Current State of Chemical Recycling of Plastic Waste: A Focus on the Italian Experience

Abstract

1. Introduction

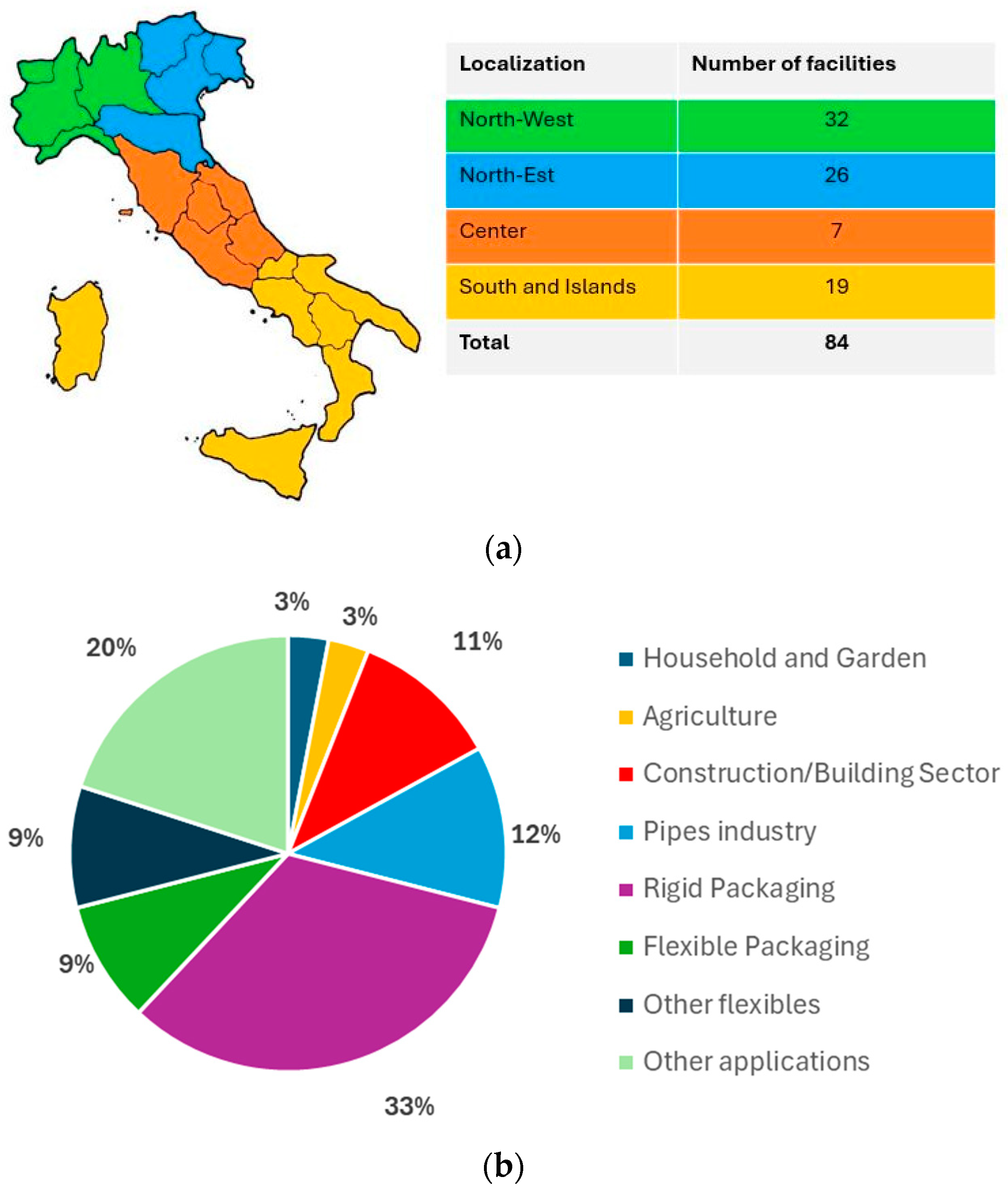

2. Mechanical Recycling

3. Chemical Recycling

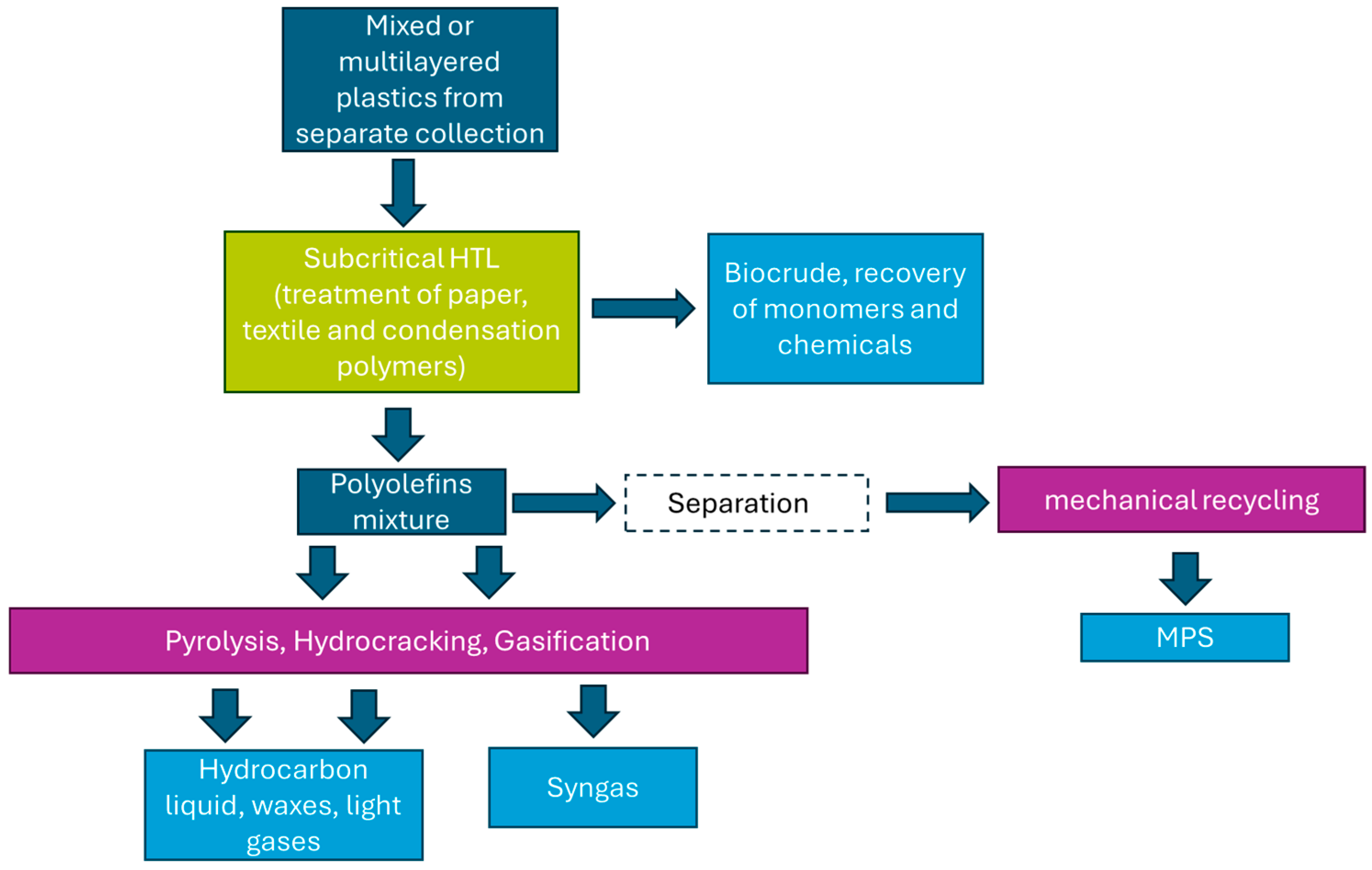

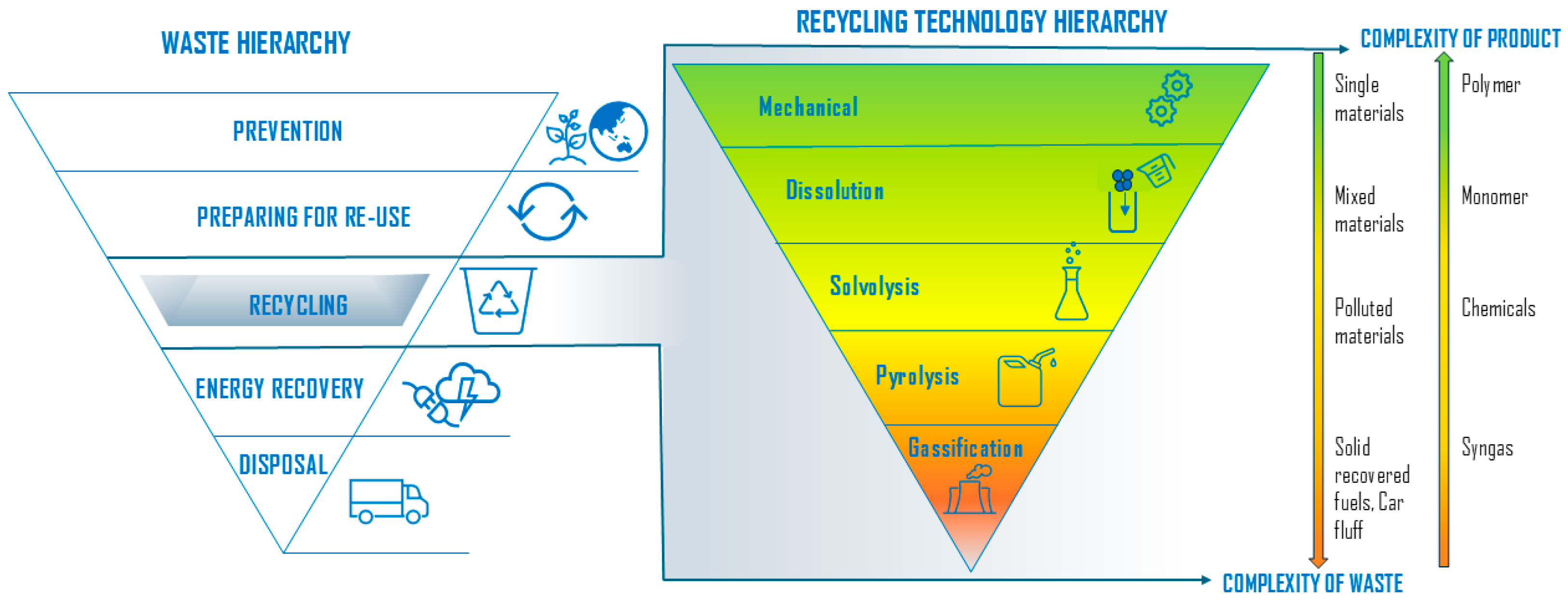

3.1. Overview

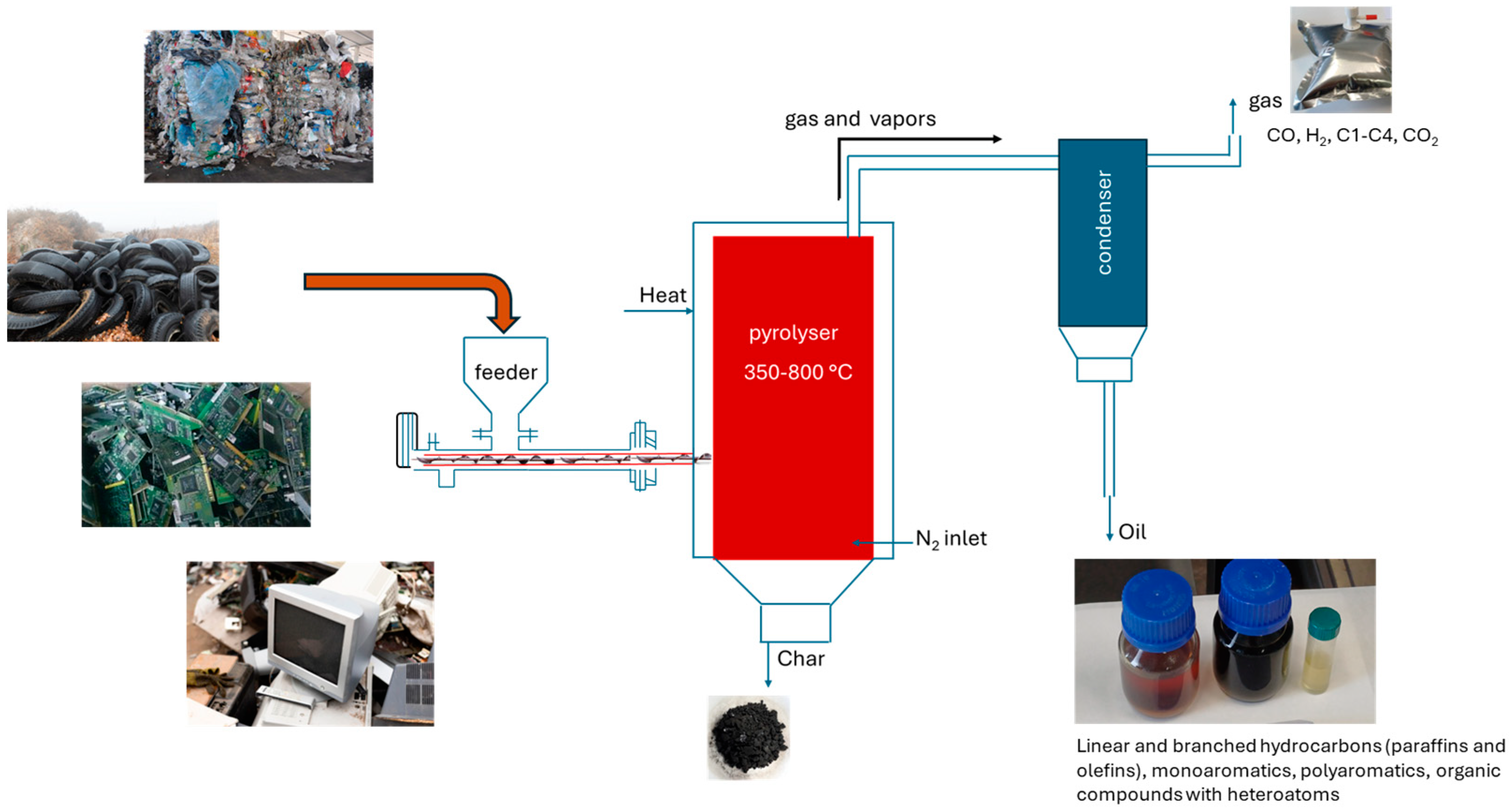

3.2. Focus on Pyrolysis

3.3. Present Situation of European Chemical Recycling

3.4. Solutions, Strategies, and Policies for the Scale-Up of Chemical Recycling Technologies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABS | acrylonitrile butadiene styrene |

| ASSORIMAP | (Italian) National Association of Recyclers and Regenerators of Plastic Materials |

| BAT | best available technology |

| BDM | Benzenedimethanol |

| BG | butyl glycol |

| BPA | bisphenol A |

| BTEX | benzene, toluene, ethylene, and xylene |

| BHET | bis(2-hydroxyethyl) terephthalate |

| BFR | brominated flame retardant |

| CA | crotonic acid |

| CEFIC | European Chemical Industry Council |

| COREPLA | (Italian) National Consortium for the Collection and Recycling of Plastic packages |

| DMT | dimethyl ester of terephthalic acid |

| EEE | electric and electronic equipment |

| EG | ethylene glycol |

| ELV | end-of-life vehicles |

| EoL | end of life |

| EoW | end of waste |

| EPS | expanded polystyrene |

| EVOH | ethylene vinyl alcohol |

| GHG | greenhouse gas |

| HTL | hydrothermal liquefaction |

| JRC | Joint Research Centre |

| HCl | hydrogen chloride |

| MDA | methylene diphenyl diamine |

| MEG | mono-ethylene-glycol |

| MMA | methyl methacrylate |

| MPO | mixed polyolefins |

| MRFs | mechanical recovery facilities |

| PA, PA6, PA66, PA12 | polyamide, polyamide 6, polyamide 66, polyamide 12 |

| PBT | polybutylene terephthalate |

| PHB | poly(3-hydroxybutyrate) |

| PC | polycarbonate |

| PC + ABS | polycarbonate/acrylonitrile butadiene styrene blend |

| PAH | poly aromatic hydrocarbons |

| PE, LDPE, HDPE | polyethylene, low-density polyethylene, high-density polyethylene |

| PET | polyethylene terephthalate |

| PIP | polyisoprene |

| PLA | poly lactic acid |

| PMMA | polymethylmethacrylate (acrylic) |

| PP | polypropylene |

| PS | polystyrene |

| PTMT | polytetramethylene terephthalate |

| PU | polyurethane |

| PUs | polyurethanes |

| PVC | polyvinyl chloride |

| REACH | Registration, Evaluation, Authorisation and Restriction of Chemicals |

| SRA | secondary reduce agent |

| SRM | secondary raw materials |

| TAM | terephthalamide |

| TDA | 2,4- and 2,6-toluenediamine |

| TPA | terephthalic acid |

| XPS | expanded extruded polystyrene |

| WEEE | waste electrical and electronic equipment |

References

- Plastics Europe. Plasticsthefastfacts2023-1. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-fast-facts-2023/ (accessed on 12 April 2024).

- OECD. Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options; OECD Publishing: Paris, France, 2022. [Google Scholar] [CrossRef]

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Change 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Handbook of Recycling, State-Of-the-art for Practitioners, Analysts, and Scientists, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 723–738. [CrossRef]

- The Circular Economy for Plastics A European Analysis. 2024. Available online: https://plasticseurope.org/knowledge-hub/the-circular-economy-for-plastics-a-european-analysis-2024/ (accessed on 9 December 2024).

- Directive (EU) 2018/852 of the European Parliament and of the Council of 30 May 2018 Amending Directive 94/62/EC on Packaging and Packaging Waste (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/eli/dir/2018/852/oj/eng (accessed on 9 December 2024).

- CPA Roadmap to 10 Mt—Untapped Potential Report. Available online: https://ec.europa.eu/docsroom/documents/46956 (accessed on 9 December 2024).

- Commission Implementing Decision (EU) 2019/665—Of 17 April 2019—Amending Decision 2005/270/EC Establishing the Formats Relating to the Database System Pursuant to European Parliament and Council Directive 94/62/EC on Packaging and Packaging Waste—(Notified Under Document C(2019) 2805). Available online: https://eur-lex.europa.eu/eli/dec_impl/2019/665/oj/eng (accessed on 9 December 2024).

- ISPRA. Rapporto Rifiuti Urbani n. 380. 2022; ISBN 978-88-448-1145-7. Available online: https://www.isprambiente.gov.it/it/pubblicazioni/rapporti/rapporto-rifiuti-urbani-edizione-2022 (accessed on 9 December 2024).

- ISPRA. Rapporto Rifiuti Urbani n. 393. 2023; ISBN 978-88-448-1200-3. Available online: https://www.isprambiente.gov.it/it/pubblicazioni/rapporti/rapporto-rifiuti-urbani-edizione-2023 (accessed on 9 December 2024).

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/eli/dir/2008/98/oj/eng (accessed on 9 December 2024).

- Squitieri, G.; Cancelli, D.; Leoni, S.; Galli, L.; Cipriano, V.; Pacilli, A.; Di Mario, V. (Edited by Edo Ronchi) IL Riciclo in Italia|Rapporto. 2023. Available online: https://www.ricicloinitalia.it/il-rapporto-2023/ (accessed on 9 December 2024).

- A European Strategy for Plastics in a Circular Economy. Available online: https://www.europarc.org/wp-content/uploads/2018/01/Eu-plastics-strategy-brochure.pdf (accessed on 9 December 2024).

- European Commission. Commitments and Deliverables of the Circular Plastics Alliance. Available online: https://single-market-economy.ec.europa.eu/industry/industrial-alliances/circular-plastics-alliance/commitments-and-deliverables-circular-plastics-alliance_en (accessed on 7 October 2024).

- Maris, J.; Bourdon, S.; Brossard, J.M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical recycling: Compatibilization of mixed thermoplastic wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- U.S. Food & Drug Administration. Use of Recycled Plastics in Food Packaging (Chemistry Considerations): Guidance for Industry. Available online: https://www.fda.gov/FoodGuidances (accessed on 9 December 2024).

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Paletta, A.; Filho, W.L.; Balogun, A.-L.; Foschi, E.; Bonoli, A. Barriers and challenges to plastics valorisation in the context of a circular economy: Case studies from Italy. J. Clean. Prod. 2019, 241, 118149. [Google Scholar] [CrossRef]

- Malik, N.; Kumar, P.; Shrivastava, S.; Ghosh, S.B. An overview on PET waste recycling for application in packaging. Int. J. Plast. Technol. 2017, 21, 1–24. [Google Scholar] [CrossRef]

- Plastics Recyclers Europe. Plastics Recycling Industry Figures. 2022. Available online: https://www.plasticsrecyclers.eu/publications/ (accessed on 3 September 2024).

- ASSORIMAP. Il Riciclo Meccanico Delle Materie Plastiche REPORT 2023. 2024. Available online: www.plasticconsult.it (accessed on 9 December 2024).

- Plastic Finder. Available online: https://www.plasticfinder.it/web/guest (accessed on 4 September 2024).

- UNI Ente Italiano di Normazione. UNI 10667-1:2010 Plastic Raw-Secondary Materials—Part 1: General. 2010. Available online: https://www.intertekinform.com/en-gb/standards/uni-10667-1-2010-1075509_saig_uni_uni_2506092/?srsltid=AfmBOoqfxN4IoyjkrCkEL4-gIGDwRsXCYgoBs65MWlRuMVV2KZtdF_WU (accessed on 15 January 2025).

- Gazzotti, S.; De Felice, B.; Ortenzi, M.A.; Parolini, M. Approaches for Management and Valorization of Non-Homogeneous, Non-Recyclable Plastic Waste. Int. J. Environ. Res. Public Health 2022, 19, 10088. [Google Scholar] [CrossRef]

- Genuino, H.C.; Ruiz, M.P.; Heeres, H.J.; Kersten, S.R.A. Pyrolysis of mixed plastic waste (DKR-350): Effect of washing pre-treatment and fate of chlorine. Fuel Process. Technol. 2022, 233, 107304. [Google Scholar] [CrossRef]

- Corepla. Relazione sulla gestione. 2023. Available online: https://www.corepla.it/wp-content/uploads/2024/06/relazione_sulla_gestione_2023_corepla.pdf (accessed on 9 December 2024).

- Colantonio, S.; Cafiero, L.; De Angelis, D.; Ippolito, N.M.; Tuffi, R.; Ciprioti, S.V. Thermal and catalytic pyrolysis of a synthetic mixture representative of packaging plastics residue. Front. Chem. Sci. Eng. 2020, 14, 288–303. [Google Scholar] [CrossRef]

- Senato della Repubblica Italiana, DDL S. 635. 2022. Available online: https://parlamento18.openpolis.it/atto/documento/id/180879 (accessed on 9 December 2024).

- Virginia Racioppi, A.G. Studio di Fattibilità nell’ambito dell’Economia Circolare Mirato al Riciclo Delle Plastiche Miste. Available online: https://www.mimit.gov.it/images/stories/documenti/allegati/coop/SF_Riciclo_PlasticheMiste.pdf (accessed on 10 October 2024).

- EcoRevive. Applicazioni EcoRevive. Available online: https://www.ecorevive.world/blog (accessed on 21 August 2024).

- iblu. Prodotti. Available online: https://www.iblu.it/it/prodotti.html (accessed on 21 August 2024).

- Corepla. Iren Rileva I.Blu e Diventa Leader nel Trattamento Della Plastica. Available online: https://www.corepla.it/news/iren-rileva-iblu-e-diventa-leader-nel-trattamento-della-plastica (accessed on 10 October 2024).

- Il Sole 24 Ore. Acciaio: La Plastica Rimpiazza il Carbone. Available online: https://seitoscana.it/parlano-di-noi/14102021-acciaio-la-plastica-rimpiazza-carbone (accessed on 10 October 2024).

- Fiore, E.; Tamborrini, P. PHOENIX: Towards a circular economy of plasmix waste—A systemic design approach. Circ. Econ. 2024, 3, 100075. [Google Scholar] [CrossRef]

- Harscoet, E.; Chouvenc, S.; Faugeras, A.-C.; Ammenti-Deloitte, F. Chemical and Physico-Chemical Recycling of Plastic Waste Final Report. 2022. Available online: www.record-net.org (accessed on 9 December 2024).

- Closed Loop Partners. Accelerating Circular Supply Chains for Plastics; Closed Loop Partners: New York, NY, USA, 2019; Available online: https://www.closedlooppartners.com/ (accessed on 12 April 2024).

- Handbook of Recycling; Elsevier: Amsterdam, The Netherlands, 2014; pp. 563–581. [CrossRef]

- Cafiero, L.; Fabbri, D.; Trinca, E.; Tuffi, R.; Ciprioti, S.V. Thermal and spectroscopic (TG/DSC–FTIR) characterization of mixed plastics for materials and energy recovery under pyrolytic conditions. J. Therm. Anal. Calorim 2015, 121, 1111–1119. [Google Scholar] [CrossRef]

- Roy, P.S.; Garnier, G.; Allais, F.; Saito, K. Strategic Approach Towards Plastic Waste Valorization: Challenges and Promising Chemical Upcycling Possibilities. ChemSusChem 2021, 14, 4007–4027. [Google Scholar] [CrossRef] [PubMed]

- Bozkurt, O.D.; Okonsky, S.T.; Alexopoulos, K.; Toraman, H.E. Catalytic conversion of SPW and products upgrading. Adv. Chem. Eng. 2022, 60, 117–168. [Google Scholar] [CrossRef]

- Li, H.; Aguirre-Villegas, H.A.; Allen, R.D.; Bai, X.; Benson, C.H.; Beckham, G.T.; Bradshaw, S.L.; Brown, J.L.; Brown, R.C.; Cecon, V.S.; et al. Expanding plastics recycling technologies: Chemical aspects, technology status and challenges. Green Chem. 2022, 24, 8899–9002. [Google Scholar] [CrossRef]

- PlasticsEurope. Plastics Convert Iron ore to Steel Feedstock Recycling in Blast Furnaces. Available online: https://legacy.plasticseurope.org/download_file/force/1108/181 (accessed on 9 December 2024).

- Mirabile, D.; Pistelli, M.I.; Marchesini, M.; Falciani, R.; Chiappelli, L. Thermal valorisation of automobile shredder residue: Injection in blast furnace. Waste Manag. 2002, 22, 841–851. [Google Scholar] [CrossRef] [PubMed]

- Lotfian, S.; Vikström, T.; Lennartsson, A.; Björkman, B.; Ahmed, H.; Samuelsson, C. Plastic-containing materials as alternative reductants for base metal production. Can. Metall. Q. 2019, 58, 164–176. [Google Scholar] [CrossRef]

- Caro, D.; Albizzati, P.F.; Cristóbal Garcia, J.; Saputra Lase, I.; Garcia-Gutierrez, P.; Juchtmans, R.; Garbarino, E.; Blengini, G.; Manfredi, S.; De Meester, S.; et al. Towards a Better Definition and Calculation of Recycling. In JRC Science for Policy Report; Publications Office of the European Union: Luxembourg, 2023; Available online: https://data.europa.eu/doi/10.2760/636900 (accessed on 9 December 2024).

- Devasahayam, S.; Raju, G.B.; Hussain, C.M. Utilization and recycling of end-of-life plastics for sustainable and clean industrial processes including the iron and steel industry. Mater. Sci. Energy Technol. 2019, 2, 634–646. [Google Scholar] [CrossRef]

- Munir, D.; Irfan, M.F.; Usman, M.R. Hydrocracking of virgin and waste plastics: A detailed review. Renew. Sustain. Energy Rev. 2018, 90, 490–515. [Google Scholar] [CrossRef]

- Vidal, F.; van der Marel, E.R.; Kerr, R.W.; McElroy, C.; Schroeder, N.; Mitchell, C.; Rosetto, G.; Chen, T.T.; Bailey, R.M.; Hepburn, C.; et al. Designing a circular carbon and plastics economy for a sustainable future. Nature 2024, 626, 7997. [Google Scholar] [CrossRef] [PubMed]

- Arena, U.; Ardolino, F. Technical and environmental performances of alternative treatments for challenging plastics waste. Resour. Conserv. Recycl. 2022, 183, 106379. [Google Scholar] [CrossRef]

- Castagnoli, A.; Salem, A.M.; Desideri, U.; Pecorini, I. Environmental assessment of gasification and green hydrogen potential role in waste management decarbonization. J. Clean. Prod. 2024, 482, 144174. [Google Scholar] [CrossRef]

- Gutierrez, G.; Amadei, P.; Klenert, A.M.; Nessi; Tonini, S. Environmental and economic assessment of plastic waste recycling. In JRC Technical Report; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, J.; Jin, H.; Guo, L. Chemical recycling methods for managing waste plastics: A review. Environ. Chem. Lett. 2024, 22, 149–169. [Google Scholar] [CrossRef]

- Krause, L.; Özgen, A.; Kern, J.; Das, S.; Carus, M.; Raschka, A. Mapping of Advanced Plastic Waste Recycling Technologies and Their Global Capacities-Short Version. 2024. Available online: https://renewable-carbon.eu/publications/product/mapping-of-advanced-plastic-waste-recycling-technologies-and-their-global-capacities-short-version-pdf/ (accessed on 9 December 2024).

- Moussa, K.; Awad, S.; Krawczak, P.; Al Takash, A.; Faraj, J.; Khaled, M. An Overview of the Non-Energetic Valorization Possibilities of Plastic Waste via Thermochemical Processes. Materials 2024, 17, 1460. [Google Scholar] [CrossRef]

- Scheirs, J.; Kaminsky, W. Feedstock Recycling and Pyrolysis of Waste Plastics: Converting Waste Plastics into Diesel and Other Fuels; John Wiley & Sons Ltd.: Chichester, UK, 2006. [Google Scholar] [CrossRef]

- Martínez-Narro, G.; Hassan, S.; Phan, A.N. Chemical recycling of plastic waste for sustainable polymer manufacturing—A critical review. J. Environ. Chem. Eng. 2024, 12, 112323. [Google Scholar] [CrossRef]

- Ahmad, I.; Khan, M.I.; Khan, H.; Ishaq, M.; Tariq, R.; Gul, K.; Ahmad, W. Pyrolysis Study of Polypropylene and Polyethylene Into Premium Oil Products. Int. J. Green Energy 2015, 12, 663–671. [Google Scholar] [CrossRef]

- Aguado, J.; Serrano, D.P.; Escola, J.M. Catalytic Upgrading of Plastic Wastes. In Feedstock Recycling and Pyrolysis of Waste Plastics; John Wiley & Sons Ltd.: Chichester, UK, 2006; pp. 73–110. [Google Scholar] [CrossRef]

- Calero, M.; Solís, R.R.; Muñoz-Batista, M.J.; Pérez, A.; Blázquez, G.; Martín-Lara, M.Á. Oil and gas production from the pyrolytic transformation of recycled plastic waste: An integral study by polymer families. Chem. Eng. Sci. 2023, 271, 118569. [Google Scholar] [CrossRef]

- Esposito, L.; Cafiero, L.; De Angelis, D.; Tuffi, R.; Ciprioti, S.V. Valorization of the plastic residue from a WEEE treatment plant by pyrolysis. Waste Manag. 2020, 112, 1–10. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, Y.; Ke, L.; Dai, L.; Wu, Q.; Cobb, K.; Zeng, Y.; Zou, R.; Liu, Y.; Ruan, R. A review on catalytic pyrolysis of plastic wastes to high-value products. Energy Convers Manag 2022, 254, 115243. [Google Scholar] [CrossRef]

- Artetxe, M.; Lopez, G.; Amutio, M.; Elordi, G.; Olazar, M.; Bilbao, J. Operating Conditions for the Pyrolysis of Poly-(ethylene terephthalate) in a Conical Spouted-Bed Reactor. Ind. Eng. Chem. Res. 2010, 49, 2064–2069. [Google Scholar] [CrossRef]

- Wan, H.; Huang, Z. Pyrolysis Evaluation of Tennis String Polyurethane and Water-Borne Polyurethane Wastes through Isoconversional Kinetic Analysis. Polymers 2022, 14, 1501. [Google Scholar] [CrossRef] [PubMed]

- Garrido, M.A.; Font, R. Pyrolysis and combustion study of flexible polyurethane foam. J. Anal. Appl. Pyrolysis 2015, 113, 202–215. [Google Scholar] [CrossRef]

- Takamoto, D.Y.; Petrich, M.A. Effect of Heterogeneous Secondary Pyrolysis Reactions on the Thermal Decomposition of Polyurethane Scrap. Ind. Eng. Chem. Res. 1994, 33, 3004–3009. [Google Scholar] [CrossRef]

- Qureshi, M.S.; Oasmaa, A.; Pihkola, H.; Deviatkin, I.; Tenhunen, A.; Mannila, J.; Minkkinen, H.; Pohjakallio, M.; Laine-Ylijoki, J. Pyrolysis of plastic waste: Opportunities and challenges. J. Anal. Appl. Pyrolysis 2020, 152, 104804. [Google Scholar] [CrossRef]

- Nyam, T.T.; Ayeleru, O.O.; Ramatsa, I.M.; Olubambi, P.A. Conversion of Waste Plastics into Value-added Materials: A Global Perspective. In Plastic Waste Management; Wiley-VCH GmbH: Weinheim, Germany, 2024; pp. 227–258. [Google Scholar] [CrossRef]

- Stefano, L.S.; Cafiero, L.; De Angelis, D.; Pavoni, S.; Tuffi, R.; Scarsella, M. Thermal pyrolysis of a real plastic sample from small WEEE and characterization of the produced oil in view of fuel or feedstock uses. Therm. Sci. Eng. Prog. 2024, 48, 102403. [Google Scholar] [CrossRef]

- Papari, S.; Bamdad, H.; Berruti, F. Pyrolytic Conversion of Plastic Waste to Value-Added Products and Fuels: A Review. Materials 2021, 14, 2586. [Google Scholar] [CrossRef] [PubMed]

- Hussin, F.; Aroua, M.K.; Kassim, M.A.; Ali, U.F.M. Transforming plastic waste into porous carbon for capturing carbon dioxide: A review. Energies 2021, 14, 8421. [Google Scholar] [CrossRef]

- Cocchi, M.; Cafiero, L.; De Angelis, D.; Falasconi, M.B.; Piemonte, V.; Tuffi, R.; Ciprioti, S.V. Conversion of Marine Plastic Litter into Chemicals and Fuels through Catalytic Pyrolysis Using Commercial and Coal Fly Ash-Synthesized Zeolites. ACS Sustain. Chem. Eng. 2023, 11, 3644–3656. [Google Scholar] [CrossRef]

- Cocchi, M.; De Angelis, D.; Mazzeo, L.; Nardozi, P.; Piemonte, V.; Tuffi, R.; Ciprioti, S.V. Catalytic pyrolysis of a residual plastic waste using zeolites produced by coal fly ash. Catalysts 2020, 10, 1113. [Google Scholar] [CrossRef]

- Benedetti, M.; Cafiero, L.; De Angelis, D.; Dell’Era, A.; Pasquali, M.; Stendardo, S.; Tuffi, R.; Ciprioti, S.V. Pyrolysis of WEEE plastics using catalysts produced from fly ash of coal gasification. Front. Environ. Sci. Eng. 2017, 11, 11. [Google Scholar] [CrossRef]

- Eldahshory, A.I.; Emara, K.; Abd-Elhady, M.S.; Ismail, M.A. Catalytic pyrolysis of waste polypropylene using low-cost natural catalysts. Sci. Rep. 2023, 13, 11766. [Google Scholar] [CrossRef]

- An, L.; Kou, Z.; Li, R.; Zhao, Z. Research Progress in Fuel Oil Production by Catalytic Pyrolysis Technologies of Waste Plastics. Catalysts 2024, 14, 212. [Google Scholar] [CrossRef]

- EU. CELEX_32006R1907_EN_TXT—REACH. 2006. Available online: https://eur-lex.europa.eu/eli/reg/2006/1907/oj/eng (accessed on 9 December 2024).

- Dogu, O.; Pelucchi, M.; Van de Vijver, R.; Van Steenberge, P.H.; D’Hooge, D.R.; Cuoci, A.; Mehl, M.; Frassoldati, A.; Faravelli, T.; Van Geem, K.M. The chemistry of chemical recycling of solid plastic waste via pyrolysis and gasification: State-of-the-art, challenges, and future directions. Prog. Energy Combust. Sci. 2021, 84, 100901. [Google Scholar] [CrossRef]

- Dai, L.; Zhou, N.; Lv, Y.; Cheng, Y.; Wang, Y.; Liu, Y.; Cobb, K.; Chen, P.; Lei, H.; Ruan, R. Pyrolysis technology for plastic waste recycling: A state-of-the-art review. Prog. Energy Combust. Sci. 2022, 93, 101021. [Google Scholar] [CrossRef]

- Kodera, Y.; Yamamoto, T.; Ishikawa, E. Energy-and economic-balance estimation of pyrolysis plant for fuel-gas production from plastic waste based on bench-scale plant operations. Fuel Commun. 2021, 7, 16. [Google Scholar] [CrossRef]

- Plastic Europe. Plastic Europe Chemical Recycling. Available online: https://plasticseurope.org/sustainability/circularity/recycling/chemical-recycling/ (accessed on 12 April 2024).

- Quantafuel. Quantafuels Plants & Projects. Available online: https://www.quantafuel.com/search?q=Quantafuels+Plants# (accessed on 12 April 2024).

- BASF. BASF ChemCycling. Available online: https://www.basf.com/global/en/who-we-are/sustainability/we-drive-sustainable-solutions/circular-economy/mass-balance-approach/chemcycling.html (accessed on 12 April 2024).

- Plastic Energy. Plastic Energy Projects. Available online: https://plasticenergy.com/projects/ (accessed on 12 April 2024).

- Polimerica. Parte Impianto di Pirolisi a Rotterdam. Available online: https://www.polimerica.it/articolo.asp?id=31171 (accessed on 3 December 2024).

- ENI Versalis. ENI Hoop. Available online: https://www.eni.com/en-IT/media/press-release/2023/10/pr-versalis-mantua-hoop-31-10-2023.html (accessed on 12 April 2024).

- The European House Ambrosetti. La Circolarità della Plastica—Opportunità Industriali, Innovazione e Ricadute Economico-Occupazionali per l’Italia. 2022. Available online: https://www.ambrosetti.eu/site/get-media/?type=doc&id=16458&doc_player=1 (accessed on 9 December 2024).

- Plast Magazine. LyondellBasell, Impianto di Riciclo con Tecnologia MoReTec in Germania. Available online: https://www.plastmagazine.it/lyondellbasell-impianto-di-riciclo-chimico-con-tecnologia-moretec-in-germania/ (accessed on 4 June 2024).

- Polimerica. NextChem si Rafforza nel Riciclo Chimico. Available online: https://www.polimerica.it/articolo.asp?id=29722 (accessed on 6 December 2024).

- Enerkem. Enerkem Ecoplanta. Available online: https://enerkem.com/projects/ecoplanta (accessed on 12 April 2024).

- SUEZ. Infinite Loop Technologies. Available online: https://www.suez.com/en/news/press-releases/selection-saint-avold-grand-est-region-france-site-infinite-loop-technology (accessed on 12 April 2024).

- Hydrocarbon Technologies. Technip Announces Successful Launch of Carbios Industrial Demonstration Plant. Available online: https://www.hydrocarbonprocessing.com/news/2021/11/technip-announces-successful-launch-of-carbios-industrial-demonstration-plant (accessed on 26 April 2024).

- petnology.com. GR3N Launches Industrial Demonstration Plant for its Microwave Assisted DEpolymerization (MADE) Recycling Technology. Available online: https://www.petnology.com/online/news-detail/gr3n-launches-industrial-demonstration-plant-for-its-microwave-assisted-depolymerization-made-recycling-technology (accessed on 26 April 2024).

- Saipem. Saipem e Garbo Insieme per lo Sviluppo di una Nuova Tecnologia per il Riciclo Delle Plastiche. Available online: https://www.saipem.com/it/media/comunicati-stampa/2023-03-15/saipem-e-garbo-insieme-lo-sviluppo-di-una-nuova-tecnologia-il (accessed on 26 April 2024).

- Zheng, L.; Wang, M.; Li, Y.; Xiong, Y.; Wu, C. Recycling and Degradation of Polyamides. Molecules 2024, 29, 1742. [Google Scholar] [CrossRef] [PubMed]

- Plasteurope.com. RETOURMATRAS. Available online: https://www.plasteurope.com/news/RETOURMATRAS_t254622/ (accessed on 26 August 2024).

- Creasolv. CreaSolv® Demonstration Plant for Research and Industry Partners. Available online: https://www.creasolv.de/en/plants-projects/loemi-creasolv-demonstration-plant.html (accessed on 26 April 2024).

- CreaSolv. CreaCycle GmbH. Available online: https://www.creasolv.de/en/our-partners/creacycle-gmbh.html (accessed on 26 April 2024).

- Bioplastics Magazine. APK New Large-Scale Newcycling Plant Will Start Construction in 2024. Available online: https://www.bioplasticsmagazine.com/en/news/meldungen/20231219-apk.php (accessed on 26 April 2024).

- Mura Tecnology. SCALING WORLDWIDE. Available online: https://muratechnology.com/global-development/ (accessed on 26 April 2024).

- The European Chemical Industry Council. Position paper on Chemical Recycling. 2022. Available online: https://cefic.org/app/uploads/2022/04/Cefic-position-paper-on-Chemical-Recycling.pdf (accessed on 9 December 2024).

- Zero Waste Europe. Recycled Content in Plastics. 2021. Available online: https://zerowasteeurope.eu/wp-content/uploads/2021/05/rpa_2021_mass_balance_booklet-2.pdf (accessed on 4 June 2024).

- The European Chemical Industry Council. Chemical Recycling: Greenhouse Gas Emission Reduction Potential of an Emerging Waste Management Route. 2020. Available online: https://cefic.org/app/uploads/2020/12/CEFIC_Quantis_report_final.pdf (accessed on 9 December 2024).

- OMV Group. ReOil: Getting Crude Oil Back out of Plastic. Available online: https://www.omv.com/en (accessed on 27 August 2024).

- Rizos, V.; Urban, P.; Righetti, E.; Kassab, A. Chemical Recycling of Plastics. Technologies, Trends and Policy Implications. Ceps In-Depth Analysis. 2023. Available online: https://www.ceps.eu/download/publication/?id=40124&pdf=CEPS-In-depth-analysis-2023-11_Chemical-recycling-of-plastics.pdf (accessed on 9 December 2024).

- European Commission. Plastics in a Circular Economy. Available online: https://research-and-innovation.ec.europa.eu/research-area/environment/circular-economy/plastics-circular-economy_en (accessed on 10 January 2024).

- Ministero Dell’ambiente e Della Sicurezza Energetica. Investimento 1.2: Progetti ‘Faro’ di Economia Circolare. Available online: https://www.mase.gov.it/pagina/investimento-1-2-progetti-faro-di-economia-circolare-0 (accessed on 29 August 2024).

| Chemical | Thermo-Chemical Processes | |||||

|---|---|---|---|---|---|---|

| Sub-Categories | Solvent/Reagent | Range of Application | Sub-Categories | Operating Conditions | Range of Application | |

| Glycolysis | EG | Limited | Pyrolysis | 400–900 °C, inert atmosphere | Wide | |

| Methanolysis | Methanol | Limited | Gasification | 700–1700 °C, partial oxidative atmosphere | Very wide | |

| Aminolysis | Amine solution | Limited | Hydrocracking | 300–500 °C, 30–100 bar | Wide | |

| Hydrolysis | Acid | H2SO4, H3PO4, HCl, etc. | Limited | Liquefaction * | Subcritical water: 200–300 °C and 10–40 bar | Medium |

| Basic | NaOH, KOH, etc. | |||||

| Enzymatic | Enzymes | Wide | ||||

| Supercritical water: T > 378 °C, P > 220 bar | ||||||

| Ammonolysis | Ammonia solution | Limited | ||||

| Resin | Major Origin of Waste | More Suitable Processes and Main Products | Less or Not Suitable Processes | |

|---|---|---|---|---|

| Processes | Products | |||

| Mixed plastics | Multilayered plastics, residue of plastic selection (e.g., packaging) | Gasification | Syngas | Solvolysis |

| Pyrolysis | Crude oil | |||

| PE, PP, and MPO | Household, industrial plastic packaging, agricultural plastics, residue of plastic packaging selection, and automotive | Gasification | Syngas | Solvolysis, HTL |

| Pyrolysis | Hydrocarbon liquid, waxes, light gases | |||

| Hydrocracking | Liquid alkanes, light gases, and lubricants | |||

| Styrene-based polymers (e.g., PS, ABS, HIPS, SAN, and their mixtures) | WEEE, household and industrial plastic packaging, construction, and demolition | Pyrolysis | Styrene, styrene oligomers, BTEX, and PAH | Solvolysis |

| Hydrocracking | Monoaromatics | |||

| PET | Household plastic packaging | Hydrolysis | EG and TPA | Pyrolysis |

| Alcoholysis | DMT and EG | |||

| Glycolysis | BHET and EG | |||

| Aminolysis | TAM and EG | |||

| Hydrogenolysis | BDM and EG | |||

| Biocatalysis | BHET, EG, and TPA | |||

| PA6 | Automotive, textile waste, and WEEE | Hydrolysis, basic or acid | ε-Caprolactam, hexamethylene diamine | Pyrolysis |

| HTL | ε-Caprolactam | |||

| PC | WEEE | Hydrolysis, basic or acid | BPA | Pyrolysis |

| HTL | BPA, phenols | |||

| PIP | Medical, healthcare, and sport equipment | Hydrocracking | Oil with low content of olefins, aromatics, and coke | Solvolysis |

| PMMA | Automotive, construction, and demolition, WEEE | Pyrolysis | MMA | - |

| Hydrolysis | MMA | |||

| HTL | MMA | |||

| PU | Construction, demolition, and automotive | Solvolysis | Di-isocyanate, polyols | Pyrolysis |

| PVC * | Construction plastic waste | Hydrocracking | HCl, liquid fuel | Solvolysis |

| Pyrolysis, after a dechlorination step | HCl, aromatics | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cafiero, L.M.; De Angelis, D.; Tuccinardi, L.; Tuffi, R. Current State of Chemical Recycling of Plastic Waste: A Focus on the Italian Experience. Sustainability 2025, 17, 1293. https://doi.org/10.3390/su17031293

Cafiero LM, De Angelis D, Tuccinardi L, Tuffi R. Current State of Chemical Recycling of Plastic Waste: A Focus on the Italian Experience. Sustainability. 2025; 17(3):1293. https://doi.org/10.3390/su17031293

Chicago/Turabian StyleCafiero, Lorenzo Maria, Doina De Angelis, Letizia Tuccinardi, and Riccardo Tuffi. 2025. "Current State of Chemical Recycling of Plastic Waste: A Focus on the Italian Experience" Sustainability 17, no. 3: 1293. https://doi.org/10.3390/su17031293

APA StyleCafiero, L. M., De Angelis, D., Tuccinardi, L., & Tuffi, R. (2025). Current State of Chemical Recycling of Plastic Waste: A Focus on the Italian Experience. Sustainability, 17(3), 1293. https://doi.org/10.3390/su17031293