Abstract

This paper presents a systematic literature review of articles that include a life cycle assessment and sustainability assessment to measure the potential impacts of seashell waste usage in concrete production, the geographical context, and existing knowledge gaps. Concrete’s extensive production has significant environmental impacts due to resource depletion and ecosystem threats. Sustainable alternatives, like seashell waste, are explored, with life cycle assessment and sustainability analysis aiding in evaluating their environmental performance and promoting circular economy principles. Following PRISMA guidelines, a comprehensive review of eco-concrete with seashell waste was conducted. Search strategies were refined to include related terms, and rigorous screening processes were employed for article selection and data extraction. A literature search yielded 66 articles on seashell waste in concrete, with 33 selected for review through initial and secondary screenings of studies. Studies primarily focused on seashells as an aggregate or cement substitute. Findings indicate that seashell waste as a construction material has been studied to a limited extent, with few studies utilizing life cycle assessment tools. However, some existing quantitative and qualitative sustainability analyses suggest seashell waste could be a promising and sustainable option for construction materials. Geographically, Spain leads in research, with China and Iran also prominent. Furthermore, we conducted a content analysis using Leximancer software to identify and evaluate concept maps through current research domains and emerging trends. Life cycle assessment, environment, and sustainability are common themes among the articles studied. This review also identifies limitations in bias, article heterogeneity, and search scope. Opportunities exist for a circular economy approach in cement production using seashell waste, but future research should explore its economic, environmental, and social impacts. Recommendations include expanding life cycle assessment studies, improving sustainability analyses, and using tools like the Integrated value model for sustainable evaluation.

1. Introduction

Concrete is one of the most extensively produced construction materials worldwide and its environmental impacts are significant [1]. It is created as a composite from cement and aggregates (fine and coarse), both obtained from rapidly depleting natural resources [2]. Environmental impacts as a result of concrete production—including threats to river ecosystems and non-reversible land erosion—have raised decision makers and manufacturers’ interest in finding sustainable alternatives [3]. Recently, different materials, including recycled wastes and byproducts, have been used to substitute cementitious binders, fine aggregates, and coarse aggregates [3,4,5].

In terms of both volume and mass, aggregates such as sand, gravel, or crushed rock are the prime component of concrete and, therefore, large quantities of natural aggregates are mined for its production [5]. Commonly used fine aggregates include alluvial silica sand, alluvial quartz sand, feldspathic crushed sand and riverbed sand; coarse aggregates are commonly river stones, crushed granite, crushed quartzite, and crushed limestone [5]. The environmental impact to river ecosystems and land erosion as a result of aggregate mining for concrete production has raised concerns, thus, finding alternative sustainable materials or substitutes is now an important area of development and research. Moreover, besides the depletion of natural raw material resources, the cement industry faces environmental challenges due to the high energy consumption needed for the production of cement clinkers [6]. During the production of cement, considerable volumes of greenhouse gas such as CO2 are released, because clinkers require fossil fuels to heat limestone at 1450 °C –1500 °C [7]. In addition, new construction techniques to increase productivity and quality, such as self-compacting concrete or 3D printing, end up increasing the cement content within mixes [8]. Recently, this problem has been addressed by replacing a percentage of cement with Supplementary Cementitious Materials (SCMs) such as fly ash, natural pozzolans, microsilica or blast furnace slag [9,10,11]. SCMs are added to concrete mixtures with the aim of improving durability, decreasing permeability, aiding in pumpability and finishability, mitigating alkali reactivity and improving the properties of concrete. However, the high demand for these materials, the declining quality of naturally occurring raw materials, and the depletion of resources are forcing the search for new SCM alternatives that can also favor recycling in other industries. Therefore, the use of waste materials as a partial or total substitute for conventional concrete-making materials (such as cement, aggregate and fiber) has raised interest. SCMs are characterized by high SiO2 (Silica, Silicon oxide, Silicon dioxide or quartz) and CaO (Calcium oxide, quicklime or lime) contents that increase the formation of hydrated calcium silicate. For this reason, some studies have focused on biomaterials with similar contents as alternatives for replacing cement, such as seashells or palm skin [5,12].

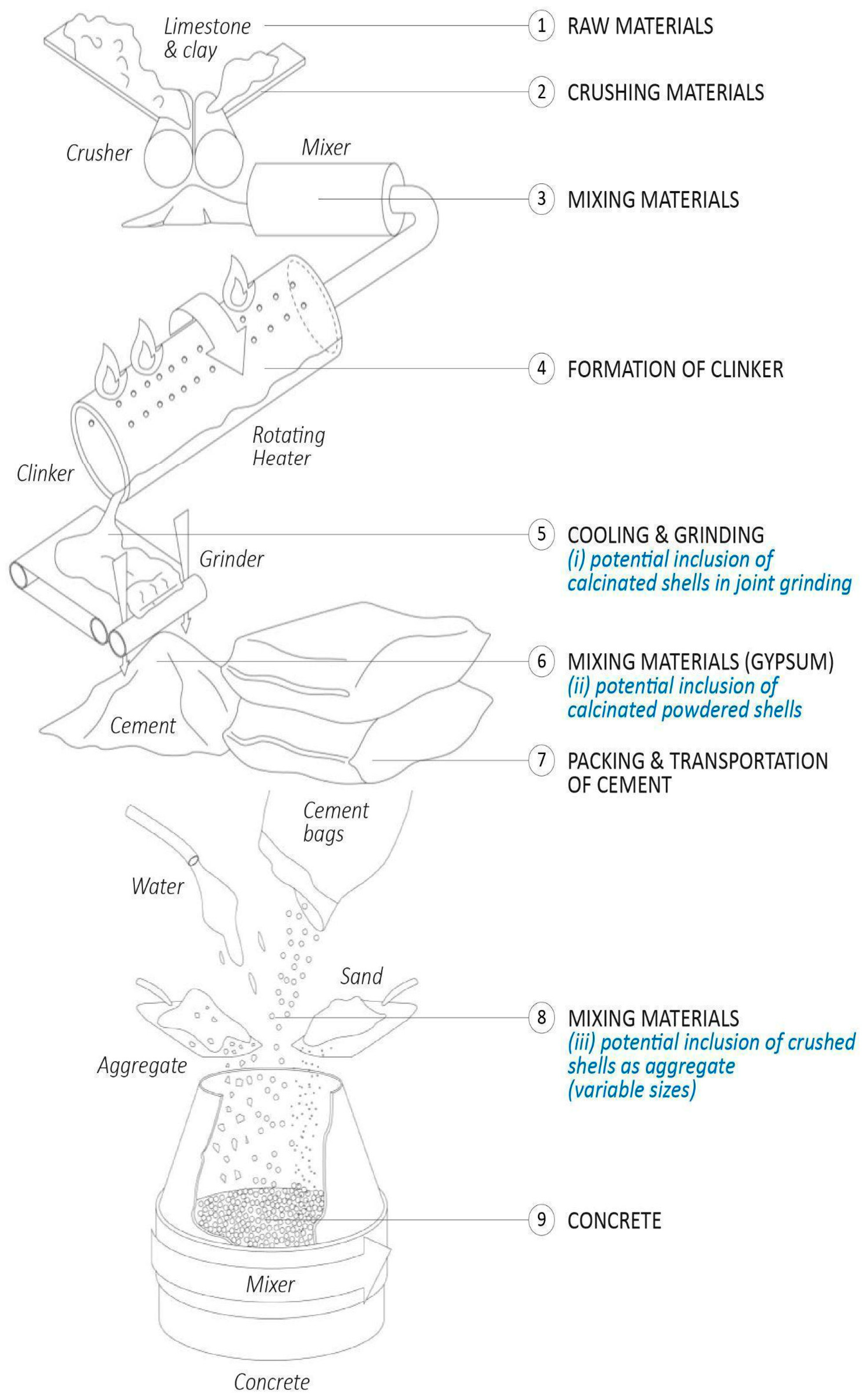

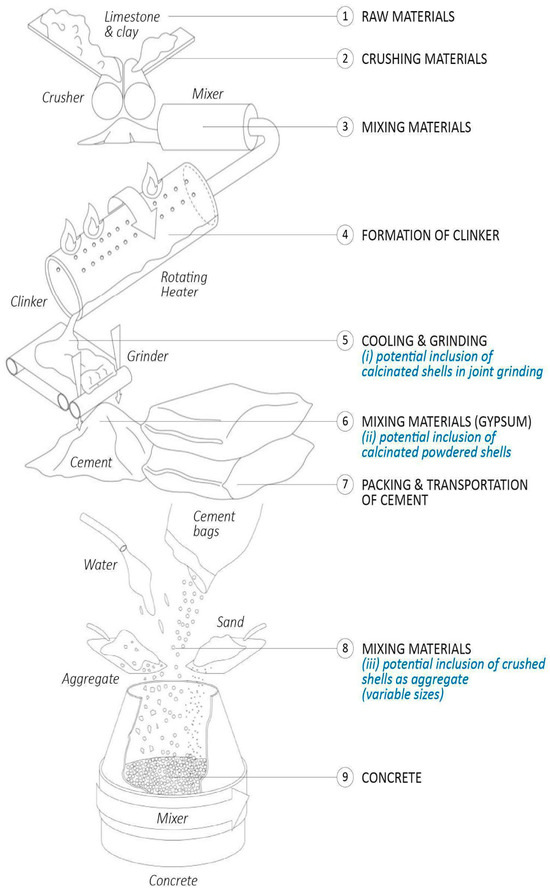

Seashells have been studied extensively as a replacement for either cement or aggregates as they have CaO contents above 97% [5]. Figure 1 shows the stages within a typical concrete production process, where seashell waste can be used as a material replacement, as reported in the existing literature. For instance, ref. [13] employed snail shell powder to replace up to 35% of cement by weight, achieving strength results comparable to those of conventional concrete. Similarly, ref. [14] used replacements of 5–20% by weight of cement, achieving an increase in compressive strength in the order of 5–10%. Ref. [6] observed similar results, highlighting that those mixes with 10% replacement did not generate greater differences in compressive strength, but they did indicate that natural pozzolans enhance the benefits of seashells. Globally, 10–20 million tons of seashells are produced annually, but the use of these wastes is low despite the benefits of using it in concrete [7]. Then, there is an opportunity for developing concrete production that can also contribute to the valorization of seashell waste [15]. Most studies have focused on the mechanical properties of concrete using seashells as a replacement, but more research is needed regarding the impact this material can have on the environment.

Figure 1.

Concrete production process; the stages where seashell waste can be used as a material replacement are indicated with blue letters.

One limitation of using seashell waste as a replacement is that the material contains chlorides, which can negatively impact reinforced concrete. However, this issue can be mitigated by rigorously washing the seashells with deionized fresh water. Because of this challenge, seashell concrete’s primary intended applications in the circular economy are for non-structural elements and plain, non-reinforced concrete. Seashell concrete is also used for reinforced concrete structures with moderate exposure, where corrosion risk is lower.

Life cycle assessment (LCA) is an internationally accepted and useful tool to assess environmental impacts [16]; it evaluates the impacts associated with all the stages of a product’s life, which is from raw material extraction through materials processing, manufacture, distribution, and use [17]. LCA is used primarily by scientists, although it is becoming better known among policymakers [18]. By conducting an LCA, areas in the concrete production can be identified where improvements can be made to reduce environmental impacts, such as using more sustainable raw materials, reducing energy consumption during production, and minimizing waste during construction [19]. Additionally, LCA can help stakeholders make informed decisions about the environmental performance of concrete, including its carbon footprint, and can be used to compare the environmental impacts of concrete to other building materials [20]. Reviews on LCA in alternative construction materials show that the potential for impact reduction is significant, especially when using byproducts and waste. Examples of solid waste include construction and demolition waste, municipal solid waste from incineration, tire rubber, volcanic ash, polyethylene terephthalate, palm kernel ash and shells, coconut shells, and sugarcane, among others [10,12,21].

Seashell waste is a byproduct generated from the seafood industry, and its disposal can result in negative impacts on the environment [22]. LCA can also help to identify opportunities to reduce these impacts, such as through recycling and reusing seashell waste as a feedstock for cement production [23], which can significantly reduce the need for traditional raw materials. Overall, LCA can provide valuable insights into the environmental performance of seashell waste and help to identify more sustainable solutions for its disposal, ultimately leading to a more circular and resource-efficient economy.

Following the same line, and in a more macro approach, is the concept of sustainability, a multi-dimensional system with three main components, namely environmental, economic, and societal [24], generally defined as the use of natural resources in such an equilibrium condition that they do not reach decay, depletion, and the nonrenewable point and are handed down to the next generations by developing them. To measure sustainability, there are various methods and tools according to their assumptions and valuation perspective. Sustainability assessment tools can be divided into three main categories: monetary, biophysical and indicator-based [25]. As a matter of fact, a measure of sustainability is fundamental to evaluating competing alternatives when a selection of materials, energy resources, production process design choices, and locations for building placement has to be performed [26].

This article is a literature review of LCA and sustainability analyses in eco-concrete with seashell waste. The paper presents the methods and boundary conditions for the literature review and then an overview of the results, which is followed by a discussion of the evidence in LCA and sustainability analysis for the use of seashell waste in eco-concrete, and geographical and knowledge gaps. Implications of the study and future research are provided in the conclusions.

2. Materials and Methods

Based on PRISMA guidelines, a structured electronic literature search of Web of Science and SCOPUS databases was conducted. Database searches were conducted in October 2022 and last consulted in December 2022. Review and data extraction was performed by one investigator and independently checked for accuracy by a second researcher.

2.1. Study Objectives

This article seeks to characterize the breadth of methods employed for environmental and sustainability analyses in eco-concrete with seashell waste, the results that these evaluations conclude, and to identify key gaps in the existing knowledge base.

To address the objectives, five research questions (RQs) are proposed:

RQ 1: What evidence exists in LCA studies for the use of seashell waste in eco-concrete?

RQ 2: What sustainability analyses are there for eco-concrete with seashell waste?

RQ 3: In what geographical contexts are these approaches being applied?

RQ 4: What gaps exist in the current knowledge regarding LCA and sustainability of eco-concrete using seashell waste?

RQ 5: What are the main research subjects covered within the studies as well as future trends from the content perspective?

2.2. Literature Identification

A literature review was carried out through Web of Science (WoS) and SCOPUS search engines. The search was focused on articles that specifically mention the use of seashell waste in eco-concrete. Based on the results of a pilot search, we noticed the low number of results returned when using only the term concrete, so the search was extended with the concepts of mortar, cement and supplementary cementitious materials. The same happened for the concept of LCA and sustainability, so the search was extended with the concept of circular economy. Finally, the keywords used were as follows:

ALL = (((LCA) OR (sustainability) OR (“life cycle assessment”) OR (“life cycle analysis”) OR (circular economy)) AND ((“Supplementary Cementitious Materials”) OR (concrete) OR (mortar) OR (cement)) AND ((seashells) OR (mussel) OR (clams) OR (oysters) OR (scallops))) = 31 results.

In a pilot search, the same keywords search in the SCOPUS database included 165 results, the first 30 results were reviewed by a researcher (titles and abstracts), where it was determined that there was a high number of articles that developed subjects outside the scope of the review, so the research keywords were limited to the words appearing in the title, abstract or keywords:

TITLE-ABS-KEY (((LCA) OR (sustainability) OR (“life cycle assessment”) OR (“life cycle analysis”) OR (“circular economy”)) AND ((“Supplementary Cementitious Materials”) OR (concrete) OR (mortar) OR (cement)) AND ((seashells) OR (mussel) OR (clams) OR (oysters) OR (scallops))) = 35 results.

Due to the low number of articles obtained, time limits (years) were not used in the search.

2.3. Selection of Articles and DATA Extraction

2.3.1. Initial Screening

A database was created, all studies were then given a unique identifier based on the databases they were retrieved from, and the results were compiled into a single excel spreadsheet. The exclusion criteria of the initial screening consisted of eliminating unavailable articles, duplicates, and it was also decided to eliminate reviews, conference articles, and editorials. This screening was carried out by one researcher, reviewing the titles of the articles (to eliminate duplicates), checking one by one the access links and the availability of the articles, and the type of article based on the “document type” information obtained from the databases.

2.3.2. Secondary Screening

For the secondary screening, the topics addressed in the articles were analyzed; despite the fact that the search focused on the use of seashell waste in eco-concrete, articles that evaluate the use of seashell waste in any other construction material were considered within the study for being considered a possible contribution of interesting information. The exclusion criteria are articles that address any other topic than the use of seashell applied as a construction material. This screening was carried out by one researcher, reviewing the abstracts and classifying the use of seashell waste, if it is a replacement or substitution of construction material and the material to replace/substitute. The classification and elimination of articles was reviewed by a second researcher. In cases where the two researchers disagreed on the inclusion and exclusion criteria, the discrepancy was resolved through a discussion facilitated by a third researcher. Automation tools were not used in the process.

2.3.3. Methods (Methods Coding, Factors, Interactions)

The methods used to decide which results to collect were based on the data needed to answer the questions in the first place. To characterize the breadth of methods employed for environmental and sustainability analyses in eco-concrete with seashell waste, the review examined three key attributes of each study: evidence in LCA applications (RQ1), evidence of sustainability analysis (RQ2), and geographical contexts (RQ3). Gaps in knowledge (RQ4) were addressed through a review of results from all attributes.

Therefore, eligible outcomes were broadly categorized into descriptors as follows: country case study, replaced component with seashell waste or replaced construction material, method, and results of the evaluation. The descriptor method indicates the main methodology used in the article; these can be LCA, experimental testing, sustainability analysis, or other. In the “Others” classification there are optimizations, environmental, statistical, economic, and social analyses.

The descriptor “results” indicate whether the authors present optimistic, beneficial, and useful results based on the evaluations carried out (positive +), or if these are rather neutral (+−), or do not present benefits or contributions (negative −). Risk of judgment bias was detected for the descriptor “results”, and assessments were made by one reviewer and verified by another to reach an overall judgment.

Other variables for which data were sought were the replacement percentages in the cases of cement replacement and concrete aggregate replacement; results are presented in Appendix A.

2.4. Content Analysis

To delve deeper into the insights, we have used the capabilities of Leximancer version 4.5 to find correlations among key concepts included in the selected papers (RQ5). This software is able to analyze text with the aim of obtaining co-occurrence and interrelationships among semantic and thematic data to uncover intricate patterns and networks among fundamental ideas that are grouped into higher-level themes [27]. The software utilizes statistical algorithms that incorporate nonlinear dynamics and machine learning techniques to identify categories, based upon frequency and similarities of the words that are clustered, and establish relationships among concepts within and between categories [28]. A conceptual map is a visual tool, in which each category is indicated with a circle with a specific color and size. The warmer the color (e.g., red and orange), the more significant the category is, the colder the color, the relatively less significant the theme is [29]. Concepts within categories are shown with nodes and their relationships are traced with lines that link these concepts [30]. The distance between concepts is calculated based on the definition of words. Thus, concepts with a strong semantic relationship are mapped closer and even overlapping, while concepts with a weak correlation are mapped apart [28,31]. This automated manner to study data safeguards our analysis from the biases that often infiltrate manually coded text and also allows reproductivity of the research.

3. Results

3.1. Literature Search Results

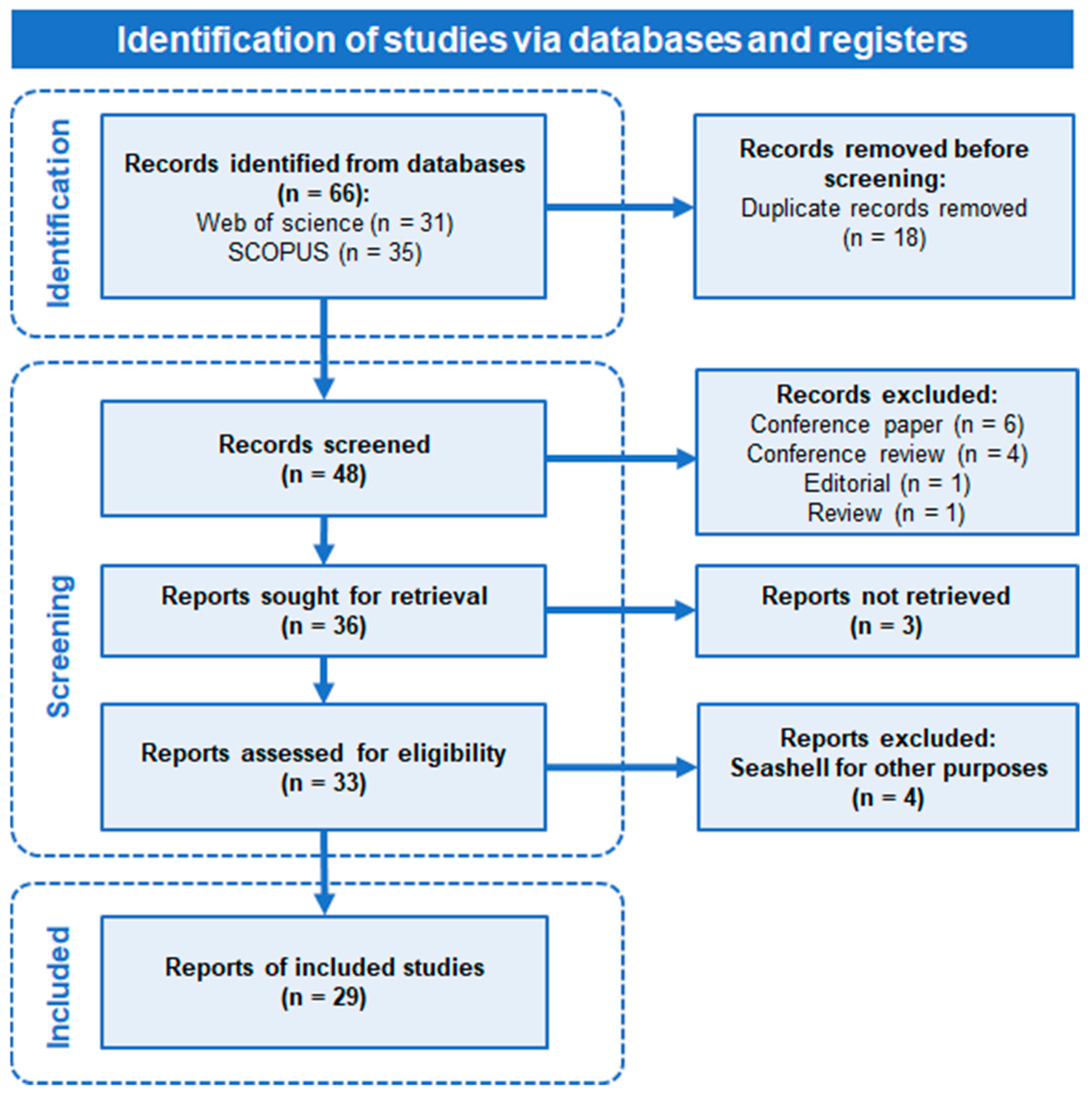

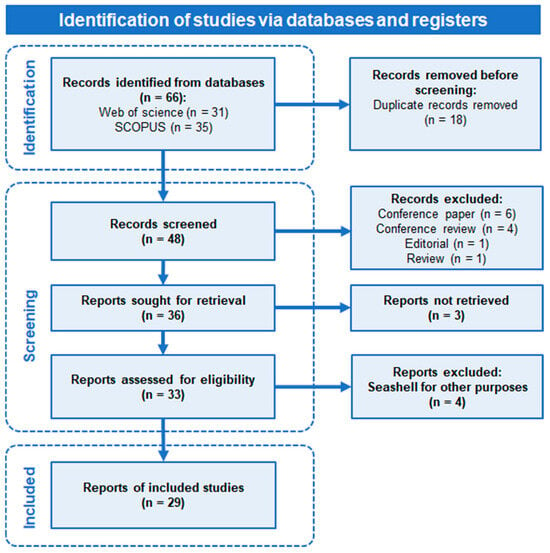

Through the search focused on analyzing the use of seashell waste on concrete, 66 articles were obtained from databases (31 in WOS and 35 in SCOPUS); in the primary screening, 18 were excluded because they were duplicates and 3 were excluded because they were not available (1 in WOS and 2 in SCOPUS). Furthermore, 12 articles were left out since it was decided to only consider the scientific articles (Conference papers, Conference reviews, Editorials and Reviews), resulting in 33 reports sought for retrieval.

In the second screening, the topics addressed in the articles were analyzed, and the applicability analysis of seashell waste in construction materials left out 4 articles. The study of [32] involves the adaptation of three different natural structures that lead to a natural flow of forces, one of them being the underside of seashells. The article of [33] aims to compare the environmental and social impacts of three types of rafts (replacement of these traditionally wooden structures for ultra-high performance concrete) for mussel farming in Spain. The case of [34] studies the current trends for non-plastic restoration projects and their state (for oyster and shoreline restoration). The paper of [35] analyzes and estimates exploitable marine residues, through quantification of fish waste and stranded debris in beaches.

Then, 29 full text articles were obtained (26 in WOS and 3 in SCOPUS) for an extensive analysis of our study’s descriptors. A PRISMA flowchart with the selection of articles included in this review is shown in Figure 2. The complete PRISMA checklist for the systematic review, indicating the location of each specific topic within this article, is available online as Supplementary Material.

Figure 2.

Preferred Reporting Items for Systematic Literature Reviews and Meta-Analyses (PRISMA) flow diagram with selection of articles included in this review.

The study’s descriptors were tabulated; country of study case, material replaced by seashell, Methods, Sustainability analysis type and Results are presented in alphabetical order in Table 1.

To tabulate heterogeneous methods used in selected articles, we analyzed the specific methodology of each study and classified them into the following categories as shown in Table 1: LCA, experimental testing, sustainability analysis, and others.

Regarding the use of seashell waste in construction materials, thirteen articles study the replacement of aggregates in concrete and ten articles study the replacement of cement in concrete (three of them study the replacement of aggregates and cement at the same time), the rest of the articles (nine) study the use of sea shells in other types of construction materials, as is the case of cement in cement-stabilized clay soils mixtures [36], seashell rocks in replacement of reef rocks [37], replacement of cement in blended cement pastes [38], binder in gravel wash mud [39], replacement of asphalt binder [40], building insulation material (loose-fill) [41], replacement of gypsum in gypsum [42,43] and replacement of concrete high-pressure bricks by oyster shell powder, and quenched blast furnace slag powder high-pressure bricks [44].

To compare the different studies, we reviewed the self-reported results of each article according to its conclusions. This allowed us to identify articles that mentioned positive, neutral or negative results. Therefore, twenty-seven articles concluded that their results were positive, one was considered neutral [42], and one was considered negative [45]. It is important to highlight that there is a risk of biasing the results due to the articles’ heterogeneity; they vary in methodology, the types of material studied, and the purpose of the analysis carried out.

It is important to recognize that concrete’s mechanical performance can decrease at high substitution rates. We compared the results presented by different authors; however, not all of the projects analyzed the mechanical properties. Therefore, it was not possible to compare this performance. In future research, it is important to consider this aspect and aim for a balance where the reduction in long-term compressive strength is minimal or acceptable.

Regarding the results of the studies, twenty-seven articles conclude that their results are positive, one is considered neutral [42] and one is considered negative [45]. Finally, concerning the percentage of replacement of cement in concrete, the papers show test compositions of 0–30% by weight of replaced cement, and the results show that the optimum is between 10 and 15%, in the case of the replacement of aggregates, the studies prove up to 100%, as can be seen in Table A1 in Appendix A.

Table 1.

Screened articles.

Table 1.

Screened articles.

| Ref. (Country) | Replaced Component | Methods | Results of the Mix/Blend | |||

|---|---|---|---|---|---|---|

| LCA | ET | SA | Other | |||

| [4] (Nigeria) | Granite in concrete | No | Yes | No | (+) Meets workability requirements, strength and split tensile strength values. | |

| [2] (Nigeria) | Sand in concrete | No | Yes | No | Correlation and Regression. ECA | (+) Meets strength requirements, and acceptable splitting tensile strength. Compressive strength has a high negative correlation with seashell percentage and a significant correlation with splitting tensile strength. Seashell as a substitute for fine aggregate is more cost-effective than traditional aggregate. |

| [46] (Spain) | Sand in concrete | No | Yes | No | (+) Better biomass colonization and mechanical properties with a mortar based on cementitious binders (glass, seashell, and limestone) compared to geopolymer-based compositions. | |

| [47] (Spain) | Cement and sand in concrete | No | Yes | No | Statistical analysis, parametric and nonparametric regression models. | (+) Blends (5–10 wt.% seashell) have good resistance of concrete against erosive degradation, for high replacement (20 wt.%), the resistance increases compared to common concrete. FANOVA application results support that replacement of high quantities of sand produces differences in erosive degradation. |

| [48] (Spain) | Sand in concrete | No | Yes | Yes | Socio-economic and environment analysis (Statistics, multivariate linear regression models). | (+) Determine the Bio/socio—economic benefits of establishing green artificial reefs. Acceptable compressive strength and higher water absorption (not suitable in marine environments). Estimate compressive strength, compressive lifetime and the water absorption of concrete based on type of sand substitute, amount of substitute, fluidizer and water. |

| [21] (Spain) | Cement and sand in concrete | No | No | Yes | Theoretical Analysis of Material Flows, Multi-criteria decision model (MIVES) | (+) A partial substitution of cement and sand and the total substitution of metal frames with eucalyptus fibers is the most advantageous outcome. The higher the number of substitutions, the higher the sustainability index. |

| [49] (Spain) | Aggregates in concrete | No | Yes | Yes | Statistics, ANOVA and multivariate regression models, mechanical properties and environmental indicator | (+) Some blends present a relatively high compressive strength and a low water absorption (comparable with the control formulation). The compressive strength of concrete depends on the age of the concrete, aggregate size, percentage of calcite and precedence of calcite (oyster or scallop). Multi-criterial methods identified the same options as being the most suitable. |

| [36] (Australia) | Cement in clay soil mix | No | Yes | No | (+) Seashell is effective to improve the sulfate resistance of cement-stabilized soil. | |

| [50] (China) | Sand in concrete | No | Yes | Yes | CO2 emissions assessment ECA | (+) Fly Ash and ground granulated blast furnace slag in oyster mortars decreased total CO2 emissions, material costs and enhanced the resistance to chloride ion penetration. Mechanical and transport properties decreased. The blends were more economical than the control group. |

| [37] (Portugal) | Seef rocks | No | Yes | No | Statistical analysis, one-way ANOVA | (+) Artificial seashell rocks promote nitrification similar to natural reef rocks. A sustainable option to safeguard a suitable biological filtration in marine aquariums. All treatments, except the control group, had an active colony of nitrifying bacteria. |

| [38] (France) | Cement in blended cement pastes | No | Yes | No | (+) Calcium carbonate present in ground oyster shells is more reactive than limestone filler, where more formed hemi- and monocarboaluminate phases were observed in mixtures containing ground oyster shells; this phase leads to increasing hydrates volume and thus improving the compressive strength. | |

| [51] (Iran) | Cement and sand in concrete | No | Yes | No | (+) Seashell powder extends setting times (advantageous for constructing in hot climates) and reduces water demand (enhances mechanical strength) of the mortars. | |

| [52] (Morocco) | Cement and additive in concrete | No | Yes | No | (+) Mussel Powder as a cement substitute (12%) or as a mineral additive (3%) to produce a non-structural concrete, meets the normative requirements in terms of compressive and tensile strength. | |

| [39] (France) | Binder in gravel wash mud | No | Yes | No | (+) Fly ash and shells in addition to gravel wash mud provides a reduction in porosity and enhanced strength. Thermal conductivity is reduced, and the specific heat capacity is enhanced compared to usual cob construction materials. | |

| [53] (Italy) | Gravel in concrete | No | Yes | No | (+) Good workability; good tensile strength. The compressive strength is reduced as mussels’ shells % increases; the force–displacement plots showed a higher peak of the failure load for specimens with a higher % of mussels’ flakes and a minimal ductility of the behavior soon after the failure is reached. | |

| [54] (France) | Gravels in concrete | No | Yes | Yes | (+) Shells reduce the strength of the material after 90 days of curing. During immersion the mechanical strengths of blends increased. Cl ions content was reduced in concrete blends immersed in natural seawater. Concrete with 20% of seashell is the most suitable mix design for the marine infrastructure. | |

| [40] (China) | Asphalt binder | No | Yes | No | (+) Seashell powder and asphalt binder represent a stable physical mixture of modified properties; improves consistency, hardness, and high-temperature performance but weakens low-temperature performance; enhances elasticity, recovery performance, and has a minimal effect on crack resistance. | |

| [55] (South Korea) | Cement in concrete | No | Yes | Yes | CO2 emissions assessment | (+) The workability of the mortar was reduced. As the replacement amount increased, hydration reaction rate of the paste accelerated, and the cumulative heat of hydration and compressive strength gradually decreased. Compressive strength of the later period increased significantly, compared to the control group. The CO2 emission per unit and compressive strength of two blends was considerably lower than pure cement mortar. |

| [56] (South Korea) | Cement in concrete | No | Yes | Yes | CO2 emissions assessment Multi-objective Optimization | (+) Both oyster shell powder and blast furnace slag can significantly reduce the heat of hydration and carbon emissions. A small amount of seashell powder increases the early compressive strength. When oyster powder and slag were added simultaneously, the compressive strength and resistivity increased significantly (synergic effect). A normalized comparison of carbon emissions based on the compressive strength suggested that ternary pastes exhibit less emissions than binary pastes. Multi-objective optimization indicates that the blend had the best overall performance when rates are 5.01% oyster powder and 25.95% blast furnace slag. |

| [57] (China) | Cement in concrete | No | Yes | No | (+) The ternary supplementary cementitious materials showed equivalent compressive strength compared to reference specimens. | |

| [58] (China) | Cement in concrete | No | Yes | No | (+) Compressive strength of concrete mixed with ternary materials (oyster shell powder-lithium slag-ground granulated blast furnace slag) was improved compared with the reference specimens and have lower porosity and permeability. | |

| [41] (Spain) | As building insulation material | No | Yes | Yes | Material Embodied Energy analysis | (+) Mussel shells have thermal and acoustic characteristics suitable for building insulation material. The embodied energy of the mussel shell as a loose-fill material is similar to that of other bio-based insulation materials. |

| [45] (Spain) | Aggregates in concrete | Yes | No | Yes | (−) All impact categories assessed involve higher environmental impacts in the replacement scenario. | |

| [43] (Spain) | Gypsum in gypsum | Yes | Yes | Yes | ECA | (+) The replacement is feasible and satisfies all requirements of European standards. 13 of the 18 impact categories showed improved environmental scenarios, impacts associated with water made worse. To achieve effective recycling, it is necessary to redesign the washing process. Costs were reduced by over 13%. |

| [42] (Chile) | Gypsum in gypsum | No | Yes | No | ECA | (+−) Lower mechanical properties than commercial standards during sulfate attacks and freeze–thaw cycles. The replacement is economically feasible. |

| [44] (China) | Concrete high-pressure bricks | No | Yes | Yes | CO2 emissions assessment | (+) The bricks (with oyster shell powder and quenched blast furnace slag powder) are in line with Taiwan CNS high-pressure brick specifications and conform to Taiwan’s green building materials standards. Each oyster shell high-pressure brick could produce 49% to 52% fewer carbon emissions than those emitted by each high-pressure concrete brick. |

| [6] (Iran) | Cement in mortar | No | Yes | No | (+) Setting time of all blended cements was higher than Portland cement (beneficial for hot climates). All blended cements containing seashell powder presented compressive strength comparable to Portland’s at 3, 7, and 28 days. | |

| [23] (Iran) | Cement in concrete | Yes | Yes | Yes | (+) Binary and ternary blends have a lower environmental impact and similar compressive strength than Portland cement. Mortars that have a compressive strength almost equal that of the reference and lower environmental impacts. | |

| [59] (Italy) | Sand in concrete | No | Yes | No | (+) Flexural strength and toughness are partially lowered but still guarantees acceptable strengths for various structural and plastering applications. No notable differences were found in compressive strength (compared to mortars used in civil applications). | |

Note: Results of the mix/blend are classified in positive (+), neutral (+−), and negative (−).

3.2. Evidence in LCA for the Use of Seashell Waste in Eco-Concrete (RQ 1)

As previously mentioned, only three articles use LCA to analyze the use of seashell waste as construction material. Below is a complete analysis of the articles, the considerations and results obtained, with the system boundaries, impact categories, software and consulted databases depicted in Table 2.

Table 2.

Articles that perform LCA.

In the study of [45], the environmental performance of conventional concrete acoustic barriers composed of natural aggregates and cement (14%) was compared with barriers composed of 80% seashell waste and 20% cement by weight. Using a cradle-to-grave LCA, the results show that for the eleven environmental impact categories considered, the substitution of natural aggregates by seashell waste implies greater environmental impacts, between 32% and 267%. This is due to the high contribution of the pretreatment of seashell waste, the higher consumption of cement and the low environmental load of the natural aggregates. Therefore, the recycling of seashells in the manufacture of acoustic barriers is not justified from an environmental point of view.

The case of [43] studies the use of seashells as a substitute of gypsum, a fireproof material suitable for use in construction. Tests had mixtures with 0, 40, 60 and 80% substitution for mechanical properties, fire insulation capacity, LCA (with a cradle-to-grave system boundary), and economic analysis. Results showed that the substitution of over 60% gypsum was technically feasible; the product’s mechanical, physical and fire resistance properties satisfy all the requirements of European standards. The 40–60% gypsum substitution resulted in a 0.4–59% environmental impact reduction for 13 of the 18 impact categories considered compared to 0% substitution and increases in the other 5 categories were analyzed due to the aquatic emissions released in the washing process of the waste pretreatment. Production costs could be reduced by 20–31% by using 40–60% gypsum substituted with seashell waste.

Finally, ref. [23] evaluates the use of seashells as a replacement in the production of mixed cement for mortar production, through a life cycle approach (with a cradle-to-gate system boundary) that integrates environmental and mechanical performance. Thirty-four cements consisting of different blends of Portland cement—seashell powder (from 4 to 30%)—natural pozzolan (up to 30%) were tested (compressive test) to identify the optimal dose of cement substitution. The results show that among the 34 introduced cements, 22 developed binary and ternary ones could be successfully replaced by Portland cement with a lower environmental impact and similar compressive strength. A risk of bias of the LCA is that the three studies test slightly different construction materials; therefore, they will not be directly comparable.

Furthermore, as shown in Table 2, besides the difference in construction materials, the methods vary as well, from the system boundary assumed for the evaluation and the impact categories assessed to the software used. As stated, two studies were conducted following a cradle-to-grave approach and one followed a cradle-to-gate approach. The assessments were conducted using the software SimaPro and Thinkstep GaBi, relying on their internal databases for the analysis, with only [45] explicating the use of Ecoinvent v.3.1 as a source database within SimaPro. Lastly, regarding the impact categories, a large variety of indicators was used in the studies. However, only two impact categories are presented in all three studies: Global Warming Potential (GWP) and Ozone Depletion Potential (ODP), which signals their widespread relevance. The measurement of Acidification Potential (AP) and Eutrophication potential (EP) are present in [23,45], while indicators derived from these, but not directly comparable, were considered in [43]: Terrestrial acidification (TAP), Freshwater eutrophication (FEP), and Marine eutrophication (MEP). This is regarded as clear evidence of the lack of standards in the evaluation and reporting of LCA results beyond Global Warming Potential, which hinders direct comparisons between studies as a starting point.

3.3. Sustainability Analysis for Eco-Concrete with Seashell Waste (RQ 2)

Within the 29 articles, two types of sustainability consideration can be distinguished, and 12 articles carry out a quantitative analysis of sustainability. The type of analysis addressed in each article was analyzed and presented in Table 3: column “Sustainability related Method”, the main types are environmental impacts analysis, CO2 emission analysis, Multi-criteria analysis and Energy consumption analysis. The remaining 17 articles only mentioned that the use of seashells (in construction materials) is sustainable.

Table 3.

Articles that perform sustainability analysis.

Among the 12 papers, only 1 indicates that the evaluation results are negative [45], concluding that in the case of noise barriers with seashell waste, they have no environmental advantages over traditional concrete noise barriers.

Sustainability is not only linked to the environment, but also to the social and economic environment, which is why it is evaluated whether the studies consider all these areas. Among the four articles that specifically analyze carbon emissions [44,50,55,56], only one includes economic analysis, and none analyze the social point of view. Of the three articles that use the LCA methodology [23,43,45], only one complements it with economic analysis; the case of [41] analyzes only energy consumption and [54] only analyzes the durability of the product, indicating that if it is more durable, it will be more sustainable. In the case of the studies that perform multi-criteria analysis, ref. [49] analyzes mechanical and environmental areas, and [21] covers the three areas. The same authors in [48] carried out a rather qualitative analysis of the social, economic, and environmental benefits and proposes a general expression to calculate generic profits. The risk of bias of these results is that there are different types of sustainability analysis and these are not comparable to each other.

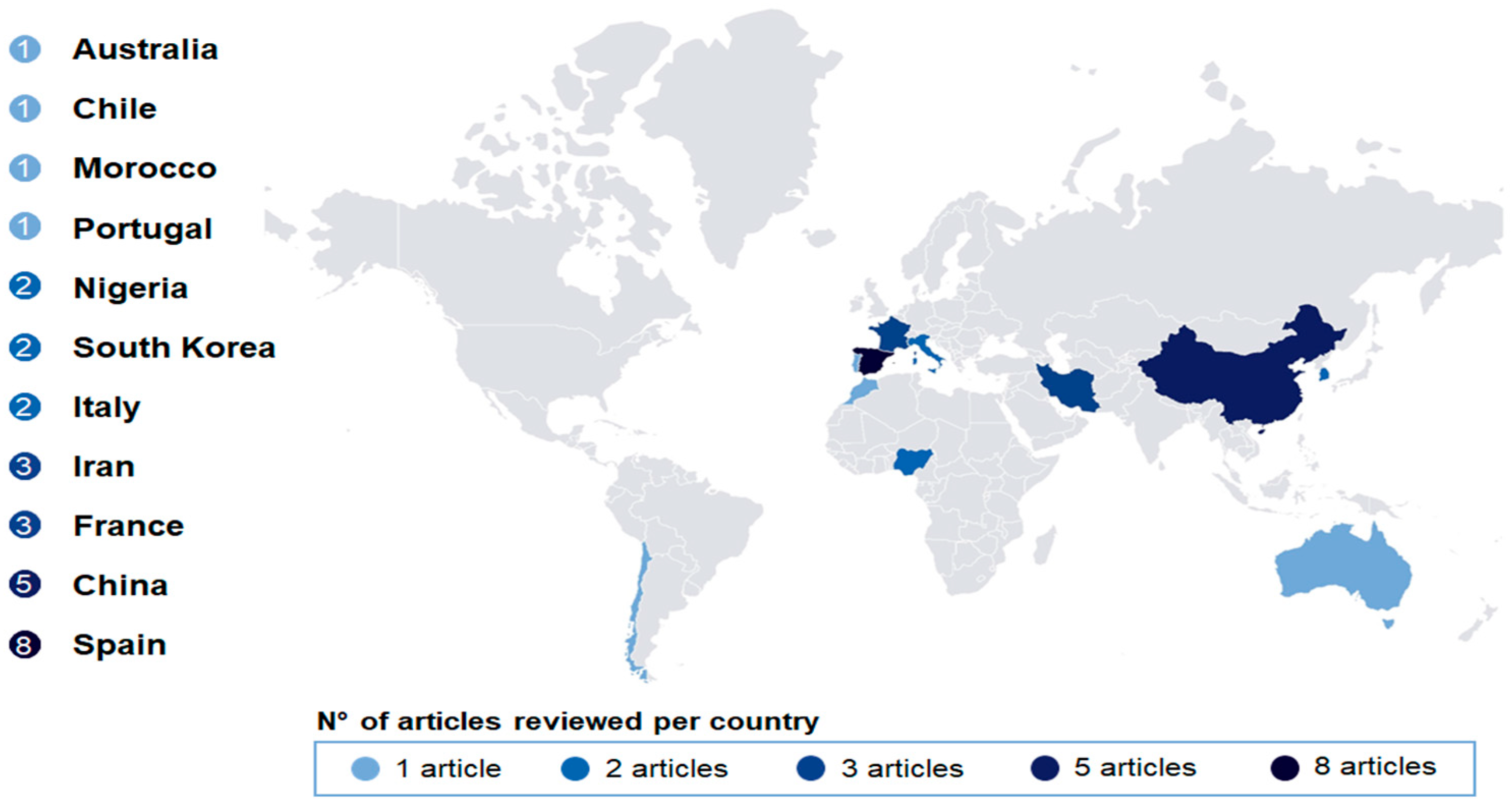

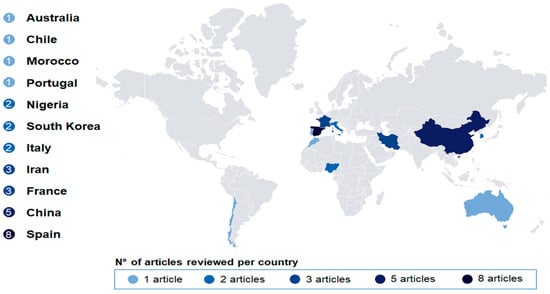

3.4. Geographical Contexts (RQ 4)

The geographical context of the 29 filtered articles is found in Figure 3. The predominance of studies developed in Spain is observed with 8 articles, followed in second place by China with 5 articles, and sharing third place with Iran and France with 3 articles. South Korea and Nigeria both have 2 articles and Morocco, Portugal, Chile and Australia only have 1 article each.

Figure 3.

Geographical distribution of the articles included in the literature review. Source: The authors generated this map with the software visme (https://www.visme.co/, accessed on 6 October 2025).

We highlight the case of two articles, where the studies were developed in parallel in more than one country. This is the case of [43] which studies the case of Galicia (Spain) using species from Spain and Chile, and in [46] where different materials with substitutes (binder and fine aggregates) were made in Spain and immersed in four different areas (France, Portugal, Spain, and the United Kingdom).

Regarding the years of publication of the articles, these begin in 2018, have a marked upward trend with an annual average of 4.83 articles between 2018 and 2023, and a maximum of 10 articles in 2021. Risks of bias regarding the geographic location of the analyzed studies are observed through the limited number of search engines (onlyWoS and SCOPUS) and the search language, since it was only conducted in English.

3.5. Gaps (RQ 4)

3.5.1. LCA Gaps

The first and most important gap observed is that the articles that perform LCA are very few; ref. [43] studies the use of seashell in gypsum, leaving [23] that studies the use of seashell waste in mortar, and [45] that studies the use of seashell waste in concrete (thematic on which the search was focused). Regarding the limitations of the studies, it can be indicated that [43] uses only one blend and replacement percentage, presenting higher impacts of using seashell in all categories of analysis, due to the impacts of the seashell waste pretreatment and to the fact that the mixture tested has more cement (+6% wt) than the control mix. Moreover, it is important to point out that besides differences in the materials being replaced within the mix, the studies reviewed followed different assumptions and methods for the evaluation, which creates a challenge for the generalization of results. Thus, there is a clear gap between both the number of studies and the existence of standardized methods and approaches to conduct them, supporting their direct comparison.

In summary, of the three LCA analyses that exist, one presents negative results and the other two obtained positive results. These data do not allow a definitive conclusion about the environmental contribution obtained by replacing cement or admixtures with seashell waste in concrete. Hence, further studies are clearly needed on the topic under a comprehensive and systematic approach. In addition, it is evident that small variations in assumptions, limits, mixture compositions and material treatments can define the results in terms of sustainability and environmental impacts, so it is important to evaluate the conditions of each particular case allowing for fair comparisons, considering the mechanical properties and their reaction to weathering, since a sustainable material must be durable and resistant over time.

3.5.2. Sustainability Gaps

With respect to the limitations detected in the sustainability approach, and as stated in Section 3.3, less than half of the articles actually address the issue beyond assuming that the use of waste will always be sustainable, and only two articles analyze the problem from the three areas (social, economic and environmental). This shows the lack of development of the comprehensive approach, since if it is even more rigorous, the participation of governments (regulations) must also be considered. Furthermore, there are largely unexplored aspects, such as long-term durability or processing costs, that are regarded as crucial to speculate about the sustainability of the replacement strategy in the long run.

3.5.3. Geographical Gaps

Based on the results presented, it is determined that it is necessary to carry out a deeper analysis and compare these data with the production of mollusk. Since it would be expected that in countries with a high production of shellfish have a high generation of shell waste as a result, solutions and revaluation applications are actively sought.

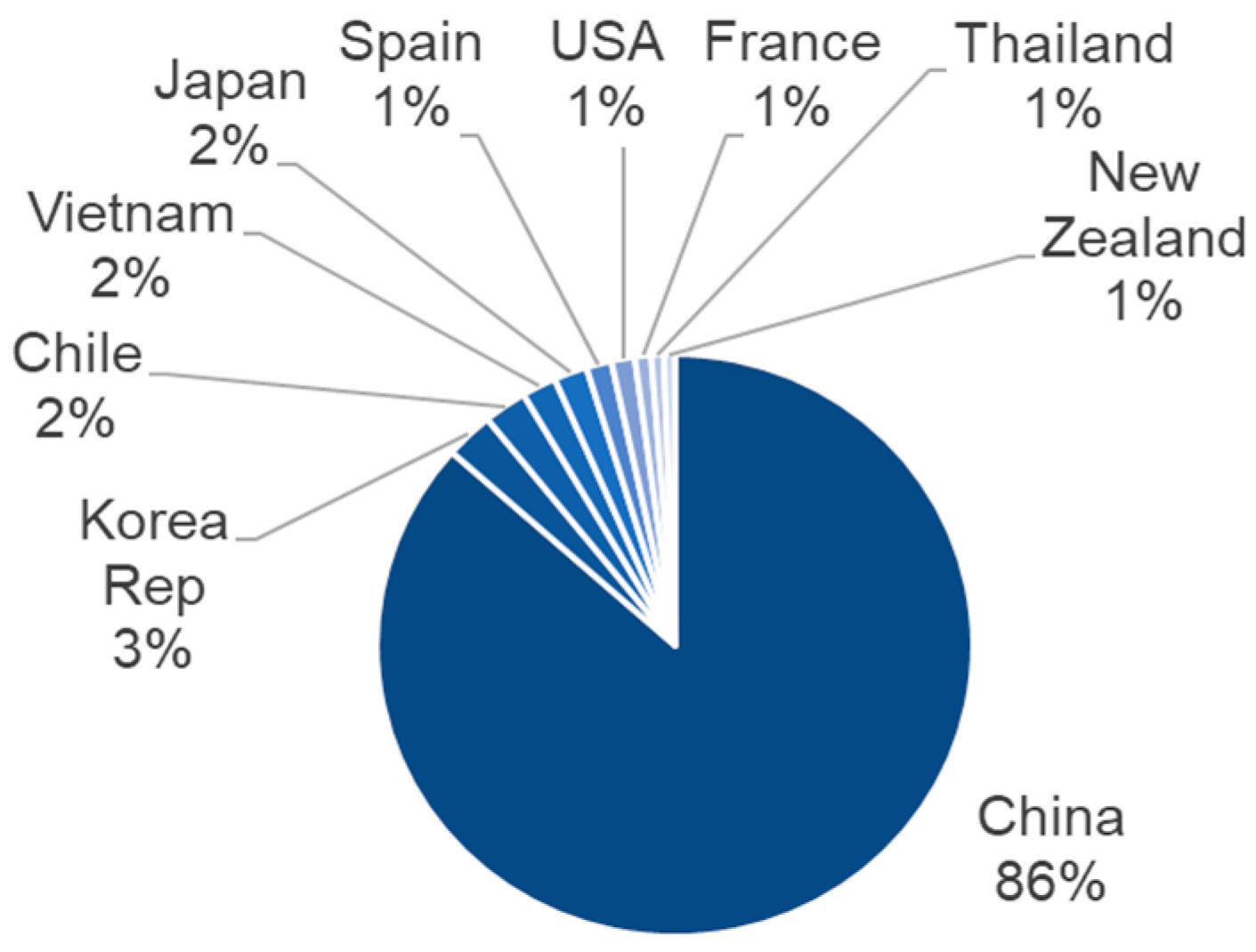

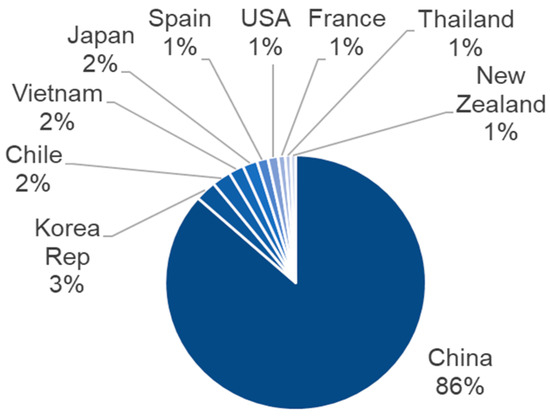

Figure 4 presents the top ten mollusk-producing countries [60], it is observed that of the countries that present articles (use of seashell waste in construction materials), six are within the ten countries that produce the highest number of mollusks; Spain, China, France, South Korea, Chile and Australia. A gap is detected between the four countries within the top ten seafood producers (Vietnam, Japan, USA and Thailand) and those that have not developed studies on the use of seashell waste in concrete with an approach in sustainability. The absence of research in these nations suggests that they have interesting opportunities for the revalorization of shellfish byproducts into construction materials and innovative waste management policies or incentives that could encourage the integration of marine byproducts into sustainable construction practices in local contexts. Furthermore, promoting international collaboration in these underrepresented, high shell-producing countries requires targeted strategies that strengthen local research capacity and ensure equitable knowledge exchange through the establishment of research networks supported by dedicated funding schemes to enable the transfer of expertise in LCA, sustainable concrete technologies, and waste valorization pathways. Aligning these initiatives with local stakeholders, including industry and policymakers, ensures that research outputs translate into actionable solutions that enhance both new knowledge and practices for circular construction.

Figure 4.

Production distribution of the top ten mollusk-producing countries in the world [60].

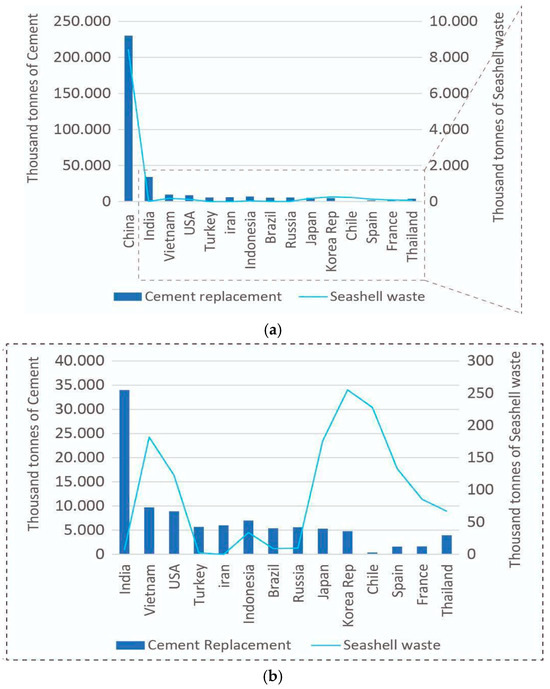

The main mollusk-producing countries and the main cement producers were analyzed, since these would be the potential consumers of seashell waste as a replacement. World shellfish production data were used for this analysis [60], and the same for the production of cement [61]; the 10 countries with the highest production were chosen for each case to later carry out the information crossing, leaving only the first 15 places.

A circular economy opportunity is established in the cement market by revalorizing seashell waste. Specifically, if the use of seashell is considered as a replacement for cement, this is ideally used in a replacement of 10% by weight, since the maximum is 15% and if it is increased up to 20%, the material loses from 27% to 63% (depending on the seashell type) of its compressive strength [62,63]. In the case of mollusk production, it is considered that 57.7% of the mollusk is shell (from mussels and cockles meat yield data) [64,65]. This demonstrates the potential for reuse and recovery of seashell waste through preprocessing as a secondary raw material, thereby extending their use and lifetime in global value chains to the manufacture of a product ready for the construction market, thus promoting new processes and commercial relationships throughout the entire supply chain. Alongside this potential are challenges, particularly in relation to the logistical approaches to collecting and processing shell waste at ports or treatment facilities, and the practical feasibility of scaling these up to industrial levels. Satellite and human sensing for monitoring and mapping marine waste accumulation, along with its sorting and processing, can help mitigate these difficulties. Effective coordination among key stakeholders throughout the value chain, both locally and globally, along with regulatory frameworks that organize these new markets as well as infrastructure for the storage of this marine waste are also factors driving the large-scale incorporation and industry acceptance of eco-concrete.

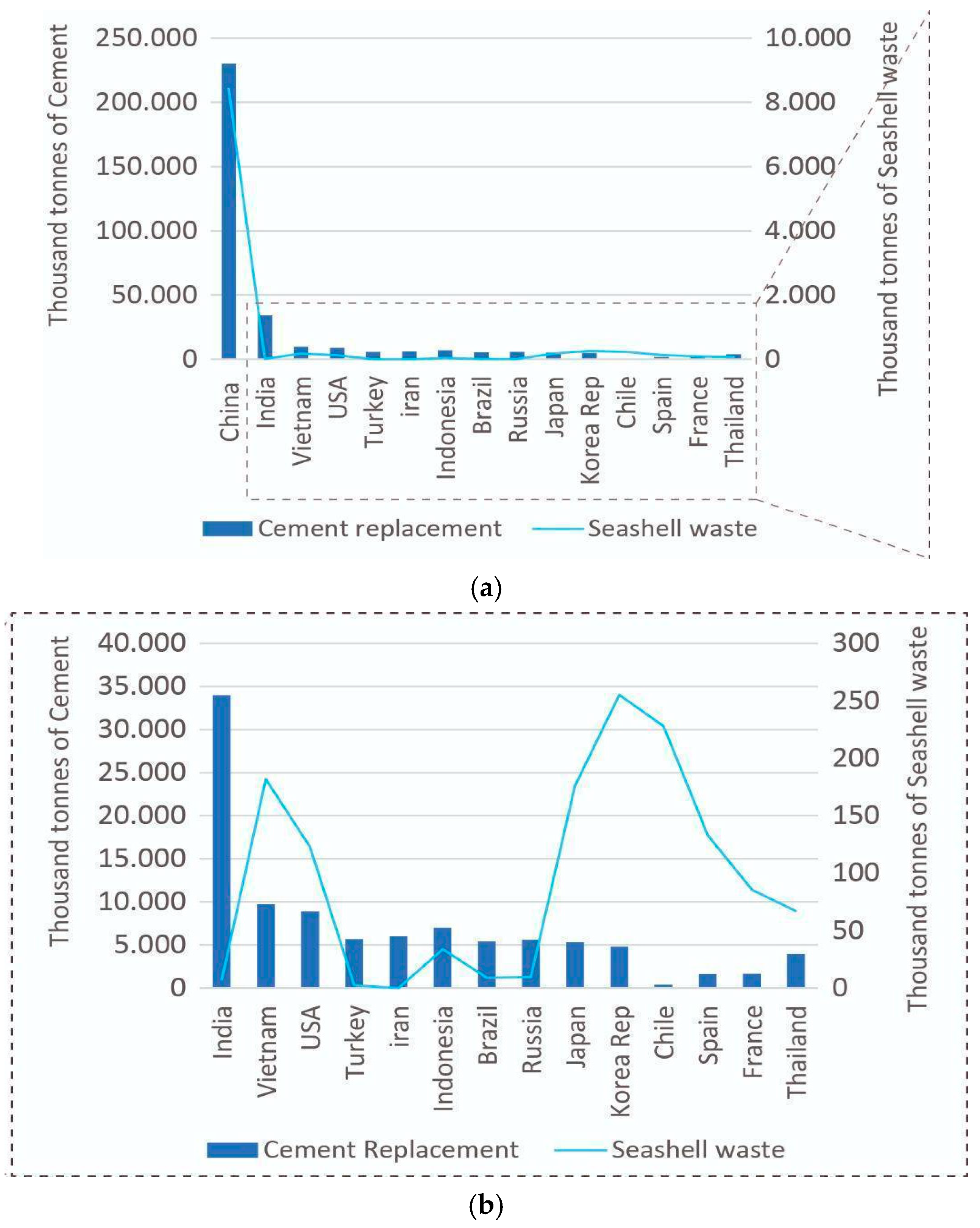

Figure 5 shows the amount of cement in the thousands of tons that could be potentially replaced by seashell waste, defined as “cement replacement” and the potential available amount of seashell waste, on the left and the right vertical axes, respectively. A zoomed graph without China is added on the right-hand side since the production volume of the former makes the info from other countries undistinguishable. It is observed that there is an opportunity for a circular economy in countries such as Vietnam, USA, Japan, South Korea, Chile, Spain, France, and Thailand.

Figure 5.

(a) Comparison of the amount of potentially replaceable cement with seashells and the amount of available seashell waste (based on seashell production), showing data for the top countries including China (b) Same as the previous panel, but excluding China to allow for a more detailed appraisal of other countries. World data on shellfish production is obtained from the Food and Agriculture Organization [60] while world data for cement production is obtained from the U.S. Geological Survey [61].

3.6. Content Analysis Results (RQ 5)

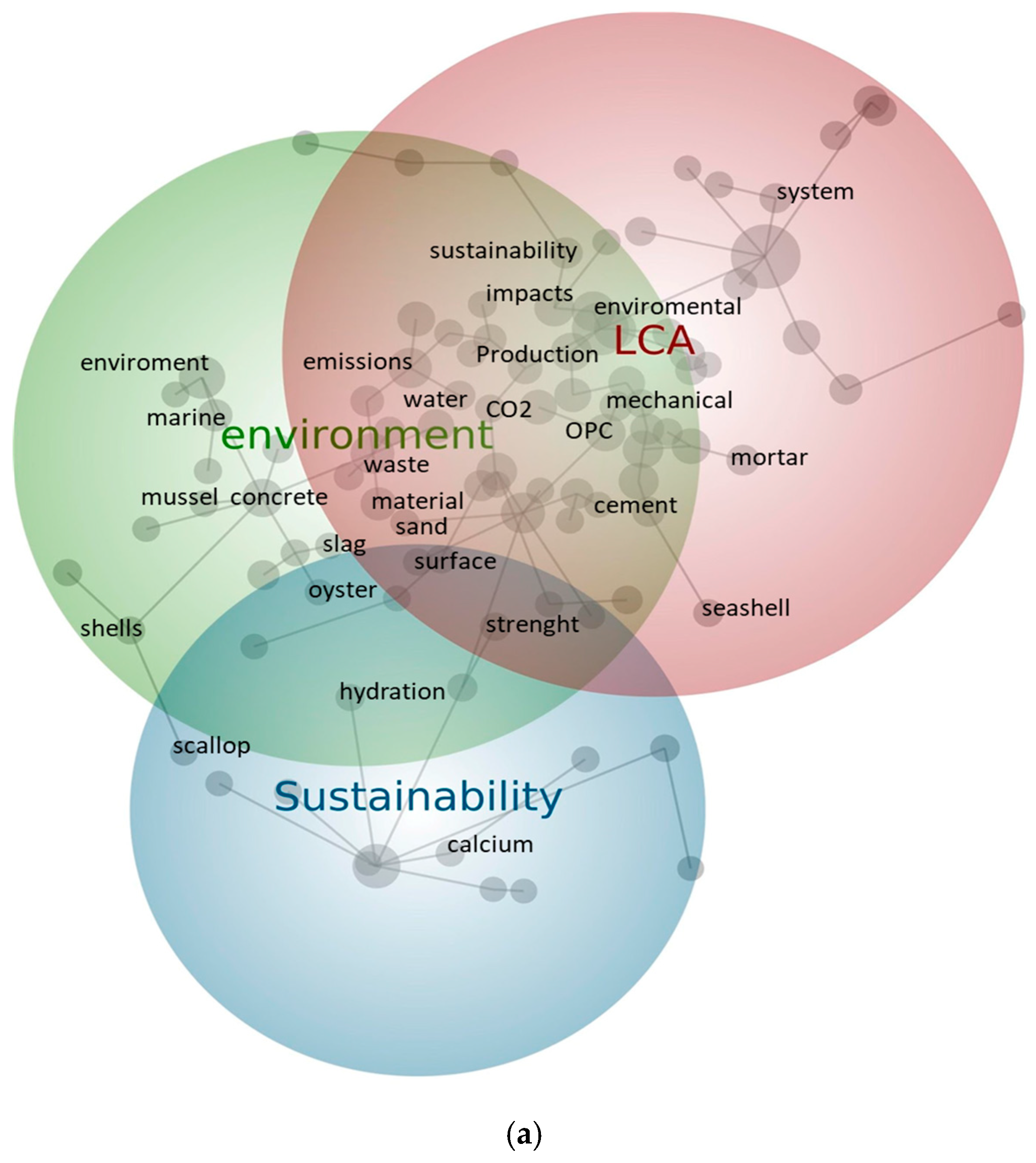

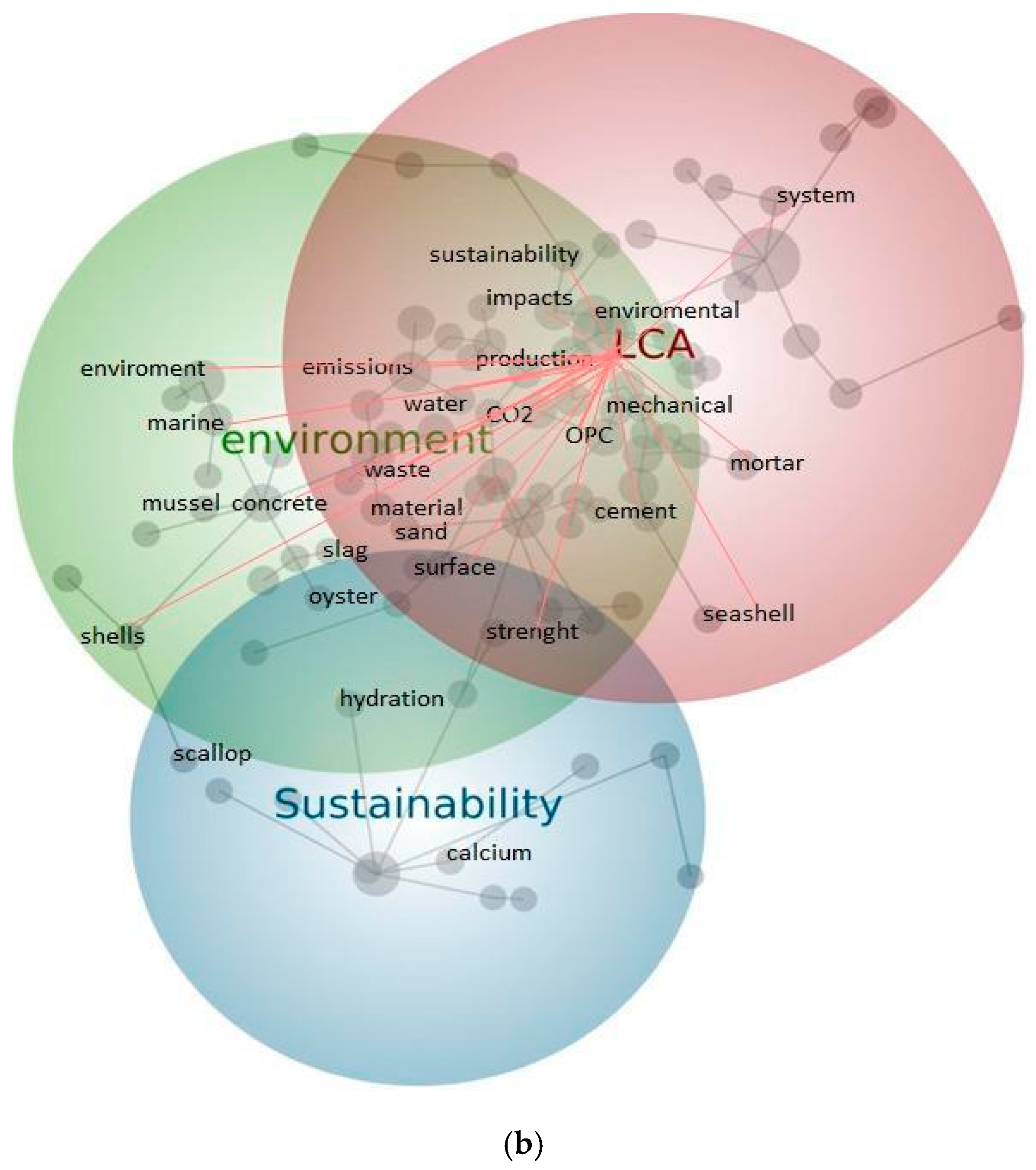

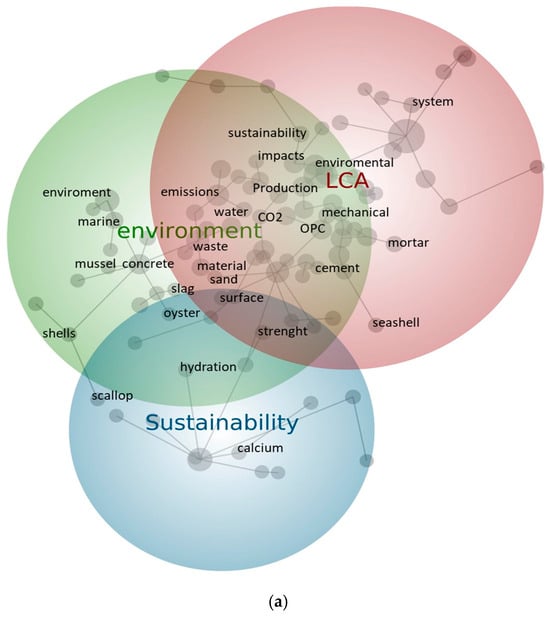

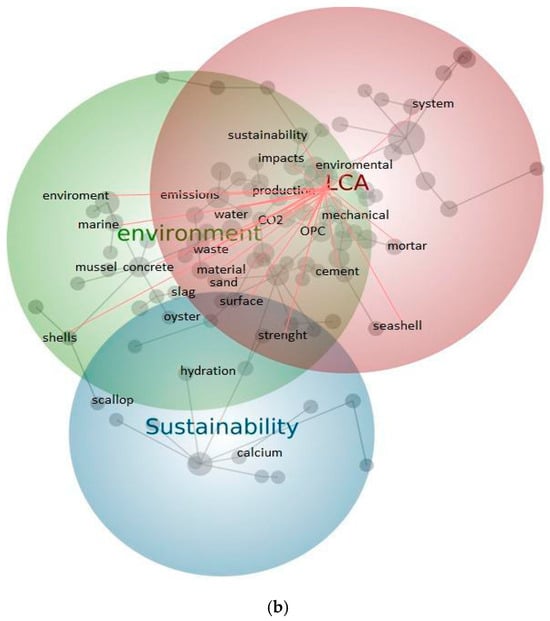

The twenty-nine articles identified in Table 1 and Table 2 were reviewed using Leximancer to identify key concepts related to LCA of eco-friendly concrete. Centering the study on LCA, the result of this content analysis indicates that the most dominant themes after LCA are environment and sustainability, with the environment being more relevant than sustainability. Figure 6a shows the results of this content analysis. The most relevant category, LCA, is represented with a red circle, followed by the environment and sustainability categories, visualized in green and blue circles, respectively. Each gray dot represents a concept relevant to each category. Dots within each category are clustered together.

The LCA category was primarily reviewed for its relevance since it is one of the fundamental pillars of this study. Through software analysis, it was determined that texts containing the LCA concept account for 38% of the total. In this category, the high correlation among the concepts of “production”, “environmental”, and “impacts” are observed through the short distance among them. These concepts emphasize the focus of life cycle assessment since they are intrinsically linked to the estimation of environmental impacts of the production system. For example, the impacts of fossil aquatic ecotoxicity and abiotic depletion potentials are mainly caused by the extraction of fossils used in the generation of heat and electricity needed in the production processes of cement [45]. Other study also identifies environmental impacts related to production [23]. In this study, the authors found that the most relevant environmental impacts associated with the production of blended cements containing seashell powder are the abiotic depletion potential for fossil resources and global warming’s potential impacts. Furthermore, other frequent concepts are “seashell”, “waste”, “mortar”, and “concrete”, which inform the focus of the approach used in the LCA studies. The strong correlation between these concepts is also discussed in the studies of [23,45], which proposed the recycling of shell waste as aggregate in mortars in the context of the concrete industry as a good alternative for waste management.

The second relevant category is environment, which encompasses 34% of the analyzed texts. Within this theme, the concepts of “marine”, “shells”, “mussel” and “oyster” are closely related to “cement”. When performing an LCA, articles such as [42,43,45] highlighted that diverse types of marine shells can be used as a replacement of cement and thus reduce the environmental impacts of concrete production.

The last category, sustainability, covers 28% of the analyzed texts and includes “scallop”, “calcium” and “hydration” as relevant concepts. The integration of scallops, given their level of calcium and hydration properties, into eco-concrete is a sustainable approach that helps to improve marine waste management, promote more ecological construction practices, and generate savings in the manufacture of construction materials [43]. Addressing sustainability challenges in cement and concrete production is critical due to the significant environmental impact associated with the resources used for their manufacture.

There are also intersections among categories, in which concepts might belong to two or more categories. For example, “material” and “emissions” are important in both LCA and environmental domains. The materials used in the cement production process are energy-intensive and generate considerable CO2 emissions, significantly contributing to climate change. By recycling marine waste and reusing it within the concrete production chain, it is possible to mitigate these negative environmental effects and, at the same time, contribute with innovative solutions to adopt a circular economy in the construction sector.

To identify a series of correlations between LCA and concepts present in all themes, a further analysis was performed. Correlations between LCA and “environment”, “marine”, “shells”, “material”, and “strength” are found and presented in Figure 6b. The connection between LCA, environment, and sustainability in the context of eco-concrete with seashell waste underscores the importance of adopting integrated and sustainable approaches in the production and application of construction materials. By considering these aspects holistically, it is possible to understand the effectiveness and benefits of this innovative material and also advance towards more responsible construction practices.

4. Discussion

Undoubtedly, this review has certain limitations that should be noted. Risk of judgment bias was detected for the descriptor “results”; to reduce this, the evaluations were carried out by one reviewer and verified by another to reach a general judgment. Risk of bias in the results due to the heterogeneity of the articles was also detected, which makes synthesizing, comparing and evaluating results more complex. There are limitations due to the fact that the search was carried out exclusively in two search engines and was only carried out in English, which reduced the possibility of obtaining results in other languages and countries. The evaluation section of the LCA consists of three studies testing slightly different building materials, so they will not be directly comparable. The restriction of the sustainability section is that there are different types of sustainability analysis and these are not comparable to each other.

4.1. LCA Relevance

The importance of the LCA tool is that it estimates the product’s ultimate effects on human health, ecosystem function, and natural resource depletion [66]. The results of this systematic literature review indicate that there is a limited development of this tool applied to the use of seashell waste in concrete, and the available information is not sufficient to draw conclusions about the environmental performance of the material. The three articles that use LCA analyze the use of seashells in different products, have different system boundaries, and show different results. This points to the evident need to develop more studies of this type to determine if the use of seashell waste in concrete is beneficial in each case and context. The determination of system boundaries and the inclusion or exclusion of processes (cut-off criteria) often has no scientific basis. Identifying which processes can be excluded from system boundaries is difficult because many of the excluded processes have never been evaluated by practitioners and, thus, there is no guarantee of their importance. When considering product life cycle studies, different people may choose different system boundaries based on personal experience, which may cause some important processes to be overlooked [67]. Therefore, beyond the need for further studies, there is a clear lack of standardized evaluation frameworks in the field that could enhance comparability across these future LCA studies to arrive at meaningful and robust conclusions that could be generalized. This extends to the development of functional units, agreement on the system boundaries and impact categories for effective evaluation across materials, potentially designing experimental frameworks or regulation for the evaluation of partial cement replacement alternatives.

In the concrete industry, it is imperative to find alternatives for cement and natural aggregate to reduce the significant environmental impact of concrete production, particularly climate change and abiotic depletion effects [68]; therefore, the inclusion of the mechanical and durability properties of the studied products over time becomes very important, and has been largely unexplored so far in the field of cement replacement under a holistic approach. Another important point to highlight is that the lack of regional databases makes it difficult to use life cycle thinking in the formulation of environmental policies and decisions, so in these geographical cases, its use as a methodology in scientific studies is also diminished. This can be reversed with the development of national databases causing a greater use of LCA in a given country and the development of collaborative open-access repositories that compile experimental results, inventory data, and case studies from high seashell-waste-producing regions, thereby enabling more accurate and context-sensitive sustainability assessments.

4.2. Sustainability Assessments

The results of the review showed that only 41% of the articles carried out some type of sustainability analysis of which only 6% covered the three fundamental pillars. Due to these limitations, recommendations are made for methodologies and tools to be used so that the sustainability analysis integrates all the actors involved.

Sustainable indicators provide manageable units of information on economic, environmental, and social conditions to monitor progress towards sustainable development. Even though the review comprised more cases of sustainability assessments compared to LCA studies on the topic, the lack of standardized approaches and methods is still regarded as a relevant gap. Furthermore, LCA evaluations are more focused and already follow certain methodologies, leaving the matter of heterogeneity largely to data availability and agreement on the approaches and methods to employ. However, sustainability assessments, holistic in nature, arguably face larger challenges in developing standard metrics and approaches that maintain the intersectoral scope while addressing meaningful bottlenecks and constraints that interest the different stakeholders involved in the production process.

Sustainability indicators relevant to the construction industry in the economic aspect include technical factors, engineering measures, and feasibility factors; a construction project can be said to be economically viable when its multifactorial productivity has increased in a specified period. The environmental attribute introduces quality factors such as parameters related to the damage to the quality of elementary environmental services and the deterioration of value of the ecosystem. The social/management factor includes communication and team elements that describe how to advantageously connect with stakeholders and local society about the construction project [69].

A set of indicators (combining the economic, environmental, and social) is important for the integration of sustainability into project management practices that can lead to sustainable project success. Regarding the set of indicators, there is an urgent need to define a generally accepted process for identifying and selecting the most appropriate indicators for sustainable project management practices in construction projects.

As noted in [21], a good methodology that can be widely promoted for assessing sustainability pillars and stakeholder perspectives is MIVES (Model of Integrated Value for Sustainable Evaluation, in Spanish). MIVES is a value-function-based method for multi-criteria decision-making, based on multi-attribute utility theory, used to select the best options from a series of alternatives. It was initially developed to introduce environmental and social indicators into civil engineering design decisions and later adapted for general evaluation and prioritization of homogeneous and heterogeneous alternatives to obtain global sustainability indexes [70]. This methodology is time-independent; it can be applied to diverse areas with different local characteristics and requirements and it can be made to take all stakeholders’ satisfaction levels and needs into account through simple adjustments to the requirements tree’s items and their weights [71]. Specifically, MIVES structures the problem within a multi-criteria analysis framework in which different alternatives may be evaluated according to a pre-established set of requirements to satisfy a pre-defined sustainable objective. These requirements, which are usually the economic, social, and environmental sustainability pillars of the problem, contain sets of criteria; these, in addition, contain a set of indicators which in turn may have sub-indicators [70].

4.3. Content Analysis Significance

Content analysis showed that existing LCA studies on eco-concrete with seashell waste cover a comprehensive range of concepts across three main themes: LCA, environment, and sustainability. Focusing on LCA, the environmental impacts of building materials production throughout all stages of its life, from raw material extraction, manufacturing, transportation, use, end-of-life to final disposal, are relevant to estimate their costs and benefits in comparison with conventional concrete alternatives. Therefore, environmental effects are highly dependent on factors included within the boundaries of these stages. For the environment category, content analysis shows that marine resources from coastal ecosystems are important concepts that need to be evaluated for precisely estimating the consequences of using them to promote sustainability in construction. Sustainability, the third key theme, is related to “waste”, “material”, and “concrete”. Avoiding material waste, such as concrete, and also using marine waste as a resource is crucial for reducing environmental impact and promoting ecological conservation. Furthermore, environmental analysis must carefully consider how both the coastal ecosystem and the construction system interact and are affected, so that the elements included in them are treated in a sustainable manner. This content analysis highlights the importance of continuing research for efficiently processing marine waste and integrating it into sustainable construction materials to evaluate the potential benefits of using recycled resources such as seashells.

4.4. Opportunities and Future Research

Integrating seashell waste as a component of concrete manufacturing is a promising strategy to reduce concrete-related emissions. However, the degree of its effectiveness is closely related to the properties of the final product and should meet the requirements of general use. This review found opportunities for its use such as in artificial reefs, building construction materials (bricks), building insulation material, application in cement-stabilized clay mixtures, mortars, and concrete. The replacement of cement in concrete has been widely studied and the studies test compositions of 0–30% by weight of replaced cement; the results show that the optimum is between 10 and 15%. In the case of the replacement of aggregates, the studies prove up to 100%, as can be seen in Appendix A (Table A1), resulted in potential products. As their properties vary, some can be applied in construction such as in pavement curbs and floor blinding and others can be used for low-bearing concrete structures [2].

Although sustainable materials have economic benefits, the cost of the final product is a major barrier that prevents industries from using sustainable concrete. This is because the use of waste materials often generates additional manufacturing costs due to complex treatment processes, the inclusion of supplementary materials and substances to activate the properties of concrete, and the fact that companies, in general, seek short term profitability. Additionally, the use of seashells for eco-concrete production involves a cleaning process that requires water, which can be challenging in water-scarce regions, a grinding stage that is energy-intensive [7], and a fuel-demanding transport service from the seashell waste disposal site to the production plant where it is mixed with cement, which might be problematic for long distances [43]. Therefore, research optimization studies and innovation in specific sites are necessary to achieve the balance between environmental benefits due to carbon footprint and production costs of these materials. Furthermore, it is crucial to conduct comparative studies between different replacement alternatives, under standardized approaches and holistic scopes, to further explore the benefits and feasibility of seashell waste in context.

Marketing of sustainable products can benefit from socially conscious campaigns that promote the multiple benefits of the use of sustainable products, especially their long-term environmental benefits to society. It is recommended to make use of sustainable product certifications, since they increase social acceptance and enable commercial possibilities for eco-concrete from waste materials. At the same time, the acceptance of the community is a critical parameter that could also accelerate governments to promote the use of such sustainable materials through legislation, subsidies, and incentives. Evidence from other industries demonstrates how certification schemes and incentive mechanisms can effectively enhance the market uptake of sustainable products and acceptance among customers. For instance, eco-labeling in the timber sector (e.g., FSC certification) and green building standards (e.g., LEED) have proven instrumental in fostering consumer trust, signaling quality, and accelerating adoption. Similarly, incentive-driven initiatives in the renewable energy sector illustrate how targeted policies and subsidies can shift market dynamics and improve social acceptance. Drawing on such cases can provide valuable parallels for the construction industry, highlighting the potential of certification and incentive-based strategies to support the diffusion of seashell-waste-based concrete.

While our study primarily emphasizes technical performance, future research should incorporate economic assessments through approaches such as cost-benefit analysis, regional case studies, or system dynamics and techno-economic modeling. These methods would provide a more comprehensive understanding of the financial viability, scalability, and policy relevance of shell-based concrete applications, ultimately enabling more informed decision-making for industry stakeholders and supporting the transition toward sustainable construction practices.

Additionally, it is crucial to investigate how the inclusion of shell waste in concrete affects its recyclability and potential for reuse, since these properties directly determine the material’s contribution to a circular economy. By understanding how shell-based concretes perform at end-of-life—whether in terms of separation, reprocessing, or reintegration into new products—research can provide evidence on their ability to close material loops and reduce reliance on virgin resources.

As discussed above, only a few studies have investigated the sustainable performance of concrete, with the research focus of most studies consisting of experimental tests of mechanical properties and durability. The results also highlighted a lack of research in LCA and the effects of using seashell waste on the recyclability and reusability of sustainable products. Therefore, it is recommended that future research efforts be conducted to analyze the economic, environmental, and social impacts of incorporating seashell waste products into mortar and concrete mixes.

5. Conclusions

This study presents a systematic review of the literature on life cycle assessment and sustainability evaluations of seashell waste in concrete. The review identifies a consistent research focus on the substitution of cement and aggregates, as well as the integration of seashell waste into other construction materials. Collectively, the findings underscore the considerable potential of seashell waste to advance more sustainable practices in concrete production.

Regarding the replacement of cement in concrete, studies tested compositions of 0–39% by weight of replaced cement, and the results show that the optimum is between 10 and 15%; in the case of the replacement of aggregates, the studies prove up to 100%, resulting in potential products and uses. This review found opportunities for use such as: artificial reefs, building construction materials (bricks), building insulation material, application in cement-stabilized clay mixtures, mortars, and concrete.

Geographically, Spain stood out as the country with the highest number of articles contributing to the topic, followed by China, Iran, and France. Interestingly, a gap was identified in four major seafood-producing countries (Vietnam, Japan, USA, and Thailand) that have yet to conduct studies on seashell waste in concrete with a sustainability focus. The study also highlights a circular economy opportunity in the cement market through the revalorization of seashell waste. Based on top countries in cement production and mollusk production, an opportunity for a circular economy is detected in countries such as Vietnam, USA, Japan, South Korea, Chile, Spain, France, and Thailand.

Content analysis and concept maps are a useful manner to understand the main aspects included in current studies through a visual network representation of the most frequent categories and main concepts involved. Three main themes were found: LCA, environment, and sustainability. They reflect the current trends in research for this area, in which studies assess the environmental impact of eco-concrete using recycled seashells throughout its entire life cycle, from raw material extraction to final disposal. Environmental analysis in these studies involves evaluating the impacts of eco-concrete, finding ways to enhance its environmental performance and promote circularity in the construction sector, proposing the minimization of marine waste to reduce environmental effects, and conserving the resources of coastal ecosystems and construction systems. Overall, the findings suggest that eco-concrete with seashell waste is a promising sustainable alternative in the construction industry. Further analysis content is needed to understand the improvement of sustainability and environmental effects in the production manufacturing of eco-concrete.

A future challenge for the current study is to analyze the impact of using shellfish waste on the recyclability and reuse of sustainable products; in addition, future research is expected to focus on determining the economic, environmental, and social impacts of the incorporation of seashell waste in mortar and concrete mixes.

For policymakers and practitioners at the macro level, the implementation of a georeferenced marketplace that connects eco-concrete production in plants and construction sites with the supply of seashell waste and other stakeholders who buy and sell construction materials throughout the entire supply chain. At the micro level, the creation of a digital platform that gathers information on the demand for eco-concrete from municipalities, neighborhood hardware stores, construction companies, local workers, and seashell collectors, together with production plants, can help accelerate the penetration of these new circular and sustainable materials into the construction industry.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su17219549/s1, The PRISMA checklist for the systematic review can be found online as Supplementary Material. Reference [72] are cited in the supplementary materials.

Author Contributions

Conceptualization, K.D.V., E.W., A.P., N.C. and L.B.-N.; methodology, K.D.V., E.W. and A.P.; investigation, L.E. and K.D.V.; resources, A.P., N.C. and C.F.; data curation, L.E.; writing—original draft preparation, K.D.V. and L.E.; writing—review and editing, E.W., A.P., N.C. and L.B.-N.; visualization, L.E. and A.P.; supervision, K.D.V. and E.W.; project administration, A.P. and N.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Fondo Nacional de Desarrollo Científico y Tecnológico (FONDECYT) INICIACION (Grant No. 11230895).

Data Availability Statement

The review has not been registered online but some or all data that support the findings of this study are available from the corresponding author upon reasonable request. The review followed the PRISMA Guidelines, following the search and review protocol outlined in Section 2 of the article.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| LCA | Life Cycle Assessment |

| SCMs | Supplementary Cementitious Materials |

| CaO | Calcium Oxide |

| RQ | Research Question |

| WoS | Web of Science |

| MIVES | Integrated Value Model for a Sustainable Evaluation (in Spanish) |

Appendix A

Table A1.

Replacement percentages of cement and aggregates in concrete/mortar.

Table A1.

Replacement percentages of cement and aggregates in concrete/mortar.

| Reference | Replaced Component with Seashell Waste | Replacement (Weight) |

|---|---|---|

| [4] Bamigboye et al. (2020) | Granite in concrete | 10%, 20%, 30%, 40% and 50% |

| [2] Bamigboye et al. (2022) | Sand in concrete | 10%, 20%, 30%, 40%, 50%, 60%, and 100% |

| [46] Boukhelf et al. (2022) | Sand in concrete | 50% |

| [47] Camba et al. (2021) | Cement and sand in concrete | 10% (cement replacement), 20% (sand replacement), and 4–5% cement with 10% sand |

| [48] Carral et al. (2018) | Sand in concrete | 20% |

| [21] Carral et al. (2020) | Cement and sand in concrete | 0%, 5%, 10% (cement replacement), and 0%,10%, 20% (sand replacement) |

| [49] Carral et al. (2023) | Aggregates in concrete | 10,2% (gravel replacement) and 9,8% (granite and silica sand replacement) |

| [50] Chen et al. (2019) | Sand in concrete | 30% |

| [51] Edalat-Behbahani et al. (2021) | Cement and sand in concrete | 30% (cement replacement), and 100% (sand replacement) |

| [52] El Biriane and Barbachi (2020) | Cement and additive in concrete | 6%, 12%, and 24% (cement replacement) and 3%, 6%, 9% and 12% (additive replacement) |

| [53] Foti and Cavallo (2018) | Gravel in concrete | 46,5% and 100%. |

| [54] Georges et al. (2021) | Gravels in concrete | 0 and 20% |

| [55] Han et al. (2022a) | Cement in concrete | 30% in binary blends. 10% and 20% in ternary blends |

| [56] Han et al. (2022b) | Cement in concrete | 5 and 10% |

| [57] Liu, Wang et al. (2022) | Cement in concrete | 10% |

| [58] Liu, Zhang et al. (2022) | Cement in concrete | 0%, 10%, 20%, and 30% |

| [45] Peceño et al. (2020) | Aggregates in concrete | 40% and 50% |

| [6] Soltanzadeh et al. (2018) | Cement in concrete | 4–30% |

| [23] Soltanzadeh et al. (2021) | Cement in mortar | 39% in binary blends and 7% in ternary blends |

| [59] Suarez-Riera et al. (2021) | Sand in concrete | 5%, 10% and 15% |

References

- Petek Gursel, A.; Masanet, E.; Horvath, A.; Stadel, A. Life-Cycle Inventory Analysis of Concrete Production: A Critical Review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Okechukwu, U.E.; Olukanni, D.O.; Bassey, D.E.; Okorie, U.E.; Adebesin, J.; Jolayemi, K.J. Effective Economic Combination of Waste Seashell and River Sand as Fine Aggregate in Green Concrete. Sustainability 2022, 14, 12822. [Google Scholar] [CrossRef]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental Impact of Cement Production and Solutions: A Review. Mater. Today Proc. 2022, 48, 741–746. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Okara, O.; Bassey, D.E.; Jolayemi, K.J.; Ajimalofin, D. The Use of Senilia Senilis Seashells as a Substitute for Coarse Aggregate in Eco-Friendly Concrete. J. Build. Eng. 2020, 32, 101811. [Google Scholar] [CrossRef]

- Eziefula, U.G.; Ezeh, J.C.; Eziefula, B.I. Properties of Seashell Aggregate Concrete: A Review. Constr. Build. Mater. 2018, 192, 287–300. [Google Scholar] [CrossRef]

- Soltanzadeh, F.; Emam-Jomeh, M.; Edalat-Behbahani, A.; Soltan-Zadeh, Z. Development and Characterization of Blended Cements Containing Seashell Powder. Constr. Build. Mater. 2018, 161, 292–304. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Nworgu, A.T.; Odetoyan, A.O.; Kareem, M.; Enabulele, D.O.; Bassey, D.E. Sustainable Use of Seashells as Binder in Concrete Production: Prospect and Challenges. J. Build. Eng. 2021, 34, 101864. [Google Scholar] [CrossRef]

- Paul, S.C.; van Zijl, G.P.A.G.; Tan, M.J.; Gibson, I. A Review of 3D Concrete Printing Systems and Materials Properties: Current Status and Future Research Prospects. RPJ 2018, 24, 784–798. [Google Scholar] [CrossRef]

- Aiken, T.A.; Kwasny, J.; Sha, W.; Tong, K.T. Mechanical and Durability Properties of Alkali-Activated Fly Ash Concrete with Increasing Slag Content. Constr. Build. Mater. 2021, 301, 124330. [Google Scholar] [CrossRef]

- Cultrone, G. The Use of Mount Etna Volcanic Ash in the Production of Bricks with Good Physical-Mechanical Performance: Converting a Problematic Waste Product into a Resource for the Construction Industry. Ceram. Int. 2022, 48, 5724–5736. [Google Scholar] [CrossRef]

- Raheem, A.A.; Abdulwahab, R.; Kareem, M.A. Incorporation of Metakaolin and Nanosilica in Blended Cement Mortar and Concrete—A Review. J. Clean. Prod. 2021, 290, 125852. [Google Scholar] [CrossRef]

- Oti, J.E.; Kinuthia, J.M.; Robinson, R.; Davies, P. The Use of Palm Kernel Shell and Ash for Concrete Production. Int. J. Civ. Environ. Eng. 2015, 9, 8. [Google Scholar]

- Alla, S.; Asadi, S.S. Experimental Investigation of Snail Shell-Based Cement Mortar: Mechanical Strength, Durability and Microstructure. Res. Sq. 2021, 9, 51–70. [Google Scholar]

- Tayeh, B.A.; Hasaniyah, M.W.; Zeyad, A.M.; Awad, M.M.; Alaskar, A.; Mohamed, A.M.; Alyousef, R. Durability and Mechanical Properties of Seashell Partially-Replaced Cement. J. Build. Eng. 2020, 31, 101328. [Google Scholar] [CrossRef]