Abstract

The development of biogas technology is essential as a renewable energy source, aiding global initiatives in sustainable energy production and waste management. Geographical, technological, and economic factors significantly vary the efficiency and viability of biogas facilities by area. This study compares the techno-economic, social, and environmental impacts of biogas plants in Germany and Pakistan using a multicriteria decision-making method that combines the Analytic Hierarchy Process and SMARTER. This research has determined the weighting factors and then assessed the comparative performance of six selected biogas facilities based on five different scenarios: (i) comprehensive base-case, (ii) environmental performance, (iii) economic performance, (iv) social performance, and (v) per-kW energy efficiency. Three of these biogas facilities are in Pakistan (a low–medium-income developing country) and three in Germany (a high-income developed country). The findings of the study indicate that technical performance is the most heavily weighted criterion, playing a crucial role in determining the overall sustainability scores. Germany’s Bioenergie Park Güstrow stood out as the leading performer, achieving sustainability scores of 63.1%, 72.9%, and 73.0% across the comprehensive base-case, environmental, and per-kW efficiency scenarios, respectively. In the same scenarios, the Gujjar Colony Biogas Plant in Pakistan recorded the lowest scores of 25.4%, 43.2%, and 53.0%. The plants selected from a developed country showed a progressive score of high impact towards sustainability in most of the scenarios. In contrast, plants selected from a developing country showed low bioenergy deployment due to various factors, highlighting the gaps and flaws in achieving optimized energy generation and sustainable growth. The critical techno-economic and socio-environmental findings of the study are vital for policymakers, industry, engineers, and other relevant stakeholders seeking to enhance the performance, scalability, and sustainability of biogas technologies across developing and developed economies.

1. Introduction

Biogas significantly affects energy, agriculture, and the environment. In both direct and indirect ways, it helps accomplish SDG 7. Biogas fights climate change, improves waste reduction, and creates employment in renewable energy [1]. Bacteria and other microorganisms break down organic wastes, including sewage, animal, and agricultural wastes, to create biogas sustainably in the absence of oxygen. Anaerobic digestion produces CO2 and CH4 as its primary byproducts, with trace amounts of ammonia (NH3) and hydrogen sulfide (H2S) [2]. To produce biogas, microorganisms break down organic waste in an oxygen-free environment in a digester, also called a biogas plant, together with water [3]. Both biogas and digestate may be preserved and used as nutrient-rich fertilizers. Experts predict that by 2050, modern bioenergy will contribute 16% to global energy consumption, a significant increase from 5% in 2025 [4].

There are 17 SDGs in the United Nations’ (UN) 2030 Agenda for Sustainable Development, and these are inter-related and significant sustainability nodes [5]. The seventh SDG aims to guarantee sustainability, reliability, and accessibility of energy. Economies that prioritize consumerism, fast urbanization, and economic expansion will exacerbate the waste problem. The United Nations projects a quadrupling of global waste production from 2016 to 2050 [6]. Waste-to-energy (WtE) technology is a widely discussed topic in the current era of circular economy and energy decarbonization. It encompasses several elements that relate to many of the Sustainable Development Goals. Considering that 10% of the global population does not have access to electricity, WtE technology has the potential to benefit local communities around the world [7].

Climate change is a significant issue, with fossil fuels accounting for nearly 80% of global energy production [8]. Countries like Pakistan face financial and technological challenges that hinder the development of infrastructure, biomass, and biofuel power facilities [9]. Natural resource depletion and environmental deterioration are surpassing current national energy mix policy frameworks, making fossil fuels better than biomass and other renewable energy sources [10]. Insufficient collaboration between the Alternative Energy Development Board (AEDB) and the Pakistan Council Renewable Energy Technologies (PCRET) is also a concern [11]. According to World Bank estimates, improper handling of one-third of global solid waste will lead to a rise from 2.01 billion tonnes in 2017 to 3.40 billion tonnes by 2050 [12]. Poor solid waste management hinders economic growth. Waste-to-energy technology can reduce and recover solid waste, and countries are increasingly adopting it for sustainable solid waste management. The World Energy Council forecasts 5.5% market growth for WTE in 2023 [13]. In 2018, Sweden, Finland, Denmark, and Norway diverted over 50% of their municipal solid waste to waste-to-energy plants, while Germany diverted only 31%. As countries shift to circular economies, WTE technology aids these new economic models [14].

Furthermore, German research has primarily concentrated on maximizing the efficiency and environmental benefits of biogas-using plants within a highly controlled and robustly supported environment. However, these studies have lacked focus on the effects of biogas production in terms of social and economic impacts, especially in rural areas where there are issues with the acceptance of biogas plants, and its economic returns are a critical element in determining the long-term viability of the projects [15]. On the other hand, Pakistan has prioritized the utilization of biogas in addressing the energy and waste crisis despite limitations such as data unavailability and a lack of definitive sustainability analysis. This approach primarily emphasizes economic benefits in short-term business feedback while neglecting broader environmental and social concerns [16].

In the field of energy from renewables, sustainability analysis has a range of assessment tools like LCA and multicriteria decision-making (MCDM) methods, with the latter being a frequently used tool for individual sustainability indicator assessments [17]. Such tools have been used to assess the suitability of local bioenergy projects in villages to support ground benefits, opportunities, and strengths and highlight the limitations in a developed country [18]. India conducted a study in developing countries to rank renewable energy projects based on sustainability scores by AHP and other MCDM tools [19]. This study made significant progress in determining the compatible energy projects through AHP and SMARTER to attain sustainable development.

It is pertinent to mention here that no published study in the literature applies decision-making models, namely Analytic Hierarchy Process (AHP) and SMARTER, to assess the sustainability of biogas facilities in these two dissimilar countries. Earlier works have analyzed these strategies individually or applied them in a specific country; meanwhile, the opportunity to understand how such approaches reveal different sustainability goals and outcomes in Germany and Pakistan remains untapped [20]. Moreover, both nations have still underexplored the extent of stakeholder involvement in the decision-making process, particularly in coordinating their diverse objectives and concerns in the sustainability assessment.

Most of the literature on biogas plants has centered on their production and use as a source of energy, emissions reduction, and impacts on waste disposal [21]. However, comparative research on commercial-scale biogas plants and the differences between developing and developed countries face some limitations [22]. First, most studies solely concentrate on the environmental, economic, or social dimensions, neglecting to include an overall sustainability perspective in the impact assessment [23]. Second, little prior research work has been conducted on the use of advanced multicriteria decision-making methods, namely, AHP with SMARTER, in a rather structured manner for measuring and ranking sustainability performance [24]. Third, while developed countries have conducted much research about how they use new technologies in anaerobic digestion systems, not much is known about how these technologies can be transferred to developing countries or how they can be changed to fit their specific socioeconomic and infrastructure needs [25]. Further, there are limited insights on how policy, subsidy, and markets contribute to circumventing sustainability gaps in relation to these regions. Last but not least, the existing literature bases its analysis mainly on small-aspirate or rural biogas plants. Simultaneously, there is a significant lack of available information regarding the complexities of large-scale commercial plants, which is crucial for replicating renewable energy solutions globally. Closing these gaps is crucial to filling the knowledge gap of the relative sustainability of biogas plants and to deriving sound recommendations for improving the biogas plants’ performance globally.

This study is an exclusive effort towards closing the relevant research gaps by integrating both AHP and SMARTER methodologies to address a critical research question regarding the comprehensive relative sustainability of commercial-scale biogas plants in developed and developing countries. The study aims to analyze the techno-economic, social, and environmental impacts of biogas plants in Germany, a developed country, and Pakistan, a developing country. This research has objectively analyzed the following relative performances of the biogas plants under study.

- (a)

- The study focuses on the environmental, economic, and social sustainability of commercial-scale biogas plants in Pakistan, a developing country, and Germany, a developed country.

- (b)

- The application of a new innovative multicriteria decision-making approach, which combines the AHP and SMARTER approaches, creates a holistic and structured approach to evaluating sustainable measures. This approach includes a sustainable ranking model of key dimensions of sustainability, which is used to select biogas plants.

- (c)

- Operational optimizations are founded on comparative analysis, with a focus on enhancing sustainability and socioeconomic advantages.

This research will be a useful and fruitful addition to the existing literature due to its unique outlook and vital multidimensional analytical comparisons of commercial-scale biogas plants operating in various situations. This will also provide a useful pool of information for relevant policymakers, industry, stakeholders, and scholars of renewable energy, as well as sustainability.

2. Materials and Methods

This study uses a structured approach to assess the long-term viability of biogas plants in Germany and Pakistan. This study has developed and applied an exclusive combination of the ‘analytical hierarchy process (AHP)’ and ’simple multi-attribute rating technique exploiting ranking (SMARTER)’. The assessment incorporates technical, economic, environmental, and social indicators to thoroughly evaluate and compare the sustainability and efficacy of six biogas facilities, three located in Pakistan and three in Germany. This methodology enhances the comprehension of regional inequalities and provides insights into the influence of geographical, technological, and economic factors on biogas plant efficacy.

2.1. Plant Sites and Data Acquisition

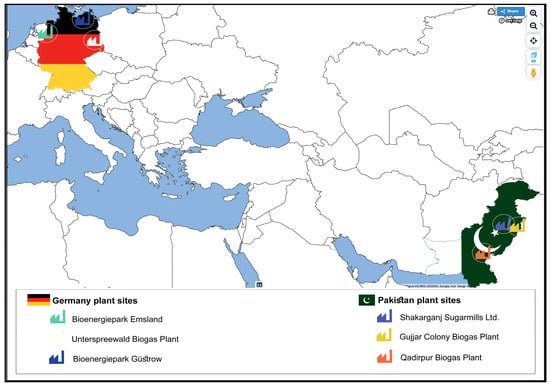

Figure 1 shows the plant sites from where the primary data were collected. Data collection includes primary sources like plant structured surveys, plant monitoring, interviews, and focus group discussions, along with inputs from secondary data, i.e., scientific literature, industry reports, and technical documentation. Primary data from biogas operators, technical experts, and stakeholders were carefully evaluated to illustrate, analyze, and depict the sustainability measures wholistically, while secondary data mainly offered a context to local biogas technologies and economic conditions.

Figure 1.

Geographical distribution of selected bioenergy plants.

The useful data were then coherently organized and examined to identify key elements related to sustainability dimensions: technical efficiency, economic viability, environmental effect, and social acceptability. The integrated AHP tool is a highly utilized and emerging method for evaluating sustainability in the energy sector [26].

The AHP-SMARTER framework evaluated these characteristics, enabling rankings and identifying strategic priorities for each plant. The study used a multicriteria decision-making (MCDM) approach, including AHP and SMARTER, to evaluate the sustainability of biogas facilities in various regional contexts. Interviews and surveys were conducted with key informants, including plant operators, technical managers, and government officials. The interviews covered topics like feedstock availability, technological challenges, energy production, cost-effectiveness, environmental management, and socioeconomic impacts. The talks led to clear sustainability metrics and extensive data on operational efficiency and area adaptation measures.

2.2. Narrative of Commercial-Scale Biogas Plants in Pakistan

2.2.1. Shakarganj Sugarmills Ltd. Biogas Plant

Shakarganj Sugar Mills, a part of the diversified firm Shakarganj Limited, is in Jhang, Punjab, Pakistan, as illustrated in Figure 2a. The facility functions across multiple sectors, including sugar processing, power generation, and the manufacture of ethanol and biogas. The mill operates on electricity and utilizes agricultural byproducts. The feedstocks include sugarcane bagasse, molasses, and/or press mud, producing around 50–200 m3 of biogas per ton [27]. It supplies approximately 5 MW of electricity to local power plants annually, thereby bolstering regional energy security. The project will substantially enhance environmental sustainability by decreasing CO2 emissions by approximately 120,000 tons annually. Shakarganj Sugar Mills’ operations contribute to local economic and environmental objectives, directly generating approximately 40 jobs and showcasing its commitment to sustainable industrial practices [28].

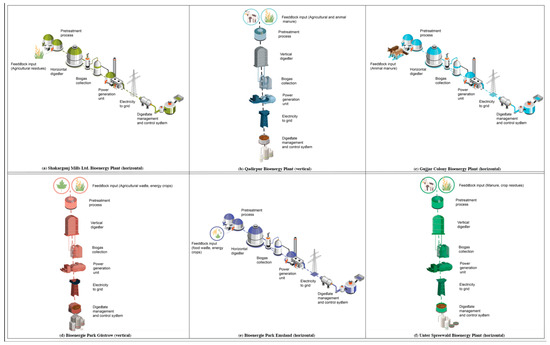

Figure 2.

(a) Shakarganj Mills Ltd. Bioenergy Plant (horizontal); (b) Qadirpur Bioenergy Plant (vertical); (c) Gujjar Colony Bioenergy Plant (horizontal); (d) Bioenergie Park Güstrow (vertical); (e) Bioenergie Park Emsland (horizontal); (f) Unter Spreewald Bioenergy Plant (horizontal).

2.2.2. Qadirpur Biogas Plant

Located in Qadirpur, Pakistan, the Qadirpur Biogas Plant is a large renewable energy installation [29]. It is among Pakistan’s largest biogas facilities. It significantly contributes to the nation’s transition to sustainable energy, as illustrated in Figure 2b. The facility produces around 8 MW of energy annually, utilizing organic waste, i.e., predominantly animal manure, as its principal biomass source. This enhances waste management while simultaneously reducing greenhouse gas emissions. The Qadirpur Biogas Plant produces clean electricity for the national grid, simultaneously enhancing the local economy by creating employment opportunities and promoting sustainable development in the region [30].

2.2.3. Gujjar Colony Biogas Plant

The Gujjar Colony Biogas Plant, a facility for sustainable waste management and renewable energy, is situated in Lahore, Punjab, Pakistan, as depicted in Figure 2c. The plant processes approximately 1600 kg of animal waste daily to generate biogas, functioning under the auspices of regional environmental and energy initiatives. The facility produces between 4000 and 5000 MWh of power annually, with an approximate capacity of 0.5 MW. The local energy system significantly benefits from this output, which enhances regional energy security. Incorporating heat production, the plant’s overall efficiency approaches 70% over its operational period of 8000 to 8760 h annually [31].

2.3. Narrative of Commercial-Scale Biogas Plants in Germany

2.3.1. Bioenergie Park Güstrow

Bioenergie Park Güstrow is a major biogas plant in Güstrow, Mecklenburg-Vorpommern, Germany. Figure 2d shows this facility as one of Europe’s largest integrated biogas facilities. It has a capacity of around 22 MW and produces about 500 GWh of electricity each year. The facility uses modern anaerobic digestion technology to process agricultural byproducts, primarily maize silage, etc. Generating electricity from this source is vital to Germany’s goal of renewable energy production. It supplies energy to households and decreases dependence on fossil fuels. The facility features a sophisticated biogas-upgrading system that converts untreated biogas into biomethane [32].

The facility converts biomethane to bio-LNG, providing a greener fuel option for transportation. The facility has a CO2 liquefaction unit that captures and repurposes about 15,000 tons of CO2 each year for industrial use [33]. Bioenergie Park Güstrow reduces greenhouse gas emissions by about 500,000 tons of CO2 equivalent each year. This supports Germany’s climate goals and showcases sustainable energy practices.

2.3.2. Bioenergiepark Emsland

It is a notable biogas facility located in Emsland, Lower Saxony, Germany. The company’s advanced biogas generation technology effectively utilizes agricultural leftovers such as maize silage, manure, and crop residues, as shown in Figure 2e. The facility possesses an annual electricity generation capacity of approximately 1.5 to 2.5 MW, yielding an energy output of between 13,000 and 20,000 MWh. Moreover, it streamlines the handling of agricultural waste, thereby diminishing the amount of waste that would otherwise end up in landfills. The Bioenergiepark Emsland directly employs around 15–30 workers locally and bolsters the regional economy by contributing to renewable energy sources. The plant’s commitment to sustainability and advanced technology underscores its status as a model of efficient and eco-friendly industrial practices.

2.3.3. The Unter Spreewald Biogas Plant

The Unter Spreewald Biogas Plant is a significant bioenergy project in Germany’s Unter Spreewald Region. This facility uses agricultural waste, mainly manure and crop residues, as its main biomass sources to sustainably generate electricity (Figure 2f). The facility has a capacity of 3000 kilowatts, supplying about 24,000,000 kilowatt-hours of electricity each year to the local grid, meeting the region’s renewable energy needs.

The Unter Spreewald Biogas Plant operates almost continuously, with about 8000 h of annual operation, ensuring a reliable renewable energy supply. This initiative achieves two goals: producing energy and significantly supporting environmental conservation by reducing greenhouse gas emissions. The goal is to reduce CO2-equivalent emissions annually. The plant helps manage agricultural waste sustainably and aligns with Germany’s goals of reducing carbon emissions and promoting renewable energy [34].

2.4. Sustainability Indicators and Selection Criteria

The decision-making process for renewable energy projects like medium- and large-scale biogas plants involves an inclusive policy framework, planning, and decision-making. These should be based on effective stakeholder engagement, incorporation of relevant targets and criteria, and formulation of a clear set of indicators regarding technical, economic, social and environmental performance to overcome the relevant barriers so as to maximize the clean energy project outcomes [35,36].

In this study, the biogas production, plant function and utilization of the final product (biogas energy) and any byproduct, e.g., digestate as biofertilizer, also involve a critical interaction with social, economic, environmental and technical spheres. Therefore, these are holistically interlinked and reflected in the relevant sustainability indicators. These are not only useful for the validation of biogas plants’ performance and efficacy, but they will also be helpful in the formulation of relevant policies and strategies in low–middle-income developing countries [36,37].

In various studies [36,37] on the assessment of the relative situation of renewable energy projects like bioenergy projects in the current study, similar relevant choices of indicators have been investigated, drawn, and developed. The authors have specifically examined and elaborated on critical and applied factors like feasibility, performance, and barriers to the expansion of renewable energy projects in the respective countries. Further, to analyze the specific context of a technically and financially advanced country, i.e., Germany, the selection and development criteria for the other indicators have been set according to a few other pertinent studies [38,39].

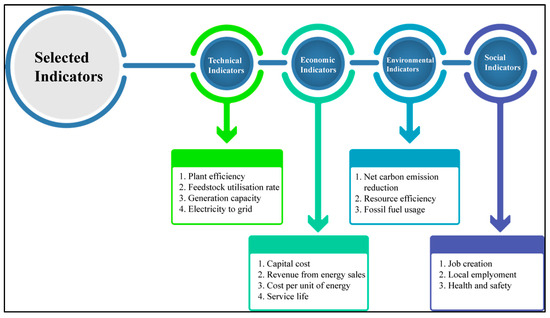

This selection, sifting and sorting of the relevant literature then led to the development of an inclusive set of indicators, as depicted in Figure 3, which are employed in the present study.

Figure 3.

Sustainability indicators for the AHP and SMARTER analysis.

2.4.1. Technical Indicators

Assessing biogas facilities involves several key technical metrics. These include plant efficiency, which evaluates feedstock conversion into energy, and yearly operation hours, reflecting the total operational time of the plant in a year. The feedstock utilization rate measures biomass efficiency in energy generation. Generation capacity refers to the total energy output a plant can produce, while electricity supplied to the grid indicates the amount of energy added to the local power grid, enhancing the region’s energy supply [40].

2.4.2. Economic Indicators

Economic variables are used to assess the financial feasibility and implications of biogas facilities. The capital cost is evaluated to determine the initial investment needed for the plant’s establishment. Revenue from energy sales is evaluated to assess the financial returns from electricity sales. The cost per unit of energy reveals the plant’s economic efficiency by comparing production costs to generated energy. The facility’s operational lifespan is assessed to determine its long-term economic viability and return on investment [41].

2.4.3. Environmental Indicators

Various indicators assess the environmental effects of biogas facilities. Net carbon emissions reduction is a key indicator, assessing the decrease in greenhouse gases from the plant’s operations. Resource efficiency evaluates how effectively the facility uses natural resources for energy production. This study assesses the plant’s reliance on fossil fuels and its overall environmental impact [42].

2.4.4. Social Indicators

Metrics that show their contribution to the local community assess the social impact of biogas facilities. The evaluation of job creation aims to comprehend the plant’s contribution to the generation of new employment possibilities throughout time. Occupational health and safety and local employment are also essential parameters [43].

2.5. Analytic Hierarchy Process (AHP) and SMARTER Technique

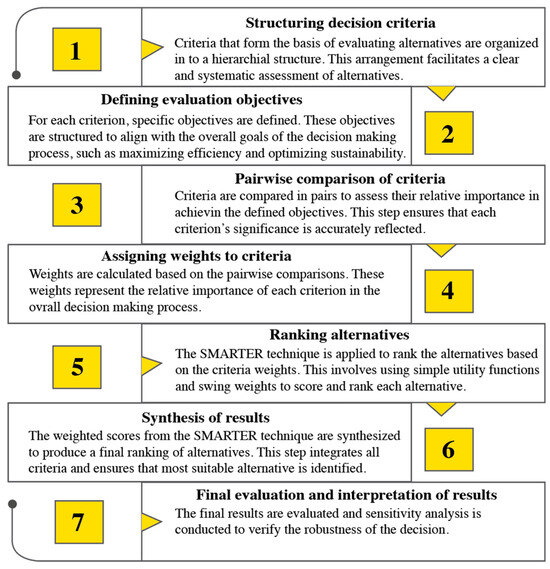

This study uses the Analytic Hierarchy Process (AHP) framework for the comparative sustainability assessment of bioenergy projects, illustrated in Figure 4. Saaty established the Analytic Hierarchy Process (AHP) in 1980 as a comprehensive multicriteria decision-making (MCDM) methodology to address complex decision-making challenges that encompass various criteria [44,45,46]. This study employs SMARTER (Simple Multi-Attribute Rating Technique Exploiting Ranks) as an additional decision-making methodology for the assessment of bioenergy projects. This approach builds on the SMART strategy, adding additional phases to enhance decision-making processes through the integration of real-time data and feedback. The studies [47,48] acknowledged SMARTER for its adaptability and efficacy in evaluating intricate situations, making it a significant instrument for renewable energy plants’ sustainability assessments.

Figure 4.

Methodological flow chart illustrating the steps of AHP and SMARTER employed in the study.

The AHP approach was employed to establish criteria weights through pairwise comparisons, guaranteeing consistency and precision in the decision-making process. After that, the SMARTER approach assigned utility values to each alternative according to the ranking of the plants across established parameters. The amalgamation of these two methodologies guarantees a thorough and resilient study, reducing bias while emphasizing the principal advantages of each assessed biogas plant. These methodologies provide a definitive and impartial framework for evaluating the sustainability, efficiency, and viability of each facility in both nations. A total of 20–25 people participated in this AHP analysis, including the technical experts, plant managers, stakeholders, policymakers, and experts from concerned departments (agriculture, energy and environment). They were contacted through email invitations, conducting focused group discussions, online and in-person interviews and surveys. The judgments of the experts show 0.09 consistency ratio, where 0.10 is considered consistent and acceptable.

The decision-makers evaluated sustainability factors across four principal dimensions: technical, economic, environmental, and social. Each dimension was studied independently, and expert input was integrated to substantiate the criteria.

Combined Steps of AHP-SMARTER Method

This study’s computational process has 7 steps, as detailed in Figure 4. Steps 1–4 delineate the discovery and assessment of sustainability criteria employing the AHP, whereas steps 5–6 highlight the ranking and sensitivity analysis utilizing the SMARTER technique.

- Step 1: Selection of the evaluation criteria and expert input

This step involves selecting the criteria for evaluating the sustainability of biogas plants. The assessment criteria cover technical, economic, environmental, and social factors, which are significant in analyzing the overall sustainability of biogas plants. Experts arranged the pairwise comparison of the selected criteria according to their relative importance.

- Step 2: Computation of AHP weights

This step uses the Analytic Hierarchy Process (AHP) to determine the relative significance of each evaluation criterion. The criteria are compared using pairwise comparisons to assess their relative importance, and the consistency ratio is evaluated to validate the judgments. The pairwise comparison matrix is developed, and normalization is performed to derive weights, as illustrated in Equation (1):

where

Sk = significance of criterion k,

Ck = importance of criterion k,

Ck−1 = importance of the previous criterion.

While devising the matrix Sk, the decision-makers employed the following scale to evaluate the criteria, illustrated in Table 1.

Table 1.

Scale required for pairwise comparisons in AHP.

- Step 3: Establishing the range for each indicator

The relevant significance for each indicator is calculated by determining the maximum and minimum values using Equation (2).

- Step 4: Utility score calculation

The utility score represents how well each plant performs for a specific indicator relative to others. The utility function is calculated using Equation (3).

where

Uf = Value − Min value/Max value − Min value

Value is the specific value for the plant under evaluation;

Min Value is the lowest observed value for the criterion;

Max Value is the highest observed value for the criterion.

- Step 5: Relative weight extraction and weight application

This step involves calculation of the relative weight. The weighted utility score for each biogas plant is calculated via Equation (4):

Overall Score (Plant) = ∑ (AHP Weight × Utility Score)

- Step 6: Simplified preference evaluation of the plants

Based on utility scores, plants are ranked from highest to lowest. The best-scoring plant is sustainable or effective.

3. Results and Discussions

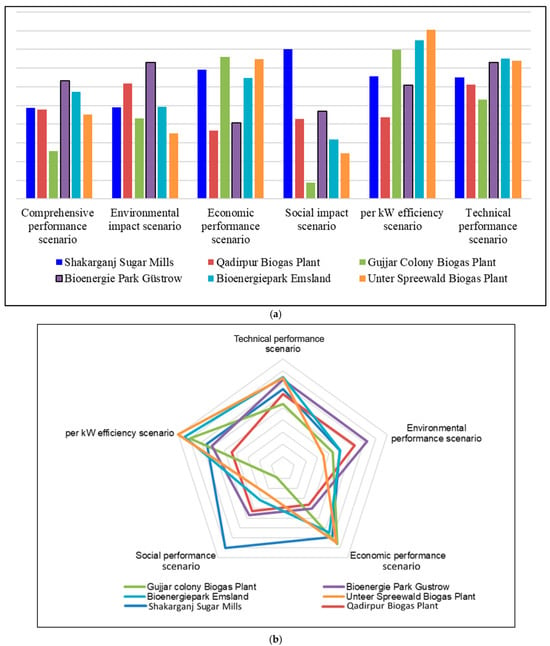

For comparing the six chosen biogas plants, five main evaluation scenarios were considered: (I) the overall performance scenario, (II) the environmental impact scenario, (III) the economic performance scenario, (IV) the social impact scenario, and (V) the per-kW efficiency scenario.

These scenarios provided a detailed and holistic view of each plant’s performance, enabling an accurate and objective comparative sustainability ranking.

3.1. Comprehensive Base-Case Performance Scenario

This scenario analyzed all the key sustainability indicators holistically to provide an overall performance evaluation for each biogas plant. In contrast, the indicators used were as follows: (a) technical efficiency, (b) electricity contribution to the grid, (c) capital cost, (d) economic benefits, (e) carbon emission reduction, (f) resource efficiency, and (g) job creation. Each plant was ranked according to its ability to maximize energy generation, minimize operational costs, reduce emissions, and create social and economic benefits. This comprehensive approach allowed a balanced assessment across all criteria to determine the most sustainable biogas plant. In contrast, this scenario evaluated all the indicators equally to obtain an overall performance score. Based on the cumulative scores of each biogas plant in the base-case scenario, Bioenergie Park Güstrow emerged as the most suitable, boasting a sustainability weight of 0.6308 and securing the top spot in the sustainability ranking. The Bioenergiepark Emsland, with a sustainability score of 0.5727, ranked second, followed by the Shakarganj Sugar Mills, with a score of 0.4865. The Qadirpur Biogas Plant had a score of 0.4777, followed by the Unter Spreewald Biogas Plant and the Gujjar Colony Biogas Plant, which ranked lowest in terms of sustainability ranking with sustainability scores of 0.4528 and 0.2548, respectively, shown in Table 2.

Table 2.

AHP and SMARTER analytical scores for comprehensive base-case scenario for chosen biogas plants.

Each bioenergy plant possesses a unique generation capacity and a diverse range of technologies, contributing to its sustainability ranking in the top spot from Germany. Pakistani plants rank in 3rd and 4th place, despite their individual contributions to local emission reduction. By incorporating financial incentives, integrating customized technology, and reducing socioeconomic barriers, we can project growth in the low sustainability score of Pakistani biogas plants [49].

3.2. Technical Performance Scenario

This scenario focuses specifically on technology optimization by emphasizing indicators such as (a) sustainable resource consumption, (b) bioenergy production potential, and (c) energy utilization. The plants have been ranked according to their ability to maximize technical performance while maintaining energy production. Key metrics are rate of feedstock utilization, efficiency of plant, energy generation capacity, and overall utilization of energy in conversion to electricity and to the grid. This scenario has provided insight into the plant with the highest optimization in terms of technological parameters and enhanced the overall plant performance. Therefore, it plays a crucial role in the assessment of sustainability.

In this case, the plant with the highest capacity optimization in terms of technology and a high technical sustainability ranking is BPE, with a criterion weight of 0.7500. Then comes the USBP, which is second in the sustainability ranking with a technical performance score of 0.7400. The plants that showed the least technical performance among the studied plants are QBP and GCBP, with environmental impact scores of 0.6100 and 0.5300, respectively. The sustainability order in the environmental impact scenario can be written as BPE > USBP > BPG > SSM > QBP > GCBP. Table 3 shows the relative score of each plant, making it clear which sub-indicators contribute to better technological performance, as shown in Table 3.

Table 3.

AHP and SMARTER analytical scores for technical performance scenarios for chosen biogas plants.

In both regions, the alternatives vary because of the availability of the feedstock raw material, i.e., organic waste or an energy crop. While in Germany, energy crops could be an ideal alternative to organic wastes for anaerobic digestion (AD), in countries like Pakistan, shortages and security food and food crops are already challenging. Thus, AD-based biogas generation is reliant on feedstock substrates like organic wastes, e.g., animal dung or manure, poultry litter, and crop/vegetable/fruit residues.

The supply-chain management of raw materials, or the availability of feedstock, is considered here as a technical efficiency regulator for both types of plants, i.e., well-equipped plants in Germany and average plants in Pakistan. Some considerations are applied more broadly; one is the utility of a variety of substrates in the process to avoid any dependence on a certain type of feedstock. For instance, the use of agricultural residues combined with organic waste (e.g., cow dung and manure) and energy crops guarantees the availability of raw materials in case one type becomes scarce. The second consideration involves the establishment of a network of supply chains, focusing on the logistics of substrate collection, transportation, and storage system management.

This requires collaboration among farmers involved in agricultural production, waste management, and biogas-energy plants, all of which must utilize locally available resources. Other innovations, such as sophisticated anaerobic digestion techniques and second-generation biofuel technologies, have also been considered. These technologies enable the utilization of feedstocks beyond primary crops, including lignocellulosic biomass and the organic fraction of municipal solid wastes. Also, the policy supports, including the provision of financial incentives for feedstock-substrate collection, tax incentives to encourage feedstock diversification and investment in feedstock supply systems, are critical in solving raw material challenges. In countries like Pakistan, supportive government policies can encourage small farmers to collect, manage, and sell their agricultural residuals for bioenergy generation.

The biogas plants in Germany have matured with technological advancement and are sustainably efficient for sharing in green electricity as the potential is up to 500 kWh per day, which justifies the sustainability factors (economic and social feasibility) [45]. Hence, these can be replicated as biogas facilities of good performance at the national and international level to achieve decarbonization of the energy system [50]. For Pakistan, the generation capacity is highly reliant on the technology used and feedstock utilization efficiency, and the regional sustainable bioenergy generation is highly dependent on technological advancements. However, based on factors such as feedstock availability and willingness to adopt the technology among farmers, the potential technical capacity can range from 12% to 50% [51].

3.3. Environmental Performance Scenario

This scenario specifically depicts environmental sustainability by emphasizing indicators like (a) emission reduction, (b) resource efficiency, and (c) water usage. The plants have been ranked based on their ability to minimize their environmental footprint while maintaining energy generation. Key metrics here are (a) carbon emissions per unit of energy produced, (b) water usage efficiency, and (c) overall resource consumption. This scenario presents valuable information regarding the plants with the least environmental impacts, which is quite useful in the sustainability evaluation regime.

Key metrics included carbon emissions per unit of energy produced, water usage efficiency, and overall resource consumption. This scenario provided insights into which plants had the least impact on the environment, making it a vital component in sustainability evaluation.

In this case, the plant that had the least environmental impact and scored a high sustainability ranking is BPG, with an environmental impact weight of 0.7285. Then comes QBP, which came in second place in the sustainability ranking with an environmental impact score of 0.6175. The least sustainable plants among the plants studied are GCBP and USBP, with environmental impact scores of 0.4315 and 0.3495. The sustainability order in the environmental impact scenario can be written as BPG > QBP > BPE > SSM > GCBP > USBP, depicted in Table 4. The environmental and sustainability performance of biogas plants in Pakistan can be estimated by the fact that under the current emission scenario, the biogas plants are projected to reduce 138.47 million metric tons to 8.71 million metric tonnes of CO2 emissions by 2050 [52]. Although the German biogas plants have scored a high sustainability ranking, a balance between technological demand and ecological sustainability must be considered, as changes in habitat quality and the local feedstock system can alter the sustainability score of bioenergy plants in Germany [53].

Table 4.

AHP and SMARTER analytical scores for environmental performance scenario for chosen biogas plants.

3.4. Economic Performance Scenario

The economic performance scenario focuses on the financial viability of each plant. Capital cost, energy sales revenue, and cost per energy unit were analyzed. Plants are ranked by (a) ability to generate economic benefits, (b) operational and maintenance costs, (c) cost recovery periods, and (d) potential carbon credit generation. This scenario has particularly emphasized the economic sustainability of each project and its potential for long-term financial returns.

Table 5 shows that GCBP is the most economically viable plant in this scenario, achieving an economic sustainability score of 0.7600 and ranking 1st in sustainability performance. USBP follows as the second-best economic performer, with a score of 0.7481. BPG and QBP are the least economically performing plants, with sustainability scores of 0.4059 and 0.3655, respectively, though they rank high in cost per unit of energy generated.

Table 5.

AHP and SMARTER analytical scores for economic performance scenario for chosen biogas plants.

The economic performance ranking of each plant is GCBP > USBP > SSM > BPE > BPG > QBP. The German biogas market, the largest globally, needs governance and adaptive legislation under the Renewable Energy Act to ensure sustainability in the fast-growing sector [54]. Assessing biogas plants in Pakistan based on monetary value offers insights into acceptable returns relative to energy demands and supply. However, by optimizing operating, administrative, and feedstock capacities, we can enhance the economic and technical efficiency of these plants for sustainability [55].

3.5. Social Performance Scenario

The social impact scenario assessed how each biogas plant contributed to the development of local communities, i.e., (a) employment opportunities, (b) job creation, and (c) health and safety records. Plants are ranked by their ability to create jobs, enhance local livelihoods, and ensure a safe, healthy working environment. This scenario examines the projects’ social sustainability and relevant impact on the social development goals.

According to Table 6, SSM ranks 1st for social feasibility and meets all sub-criteria, significantly contributing to local job creation, with a social sustainability score of 0.8000. BPG follows with a score of 0.4689. UNBP and GCBP ranked lowest, with sustainability scores of 0.2433 and 0.0873, respectively. The sustainability order is SSM > BPG > QBP > BPE > USBP > GCBP. SSM, a plant based in Pakistan, received higher scores due to the need for employment opportunities in a developing country to boost the economy and enhance livelihoods. The ranking of German biogas plants stems from advanced health and safety protocols, strict labor laws, and a focus on indigenous values. Developing countries like Pakistan face energy poverty, and biogas could help address the energy crisis [56]. However, institutional incapacity, lack of financial resources, R&D, and education are significant barriers to achieving sustainability [57], along with limited employment opportunities. In developed countries like Germany, the rapid growth of bioenergy can alter local landscapes and species due to the demand for feedstock, leading to conflicts with biodiversity protection and indigenous communities [58,59].

Table 6.

AHP and SMARTER analytical scores for social performance scenario for chosen biogas plants.

3.6. Per-kW Efficiency Scenario

The generation capacities of the selected biogas plants normalized all key indicators for an accurate per-kW output comparison. Newly inducted sustainability indicators include operational and maintenance cost per kW (US$), emission reduction per kW (tCO2e), fossil fuel usage per kW, economic benefit from carbon credits per kW (million US$), and job creation per kW (number of people employed). The results offer a clear understanding of each plant’s efficiency in relation to its energy generation capacity, which is crucial for assessing both technical and economic efficiency.

Table 7 shows the scenario ranking matrix for all four sustainability indicators across the six plants, with USBP ranked highest in this scenario. The results show plant efficiency per kW produced, illustrating a sustainability score in relation to generation capacity. The plants can be ranked by sustainability preference as follows: USBP > BPE > GCBP > SSM > BPG > QBP. Biogas plants can enhance future renewable electricity generation and help phase out fossil fuels, as their economic value demonstrates flexibility and feasibility in the energy mix [60]. The per-kW energy produced shows the plants’ sustainable growth and development, highlighting their economic, technical, social, and environmental benefits for further clean energy integration. Pakistan can generate 3.24 billion m3 of biogas, enhancing electricity production with a potential of 19.79 TWh per day [61]. Currently, biogas accounts for 0.98% of the country’s electricity mix, equating to 1 TWh of green electricity [62,63,64]. Each plant’s sustainability for every kW produced enhances green electricity share and supports sustainability goals, contributing to better economic development in developing countries like Pakistan.

Table 7.

AHP and SMARTER analytical scores for per-KW efficiency scenario for chosen biogas plants.

3.7. Discussion on Overall Performance Scenarios

The comparative analysis of bioenergy systems in developed and developing countries presented in this study highlights the key challenges and opportunities in transitioning to a vital renewable energy source, i.e., biogas energy. They are also contributing to significant development in terms of SDG 7 and planning for waste-to-energy systems. The findings and rankings, as depicted in this study, clearly prove they are quite critical, i.e., for the optimal development and performance optimization of biogas plants, especially from the perspective of developing countries. They can still manage and maintain the prime productivities, output scenarios, and efficacy and efficiencies in terms of sustainability and performance-based indicators, as also discussed in a study [65].

The findings from other literature studies strengthen the argument that despite the spatial placement of a bioenergy plant, it must be productive and efficient in terms of substrate resources and water consumption so that the essence of reducing emissions and fossil consumption cannot be lost. These exclusively elaborate on how bioenergy plants can be sustainable and reliable [66,67].

The bioenergy plants, as illustrated in the present study, reflect respectable scores and rankings for the respective economic and technical indicators. This represents their viability and optimal relative performance, i.e., in terms of developed and developing regions, and a study by Raha et al. [66] depicted similar facts and figures.

Specific economic and operational characteristics like lack of clear supply chains and markets and the availability of feedstock substrate can be the limiting factors. While they significantly contribute towards the long-term sustainability of a bioenergy plant, similar facts are also described in a study by Jamal et al. [65].

In another study [67], the authors specified how labor, quality, operational efficiencies, and plant maintenance are crucial factors for plant sustainability, which is in line with the findings of the current study. The wider variations among regulations regarding biogas plant operations, feedstock-substate markets, and the health and safety of the labor deployed also differentiate the social and technical performance of the plants located in Pakistan and Germany.

In view of the criticality of the various encumbering factors elaborated here, they must be linked to the policy decisions which can precisely reflect the needs and environment of the specific regions, e.g., low–middle-income developing countries in Asia and/or Africa. This can ensure scalability, reliable and consistent performance, and more efficient production of renewable energy [62,68]. Similar developments can effectively manage bioenergy assets and provide an edge to ensure compliance in competitive renewable energy markets and industries [65].

Figure 5a highlights the comparative scores of each plant in the respective scenarios discussed above; hence, the sustainable efficiency of each plant can be projected, and incompetence can be reduced. Figure 5b depicts the scores of environmental, economic, social, technical and per-KW scenarios for the selected bioenergy plants.

Figure 5.

(a) Comparative illustration of selected scenarios for the chosen bioenergy plants. (b) Sustainability score of bioenergy plants for four scenarios.

4. Conclusions

The analysis of biogas facilities through AHP and SMARTER methodologies highlighted notable disparities in sustainability outcomes between Pakistan and Germany. Bioenergie Park Güstrow in Germany demonstrated superior performance compared to other plants, attaining the highest scores across multiple scenarios: 63.1% in the comprehensive base-case scenario, 72.9% in the environmental scenario, and 73.0% in per-kW efficiency. This highlights Germany’s superior technological and environmental benchmarks, greatly improving the sustainability of biogas facilities. The performance metrics of biogas plants in Pakistan, exemplified by the Gujjar Colony Biogas Plant, are notably low, with scores of 25.4%, 43.2%, and 53.0% across various scenarios, indicating substantial potential for enhancement. Challenges regarding technical–technological efficiency and environmental management significantly compromise the sustainability of these plants in Pakistan. The study calls for policy reforms, technological advancements, and initiatives to improve capacity in Pakistan. To improve the sustainability of biogas plants in developing regions, it is crucial to build local expertise, optimize resource management, and promote international collaborations. The research provides a framework for stakeholders to collaborate on technical innovation and environmental responsibility, enhancing biogas plant performance and supporting global sustainability goals.

Implications and Future Research Directions

The policy implications of this study for government, scholars, and business leaders working towards increasing the sustainability of biogas technologies are profound. Thus, this research, while focusing on the environmental, economic, and social performance of large-scale biogas plants in developed and developing nations, offers a framework for evaluating the sustainability of renewable energy systems. The government has invested in various sustainable energy initiatives to address energy security issues and promote renewable energy utilization, as apparent in the Pakistan Alternative and Renewable Energy Policy 2019 and other energy programs; however, an integrated action plan is still required.

Consequently, the study calls for subsidies and regulatory and capacity-building efforts, especially in countries with limited resources, such as Pakistan. It highlights, for industries, the relevance of incorporating new technologies and improving feedstock usability to boost the efficacy of a biogas plant. Future research should seek to consider new technologies, including biomethane-upgrading technologies, digital monitoring systems, and hybrid energy technologies, to improve the sustainability factor. Expanding the study basis by the inclusion of economic–environmental modeling tools like LCA-LCC and linking the circular economy with biogas systems can provide more critical sustainability analytics.

Author Contributions

Conceptualization, R.R. and F.T.; methodology, R.R.; software, M.F.; validation, R.R., F.B. and A.-S.N.; formal analysis, F.B. and M.F.; investigation, R.R.; resources, F.T.; data curation, F.B.; writing—original draft preparation, F.T.; writing—review and editing, R.R., F.B., M.F. and A.-S.N.; visualization, R.R.; supervision, R.R.; project administration, R.R. and M.F.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

We would like to clarify that the data collection mentioned in Section 2.1 of our manuscript did not involve surveys or interviews with members of the general public or private individuals. Instead, the data were collected from structured surveys, interviews, and focus group discussions with key informants such as plant operators, technical managers, and government officials at large commercial- or industrial-scale plants in Pakistan and Germany.

Informed Consent Statement

Plant operators, technical managers, and government officials at large commercial- or industrial-scale plants in Pakistan and Germany. Since these are specialized personnel engaged in professional roles within an institutional framework, no direct consent to participate as private individuals was applicable, but they knew the purpose of the experiment.

Data Availability Statement

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Acknowledgments

This work is financially supported by the Office of Research, Innovation, and Commercialization (ORIC), Government College University Lahore, through Award Letter No. 35/ORIC/24 dated 04.01.2024 to Fizza Tahir. The authors are also grateful to the German Academic Exchange Service (DAAD) for awarding the PhD Research Grant Fellowship to Fizza Tahir and to Technical University Berlin for providing research support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Obaideen, K.A. Biogas role in achievement of the sustainable development goals: Evaluation, Challenges, and Guidelines. J. Taiwan Inst. Chem. Eng. 2022, 131, 104207. [Google Scholar] [CrossRef]

- Abubakar, A.M.; Silas, K.; Aji, M.M. An elaborate breakdown of the essentials of biogas production. J. Eng. Res. Sci. 2022, 1, 93–118. [Google Scholar] [CrossRef]

- Atelge, M.R. Biogas Production from Organic Waste: Recent Progress and Perspectives; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Duarah, P.H. A review on global perspectives of sustainable development in bioenergy generation. Bioresour. Technol. 2022, 348, 126791. [Google Scholar] [CrossRef]

- Saxena, A.R. Striving for the United Nations (UN) sustainable development goals (SDGs): What will it take? Discov. Sustain. 2021, 2, 20. [Google Scholar] [CrossRef]

- Vlachokostas, C.M. Multicriteria Decision Analysis Towards Promoting Waste-to-Energy Management Strategies: A Critical Review; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Vlachokostas, C. Closing the loop between energy production and waste management: A conceptual approach towards sustainable development. Sustainability 2020, 12, 5995. [Google Scholar] [CrossRef]

- Kalair, A.R. Waste to energy conversion for a sustainable future. Heliyon 2021, 7, e08155. [Google Scholar] [CrossRef] [PubMed]

- Rasheed, R.J. Sustainability and CDM Potential Analysis of a Novel vs. Conventional Bioenergy Projects in South Asia by Multicriteria Decision-Making Method; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Khan, M. Policy Review and Recommendations on the Promotion of Renewable Energy and Energy Efficiency; UNIDO: Islamabad, Pakistan, 2020. [Google Scholar]

- Sharma, K.D. Municipal solid waste generation, composition, and management: The global scenario. Soc. Responsib. J. 2020, 16, 917–948. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018. [Google Scholar]

- Venus, T.E. Understanding stakeholder preferences for future biogas development in Germany. Land Use Policy 2021, 109, 105704. [Google Scholar] [CrossRef]

- Rezania, S.O. Review on waste-to-energy approaches toward a circular economy in developed and developing countries. Processes 2023, 11, 2566. [Google Scholar] [CrossRef]

- Cadiou, J.A. The importance of considering agricultural dynamics when discussing agro-environmental sustainability in futures studies of biogas. Futures 2023, 153, 103218. [Google Scholar] [CrossRef]

- Xin, Y.B. Analyzing Pakistan’s renewable energy potential: A review of the country’s energy policy, its challenges, and recommendations. Sustainability 2022, 14, 16123. [Google Scholar] [CrossRef]

- Wulf, C.H. Multicriteria decision analysis methods used for sustainability assessment. In Proceedings of the 17th International Conference on Society & Materials (SAM), Karlsruhe, Germany, 9–10 May 2023. [Google Scholar]

- Lerche, N.W.-T. Using methods of Multicriteria Decision Making to provide decision support con-cerning local bioenergy projects. Socio-Econ. Plan. Sci. 2019, 68, 100594. [Google Scholar] [CrossRef]

- Shaktawat, A. Ranking of hydropower projects based on sustainability criteria in India using mul-ticriteria decision making methods. CRORR 2021, 12, 1. [Google Scholar] [CrossRef]

- Kabir, K.H. Smart power management in OIC countries: A critical overview using SWOT-AHP and hybrid MCDM analysis. Energies 2021, 14, 6480. [Google Scholar] [CrossRef]

- Shah, A.V.; Srivastava, V.K.; Mohanty, S.S.; Varjani, S. Municipal solid waste as a sustainable resource for energy production: State-of-the-art review. J. Environ. Chem. Eng. 2021, 9, 105717. [Google Scholar] [CrossRef]

- Sequeira, R.A.; Mondal, D.; Prasad, K. Neoteric solvent-based blue biorefinery: For chemicals, functional materials and fuels from oceanic biomass. Green Chem. 2021, 23, 8821–8847. [Google Scholar] [CrossRef]

- Massuca, J.; Marta-Costa, A.; Lucas, M.R. Social dimension of sustainability: Assessment in the agribusiness context. New Medit. 2023, 63, 63–80. [Google Scholar] [CrossRef]

- Demircan, B.G.; Yetilmezsoy, K. A hybrid fuzzy AHP-TOPSIS approach for implementation of smart sustainable waste management strategies. Sustainability 2023, 15, 6526. [Google Scholar] [CrossRef]

- Magnusson, T.; Zanatta, H.; Larsson, M.; Kanda, W.; Hjelm, O. Circular economy, varieties of capitalism and technology diffusion: Anaerobic digestion in Sweden and Paraná. J. Clean. Prod. 2022, 335, 130300. [Google Scholar] [CrossRef]

- Borges, R. Delphi/AHP-Based Method for Biomass Sustainable Assessment in the Sugar Industry. Eng 2024, 5, 2300–2319. [Google Scholar] [CrossRef]

- Chandgude, R.A.; Patil, P.G. Enhancement of mill performance by adopting low-speed milling in the sugar industry. Pak. Sugar J. 2021, 36, 1. [Google Scholar]

- Khan, M.T.; Khan, I.A.; Yasmeen, S.; Nizamani, G.S.; Afghan, S. Sugarcane Biofuels and Bioenergy Production in Pakistan: Current Scenario, Potential, and Future Avenues; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 175–202. [Google Scholar]

- Imran, M.; Rashid, Z.; Amjad, M.; Baloch, S.K.; Mustafa, A. Analysis and implementation of a solar/biogas hybrid system for centralized generation at Qadirpur Ran. Energy Rep. 2022, 8, 13484–13493. [Google Scholar] [CrossRef]

- Khatri, K.L.; Muhammad, A.R.; Soomro, S.A.; Tunio, N.A.; Ali, M.M. Investigation of possible solid waste power potential for distributed generation development to overcome the power crises of Karachi city. Renew. Sustain. Energy Rev. 2021, 143, 110882. [Google Scholar] [CrossRef]

- Daniel-Gromke, J.; Rensberg, N.; Denysenko, V.; Stinner, W.; Schmalfuß, T.; Scheftelowitz, M.; Nelles, M.; Liebetrau, J. Current developments in production and utilization of biogas and biomethane in Germany. Chemie Ingenieur Technik. 2018, 90, 17–35. [Google Scholar] [CrossRef]

- Luostarinen, S.; Normak, A.; Edström, M. Overview of biogas technology. Baltic Forum for Innovative Technologies for Sustainable Manure Management WP6 Energy Potentials 2011. p. 47. Available online: http://www.build-a-biogas-plant.com/PDF/baltic_manure_biogas_final_total.pdf (accessed on 20 December 2024).

- Platania, M. Assessment of a Biomethane Production Route for Public Transport in the Context of the Italian Incentivation Framework. Doctoral Dissertation, Politecnico di Torino, Turin, Italy, 2024. [Google Scholar]

- Schwarz, L.; Bosch, S. Behaviorism and renewable energies—Plant operators as key to a low-conflict and inclusive energy system transition. Standort 2020, 44, 160–167. [Google Scholar] [CrossRef]

- Cox, S.L. Renewable Energy Data, Analysis, and Decisions: A Guide for Practitioners; U.S. Department of Energy: Oak Ridge, TN, USA, 2018. [Google Scholar]

- Mukeshimana, M.C.; Zhao, Z.; Ahmad, M.; Irfan, M. Analysis on barriers to biogas dissemination in Rwanda: AHP approach. Renew. Energy 2020, 163, 1127–1137. [Google Scholar] [CrossRef]

- Amin, I.K.; Islam, M.N.; Jaman, A.; Hasan, M.K.; Parvez, S.H.; Shajid, M.S.S. Analytical hierarchy process and economic analysis for optimal renewable sites in Bangladesh. Environ. Sci. Pollut. Res. 2023, 30, 92332–92358. [Google Scholar] [CrossRef]

- Gottfried, O.; De Clercq, D.; Blair, E.; Weng, X.; Wang, C. SWOT-AHP-TOWS analysis of private investment behavior in the Chinese biogas sector. J. Clean. Prod. 2018, 184, 632–647. [Google Scholar] [CrossRef]

- Djatkov, D.; Effenberger, M.; Lehner, A.; Martinov, M.; Tesic, M.; Gronauer, A. New method for assessing the performance of agricultural biogas plants. Renew. Energy 2011, 40, 104–112. [Google Scholar] [CrossRef]

- Spagnolo, S.; Chinellato, G.; Cristiano, S.; Zucaro, A.; Gonella, F. Sustainability assessment of bioenergy at different scales: An emergy analysis of biogas power production. J. Clean. Prod. 2020, 277, 124038. [Google Scholar] [CrossRef]

- Balibrea-Iniesta, J.; Rodríguez-Monroy, C.; Núnez-Guerrero, Y.M. Economic analysis of the German regulation for electrical generation projects from biogas applying the theory of real options. Energy 2021, 231, 120976. [Google Scholar] [CrossRef]

- Kiselev, A.; Magaril, E.; Karaeva, A. Environmental and economic efficiency assessment of biogas energy projects in terms of greenhouse gas emissions. Energy Ecol. Environ. 2024, 9, 68–83. [Google Scholar] [CrossRef]

- Tamburini, M.; Pernetti, R.; Anelli, M.; Oddone, E.; Morandi, A.; Osuchowski, A.; Monti, M.C. Analyzing the Impact on Health and Environment from Biogas Production Process and Biomass Combustion: A Scoping Review. Int. J. Environ. Res. Public Health 2023, 20, 5305. [Google Scholar] [CrossRef] [PubMed]

- Ilbahar, E.C. A state-of-the-art review on multi-attribute renewable energy decision making. Energy Strateg. Rev. 2019, 25, 18–33. [Google Scholar] [CrossRef]

- Vaidya, O.S. Analytic hierarchy process: An overview of applications. Eur. J. Oper. Res. 2004, 169, 1–29. [Google Scholar] [CrossRef]

- Soomro, H.; Shah, S.F.; Sahito, W.S.; Uqaili, M.A.; Kumar, L.; Nixon, J.D.; Harijan, K. Assessment of sustainable biomass energy technologies in Pakistan using the analytical hierarchy process. Sustainability 2022, 14, 11388. [Google Scholar] [CrossRef]

- Barron, F. The efficacy of SMARTER—Simple Multi-Attribute Rating Technique Extended to Ranking. Acta Psychol. 1996, 93, 23–36. [Google Scholar] [CrossRef]

- Taylor, J.M. Simple multi-attribute rating technique for renewable energy deployment decisions (SMART REDD). J. Def. Model. Simul. Appl. Methodol. Technol. 2014, 11, 227–232. [Google Scholar] [CrossRef]

- Batool, K.Z. Assessing and prioritizing biogas barriers to alleviate energy poverty in Pakistan: An integrated AHP and G-TOPSIS model. Environ. Sci. Pollut. Res. 2023, 30, 94669–94693. [Google Scholar] [CrossRef]

- Sobczak, A.; Chomać-Pierzecka, E.; Kokiel, A.; Różycka, M.; Stasiak, J.; Soboń, D. Economic conditions of using biodegradable waste for biogas production, using the example of Poland and Germany. Energies 2022, 15, 5239. [Google Scholar] [CrossRef]

- Martínez-Hernández, C. Biogas plants in Germany: Revision and analysis. Rev. Cienc. Técnicas Agropecu. 2021, 30, e09. [Google Scholar]

- Kurka, T. Application of the analytic hierarchy process to evaluate the regional sustainability of bio-energy developments. Energy 2013, 62, 393–402. [Google Scholar] [CrossRef]

- Zia, U.U. Quantification and technological assessment of bioenergy generation through agricultural residues in Punjab (Pakistan). Biomass Bioenergy 2020, 139, 105612. [Google Scholar]

- Rehan, M.R. Untapping the potential of bioenergy for achieving sustainable energy future in Pakistan. Energy 2023, 275, 127472. [Google Scholar] [CrossRef]

- Kalu, A.V. Considering the environmental impacts of bioenergy technologies to support German energy transition. Energies 2021, 14, 1534. [Google Scholar] [CrossRef]

- Thrän, D.S. Governance of sustainability in the German biogas sector—Adaptive management of the Renewable Energy Act between agriculture and the energy sector. Energy Sustain. Soc. 2020, 10, 3. [Google Scholar] [CrossRef]

- Bai, D.; Jain, V.; Tripathi, M.; Ali, S.A.; Shabbir, M.S.; Mohamed, M.A.; Ramos-Meza, C.S. Performance of biogas plant analysis and policy implications: Evidence from the commercial sources. Energy Policy 2022, 169, 113173. [Google Scholar] [CrossRef]

- Tareen, W.U. The prospective Non-Conventional Alternate and Renewable Energy Sources in Pakistan—A focus on biomass energy for power generation, transportation, and industrial fuel. Energies 2018, 11, 2431. [Google Scholar] [CrossRef]

- Rasheed, R.; Tahir, F.; Yasar, A.; Ahmad, S.R.; Tabinda, A.B.; Sharif, F.; Su, Y. An industrial scale testing and analysis of waste-to-energy production from various substrates by employing a modern anaerobic digestion plant. Biomass Bioenergy 2020, 138, 105571. [Google Scholar] [CrossRef]

- Gelani, H.E. Barriers in the progress of domestic biogas plants in rural Pakistan. Int. J. Sustain. Energy 2021, 41, 713–729. [Google Scholar] [CrossRef]

- Ponitka, J. Challenges of future energy landscapes in Germany—A nature conservation perspective. Energy, Sustain. Soc. 2020, 10, 17. [Google Scholar] [CrossRef]

- Rasheed, R.; Yasar, A.; Ahmad, S.R.; Tabinda, A.B.; Khan, S.A.; Su, Y. Bioenergy recovery analysis from various waste substrates by employing a novel industrial scale AD plant. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 1935–1946. [Google Scholar] [CrossRef]

- Arshad, M.; Ansari, A.R.; Qadir, R.; Tahir, M.H.; Nadeem, A.; Mehmood, T.; Khan, N. Green electricity generation from biogas of cattle manure: An assessment of potential and feasibility in Pakistan. Front. Energy Res. 2022, 10, 911485. [Google Scholar] [CrossRef]

- Rasheed, R.; Tahir, F.; Yasar, A.; Sharif, F.; Tabinda, A.B.; Ahmad, S.R.; Wang, Y.; Su, Y. Environmental life cycle analysis of a modern commercial-scale fibreglass composite-based biogas scrubbing system. Renew. Energy 2022, 185, 1261–1271. [Google Scholar] [CrossRef]

- Jamal, H.; Loganathan, M.K.; Ramesh, P.G.; Singh, M. The selection of biogas plants in the Indian context based on Performability—An analytic hierarchy process and weighted aggregated sum product assessment approach. Fuels 2024, 5, 222–242. [Google Scholar] [CrossRef]

- Raha, D.; Mahanta, P.; Clarke, M.L. The implementation of decentralized biogas plants in Assam, NE India: The impact and effectiveness of the National Biogas and Manure Management Programme. Energy Policy 2014, 68, 80–91. [Google Scholar] [CrossRef]

- Mukumba, P.; Makaka, G.; Mamphweli, S. Biogas technology in South Africa, problems, challenges and solutions. Int. J. Sustain. Energy Environ. Res. 2016, 5, 58–69. [Google Scholar] [CrossRef]

- Rasheed, R.; Rizwan, A.; Javed, H.; Yasar, A.; Tabinda, A.B.; Bhatti, S.G.; Su, Y. An analytical study to predict the future of Pakistan’s energy sustainability versus rest of South Asia. Sustain. Energy Technol. Assess. 2020, 39, 100707. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).