Research on the Relationship Between Lean Management and Digital Transformation Strategy and Sustainable Development: A Case Study of the Automotive Industry in Taiwan

Abstract

1. Introduction

1.1. Research Background

1.2. Research Motivation and Purpose

2. Literature Review

2.1. Sustainable Development

2.2. Lean Management

2.3. Digital Transformation

3. Research Method

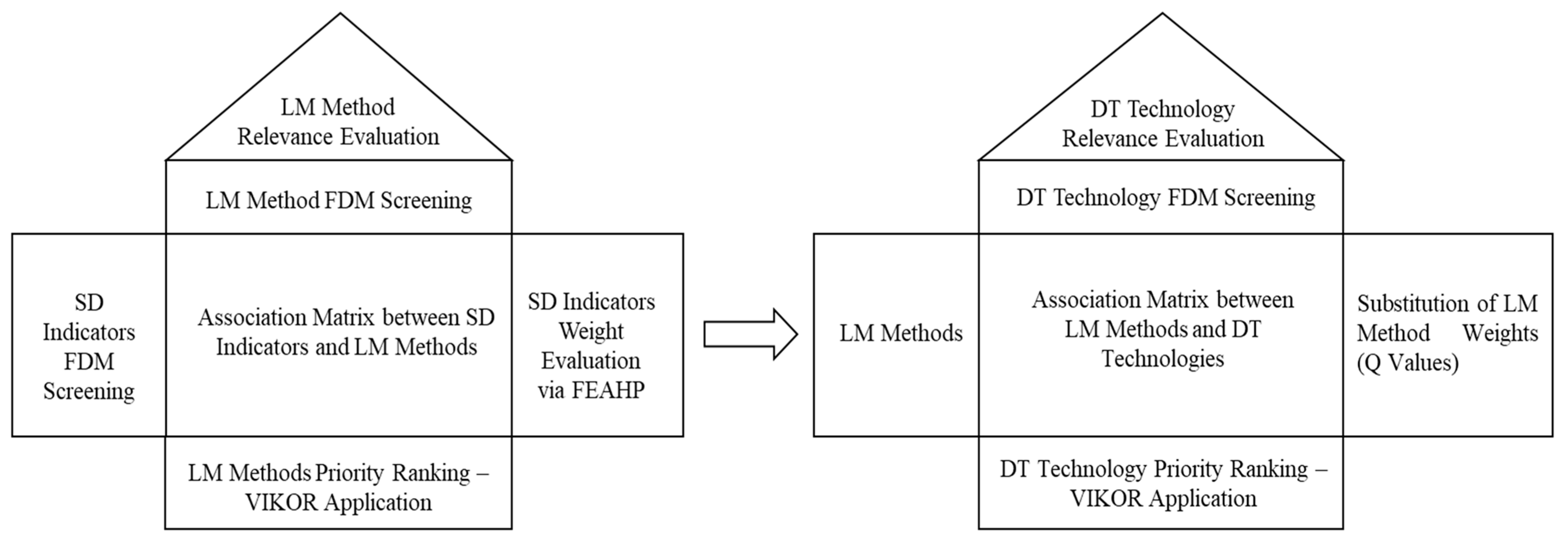

3.1. Research Framework

3.2. The Fuzzy Delphi Method

- 1.

- If two triangular fuzzy numbers do not overlap, then (). The “value of importance degree of consensus,” , of the evaluation item i is equal to the arithmetic mean of and . This is expressed as

- 2.

- If two triangular fuzzy numbers overlap, then () and < , where , which represents that the grey area of the fuzzy relationships is smaller than the experts’ interval of the evaluation item’s “geometric mean of optimistic cognition” and “geometric mean of the conservative cognition.” Although the interval values of expert opinions do not overlap—indicating no direct consensus—the divergence between the most extreme opinions and those of other experts is not substantial. In such cases, the importance consensus value for evaluation item i is calculated using Equation (2) [9,115].

- 3.

- If the two triangular fuzzy numbers overlap—that is, when () and , this indicates that the experts’ interval values lack a segment of consensus. In other words, the range of expert opinions is too divergent to reflect agreement. Consequently, such evaluation items are considered non-convergent. These items should be returned to the expert panel for further review through an additional round of the questionnaire process, until consensus is reached and a definitive importance consensus value can be established.

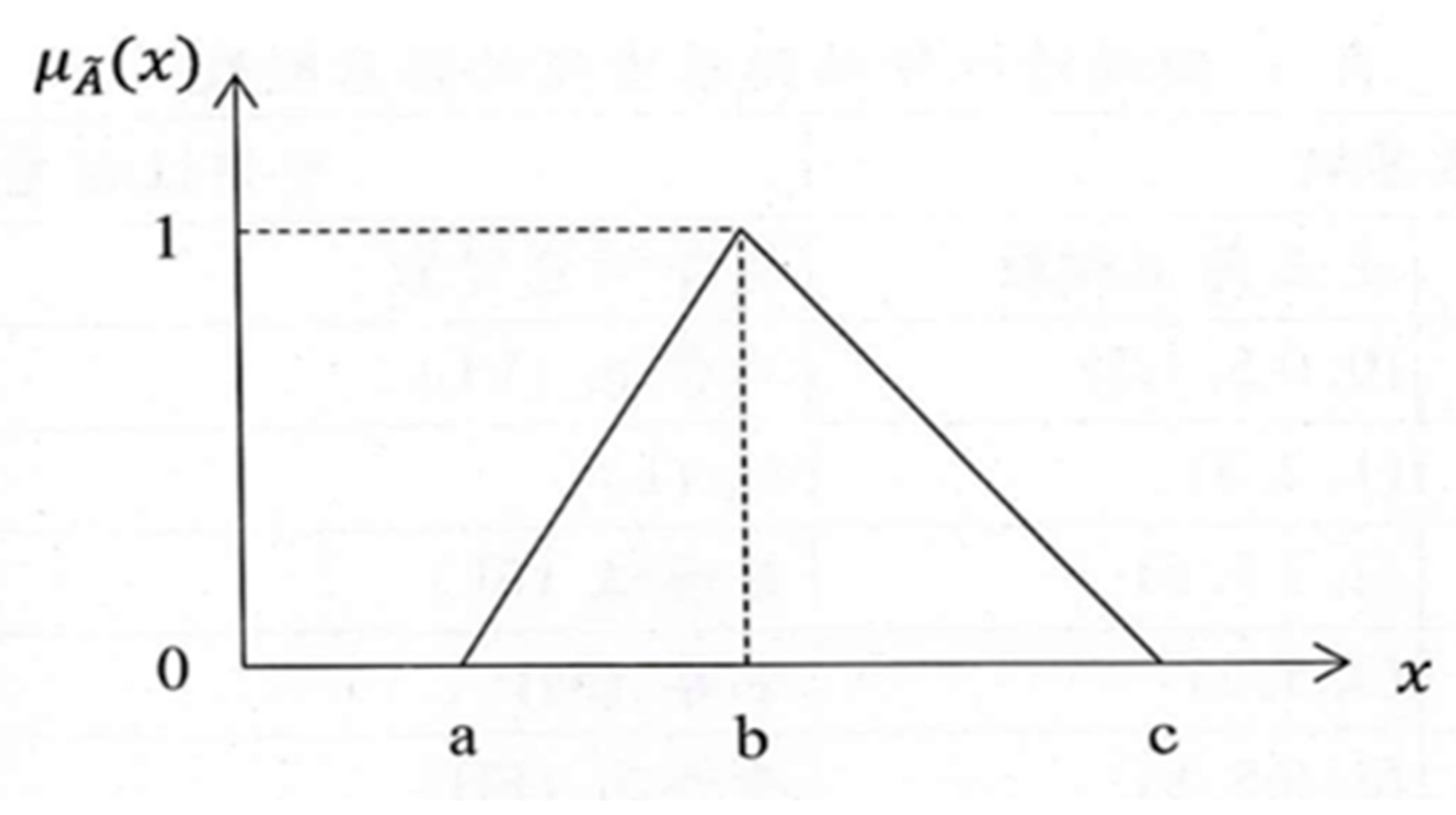

3.3. The Fuzzy Logic

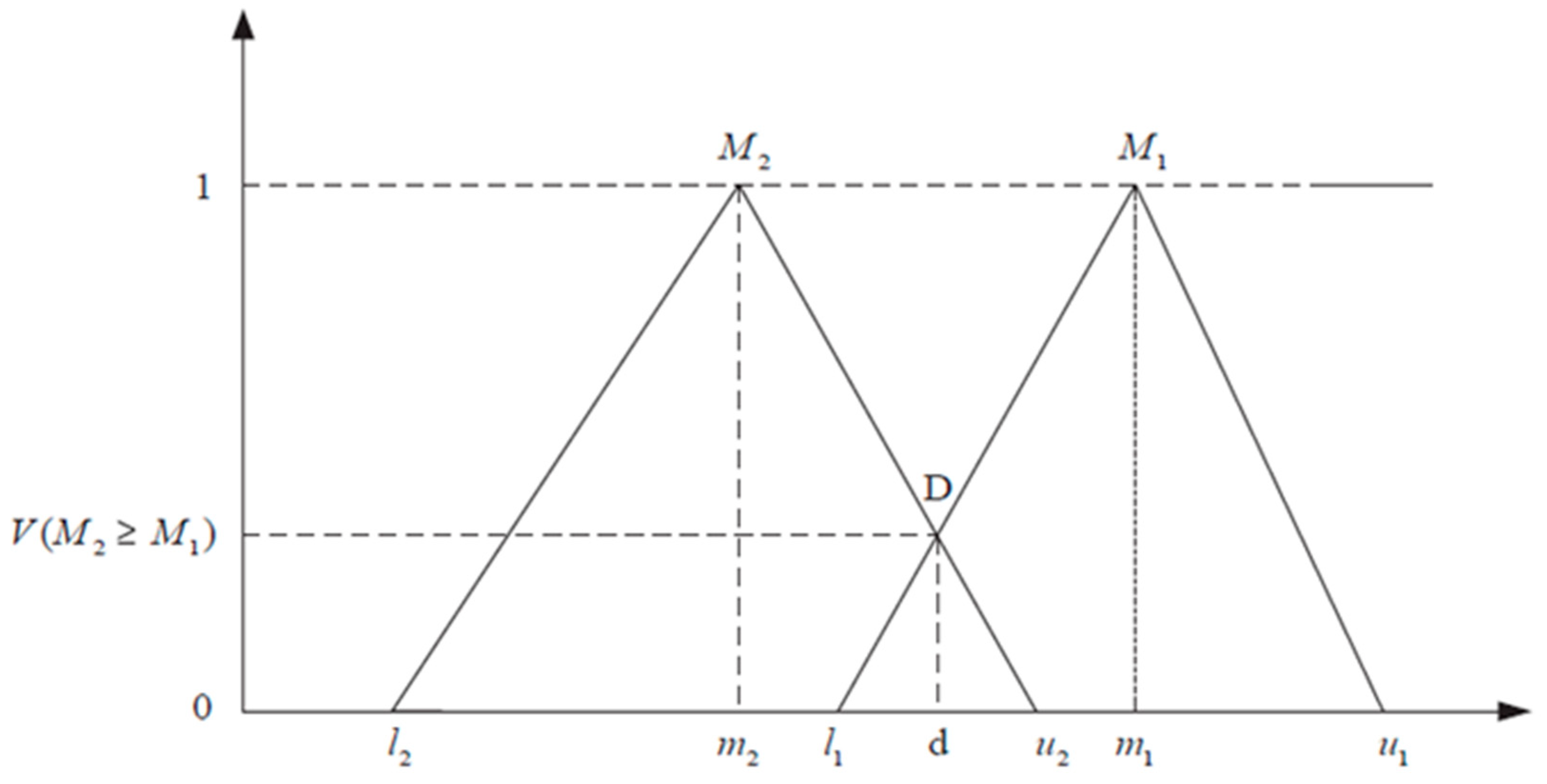

3.4. The Fuzzy Extended Analytical Hierarchy Process

- denotes the weight of the second-level dimension.

- denotes the weight of the third-level criterion.

- represents the overall weight obtained by multiplying the second-level and third-level weights.

3.5. The Quality Function Deployment

3.6. The VlseKriterijuska Optimizacija I Komoromisno Resenje

4. Empirical Research

4.1. Findings Derived from the Fuzzy Delphi Method

4.2. Results of the Fuzzy Extended Analytic Hierarchy Process

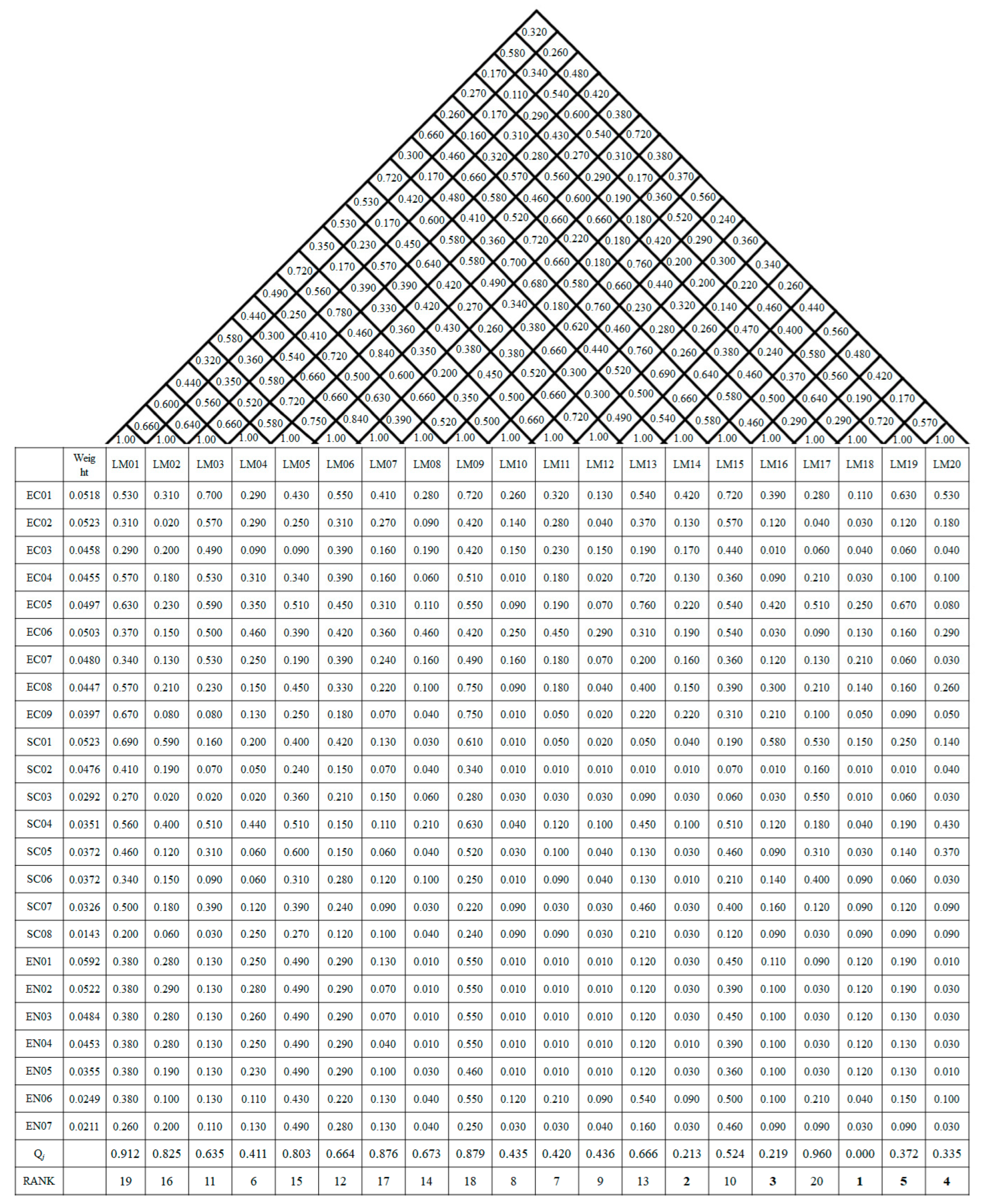

4.3. Analysis and Results of the First House of Quality

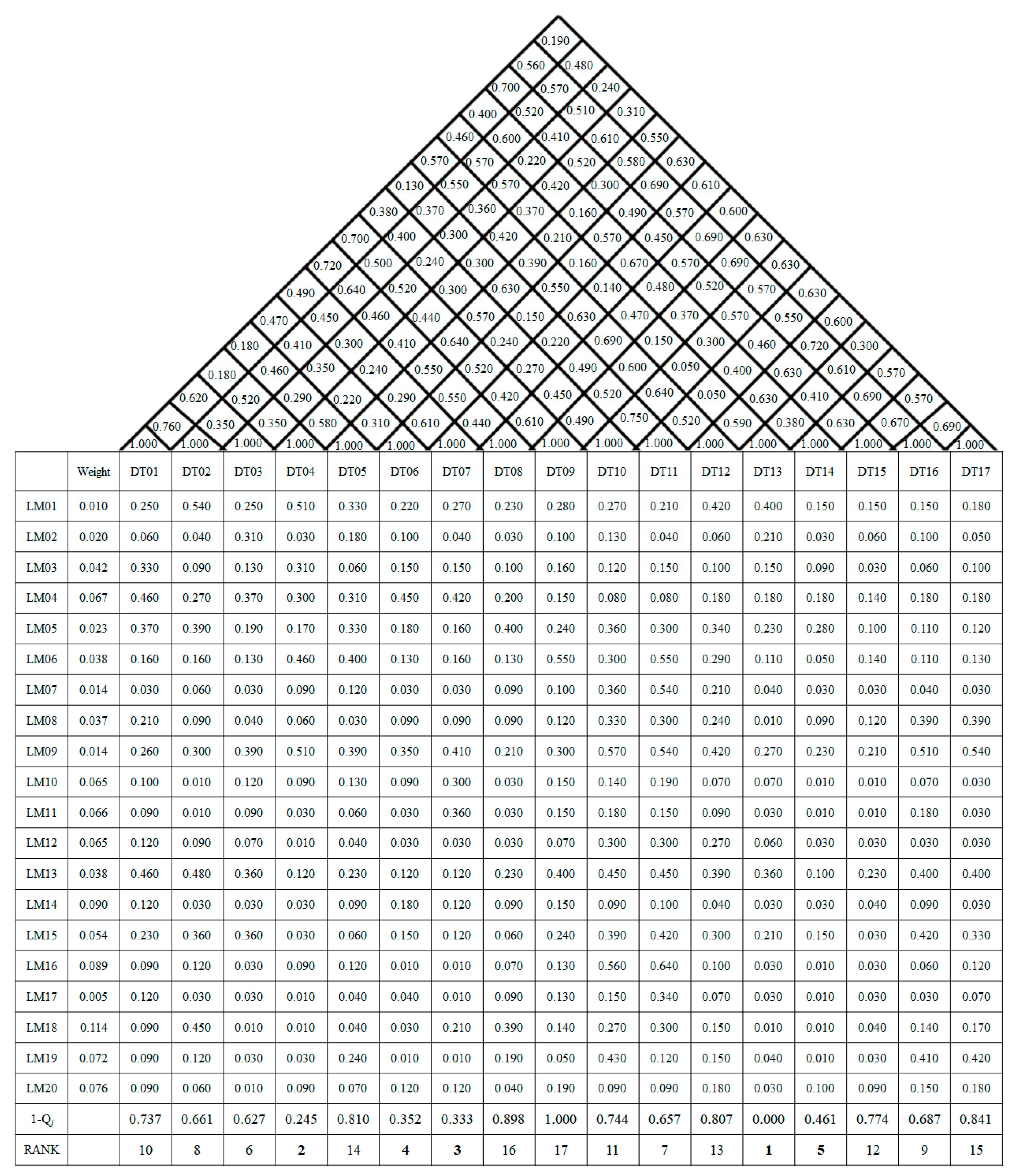

4.4. Analysis and Results of the Second House of Quality

4.5. Results and Discussion

- Safety measures—including Andon systems, error-proofing devices, and the elimination of non-value-added operations—play a crucial role in reducing the incidence of accidents and improving overall factory safety. Coupled with CAD, it is possible to design safer work environments and operating processes from the source, further improving overall factory safety. CAD technologies can precisely simulate and analyze various operational scenarios, helping engineers and designers identify and resolve potential safety risks at the design stage, thereby effectively preventing accidents and safeguarding employee health and safety.

- Quality improvement can be achieved by applying LM methods such as U-shaped production lines combined with error-proofing devices, and by identifying the true causes and locations of equipment failures. Reducing errors and defects during the manufacturing process effectively minimizes waste generation, thus reducing emissions of hazardous substances. Through precise design and efficient production management, factories can achieve more environmentally friendly manufacturing processes, contributing to the SD indicator target of reducing water pollution. Furthermore, integrating CRM systems can enhance product quality control and customer satisfaction.

- Cost management can be significantly enhanced through the adoption of DT technologies, such as Energy Management Systems and Carbon Management System Platforms, which help reduce energy and resource expenses. When integrated with Smart Grid technology, energy consumption can be efficiently controlled at the source, leading to improved energy efficiency and a reduction in unnecessary usage. This not only lowers energy costs but also decreases carbon emissions. Additionally, minimizing wastewater generation helps mitigate the risk of water pollution. In automotive manufacturing, for instance, significant amounts of water are used during sheet metal welding to cool joints and during vehicle surface treatment for cleaning, rinsing, and equipment maintenance. These examples highlight the importance of implementing effective water resource management and pollution control measures in the automotive industry to reduce water pollution and enhance water use efficiency.

- On-time delivery can be achieved by utilizing LM methods such as U-shaped production lines, which enhance production flexibility and responsiveness to market changes. Faster delivery times reduce inventory requirements, lower inventory costs, and consequently reduce procurement costs. Furthermore, CRM systems, built upon the foundations of high product quality and short lead times, ensure product quality, ultimately boosting customer satisfaction and business efficiency.

4.6. Comparison with Previous Studies

5. Conclusions

5.1. Managerial Implications

5.2. Limitations and Directions for Future Research

- Due to time and budget constraints, the sample size for the HoQ questionnaires was relatively limited. The survey was administered exclusively to core manufacturers and first-tier component suppliers within the automotive industry.

- In assessing the importance of SD indicators, this study considered only fuzzy uncertainty and did not account for the interrelationships among the indicators.

- The framework developed in this study could be expanded to incorporate second-tier component suppliers, allowing for a more comprehensive and detailed analysis.

- Since the importance evaluation of SD indicators in this study only addressed fuzzy uncertainty, future researchers are encouraged to adopt the fuzzy ANP to capture the interdependencies among indicators and thereby produce results that are more applicable to real-world scenarios.

- The findings indicate that experts in the automotive industry place relatively high importance on the economic dimension of SD. Therefore, future studies could focus on identifying specific methods and indicators within the economic dimension that enterprises should adopt to improve their economic sustainability performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SD | Sustainable Development |

| LM | Lean Management |

| DT | Digital Transformation |

| HoQ | House of Quality |

| MADM | Multiple Attribute Decision Making |

| QFD | Quality function deployment |

| FEAHP | Fuzzy Extended Analytic Hierarchy Process |

| FDM | Fuzzy Delphi method |

| VIKOR | VlseKriterijumska Optimizacija I Kompromisna Resenje |

References

- Yang, M.; Chen, L.; Wang, J.; Msigwa, G.; Osman, A.I.; Fawzy, S.; Rooney, D.W.; Yap, P.S. Circular economy strategies for combating climate change and other environmental issues. Environ. Chem. Lett. 2023, 21, 55–80. [Google Scholar] [CrossRef]

- Ideris, F.; Nomanbhay, S.; Kusumo, F.; Silitonga, A.S.; Ong, M.Y.; Ong, H.C.; Mahlia, T.M.I. Optimization of ultrasound-assisted oil extraction from Canarium odontophyllum kernel as a novel biodiesel feedstock. J. Clean. Prod. 2021, 288, 125563. [Google Scholar] [CrossRef]

- Ližbetin, J.; Hlatká, M.; Bartuška, L. Issues concerning declared energy consumption and greenhouse gas emissions of FAME biofuels. Sustainability 2018, 10, 3025. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Dugmore, T.I.; Matharu, A.; Martinez-Hernandez, E.; Aburto, J.; Rahman, P.K.; Lynch, J. Perspectives on “game changer” global challenges for sustainable 21st century: Plant-based diet, unavoidable food waste biorefining, and circular economy. Sustainability 2020, 12, 1976. [Google Scholar] [CrossRef]

- Summary for Policymakers. In Global Warming of 1.5 °C; World Meteorological Organization: Geneva, Switzerland, 2018; 32p.

- Peña, C.; Civit, B.; Gallego-Schmid, A.; Druckman, A.; Pires, A.C.; Weidema, B.; Mieras, E.; Wang, F.; Fava, J.; Canals, L.M.; et al. Using life cycle assessment to achieve a circular economy. Int. J. Life Cycle Assess. 2021, 26, 215–220. [Google Scholar] [CrossRef]

- Serrano, T.; Aparcana, S.; Bakhtiari, F.; Laurent, A. Contribution of circular economy strategies to climate change mitigation: Generic assessment methodology with focus on developing countries. J. Ind. Ecol. 2021, 25, 1382–1397. [Google Scholar] [CrossRef]

- Akdoğan, M.Ş.; Coşkun, A. Drivers of reverse logistics activities: An empirical investigation. Proc. Soc. Behav. Sci. 2012, 58, 1640–1649. [Google Scholar] [CrossRef]

- Hsu, C.H.; Chang, A.Y.; Luo, W. Identifying key performance factors for sustainability development of SMEs-integrating QFD and fuzzy MADM methods. J. Clean. Prod. 2017, 161, 629–645. [Google Scholar] [CrossRef]

- Hopkins, M.S.; Haanaes, K.; Balagopal, B.; Velken, I.; Kruschwitz, N.; Arthur, D. New sustainability study: The embracers seize advantage. MIT Sloan Manag. Rev. 2011, 52, 23–35. [Google Scholar]

- Lenort, R.; Wicher, P.; Zapletal, F. On influencing factors for sustainable development goal prioritisation in the automotive industry. J. Clean. Prod. 2023, 387, 135718. [Google Scholar] [CrossRef]

- Choudhary, S.; Nayak, R.; Dora, M.; Mishra, N.; Ghadge, A. An integrated lean and green approach for improving sustainability performance: A case study of a packaging manufacturing SME in the UK. Prod. Plan. Control 2019, 30, 353–368. [Google Scholar] [CrossRef]

- Thanki, S.J.; Thakkar, J.J. Value–value load diagram: A graphical tool for lean–green performance assessment. Prod. Plan. Control 2016, 27, 1280–1297. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Eshragh, A. A tradeoff model for green supply chain planning: A leanness-versus-greenness analysis. Omega 2015, 54, 173–190. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A. Lean and green–A systematic review of the state of the art literature. J. Clean. Prod. 2015, 102, 18–29. [Google Scholar] [CrossRef]

- George, G.; Schillebeeckx, S.J. Digital transformation, sustainability, and purpose in the multinational enterprise. J. World Bus. 2022, 57, 101326. [Google Scholar] [CrossRef]

- Okorie, O.; Russell, J.; Cherrington, R.; Fisher, O.; Charnley, F. Digital transformation and the circular economy: Creating a competitive advantage from the transition towards net zero manufacturing. Resour. Conserv. Recycl. 2023, 189, 106756. [Google Scholar] [CrossRef]

- Chang, W.J.; Liao, S.H.; Wu, T.T. Relationships among organizational culture, knowledge sharing, and innovation capability: A case of the automobile industry in Taiwan. Knowl. Manag. Res. Pract. 2017, 15, 471–490. [Google Scholar] [CrossRef]

- Llopis-Albert, C.; Rubio, F.; Valero, F. Impact of digital transformation on the automotive industry. Technol. Forecast. Soc. Change 2021, 162, 120343. [Google Scholar] [CrossRef]

- Carlier, M. Global Automotive Manufacturing Industry Revenue Between 2019 and 2022. 2022. Available online: https://www.icaew.com/library/industry-profiles/automotive-manufacturing (accessed on 30 December 2022).

- ACEA. R&D Investment by Industry and World Region. Available online: https://www.acea.auto/figure/rd-investment-in-the-automobile-sector-by-world-region/ (accessed on 30 December 2022).

- Martínez-Jurado, P.J.; Moyano-Fuentes, J. Lean management, supply chain management and sustainability: A literature review. J. Clean. Prod. 2014, 85, 134–150. [Google Scholar] [CrossRef]

- Pampanelli, A.B.; Found, P.; Bernardes, A.M. A lean & green model for a production cell. J. Clean. Prod. 2014, 85, 19–30. [Google Scholar] [CrossRef]

- Farias, L.M.S.; Santos, L.C.; Gohr, C.F.; de Oliveira, L.C.; da Silva Amorim, M.H. Criteria and practices for lean and green performance assessment: Systematic review and conceptual framework. J. Clean. Prod. 2019, 218, 746–762. [Google Scholar] [CrossRef]

- Mora, E.; Gaiardelli, P.; Resta, B.; Powell, D. Exploiting lean benefits through smart manufacturing: A comprehensive perspective. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Hamburg, Germany, 3–7 September 2017. [Google Scholar]

- Ulas, D. Digital transformation process and SMEs. Proc. Comput. Sci. 2019, 158, 662–671. [Google Scholar] [CrossRef]

- Gillani, F.; Chatha, K.A.; Jajja, M.S.S.; Farooq, S. Implementation of digital manufacturing technologies: Antecedents and consequences. Int. J. Prod. Econom. 2020, 229, 107748. [Google Scholar] [CrossRef]

- Wagner, T.; Herrmann, C.; Thiede, S. Industry 4.0 impacts on lean production systems. Proc. CIRP 2017, 63, 125–131. [Google Scholar] [CrossRef]

- Rossini, M.; Cifone, F.D.; Kassem, B.; Costa, F.; Portioli-Staudacher, A. Being lean: How to shape digital transformation in the manufacturing sector. J. Manuf. Technol. Manag. 2021, 32, 239–259. [Google Scholar] [CrossRef]

- Alvarado-Herrera, A.; Bigne, E.; Aldas-Manzano, J.; Curras-Perez, R. A scale for measuring consumer perceptions of corporate social responsibility following the sustainable development paradigm. J. Bus. Ethics 2017, 140, 243–262. [Google Scholar] [CrossRef]

- Gore, C. The post-2015 moment: Towards sustainable development goals and a new global development paradigm. J. Int. Dev. 2015, 27, 717–732. [Google Scholar] [CrossRef]

- Chang, A.Y.; Cheng, Y.T. Analysis model of the sustainability development of manufacturing small and medium-sized enterprises in Taiwan. J. Clean. Prod. 2019, 207, 458–473. [Google Scholar] [CrossRef]

- Helleno, A.L.; de Moraes, A.J.I.; Simon, A.T. Integrating sustainability indicators and lean manufacturing to assess manufacturing processes: Application case studies in Brazilian industry. J. Clean. Prod. 2017, 153, 405–416. [Google Scholar] [CrossRef]

- WCED. World commission on environment and development. In Our Common Future; Oxford University Press: Oxford, UK, 1987; Volume 17, pp. 1–91. [Google Scholar]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Waddock, S.A.; Graves, S.B. The corporate social performance–Financial performance link. Strat. Manag. J. 1997, 18, 303–319. [Google Scholar] [CrossRef]

- Margolis, J.D.; Walsh, J.P. People and Profits? The Search for a Link Between a Company’s Social and Financial Performance; Psychology Press: New York, NY, USA, 2001. [Google Scholar]

- Ciliberti, F.; Pontrandolfo, P.; Scozzi, B. Logistics social responsibility: Standard adoption and practices in Italian companies. Int. J. Prod. Econ. 2008, 113, 88–106. [Google Scholar] [CrossRef]

- Stocchetti, A. The sustainable firm: From principles to practice. Int. J. Bus. Manag. 2012, 7, 34–47. [Google Scholar] [CrossRef]

- Elkington, J.; Rowlands, I.H. Cannibals with forks: The triple bottom line of 21st century business. Altern. J. 1999, 25, 42–43. [Google Scholar] [CrossRef]

- Barber, K.D.; Beach, R.; Zolkiewski, J. Environmental sustainability: A value cycle research agenda. Prod. Plan. Control 2012, 23, 105–119. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Tanguay, G.A.; Rajaonson, J.; Lefebvre, J.F.; Lanoie, P. Measuring the sustainability of cities: An analysis of the use of local indicators. Ecol. Indic. 2010, 10, 407–418. [Google Scholar] [CrossRef]

- Vinodh, S.; Girubha, R.J. PROMETHEE based sustainable concept selection. Appl. Math. Model. 2012, 36, 5301–5308. [Google Scholar] [CrossRef]

- Seuring, S. A review of modeling approaches for sustainable supply chain management. Decis. Support Syst. 2013, 54, 1513–1520. [Google Scholar] [CrossRef]

- Govindan, K.; Shankar, K.M.; Kannan, D. Sustainable material selection for construction industry–A hybrid multi criteria decision making approach. Renew. Sustain. Energy Rev. 2016, 55, 1274–1288. [Google Scholar] [CrossRef]

- Liang, X.; Zhao, X.; Wang, M.; Li, Z. Small and medium-sized enterprises sustainable supply chain financing decision based on triple bottom line theory. Sustainability 2018, 10, 4242. [Google Scholar] [CrossRef]

- Liu, A.; Xiao, Y.; Lu, H.; Tsai, S.B.; Song, W. A fuzzy three-stage multi-attribute decision-making approach based on customer needs for sustainable supplier selection. J. Clean. Prod. 2019, 239, 118043. [Google Scholar] [CrossRef]

- Amrina, E.; Yusof, S.M. Key performance indicators for sustainable manufacturing evaluation in automotive companies. In Proceedings of the 2011 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 6–9 December 2011. [Google Scholar]

- Azadnia, A.H.; Saman, M.Z.M.; Wong, K.Y.; Ghadimi, P.; Zakuan, N. Sustainable supplier selection based on self-organizing map neural network and multi criteria decision making approaches. Proc. Soc. Behav. Sci. 2012, 65, 879–884. [Google Scholar] [CrossRef]

- Chardine-Baumann, E.; Botta-Genoulaz, V. A framework for sustainable performance assessment of supply chain management practices. Comput. Ind. Eng. 2014, 76, 138–147. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Jafarian, A. A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach. J. Clean. Prod. 2013, 47, 345–354. [Google Scholar] [CrossRef]

- Mavi, R.K.; Goh, M.; Zarbakhshnia, N. Sustainable third-party reverse logistic provider selection with fuzzy SWARA and fuzzy MOORA in plastic industry. Int. J. Adv. Manuf. Technol. 2017, 91, 2401–2418. [Google Scholar] [CrossRef]

- Zarbakhshnia, N.; Soleimani, H.; Ghaderi, H. Sustainable third-party reverse logistics provider evaluation and selection using fuzzy SWARA and developed fuzzy COPRAS in the presence of risk criteria. Appl. Soft Comput. 2015, 65, 307–319. [Google Scholar] [CrossRef]

- Prakash, C.; Barua, M.K. An analysis of integrated robust hybrid model for third-party reverse logistics partner selection under fuzzy environment. Resour. Conserv. Recycl. 2016, 108, 63–81. [Google Scholar] [CrossRef]

- Cagno, E.; Neri, A.; Howard, M.; Brenna, G.; Trianni, A. Industrial sustainability performance measurement systems: A novel framework. J. Clean. Prod. 2019, 230, 1354–1375. [Google Scholar] [CrossRef]

- Narwane, V.S.; Yadav, V.S.; Raut, R.D.; Narkhede, B.E.; Gardas, B.B. Sustainable development challenges of the biofuel industry in India based on integrated MCDM approach. Renew. Energy 2021, 164, 298–309. [Google Scholar] [CrossRef]

- Chen, T.C.T.; Wang, Y.C. Basics in lean management. In Artificial Intelligence and Lean Manufacturing; Chen, T.C.T., Wang, Y.C., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–12. [Google Scholar]

- Helmold, M. Basics in Lean Management; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine That Changed the World: Based on the MIT 5-Million-Dollar 5-Year Study on the Future of the Automobile; Rawson Associates: New York, NY, USA, 1990. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean Solutions: How Companies and Customers Can Create Value and Wealth Together; Free Press: New York, NY, USA, 2005. [Google Scholar]

- Shahin, M.; Chen, F.F.; Bouzary, H.; Krishnaiyer, K. Integration of lean practices and industry 4.0 technologies: Smart manufacturing for next-generation enterprises. Int. J. Adv. Manuf. Technol. 2020, 107, 2927–2936. [Google Scholar] [CrossRef]

- Shah, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T. Lean thinking—Banish waste and create wealth in your corporation. J. Oper. Res. Soc. 1997, 48, 1148. [Google Scholar] [CrossRef]

- Inman, R.A.; Green, K.W. Lean and green combine to impact environmental and operational performance. Int. J. Prod. Res. 2018, 56, 4802–4818. [Google Scholar] [CrossRef]

- Vinodh, S.; Ramesh, K.; Arun, C.S. Application of interpretive structural modelling for analysing the factors influencing integrated lean sustainable system. Clean Technol. Environ. Policy 2016, 18, 413–428. [Google Scholar] [CrossRef]

- Zhan, Y.; Tan, K.H.; Ji, G.; Chung, L.; Chiu, A.S. Green and lean sustainable development path in China: Guanxi, practices and performance. Resour. Conserv. Recycl. 2018, 128, 240–249. [Google Scholar] [CrossRef]

- Viles, E.; Santos, J.; Muñoz-Villamizar, A.; Grau, P.; Fernández-Arévalo, T. Lean–green improvement opportunities for sustainable manufacturing using water telemetry in agri-food industry. Sustainability 2021, 13, 2240. [Google Scholar] [CrossRef]

- Anvari, A.; Zulkifli, N.; Sorooshian, S.; Boyerhassani, O. An integrated design methodology based on the use of group AHP-DEA approach for measuring lean tools efficiency with undesirable output. Int. J. Adv. Manuf. Technol. 2014, 70, 2169–2186. [Google Scholar] [CrossRef]

- Leksic, I.; Stefanic, N.; Veza, I. The impact of using different lean manufacturing tools on waste reduction. Adv. Prod. Eng. Manag. 2020, 15, 81–92. [Google Scholar] [CrossRef]

- Kumar, N.; Hasan, S.S.; Srivastava, K.; Akhtar, R.; Yadav, R.K.; Choubey, V.K. Lean manufacturing techniques and its implementation: A review. Mater. Today Proc. 2022, 64, 1188–1192. [Google Scholar] [CrossRef]

- Junior, R.G.P.; Inácio, R.H.; da Silva, I.B.; Hassui, A.; Barbosa, G.F. A novel framework for single-minute exchange of die (SMED) assisted by lean tools. Int. J. Adv. Manuf. Technol. 2022, 119, 6469–6487. [Google Scholar] [CrossRef]

- Sanders, A.; Elangeswaran, C.; Wulfsberg, J.P. Industry 4.0 implies lean manufacturing: Research activities in industry 4.0 function as enablers for lean manufacturing. J. Ind. Eng. Manag. 2016, 9, 811–833. [Google Scholar] [CrossRef]

- Bertagnolli, F.; Herrmann, K.; Rittmann, I.; Viere, T. The application of lean methods in corporate sustainability—A systematic literature review. Sustainability 2021, 13, 12786. [Google Scholar] [CrossRef]

- Vinodh, S.; Arvind, K.R.; Somanaathan, M. Tools and techniques for enabling sustainability through lean initiatives. Clean Technol. Environ. Policy 2011, 13, 469–479. [Google Scholar] [CrossRef]

- Gupta, A.; Kundra, T.K. A review of designing machine tool for leanness. Sadhana 2012, 37, 241–259. [Google Scholar] [CrossRef]

- Mahapatra, S.S.; Mohanty, S.R. Lean manufacturing in continuous process industry: An empirical study. J. Sci. Ind. Res. 2007, 66, 19–28. [Google Scholar]

- Minh, N.D.; Kien, D.T. A four-phase framework for Lean implementation in small and medium enterprises. Management 2021, 25, 259–277. [Google Scholar] [CrossRef]

- Zhou, B. Lean principles, practices, and impacts: A study on small and medium-sized enterprises (SMEs). Ann. Oper. Res. 2016, 241, 457–474. [Google Scholar] [CrossRef]

- Yadav, O.P.; Nepal, B.P.; Rahaman, M.M.; Lal, V. Lean implementation and organizational transformation: A literature review. Eng. Manag. J. 2017, 29, 2–16. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- ElMassah, S.; Mohieldin, M. Digital transformation and localizing the sustainable development goals (SDGs). Ecol. Econom. 2020, 169, 106490. [Google Scholar] [CrossRef]

- Manogaran, G.; Thota, C.; Lopez, D.; Sundarasekar, R. Big data security intelligence for healthcare industry 4.0. In Cybersecurity for Industry 4.0. Springer Series in Advanced Manufacturing; Thames, L., Schaefer, D., Eds.; Springer: Cham, Switzerland, 2017; pp. 103–126. [Google Scholar]

- Frank, A.G.; Mendes, G.H.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Change 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Loebbecke, C.; Picot, A. Reflections on societal and business model transformation arising from digitization and big data analytics: A research agenda. J. Strateg. Inform. Syst. 2015, 24, 149–157. [Google Scholar] [CrossRef]

- Singhdong, P.; Suthiwartnarueput, K.; Pornchaiwiseskul, P. Factors influencing digital transformation of logistics service providers: A case study in Thailand. J. Asian Financ. Econom. Bus. 2021, 8, 241–251. [Google Scholar] [CrossRef]

- Costa, I.; Riccotta, R.; Montini, P.; Stefani, E.; de Souza Goes, R.; Gaspar, M.A.; Martins, F.S.; Fernandes, A.A.; Machado, C.; Loçano, R.; et al. The degree of contribution of digital transformation technology on company sustainability areas. Sustainability 2022, 14, 462. [Google Scholar] [CrossRef]

- Hrustek, L. Sustainability driven by agriculture through digital transformation. Sustainability 2020, 12, 8596. [Google Scholar] [CrossRef]

- Ardolino, M.; Rapaccini, M.; Saccani, N.; Gaiardelli, P.; Crespi, G.; Ruggeri, C. The role of digital technologies for the service transformation of industrial companies. Int. J. Prod. Res. 2018, 56, 2116–2132. [Google Scholar] [CrossRef]

- Barge, P.; Biglia, A.; Comba, L.; Ricauda Aimonino, D.; Tortia, C.; Gay, P. Radio frequency identification for meat supply-chain digitalisation. Sensors 2020, 20, 4957. [Google Scholar] [CrossRef]

- Choi, J.K.; Thangamani, D.; Kissock, K. A systematic methodology for improving resource efficiency in small and medium-sized enterprises. Resour. Conserv. Recycl. 2019, 147, 19–27. [Google Scholar] [CrossRef]

- Dileep, G.J.R.E. A survey on smart grid technologies and applications. Renew. Energy 2020, 146, 2589–2625. [Google Scholar] [CrossRef]

- Fuentes-Pacheco, J.; Ruiz-Ascencio, J.; Rendón-Mancha, J.M. Visual simultaneous localization and mapping: A survey. Artif. Intell. Rev. 2015, 43, 55–81. [Google Scholar] [CrossRef]

- Olokundun, M.; Ogbari, M.E.; Falola, H.; Ibidunni, A.S. Leveraging 5G network for digital innovation in small and medium enterprises: A conceptual review. J. Innov. Entrepr. 2022, 11, 41. [Google Scholar] [CrossRef] [PubMed]

- Popescu, V.F.; Scarlat, C. Supervisory Control and Data Acquisition (SCADA) systems for industrial automation and control systems in industry 4.0. Land Forces Acad. Rev. 2022, 27, 309–315. [Google Scholar] [CrossRef]

- Shen, X. A meta-analysis of the relationships among digital transformation, innovation and firm performance: The moderating effects of country-specific factors. Int. J. Phys. Distrib. Logist. Manag. 2025, 55, 701–737. [Google Scholar] [CrossRef]

- Kim, S.; Choi, B.; Lew, Y.K. Where is the age of digitalization heading? The meaning, characteristics, and implications of contemporary digital transformation. Sustainability 2021, 13, 8909. [Google Scholar] [CrossRef]

- Slavković, M.; Pavlović, K.; Depalov, V.R.; Vučenović, T.; Bugarčić, M. Effects of digital citizenship and digital transformation enablers on innovativeness and problem-solving capabilities. Appl. Sci. 2024, 14, 4827. [Google Scholar] [CrossRef]

- Kao, L.J.; Chiu, C.C.; Lin, H.T.; Hung, Y.W.; Lu, C.C. Unveiling the dimensions of digital transformation: A comprehensive taxonomy and assessment model for business. J. Bus. Res. 2024, 176, 114595. [Google Scholar] [CrossRef]

- Saini, N.; Kharb, R. Empowering sustainable development through digital transformation: Insights from Digital India. J. Asia Bus. Stud. 2025, 19, 606–634. [Google Scholar] [CrossRef]

- Heavin, C.; Power, D.J. Challenges for digital transformation–towards a conceptual decision support guide for managers. J. Decis. Syst. 2018, 27, 38–45. [Google Scholar] [CrossRef]

- Majstorovic, V.; Jankovic, G.; Zivkov, S.; Stojadinovic, S. Digital manufacturing in SMEs based on the context of the Industry 4.0 framework–one approach. Proc. Manuf. 2021, 54, 52–57. [Google Scholar] [CrossRef]

- Mastos, T.D.; Nizamis, A.; Vafeiadis, T.; Alexopoulos, N.; Ntinas, C.; Gkortzis, D.; Papadopoulos, A.; Ioannidis, D.; Tzovaras, D. Industry 4.0 sustainable supply chains: An application of an IoT enabled scrap metal management solution. J. Clean. Prod. 2020, 269, 122377. [Google Scholar] [CrossRef]

- Said, O.; Al-Makhadmeh, Z.; Tolba, A.M.R. EMS: An energy management scheme for green IoT environments. IEEE Access 2020, 8, 44983–44998. [Google Scholar] [CrossRef]

- Yan, J.; Lu, Q.; Tang, J.; Chen, L.; Hong, J.; Broyd, T. Digital tools for revealing and reducing carbon footprint in infrastructure, building, and city scopes. Buildings 2022, 12, 1097. [Google Scholar] [CrossRef]

- Ishikawa, T. Photoionization spectra of Pd in high Rydberg states. Jpn. J. Appl. Phys. 1993, 32, 4779. [Google Scholar] [CrossRef]

- Murray, T.J.; Pipino, L.L.; Van Gigch, J.P. A pilot study of fuzzy set modification of Delphi. Hum. Syst. Manag. 1985, 5, 76–80. [Google Scholar] [CrossRef]

- Buckley, J.J. Fuzzy hierarchical analysis. Fuzzy Sets Syst. 1985, 17, 233–247. [Google Scholar] [CrossRef]

- Chang, D.Y. Extent analysis and synthetic decision. Optim. Technol. Appl. 1992, 1, 352–355. [Google Scholar]

- Chang, D.Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Opricovic, S.; Tzeng, G.H. Compromise solution by MCDM methods: A comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 2004, 156, 445–455. [Google Scholar] [CrossRef]

- Sullivan, L.P. Quality function deployment. Qual. Progr. 1986, 19, 39–50. [Google Scholar]

- Chan, L.K.; Wu, M.L. Quality function deployment: A literature review. Eur. J. Oper. Res. 2002, 143, 463–497. [Google Scholar] [CrossRef]

- Carnevalli, J.A.; Miguel, P.C. Review, analysis and classification of the literature on QFD—Types of research, difficulties and benefits. Int. J. Prod. Econom. 2008, 114, 737–754. [Google Scholar] [CrossRef]

- Hsu, Y.L.; Lee, C.H.; Kreng, V.B. The application of Fuzzy Delphi Method and Fuzzy AHP in lubricant regenerative technology selection. Exp. Syst. Appl. 2010, 37, 419–425. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inform. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytical Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Saaty, T.L. An exposition of the AHP in reply to the paper remarks on the analytic hierarchy process. Manag. Sci. 1990, 36, 259–268. [Google Scholar] [CrossRef]

- Gul, M.; Celik, E.; Aydin, N.; Gumus, A.T.; Guneri, A.F. A state of the art literature review of VIKOR and its fuzzy extensions on applications. Appl. Soft Comput. 2016, 46, 60–89. [Google Scholar] [CrossRef]

- Lin, Y.C.; Lai, H.H.; Yeh, C.H. Consumer-oriented product form design based on fuzzy logic: A case study of mobile phones. Int. J. Ind. Ergon. 2007, 37, 531–543. [Google Scholar] [CrossRef]

- Vinodh, S.; Devadasan, S.R. Twenty criteria based agility assessment using fuzzy logic approach. Int. J. Adv. Manuf. Technol. 2011, 54, 1219–1231. [Google Scholar] [CrossRef]

- Hsu, C.H.; He, X.; Zhang, T.Y.; Chang, A.Y.; Liu, W.L.; Lin, Z.Q. Enhancing supply chain agility with industry 4.0 enablers to mitigate ripple effects based on integrated QFD-MCDM: An empirical study of new energy materials manufacturers. Mathematics 2022, 10, 1635. [Google Scholar] [CrossRef]

- Hsu, C.H.; Li, M.G.; Zhang, T.Y.; Chang, A.Y.; Shangguan, S.Z.; Liu, W.L. Deploying big data enablers to strengthen supply chain resilience to mitigate sustainable risks based on integrated HOQ-MCDM framework. Mathematics 2022, 10, 1233. [Google Scholar] [CrossRef]

| Dimension | Indicator | Reference | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||

| Economy | Reduction in manufacturing costs | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| Reduction in procurement costs | ● | ● | ● | ● | ● | ● | ● | ||||||

| Reduction in transportation costs | ● | ||||||||||||

| Improvement of service quality | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Improvement of product quality | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| Enhancement of on-time delivery rate | ● | ● | ● | ● | ● | ● | ● | ||||||

| Reduction in transportation time | ● | ● | ● | ● | ● | ● | |||||||

| Enhancement of enterprise innovation | ● | ● | ● | ||||||||||

| Advancement of manufacturing technology | ● | ● | ● | ● | ● | ||||||||

| Continuous improvement and reduction in information security risks | ● | ||||||||||||

| Acquisition of relevant information security certifications | ● | ||||||||||||

| Society | Reduction in impact on local communities | ● | ● | ● | ● | ||||||||

| Support for community development programs | ● | ● | ● | ||||||||||

| Support for local educational institutions | ● | ● | |||||||||||

| Increase in local employment opportunities | ● | ● | |||||||||||

| Reduction in health and accident incidents within the company | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Reduction in discrimination incidents within the company | ● | ● | ● | ||||||||||

| Support for employees obtaining job-related professional certifications | ● | ● | ● | ● | ● | ● | ● | ||||||

| Top management’s commitment to sustainable development | ● | ||||||||||||

| Reduction in employee turnover rate | ● | ||||||||||||

| Acquisition of relevant labor safety or human rights certifications | ● | ||||||||||||

| Enhancement of customer health and safety during product use | ● | ● | ● | ● | |||||||||

| Society | Top management’s commitment to sustainable development | ● | |||||||||||

| Reduction in employee turnover rate | ● | ||||||||||||

| Acquisition of relevant labor safety or human rights certifications | ● | ||||||||||||

| Enhancement of customer health and safety during product use | ● | ● | ● | ● | |||||||||

| Increase in channels for communicating product information to customers | ● | ● | ● | ● | ● | ||||||||

| Environment | Reduction in hazardous substance emissions | ● | ● | ● | ● | ● | |||||||

| Reduction in water pollution | ● | ● | |||||||||||

| Reduction in land pollution | ● | ● | ● | ||||||||||

| Reduction in air pollution | ● | ● | ● | ● | ● | ● | |||||||

| Reduction in greenhouse gas emissions | ● | ● | |||||||||||

| Reduction in land use | ● | ||||||||||||

| Reduction in water consumption | ● | ● | ● | ||||||||||

| Reduction in energy consumption | ● | ● | ● | ||||||||||

| Development of recyclable products | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Development of products with lower energy consumption | ● | ● | ● | ● | |||||||||

| Green design | ● | ● | ● | ● | |||||||||

| Green packaging | ● | ||||||||||||

| Establishment of sustainable supply chains | ● | ||||||||||||

| Increase in the use of green energy | ● | ● | |||||||||||

| Acquisition of relevant environmental certifications | ● | ● | ● | ● | ● | ||||||||

| Strengthening environmental protection | ● | ||||||||||||

| Actions to enhance natural resource and environmental protection | ● | ● | ● | ● | |||||||||

| Dimension | Indicator | Reference | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||

| Worksite Physical Improvement | PDCA cycle | ● | ● | ● | ● | ||||||||

| 5S Activities | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| Waster elimination | ● | ● | ● | ||||||||||

| Visual Management | ● | ● | ● | ● | ● | ● | ● | ||||||

| Cross-Functional Participation | ● | ||||||||||||

| Standardized Work | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Standardized Work Combination Sheet | ● | ||||||||||||

| Production Control Board | ● | ||||||||||||

| Continuous Improvement | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Just-in-Time | Value Stream Mapping | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| Synchronized Operations | ● | ||||||||||||

| Pull Production | ● | ● | |||||||||||

| Production Leveling | ● | ● | ● | ● | ● | ● | ● | ||||||

| Kanban System | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Total Quality Management | ● | ● | |||||||||||

| U-shaped Production Line | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Small Lot Production | ● | ||||||||||||

| Improvement of Mixed-Model Production | ● | ||||||||||||

| Mixed-Load Transport | ● | ||||||||||||

| High-Frequency Transport | ● | ||||||||||||

| Jidoka | Total Productive Maintenance | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| Quick Changeover | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| Error-Proofing | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Multi-skilled Workers | ● | ||||||||||||

| Andon System | ● | ● | |||||||||||

| Passive Mechanical Devices | ● | ||||||||||||

| Six Sigma | ● | ● | ● | ● | ● | ||||||||

| Separation of Man and Machine | ● | ||||||||||||

| Identification of Bottleneck Equipment | ● | ||||||||||||

| Improvement of Equipment Cycle Time Variability | ● | ||||||||||||

| Identification of Equipment Failure Points and Root Causes | ● | ||||||||||||

| Elimination of Non-Loaded Operations | ● | ||||||||||||

| Dimension | Indicator | Code | ||

|---|---|---|---|---|

| Economy | Reduction in manufacturing costs | EC | EC01 | 8.57 |

| Reduction in procurement costs | EC02 | 8.64 | ||

| Reduction in transportation costs | EC03 | 8.53 | ||

| Improvement of service quality | EC04 | 8.61 | ||

| Improvement of product quality | EC05 | 8.84 | ||

| Enhancement of on-time delivery rate | EC06 | 8.93 | ||

| Reduction in transportation time | EC07 | 8.73 | ||

| Advancement of manufacturing technology | EC08 | 8.51 | ||

| Continuous improvement and reduction in information security risks | EC09 | 8.40 | ||

| Society | Reduction in health and accident incidents within the company | SC | SC01 | 8.84 |

| Reduction in discrimination incidents within the company | SC02 | 9.28 | ||

| Support for employees obtaining job-related professional certifications | SC03 | 8.46 | ||

| Top management’s commitment to sustainable development | SC04 | 8.56 | ||

| Reduction in employee turnover rate | SC05 | 8.71 | ||

| Acquisition of relevant labor safety or human rights certifications | SC06 | 8.43 | ||

| Enhancement of customer health and safety during product use | SC07 | 8.57 | ||

| Increase in channels for communicating product information to customers | SC08 | 8.27 | ||

| Environment | Reduction in hazardous substance emissions | EN | EN01 | 8.81 |

| Reduction in water pollution | EN02 | 8.56 | ||

| Reduction in land pollution | EN03 | 8.78 | ||

| Reduction in air pollution | EN04 | 8.84 | ||

| Reduction in greenhouse gas emissions | EN05 | 8.77 | ||

| Establishment of sustainable supply chains | EN06 | 8.33 | ||

| Acquisition of relevant environmental certifications | EN07 | 8.36 | ||

| Dimension | Method | Code | |

|---|---|---|---|

| Worksite Physical Improvement | PDCA cycle | LM01 | 7.89 |

| 5S Activities | LM02 | 8.73 | |

| Waster elimination | LM03 | 8.71 | |

| Visual Management | LM04 | 8.00 | |

| Cross-Functional Participation | LM05 | 7.58 | |

| Standardized Work | LM06 | 9.05 | |

| Standardized Work Combination Sheet | LM07 | 7.82 | |

| Production Control Board | LM08 | 8.12 | |

| Continuous Improvement | LM09 | 8.76 | |

| Just-in-Time | Pull Production | LM10 | 7.55 |

| Production Leveling | LM11 | 7.68 | |

| Kanban System | LM12 | 7.57 | |

| Total Quality Management | LM13 | 8.59 | |

| Total Quality Management | LM14 | 7.56 | |

| Jidoka | Total Productive Maintenance | LM15 | 7.72 |

| Error-Proofing | LM16 | 9.72 | |

| Multi-skilled Workers | LM17 | 7.67 | |

| Andon System | LM18 | 7.76 | |

| Identification of Equipment Failure Points and Root Causes | LM19 | 8.14 | |

| Elimination of Non-Loaded Operations | LM20 | 7.89 |

| Dimension | Technology | Code | |

|---|---|---|---|

| Infrastructure and Platform | Enterprise Resource Planning | DT01 | 7.52 |

| Information Security Management System | DT02 | 7.79 | |

| Product Lifecycle Management | DT03 | 7.50 | |

| Computer-Aided Design | DT04 | 7.29 | |

| Computer-Aided Manufacturing | DT05 | 7.88 | |

| Carbon Management System Platform | DT06 | 7.28 | |

| Energy Management System | DT07 | 7.22 | |

| Smart Manufacturing and Production Optimization | Internet of Things | DT08 | 7.79 |

| Manufacturing Execution System | DT09 | 7.35 | |

| Robotics, e.g., autonomous and collaborative | DT10 | 7.31 | |

| Human–Robot Collaboration | DT11 | 7.27 | |

| Data Analytics and Intelligent Decision-Making | Big Data Analytics | DT12 | 7.65 |

| Customer Relationship Management | DT13 | 7.55 | |

| Smart Grid | DT14 | 7.28 | |

| Cloud and Network Connectivity | Cloud Computing | DT15 | 7.26 |

| Supervisory Control and Data Acquisition | DT16 | 7.21 | |

| Sensor Technology | DT17 | 8.12 |

| Expert | EC | SC | EN | |

|---|---|---|---|---|

| EC | 1 | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) |

| 2 | (1.00, 1.00, 1.00) | (1/3, 1/2, 1.00) | (1/4, 1/3, 1/2) | |

| 3 | (1.00, 1.00, 1.00) | (1.00, 2.00, 3.00) | (1/3, 1/2, 1.00) | |

| 4 | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | (1.00, 2.00, 3.00) | |

| 5 | (1.00, 1.00, 1.00) | (1.00, 2.00, 3.00) | (1.00, 2.00, 3.00) | |

| 6 | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | (1.00, 2.00, 3.00) | |

| 7 | (1.00, 1.00, 1.00) | (6.00, 7.00, 8.00) | (1.00, 2.00, 3.00) | |

| 8 | (1.00, 1.00, 1.00) | (1.00, 2.00, 3.00) | (2.00, 3.00, 4.00) | |

| 9 | (1.00, 1.00, 1.00) | (2.00, 3.00, 4.00) | (2.00, 3.00, 4.00) | |

| 10 | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | (1.00, 2.00, 3.00) | |

| SC | 1 | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | (1.00, 2.00, 3.00) |

| 2 | (1.00, 2.00, 3.00) | (1.00, 1.00, 1.00) | (1/4, 1/3, 1/2) | |

| 3 | (1/3, 1/2, 1.00) | (1.00, 1.00, 1.00) | (1/3, 1/2, 1.00) | |

| 4 | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | |

| 5 | (1/3, 1/2, 1.00) | (1.00, 1.00, 1.00) | (1.00, 2.00, 3.00) | |

| 6 | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | |

| 7 | (1/8, 1/7, 1/6) | (1.00, 1.00, 1.00) | (1/9, 1/9, 1/9) | |

| 8 | (1/3, 1/2, 1.00) | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | |

| 9 | (1/4, 1/3, 1/2) | (1.00, 1.00, 1.00) | (1.00, 2.00, 3.00) | |

| 10 | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | |

| EN | 1 | (1.00, 1.00, 1.00) | (1/3, 1/2, 1.00) | (1.00, 1.00, 1.00) |

| 2 | (2.00, 3.00, 4.00) | (2.00, 3.00, 4.00) | (1.00, 1.00, 1.00) | |

| 3 | (1.00, 2.00, 3.00) | (1.00, 2.00, 3.00) | (1.00, 1.00, 1.00) | |

| 4 | (1/3, 1/2, 1.00) | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | |

| 5 | (1/3, 1/2, 1.00) | (1/3, 1/2, 1.00) | (1.00, 1.00, 1.00) | |

| 6 | (1/3, 1/2, 1.00) | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | |

| 7 | (1/3, 1/2, 1.00) | (9.00, 9.00, 9.00) | (1.00, 1.00, 1.00) | |

| 8 | (1/4, 1/3, 1/2) | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) | |

| 9 | (1/4, 1/3, 1/2) | (1/3, 1/2, 1.00) | (1.00, 1.00, 1.00) | |

| 10 | (1/3, 1/2, 1.00) | (1.00, 1.00, 1.00) | (1.00, 1.00, 1.00) |

| V | W′ | W | |

|---|---|---|---|

| EC | 1.000 | 1.000 | 0.428 |

| SC | 0.667 | 0.667 | 0.286 |

| EN | 0.670 | 0.670 | 0.287 |

| EC01 | 0.991 | 0.991 | 0.121 |

| EC02 | 1.000 | 1.000 | 0.122 |

| EC03 | 0.875 | 0.875 | 0.107 |

| EC04 | 0.871 | 0.871 | 0.106 |

| EC05 | 0.950 | 0.950 | 0.116 |

| EC06 | 0.961 | 0.961 | 0.118 |

| EC07 | 0.918 | 0.918 | 0.112 |

| EC08 | 0.855 | 0.855 | 0.105 |

| EC09 | 0.758 | 0.758 | 0.093 |

| SC01 | 1.000 | 1.000 | 0.183 |

| SC02 | 0.910 | 0.910 | 0.167 |

| SC03 | 0.558 | 0.558 | 0.102 |

| SC04 | 0.672 | 0.672 | 0.123 |

| SC05 | 0.712 | 0.712 | 0.130 |

| SC06 | 0.712 | 0.712 | 0.130 |

| SC07 | 0.623 | 0.623 | 0.114 |

| SC08 | 0.273 | 0.273 | 0.050 |

| EN01 | 1.000 | 1.000 | 0.207 |

| EN02 | 0.882 | 0.882 | 0.182 |

| EN03 | 0.817 | 0.817 | 0.169 |

| EN04 | 0.765 | 0.765 | 0.158 |

| EN05 | 0.599 | 0.599 | 0.124 |

| EN06 | 0.420 | 0.420 | 0.087 |

| EN07 | 0.356 | 0.356 | 0.074 |

| SD Dimension | Dimension Weight | SD Indicator | Indicator Weight | Overall Weight | Rank |

|---|---|---|---|---|---|

| EC | 0.428 | EC01 | 0.121 | 0.0518 | 5 |

| EC02 | 0.122 | 0.0523 | 3 | ||

| EC03 | 0.107 | 0.0458 | 11 | ||

| EC04 | 0.106 | 0.0455 | 12 | ||

| EC05 | 0.116 | 0.0497 | 7 | ||

| EC06 | 0.118 | 0.0503 | 6 | ||

| EC07 | 0.112 | 0.0480 | 9 | ||

| EC08 | 0.105 | 0.0447 | 14 | ||

| EC09 | 0.093 | 0.0397 | 15 | ||

| SC | 0.286 | SC01 | 0.183 | 0.0523 | 2 |

| SC02 | 0.167 | 0.0476 | 10 | ||

| SC03 | 0.102 | 0.0292 | 21 | ||

| SC04 | 0.123 | 0.0351 | 19 | ||

| SC05 | 0.130 | 0.0372 | 16 | ||

| SC06 | 0.130 | 0.0372 | 16 | ||

| SC07 | 0.114 | 0.0326 | 20 | ||

| SC08 | 0.050 | 0.0143 | 24 | ||

| EN | 0.287 | EN01 | 0.207 | 0.0592 | 1 |

| EN02 | 0.182 | 0.0522 | 4 | ||

| EN03 | 0.169 | 0.0484 | 8 | ||

| EN04 | 0.158 | 0.0453 | 13 | ||

| EN05 | 0.124 | 0.0355 | 18 | ||

| EN06 | 0.087 | 0.0249 | 22 | ||

| EN07 | 0.074 | 0.0211 | 23 |

| LM1 | LM2 | LM3 | LM4 | LM5 | LM6 | LM7 | LM8 | LM9 | LM10 | LM11 | LM12 | LM13 | LM14 | LM15 | LM16 | LM17 | LM18 | LM19 | LM20 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EC01 | 4.63 | 3.46 | 5.03 | 4.75 | 4.70 | 5.23 | 4.39 | 3.75 | 5.72 | 3.27 | 4.04 | 3.76 | 4.65 | 4.32 | 5.52 | 4.01 | 3.71 | 2.90 | 4.23 | 4.09 |

| EC02 | 2.59 | 1.94 | 2.88 | 2.64 | 2.59 | 2.90 | 2.53 | 2.16 | 3.13 | 1.83 | 2.36 | 2.23 | 2.61 | 2.37 | 3.11 | 2.10 | 2.01 | 1.49 | 2.20 | 2.14 |

| EC03 | 2.28 | 1.72 | 2.44 | 2.18 | 2.12 | 2.38 | 2.11 | 1.85 | 2.63 | 1.63 | 2.06 | 1.89 | 2.13 | 1.97 | 2.64 | 1.63 | 1.68 | 1.13 | 1.72 | 1.75 |

| EC04 | 3.02 | 2.33 | 3.16 | 2.86 | 2.90 | 3.14 | 2.73 | 2.30 | 3.51 | 1.86 | 2.34 | 2.31 | 3.10 | 2.49 | 3.31 | 2.35 | 2.25 | 1.65 | 2.40 | 2.21 |

| EC05 | 4.14 | 3.09 | 4.37 | 4.22 | 4.24 | 4.50 | 3.82 | 3.18 | 5.10 | 2.74 | 3.32 | 3.18 | 4.40 | 3.68 | 4.77 | 3.67 | 3.33 | 2.87 | 3.84 | 3.31 |

| EC06 | 3.38 | 2.49 | 3.70 | 3.66 | 3.45 | 3.85 | 3.32 | 3.11 | 4.05 | 2.58 | 3.23 | 3.09 | 3.29 | 3.03 | 4.11 | 2.62 | 2.61 | 1.89 | 2.85 | 2.83 |

| EC07 | 2.44 | 1.88 | 2.70 | 2.51 | 2.46 | 2.74 | 2.43 | 2.04 | 3.00 | 1.76 | 2.16 | 2.01 | 2.45 | 2.21 | 2.88 | 2.00 | 1.97 | 1.49 | 2.06 | 1.94 |

| EC08 | 3.01 | 2.26 | 3.11 | 2.87 | 3.08 | 3.32 | 2.81 | 2.35 | 3.75 | 2.00 | 2.46 | 2.35 | 3.07 | 2.63 | 3.44 | 2.60 | 2.49 | 1.82 | 2.60 | 2.46 |

| EC09 | 2.23 | 1.64 | 2.16 | 1.89 | 2.08 | 2.25 | 1.96 | 1.62 | 2.65 | 1.38 | 1.70 | 1.68 | 2.23 | 1.84 | 2.39 | 1.82 | 1.71 | 1.23 | 1.83 | 1.62 |

| SC01 | 2.87 | 2.39 | 2.91 | 2.81 | 2.92 | 3.21 | 2.66 | 2.10 | 3.64 | 1.78 | 2.13 | 1.96 | 2.87 | 2.37 | 3.14 | 2.54 | 2.43 | 1.83 | 2.54 | 2.36 |

| SC02 | 1.20 | 0.98 | 1.15 | 1.00 | 1.14 | 1.21 | 1.09 | 0.88 | 1.42 | 0.71 | 0.86 | 0.81 | 1.08 | 0.84 | 1.21 | 0.78 | 0.95 | 0.52 | 0.88 | 0.84 |

| SC03 | 1.20 | 0.86 | 1.22 | 1.16 | 1.50 | 1.53 | 1.43 | 0.99 | 1.73 | 0.92 | 1.01 | 0.93 | 1.24 | 1.13 | 1.44 | 0.99 | 1.43 | 0.70 | 0.96 | 1.04 |

| SC04 | 3.33 | 2.74 | 3.58 | 3.32 | 3.27 | 3.53 | 2.99 | 2.71 | 4.01 | 2.13 | 2.69 | 2.67 | 3.34 | 2.65 | 3.75 | 2.60 | 2.46 | 1.83 | 2.92 | 2.70 |

| SC05 | 2.25 | 1.76 | 2.43 | 2.12 | 2.43 | 2.56 | 2.20 | 1.81 | 2.97 | 1.56 | 1.95 | 1.83 | 2.26 | 1.90 | 2.65 | 1.82 | 2.00 | 1.26 | 2.04 | 2.01 |

| SC06 | 1.57 | 1.19 | 1.59 | 1.55 | 1.71 | 1.85 | 1.62 | 1.27 | 2.04 | 1.08 | 1.30 | 1.19 | 1.60 | 1.35 | 1.83 | 1.30 | 1.48 | 0.95 | 1.29 | 1.28 |

| SC07 | 2.24 | 1.74 | 2.30 | 2.12 | 2.13 | 2.32 | 1.93 | 1.67 | 2.64 | 1.39 | 1.74 | 1.70 | 2.33 | 1.77 | 2.45 | 1.76 | 1.61 | 1.29 | 1.91 | 1.63 |

| SC08 | 1.22 | 0.94 | 1.30 | 1.32 | 1.34 | 1.40 | 1.18 | 1.06 | 1.51 | 0.87 | 1.03 | 1.05 | 1.31 | 1.07 | 1.42 | 1.12 | 0.99 | 0.82 | 1.14 | 0.99 |

| EN01 | 2.13 | 1.76 | 2.23 | 2.11 | 2.26 | 2.32 | 2.06 | 1.72 | 2.62 | 1.32 | 1.66 | 1.60 | 2.15 | 1.72 | 2.41 | 1.77 | 1.71 | 1.31 | 1.90 | 1.65 |

| EN02 | 2.07 | 1.74 | 2.17 | 2.06 | 2.18 | 2.22 | 1.95 | 1.68 | 2.52 | 1.27 | 1.59 | 1.55 | 2.08 | 1.64 | 2.30 | 1.73 | 1.59 | 1.27 | 1.87 | 1.60 |

| EN03 | 2.06 | 1.72 | 2.16 | 2.03 | 2.16 | 2.23 | 1.96 | 1.67 | 2.52 | 1.27 | 1.61 | 1.56 | 2.08 | 1.64 | 2.31 | 1.71 | 1.60 | 1.23 | 1.83 | 1.59 |

| EN04 | 2.00 | 1.68 | 2.09 | 1.96 | 2.10 | 2.14 | 1.87 | 1.62 | 2.43 | 1.23 | 1.54 | 1.50 | 2.01 | 1.56 | 2.22 | 1.66 | 1.54 | 1.20 | 1.78 | 1.53 |

| EN05 | 1.88 | 1.53 | 1.97 | 1.89 | 2.01 | 2.08 | 1.83 | 1.56 | 2.31 | 1.17 | 1.47 | 1.43 | 1.92 | 1.52 | 2.12 | 1.58 | 1.48 | 1.15 | 1.68 | 1.45 |

| EN06 | 2.47 | 1.77 | 2.50 | 2.28 | 2.52 | 2.58 | 2.25 | 1.91 | 3.01 | 1.72 | 2.09 | 2.05 | 2.56 | 2.13 | 2.85 | 2.02 | 2.04 | 1.43 | 2.04 | 1.87 |

| EN07 | 1.68 | 1.35 | 1.77 | 1.72 | 1.84 | 1.95 | 1.71 | 1.41 | 2.11 | 1.10 | 1.41 | 1.34 | 1.73 | 1.42 | 1.98 | 1.38 | 1.39 | 0.96 | 1.45 | 1.35 |

| PIS | NIS | |

|---|---|---|

| LM01 | 4.625 | 1.195 |

| LM02 | 3.458 | 0.856 |

| LM03 | 5.029 | 1.153 |

| LM04 | 4.753 | 1.003 |

| LM05 | 4.697 | 1.143 |

| LM06 | 5.234 | 1.211 |

| LM07 | 4.388 | 1.094 |

| LM08 | 3.755 | 0.881 |

| LM09 | 5.724 | 1.419 |

| LM10 | 3.274 | 0.707 |

| LM11 | 4.037 | 0.859 |

| LM12 | 3.763 | 0.808 |

| LM13 | 4.655 | 1.082 |

| LM14 | 4.324 | 0.840 |

| LM15 | 5.517 | 1.212 |

| LM16 | 4.006 | 0.784 |

| LM17 | 3.709 | 0.953 |

| LM18 | 2.898 | 0.519 |

| LM19 | 4.229 | 0.883 |

| LM20 | 4.093 | 0.841 |

| LM Methods | Rank | |||

|---|---|---|---|---|

| LM01 | 1.336 | 0.079 | 0.912 | 19 |

| LM02 | 1.312 | 0.078 | 0.825 | 16 |

| LM03 | 1.286 | 0.076 | 0.635 | 11 |

| LM04 | 1.256 | 0.074 | 0.411 | 6 |

| LM05 | 1.309 | 0.078 | 0.803 | 15 |

| LM06 | 1.290 | 0.076 | 0.664 | 12 |

| LM07 | 1.319 | 0.078 | 0.876 | 17 |

| LM08 | 1.291 | 0.077 | 0.673 | 14 |

| LM09 | 1.320 | 0.078 | 0.879 | 18 |

| LM10 | 1.258 | 0.075 | 0.435 | 8 |

| LM11 | 1.257 | 0.075 | 0.420 | 7 |

| LM12 | 1.259 | 0.075 | 0.436 | 9 |

| LM13 | 1.291 | 0.077 | 0.666 | 13 |

| LM14 | 1.229 | 0.073 | 0.213 | 2 |

| LM15 | 1.271 | 0.075 | 0.524 | 10 |

| LM16 | 1.230 | 0.073 | 0.219 | 3 |

| LM17 | 1.330 | 0.079 | 0.960 | 20 |

| LM18 | 1.200 | 0.071 | 0.000 | 1 |

| LM19 | 1.251 | 0.074 | 0.372 | 5 |

| LM20 | 1.245 | 0.074 | 0.335 | 4 |

| DT01 | DT02 | DT03 | DT04 | DT05 | DT06 | DT07 | DT08 | DT09 | DT10 | DT11 | DT12 | DT13 | DT14 | DT15 | DT16 | DT17 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LM01 | 2.400 | 2.718 | 1.999 | 2.202 | 2.233 | 2.065 | 2.085 | 2.743 | 2.563 | 2.124 | 1.995 | 2.833 | 1.982 | 2.299 | 2.555 | 3.029 | 2.453 |

| LM02 | 0.784 | 0.770 | 0.815 | 0.637 | 0.715 | 0.659 | 0.602 | 0.852 | 0.834 | 0.663 | 0.634 | 0.858 | 0.693 | 0.631 | 0.786 | 0.982 | 0.758 |

| LM03 | 1.174 | 1.244 | 1.001 | 0.976 | 0.972 | 1.005 | 1.004 | 1.290 | 1.253 | 0.965 | 0.879 | 1.302 | 0.856 | 1.071 | 1.237 | 1.420 | 1.098 |

| LM04 | 2.202 | 2.257 | 1.841 | 1.685 | 1.744 | 2.081 | 2.039 | 2.374 | 2.255 | 1.637 | 1.483 | 2.349 | 1.584 | 2.025 | 2.211 | 2.606 | 2.073 |

| LM05 | 2.235 | 2.413 | 1.748 | 1.745 | 1.985 | 1.878 | 1.875 | 2.561 | 2.362 | 2.059 | 1.944 | 2.566 | 1.622 | 2.056 | 2.310 | 2.687 | 2.241 |

| LM06 | 1.741 | 2.007 | 1.561 | 1.831 | 2.156 | 1.583 | 1.582 | 2.207 | 2.355 | 2.067 | 2.072 | 2.277 | 1.186 | 1.716 | 2.075 | 2.487 | 2.162 |

| LM07 | 0.702 | 0.882 | 0.642 | 0.736 | 1.035 | 0.624 | 0.666 | 1.025 | 1.029 | 1.212 | 1.233 | 1.132 | 0.456 | 0.794 | 0.974 | 1.139 | 1.087 |

| LM08 | 1.273 | 1.410 | 1.017 | 1.060 | 1.300 | 1.312 | 1.296 | 1.601 | 1.592 | 1.578 | 1.474 | 1.721 | 0.908 | 1.407 | 1.590 | 1.835 | 1.692 |

| LM09 | 2.896 | 3.301 | 2.576 | 2.763 | 3.097 | 2.905 | 2.901 | 3.592 | 3.530 | 3.201 | 3.071 | 3.789 | 2.261 | 3.109 | 3.465 | 4.151 | 3.620 |

| LM10 | 0.743 | 0.771 | 0.673 | 0.616 | 0.770 | 0.710 | 0.783 | 0.859 | 0.897 | 0.760 | 0.735 | 0.924 | 0.461 | 0.724 | 0.805 | 0.992 | 0.865 |

| LM11 | 0.757 | 0.744 | 0.631 | 0.565 | 0.715 | 0.721 | 0.829 | 0.838 | 0.878 | 0.776 | 0.725 | 0.940 | 0.440 | 0.752 | 0.805 | 0.988 | 0.873 |

| LM12 | 0.730 | 0.788 | 0.596 | 0.554 | 0.734 | 0.580 | 0.620 | 0.871 | 0.852 | 0.950 | 0.890 | 0.992 | 0.492 | 0.695 | 0.848 | 0.949 | 0.850 |

| LM13 | 2.790 | 2.940 | 2.319 | 2.134 | 2.467 | 2.310 | 2.266 | 3.129 | 3.029 | 2.677 | 2.518 | 3.197 | 2.119 | 2.492 | 2.948 | 3.411 | 2.880 |

| LM14 | 0.676 | 0.666 | 0.529 | 0.484 | 0.609 | 0.676 | 0.630 | 0.763 | 0.772 | 0.609 | 0.566 | 0.764 | 0.385 | 0.619 | 0.697 | 0.840 | 0.723 |

| LM15 | 1.933 | 2.077 | 1.683 | 1.495 | 1.763 | 1.741 | 1.717 | 2.213 | 2.175 | 1.991 | 1.913 | 2.344 | 1.497 | 1.894 | 2.101 | 2.518 | 2.176 |

| LM16 | 0.837 | 1.066 | 0.754 | 0.846 | 1.259 | 0.709 | 0.752 | 1.202 | 1.245 | 1.521 | 1.513 | 1.300 | 0.479 | 0.903 | 1.171 | 1.341 | 1.321 |

| LM17 | 0.560 | 0.613 | 0.483 | 0.434 | 0.638 | 0.473 | 0.468 | 0.722 | 0.735 | 0.740 | 0.753 | 0.733 | 0.322 | 0.530 | 0.667 | 0.761 | 0.710 |

| LM18 | 1.317 | 1.467 | 0.909 | 0.966 | 1.238 | 1.113 | 1.165 | 1.571 | 1.413 | 1.355 | 1.312 | 1.543 | 0.838 | 1.244 | 1.350 | 1.571 | 1.477 |

| LM19 | 1.047 | 1.259 | 0.868 | 1.006 | 1.347 | 1.108 | 1.057 | 1.462 | 1.417 | 1.487 | 1.379 | 1.491 | 0.836 | 1.126 | 1.331 | 1.640 | 1.555 |

| LM20 | 0.831 | 0.899 | 0.643 | 0.714 | 0.798 | 0.883 | 0.871 | 0.992 | 1.014 | 0.854 | 0.801 | 1.074 | 0.578 | 0.912 | 0.975 | 1.147 | 1.029 |

| PIS | NIS | |

|---|---|---|

| DT01 | 2.896 | 0.560 |

| DT02 | 3.301 | 0.613 |

| DT03 | 2.576 | 0.483 |

| DT04 | 2.763 | 0.434 |

| DT05 | 3.097 | 0.609 |

| DT06 | 2.905 | 0.473 |

| DT07 | 2.901 | 0.468 |

| DT08 | 3.592 | 0.722 |

| DT09 | 3.530 | 0.735 |

| DT10 | 3.201 | 0.609 |

| DT11 | 3.071 | 0.566 |

| DT12 | 3.789 | 0.733 |

| DT13 | 2.261 | 0.322 |

| DT14 | 3.109 | 0.530 |

| DT15 | 3.465 | 0.667 |

| DT16 | 4.151 | 0.761 |

| DT17 | 3.620 | 0.710 |

| DT Technologies | Rank | |||

|---|---|---|---|---|

| DT01 | 1.221 | 0.139 | 0.734 | 11 |

| DT02 | 1.211 | 0.138 | 0.643 | 7 |

| DT03 | 1.210 | 0.139 | 0.647 | 8 |

| DT04 | 1.167 | 0.134 | 0.229 | 2 |

| DT05 | 1.227 | 0.140 | 0.802 | 14 |

| DT06 | 1.176 | 0.135 | 0.307 | 4 |

| DT07 | 1.174 | 0.134 | 0.282 | 3 |

| DT08 | 1.236 | 0.141 | 0.886 | 16 |

| DT09 | 1.247 | 0.143 | 1.000 | 17 |

| DT10 | 1.217 | 0.139 | 0.708 | 10 |

| DT11 | 1.208 | 0.138 | 0.612 | 6 |

| DT12 | 1.225 | 0.140 | 0.786 | 13 |

| DT13 | 1.144 | 0.131 | 0.000 | 1 |

| DT14 | 1.188 | 0.136 | 0.423 | 5 |

| DT15 | 1.222 | 0.140 | 0.759 | 12 |

| DT16 | 1.211 | 0.139 | 0.651 | 9 |

| DT17 | 1.228 | 0.140 | 0.814 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, P.-Y.; Chang, A.-Y. Research on the Relationship Between Lean Management and Digital Transformation Strategy and Sustainable Development: A Case Study of the Automotive Industry in Taiwan. Sustainability 2025, 17, 9572. https://doi.org/10.3390/su17219572

Lai P-Y, Chang A-Y. Research on the Relationship Between Lean Management and Digital Transformation Strategy and Sustainable Development: A Case Study of the Automotive Industry in Taiwan. Sustainability. 2025; 17(21):9572. https://doi.org/10.3390/su17219572

Chicago/Turabian StyleLai, Po-Yen, and An-Yuan Chang. 2025. "Research on the Relationship Between Lean Management and Digital Transformation Strategy and Sustainable Development: A Case Study of the Automotive Industry in Taiwan" Sustainability 17, no. 21: 9572. https://doi.org/10.3390/su17219572

APA StyleLai, P.-Y., & Chang, A.-Y. (2025). Research on the Relationship Between Lean Management and Digital Transformation Strategy and Sustainable Development: A Case Study of the Automotive Industry in Taiwan. Sustainability, 17(21), 9572. https://doi.org/10.3390/su17219572