Unlocking Sustainability Transitions in Construction Materials in Europe: A Multi-Level Perspective on the Adoption of Rice Straw Ash

Abstract

1. Introduction

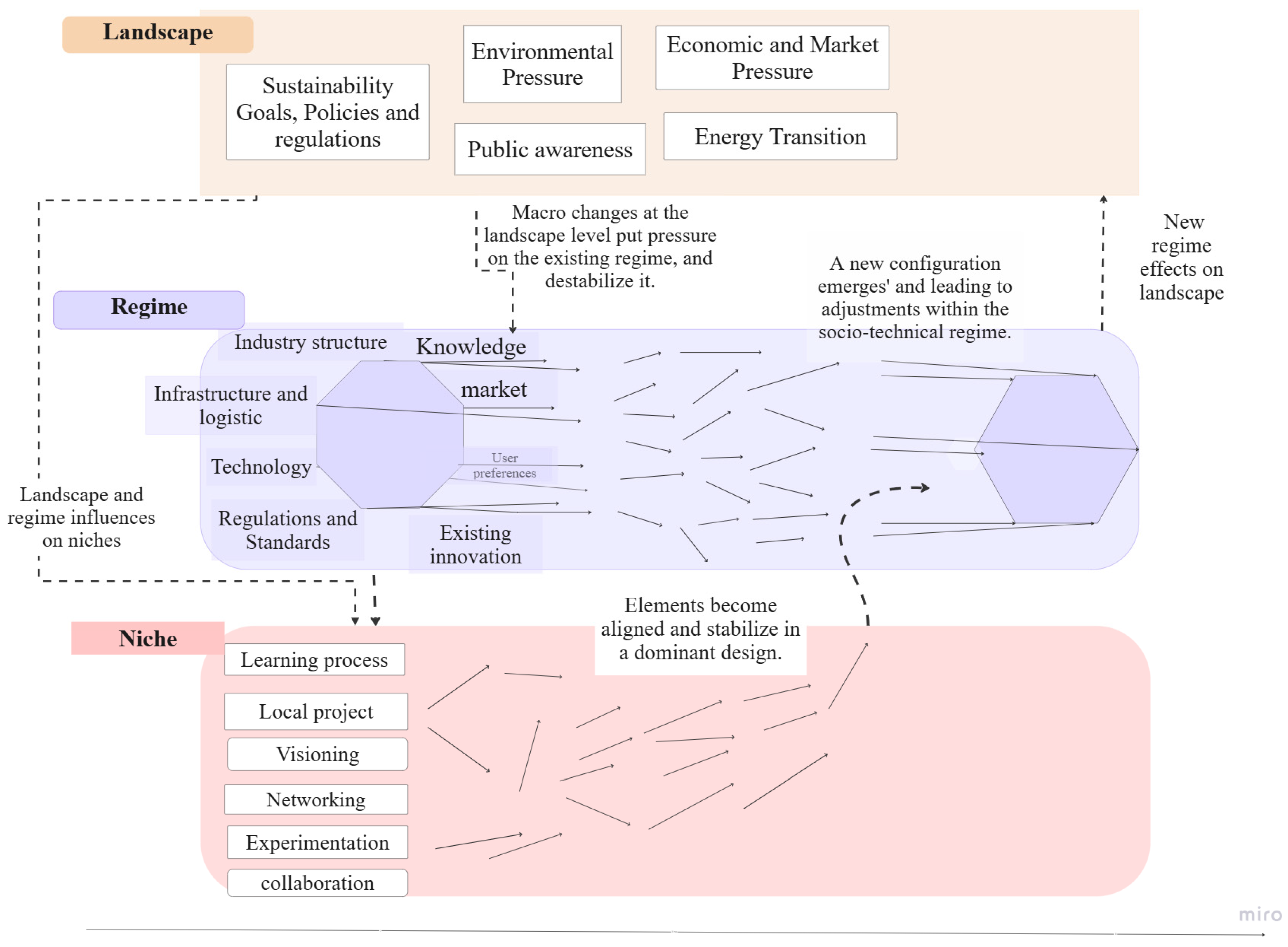

2. Theoretical Framework

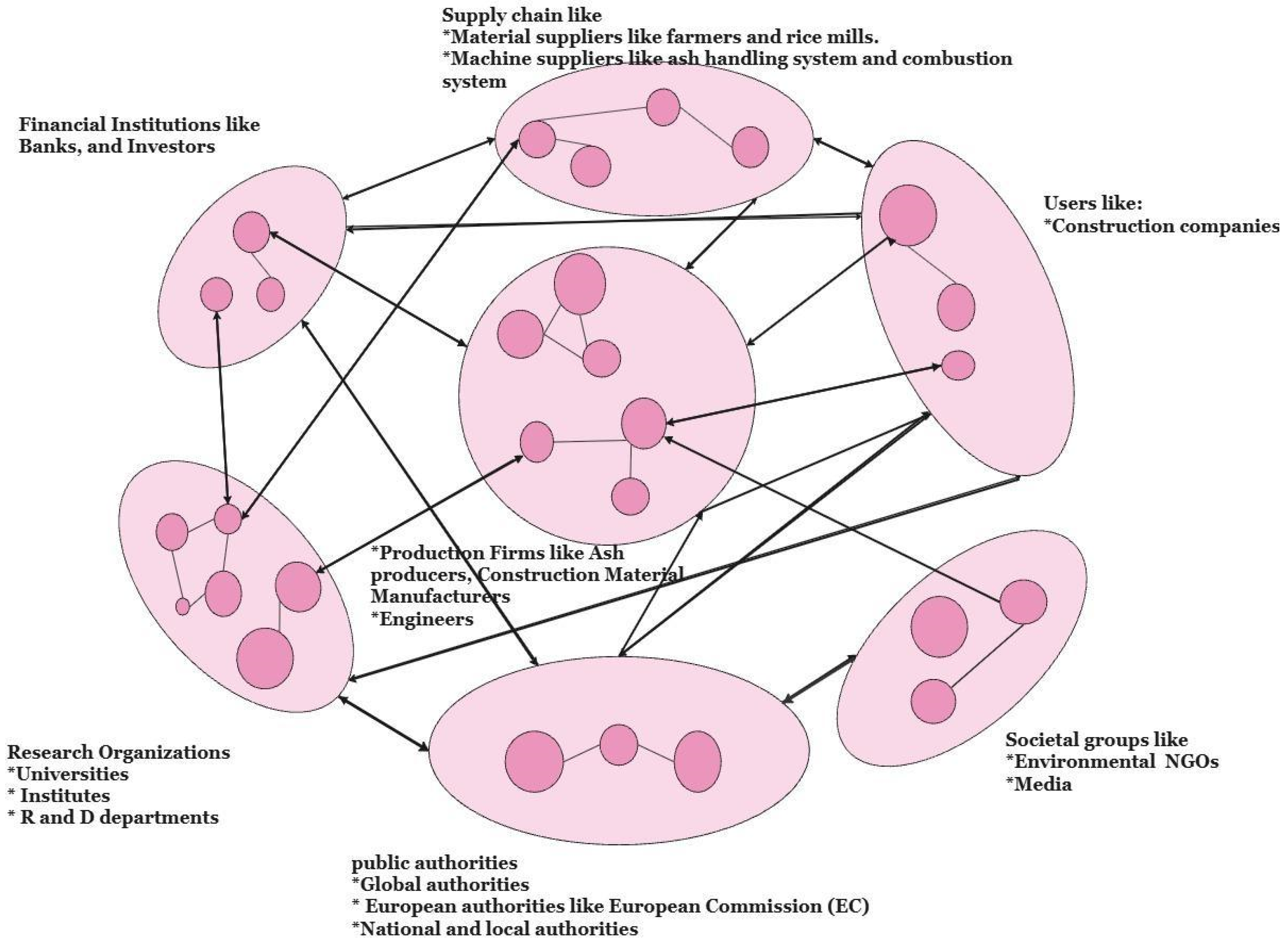

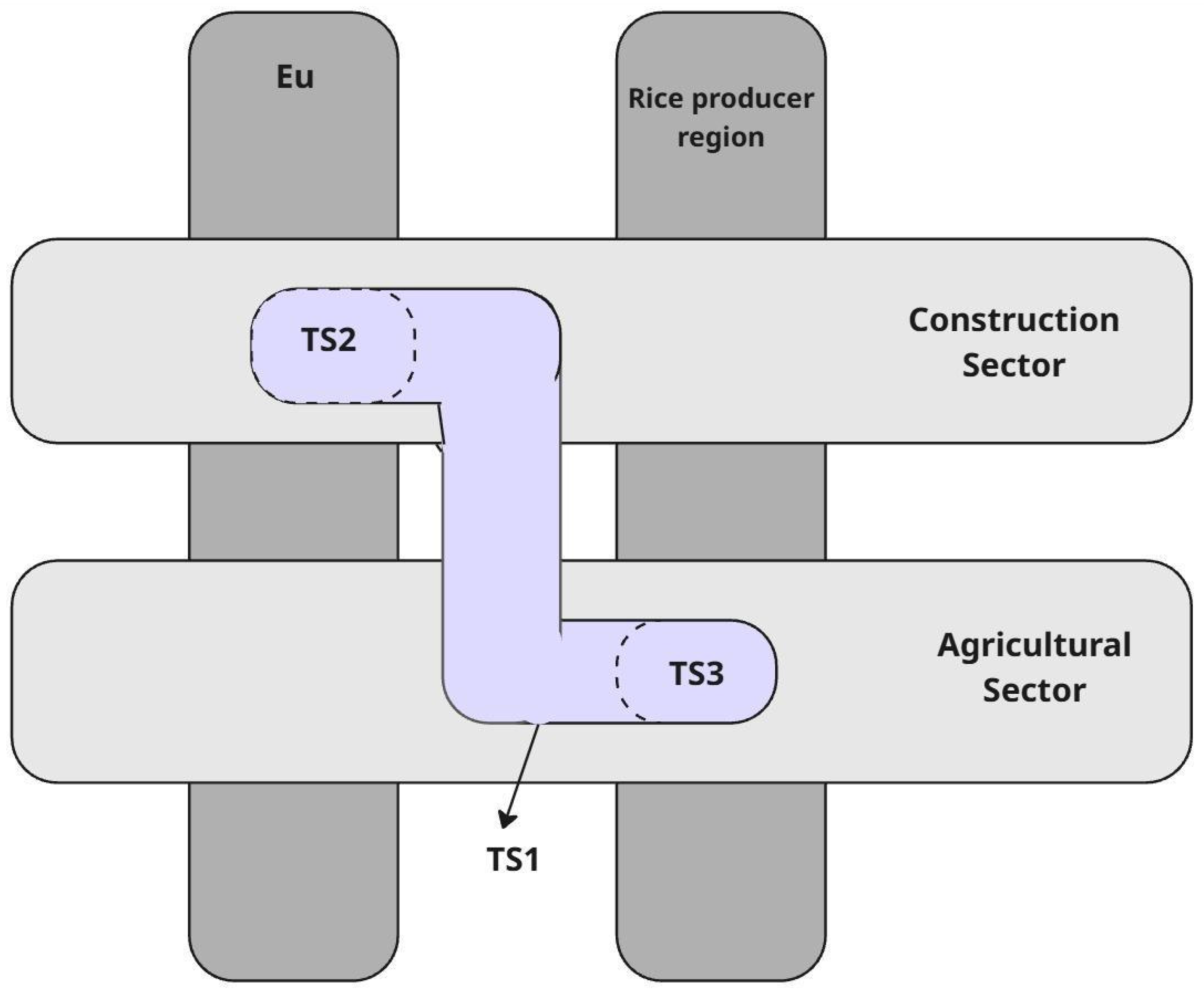

2.1. The Socio-Technical System

2.2. Multi-Level Socio-Technical Transition

2.3. System Boundary

3. Materials and Methods

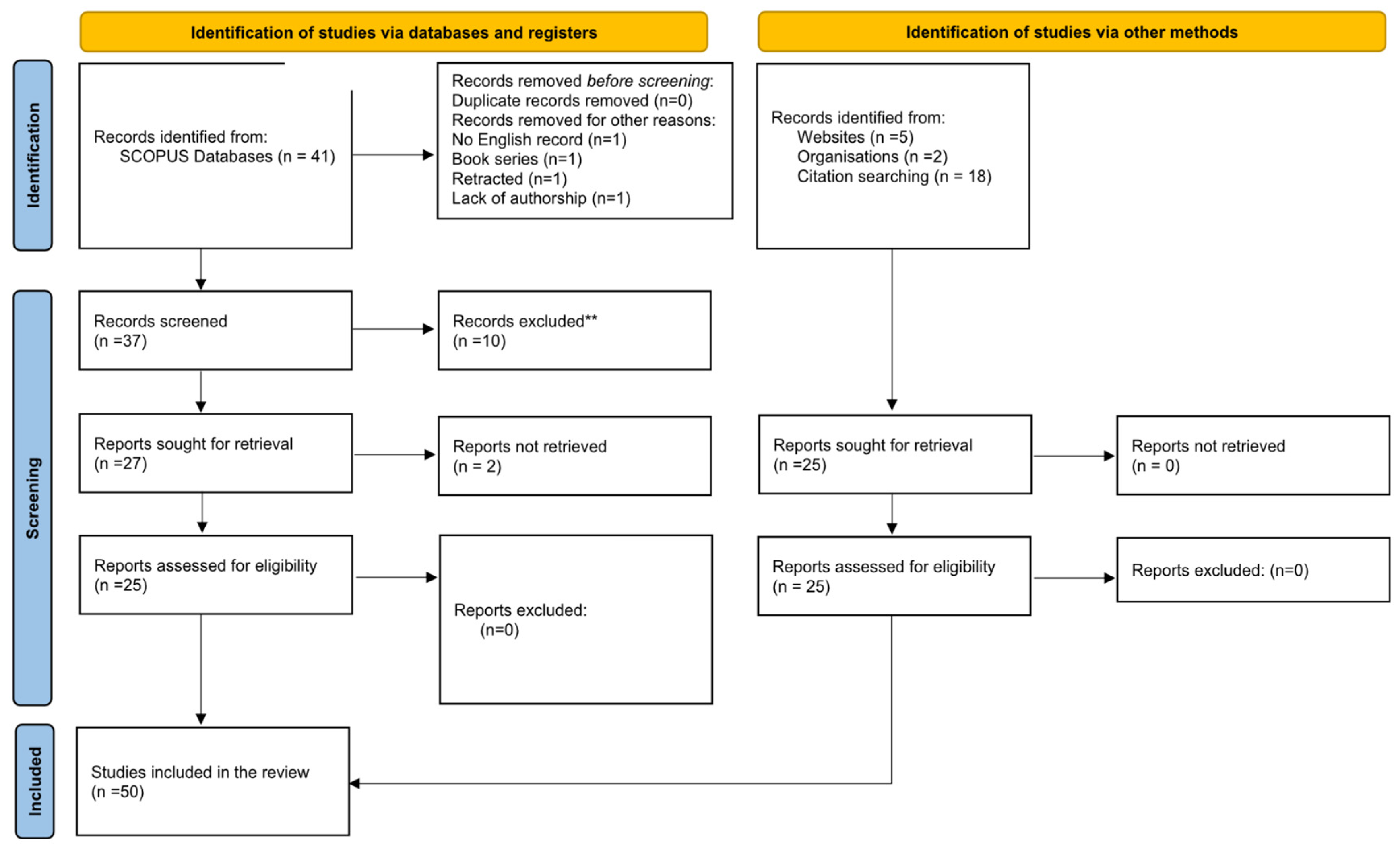

3.1. Systematic Literature Review

3.2. SWOT, PESTLE, and Multi-Level Perspective Analysis

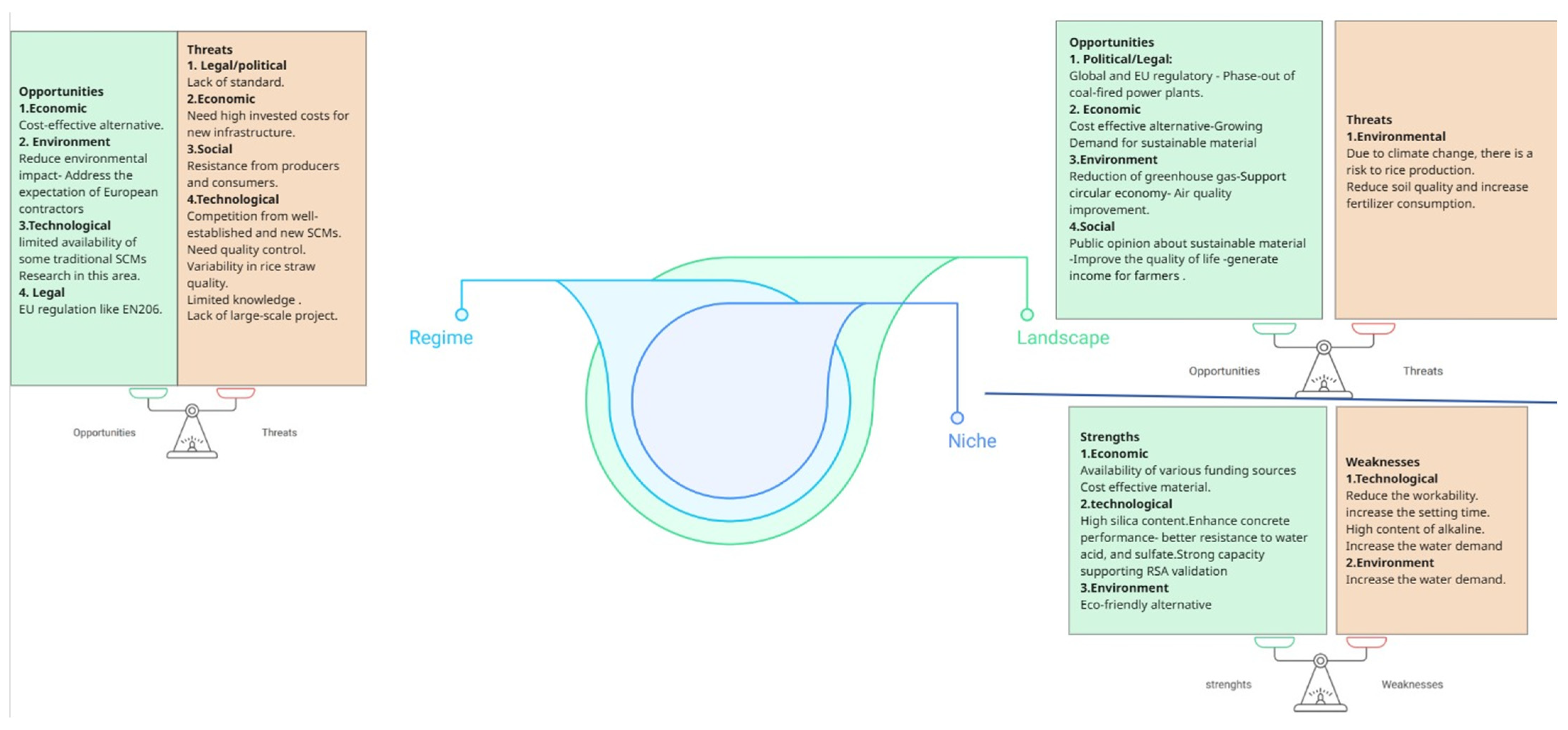

4. Results and Discussion

4.1. Landscape Level

4.1.1. Opportunities

4.1.2. Threats

4.2. Regime

4.2.1. Opportunities

4.2.2. Threats

4.3. Niche Innovation

4.3.1. Weaknesses

4.3.2. Strengths

5. Conclusions

- (a)

- Developing European standards to ensure quality and market acceptance.

- (b)

- Establishing supply chain infrastructure for processing, transport, and storage.

- (c)

- Investing in research and technological innovation: research is needed to develop standards for the use of RSA in concrete. Investigating the long-term performance of RSA in concrete applications and exploring innovative processing techniques to enhance its properties will be vital.

- (d)

- Collaboration among industry stakeholders, policymakers, and researchers is essential to create the infrastructure and market conditions that support the integration of RSA.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CE | Circular economy |

| CO2 eq | Carbon Dioxide Equivalent |

| EU | European Union |

| EN | European Norm |

| MLP | Multi-Level Perspective |

| PESTLE | Political, Economic, Social, Technology, Legal, and Environment |

| RSA | Rice straw ash |

| SCMs | Supplementary Cementitious Materials |

| SWOT | Strength-Weakness-Opportunity-Threat |

Appendix A

| Multi-Level Perspective | SWOT Analysis | PESTLE | Explanation |

|---|---|---|---|

| Landscape Level | Opportunities | Policy and Regulations | Increasing regulatory pressure to reduce greenhouse gas emissions and promote a circular economy on a global and EU scale. Energy transition from coal-fired power plants across Europe [58]. Existing sustainability and waste management policies [61]. |

| Economic | RSA is a cost-effective alternative to traditional cement, offering a more affordable option [57]. Growing demand for more sustainable materials in the EU. | ||

| Social | Increasing environmental consciousness and public awareness about the environmental effects of products and changing their preferences [62,63]. Growing demand for more sustainable materials in the EU. | ||

| Threats | Environmental | Due to climate change, there is a risk to rice production [65]. | |

| Environmental | Diverting rice straw for ash production, instead of using it in an agricultural field, can reduce soil quality and increase fertilizer consumption [48]. | ||

| Regime Level | Opportunities | Technological and Legal | The limited availability of some traditional SCMs, such as fly ash, in the future opens opportunities for others, like RSA. |

| Legal | Within the EU, there is a well-established standard (EN206) related to replacing cement with inert or pozzolanic materials [71] | ||

| Economic and Environmental | The RSA can be considered a product that addresses the expectations of European contractors. | ||

| Technological | Research and innovations are being carried out in this area. | ||

| Threats | Economic and Technological | Competition from well-established SCMs RSA faces competition from new SCMs. RSA faces competition from traditional SCMs (without a standard). | |

| Legal | The lack of established standards for the implementation of RSA may make it harder for construction companies to use [79,80,81]. | ||

| Technological | The EU’s existing logistics and supply chains are optimized for traditional SCMs, so integrating RSA into them will be challenging. The integration of RSA in the construction sector requires precise treatment and quality control, which can be costly and require new technologies. Rice straw variability and the treatment process have a significant impact on the quality of RSA and concrete performance [48,81]. Limited knowledge about RSA and a lack of large-scale projects can hinder the adoption of RSA in the construction sector. | ||

| Economic | New infrastructure and technology will be costly. | ||

| Social | Sometimes, producers and consumers resist switching from traditional materials to new alternatives due to perceived risks and uncertainty [81]. | ||

| Niche | Strength | Economic | RSA is a cost-effective option that decreases the amount of cement needed. |

| Environmental | RSA reduces dependency on traditional cement, one of the significant contributors to greenhouse gas emissions. | ||

| Technological | RSA has a proper amount of silica [26,87]. It increases the quality of the concrete. Concrete containing RSA has strong resistance to chemical attacks. RSA can be combined with other SCMs to improve the quality of the concrete. | ||

| Weaknesses | Environmental and Technological | Increase the water demand for cement [14,21,83]. | |

| Technological | Increase the setting time of concrete [14,83,84,89] Requires more research. The seasonal availability of rice straw affects industries that rely on a consistent supply. The alkaline content of RSA is high [28]. |

References

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An Overview of the Waste Hierarchy Framework for Analyzing the Circularity in Construction and Demolition Waste Management in Europe. Sci. Total Environ. 2022, 803, 149892. [Google Scholar] [CrossRef]

- Josa, I.; Borrion, A. Key Indicators to Assess Construction Supply Chains from an Environmental Perspective: Taxonomy and Critical Insights. Sustain. Futures 2025, 10, 100824. [Google Scholar] [CrossRef]

- Ly, D.H.; Le, Q.H.; Hoang Nhat Nguyen, T.D.; Ahn, Y.; Kim, K.; Kwon, N. Advancing Modular Construction through Circular Economy: Insights from Semi-Automated PRISMA Analysis and Topic Modeling. J. Build. Eng. 2024, 98, 111232. [Google Scholar] [CrossRef]

- European Commission. Buildings and Construction-Internal Market, Industry, Entrepreneurship and SMEs. Available online: https://single-market-economy.ec.europa.eu/industry/sustainability/buildings-and-construction_en (accessed on 14 October 2025).

- Krishna, V.V.; Mkondiwa, M. Economics of Crop Residue Management. Annu. Rev. Resour. Econ. 2023, 15, 19–39. [Google Scholar] [CrossRef]

- Harun, S.N.; Hanafiah, M.M.; Noor, N.M. Rice Straw Utilisation for Bioenergy Production: A Brief Overview. Energies 2022, 15, 5542. [Google Scholar] [CrossRef]

- Bhuvaneshwari, S.; Hettiarachchi, H.; Meegoda, J.N. Crop Residue Burning in India: Policy Challenges and Potential Solutions. Int. J. Environ. Res. Public Health 2019, 16, 832. [Google Scholar] [CrossRef]

- Zhang, Y.; Ghaly, A.E.; Li, B. Physical Properties of Wheat Straw Varieties Cultivated Under Different Climatic and Soil Conditions in Three Continents. Am. J. Eng. Appl. Sci. 2012, 5, 98–106. [Google Scholar] [CrossRef]

- Khalife, E.; Sabouri, M.; Kaveh, M.; Szymanek, M. Recent Advances in the Application of Agricultural Waste in Construction. Appl. Sci. 2024, 14, 2355. [Google Scholar] [CrossRef]

- Zhang, Q.; Sajjad, A.; Khoualdi, K.; Kautish, P.; Yaqub, M.Z. The Switching towards Smart Energy Technologies for Sustainable Development: Individual, Institutional and Regional Perspectives. Sustain. Futures 2025, 10, 100789. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary Cementitious Materials: New Sources, Characterization, and Performance Insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Lallas, Z.N.; Gombeda, M.J.; Mendonca, F. Review of Supplementary Cementitious Materials with Implications for Age-Dependent Concrete Properties Affecting Precast Concrete. PCI J. 2023, 68, 46–64. [Google Scholar] [CrossRef]

- Singh, R.; Patel, M. Strength and Durability Performance of Rice Straw Ash-Based Concrete: An Approach for the Valorization of Agriculture Waste. Int. J. Environ. Sci. Technol. 2023, 20, 9995–10012. [Google Scholar] [CrossRef]

- El-Sayed, M.A.; El-Samni, T.M. Physical and Chemical Properties of Rice Straw Ash and Its Effect on the Cement Paste Produced from Different Cement Types. J. King Saud Univ.-Eng. Sci. 2006, 19, 21–29. [Google Scholar] [CrossRef]

- Pandey, A.; Kumar, B. Effects of Rice Straw Ash and Micro Silica on Mechanical Properties of Pavement Quality Concrete. J. Build. Eng. 2019, 26, 100889. [Google Scholar] [CrossRef]

- Oliko, C.; Kabubo, C.K.; Mwero, J.N. Rice Straw and Eggshell Ash as Partial Replacements of Cement in Concrete. Eng. Technol. Appl. Sci. Res. 2020, 10, 6481–6487. [Google Scholar] [CrossRef]

- Hakeem, I.Y.; Amin, M.; Agwa, I.S.; Abd-Elrahman, M.H.; Ibrahim, O.M.O.; Samy, M. Ultra-High-Performance Concrete Properties Containing Rice Straw Ash and Nano Eggshell Powder. Case Stud. Constr. Mater. 2023, 19, e02291. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, V.; Bansal, A.; Singla, A.K.; Singla, J.; Gupta, S.; Rajput, A.; Singh, J.; Khanna, N. Experimental Research on the Physical and Mechanical Properties of Rice Straw-Rice Straw Ash Composite Materials. Int. J. Interact. Des. Manuf. 2024, 18, 721–731. [Google Scholar] [CrossRef]

- Roselló, J.; Soriano, L.; Santamarina, M.P.; Akasaki, J.L.; Monzó, J.; Payá, J. Rice Straw Ash: A Potential Pozzolanic Supplementary Material for Cementing Systems. Ind. Crops Prod. 2017, 103, 39–50. [Google Scholar] [CrossRef]

- Miller, S.A.; Cunningham, P.R.; Harvey, J.T. Rice-Based Ash in Concrete: A Review of Past Work and Potential Environmental Sustainability. Resour. Conserv. Recycl. 2019, 146, 416–430. [Google Scholar] [CrossRef]

- Heniegal, A.M.; Amin, M.; Zeyad, A.M.; Agwa, I.S.; Samy, M. Effect of Rice Straw Ash at Different Burning Temperatures on High-Strength Concrete Properties. Innov. Infrastruct. Solut. 2025, 10, 1–18. [Google Scholar] [CrossRef]

- Adhikary, S.K.; Ashish, D.K.; Rudžionis, Ž. A Review on Sustainable Use of Agricultural Straw and Husk Biomass Ashes: Transitioning towards Low Carbon Economy. Sci. Total Environ. 2022, 838, 156407. [Google Scholar] [CrossRef] [PubMed]

- Seifelnasr, A.; Abdelsalam, E.M.; Moselhy, M.A.; Ibrahim, H.H.A.; Ali, A.S.; Faried, M.; Attia, Y.A.; Samer, M. The Effect of Agricultural Crop Residues and Bacteria on the Chemical and Engineering Properties of Eco-Cement Produced. Egypt J. Chem. 2023, 66, 225–234. [Google Scholar] [CrossRef]

- Duppati, S.; Gopi, R. Strength and Durability Studies on Paver Blocks with Rice Straw Ash as Partial Replacement of Cement. Mater. Today Proc. 2022, 52, 710–715. [Google Scholar] [CrossRef]

- Rani, G.Y.; Jaya Krishna, T. Effect of Rice Straw Ash and Micro Silica on Strength and Durability of Concrete. Mater. Today Proc. 2022, 60, 2151–2156. [Google Scholar] [CrossRef]

- Hakeem, I.Y.; Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Maglad, A.M.; Agwa, I.S. Effects of Nano Sized Sesame Stalk and Rice Straw Ashes on High-Strength Concrete Properties. J. Clean. Prod. 2022, 370, 133542. [Google Scholar] [CrossRef]

- Butt, A.A.; Filani, I.O.; Zarei, A.; Pandit, G.A.; Miller, S.A.; Harvey, J.T.; Nassiri, S. Environmental and Economic Impacts of Processing Rice Straw with Water for Energy and Coproducts. Resour. Conserv. Recycl. 2025, 212, 107952. [Google Scholar] [CrossRef]

- Cunningham, P.R.; Wang, L.; Nassiri, S.; Thy, P.; Harvey, J.T.; Jenkins, B.M.; Miller, S.A. Compressive Strength and Regional Supply Implications of Rice Straw and Rice Hull Ashes Used as Supplementary Cementitious Materials. Resour. Conserv. Recycl. 2025, 214, 108024. [Google Scholar] [CrossRef]

- Geels, F.W. From Sectoral Systems of Innovation to Socio-Technical Systems: Insights about Dynamics and Change from Sociology and Institutional Theory. Res. Policy 2004, 33, 897–920. [Google Scholar] [CrossRef]

- van Rijnsoever, F.J.; Leendertse, J. A Practical Tool for Analyzing Socio-Technical Transitions. Environ. Innov. Soc. Transit. 2020, 37, 225–237. [Google Scholar] [CrossRef]

- Geels, F.W. Technological Transitions as Evolutionary Reconfiguration Processes: A Multi-Level Perspective and a Case-Study. Res. Policy 2002, 31, 1257–1274. [Google Scholar] [CrossRef]

- Geels, F.W. Processes and Patterns in Transitions and System Innovations: Refining the Co-Evolutionary Multi-Level Perspective. Technol. Forecast. Soc. Change 2005, 72, 681–696. [Google Scholar] [CrossRef]

- Schot, J.; Geels, F.W. Strategic Niche Management and Sustainable Innovation Journeys: Theory, Findings, Research Agenda, and Policy. Technol. Anal. Strat. Manag. 2008, 20, 537–554. [Google Scholar] [CrossRef]

- Rip, A.; Kemp, R. Technological Change; Rayner, S., Malone, E.L., Eds.; Battelle Press: Columbus, OH, USA, 1998. [Google Scholar]

- Geels, F.W. A Socio-Technical Analysis of Low-Carbon Transitions: Introducing the Multi-Level Perspective into Transport Studies. J. Transp. Geogr. 2012, 24, 471–482. [Google Scholar] [CrossRef]

- Geels, F.W. The Impact of the Financial–Economic Crisis on Sustainability Transitions: Financial Investment, Governance and Public Discourse. Environ. Innov. Soc. Transit. 2013, 6, 67–95. [Google Scholar] [CrossRef]

- Falcone, P.M.; Tani, A.; Tartiu, V.E.; Imbriani, C. Towards a Sustainable Forest-Based Bioeconomy in Italy: Findings from a SWOT Analysis. For. Policy Econ. 2020, 110, 101910. [Google Scholar] [CrossRef]

- Yang, J.; Jung, S.U. Harnessing FinTech for Sustainable Finance in Developing Countries: An Integrated SWOT–Multi-Level Perspective Analysis of Mongolia. Sustainability 2024, 16, 4102. [Google Scholar] [CrossRef]

- Markard, J.; Truffer, B. Technological Innovation Systems and the Multi-Level Perspective: Towards an Integrated Framework. Res. Policy 2008, 37, 596–615. [Google Scholar] [CrossRef]

- PRISMA. PRISMA 2020 Statement—PRISMA Statement. Available online: https://www.prisma-statement.org/prisma-2020 (accessed on 14 October 2025).

- Lachman, D.A. A Survey and Review of Approaches to Study Transitions. Energy Policy 2013, 58, 269–276. [Google Scholar] [CrossRef]

- Nath, S.K. Fly Ash and Zinc Slag Blended Geopolymer: Immobilization of Hazardous Materials and Development of Paving Blocks. J. Hazard. Mater. 2020, 387, 121673. [Google Scholar] [CrossRef]

- Dzhengiz, T.; Haukkala, T.; Sahimaa, O. (Un)Sustainable Transitions towards Fast and Ultra-Fast Fashion. Fash. Text. 2023, 10, 19. [Google Scholar] [CrossRef]

- Shehu, M.O.; Almeida, R.; Mahapatra, K. Opportunities for Digital Tracking Technologies in the Precast Concrete Sector in Sweden. Front. Built Environ. 2025, 11, 1566784. [Google Scholar] [CrossRef]

- Vardopoulos, I.; Tsilika, E.; Sarantakou, E.; Zorpas, A.; Salvati, L.; Tsartas, P. An Integrated SWOT-PESTLE-AHP Model Assessing Sustainability in Adaptive Reuse Projects. Appl. Sci. 2021, 11, 7134. [Google Scholar] [CrossRef]

- Mainali, B.; Mahapatra, K.; Pardalis, G. Strategies for Deep Renovation Market of Detached Houses. Renew. Sustain. Energy Rev. 2021, 138, 110659. [Google Scholar] [CrossRef]

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting Future Carbon Emissions from Cement Production in Developing Countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [CrossRef]

- Chivenge, P.; Rubianes, F.; Van Chin, D.; Van Thach, T.; Khang, V.T.; Romasanta, R.R.; Van Hung, N.; Van Trinh, M. Rice Straw Incorporation Influences Nutrient Cycling and Soil Organic Matter. In Sustainable Rice Straw Management; Springer International Publishing: Cham, Switzerland, 2020; pp. 131–144. [Google Scholar]

- Sodhi, A.K.; Bhanot, N.; Singh, R.; Alkahtani, M. Effect of Integrating Industrial and Agricultural Wastes on Concrete Performance with and without Microbial Activity. Environ. Sci. Pollut. Res. 2022, 29, 86092–86108. [Google Scholar] [CrossRef]

- McKinsey and Company. Cementing Your Lead in the Green Transition|McKinsey. Available online: https://www.mckinsey.com/industries/engineering-construction-and-building-materials/our-insights/cementing-your-lead-the-cement-industry-in-the-net-zero-transition (accessed on 14 October 2025).

- UNFCCC. The Paris Agreement|UNFCCC. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement (accessed on 14 October 2025).

- European Commision. The European Green Deal-European Commission. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 14 October 2025).

- European Commission. Energy Performance of Buildings Directive. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-performance-buildings/energy-performance-buildings-directive_en (accessed on 14 October 2025).

- European Commission. Commission Delegated Regulation (EU) 2021/2139 of 4 June 2021 Supplementing Regulation (EU) 2020/852 by Establishing Technical Screening Criteria for Determining the Conditions Under Which an Economic Activity Qualifies as Contributing Substantially to Climate Change Mitigation or Adaptation, and for Determining Whether It Causes No Significant Harm to Other Environmental Objectives. Official Journal of the European Union. Available online: https://eur-lex.europa.eu/eli/reg_del/2021/2139/oj/eng (accessed on 20 June 2025).

- European Commision. Carbon Border Adjustment Mechanism. Available online: https://taxation-customs.ec.europa.eu/carbon-border-adjustment-mechanism_en (accessed on 16 October 2025).

- European Parliament and Council. Directive 2008/98/EC of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/eli/dir/2008/98/oj/eng (accessed on 20 June 2025).

- S&P Global. Essential Intelligence to Make Decisions with Conviction. Available online: https://www.spglobal.com/en (accessed on 14 October 2025).

- McNamee, E. Propelling the Commercialization of “Novel Cements” An Investigation of Demand-Side Factors to Accelerate Decarbonizing Technologies within the Cement Industry. Master Thesis, Lund University, Lund, Sweden, 2015. [Google Scholar]

- Saliem, H.P.; Suryana, A.; Sumedi; Suryani, E.; Mardianto, S. Increasing Rice Farmers’ Income through Added Value and Implementing a Circular Economy. BIO Web. Conf. 2024, 119, 02011. [Google Scholar] [CrossRef]

- Kim Oanh, N.T.; Ly, B.T.; Tipayarom, D.; Manandhar, B.R.; Prapat, P.; Simpson, C.D.; Sally Liu, L.-J. Characterization of Particulate Matter Emission from Open Burning of Rice Straw. Atmos Environ. 2011, 45, 493–502. [Google Scholar] [CrossRef]

- CORDIS-EU Research Results. Organic Rankine Cycle Cogeneration Plant of One-Farm Size Using Rice Straw as Single Fuel. Available online: https://cordis.europa.eu/project/id/745062 (accessed on 3 July 2025).

- Precedence Research. Sustainable Construction Materials Market Size to Surge USD 1395.50 Bn by 2034. Available online: https://www.precedenceresearch.com/sustainable-construction-materials-market (accessed on 14 October 2025).

- Barbhuiya, S.; Kanavaris, F.; Das, B.B.; Idrees, M. Decarbonising Cement and Concrete Production: Strategies, Challenges and Pathways for Sustainable Development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- MarkWide Research. Rice Straw Market Analysis-Industry Size, Share, Research Report, Insights, COVID-19 Impact, Statistics, Trends, Growth and Forecast 2025–2034|Size, Share, Growth. Available online: https://markwideresearch.com/rice-straw-market/ (accessed on 14 October 2025).

- Baishakhy, S.D.; Islam, M.A.; Kamruzzaman, M.d. Overcoming Barriers to Adapt Rice Farming to Recurring Flash Floods in Haor Wetlands of Bangladesh. Heliyon 2023, 9, e14011. [Google Scholar] [CrossRef]

- Jin, Z.; Shah, T.; Zhang, L.; Liu, H.; Peng, S.; Nie, L. Effect of Straw Returning on Soil Organic Carbon in Rice–Wheat Rotation System: A Review. Food Energy Secur. 2020, 9, e200. [Google Scholar] [CrossRef]

- Nghi, N.T.; Romasanta, R.R.; Van Hieu, N.; Vinh, L.Q.; Du, N.X.; Vo Chau Ngan, N.; Chivenge, P.; Van Hung, N. Rice Straw-Based Composting. In Sustainable Rice Straw Management; Springer International Publishing: Cham, Switzerland, 2019; pp. 33–41. [Google Scholar] [CrossRef]

- Thuc, L.V.; Corales, R.G.; Sajor, J.T.; Truc, N.T.T.; Hien, P.H.; Ramos, R.E.; Bautista, E.; Tado, C.J.M.; Ompad, V.; Son, D.T.; et al. Rice-Straw Mushroom Production. In Sustainable Rice Straw Management; Springer International Publishing: Cham, Switzerland, 2019; pp. 93–109. [Google Scholar] [CrossRef]

- Wu, H.; MacDonald, G.K.; Galloway, J.N.; Zhang, L.; Gao, L.; Yang, L.; Yang, J.; Li, X.; Li, H.; Yang, T. The Influence of Crop and Chemical Fertilizer Combinations on Greenhouse Gas Emissions: A Partial Life-Cycle Assessment of Fertilizer Production and Use in China. Resour. Conserv. Recycl. 2021, 168, 105303. [Google Scholar] [CrossRef]

- Volza. Fly Ash Imports in Germany-Volza. Available online: https://www.volza.com/p/fly-ash/import/import-in-germany/ (accessed on 14 October 2025).

- Łagosz, A.; Olszowski, D.; Pichór, W.; Kotwica, Ł. Quantitative Determination of Processed Waste Expanded Perlite Performance as a Supplementary Cementitious Material in Low Emission Blended Cement Composites. J. Build. Eng. 2021, 40, 102335. [Google Scholar] [CrossRef]

- Scrivener, K.; Haha, M.B.; Juilland, P.; Levy, C. Research Needs for Cementitious Building Materials with Focus on Europe. RILEM Tech. Lett. 2022, 7, 220–252. [Google Scholar] [CrossRef]

- ECOBA. Ecoba European Coal Combustion Products Association Examples. Available online: https://www.ecoba.com/ecobaccpexs.html (accessed on 14 June 2025).

- Business Market Insights. Europe Fly Ash Market. Available online: https://www.businessmarketinsights.com/reports/europe-fly-ash-market (accessed on 16 August 2025).

- Snellings, R.; Suraneni, P.; Skibsted, J. Future and Emerging Supplementary Cementitious Materials. Cem. Concr. Res. 2023, 171, 107199. [Google Scholar] [CrossRef]

- Favier, A.; De Wolf, C.; Scrivener, K.; Habert, G. A Sustainable Future for the European Cement and Concrete Industry: Technology Assessment for Full Decarbonisation of the Industry by 2050; ETH Zurich: Zürich, Switzerland, 2018. [Google Scholar] [CrossRef]

- EP Power mineral. Biggest Investment Project in the History of EP Power Minerals:|EP Power Minerals. Available online: https://www.eppowerminerals.com/en/blog/biggest-investment-project-in-the-history-of-ep-power-minerals (accessed on 16 October 2025).

- Bech, N.; Feuerborn, H.-J. Ash Quality in Europe-Primary and Secondary Measures. In Proceedings of the World of Coal Ash (WOCA) Conference, Denver, CO, USA, 9–12 May 2011. [Google Scholar]

- Ohene, E.; Chan, A.P.C.; Darko, A. Prioritizing Barriers and Developing Mitigation Strategies toward Net-Zero Carbon Building Sector. Build Environ. 2022, 223, 109437. [Google Scholar] [CrossRef]

- Omopariola, E.D.; Olanrewaju, O.I.; Albert, I.; Oke, A.E.; Ibiyemi, S.B. Sustainable Construction in the Nigerian Construction Industry: Unsustainable Practices, Barriers and Strategies. J. Eng. Des. Technol. 2024, 22, 1158–1184. [Google Scholar] [CrossRef]

- Akadiri, P.O. Understanding Barriers Affecting the Selection of Sustainable Materials in Building Projects. J. Build. Eng. 2015, 4, 86–93. [Google Scholar] [CrossRef]

- Kemp, R.; Barteková, E.; Türkeli, S. The Innovation Trajectory of Eco-Cement in the Netherlands: A Co-Evolution Analysis. Int. Econ. Econ. Policy 2017, 14, 409–429. [Google Scholar] [CrossRef]

- Raina, A.; Kaur, G.; Tangri, A. Experimental Studies of Marble Concrete Prepared with Micro Silica and Rice Straw Ash. IOP Conf. Ser. Earth Environ. Sci. 2021, 889, 012048. [Google Scholar] [CrossRef]

- Abitha, A.; Jesty, C.A.; Siyad, S.; Vijay, P.C.; Sreerekha Raj, S.; Dhanya, B.S. Feasibility Assessment of Rice Straw Ash as a Supplementary Cementitious Material. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Pratama, Y.W.; Gidden, M.J.; Greene, J.; Zaiser, A.; Nemet, G.; Riahi, K. Learning, Economies of Scale, and Knowledge Gap Effects on Power Generation Technology Cost Improvements. iScience 2025, 28, 111644. [Google Scholar] [CrossRef] [PubMed]

- Chandra Paul, S.; Mbewe, P.B.K.; Kong, S.Y.; Šavija, B. Agricultural Solid Waste as Source of Supplementary Cementitious Materials in Developing Countries. Materials 2019, 12, 1112. [Google Scholar] [CrossRef] [PubMed]

- Munshi, S.; Dey, G.; Prasad Sharma, R. Use of Rice Straw Ash as Pozzolanic Material in Cement Mortar. Int. J. Eng. Technol. 2013, 5, 603–606. [Google Scholar] [CrossRef]

- Agwa, I.S.; Omar, O.M.; Tayeh, B.A.; Abdelsalam, B.A. Effects of Using Rice Straw and Cotton Stalk Ashes on the Properties of Lightweight Self-Compacting Concrete. Constr. Build Mater. 2020, 235, 117541. [Google Scholar] [CrossRef]

- Hidalgo, S.; Soriano, L.; Monzó, J.; Payá, J.; Font, A.; Borrachero, M.V. Evaluation of Rice Straw Ash as a Pozzolanic Addition in Cementitious Mixtures. Appl. Sci. 2021, 11, 773. [Google Scholar] [CrossRef]

- Amiruddin, A.A.; Tumpu, M.; Rangan, P.R.; Irmawaty, R.; Bakri, B.; Mansyur. A Potential Pozzolanic Material Consisting of Rice Straw Ash and Fly Ash for Geopolymer Mortar Production-Based Cementitious System. Eng. Technol. Appl. Sci. Res. 2024, 14, 18189–18198. [Google Scholar] [CrossRef]

- El-Sayed, T.A. Performance of Heavy Weight Concrete Incorporating Recycled Rice Straw Ash as Radiation Shielding Material. Prog. Nucl. Energy 2021, 135, 103693. [Google Scholar] [CrossRef]

- da Silva, P.B.; Neves, F.R. Thinking Inside the Sandbox: Beyond Public Services Digitalization with Co-Production. In Transforming Public Services—Combining Data and Algorithms to Fulfil Citizen’s Expectations; Springer Nature: Cham, Switzerland, 2024; pp. 87–106. [Google Scholar]

- Baron, J.; Ménière, Y.; Pohlmann, T. Standards, Consortia, and Innovation. Int. J. Ind. Organ. 2014, 36, 22–35. [Google Scholar] [CrossRef]

- Wang, X.; Lo, K. Just Transition: A Conceptual Review. Energy Res. Soc. Sci. 2021, 82, 102291. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gheitasi, F.; Shah, T.; Mahapatra, K. Unlocking Sustainability Transitions in Construction Materials in Europe: A Multi-Level Perspective on the Adoption of Rice Straw Ash. Sustainability 2025, 17, 9707. https://doi.org/10.3390/su17219707

Gheitasi F, Shah T, Mahapatra K. Unlocking Sustainability Transitions in Construction Materials in Europe: A Multi-Level Perspective on the Adoption of Rice Straw Ash. Sustainability. 2025; 17(21):9707. https://doi.org/10.3390/su17219707

Chicago/Turabian StyleGheitasi, Farideh, Tejasi Shah, and Krushna Mahapatra. 2025. "Unlocking Sustainability Transitions in Construction Materials in Europe: A Multi-Level Perspective on the Adoption of Rice Straw Ash" Sustainability 17, no. 21: 9707. https://doi.org/10.3390/su17219707

APA StyleGheitasi, F., Shah, T., & Mahapatra, K. (2025). Unlocking Sustainability Transitions in Construction Materials in Europe: A Multi-Level Perspective on the Adoption of Rice Straw Ash. Sustainability, 17(21), 9707. https://doi.org/10.3390/su17219707