Abstract

In recent decades, the construction industry in China has experienced significant growth, leading to substantial consumption of non-renewable natural resources and a large amount of construction and demolition waste (CDW). As a result, the effective utilization of CDW has become critically important in China. This study focuses on the processing of CDW to produce recycled fine aggregates (RFAs) and recycled coarse aggregates (RCAs), which were subsequently used to produce recycled aggregate concrete (RAC). A total of 12 RAC composites incorporating RFAs and RCAs were prepared, and their compressive strength was evaluated in detail. The life cycle assessment (LCA) methodology was employed to assess the environmental impact of 1 m3 of RAC within a “cradle-to-gate” system boundary. Furthermore, the life cycle cost analysis (LCCA) method was applied to evaluate the economic benefits of RAC. The contributions of RCAs and RFAs were analyzed in detail. Lastly, multi-criteria decision analysis (MCDA) using the Data Envelopment Analysis (DEA) approach was proposed to comprehensively compare the environmental and economic impacts of RAC and ordinary concrete. The results of the LCA and LCCA indicate that the inclusion of RCAs and RFAs in composite mixtures leads to significant environmental and economic benefits. The MCDA identified the optimized RAC mixture as one containing 70% RCA and 100% RFA, which demonstrated the best performance in terms of mechanical properties, environmental impact, and economic cost. The composite addition of RCA and RFA in RAC production can significantly reduce both environmental impacts and economic costs, thereby enhancing the sustainability of the concrete industry.

1. Introduction

Since the 1990s, the rapid urbanization and the reconstruction of old cities have led to a significant increase in the production of construction and demolition waste (CDW) in many cities across China. Currently, CDW is projected to reach approximately 20 billion tons, based on statistics from relevant authorities, with an annual growth rate of about 3.5 billion tons. At present, the primary methods of CDW disposal in China include transportation to external sites, landfilling, and open-air storage. These practices not only consume vast amounts of land resources but also release hazardous substances and noxious gases, resulting in pollution of groundwater, soil, and air, and posing serious risks to both the environment and public health [1].

Concrete, the most widely used engineering material in the construction industry, is known for its high compressive strength, ease of construction, and low cost [2]. Over the past decade, a substantial amount of concrete has been produced, leading to the depletion of many non-renewable natural resources, such as limestone and river sand, on an annual basis in China. Moreover, the concrete manufacturing process is associated with significant greenhouse gas emissions. It is estimated that concrete production contributes approximately 7% of global carbon dioxide emissions [3].

Recycling waste concrete as recycled aggregates (both coarse and fine) to produce recycled aggregate concrete (RAC) not only conserves non-renewable natural resources but also reduces the amount of waste concrete disposed of in landfills, thereby effectively mitigating environmental issues associated with concrete production and enhancing the sustainability of the concrete industry. Over the past few decades, numerous studies have been conducted to investigate the mechanical and durability properties of RAC, as well as the performance of RAC elements. The test results have shown that it is feasible to produce RAC incorporating both recycled coarse and fine aggregates. Recently, RAC has been successfully applied in practical engineering projects worldwide [4,5].

Life cycle assessment (LCA), a method used to evaluate the environmental impacts of products, production processes, and activities across their entire life cycle (from cradle to gate), has been widely applied to examine the environmental impacts of concrete in previous research, with the aim of identifying effective strategies to reduce greenhouse gas emissions. The environmental benefits of using recycled coarse aggregates (RCAs) in concrete production have been well established [6]. Xing et al. [7] employed LCA to evaluate the environmental impacts of concrete produced with recycled aggregates (RAs) and supplementary cementitious materials, demonstrating that environmental impacts are influenced by factors such as compressive strength, water-to-binder ratio, and highlighting the potential of alternative fuel utilization in cement production to significantly reduce carbon emissions and energy consumption. Guo et al. [8] conducted an LCA to assess the environmental impact of RAC blocks across five different environmental impact categories and found that RAC blocks have a lower environmental impact compared to conventional concrete blocks. Tereza et al. [9] used the LCA approach to compare the environmental impact of natural aggregate concrete and RAC and found that the use of recycled materials reduced both environmental impact and reliance on primary resources.

Extensive LCA studies have shown that the environmental benefits of RAC are primarily associated with the use of RAs and the reduction in transportation distances. RAs are typically the second most influential factor in the environmental impacts of RAC, with the transportation stage being the most critical process. Therefore, when the recycling plant is located in proximity to the concrete production facility, the environmental advantages of using RCAs are further enhanced.

Recently, there has been growing interest in exploring the economic benefits of RAC using the life cycle cost assessment (LCCA) approach. Daman et al. [3] analyzed the production process of RAC using the LCCA approach and found a significant correlation between the economic feasibility and environmental benefits of RAC. The use of RAC not only reduces environmental impacts but also lowers costs. Younis et al. [10] applied LCCA to compare three types of materials and found that the life cycle cost of structural concrete combined with seawater, RCA, and glass fiber reinforced polymer was approximately 50% lower than that of conventional concrete over a 100-year study period. Han et al. [11] evaluated the combined use of recycled materials—municipal solid waste incineration bottom ash, recycled asphalt shingle, and RCA, and a cost–benefit analysis revealed that using them in HMA overlays can be 60–80% more cost-effective than conventional HMA, offering substantial savings in road construction.

To comprehensively analyze RAC in terms of both environmental impact and economic benefits, and to ensure the selection of the optimal option based on compressive strength, environmental, and economic criteria, multi-criteria decision analysis (MCDA) is employed. MCDA is a set of methods and procedures specifically designed for evaluating multiple alternatives, enabling prioritization based on various criteria of different units and selecting the best alternative from the available options [12]. It encompasses approaches such as the Analytic Hierarchy Process (AHP), VIKOR (Visekriterijumska Optimizacija I Kompromisno Rešenje), and Data Envelopment Analysis (DEA), and others [13].

Sánchez-Garrido et al. [14] employed the VIKOR method, an MCDA technique that considers technological, economic, and environmental factors, to determine the optimal alternative for concrete production. The results indicated that the best solution was coarse aggregate concrete with an RCA replacement ratio of 50%. Suárez et al. [12] applied VIKOR to identify the most suitable concrete production solution based on environmental assessment criteria derived from LCA and economic criteria determined by Spanish reference costs. Their findings revealed that the use of recycled gypsum cement and RAs was the optimal choice, with potential benefits in reducing environmental pollution and economic costs. Kurda et al. [15] utilized MCDA to optimize conventional concrete mixtures and recycled concrete, considering four perspectives: mechanical properties, durability, life cycle cost, and environmental impact. Their results indicated that the combination of fly ash and RCA provided the best balance of concrete characteristics, cost, and environmental performance. Hafez et al. [16] using the MCDA framework, evaluated the impact of recycled fine aggregates (RFAs) on the functional, environmental, and economic parameters of concrete. Their findings suggested that concrete alternatives incorporating RFAs were more sustainable.

Most previous studies on RAC have focused on LCA or LCCA, with few addressing a comparative evaluation of the mechanical properties, environmental impact, and economic benefits of concrete. However, the concept of sustainability necessitates a comprehensive assessment of concrete that integrates environmental, technical, and economic considerations. This approach inherently involves the evaluation of multiple factors, often requiring complex trade-offs. Therefore, MCDA based on the DEA method was employed to analyze RAC comprehensively. In this study, 12 RAC mixtures were prepared by substituting natural coarse and fine aggregates with RCAs and recycled fine aggregates (RFAs), respectively. The mechanical properties and durability of concrete incorporating RCA and RFA have been examined in previous work [17]. The test results indicated that although both recycled coarse and fine aggregates negatively affected the mechanical and durability properties of concrete, it is still feasible to produce concrete incorporating various RCAs and RFAs for structural engineering applications. This study aims to conduct a comprehensive LCA and LCCA of RAC, evaluating its performance from engineering, environmental, and economic perspectives. The LCA and LCCA methodologies were applied to quantify the environmental and economic impacts of RAC with varying proportions of RCA and RFA. Additionally, an MCDA framework was utilized to compare the production of RAC, incorporating RCAs and RFAs, with conventional concrete made from natural aggregates and ordinary Portland cement. To identify the optimal mix proportion, a DEA-based MCDA approach was employed, integrating environmental, economic, and technical criteria. The DEA model assessed 12 different RAC mixtures by using economic cost as input indicators, and environmental emissions and performance as output indicators. The analysis aimed to determine the optimal RAC mix that delivers the best overall performance, balancing mechanical properties, environmental impact, and economic cost.

2. RCA Mixtures

2.1. Materials

The RAC used in this study consisted of water, cement, natural fine aggregates (NFAs), NCAs, RCAs, and RFAs. Ordinary Portland cement (OPC) with a nominal compressive strength grade of 42.5 MPa at 28 days was used as the cementitious material. The RCAs and RFAs used throughout the experimental program were sourced from a 30-year-old demolished concrete structure, which was manually crushed. Washing, air drying, sieving, and separation were performed before using the RCA and RFA. The maximum nominal size of the RCA was 31.5 mm, and the minimum nominal size was 4.75 mm, with 60% of the RCA in the 5–15 mm range and 40% in the 15–31.5 mm range. Meanwhile, the well-graded RFA, with a fineness modulus of 3.1 and a particle size of less than 5 mm, was used in this experimental study. The NCAs used were crushed limestone, with a nominal size range of 4.75–31.5 mm, an apparent density of 2725 kg/m3, and water absorption of 0.5% in a saturated surface dry (SSD) condition. River sand, which served as the NFA, had an apparent density of 2615 kg/m3 and a water absorption of 1.3% in SSD condition and was classified as medium sand. Additionally, basic tests were conducted to determine the physical properties of the recycled aggregates. The test results are provided in Table 1. Compared to natural aggregates (NAs), both RCAs and RFAs exhibit lower density and higher water absorption, primarily due to their higher porosity and the presence of adhesive mortar.

Table 1.

Properties of RCA and RFA.

2.2. Mix Design

In this experiment, 12 different mixes of RCAs and RFAs were prepared. To facilitate a fair comparison of the properties, the total amounts of coarse aggregates and fine aggregates in all mix designs were fixed at 1167.9 kg/m3 and 549.6 kg/m3, respectively. Since RAC mixes require more water than traditional concrete to maintain the same slump, the water consumption for each RAC mix is divided into two components: one is the mixing water, which participates in the hydration reaction of the cement paste, and the other is the additional water absorbed by the RCAs and RFAs. In other words, the recycled aggregates absorb water when in an SSD condition. The RCA replacement ratios were 0%, 75%, and 100%, while the RFA replacement ratios were 0%, 30%, 60%, and 100%. The proportions for all mixes are provided in Table 2, which can be used to study the influence of recycled coarse and fine aggregates on the mechanical properties of RAC. The concrete mixture notation represents the replacement ratios of the recycled coarse and fine aggregates used in the corresponding mix. For example, the notation “0–30” indicates that the replacement ratios of the RCA and RFA are 0% and 30%, respectively.

Table 2.

Mix proportion of RAC.

3. Mechanical Properties of RAC with RCAs and RFAs

To accurately compare the environmental impact and economic benefits of RAC while considering its mechanical properties, compressive strength must be evaluated to assess the material quality and determine the optimal concrete mix ratio.

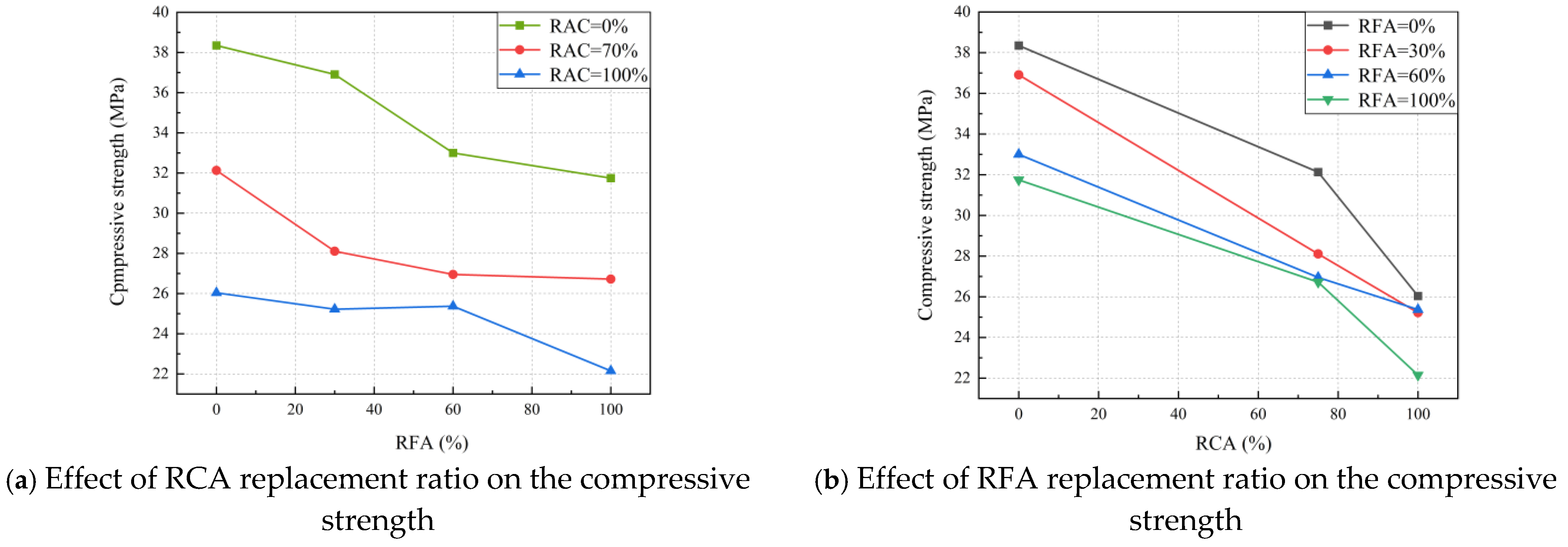

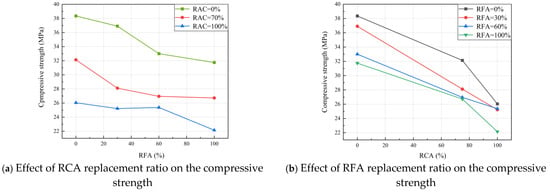

Compressive strength is one of the most critical parameters determining the bearing capacity of a concrete component. It typically depends on factors such as the age of the concrete, water–binder ratio, proportion of RA, use of additives, quality of raw materials, and moisture content [18]. Table 3 summarizes the cubic compressive strength of all RAC mixes at 28 days, which was measured according to the Standard for Test Methods of Mechanical Properties of Ordinary Concrete (GB/T 50081-2002) [19]. As can be seen from Table 3, the cubic compressive strength of RAC decreases progressively as the replacement rate of RCA and RFA increases. Figure 1a illustrates the effect of substituting RCA for NCA on the 28-day cubic compressive strength of concrete with varying RFA replacement ratios. It can be observed that the strength of concrete mixed with 80–100% RCA is significantly reduced. This reduction can be attributed to two primary factors. First, the weak bonding strength between RCA and the mortar adhered to its surface contributes to this decline. Second, when RCA is further broken, micro-cracks develop, resulting in increased porosity in the RAC, which, in turn, leads to stress concentration at these cracks under compressive load. As the RCA replacement ratio increases, this effect becomes more pronounced, leading to further strength reduction [20]. Figure 1b presents the effect of replacing NFA with RFA on the compressive strength of RAC with varying RCA replacement ratios. The figure shows a systematic decrease in compressive strength, with the strength of concrete containing 100% RFA reduced by 19% to 30%. This reduction is primarily due to the destruction of RFA by old cement mortar in the waste concrete, resulting in a lower strength compared to NFA, which hinders the development of RAC strength. The negative impact of this reduction outweighs the positive effect of secondary hydration from unhydrated particles in the RFA, and the adverse effect becomes more pronounced as the fine aggregate replacement ratio increases [21]. Additionally, it is worth noting that under a 100% RCA replacement ratio, the compressive strength slightly increases with a 40–60% RFA replacement ratio. This is likely due to the presence of both hydrated and non-hydrated cement in the RFA, which accounts for up to 25% of its weight, leading to an increase in the overall cement content and a reduction in the water-to-cement (W/C) ratio [22]. A comparison of Figure 1a,b reveals that the impact of RFA on compressive strength is less significant than that of RCA. This is likely because RFA contains a substantial amount of cement particles and mineral admixture particles that are not fully hydrated. The large specific surface area of fine aggregate particles in RFA promotes secondary hydration reactions, which improve the adhesion and compactness between the aggregates and mortar, thereby partially compensating for the reduction in strength.

Table 3.

Cube compressive strength of RAC.

Figure 1.

Cube compressive strength of concrete specimen.

Compared to ordinary concrete, the compressive strength of concrete mixed with 100% RCA and RFA is reduced by 36% to 42%, respectively. This indicates that the complete replacement of NA with RA significantly affects the mechanical properties of RAC. Therefore, it is essential to carefully control the replacement ratio of RA in concrete production.

4. Methodology

To quantitatively assess the environmental and economic impacts of recycling solid waste throughout its entire life cycle, two evaluation techniques are employed: LCA and LCCA. The integration of LCA and LCCA offers several advantages, as these two models complement each other and provide decision-makers with comprehensive environmental and economic analyses [23]. Furthermore, incorporating an MCDA using the DEA approach enables a combination of quantitative and qualitative analysis, focusing on prioritizing and selecting the optimal alternative when conflicting perspectives are present.

4.1. Life Cycle Assessment

LCA is a method used to qualitatively and quantitatively evaluate, assess, and compare the environmental impacts of products or services throughout their life cycle. Typically, the life cycle of a product encompasses stages such as raw material extraction, transportation, production, use, and final disposal or reuse of the product [24]. The environmental evaluation of the entire life cycle is commonly divided into input and output factors. Input refers to all energy types required to produce the product, such as materials, water, and energy, while output pertains to the environmental emissions associated with the product’s life cycle, including CO2 emissions, solid waste, and liquid waste. According to ISO 14040 and ISO 14044 standards [25,26], the LCA process is divided into four phases: (1) goal and scope definition, (2) life cycle inventory (LCI), (3) life cycle impact assessment (LCIA), and (4) interpretation. In this study, the LCA method is employed to compare and analyze the environmental impacts of concrete incorporating recycled coarse aggregates (RCAs) and recycled fine aggregates (RFAs) within a “cradle-to-gate” system boundary.

4.1.1. Goal and Scope Definition

The goal and Scope definition is the first phase of the LCA methodology. Definitions of the product system, system boundaries, and functional unit are outlined in ISO 14041 [27,28]. The primary objective of this study is to apply standardized life cycle environmental assessment principles to evaluate and optimize the production process of RAC, comparing its environmental and economic performance with that of ordinary concrete. The functional unit is determined based on the goal of the LCA study and serves as the benchmark for comparison throughout the entire assessment [25,26]. The functional unit adopted in this study is the concrete volume (i.e., 1 m3), which is commonly used in most concrete LCA studies.

In the concrete industry, three primary system boundaries are commonly used: cradle-to-gate, cradle-to-grave, and cradle-to-cradle. Since RAC and ordinary concrete are designed to meet similar functional requirements, there is no distinction in the construction process, use phase, or end-of-life (EOL) phase, and thus, these stages do not influence the LCA results. This study adopts the cradle-to-gate system boundary, which encompasses the extraction, transportation, and production of raw materials.

4.1.2. Life Cycle Inventory Analysis

Once the objectives are clearly defined and the boundary conditions are established, data collection and statistical analysis are initiated for all input and output activities within the evaluation scope. Inputs include raw materials, energy, and water consumed during the extraction, transportation, and preparation of concrete. At the concrete plant, electricity and fuel are utilized for mixing, conveying, and pumping concrete ingredients and mixes, as well as for molding the concrete. Outputs consist of air emissions generated at all stages, including NH3, CO2, CO, CH4, NOx, SO2, NMVOC, N2O, and PM10 [29,30].

The material transport vehicle used is an 18-ton truck, with the transportation distance for OPC from the cement plant to the concrete plant being 50 km. The transportation distance for NCA from the quarry to the concrete plant is 200 km, while the NFA are sourced from a supplier located 100 km away. The recycled coarse and fine aggregates used in this study are obtained from demolition sites 20 km away. Table 4 presents the LCI for the production of 1 m3 of concrete containing RCA and RFA. This data primarily come from the published literature, monitoring analyses, interviews, field investigations with local manufacturers and suppliers, as well as databases developed by the China Centre for National Material Life Cycle Assessment [31] at the Beijing University of Technology, and the Chinese Life Cycle Database [32] developed by Integrated Knowledge for our Environment (IKE) at Sichuan University [28].

Table 4.

Life cycle inventory for the production of 1 m3 concrete with RCA and RFA [31,32].

4.1.3. Life Cycle Impact Assessment

The impact assessment aims to convert inventory data into potential environmental impacts and demonstrate how these impacts could influence the environment. This process involves both qualitative and quantitative analyses. Environmental impact indicators are classified, characterized, and quantitatively calculated using an LCI instrument, based on different evaluation purposes. Environmental impact classification is a qualitative process in which inventory analysis results are categorized according to their environmental impacts. In this study, six environmental impact categories were considered: global warming potential (GWP), acidification potential (AP), eutrophication potential (EP), photochemical ozone production potential (POCP), human toxicity potential (HTP), and abiotic depletion potential (ADP). Table 5 presents these six environmental impact categories and their corresponding quantification methods. The CML baseline method was employed for the LCIA analysis in this study. The six impact categories were also normalized using the method outlined in ISO 14042 [33], enabling a detailed analysis of the various categories at a consistent level. According to ISO 14042 [33], normalization refers to estimating the index result relative to a normalization factor, which is provided by the CML baseline.

Table 5.

Environmental impact categories and quantification methods.

4.2. Life Cycle Cost Analysis

The American Institute of Architects (AIA) posits that LCCA constitutes an economic decision-making process that encompasses budgeting for product investments, forecasting future economic benefits, and evaluating various alternatives to select the most effective option. Kurda et al. [15] similarly assert that, when assessing the sustainability of materials, it is crucial to consider the economic impacts involved.

4.2.1. Goal and Scope Definition

The purpose of this study in establishing the LCCA is to quantify costs, assess the cost-effectiveness of RAC, and provide data to support the selection of optimal building materials and construction strategies.

The system boundary adopted for this study follows that of LCA, specifically the ‘cradle-to-gate’ model, which primarily encompasses upstream processes such as raw material acquisition, material transportation, and concrete preparation, in order to calculate the cost of 1 m3 of concrete.

4.2.2. Life Cycle Economic Impact Assessment

The life cycle cost of RAC in this study is divided into three components: the cost of raw materials, the fuel consumption cost of transportation, and the energy consumption cost of concrete preparation.

Material costs are calculated based on the expenses associated with the manufacturing and purchase of raw materials, including cement, aggregates, and water. Table 6 presents the unit costs of the materials used in this study, with most of the raw material data obtained from a site investigation of the manufacturer. Equation (1) is employed to calculate the cost of each material per cubic meter (m3) of concrete.

where Cm represents the price of raw materials. Qi is the amount of the ith raw material. Pi represents the unit price of ith raw materials.

Table 6.

Unit costs considered in the life cycle cost analysis.

The fuel cost can be considered as the cost of transporting different raw materials to the concrete plants. Transportation distance is shown in Section 5.1.2. Equation (2) is used to calculate the energy cost of transportation.

where Qi represents the amount of the ith raw material. FCi represents the fuel cost per unit of building materials transported for 1 km. Si represents the ith raw material transportation distance.

The energy consumption cost of concrete preparation refers to the expenses associated with the energy consumed by machinery and equipment used in concrete preparation, such as mixers and other devices.

4.2.3. Sensitivity Analysis

A substantial amount of data were utilized in this study, which may result in fluctuations in LCCA and significantly impact the calculations. Therefore, to accurately establish the LCCA, it is essential to employ techniques such as sensitivity analysis to assess the influence of these uncertain variables [34].

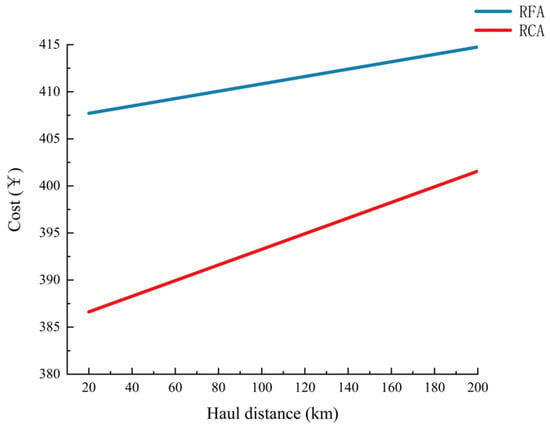

In this study, the transportation distance significantly impacts the LCCA. Therefore, it is recommended to conduct a sensitivity analysis on the transportation distance of recycled coarse and fine aggregates.

4.3. Multi-Criteria Design Analysis

Given the variety of mix proportions of RAC, selecting the optimal RAC with excellent mechanical properties that meet production requirements, is cost-effective, low-carbon and environmentally friendly constitutes an MCDA problem. This selection process requires a comprehensive consideration of the underlying principles and influencing factors. While several scholars have proposed various RAC evaluation models and systems, these methods face challenges in integrating the effects of multiple factors. Most existing evaluation models primarily focus on economic assessment, the combination of technical and economic factors, or individual environmental impacts, but they lack a comprehensive approach that considers the interplay of economic, technical, and environmental aspects. To address this gap, a preferred RAC evaluation index system is proposed, and the DEA model is introduced.

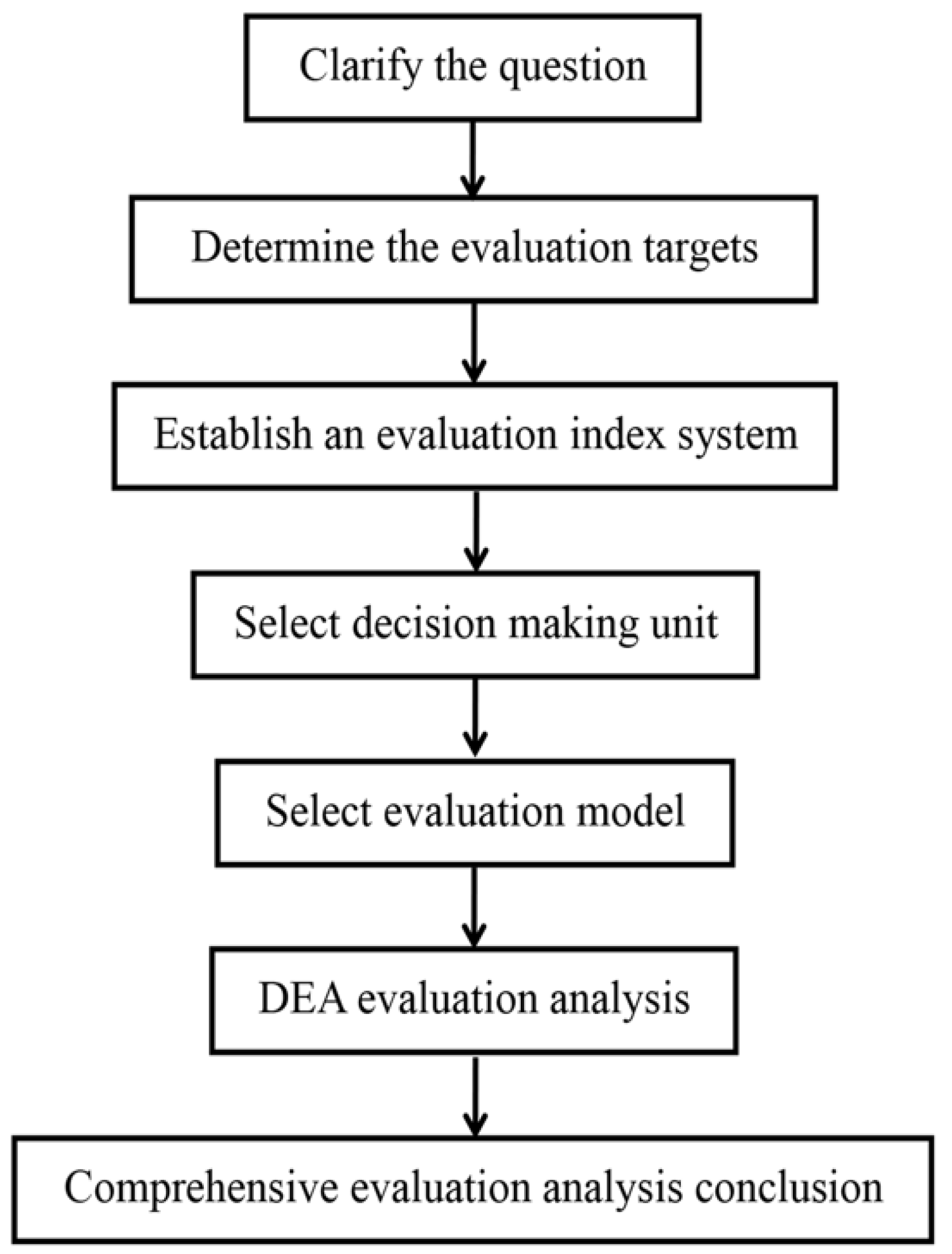

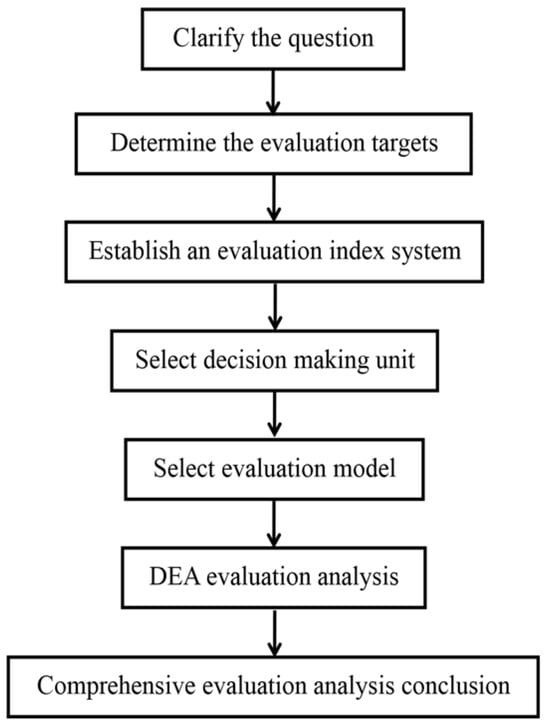

DEA is a multi-input, multi-output analytical method based on the concept of relative efficiency, first proposed and developed by A. Charnes and W. W. Cooper. This method primarily employs linear programming to evaluate the relative effectiveness of comparable decision-making units (DMUs) [35]. The fundamental concept involves treating the evaluated units, each with multiple inputs and outputs, as DMUs. These DMUs collectively form an evaluation group, which is then analyzed to assess the relative efficiency of the input-output ratios. The workflow of DEA is presented in Figure 2.

Figure 2.

Flow chart of DEA method.

The DEA method includes a variety of models, one of which is cross-efficiency evaluation. This extension of DEA can identify effective decision-making units (DMUs) and rank them using cross-efficiency scores derived from all DMUs [36]. Li et al. [1] proposed a novel hybrid approach that integrates DEA with energy simulation and orthogonal array testing to determine the optimal solution for retrofitting building envelopes. The identified optimal solution is also cost-effective. In the context of RAC, cross-efficiency evaluation serves as a comprehensive and precise tool, assisting in optimizing the production process, reducing costs, enhancing performance, and promoting the economic and environmental benefits of recycled aggregate utilization. Despite its widespread use, this method has several limitations, such as the non-uniqueness of DEA optimal weights, which can reduce the effectiveness of cross-efficiency evaluation [37]. To address this issue, Sexton et al. [36] and Doyle and Green [37] proposed several secondary target models, including the benevolent and aggressive models. This study applies the aggressive model, selecting economic costs as input indicators and environmental emissions and work performance as output indicators. The model is used to evaluate 12 RAC mixes to identify the optimal weight that maximizes the efficiency of the evaluated DMU while minimizing the average efficiency of other units.

Consider n DMUs, and each DMUj (j = 1, 2, …, n) produces s different outputs using m different inputs which are denoted as xij (i = 1, 2, …, m) and yrj (r = 1, 2, …, s), respectively. Use the following CCR model to calculate the efficiency of DMUd (d = 1, 2, …, n), denoted as Edd.

Since the optimal solution of model (3) is not unique, it will reduce the effectiveness of cross-evaluation, so aggressive cross-evaluation is adopted.

In model (4), ωid represents the weight of the ith input, μrd represents the weight of the rth output, and the cross-efficiency of each DMUj, namely Edj, is calculated as follows:

For each DMUj, the average of all Edj (e.g., ) can be treated as the cross-efficiency score to evaluate the quality of DMUj, the larger the calculated average Edj, the better the DMUj.

5. Results and Discussions

5.1. LCA Results and Discussions

This paper conducts an environmental impact study based on the midpoint model recommended by CML, investigating the impact of concrete production using recycled concrete aggregate (RCA) and recycled fine aggregate (RFA). The midpoint method focuses on the impact level, which infers the potential environmental impact based on the substances exerting influence and various load or emission factors. Table 7 provides details of the characterization results from the midpoint impact assessment.

Table 7.

Characterization results of mid-point impact assessment.

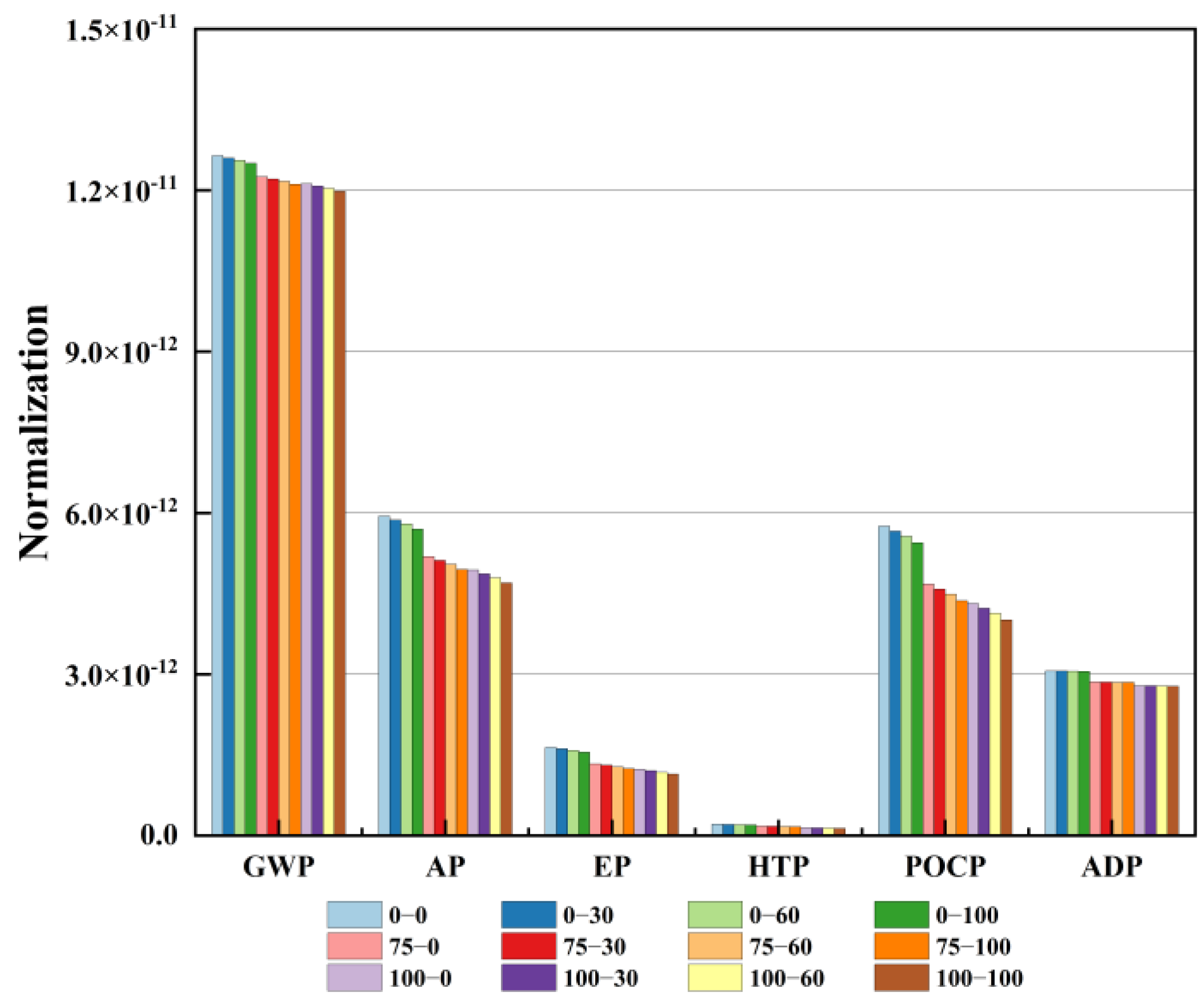

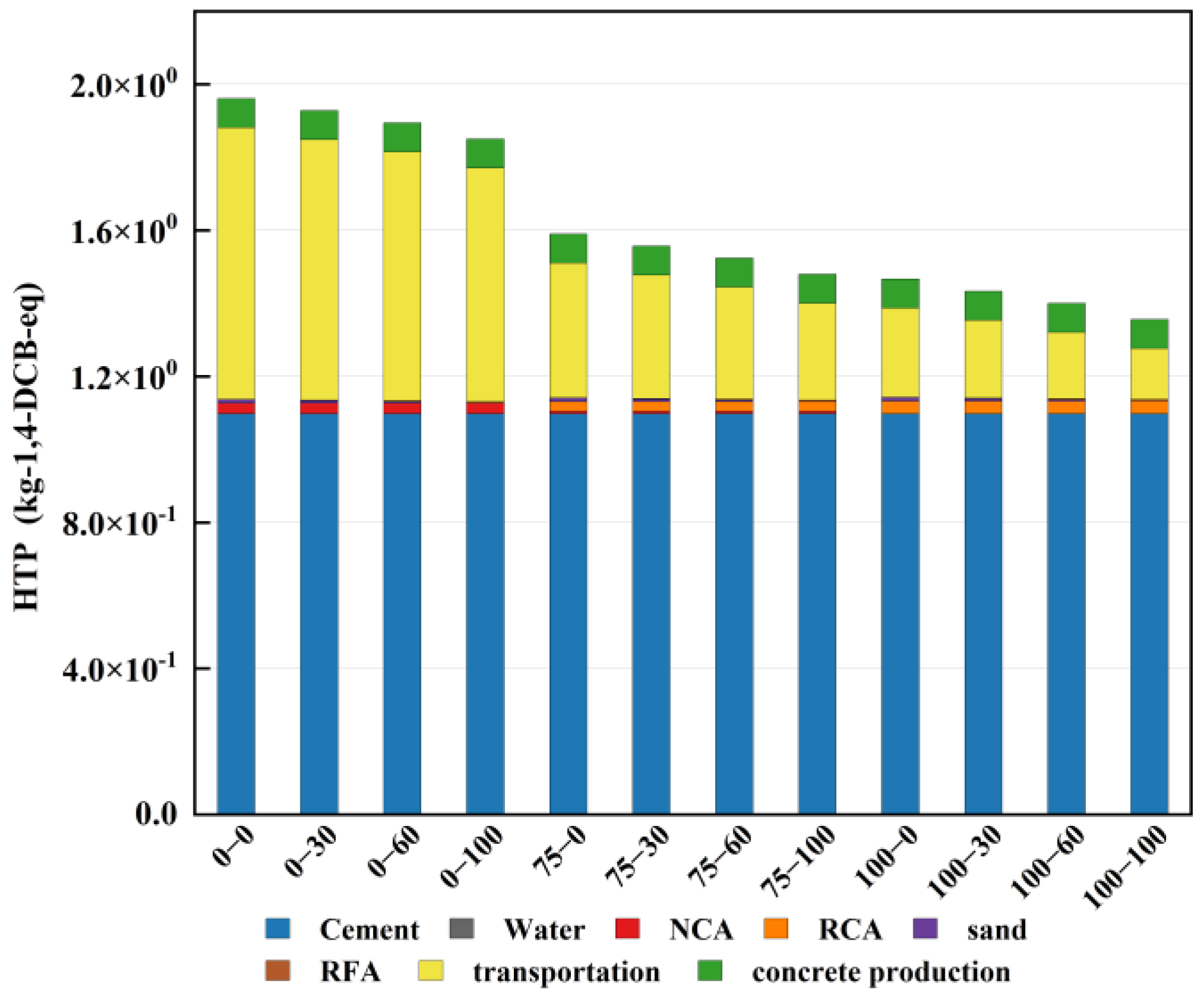

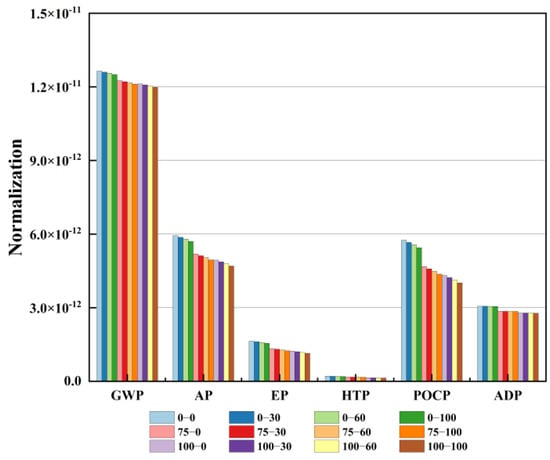

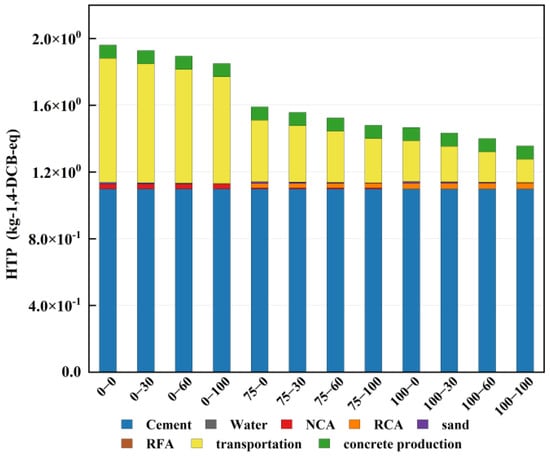

To compare and quantify different types of environmental impacts, the inventory data characterization results are normalized, assigning relative weights to the various categories of environmental impacts. The normalized results are shown in Figure 3. As illustrated in Figure 3, compared to ordinary concrete, concrete containing recycled concrete aggregate (RCA) and recycled fine aggregate (RFA) significantly reduces the environmental burden, thereby improving the environmental footprint of concrete. Notably, the environmental impact decreases as the replacement ratio increases. Among the six environmental impact categories, the concrete mixture with 100% NCAs and 100% NFAs (denoted as 0-0) has the highest overall environmental impact, while the 100-100 mixture exhibits the lowest overall environmental impact. Furthermore, Figure 3 highlights that the most significant environmental impact of RAC is GWP, which refers to climate change. The normalized result for HTP is relatively low, indicating that concrete production has a minor impact on human health.

Figure 3.

Normalized life cycle impact categories.

5.1.1. Identification of Key Processes

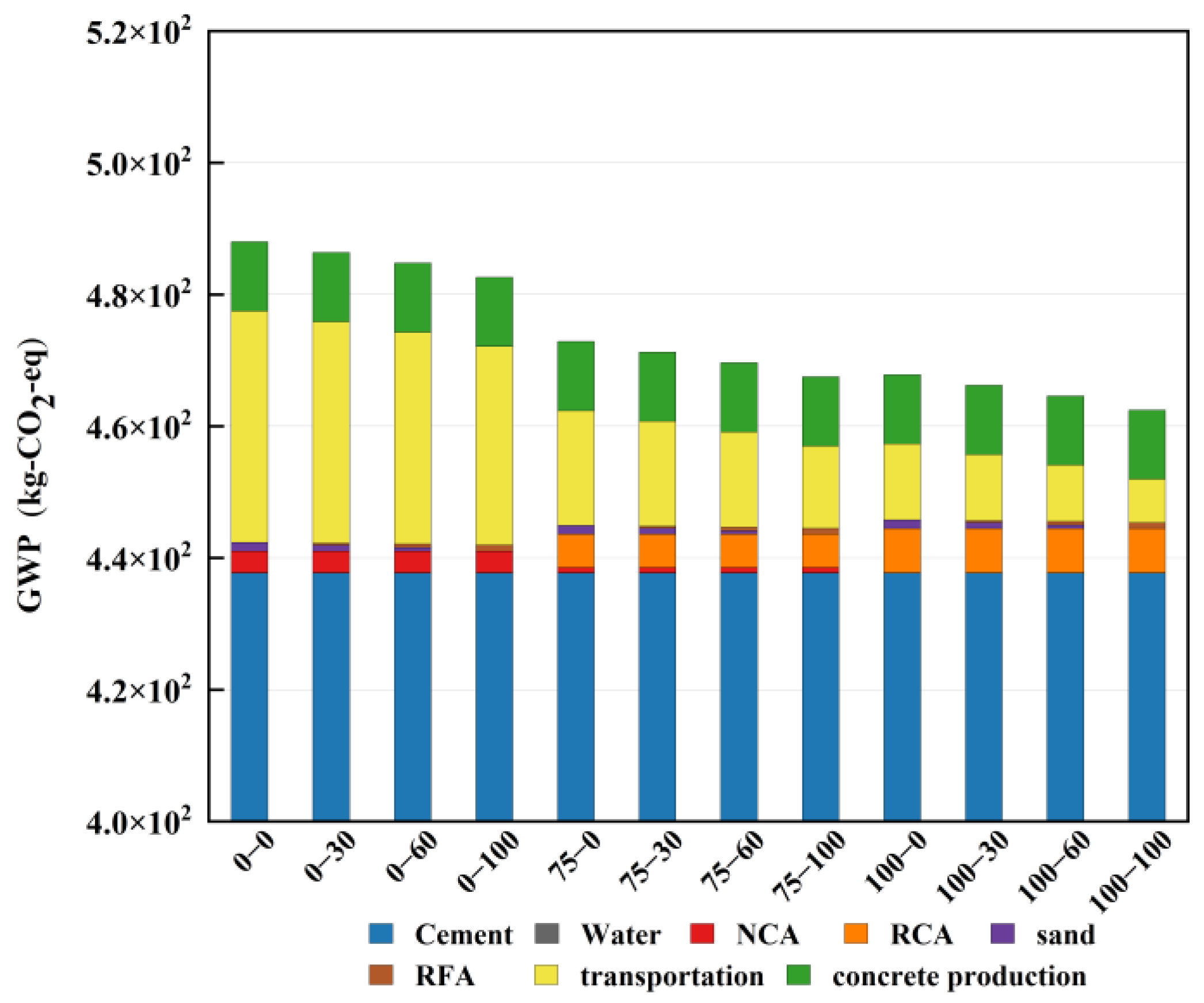

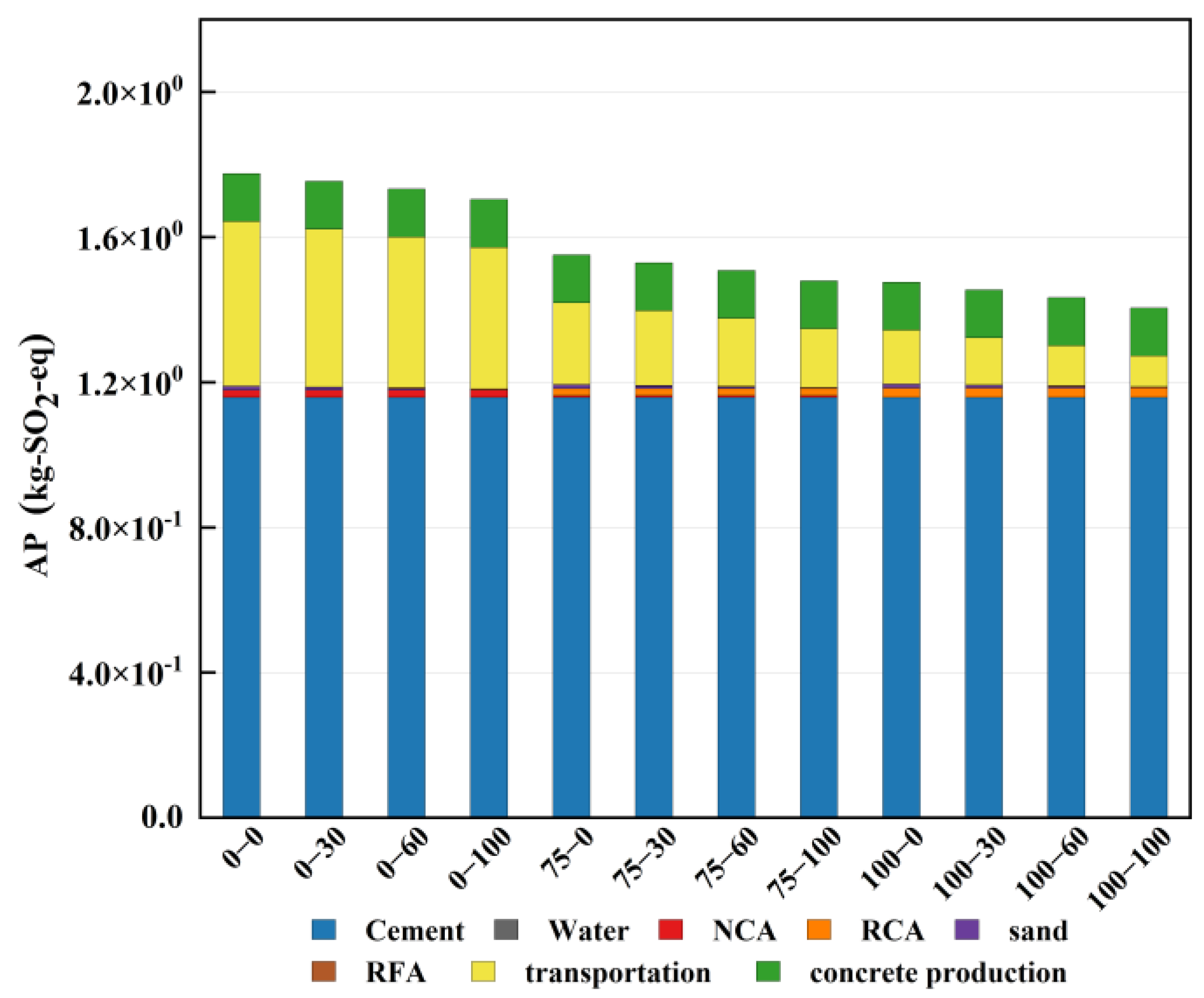

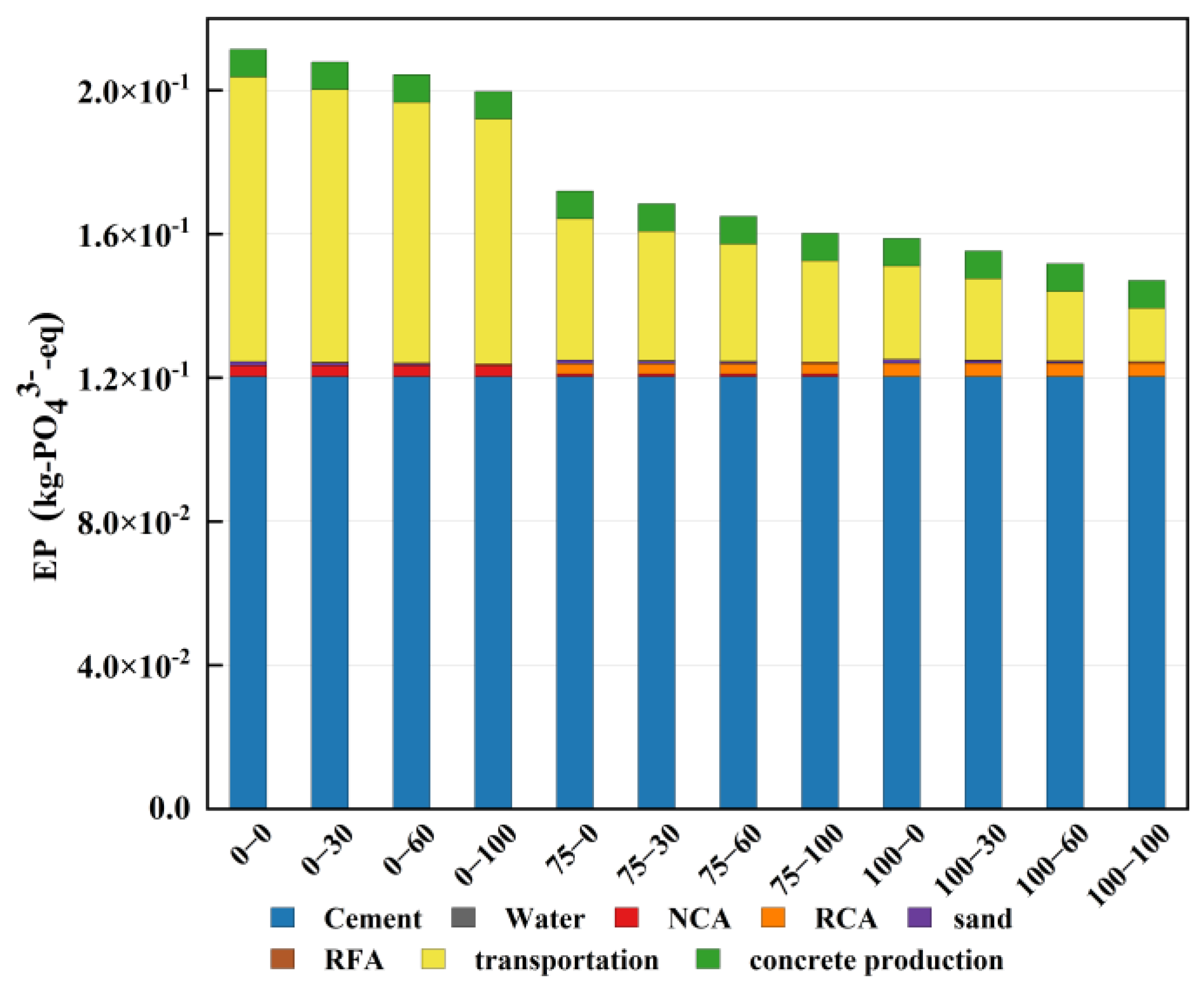

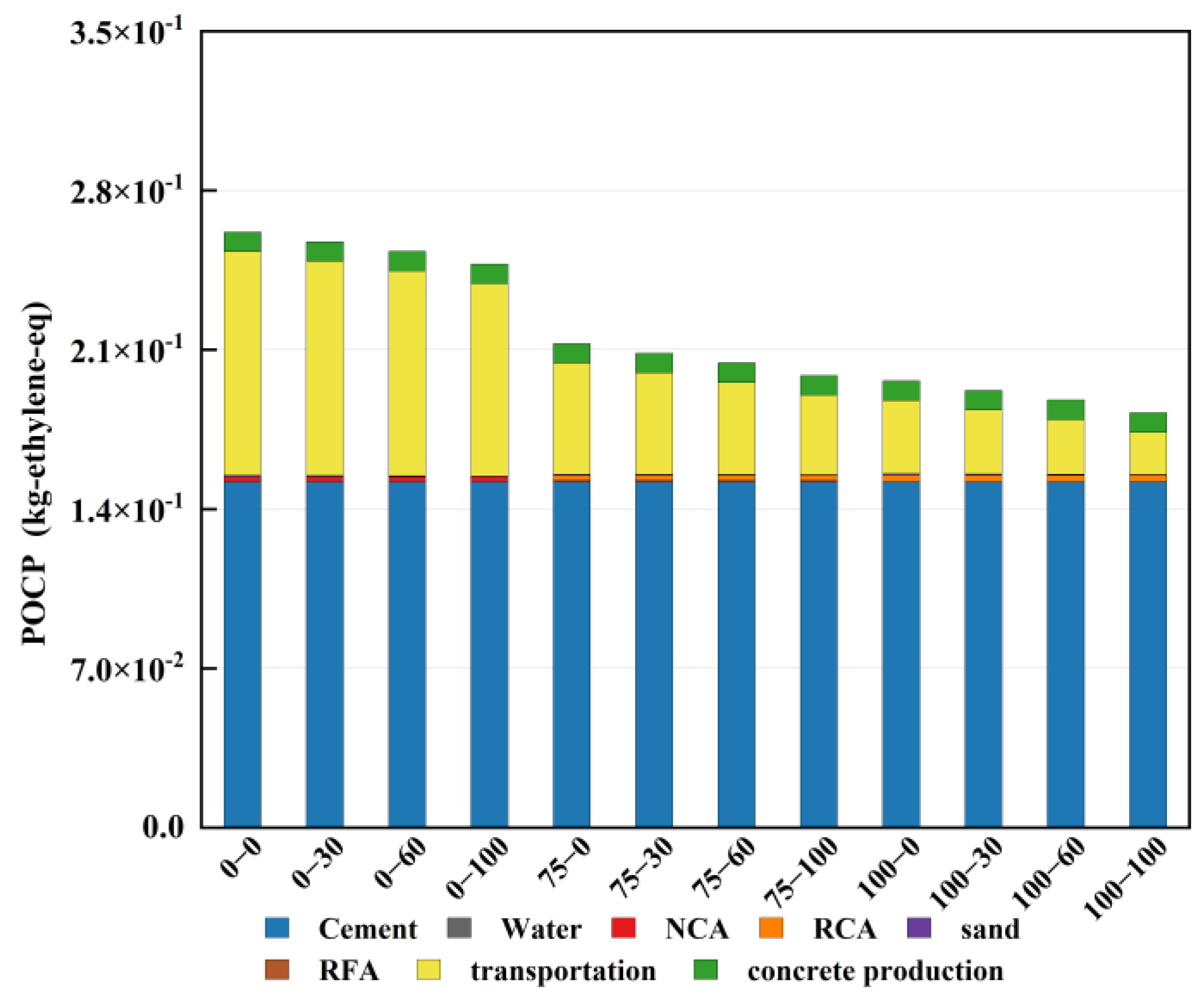

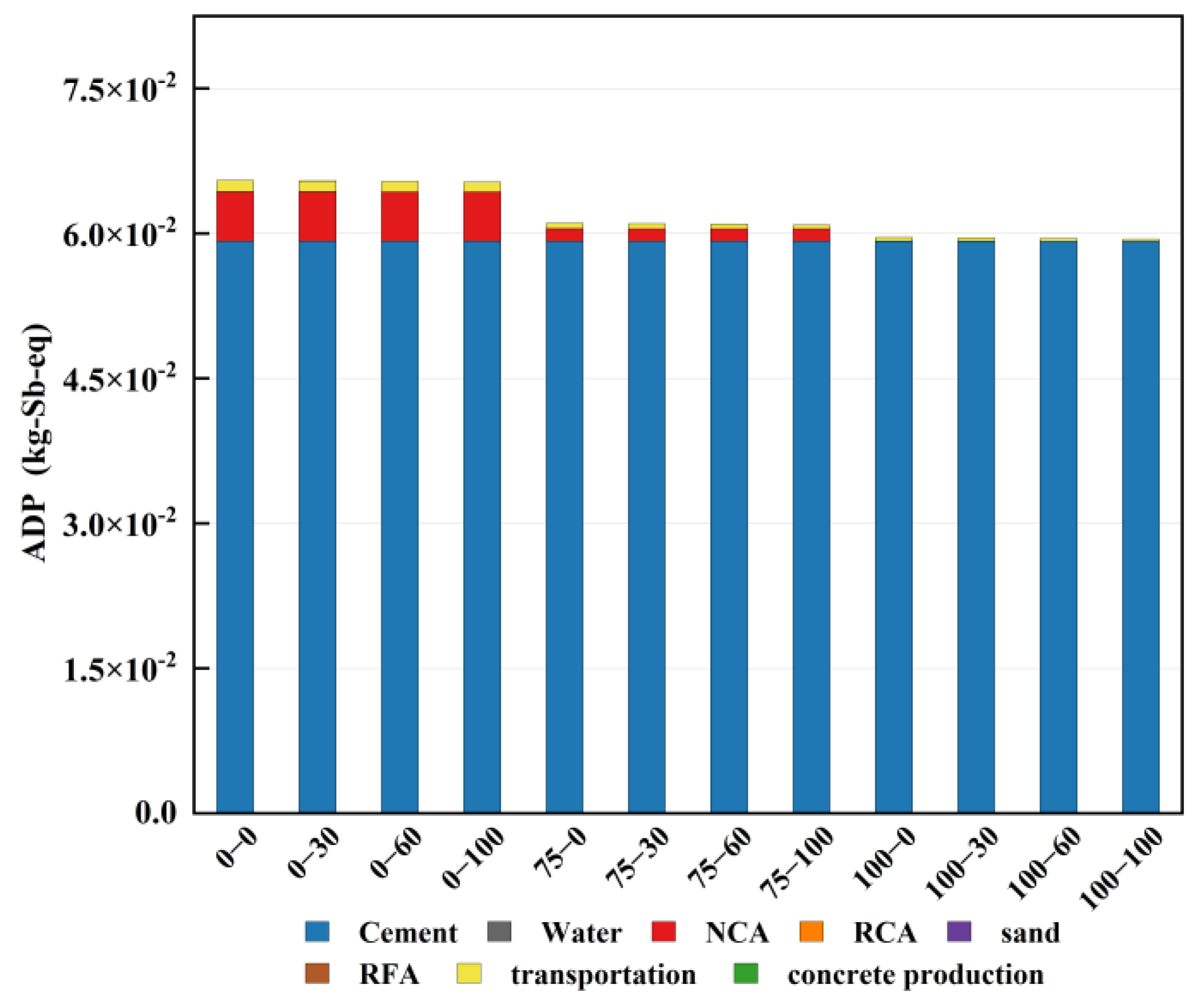

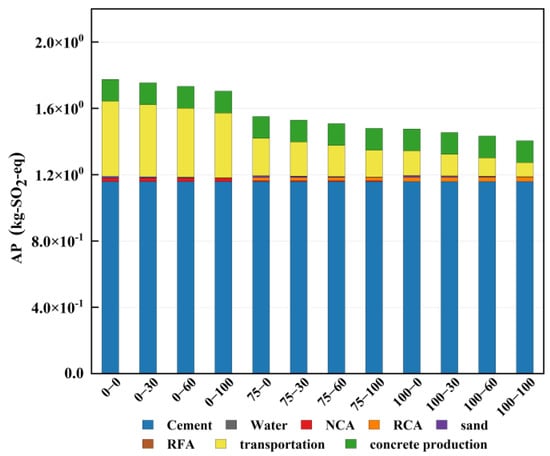

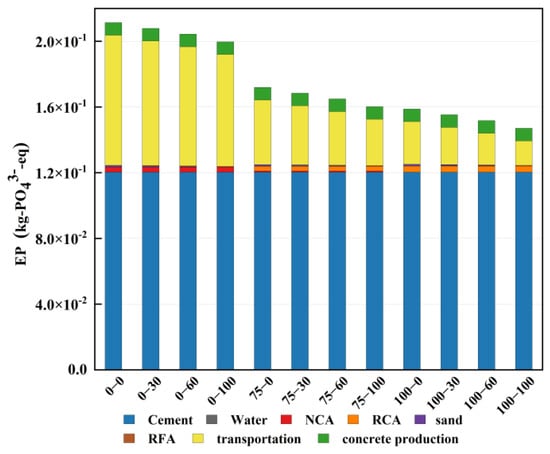

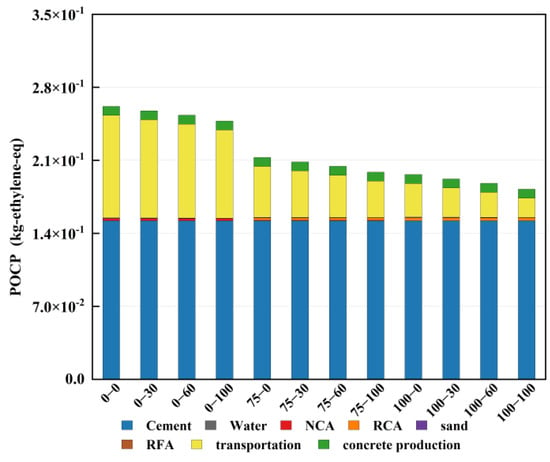

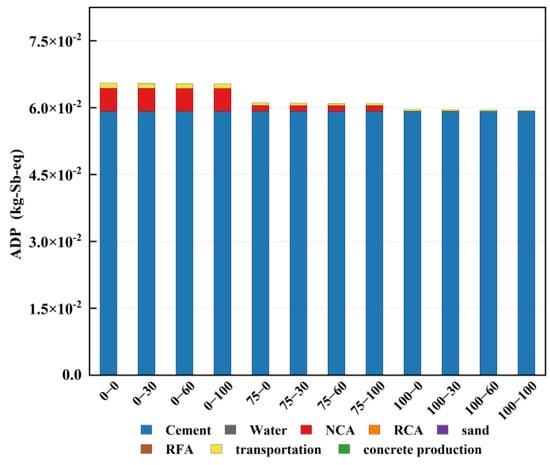

To gain insight into the key processes responsible for the major environmental impacts during RAC production, it is essential to analyze six environmental impact categories (see Figure 4, Figure 5, Figure 6, Figure 7, Figure 8 and Figure 9). The results indicate that transportation is the primary contributor. Among the categories of GWP, AP, EP, HTP, and POCP, transportation accounted for 7.19%, 25.51%, 37.58%, 37.96%, and 37.52%, respectively. Furthermore, as the replacement ratio of recycled coarse and fine aggregates increases, the environmental impact from transportation decreases, leading to a reduction in the total environmental impact. This decrease is primarily attributed to the shorter transportation distance for recycled aggregates. The distance between the stone quarry and the concrete plant is considerably longer than that between the crushing plant and the concrete plant, which aligns with findings by Hafez et al. [16] and Kurda et al. [38].

Figure 4.

Comparison of GWP for the RAC production.

Figure 5.

Comparison of AP for the RAC production.

Figure 6.

Comparison of EP for the RAC production.

Figure 7.

Comparison of HTP for the RAC production.

Figure 8.

Comparison of POCP for the RAC production.

Figure 9.

Comparison of ADP for the RAC production.

5.1.2. Identification of Key Materials

The figure clearly demonstrates that the materials with the greatest environmental impact are cement and coarse aggregate. The environmental impact load of cement accounts for approximately 92.5%, 74.58%, 69.65%, 69.03%, 71.2%, and 95.69% across the six environmental impact categories—GWP, AP, EP, HTP, and POCP. The primary source of impacts stems from the combustion of fossil fuels during the cement production process [39]. However, since the cement content remains constant across different mix ratios, coarse aggregate emerges as the main material responsible for variations in environmental impact. Notably, except for ADP, which decreases as RCA replaces NCA, all other environmental impacts increase. This can be attributed to the higher electricity consumption during the crushing of recycled concrete aggregates compared to the extraction of natural aggregates.

5.2. LCCA Results and Discussions

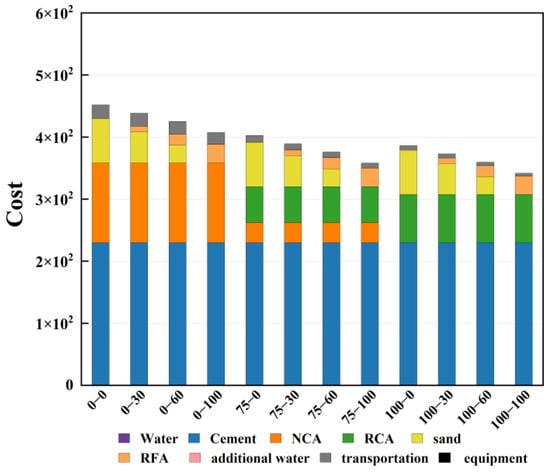

Considering the costs of raw materials, fuel consumption for transportation, and energy consumption by equipment during the production process, the impact of concrete incorporating RCA and RFA on overall costs is illustrated in Table 8.

Table 8.

Summary of life cycle cost (RMB).

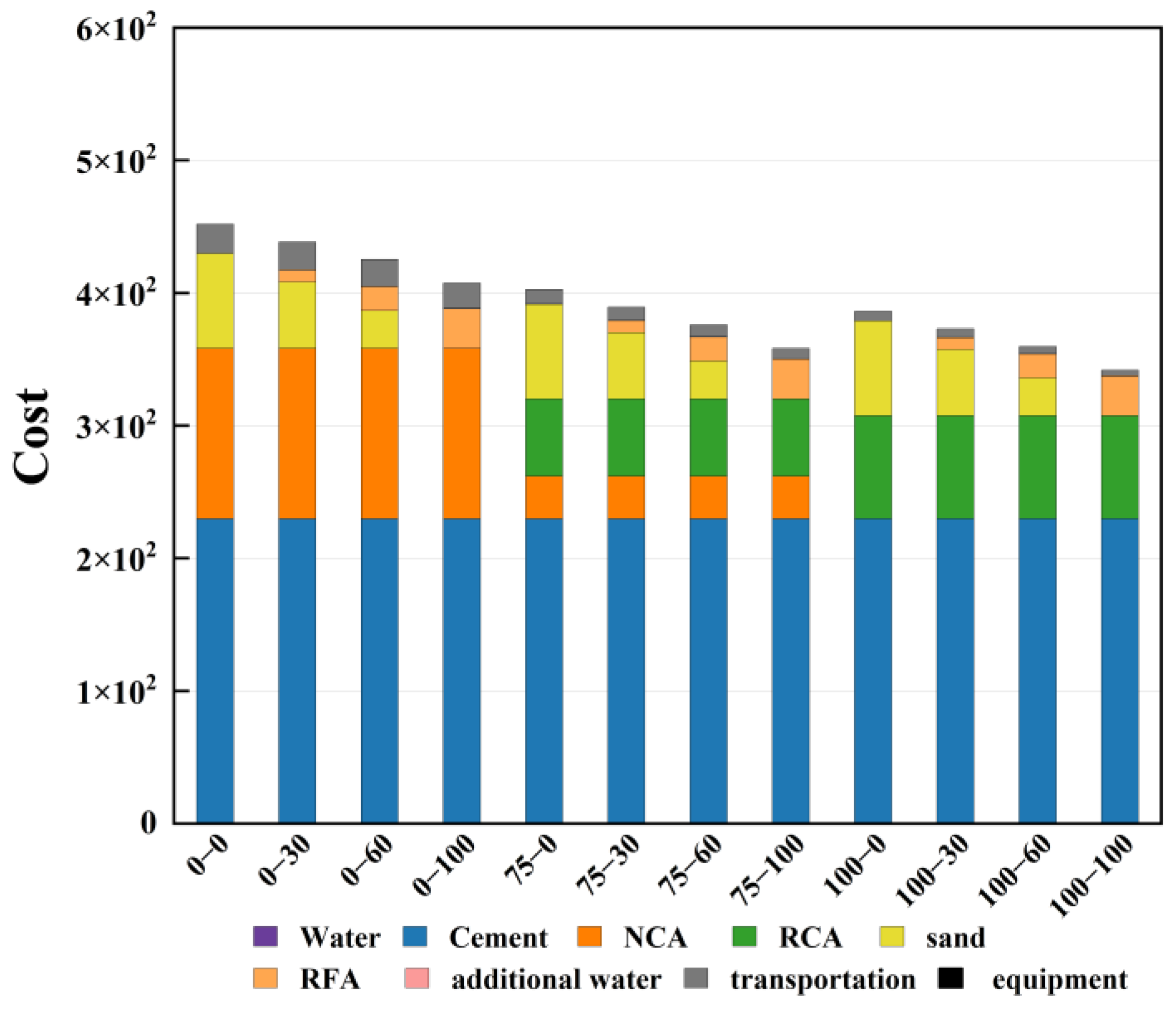

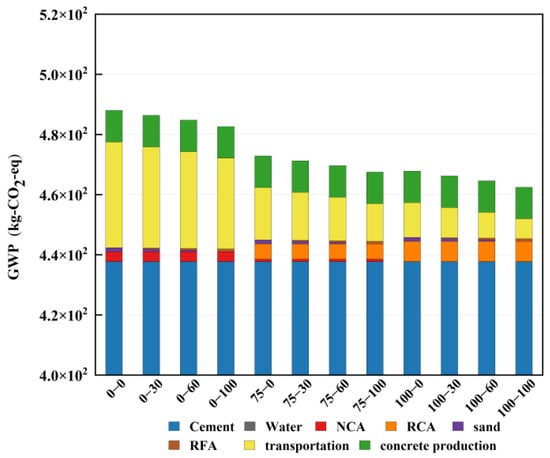

Analysis of the cost impact of concrete incorporating RCA and RFA, as shown in Figure 10, reveals a trend similar to the LCA results. Specifically, ordinary concrete reaches its cost peak in 12 mix configurations, with cement and coarse aggregate representing a significant proportion of the overall cost. As the RCA replacement ratio increases, the concrete cost gradually decreases, primarily due to the lower cost of RCA and the shorter transportation distance. Compared to ordinary concrete, when the RCA replacement ratio is 75%, the cost decreases by approximately 11%. At a 100% RCA replacement ratio, the cost reduction is around 15%. Similarly, as the RFA replacement ratio increases, the cost decreases, owing to the lower price of RFA compared to natural fine aggregate (NFA) and the shorter transportation distance. When the RFA replacement ratio is 30%, 60%, and 100%, the cost reductions are approximately 3%, 6%, and 11%, respectively. The lowest cost is observed when both RCA and RFA replacement ratios are 100%, resulting in a 24% reduction. These results indicate that RA is less expensive than NA, and the shorter transportation distance for RA further contributes to the cost reduction. Collectively, these findings underscore the economic benefits of utilizing RA in concrete production.

Figure 10.

Cost contribution analysis of concrete based on different ratios (RMB).

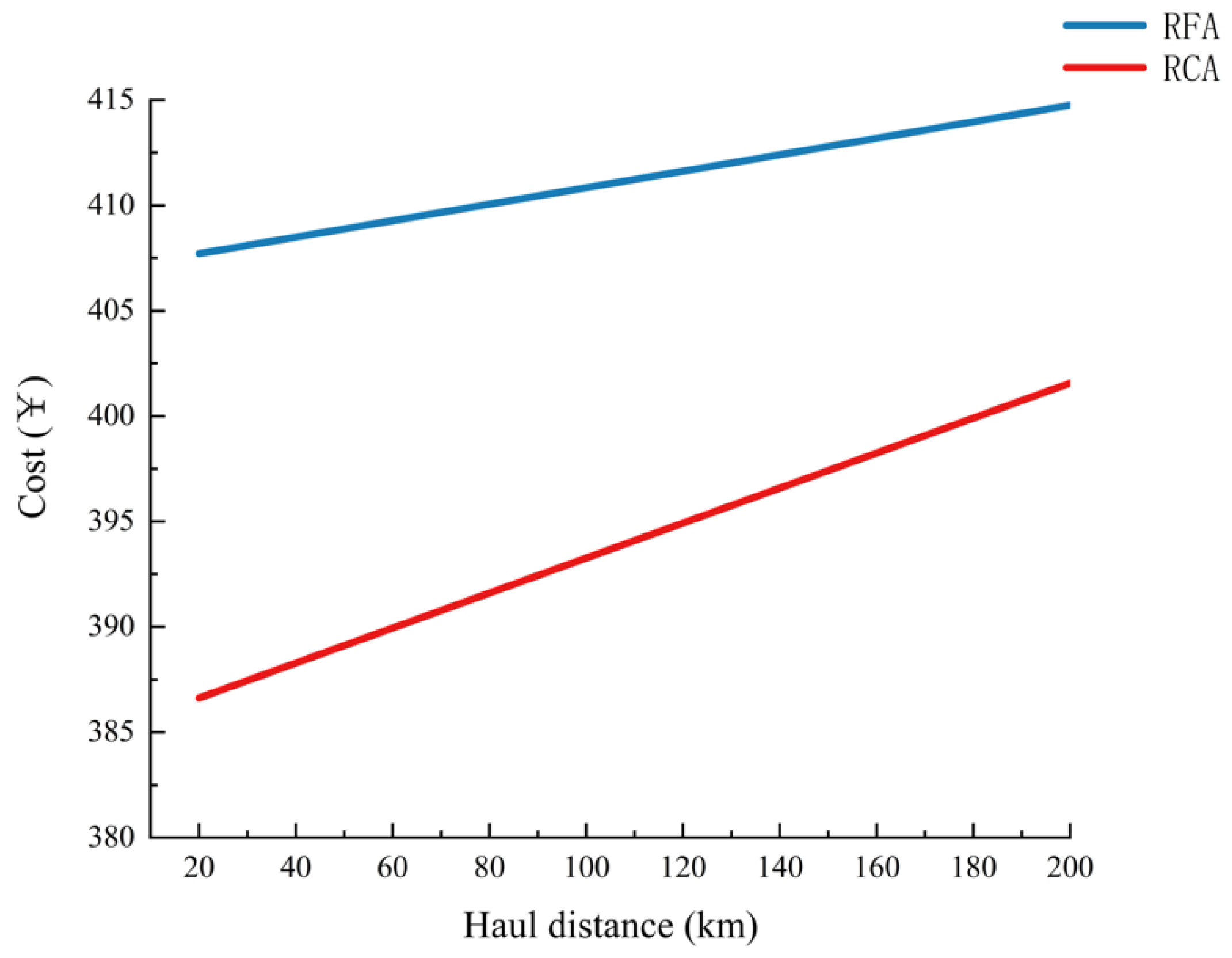

According to the sensitivity analysis of the haul distance for recycled coarse and fine aggregates presented in Figure 11, the results indicate that RCA is more sensitive to price fluctuations and, therefore, offers greater advantages when substituted alone. This is primarily due to RCA being a major component in the concrete production process, which tends to be relatively expensive.

Figure 11.

Influence of haul distance of RCA and RFA on cost of recycled concrete.

5.3. Integrated Analysis of Mechanical Properties, LCA and LCCA Results

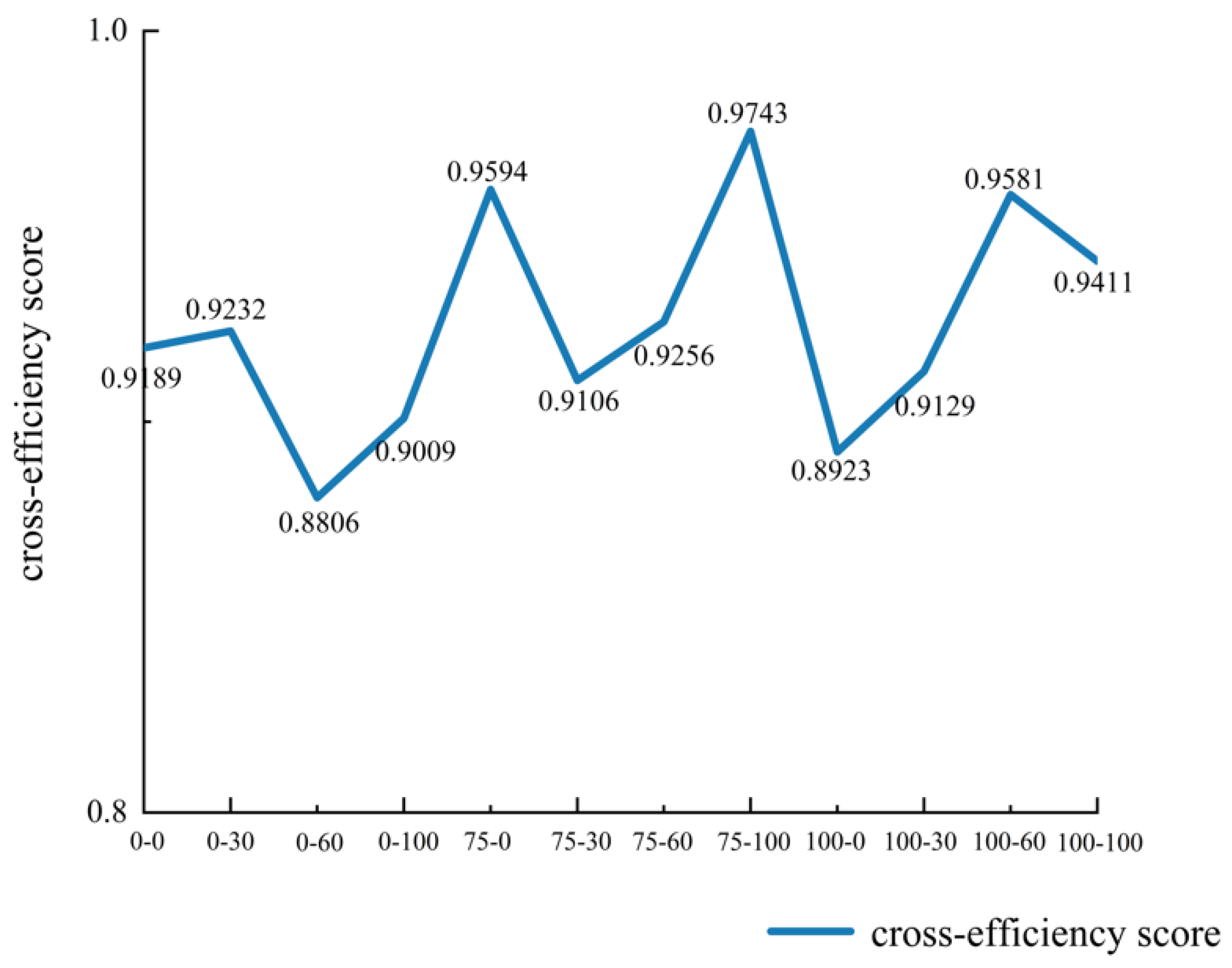

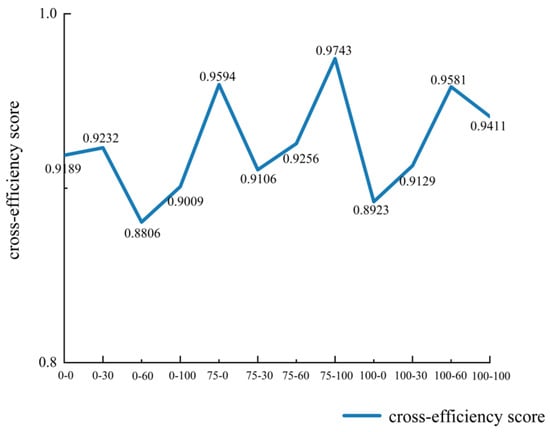

MCDA using DEA was conducted to qualitatively and quantitatively evaluate 12 mixing proportions of RAC mixtures. Economic costs were used as input indicators, while environmental emissions and work performance served as output indicators to determine the optimal mixing proportion. By incorporating the concrete index values for RCA and RFA into models (3) and (4), the aggressive cross-efficiency matrix of the concrete mixtures was derived, as shown in Table 9, in accordance with Equation (5).

Table 9.

Aggressive cross-efficiency matrix.

Following the quantitative evaluation and optimization, the final cross-efficiency scores of each DMU, calculated using the aforementioned program, are presented in Figure 12. Generally, a higher average cross–efficiency score corresponds to better performance by the evaluation unit. It is evident that the cross–efficiency score of DMU75–100 is the highest, indicating that the concrete mix with a 75% RCA replacement ratio and a 100% RFA replacement ratio exhibits superior compressive strength while minimizing environmental impact and cost. Compared to DMU75–0, the DMU75–100 specimens showed reductions in environmental loads, economic costs, and mechanical properties by 1.1%, 11%, and 16.8%, respectively. The greater reduction in economic cost contributes to the superior overall performance of DMU75–100, largely due to the lower cost of the concrete. Additionally, DMU75–0 and DMU100–60 demonstrate strong comprehensive benefits, primarily attributable to the high compressive strength of the concrete at these respective mix ratios. In contrast, the comprehensive benefit of DMU100–0 is relatively poor, which is likely due to the high economic cost, with a significant portion of this cost stemming from the high material cost of NA. Furthermore, the overall comprehensive benefits of RAC are generally superior to those of conventional concrete, suggesting that the combined use of recycled coarse and fine aggregates improves compressive strength, reduces environmental emissions and economic costs, and enhances the sustainability of CDW recycling.

Figure 12.

The ultimate cross-efficiency scores of each DMU.

According to the DEA–MCDA results, the 75–100 mix, comprising 75% RCA and 100% RFA, was identified as the optimal mix proportion. It offers significantly improved benefits in terms of mechanical properties, environmental impact, and economic cost compared to the other mixtures. This advantage is primarily attributed to the effective utilization of CDW, which reduces the consumption of natural resources, thereby significantly lowering the carbon footprint and economic costs associated with RAC.

6. Conclusions

This research aims to develop sustainable concrete by substantially replacing natural coarse and fine aggregates with recycled coarse and fine aggregates, respectively. A novel methodology of MCDA for concrete composite incorporating recycled coarse and fine aggregates was proposed. LCA and LCCA were performed to quantify the environmental and economic impacts of concrete composite incorporating recycled coarse and fine aggregates. The DEA MCDA method was employed to identify the optimal concrete mixture with superior mechanical properties and lower carbon footprint and economic cost by integrating technical, environmental and economic performance.

1. A total of 12 RAC composites comprising recycled coarse and fine aggregates were prepared. The mechanical properties in terms of compressive strength were determined and analyzed in detail. The test results show that the inclusion of RCA and RFA both reduced the compressive strength of concrete. In addition, the composite comprising RCA and RFA considerably impaired the mechanical properties.

2. By adopting the LCA method, the environmental impacts of concrete mixes with various RCAs and RFAs were quantified, analyzed and compared in the system boundary of “cradle–to–gate”. The comparison of LCA results with respect to mechanical properties was conducted. LCA results indicate that the inclusion of RCA and RFA both reduced the environmental impact. In addition, a composite comprising RCA and RFA significantly improved the environmental performance. Normalized results indicate that HTP is the smallest value, indicating that the impact of concrete production on human health is the lowest.

3. LCCA results indicate that the economic cost of RAC production is much lower than that of ordinary concrete, indicating that the substitution of natural aggregates with RCA and RFAs significantly reduced the total economic cost. Replacement of natural coarse aggregate with 100% RCAs reduced the economic cost by about 15%. Replacement of natural fine aggregate with 100% RFAs reduced the economic cost by about 11%. Moreover, sensitivity analysis results reveal that the inclusion of RCA is more sensitive to price fluctuations.

4. MCDA results indicate that the best option, considering technical performance, environmental impact, and economic cost, was the RAC composite comprising 75% RCAs and 100% RFAs, which had superior environmental performance and low economic cost. Conventional concrete was identified as the worst option in all classifications of the criteria.

By conducting LCA, LCCA and MCDA, the technical, economic and environmental benefits of incorporating RCA and RFA into concrete production were highlighted. This study specifically addressed the application of DEA MCDA to determine the optimal solution to produce sustainable concrete by integrating technical, environmental and economic performances as well as presented a new way for prioritizing materials selection, thus facilitating the sustainability of recycling of waste concrete.

Author Contributions

Conceptualization, Z.G.; methodology, H.D.; software, F.G.; L.Z.; formal analysis, Z.D.; investigation, J.W.; resources, H.D.; data curation, Q.L.; writing—original draft preparation, Y.Z. and Q.L.; writing—review and editing, L.Z.; visualization, Q.L.; supervision, Z.G.; project administration, Z.D.; funding acquisition, Z.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China grant number 52178144, Postgraduate Research & Practice Innovation Program of Jiangsu Province grant number SJCX24_0515.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are contained within the article.

Acknowledgments

We would like to thank the anonymous reviewers for their time and effort devoted to improving the quality of this research.

Conflicts of Interest

Author Yi Zheng and Qian Li was employed by the company CCCC Urban Construction (Sichuan) Co., Ltd. Author Zuiliang Deng was employed by the company Shanghai Sunrise Polymer Materials Co. Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Li, X.; Ning, S.; Zhang, P.; Yang, W. Environmental pollution and health risks of heavy metals in the soil around a construction waste landfill. Int. J. Des. Nat. Ecodyn. 2020, 15, 393–399. [Google Scholar] [CrossRef]

- Mah, C.M.; Fujiwara, T.; Ho, C.S. Life cycle assessment and life cycle costing toward eco-efficiency concrete waste management in Malaysia. J. Clean. Prod. 2018, 172, 3415–3427. [Google Scholar] [CrossRef]

- Daman, K.P.; Deepak, K.; Yasar, A. Effect of transportation of fly ash: Life cycle assessment and life cycle cost analysis of concrete. Cement Concr. Compos. 2019, 99, 214–224. [Google Scholar] [CrossRef]

- Bai, G.L.; Zhu, C.; Liu, C.; Liu, B. An evaluation of the recycled aggregate characteristics and the recycled aggregate concrete mechanical properties. Construct. Build. Mater. 2020, 240, 117978. [Google Scholar] [CrossRef]

- Lin, C.; Sun, Y.; Jiao, W.; Zheng, J.; Li, Z.; Zhang, S. Prediction of compressive strength and elastic modulus for recycled aggregate concrete based on AutoGluon. Sustainability 2023, 15, 12345. [Google Scholar] [CrossRef]

- Serres, N.; Braymand, S.; Feugeas, F. Environmental evaluation of concrete made from recycled concrete aggregate implementing life cycle assessment. J. Build. Eng. 2016, 5, 24–33. [Google Scholar] [CrossRef]

- Xing, W.; Tam, V.W.; Le, K.N.; Hao, J.L.; Wang, J. Life cycle assessment of sustainable concrete with recycled aggregate and supplementary cementitious materials. Resour. Conserv. Recycl. 2023, 193, 106947. [Google Scholar] [CrossRef]

- Guo, Z.G.; Tu, A.; Chen, C.; Lehman, D.E. Mechanical properties, durability, and life-cycle assessment of concrete building blocks incorporating recycled concrete aggregates. J. Clean. Prod. 2018, 199, 136–149. [Google Scholar] [CrossRef]

- Pavlů, T.; Kočí, V.; Hájek, P. Environmental Assessment of Two Use Cycles of Recycled Aggregate Concrete. Sustainability 2019, 11, 6185. [Google Scholar] [CrossRef]

- Younis, A.; Ebead, U.; Judd, S. Life cycle cost analysis of structural concrete using seawater, recycled concrete aggregate, and GFRP reinforcement. Construct. Build. Mater. 2018, 175, 152–160. [Google Scholar] [CrossRef]

- Han, H.S.; Golestani, B.; Park, K.; Cho, B.; Nam, B.H. Utilization of Multiple Recycled Materials in Asphalt Concrete: Mechanical Characterization and Cost–Benefit Analysis. Materials 2024, 17, 4742. [Google Scholar] [CrossRef] [PubMed]

- Silgado, S.S.; Valdiviezo, L.C.; Domingo, S.G.; Roca, X. Multi-criteria decision analysis to assess the environmental and economic performance of using recycled gypsum cement and recycled aggregate to produce concrete: The case of Catalonia (Spain). Resour. Conserv. Recycl. 2018, 133, 120–131. [Google Scholar] [CrossRef]

- Ruiz LA, L.; Ramon, X.R.; Mercedes CM, L.; Domingo, S.G. Multicriteria analysis of the environmental and economic performance of circularity strategies for concrete waste recycling in Spain. Waste Manag. 2022, 144, 387–400. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Garrido, A.J.; Navarro, I.J.; Yepes, V. Neutrosophic multi-criteria evaluation of sustainable alternatives for the structure of single-family homes. Environ. Impact Assess. Rev. 2021, 89, 106572. [Google Scholar] [CrossRef]

- Kurda, R.; Brito, J.D.; Silvestre, J.D. CONCRE Top method: Optimization of concrete with various incorporation ratios of fly ash and recycled aggregates in terms of quality performance and life-cycle cost and environmental impacts. J. Clean. Prod. 2019, 226, 642–657. [Google Scholar] [CrossRef]

- Hafez, H.; Kurda, R.; Kurda, R.; Al-Hadad, B.; Mustafa, R.; Ali, B. A Critical Review on the Influence of Fine Recycled Aggregates on Technical Performance, Environmental Impact and Cost of Concrete. Appl. Sci. 2020, 10, 1018. [Google Scholar] [CrossRef]

- Guo, Z.; Chen, C.; Lehman, D.E.; Xiao, W.; Zheng, S.; Fan, B. Mechanical and durability behaviours of concrete made with recycled coarse and fine aggregates. Eur. J. Environ. Civ. Eng. 2017, 24, 171–189. [Google Scholar] [CrossRef]

- Pallapothu SN, R.G.; Pancharathi, R.K.; Midathada, L. Integrating particle packing approach with ML techniques to optimise the compressive strength of RCA based concrete mixes. J. Build. Eng. 2024, 94, 109994. [Google Scholar] [CrossRef]

- GB/T 50081-2002; Standard for Test Method of Mechanical Properties of Ordinary Concrete. China Academy of Building Research: Beijing, China, 2002. (In Chinese)

- Chen, L.; Nouri, Y.; Allahyarsharahi, N.; Naderpour, H.; Rezazadeh Eidgahee, D.; Fakharian, P. Optimizing compressive strength prediction in eco-friendly recycled concrete via artificial intelligence models. Multiscale Multi Mod. Exp. Des. 2025, 8, 24. [Google Scholar] [CrossRef]

- Jeon, M.K.; Kim, J.; Ham, S.M.; Kim, S.; Han, A.T.; Kim, H.; Kwon, T.H. CO2 treatment of recycled concrete aggregates with high mortar contents: From finding optimal treatment condition, quality enhancement, to life cycle assessment. Construct. Build. Mater. 2024, 447, 137953. [Google Scholar] [CrossRef]

- Chen, K.; Cheng, S.; Wu, Q.; Chen, X.; Zhao, C.; Li, S.; Lu, J. Utilization of recycled fine aggregate in ultra-high performance concrete: Mechanical strength, microstructure and environment impacts. Construct. Build. Mater. 2024, 439, 137364. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, X.; Kong, L. Evaluation of carbon and economic benefits of producing recycled aggregates from construction and demolition waste. J. Clean. Prod. 2023, 425, 138946. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, W.; Wang, J.; Wang, Y.; Xu, Y.; Xiao, J. A review of life cycle assessment of recycled aggregate concrete. Construct. Build. Mater. 2019, 209, 115–125. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 1 December 2024).

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 1 December 2024).

- ISO 14041; Environmental Management—Life Cycle Assessment—Objectives and Scope Definition and Inventory Analysis. International Organization for Standardization: Geneva, Switzerland, 2006.

- Pacheco-Torgal, F.; Colangelo, F.; Tuladhar, R.; Ding, Y. (Eds.) Advances in Construction and Demolition Waste Recycling: Management, Processing and Environmental Assessment; Woodhead Publishing: Cambridge, UK, 2020. [Google Scholar]

- Balaguera, A.; Carvajal, G.I.; Albertí, J.; Fullana-i-Palmer, P. Life cycle assessment of road construction alternative materials: A literature review. Resour. Conserv. Recycl. 2018, 132, 37–48. [Google Scholar] [CrossRef]

- Gheibi, M.; Karrabi, M.; Shakerian, M.; Mirahmadi, M. Life cycle assessment of concrete production with a focus on air pollutants and the desired risk parameters using genetic algorithm. J. Environ. Health Sci. Eng. 2018, 16, 89–98. [Google Scholar] [CrossRef] [PubMed]

- CNMLCA, Material Life Cycle Assessment Database. China Centre of National Material Life Cycle Assessment (CNMLCA); Beijing University of Technology (BJUT): Beijing, China, 2010. [Google Scholar]

- CLCD, Chinese Life Cycle Database (CLCD). Integrated Knowledge for Our Environment (IKE); Sichuan University: Sichuan, China, 2012. [Google Scholar]

- ISO 14042; Environmental Management-Life Cycle Assessment–Life Cycle Assessment. International Organization for Standardization: Geneva, Switzerland, 2000.

- Illankoon, I.M.; Chethana, S.; Tam Vivian, W.Y.; Le Khoa, N.; Wang, J.Y. Life cycle costing for obtaining concrete credits in green star rating system in Australia. J. Clean. Prod. 2018, 172, 4212–4219. [Google Scholar] [CrossRef]

- Balf, F.R.; Kordkheili, M.H.; Kordkheili, A.M. A New Method for Predicting the Ingredients of Self-Compacting Concrete (SCC) Including Fly Ash (FA) Using Data Envelopment Analysis (DEA). Arab. J. Sci. Eng. 2020, 46, 4439–4460. [Google Scholar] [CrossRef]

- Sexton, T.R.; Silkman, R.H.; Hogan, A.J. Data envelopment analysis: Critique and extensions. New Directions for Program Evaluation: 1986; pp. 73–105. [CrossRef]

- Doyle, J.; Green, R. Deficiency and cross-effificiency in DEA: Derivations, meanings and uses. J. Oper. Res. Soc. 1994, 45, 567–578. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; Brito, J. Life cycle assessment of concrete made with high volume of recycled concrete aggregates and fly ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Kleijer, A.L.; Lasvaux, S.; Citherlet, S.; Viviani, M. Product-specific Life Cycle Assessment of ready mix concrete: Comparison between a recycled and an ordinary concrete. Resour. Conserv. Recycl. 2017, 122, 210–218. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).