 | 3.064 | 0.002 | 0.040 | 0.125 | 0.066 | 1.889 | 0.059 | 0.035 | 0.152 | 0.061 | 2.491 | 0.013 | 0.053 |

| Hypothesis | Complete | Manufacturing Industry Group | Services Industry Group | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| β | STDEV | t-Value | p-Value | β | STDEV | t-Value | p-Value | β | STDEV | t-Value | p-Value | ||

| H6, H7: | Green Supply Chain Management Practices → Green Technological Innovation → Firm Sustainable Performance | 0.163 | 0.031 | 5.193 | 0 | 0.171 | 0.041 | 4.161 | 0 | 0.149 | 0.05 | 3 | 0.003 |

| Green Supply Chain Management Practices → Green Managerial Innovation → Firm Sustainable Performance | 0.064 | 0.022 | 2.851 | 0.004 | 0.072 | 0.041 | 1.758 | 0.05 | 0.062 | 0.029 | 2.109 | 0.035 | |

| Hypothesis | Complete | Manufacturing Industry Group | Services Industry Group | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| β | STDEV | t-Value | p-Value | β | STDEV | t-Value | p-Value | β | STDEV | T-Value | p-Value | ||

| Green Supply Chain Management Practices * Green Organizational Culture → Firm Sustainable Performance | 0.08 | 0.039 | 2.03 | 0.042 | 0.51 | 0.053 | 2.07 | 0.038 | 0.081 | 0.069 | 1.175 | 0.024 | |

| Difference (Manufacturing—Services) | One-Tailed (Manufacturing vs. Services) p Value | Two-Tailed (Manufacturing vs. Services) p Value | |

|---|---|---|---|

| Direct Effects | |||

| Green Supply Chain Management Practices → Green Technological Innovation | 0.023 | 0.388 | 0.776 |

| Green Supply Chain Management Practices → Green Managerial Innovation | 0.165 | 0.047 | 0.095 |

| Green Supply Chain Management Practices → Firm Sustainable Performance | −0.002 | 0.506 | 0.988 |

| Green Technological Innovation → Firm Sustainable Performance | 0.027 | 0.4 | 0.799 |

| Green Managerial Innovation → Firm Sustainable Performance | −0.027 | 0.618 | 0.763 |

| Mediating Effects | |||

| Green Supply Chain Management Practices → Green Technological Innovation → Firm Sustainable Performance | 0.022 | 0.367 | 0.734 |

| Green Supply Chain Management Practices → Green Managerial Innovation → Firm Sustainable Performance | 0.09 | 0.427 | 0.854 |

| Moderating Effects | |||

| Green Supply Chain Management Practices * Green Organizational Culture → Firm Sustainable Performance | 0.03 | 0.637 | 0.726 |

| Construct | Compositional Invariance (c) | 5% Quantile (Threshold) | Permutation p-Value (Step 2) | Equality of Mean | Equality of Variance | Measurement Invariance Achieved |

|---|---|---|---|---|---|---|

| FSP | 0.999 | 0.997 | 0.262 | Yes | Yes | Full |

| GMI | 1 | 0.997 | 0.823 | Yes | No | Partial |

| GOC | 0.963 | 0.157 | 0.87 | Yes | Yes | Full |

| GSCMPs | 0.995 | 0.992 | 0.138 | Yes | Yes | Full |

| GTI | 0.999 | 0.998 | 0.428 | Yes | Yes | Full |

| Complete | Manufacturing | Services | ||||

|---|---|---|---|---|---|---|

| Total Effects | Performance | Total Effects | Performance | Total Effects | Performance | |

| GMI | 0.132 | 68.171 | 0.125 | 66.657 | 0.152 | 69.567 |

| GOC | 0.072 | 71.898 | 0.056 | 71.876 | 0.106 | 71.533 |

| GSCMPs | 0.787 | 74.744 | 0.807 | 75.414 | 0.777 | 74.064 |

| GTI | 0.275 | 77.144 | 0.28 | 76.919 | 0.254 | 77.345 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahar, A.S.; Zhang, Y.; Sadiq, B.; Gul, R.F. Sustainability Transformation Through Green Supply Chain Management Practices and Green Innovations in Pakistan’s Manufacturing and Service Industries. Sustainability 2025, 17, 2204. https://doi.org/10.3390/su17052204

Mahar AS, Zhang Y, Sadiq B, Gul RF. Sustainability Transformation Through Green Supply Chain Management Practices and Green Innovations in Pakistan’s Manufacturing and Service Industries. Sustainability. 2025; 17(5):2204. https://doi.org/10.3390/su17052204

Chicago/Turabian StyleMahar, Atif Sattar, Yang Zhang, Burhan Sadiq, and Rana Faizan Gul. 2025. "Sustainability Transformation Through Green Supply Chain Management Practices and Green Innovations in Pakistan’s Manufacturing and Service Industries" Sustainability 17, no. 5: 2204. https://doi.org/10.3390/su17052204

APA StyleMahar, A. S., Zhang, Y., Sadiq, B., & Gul, R. F. (2025). Sustainability Transformation Through Green Supply Chain Management Practices and Green Innovations in Pakistan’s Manufacturing and Service Industries. Sustainability, 17(5), 2204. https://doi.org/10.3390/su17052204