Abstract

The industrial motor systems account for 45% of global electricity consumption. A life cycle model is established to quantify the potential environmental benefits of typical adjustable permanent magnet drives (APMDs, 1250 kW) versus variable frequency drives (VFDs) in China. The model covers mining of metals, manufacturing, operation, and recycling phases of APMDs, incorporating empirical data from China’s 3232 coal-fired units. Four scenarios are set up: business-as-usual, moderate, aggressive, and full-retrofit. Key findings demonstrate that APMDs reduce operational energy consumption by 94.5% compared to VFDs through significantly declining frequency conversion losses and cooling requirements. The life cycle carbon emissions of APMDs (29.7 tonnes CO2_eq) represent merely 5% of VFDs emissions (570 tonnes CO2_eq), achieving a 95% reduction. Within APMDs’ footprint, recycling contributes a 45% emission offset (−13.3 tonnes CO2-eq), while operational efficiency drives the majority of the reduction. Sensitivity analysis identifies electricity emission factors, NdFeB production emissions, and metal recycling rates as primary sensitivity drivers (sensitivity index ST = 0.80). Scenario simulations confirm that the aggressive retrofit strategy (covering high- and moderate-potential units) could reduce annual GHG emissions of 3.12 million tonnes CO2_eq., with corresponding 89% decreases in particulate matter (PM). This research demonstrates that APMDs are an effective pathway for the low-carbon transition in coal power systems. Their large-scale implementation can potentially necessitate breakthroughs in tiered retrofit policies, thereby providing crucial technological support for industrial carbon neutrality.

1. Introduction

In the electrification era, industrial motor systems constitute a critical nexus within the global energy infrastructure, accounting for approximately 45% of electricity consumption [1,2,3]. Among these systems, pumps and fans—widely deployed in the power generation, metallurgy, and chemical industries—contribute 30–55% of total industrial energy use [4]. Most pumps and fans currently employ variable-frequency drives (VFDs) based on power electronics [5,6]. While VFDs achieve IE4 (superpremium efficiency) and outperform traditional drives in energy utilization [3,7], their potential upgrade to IE5 (ultrapremium efficiency) remains constrained by three critical barriers [8,9]. First, converter losses (5–8% of system energy) and auxiliary cooling requirements (>300,000 kWh/MW annually) create an ironic situation in which efficiency improvements paradoxically increase consumption [10]. This contradicts global industrial carbon neutrality goals. Projections indicate that maintaining current technologies would limit emission reductions from high-efficiency motors to ~2.5 billion tonnes CO2_eq by 2030 [11,12], with motor systems contributing 1.23 billion tonnes CO2_eq (29% of China’s industrial emissions) [13]. Second, high-order harmonics (THD≥30%) generated by insulated gate bipolar transistors cause voltage distortion, which threatens precision equipment security [14,15]. Furthermore, the life cycle maintenance costs for medium-voltage VFDs exceed 120% of the initial capital investment (per analyses of industry leaders, including ABB and Siemens), primarily because of the recurrent replacement of capacitors and cooling fans [16,17]. Thus, the development of novel speed-regulation technologies reconciling high efficiency, operational reliability, and environmental compatibility represents a critical necessity for industrial decarbonization.

APMD technology enables contactless torque transmission via magnetic field coupling, with its fundamental breakthrough in the slip power recovery mechanism [18,19]. Exemplified by the wound-rotor permanent magnet adjustable-speed drives, this technology recovers slip energy through rectification and inversion for grid feedback when the load speed falls below the motor speed, achieving up to 98% comprehensive system efficiency under 75–100% load conditions, representing a 12–15% improvement over VFDs’ typical 83–86% efficiency range in comparable applications [20,21]. The resultant advantages include near-zero harmonic pollution (eliminating power electronics interference), 60% reduced maintenance costs from lower failure rates, and stable wide-range speed regulation (<5% torque fluctuation across 0–100% loads). These technological merits have spurred significant global regulatory responses: the EU’s 2019 Eco-design Directive establishes efficiency thresholds achievable by APMDs for IE3/IE4 compliance while classifying NdFeB magnets as strategic materials [22,23]; simultaneously, China’s GB 30253-2024 standard establishes permanent magnet motor efficiency thresholds alongside 15–20% procurement subsidies [24,25]; and the U.S. Inflation Reduction Act provides 25% advanced manufacturing tax credits for permanent magnet production [26]. However, critical research gaps persist, particularly regarding holistic life cycle assessment (LCA) comparing the environmental impacts of APMDs and VFDs. Most current LCAs terminate at cradle-to-gate boundaries or narrowly focus on NdFeB recycling [27,28], failing to quantify systemic synergies between operational efficiency gains and end-of-life recovery [29]. Further limitations include overdependence on idealized operating conditions rather than empirical industrial validations [30,31].

APMD systems demonstrate broad applicability across the power generation, manufacturing, and transportation sectors [32,33,34]. Within China’s dual carbon goal framework, APMDs integration into coal-fired power plants emerges as a critical pathway for enhancing operational efficiency and reducing carbon intensity. As of 2024, coal-dominated power generation still constituted nearly 60% of China’s energy supply [35] and contributed approximately 50% of national carbon emissions [36]. With more than 140 GW of coal power capacity nationwide, auxiliary systems—including boiler feed pumps, induced draft fans, and circulating water pumps—primarily utilize traditional drives such as hydraulic couplings and induction motors. These systems consume 7–12% of total electricity output [37], whereas APMD technology eliminates inherent energy losses in mechanical transmission (e.g., 15–20% slip losses in hydraulic couplings and 7% friction losses in gears), thereby achieving substantial energy conservation and emission reduction [38]. Furthermore, APMDs enhance grid stability through torque response times <100 ms, which is crucial for load-following operations, while their oil-free operation and patented dust-proof encapsulation extend maintenance intervals, thus reducing operational costs. This positions APMDs as an indispensable solution for reconciling coal power’s base-load role with decarbonization imperatives during China’s energy transition [39]. Notably, the energy-saving potential of motor systems depends not only on intrinsic efficiency but also on demand-side operational patterns, as demonstrated by load-profile optimization in Brisbane’s public transport network [40]. This underscores the need for context-specific implementation strategies.

In this study, an LCA model for a 1250 kW APMD was developed, encompassing rare earth mining, manufacturing, use phase, and end-of-life recycling. The model quantifies and compares the environmental impacts of APMDs and VFDs across five key categories: climate change, fine particulate matter formation, fossil resource depletion, photochemical ozone formation, and terrestrial acidification. With a focus on auxiliary systems within Chinese coal-fired power plants, this work analyses the implementation potential and environmental benefits of APMDs technology in this sector. As a case study grounded in real-world applications, this research addresses a critical research gap in the field. It provides a robust scientific foundation for decarbonizing China’s coal power infrastructure.

2. Methodology

2.1. Boundary and Functional Unit

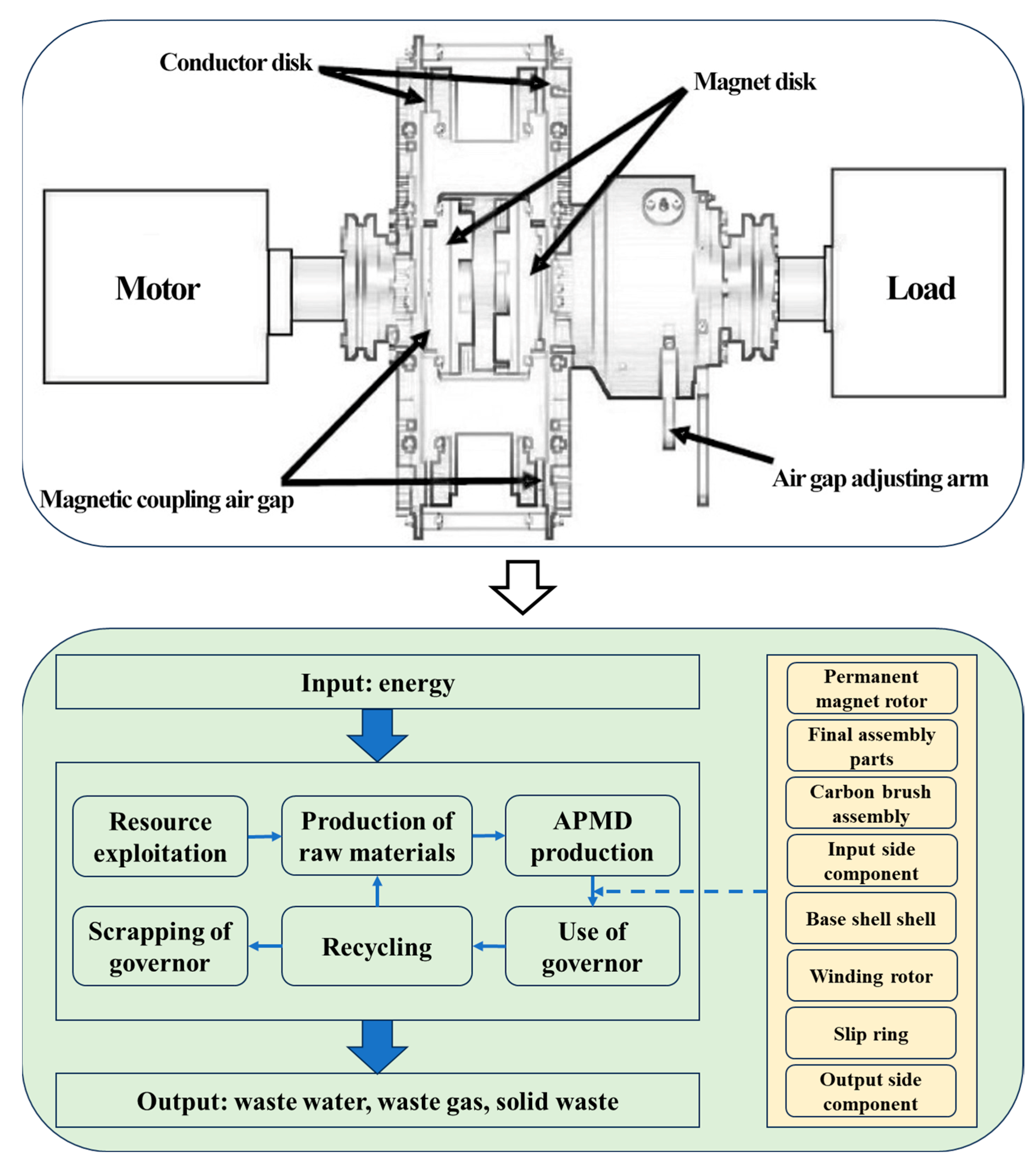

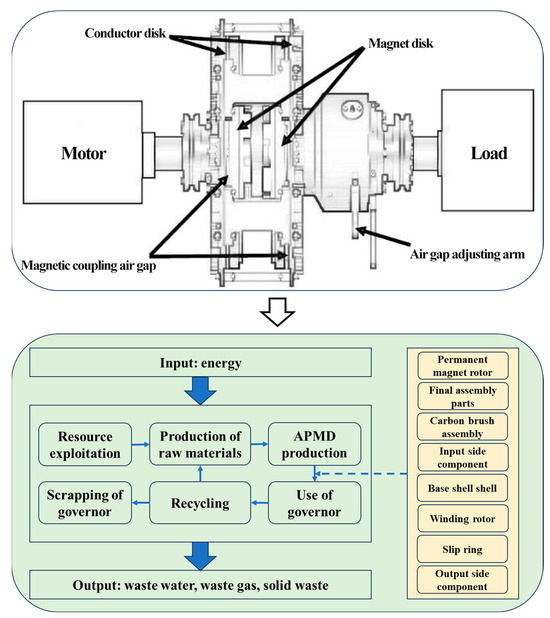

This study focused on the APMDs, an electromechanical drive system comprising copper conductor disks and neodymium-based rotor assemblies, aimed to evaluate the environmental impact differences between APMDs and VFDs, and further promoted the green transformation of coal-fired power systems. Torque transmission occurs through adjustable air gaps (0.1–10 mm) between rotating components, enabled by gap-regulation arms that dynamically modulate magnetic coupling efficiency (Figure 1).

Figure 1.

System boundary of life cycle assessment.

The assessment employed a cradle-to-grave life cycle boundary, structured across four phases:

- Upstream processes: Resource extraction (rare earth, copper, and steel) and material production.

- Manufacturing: Component fabrication (permanent magnet rotors and winding stators) and assembly.

- Use phase: 30-year operational energy consumption and maintenance.

- End of life: Disassembly, material recycling, and waste treatment.

We selected one of the most widely adopted power ratings (1.25 MW) as the study object, defining the functional unit as having a 30-year lifespan. The critical in-scope elements include the following:

- Material/energy flows of primary materials (NdFeB magnets and copper windings)

- Emission vectors from key industrial processes

- Slip-power recovery during operation

- Material recycling contributions

Exclusions encompassed infrastructure construction and transportation, with minor contributions to total impacts [41,42]. The boundary enabled holistic environmental burden quantification while maintaining methodological rigor.

2.2. Data Collection and Inventory Analysis

This life cycle assessment documented distinct resource profiles for APMDs and VFDs systems. The APMDs production phase consumed critical materials [43], including 72 kg of neodymium–iron–boron magnets, 4616 kg of steel, 54 kg of stainless steel, 265 kg of copper, 6.3 kg of epoxy board, 168 kg of chromium, and 18 kg of graphite. During operation, 169.8 thousand kWh of electricity, 270 carbon brushes, 90 kg of lubricant, and 5 collector rings. Its end-of-life recycling yielded 3532.1 kg steel and 251.75 kg copper. Conversely, VFDs manufacturing uses 2750 kg of steel, 1060 kg of copper, 30 kg of composite panels, 7.5 kg of waterproof membranes, and 63 kg of electronic components, with an operational consumption of 3087 thousand kWh of electricity and 30 kg of lubricant. VFD recycling results in the recovery of 2612.5 kg steel and 1007 kg copper. The inventory demonstrated the reliance of APMDs on strategic materials versus the higher operational energy intensity of VFDs. The detailed composition of each component material was shown in Table 1.

Table 1.

Inputs and outputs list of APMDs and VFDs.

2.3. Method of LCIA

The LCA in this study employed a standardized methodology framework in which the carbon footprint was calculated using the global warming potential over a 100-year horizon (GWP100) approach in accordance with ISO 14067 [44], whereas the quantification of other environmental impact categories utilized the ReCiPe 2016 midpoint characterization model.

2.4. Scenario Settings

In this study, the distribution and unit capacity data of coal-fired power plants in mainland China were first obtained from Global Energy Monitor (https://globalenergymonitor.org/), encompassing a total of 3232 units with a combined capacity of 1170.89 GW. Given the significant variations in installed capacity and commissioning year, the units were classified into three potential groups (high, moderate, and low) on the basis of the following criteria: (1) high-potential units: capacity > 300 MW and commissioned after 2000 (1960 units); (2) moderate-potential units: capacity > 300 MW and commissioned between 1990 and 1999 (171 units); and (3) low-potential units: capacity < 300 MW (1101 units). A 1.25 MW APMD was considered for replacing the circulating water pumps in coal-fired units, matching the 1.25 MW drive system specified in this study. According to actual power requirements, the number of APMDs required per unit is further stratified within each potential group as follows:

- (1)

- High-potential group:

- Capacity [300, 500) MW: 2 × 1.25 MW APMDs

- Capacity [500, 800) MW: 4 × APMDs

- Capacity ≥ 800 MW: 6 × APMDs

- (2)

- Moderate-potential group:

- Capacity [300, 500) MW: 1 × APMDs

- Capacity [500, 800) MW: 3 × APMDs

- Capacity ≥ 800 MW: 5 × APMDs

- (3)

- Low-potential group:

- Capacity ≥ 200 MW: 1 × APMDs

- Capacity < 200 MW: Deemed to have no retrofitting value.

Consequently, full replacement would require an estimated 6552 APMDs. On the basis of this framework, this study investigated the environmental benefits of replacing current drive systems with APMDs.

Furthermore, four scenarios were established: (1) business as usual (BAU): no APMDs retrofitting, continuing the current technology pathway (assumed to be all variable-frequency drives); (2) moderate (MOD): retrofitting only high-potential units; (3) aggressive (AGG): retrofitting both high- and moderate-potential units; and (4) FULL: retrofitting all unit types.

3. Results

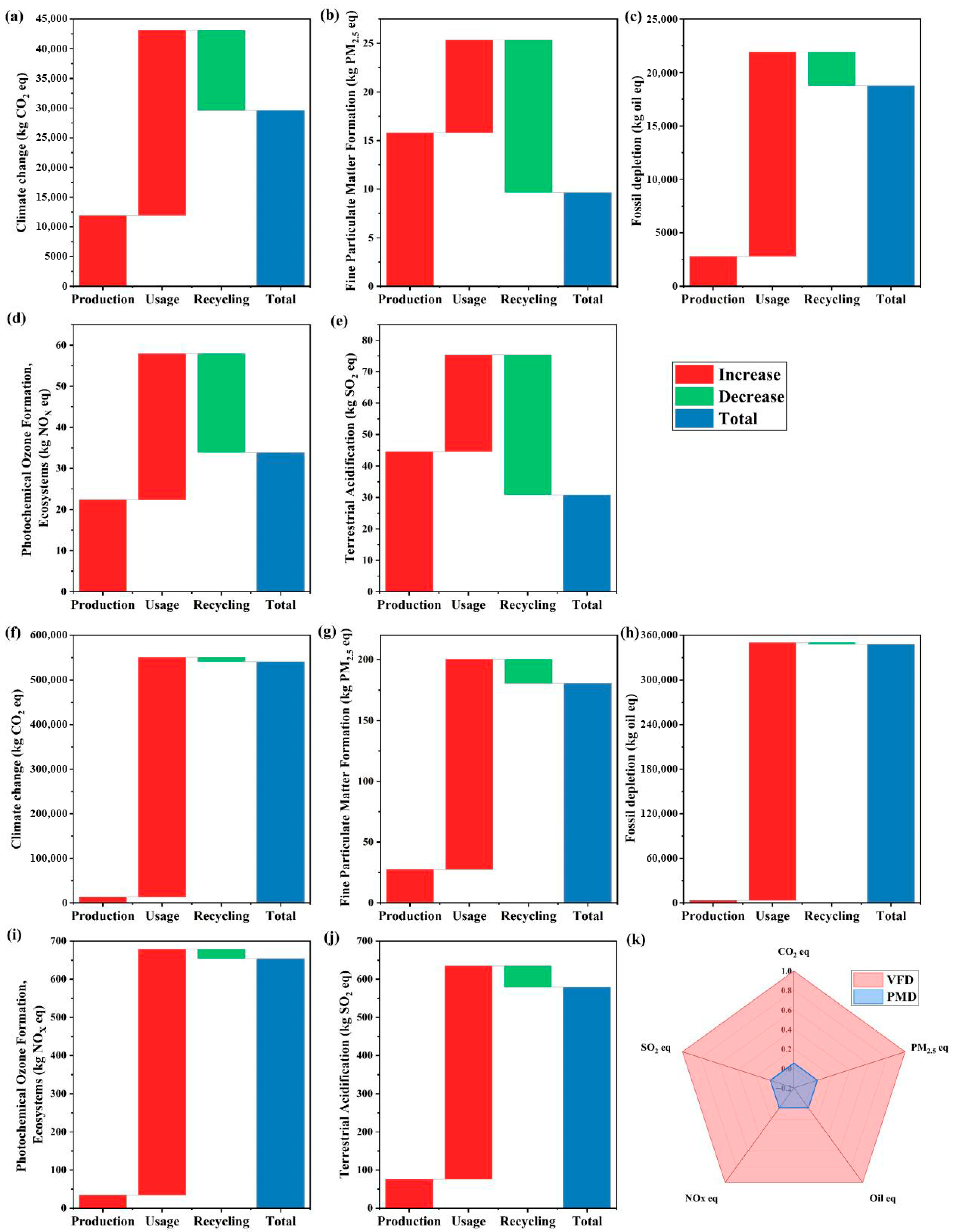

3.1. Life Cycle Environmental Impacts

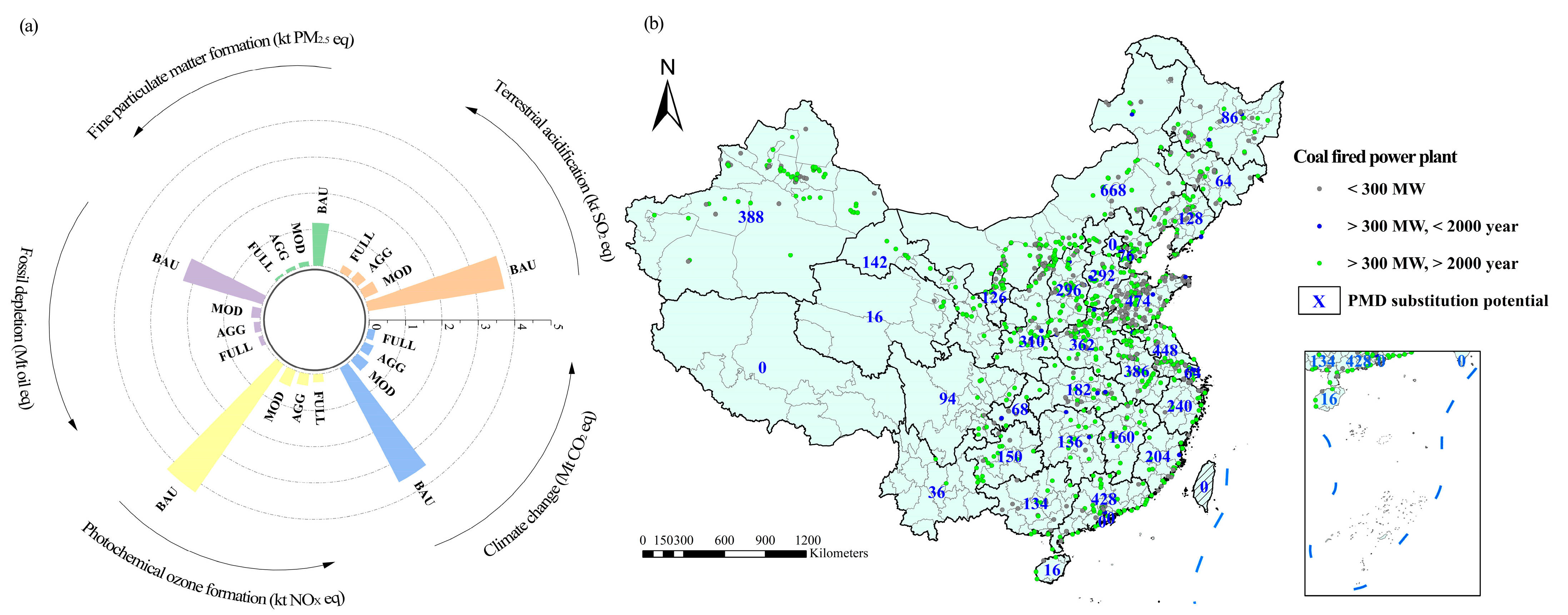

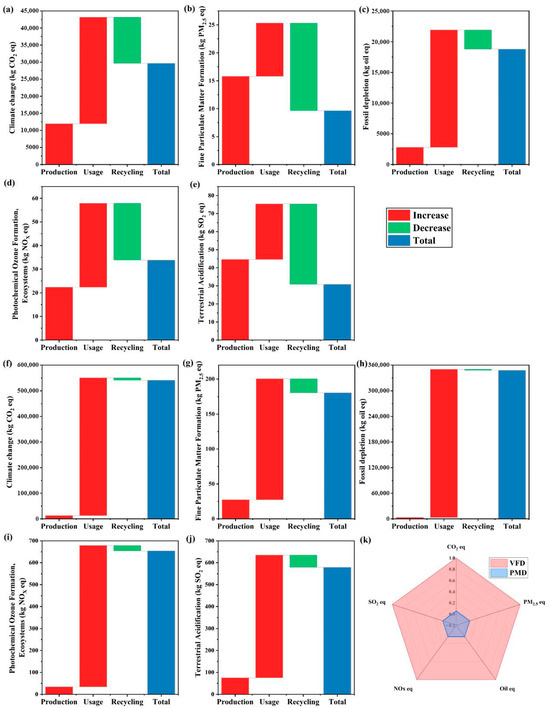

The comparative LCA between APMDs and VFDs reveals distinct environmental impact patterns across the production, usage, and recycling stages, as substantiated by comprehensive inventory data and visualized through bridge plots and radar charts (Figure 2). This analysis employed a standardized methodological framework, including climate change (kg CO2_eq), fine particulate matter formation (kg PM_eq), fossil depletion (kg oil _eq), photochemical ozone formation (kg NOX_eq), and terrestrial acidification (kg SO2_eq).

Figure 2.

Environmental impact assessment of APMDs and VFDs. (a,f): Climate change (kg CO2_eq); (b,g): fine particulate matter formation (kg PM_eq); (c,h): fossil depletion (kg oil_eq); (d,i): photochemical ozone formation (kg NOX_eq); (e,j): terrestrial acidification (kg SO2_eq); (k): different life cycle inventory values for various impact categories.

For both technologies, the production and usage stages contribute significantly to environmental burdens because of intensive material extraction, manufacturing emissions, and operational energy consumption, as previously described in the material flow inventory. Specifically, APMD production involves high inputs of rare-earth elements (e.g., neodymium–iron–boron magnets) and structural materials such as steel and copper, resulting in elevated initial impacts; this contrasts with VFDs production, which consumes substantial amounts of copper and electronics but is dominated by high electricity usage (e.g., 3087 MWh for VFDs vs. 169.8 MWh for APMDs) and associated losses from power conversion inefficiencies. Conversely, recycling provides critical offsets through resource recovery—the APMD excels here owing to the reclaimable value of its magnets and metals, yielding up to 3532.1 kg steel and 251.75 kg copper in recycling credits, whereas VFD recycling recovers 2612.5 kg steel and 1007 kg copper but with proportionally lower environmental benefits.

Radar chart quantification confirms the superior overall performance of the APMDs across all categories despite its higher production-phase burdens. APMDs demonstrate significant reductions across all environmental categories versus VFDs. Key findings include:

- GWP: 95% reduction in cumulative emissions (29.7 vs. 570 t CO2_eq)

- PMFP: 19.3% reduction (3.42 vs. 4.24 kg PM_eq)

- FDP: 22.1% decrease (1820 vs. 2335 kg oil_eq)

- POFP: 17.8% decrease (9.7 vs. 11.8 kg NOX_eq)

- AP: 14.6% decrease (12.3 vs. 14.4 kg SO2_eq)

This systemic advantage stems from the APMDs’ operational efficiency in noncontact torque transmission and its recyclability, which partially mitigates its rare-earth dependency. The findings highlight the APMDs as a viable decarbonization technology for industrial applications, contingent on enhanced rare-earth recovery infrastructure to maximize recycling benefits. Future research should investigate hybrid designs that optimize material efficiency in production while retaining operational gains to further advance sustainability outcomes.

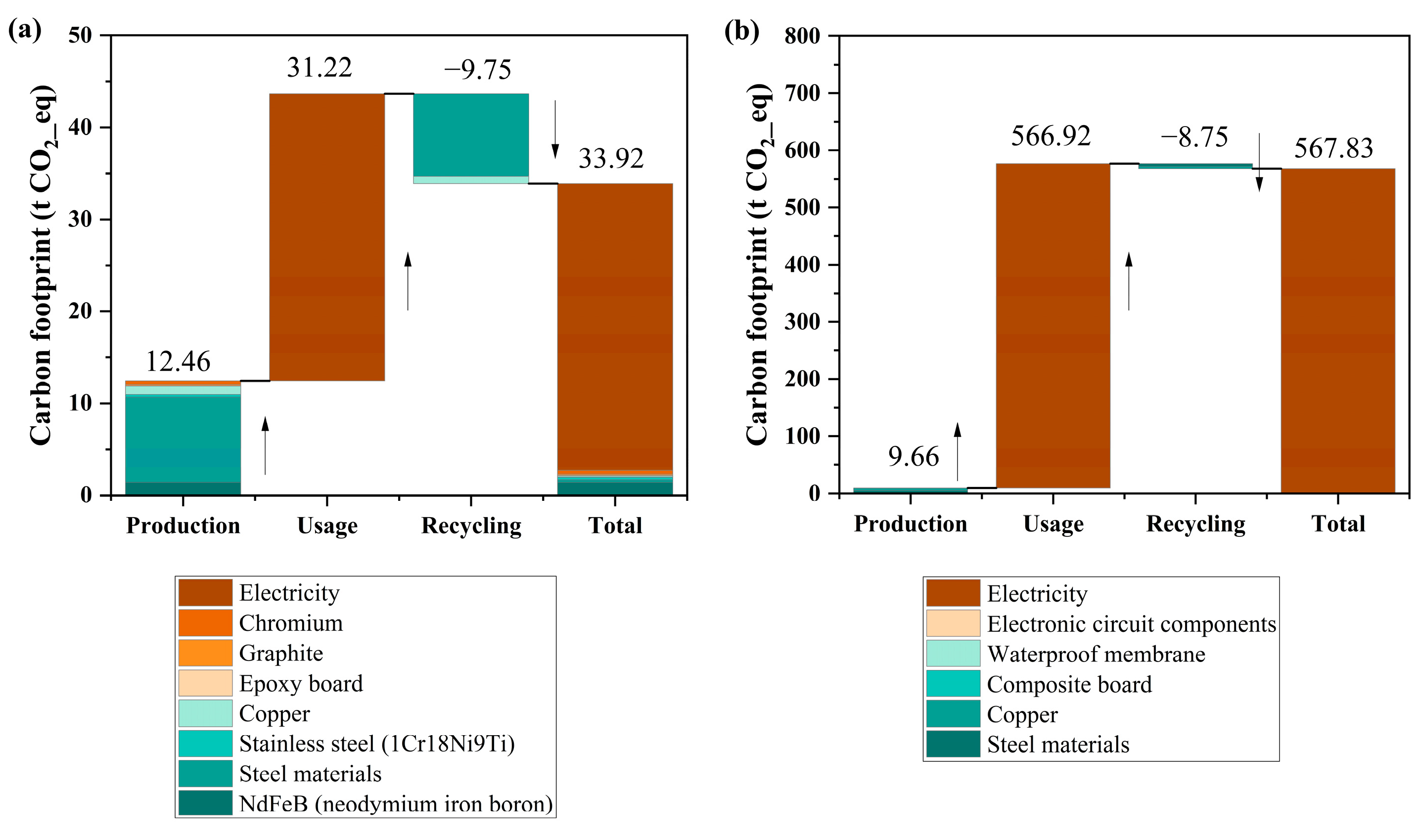

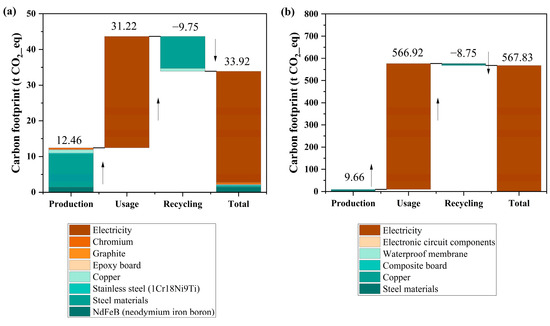

3.2. Comparison of Carbon Footprints

The comparative carbon footprint analysis of APMDs and VFDs, as visually represented in Figure 3, reveals stark differences in greenhouse gas emissions across life cycles. With respect to APMD technology, the total global warming potential is 29.7 tonnes of CO2_eq, with distinct phase-specific contributions shaping this outcome. Production activities, primarily involving resource-intensive fabrication of neodymium iron–boron magnets and structural steel, contribute approximately 11.9 tonnes (40% of the total), whereas operational energy consumption during the usage phase is 31.1 tonnes (105%). Crucially, the recycling phase delivers a substantial environmental credit of −13.3 tonnes (−45%) through the recovery and reuse of valuable materials, including 3532 kg of steel and 252 kg of copper, significantly offsetting earlier emissions through circular economy mechanisms. In contrast, VFDs technology results in an order-of-magnitude greater carbon footprint at 570 tonnes CO2_eq, characterized by fundamentally different phase distributions. The production impacts remain relatively low at 13.1 tonnes (2.3% of total), reflecting less material complexity than those associated with APMDs, yet these impacts are dwarfed by the overwhelming operational burden of 564 tonnes (99%) stemming from protracted, energy-intensive usage. This operational dominance arises from power conversion inefficiencies compounded by ancillary thermal management requirements, resulting in electricity consumption reaching 3087 MWh—nearly twenty times higher than APMDs’ operational demand. The recycling contributions for the VFDs remain marginal at −10.3 tonnes (−1.8%) owing to the limited recovery potential of heterogeneous electronic assemblies despite the retrieval of 2612 kg steel and 1007 kg copper.

Figure 3.

Life cycle carbon footprint of (a) APMDs and (b) VFDs.

The technical distinctions underpinning these divergent profiles warrant emphasis. APMDs’ noncontact torque transmission design virtually eliminates friction losses that typically necessitate auxiliary cooling systems in VFDs, thereby reducing operational energy penalties despite its material-intensive production. Moreover, the high irreclaimability of APMDs’ rare-earth magnets and metals enable significant end-of-life carbon sequestration to be absent in VFDs architectures where integrated circuitry and mixed-material assemblies constrain recycling efficiency. Consequently, while both technologies exhibit production-phase carbon liabilities—APMDs from strategic materials such as chromium and graphite and VFDs from electronic components—their lifecycle divergence originates primarily from usage efficiency differentials and recyclability potential. Collectively, the APMD demonstrates a 95% carbon footprint reduction relative to the VFDs, establishing its viability for industrial decarbonization where variable-speed applications prevail. This advantage, however, remains contingent on advancing rare-earth recovery infrastructure to further mitigate production impacts, as current recycling offsets cannot fully compensate for APMDs’ initial material intensity. The findings underscore that operational energy savings and circular design principles—rather than production optimization alone—dominate carbon reduction pathways for industrial drive systems, suggesting that future research should prioritize innovations that hybridize APMDs’ operational superiority with VFDs’ material efficiency to achieve synergistic sustainability gains.

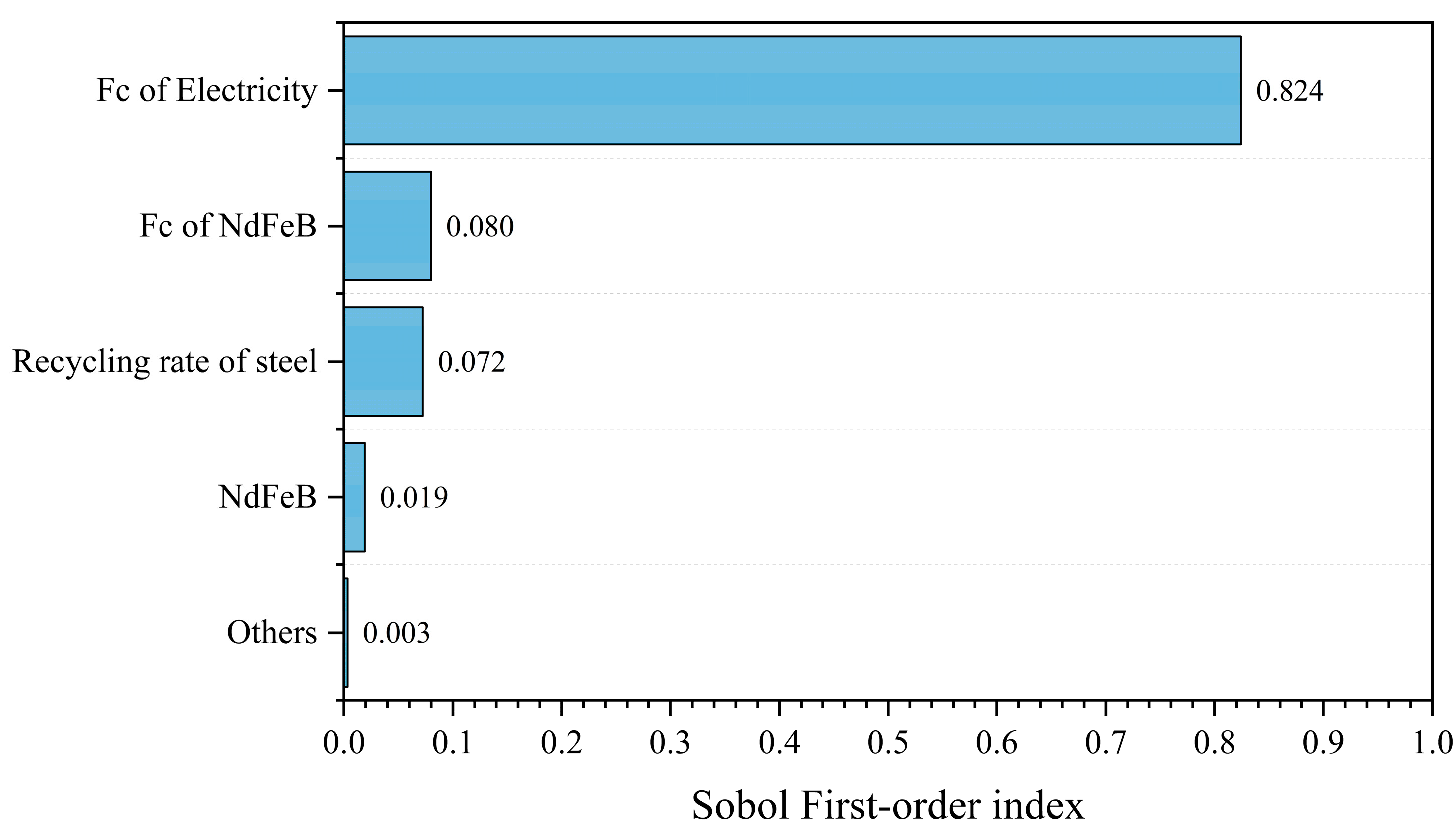

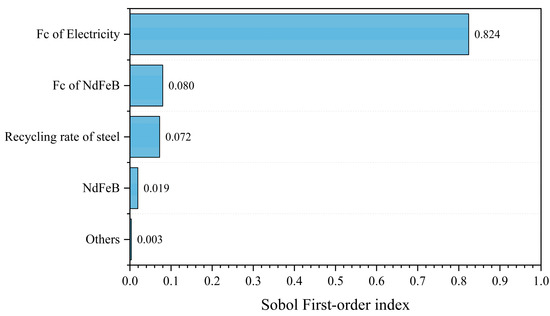

3.3. Sensitivity Analysis

The global sensitivity analysis conducted using the Sobol method implemented in Python 3.12 SALib revealed a highly skewed parameter importance structure (Figure 4). From the 155,648 parameter combinations generated through Saltelli sampling (N = 4096 base samples), the total-order sensitivity indices (ST) exhibited a striking polarization, with a single parameter dominating the model’s output variance. Specifically, the “Fc of electricity” parameter had an ST value of 0.80 (±0.01), indicating that it independently accounted for 80% of the total output variability. The next two most influential parameters were “Fc of NdFeB” and “recycling rate of steel”, with ST values of 0.08 and 0.07, respectively, collectively explaining an additional 15% of the variance. In contrast, the remaining parameters all exhibited ST values less than 0.02, suggesting their negligible contribution to the model’s output variability.

Figure 4.

Sensitivity analysis of carbon emissions. Note: Fc refers to carbon footprint factors.

This extreme sensitivity concentration implies that the model’s behavior is governed primarily by the “Fc of electricity” parameter, whereas the other inputs play a relatively minor role within the current parameter space. Such a clear sensitivity structure provides a clear direction for reducing carbon footprint, suggesting that future research should focus on reducing the “Fc of electricity” and “Fc of NdFeB”, and increasing the “steel recycling rate”.

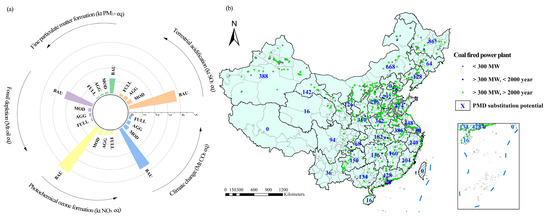

3.4. Scenario Analysis

The analysis presented in Figure 5 examines the reductions in potential carbon emissions and environmental impacts from adopting APMDs in China’s coal-fired power sector. The results demonstrate significant environmental benefits across multiple impact categories compared with the business-as-usual (BAU) scenario. In the BAU case, annual carbon emissions are projected to reach 3.543 Mt CO2_eq, whereas fine particulate matter emissions are projected to reach 1.183 kt, fossil fuel consumption is projected to reach 2.279 Mt of oil_eq, photochemical oxidant formation is projected to reach 4.284 kt NOx_eq, and acidification is projected to reach 3.794 kt SO2_eq. However, transitioning to a moderate (MOD) APMDs adoption scenario could reduce carbon emissions by 89% to 0.388 Mt CO2_eq, PM by 89% to 0.128 kt, fossil fuel use by 89% to 0.247 Mt oil_eq, photochemical oxidants by 89% to 0.456 kt NOx_eq, and acidification by 89% to 0.409 kt SO2_eq. Even greater environmental improvements are possible under more aggressive (AGG) and full (FULL) APMDs adoption scenarios. In the FULL case, carbon emissions decrease by 95% to 0.194 Mt CO2_eq, PM by 95% to 0.063 kt, fossil fuels by 95% to 0.123 Mt oil_eq, photochemical oxidants by 95% to 0.222 kt NOx_eq, and acidification by 95% to 0.202 kt SO2_eq. These findings highlight the significant potential for APMDs to deliver substantial environmental benefits in China’s coal power sector. Prioritizing the upgrade of high-potential power plants would be the most cost-effective approach, as it could achieve large-scale emissions reductions with relatively modest investments. Policy-makers and industry stakeholders should consider accelerating the adoption of APMDs technologies to realize these environmental and climate change mitigation advantages.

Figure 5.

Potential carbon emission and environmental impact reduction resulting from the adoption of permanent magnet drive systems in China’s coal-fired power sector. (a). Changes in five types of environmental impacts under the four scenarios; (b). distribution of coal-fired power plants in mainland China; and APMDs replacement potential of coal-fired power plants in each province of mainland China.

4. Discussion

4.1. Environmental Benefit Mechanism and System Advantages of APMDs

In this study, an LCA revealed the significant advantages of APMDs over VFDs in terms of carbon emission reduction and energy efficiency. The core findings indicate that APMDs can achieve a 95% reduction in lifecycle carbon emissions (29.7 tonnes vs. 570 tonnes CO2_eq, respectively). Energy savings during the operational phase constitute the dominant factor. By employing noncontact magnetic coupling transmission, APMDs eliminate power electronics conversion losses (5–8%) inherent in VFDs and the associated energy consumption of the cooling system. Consequently, the operational energy consumption of APMDs is merely 5.5% of that of VFDs (169.8 vs. 3087 MWh, respectively). The carbon compensation effect derived from material recycling is particularly pronounced for APMDs. The recycling of high-value materials (NdFeB magnets, copper, and specialty steel) contributes a significant negative 45% carbon offset. In contrast, VFDs achieve only a −1.8% offset because of the complexity of their electronic components and lower recycling rates. Enhanced system reliability indirectly decreases environmental impact. The dust-proof design and oil-free operation of APMDs reduce failure rates by 60%, thereby decreasing resource consumption associated with maintenance activities. Notably, although rare earth (NdFeB) mining during the APMDs production phase results in higher initial emissions (11.9 tonnes CO2_eq, accounting for 40% of its total footprint), this cost is fully offset by energy efficiency gains during the use phase and recycling benefits. This outcome validates the sustainable paradigm of “initial investment for long-term gains” in industrial green technologies [45].

4.2. Key Constraints in Technology Promotion

Sensitivity analysis revealed the vulnerability thresholds for the environmental benefits of APMDs (Figure 4). The “Fc of electricity” (ST = 0.80) parameter emerged as the primary source of sensitivity dominating the carbon footprint of APMDs. Taking China’s current coal-dominated power grid structure (60% share in 2024) as an example, a 0.1 kg CO2_eq/kWh increase in the grid carbon emission factor attenuates the carbon reduction benefit of APMDs by 22%. This highlights the deep coupling between technological benefits and energy structure transition—the carbon footprint of APMDs can be further reduced as grid decarbonization progresses. In other words, carbon reduction constraints on coal power systems serve as the primary driver for retrofitting transmission systems in coal-fired power plants [46]. Another critical constraint lies in rare earth supply chain risk. The “Fc of NdFeB” (ST = 0.08) and “recycling rate of steel” (ST = 0.07) parameters rank as the second and third most sensitive parameters, respectively. However, China’s current rare earth recycling rate remains below 5%, leading to an underestimation of the carbon offset potential during the recycling phase in the model. This finding aligns with the rationale behind the US Inflation Reduction Act’s designation of permanent magnets as strategic materials. Consequently, future technology iterations should prioritize “low-rare-earth magnet design” and “closed-loop material flow” pathways [26].

4.3. Renovation Path and Potential for Reducing the Emissions of Coal-Fired Power Systems

A scenario analysis based on 3232 coal-fired units (Figure 5) revealed that tiered emission reduction benefits from deploying APMDs in auxiliary systems. High-potential units (≥300 MW, commissioned post-2000) should be prioritized for retrofitting, as they demonstrate favorable carbon abatement economics compared to conventional drives and are also more practically significant relative to medium- and low-potential units. Under an “aggressive scenario” (retrofitting high- + medium-potential units), annual CO2_eq emissions from China’s coal power auxiliary systems could decrease from 3.543 million tonnes to 0.426 million tonnes, which is equivalent to reducing coal consumption by 1.2 million tonnes. This would concurrently mitigate secondary environmental burdens, including those of PM (−89%) and acidifying pollutants (−89%). The economic viability of this transition is emerging: compared with current practices where VFDs incur lifecycle maintenance costs reaching 120% of procurement expenses, APMDs reduce operation and maintenance costs by nearly 40% because they eliminate frequency converters and cooling requirements [16,47]. Furthermore, studies have indicated that asynchronous motors can be retrofitted into APMDs with limited investment to optimize environmental and economic returns [48]. Policy leverage could accelerate adoption by extending China’s GB 30253-2024 permanent magnet motor subsidies (15–20% procurement incentives) to transmission systems, while simultaneously integrating verified emission reductions—such as the 3.12 Mt CO2_eq/yr achievable under aggressive retrofit scenarios—into provincial carbon markets as tradeable credits. Furthermore, adopting the US Inflation Reduction Act’s strategic model of 25% tax credits for permanent magnet production would de-risk material supply chains. Collectively, these mechanisms incentivize ‘efficiency-for-carbon-quota’ strategies by leveraging both APMDs’ <100 ms torque response for grid stability and their quantified emission reduction potential.

4.4. Research Limitations and Future Directions

This study has several limitations that require further investigation. A primary limitation is the omission of permanent magnet recycling processes from the model. Although NdFeB magnets constitute 1.5% (72 kg per unit) of the APMDs mass, the current global rare-earth recycling rate is only 5–10%, and hydrometallurgical recycling routes generate hydrofluoric acid emissions [49]. Enhanced future recycling rates could further reduce the environmental impacts of APMDs, including their carbon footprint [50]. Second, the simplified system boundary may lead to an underestimation of benefits: the model did not account for the indirect benefits associated with grid harmonic mitigation, nor did it quantify the amplifying effect of dusty environments on the failure rate of VFDs.

5. Conclusions

Through LCA, this study demonstrates that replacing VFDs with APMDs significantly improves the environmental performance of auxiliary equipment in coal-fired power plants. The analysis establishes APMDs as a dual-enabler for coal power decarbonization through two novel advances: first, LCA proves recycling offsets (45%) amplify operational gains (94.5% energy reduction vs. VFDs), achieving 95% lifecycle carbon reduction; sensitivity analysis (ST = 0.80 for electricity factors) confirms APMDs benefits scale with grid decarbonization, while aggressive retrofits on high-potential units (>300 MW post-2000) unlock 3.12 Mt CO2_eq/year reductions while simultaneously cutting PM and associated pollutants by 89%.

Author Contributions

Conceptualization, B.L. and C.Z.; methodology, J.P.; validation, J.P.; formal analysis, Y.Z.; investigation, Y.Z. and D.L.; data curation, Y.Z.; writing—original draft preparation, Y.Z.; writing—review and editing, C.Z. and B.L.; supervision, B.L. and C.Z.; project administration, M.G. and R.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Engineering Research Center of UHV Technology and Novel Electrical Equipment Basis.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

We acknowledge the support of National Engineering Research Center of UHV Technology and Novel Electrical Equipment Basis. We pay tribute to the practitioners who provided us with detailed information.

Conflicts of Interest

Authors Meng Gao and Ran Zhuo were employed by the CSG Electric Power Research Institute Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- IEA. Energy Efficiency Policy Opportunities for Electric Motor-Driven Systems. 2011. Available online: https://www.iea.org/reports/energy-efficiency-policy-opportunities-for-electric-motor-driven-systems (accessed on 15 September 2025).

- Oliveira, F.; Ukil, A. Comparative Performance Analysis of Induction and Synchronous Reluctance Motors in Chiller Systems for Energy Efficient Buildings. IEEE Trans. Ind. Inf. 2019, 15, 4384–4393. [Google Scholar] [CrossRef]

- Kapp, S.; Wang, C.; McNelly, M.; Romeiko, X.; Choi, J.-K. A comprehensive analysis of the energy, economic, and environmental impacts of industrial variable frequency drives. J. Clean. Prod. 2024, 434, 140474. [Google Scholar] [CrossRef]

- Lavrič, H.; Drobnič, K.; Fišer, R. Model-Based Assessment of Energy Efficiency in Industrial Pump Systems: A Case Study Approach. Appl. Sci. 2024, 14, 10430. [Google Scholar] [CrossRef]

- Creamer, J.; Van Hemert, G. Energy savings—VFDs and more. World Pumps 2010, 2010, 24–28. [Google Scholar] [CrossRef]

- Abdelaziz, E.A.; Saidur, R.; Mekhilef, S. A review on energy saving strategies in industrial sector. Renew. Sustain. Energy Rev. 2011, 15, 150–168. [Google Scholar] [CrossRef]

- Yan, X.; Chen, B. Analysis of a novel energy-efficient system with a bidirectional supercharger for forging hydraulic press. J. Clean. Prod. 2021, 286, 125520. [Google Scholar] [CrossRef]

- Li, H.; Liu, J.; Li, K.; Liu, Y. A review of recent studies on piezoelectric pumps and their applications. Mech. Syst. Sig. Process. 2021, 151, 107393. [Google Scholar] [CrossRef]

- De Almeida, A.; Fong, J.; Brunner, C.U.; Werle, R.; Van Werkhoven, M. New technology trends and policy needs in energy efficient motor systems—A major opportunity for energy and carbon savings. Renew. Sustain. Energy Rev. 2019, 115, 109384. [Google Scholar] [CrossRef]

- Arun Shankar, V.K.; Umashankar, S.; Paramasivam, S.; Hanigovszki, N. A comprehensive review on energy efficiency enhancement initiatives in centrifugal pumping system. Appl. Energy 2016, 181, 495–513. [Google Scholar] [CrossRef]

- O’Brien, M. Reducing Industrial CO2 Emissions Through Increased Motion Efficiency; Analog Devices, Inc.: Wilmington, DC, USA, 2023. [Google Scholar]

- IEA. Electricity Market Report 2023. Available online: https://www.iea.org/reports/electricity-market-report-2023 (accessed on 12 September 2025).

- Eichhammer, W.; Fleiter, T. Energy Efficiency in Electric Motor Systems: Technology, Saving Potentials and Policy Options for Developing Countries; UNIDO: Vienna, Austria, 2012. [Google Scholar]

- An, Q.; Lu, Y.; Zhao, M. Review of Key Technologies of the High-Speed Permanent Magnet Motor Drive. Energies 2024, 17, 5252. [Google Scholar] [CrossRef]

- IEEE Std 519-2022 (Revision of IEEE Std 519-2014); IEEE Standard for Harmonic Control in Electric Power Systems. IEEE: New York, NY, USA, 2022; pp. 1–31.

- Siemens. Cost Considerations When Selecting Variable Frequency Drive Solutio. 2017. Available online: https://d3mm496e6885mw.cloudfront.net/manufacturer_product/5919d9d2e4b0b6f46aff2a4b/project/projects/original/Cost_Considerations_VFD_FINAL.pdf (accessed on 10 September 2025).

- Precision Electric, Inc. ABB VFD: A Comprehensive Guide to Variable Frequency Drives; Precision Electric, Inc.: Mishawaka, IN, USA, 2022. [Google Scholar]

- Hughes, A.; Drury, B. Chapter 9—Synchronous, permanent magnet and reluctance motors and drives. In Electric Motors and Drives, 5th ed.; Hughes, A., Drury, B., Eds.; Newnes: Oxford, UK, 2019; pp. 307–373. [Google Scholar]

- Ormerod, J. Chapter 12—Permanent magnet markets and applications. In Modern Permanent Magnets; Croat, J., Ormerod, J., Eds.; Woodhead Publishing: Cambridge, MA, USA, 2022; pp. 403–434. [Google Scholar]

- de Almeida, A.T.; Fong, J.; Falkner, H.; Bertoldi, P. Policy options to promote energy efficient electric motors and drives in the EU. Renew. Sustain. Energy Rev. 2017, 74, 1275–1286. [Google Scholar] [CrossRef]

- Hughes, A.; Drury, B. Chapter Nine—Synchronous and Brushless Permanent Magnet Machines and Drives. In Electric Motors and Drives, 4th ed.; Hughes, A., Drury, B., Eds.; Newnes: Boston, MA, USA, 2013; pp. 281–313. [Google Scholar]

- Baldassarre, B.; Carrara, S. Critical raw materials, circular economy, sustainable development: EU policy reflections for future research and innovation. Resour. Conserv. Recycl. 2025, 215, 108060. [Google Scholar] [CrossRef]

- Kumari, A.; Sahu, S.K. A comprehensive review on recycling of critical raw materials from spent neodymium iron boron (NdFeB) magnet. Sep. Purif. Technol. 2023, 317, 123527. [Google Scholar] [CrossRef]

- GB 30253-2024; Minimum Allowable Values of Energy Efficiency and Energy Efficiency Grades for Permanent Magnet Synchronous Motors. State Administration for Market Regulation: Beijing, China, 2024.

- Ministry of Industry and Information Technology, PRC. National Directory of Energy-Saving and Carbon Reduction Technology and Equipment for the Industrial and Information Technology Sectors. 2025. Available online: https://www.miit.gov.cn/zwgk/zcwj/wjfb/gg/art/2024/art_28ce8b3d62454e05a2da551cfc1412e8.html (accessed on 7 October 2025).

- Congress, USA. H.R.5376—Inflation Reduction Act of 2022. In Proceedings of the 117th Congress (2021–2022), Washington, DC, USA, 8–27 April 2022. [Google Scholar]

- Kaya, M. An overview of NdFeB magnets recycling technologies. Curr. Opin. Green Sustain. Chem. 2024, 46, 100884. [Google Scholar] [CrossRef]

- Schulze, R.; Buchert, M. Estimates of global REE recycling potentials from NdFeB magnet material. Resour. Conserv. Recycl. 2016, 113, 12–27. [Google Scholar] [CrossRef]

- Koenen, C.; Reuss, H.C. Sustainability optimization of the NdFeB magnet system of PMSMs by linking electromagnetic calculation and life cycle assessment. In Proceedings of the Elektromechanische Antriebssysteme 2023; 9. Fachtagung (VDE OVE), Wien, Austria, 8–9 November 2023; pp. 31–37. [Google Scholar]

- Li, Z.; Che, S.; Zhao, H.; Zhang, L.; Wang, P.; Du, S.; Zhang, H.; Feng, Y.; Sun, H. Loss analysis of high-speed permanent magnet motor based on energy saving and emission reduction. Energy Rep. 2023, 9, 2379–2394. [Google Scholar] [CrossRef]

- Auer, J.; Meincke, A. Comparative life cycle assessment of electric motors with different efficiency classes: A deep dive into the trade-offs between the life cycle stages in ecodesign context. Int. J. Life Cycle Assess. 2018, 23, 1590–1608. [Google Scholar] [CrossRef]

- Jung, S.-W.; Kang, D.; Palanimuthu, K.; Joo, Y.H.; Jung, S.-Y. Design of 20 MW direct-drive permanent magnet synchronous generators for wind turbines based on constrained many-objective optimization. Wind Energy 2024, 27, 847–872. [Google Scholar] [CrossRef]

- Wardach, M.; Palka, R.; Prajzendanc, P.; Gundabattini, E.; Cierzniewski, K.; Pstrokonski, R.; Cichowicz, M.; Wiszniewski, M.; Pacholski, S.; Singh Rassiah, R.; et al. Permanent magnet assisted synchronous reluctance machine for drives of light vehicles. Sustain. Energy Technol. Assess. 2024, 65, 103780. [Google Scholar] [CrossRef]

- Zhao, X.; Zhou, Y.; Song, Y.; Xu, J.; Li, J.; Tat, T.; Chen, G.; Li, S.; Chen, J. Permanent fluidic magnets for liquid bioelectronics. Nat. Mater. 2024, 23, 703–710. [Google Scholar] [CrossRef]

- National Bureau of Statistics, PRC. Statistical Bulletin of the National Economic and Social Development of the People’s Republic of China for the Year, 2024. Available online: https://www.stats.gov.cn/sj/zxfb/202502/t20250228_1958817.html (accessed on 12 October 2025).

- Kao, X.; Liu, Y.; Wang, W.; Wen, Q.; Zhang, P. The pressure of coal consumption on China’s carbon dioxide emissions: A spatial and temporal perspective. Atmos. Pollut. Res. 2024, 15, 102188. [Google Scholar] [CrossRef]

- Mandi, R.P.; Yaragatti, U.R. Control of CO2 emission through enhancing energy efficiency of auxiliary power equipment in thermal power plant. Int. J. Electr. Power Energy Syst. 2014, 62, 744–752. [Google Scholar] [CrossRef]

- Shajahan, M.S.M.; Jamal, D.N.; Mathew, J.; Ali Akbar, A.A.; Sivakumar, A.; Shahul Hameed, M.S. Improvement in efficiency of thermal power plant using optimization and robust controller. Case Stud. Therm. Eng. 2022, 33, 101891. [Google Scholar] [CrossRef]

- Wang, R.; Cai, W.; Cui, R.Y.; Huang, L.; Ma, W.; Qi, B.; Zhang, J.; Bian, J.; Li, H.; Zhang, S.; et al. Reducing transition costs towards carbon neutrality of China’s coal power plants. Nat. Commun. 2025, 16, 241. [Google Scholar] [CrossRef] [PubMed]

- Su, C.; Xu, Z.; Wang, X.; Li, B. Research on the Co-Evolution Mechanism of Electricity Market Entities Enabled by Shared Energy Storage: A Tripartite Game Perspective Incorporating Dynamic Incentives/Penalties and Stochastic Disturbances. Sustainability 2025, 13, 817. [Google Scholar] [CrossRef]

- Kuru, H. A Carbon Footprint Study of Electric Motor Production Using Life Cycle Assessment and Greenhouse Gas Protocol; LUT University: Lappeenranta, Finland, 2024. [Google Scholar]

- Johansson, S.S.E.; Isberg, P.J.; Westberg, E. Sustainability in the life of an electric motor: A circular future. ABB Rev. 2023, 1, 56–61. Available online: https://library.e.abb.com/public/5ea2f58712a546188d17f51424a87b6c/56-61+ABB+Review+Special+Edition+-+Women+in+STEM+2024+A+circular+future.pdf?x-sign=byF%2FkmResPlSOnpYrbqe7uadID74GX8FmcYXfdh0z8sbFfSFXNR8mLmx2hbmy34%2F (accessed on 15 October 2025).

- Li, H.; Huang, W.; Xu, J.; Huang, Q. Application of wound permanent magnet coupling speed regulator in speed regulation and energy saving. High-Technol. Commer. 2017, 42–45. Available online: https://qikan.cqvip.com/Qikan/Article/Detail?id=71757067504849554850484952 (accessed on 17 October 2025).

- ISO 14067:2018; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. International Organization for Standardization (ISO): Geneva, Switzerland, 2018.

- Orlova, S.; Rassõlkin, A. Permanent Magnets in Sustainable Energy: Comparative Life Cycle Analysis. Energies 2024, 17, 6384. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Tian, Y.; Cheng, W.; Yang, J.; Xu, D.; Wang, Y.; Xie, K.; Ku, A.Y. Reduction of carbon emissions from China’s coal-fired power industry: Insights from the province-level data. J. Clean. Prod. 2020, 242, 118518. [Google Scholar] [CrossRef]

- Gündoğdu, T.; Kömürgöz, G. Technological and economical analysis of salient pole and permanent magnet synchronous machines designed for wind turbines. J. Magn. Magn. Mater. 2012, 324, 2679–2686. [Google Scholar] [CrossRef]

- Li, Z.; Che, S.; Wang, P.; Du, S.; Zhao, Y.; Sun, H.; Li, Y. Implementation and analysis of remanufacturing large-scale asynchronous motor to permanent magnet motor under circular economy conditions. J. Clean. Prod. 2021, 294, 126233. [Google Scholar] [CrossRef]

- Adibi, N.; Lafhaj, Z.; Payet, J. New resource assessment characterization factors for rare earth elements: Applied in NdFeB permanent magnet case study. Int. J. Life Cycle Assess. 2019, 24, 712–724. [Google Scholar] [CrossRef]

- Hernandez, M.; Messagie, M.; De Gennaro, M.; Van Mierlo, J. Resource depletion in an electric vehicle powertrain using different LCA impact methods. Resour. Conserv. Recycl. 2017, 120, 119–130. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).