Abstract

To meet the growing demand for sustainable building materials in modern construction projects, nanomaterials are widely used in concrete to improve its mechanical properties, durability, and environmental adaptability. The effects of different calcium carbonate nanoparticles (NC) and titanium carbide nanoparticles (NT) substitution rates (0%, 0.5%, 1% and 1.5%) on the mechanical and durability properties of steel fiber-reinforced concrete (SFRC) were analyzed by experimental studies. We also analyzed the evolution of the microstructure, chemical composition, and the evolution of functional groups of concrete by scanning electron microscopy (SEM), energy-dispersive spectroscopy (EDS), X-ray diffraction (XRD), and Fourier transform infrared spectroscopy (FT-IR). The results demonstrated that NC replacement of 0.5% and NT replacement of 1% was the optimal combination for the preparation of composite concrete. Compared to SFRC with 0% substitution for both NC and NT (CG), the 28-day compressive strength of NC0.5NT1 increased by 35.5%, the flexural strength increased by 26.5%, and the splitting tensile strength increased by 16.3%. The durability performance of SFRC has been significantly improved. After 150 freeze–thaw cycles, the quality loss rate of SFRC cured for 28 days decreased by 40.6%, and the relative dynamic elastic modulus increased by 7.7%. Microscopic analysis indicates that an appropriate amount of NC and NT replacing cement improves the hydration reaction process of SFRC, increases the content of chemically more stable C-S-H gel, but does not change the types of hydration products of the cement. NC and NT have a filling effect, improving the pore structure of concrete, which helps enhance the mechanical and durability performance of concrete. The results of the study provide a theoretical basis for the application of NC and NT as reinforcing particles for cementitious materials in sustainable building materials.

1. Introduction

Concrete is one of the most widely used structural materials in the world, and its strength and durability are critical to the safety and longevity of buildings. When faced with a number of complex environments or high-intensity loads, conventional concrete can crack, leading to deterioration in its performance [1]. To overcome the performance deficiencies of concrete, fibers such as metal fibers, synthetic fibers, and mineral fibers are widely used in concrete [2]. However, some fibers affect the fluidity of the concrete and are prone to aging and other issues [3]. Steel fibers possess extremely high toughness and elastic modulus, and they also have good dispersion performance in cement-based materials, making them an ideal reinforcement material [4]. Research shows that the incorporation of steel fiber can significantly improve the compressive strength, flexural strength, fracture toughness, and elastic modulus of concrete. The interfacial bonding between steel fiber and the concrete matrix is a key factor in enhancing the performance of concrete. Using methods such as SEM, XRD, and universal testing machines, the mechanical properties of steel fiber-reinforced concrete under different loads and varying types of steel fiber-reinforced concrete were studied. The results indicate that the overall mechanical performance of steel fiber-reinforced concrete [5]. Through quantitative research, it was found that steel fibers can significantly affect the deformation characteristics of concrete and improve its fracture resistance and fatigue resistance compared to plain concrete [6]. Based on these advantages, steel fiber-reinforced concrete has been widely used in structural reinforcement, roads and bridges, hydraulic engineering, and other fields [7]. Especially applied in cold regions, it enhances the structural stability of buildings. At the same time, due to its excellent impact resistance, steel fiber-reinforced concrete is an ideal material for wear-resistant pavements in cold regions [8]. However, due to the long-term freeze–thaw cycles reducing the density of the concrete matrix, internal frost heave cracking occurs, leading to a downward trend in the relative dynamic elastic modulus, thereby reducing the durability of steel fiber-reinforced concrete [9].

Research shows that incorporating nanomaterials can reduce defects in cement-based materials at the nanoscale, affecting the hydration of cement [10]. These in turn improve the macroscopic properties of cementitious materials to some extent [11]. Nanomaterials, as auxiliary cementitious materials replacing cement in concrete preparation, not only improve the performance of concrete but also reduce the clinker content in concrete, thereby lowering the CO2 emissions from cement production [12,13]. The unique physical and chemical characteristics of nano CaCO3 include its huge specific surface area, strong surface adsorption capacity, and strong chemical activity, and it has a wide range of applications in many fields [14]. The application of composite cement-based materials containing nano CaCO3 in the field of building materials is receiving increasing attention. Liu et al. [15] studied the mechanical performance test results and found that with the increase in NC content, the flexural strength and compressive strength of the cement at 7 days and 28 days both improved. Yao et al. [16] found that due to the filling effect and chemical effect of NC, replacing 3% of the cement mass with nano CaCO3 in the preparation of ultra-high-performance concrete results in the best compressive strength and flexural performance. Ming and Ming [17] found that incorporating nano CaCO3 can improve the pore structure of concrete and increase its frost resistance, with an optimal dosage of 1%. Meng et al. [18] demonstrated through experiments that the filling effect of nano CaCO3 helps to improve the mechanical properties of concrete. Huang and Zu [19] found through observing the microstructure of UHPC that the micro-aggregate and surface effects of nano CaCO3 significantly improve the pore structure of UHPC, causing the hydration products to interconnect in narrow spaces and form a continuous phase. Thermodynamic modeling and microanalysis have found that nano CaCO3 effectively increases the content of hemicarbonate and monocarbonate in the cement matrix, thereby effectively inhibiting the decomposition of ettringite, leading to an increase in the volume of Portland cement hydration products and a decrease in porosity [20]. Nano CaCO3, as an economical and effective nanomaterial, can improve the mechanical and durability properties of concrete to a certain extent. However, its dosage needs to be strictly controlled to avoid negative impacts on the performance of concrete. To achieve its large-scale application in concrete, further exploration of the optimal dosage of nano CaCO3 is the main task at present.

Nano TiC is an important transition metal carbide, widely used in the fields of materials science and engineering applications due to its high conductivity, good chemical stability, oxidation resistance, and corrosion resistance [21]. Adding a small amount of nano TiC to traditional alloys that are difficult to cast can reduce production costs, simplify casting operations, improve material properties, and produce alloy products with high performance [22,23,24,25]. Chen et al. [26] studied the SEM images of forged aluminum alloy AA 6063 and found that dispersing 1 vol% nano TiC into the alloy melt can restrict the growth of crystal particles during the solidification process, significantly refine the microstructure of the alloy, improve the alloy’s fluidity, eliminate hot cracks, and enhance the surface quality of the castings. Zheng et al. [27] found that adding a small amount of nano TiC during the casting process of Al-Mg-Si-Cu alloys can refine the microstructure and eliminate hot cracks, promote the dissolution of alloying elements, improve the microstructure of the alloy, and thereby enhance the tensile strength of the alloy. With technological advancements, the preparation process of nano TiC has rapidly developed. For instance, the microwave sintering method can reduce the sintering temperature and shorten the preparation time, making the process energy-efficient and environmentally friendly. The cost/performance ratio of nano TiC has increased, and its application fields are gradually expanding. Referring to the relevant literature, the authors conjecture that nano TiC possesses the potential to fill the tiny pores inside the concrete, change the composition and proportion of hydration products, and improve the mechanical and durability properties of concrete. However, existing research rarely involves the application of nano TiC in cement-based materials concerning mechanical and durability performance. The physical and chemical properties of nano TiC differ from those of concrete, and the physical and chemical compatibility between them is a key issue that needs to be addressed. Exploring the influence of nano TiC on the mechanical and durability properties of steel fiber-reinforced concrete is of great significance for expanding the application field of nano TiC.

This paper studies the effects of nano CaCO3 and nano TiC on the mechanical and durability properties of steel fiber-reinforced concrete based on mechanical tests and freeze–thaw cycle experiments. Using analysis methods such as SEM, EDS, XRD, and FT-IR, this study reveals the mechanisms by which nano CaCO3 and the nano TiC substitution of cement affect the strength changes in steel fiber-reinforced concrete at the microscopic level, providing a theoretical basis for the application of nano CaCO3 and nano TiC in cement-based materials.

2. Materials and Methods

2.1. Experimental Materials

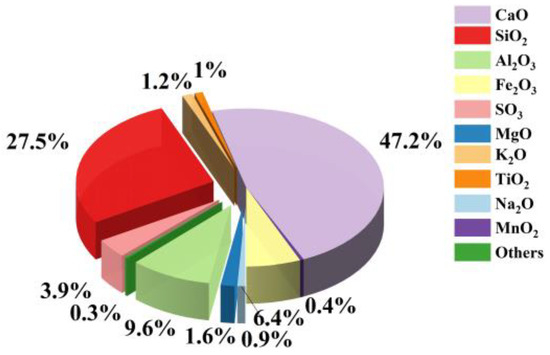

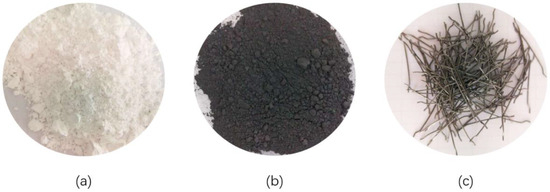

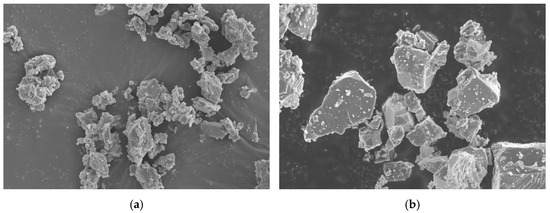

Concrete specimens were prepared using cement, river sand, gravel, water, double-end hooked steel fibers, nano CaCO3, and nano TiC. Cement was ordinary silicate cement with a specific surface area of 355 m2/kg. The chemical composition and mass percentage of the cement were determined through X-ray fluorescence (XRF) tests, as shown in Figure 1. The fine aggregates were selected as river sand with a fineness modulus of 2.6 cm2/g and a particle size of less than 3 mm. Coarse aggregates were chosen as natural crushed stone with a particle size of 10–31 mm. Throughout the study, tap water was used to prepare the concrete samples. In this experiment, double-end hooked steel fibers with a length of 35 mm, a diameter of 1 mm, and a tensile strength of 1000 MPa were used. Nano CaCO3 used for the test was white powder with a particle size in the ranges of 15–40 nm and a purity of 99%. Nano TiC powder was grayish black, with an average particle size of 40 nm, a purity of 99% and a specific surface area of 65 m2/g. Figure 2 shows the morphology of nano CaCO3, nano TiC, and steel fibers used for the test. The microscopic images of nano CaCO3 and nano TiC are shown in Figure 3.

Figure 1.

Chemical composition and mass percentage of cement based on XRF analysis.

Figure 2.

Forms of raw materials. ((a) Nano CaCO3; (b) Nano TiC; (c) steel fibers).

Figure 3.

SEM images of nano CaCO3 and nano TiC. ((a) nano CaCO3; (b) nano TiC).

2.2. Specimen Preparation and Curing

The proportions shown in Table 1 were used to configure the concrete specimens. The ratio of water to cement was 0.4. The experiment was divided into two parts. The first part consisted of seven experimental groups of steel fiber-reinforced concrete prepared by nano CaCO3 and nano TiC with 0%, 0.5%, 1%, and 1.5% of cement mass in place of cement, respectively. The second part was the preparation of concrete specimens with nano CaCO3 and a nano TiC composite blended in place of cement. Nanomaterials are prone to clump together, have a high surface energy, and a large specific surface area. To increase the dispersibility of the nanopowdery materials used in the experiment, the use of ultrasonic dispersion is more conducive to its dispersion effect. In this experiment, nano CaCO3 and nano TiC were added to the mixing water, and ultrasonic dispersion was carried out for 10 min, followed by hand mixing for 2 min. We used a forced mixer and adopted a wet mixing process for stirring. First, the coarse aggregate, fine aggregate, and cement for 2 min were dry mixed, then the mixed dispersion liquid of water, nano CaCO3, nano TiC, and mixing water was added. Steel fibers were added while stirring. To ensure an even distribution of steel fibers, we stirred for another 3–5 min. After mixing, we poured it into the mold. After demolding, the specimens were kept for a predetermined amount of time at a typical curing room temperature of 20 ± 2 °C and a relative humidity of greater than 95% [28,29].

Table 1.

Composition mass of concrete mix (kg/m3).

2.3. Experimental Index Test

2.3.1. Mechanical Performance Testing

Mechanical property tests were conducted at 7 and 28 days of maintenance, respectively. According to the relevant provisions of the Chinese national standard GB/T 50081-2019 [28], a cubic standard specimen with a side length of 150 × 150 × 150 mm is used for the compressive strength and split tensile strength tests. The flexural strength test uses a prismatic standard specimen of 150 × 150 × 600 mm. The test was conducted using a universal testing machine (CSS-WAW1000, Jinan Zhonglu Chang Testing Machine Manufacturing Co., Ltd., Jinan, China), with the compressive strength test being continuously and uniformly loaded at a rate of 50 N/s. The split tensile strength test was conducted using a locating steel bracket to fix the specimen, which was loaded continuously and uniformly at a loading rate of 50 N/s. The split tensile strength test was conducted by using a universal pressure testing machine (CSS-WAW1000). The flexural strength test was loaded continuously and uniformly at a loading speed of 30 N/s. Each group had three test samples, and the test results were determined by averaging the three samples.

2.3.2. Frost Resistance Test and Relative Dynamic Modulus of Elasticity

The rate of mass loss most visually characterizes the change in cementitious materials from dense to loose and dislodged during freeze–thaw cycles [30]. The root cause of mass loss is the expansion of cracks due to the freezing and expansion of moisture within the specimen, which reduces the integrity of the material. Concerning the relevant provisions of the Chinese national standard GB/T50082-2009 [31], a mass loss greater than 5% indicates that the frost resistance of the cementitious material is not effective. The ability of a material to regain its elasticity upon exposure to a specific stress level is indicated by its relative dynamic modulus of elasticity. It is a crucial indicator for assessing the frost resistance of concrete since it can somewhat represent the amount of damage that freeze–thaw cycles have caused to the performance of concrete [32]. This test adopts a prismatic standard specimen with the size of 100 × 100 × 400 mm to carry out the freezing test using the fast-freezing method. After the curing period of the specimen reaches 24 days, soak it in water at 20 ± 2 °C for 4 days. The specimens were removed at 28 days, the water on their surfaces was wiped off with a damp cloth, and their external dimensions were determined. The initial weight and modulus of elasticity of the specimens were tested using the resonance method. The specimens were placed in a specimen box after the test, and water was added to the top 5 mm of each specimen. Each freeze–thaw cycle was 2–4 h. The freeze–thaw tests were removed after 25 freeze–thaw cycles, the surface water was wiped off, the specimens were weighed, and the rate of weight loss was calculated. Then, the relative dynamic elastic modulus of the rectangular specimens was measured and calculated.

2.3.3. SEM and EDS Analysis

After the compressive strength test, some irregular fragments were taken from the specimens and used as test samples. The fragments were soaked in anhydrous ethanol for 24 h and dried in an oven until it reached a constant weight before microscopic testing. Before the start of the test, each sample was sprayed with gold in a vacuum environment to enhance the conductivity of the sample and improve the image quality. SEM (Hitachi SU8100, Hitachi High-Tech Corporation, Tokyo, Japan) was used to microimage the microstructure of different groups of fragments. EDS was also used to analyze the constituent elements and content of the specimen materials.

2.3.4. XRD and FT-IR Analysis

Samples of the specimens after standard curing were soaked until the termination of hydration. They were dried to a constant weight and ground into powder. The mineralogical composition of the different groups of samples was studied using XRD (Bruker D8 Advance, Bruker Corporation, Karlsruhe, Germany) with a 2θ scanning range of 0° to 90° and a scanning speed of 2°/min. The infrared absorption spectra of the steel fiber-reinforced concrete specimens were analyzed using FT-IR (Thermo Scientific Nicolet iS50, Thermo Fisher Scientific, Waltham, MA, USA).

3. Results

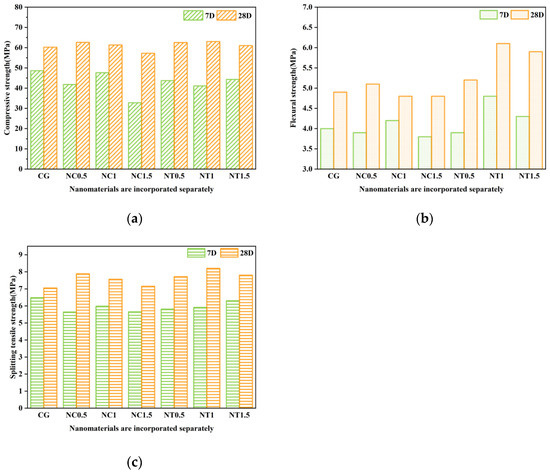

3.1. Mechanical Properties of SFRC When NC and NT Are Mixed Single

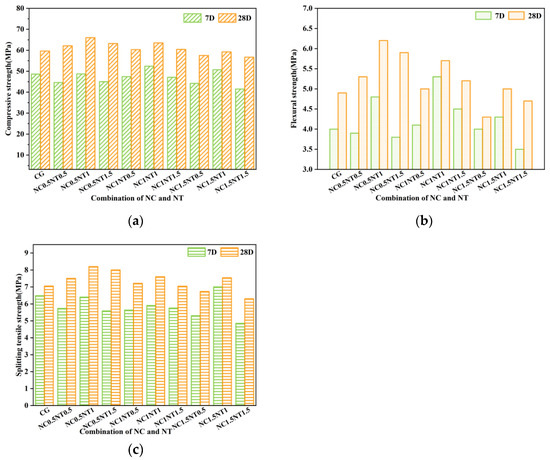

The results of compressive strength, flexural strength, and splitting tensile strength of SFRC at 7 d and 28 d after the addition of NC and NT to SFRC, respectively, are shown in Figure 4. The experimental data indicate that the addition of both NC and NT in appropriate amounts can improve the mechanical properties of SFRC concrete with standard curing for 28 days. When equal amounts of NC and NT were added, respectively, NT affected the mechanical properties of SFRC to a greater extent than NC, with the largest increase in flexural strength.

Figure 4.

The mechanical properties of concrete at 7 and 28 days when NC and NT are added separately. ((a) Compressive strength; (b) flexural strength; (c) splitting tensile strength).

As shown in Figure 4, it can be seen that the compressive and split tensile strengths of SFRC in standard curing for 7 d tended to decrease with increasing NC content. As the NC content increases, the tensile strength of the sample also increases and then decreases. The compressive strength was the highest when the NC substitution rate was 1%, and the compressive strength increased by 5%. A small amount of NC has the filling effect of microaggregate. As its particle size is much smaller than cement particles and it has good dispersion in the slurry, the fine voids between cement particles are filled, and the particle gradation of cementitious materials becomes more reasonable, leading to an increase in microstructure compactness [33,34]. Because of its high specific surface area and porous nature, the NC employed in the experiment has a small particle size and a particular capacity to absorb water. Reducing the proportion of free water inside the cementitious material at the beginning of the experiment hinders the formation of hydration products and the hydration process, and the mechanical properties of the specimens are lower [35,36]. The maximum mechanical properties of SFRC with 0.5% NC substitution are at 28 days of standard curing. The compressive strength increased by 4.0%, flexural strength by 4.1%, and split tensile strength by 11.8%. During the hydration process, NC reacts with tricalcium aluminate to produce hydrated calcium carbon-aluminate in the form of high or low carbonate, which promotes the hydration of the cement and improves the hardened strength, and the chemical reaction equations are shown in Formulas (1) and (2). It was found that excessive use of NC to replace cement decreased the mechanical properties of concrete. With the increase in the amount of NC admixture, the amount of cement decreases, and the percentage of water-reducing agents increases, which adversely affects the mechanical properties of the specimens to some extent [37]. Therefore, it can be stated that the optimum amount of NC admixture at 28 days of maintenance is 0.5% of cement mass.

The 7-day compressive strength and splitting tensile strength of SFRC with added NT were both lower than those of the control group CG, according to a study on the impact of NT incorporation on SFRC’s mechanical properties. The minimum value of compressive strength was reached by reducing it by 15.4% at a replacement rate of 1%. The lowest splitting tensile strength of SFRC was observed at 0.5% replacement, which decreased by 10.3%. As the dosage increases, the 7-day compressive strength of SFRC first increases and then decreases. The flexural strength was maximized at 1% replacement of NT with an increase of 20%. According to the test results, the specimens’ mechanical qualities significantly improved as they grew older. With the increase in NT substitution rate, the mechanical properties of 28-day specimens show a tendency of increasing and then decreasing, and reached the maximum value when the substitution rate was 1%. Compared with the control CG, the compressive strength of the concrete specimens prepared by NT replacement cement increased by 1.3–4.7%, flexural strength increased by 6.1–24.5%, and split tensile strength increased by 9.4–16.3%. NT can reduce the porosity of the cement matrix through the filling effect of its fine particles to form a denser microcosmic overall structure, which improves the properties of the cementitious materials. NT particles can also fill in the pores of the interfacial transition zone between the hardened cement paste and aggregates, and interact with the cement hydration products to form a denser interfacial structure, enhance the strength and toughness of the interfacial transition zone, reduce the weak links in the interfacial transition zone, and improve the overall mechanical properties of SFRC. In addition, NT can also induce the formation of a new ultra-hard calcium silicate hydrate gel phase. The generation of ultra-hard calcium silicate hydrate enables NT to significantly improve the mechanical properties of the hydration products inside the concrete without significantly increasing the degree of cement hydration, thus achieving a substantial improvement in concrete performance at a low replacement rate. Continuing to increase the replacement rate of NT, while the aggregation effect of micro aggregate weakens the transition zone of the microstructure, all the strengths begin to show a decreasing trend.

3.2. Mechanical Properties of SFRC When NC Is Compounded with NT

Figure 5 demonstrates the results of the effect of composite incorporation of NC and NT on the compressive strength, flexural strength and spilt tensile of SFRC at different age maintenance. It was discovered that once the amount of NT replacement increased, the compressive strength, flexural strength, and split tensile strength of SFRC with standard curing for 7 and 28 days at the same NC admixture tended to increase and then decrease, and all three of them reached the maximum value at a replacement rate of 1%. The 7-day compressive strength and flexural strength of SFRC increased the most when the replacement rate of NT was 1% and the replacement rate of NC was 1%, with an increase of 7.8% and 32.5%, respectively, and the 7-day splitting tensile strength of SFRC increased the most when the replacement rate of NC was 1.5% and the replacement rate of NT was 1%, with an increase of 8.0%. The increase in the 28-day mechanical properties of SFRC was maximized when 0.5% NC and 1% NT of cement mass were used. The increase was ranked as flexural strength > split tensile strength > compressive strength. The mechanical properties of SFRC with 0.5% NC were higher than those of concrete specimens with 1% NC and 1.5% NC at any admixture of NT. The mechanical properties of cementitious materials are often affected by the weak interfacial zones, and the incorporation of NC resulted in a significant improvement in the hydration products as well as the inhomogeneous microstructure in the interfacial excess zones [38], which reduced the porosity and the number of cracks in the weak zones and thus led to the optimization effect. At the end of the hydration process, the dilution effect of NC is higher than its packing and nucleation effects [38,39], so the incorporation of too much NC may reduce the compressive strength. Meanwhile, the mechanical properties of SFRC decrease with the increase in NC admixture in the case of an equal amount of NT. On the one hand, because NC has no gelling ability, higher NC replacement reduces the amount of cement, which is unfavorable for the development of mechanical properties [40]. On the other hand, as the admixture increases, the dilution effect of NC becomes more effective, and the effective water/cement ratio in the cement matrix rises, reducing the strength of SFRC [41]. Compared to the separate incorporation of NC and NT, the mechanical properties of SFRC are significantly improved when NC and NT are used in combination. This indicates that the mechanical properties of SFRC can be synergistically improved by mixing NC and NT. The filling effect of NC makes the concrete matrix denser and provides a better environment for NT to exert its nucleation effect. At the same time, the hydration reaction products promoted by NT can further fill the tiny spaces that NC has not completely filled and enhance the bonding strength between NC and the concrete matrix, collectively improving the mechanical properties and durability of the concrete. At 28 days of standard curing, the optimum replacement rate of NC and NT in SFRC were 0.5% and 1% of cement mass, respectively, from the perspective of the mechanical properties.

Figure 5.

The mechanical properties of concrete with NC and NT composite incorporation at 7 days and 28 days. ((a) Compressive strength; (b) flexural strength; (c) spslitting tensile strength).

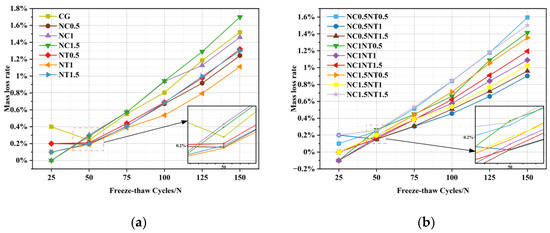

3.3. Analysis of the Mass Loss Rate

Figure 6 shows the test results of mass loss after freeze–thaw cycles of SFRC with NC and NT added, cured under standard conditions for 28 days. As shown in Figure 6a, the rate of concrete mass loss increased with the number of freeze–thaw cycles. During the freeze–thaw process, the free water in the microscopic pores of concrete will generate fatigue stresses under the combined effect of expansion pressure and osmotic pressure, causing microcracks within the concrete and spalling of the surface layer, thus increasing the rate of quality loss of concrete [42]. It was found that the quality loss rate of SFRC could be effectively reduced by adding NC in an appropriate amount. The mass loss rate of NC0.5 samples was lower than that of the control CG throughout the freeze–thaw cycle. The use of an appropriate amount of NC to replace the cement can effectively reduce the amount of Ca(OH)2 generation. In addition, NC has a packing effect and forms a denser matrix [41]. The mass loss rates of NC1 specimens and NC1.5 specimens after 100 freeze–thaw cycles were higher than those of the CG, which were 0.936% and 0.942%. An excessive amount of NC could create a denser matrix that is unable to accommodate the formation of hydration products [43]. However, the rate of mass loss of NC1 was lower than that of the baseline group CG when the number of iterations reaches 125, and the increase was reduced. During 0–150 freeze–thaw cycles, the maximum change in the mass loss rate was observed for NC1.5. The high surface energy of NC enabled Ca2+ and OH− in the concrete matrix to be adsorbed on its surface and Ca(OH)2 crystals to take the lead in nucleation, with a reduced degree of orientation as well as improved enrichment and alignment, which promoted the hydration and growth of tricalcium silicate in the interfacial transition zone [44]. On the other hand, its high specific surface area increases the area in contact with water and promotes the hydration of tricalcium silicate. The C-S-H gel takes NC as the growth point, which lowers the nucleation barrier and forms bonds on its surface, gradually transforming from flocculent to a columnar network structure with distinctive contours and overlapping intersections, which fills up the harmful pore spaces in the slurry and improves the interfacial structure of the cementitious stone and the aggregate. Meanwhile, the test results show that the admixture of NT can reduce its mass loss rate and effectively improve the durability performance of concrete specimens. During 0–150 freeze–thaw cycles, the mass loss rate of NT0.5, NT1, and NT1.5 was lower than that of the CG group. Under the same quality conditions, the improvement effect of NT concrete on mass loss due to freeze-–thaw damage is superior to that of NC concrete.

Figure 6.

Mass loss rate of concrete after freeze–thaw cycles. ((a) NC and NT were added separately; (b) NC and NT composite incorporation).

The mass loss rate of NCNT samples after different freeze–thaw cycles is shown in Figure 6b. Repeated freeze–thaw cycle damage leads to fine structure degradation, surface peeling, crack extension, and even structural fracture of cementitious materials [45]. After 150 cycles, the mass loss rate of all samples in NCNT was below 5%. After 25 freeze–thaw cycles, the mass loss rates of NC1NT1.5, NC1.5NT0.5, and NC1.5NT1 were 0, and the masses of NC0.5NT1.5, NC1NT0.5, and NC1NT1 all increased by 0.1%. According to the results of the mass loss experiments, the degree of shedding of concrete materials after 150 freeze–thaw cycles was NC0.5NT0.5 > NC1.5NT1.5 > NC1NT0.5 > NC1.5NT0.5 > NC1NT1 > NC0.5NT1 > NC0.5NT1 > NC0.5NT1.5 > NC0.5NT1. The NC0.5NT1 sample had the lowest degree of shedding and lowering, which was the same as the results of the mechanical property tests in Section 3.2. The weight loss of the NC and NT compounded SFRC was less than that of NC and NT alone. The weight loss rate of NC0.5NT1 was reduced by 0.34% compared to NC0.5. The mass loss rate of NC0.5NT1 was reduced by 0.209% as compared to NT1. The improvement in the concrete sample shedding by NC and NT compounding was better than NC and NT alone. A lower mass loss rate indicates that when the mass fractions of NC and NT are 0.5% and 1%, respectively, the internal structure of SFRC can be significantly improved, enhancing its freeze–thaw resistance.

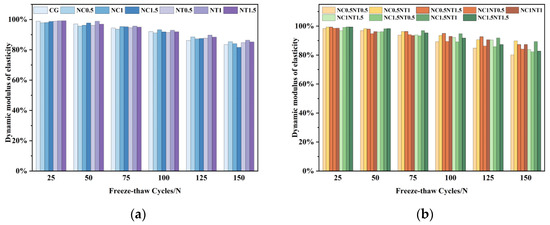

3.4. Relative Dynamic Modulus of Elasticity Analysis

Figure 7 demonstrates the relative dynamic modulus of elasticity for different number of freeze–thaw cycles of SFRC doped with NC and NT for 28 days of standard curing. Figure 7a shows the relative dynamic elastic modulus of NC and NT samples with single incorporation. Concrete in a freeze–thaw environment is subjected to internal expansion pressure and infiltration pressure generated by the repeated freezing and expansion of free water inside the concrete, resulting in further extension of existing internal cracks as well as the generation of new microcracks during the freeze–thaw process, leading to the degradation of the mechanical properties of the concrete [46]. After 25 freeze–thaw cycles, the relative dynamic modulus of elasticity of NC0.5 and NC1 was lower than that of the control CG. As the freeze–thaw cycles progressed, the decrease in NC0.5 was smaller, and the rate of decrease in NC1.5 was gradually enhanced. The frost resistance of concrete is significantly affected by its pore structure and porosity. Not only did NC make the concrete structure denser through the packing effect, but NC also resisted the development of internal microcracks by increasing the dispersion of steel fibers in the concrete [47,48]. The relative dynamic modulus of elasticity of NC0.5 was maximum after 150 freeze–thaw cycles. When water molecules are present at the interface, the carbonate molecules (CO32−) in NC absorb the H2O molecules to form strong bonds and absorb the excess energy in the system, thus maintaining the relative stability of the system. When NC and C-S-H are in contact, the negative charge generated by the ionization of silanol groups on the silicate tetrahedral bonding boundary by calcium hydroxide is balanced by Ca2+ in the interlayer. The OSiOH-H2O-HOSiO bond is replaced by the ionic covalent bond SiO−-Ca2+-SiO−, which leads to a decrease in the interlayer space between the two calcium layers and an increase in the modulus of elasticity [49,50]. The relative dynamic modulus of elasticity of NC1.5 is 81.626%, which decreases to become the smallest value of all the experimental groups. This indicates that excessive use of NC adversely affects the concrete. The relative kinetic elastic modulus of NT samples decreased slightly after 25 freeze–thaw cycles. The NT1 content decreased with the number of freeze–thaw cycles. The relative kinetic elastic modulus of NT was greater than that of NC following 150 freeze–thaw cycles. This indicates that the use of NT can resist freeze–thaw cycles to a certain extent and has a stronger resistance than NC. Figure 7b illustrates the variations in the relative dynamic modulus of elasticity of the NC and NT compounded specimens. As more tests are conducted, the relative dynamic modulus of concrete gradually drops as damage builds up throughout the freeze–thaw cycle. After 150 freeze–thaw cycles, the relative dynamic modulus of elasticity of CG dropped to 83.426%, while the NCNT group’s specimens had relative dynamic moduli of elasticity ranging from 82% to 90%. The test results indicate that the appropriate amount of NC compounded with NT into SFRC can effectively inhibit the formation and development of cracks in SFRC and improve the microstructure of the specimens.

Figure 7.

Dynamic elastic modulus of concrete after freeze–thaw cycles. ((a) NC and NT were added separately; (b) NC and NT composite incorporation).

3.5. Material Micro-Property Testing

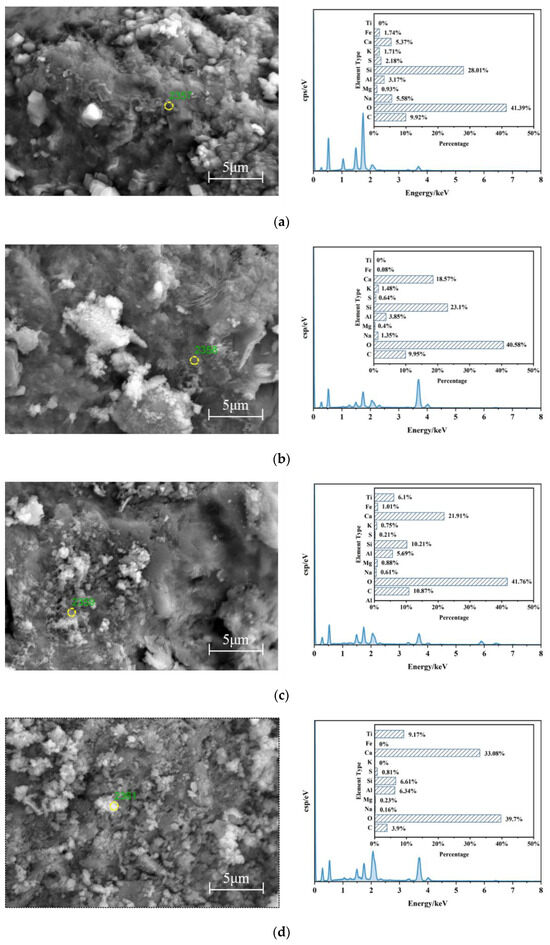

3.5.1. SEM and EDS Analysis Results

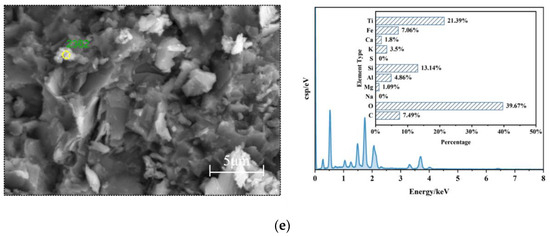

Figure 8 shows the high magnification morphology and elemental composition of CG, NC0.5, NC0.5NT0.5, NC0.5NT1, and NC0.5NT1.5 for 28 days of standard maintenance. EDS was used to detect the elemental content of the hydration products predominantly present in the SEM images, and the changes in the elemental content reflected the results of the changes in the microstructure [51,52]. From Figure 8a, it can be seen that the microstructure of the CG group is loose, with more cavities under standard conditions. The microstructure of the specimen containing 0.5% NC was significantly denser, and the fine size of NC increased the number of surface atoms, surface area, and surface area energy, which resulted in more C-S-H gel adsorbed on the surface of the particles. The new three-dimensional network structure with NC as the core and bonding synthesis strengthens the interfacial layer between steel fibers and cementitious materials, leading to enhanced mechanical properties and durability of concrete [32]. When NT was used to replace cement at 1%, a dense microstructure appeared in the concrete samples at 28 d, along with a large number of flocculated gel products. The C-S-H gel structure grew into a spherical shape with better stability, and the hydration products of the C-S-H gel structure grew to a more stable spherical shape, and the hydration products were more complete, fine, and uniformly distributed, and the pores were significantly reduced [53]. Observation of Figure 8e reveals the presence of equilateral prisms or thin slabs of CH, O and I-type C-S-H gels and a large number of hexagonal lamellar hydration products AFm in the microstructure. According to spectroscopic study, as the quantity of NT substitution increases, the content of the Al element tends to rise and subsequently fall. The Al-containing oxides can participate in the secondary hydration reaction during hydration and affect the microstructure and durability properties of cementite.

Figure 8.

SEM images and EDS analysis results of concrete. ((a) CG; (b) NC0.5; (c) NC0.5NT0.5; (d) NC0.5NT1; (e) NC0.5NT1.5).

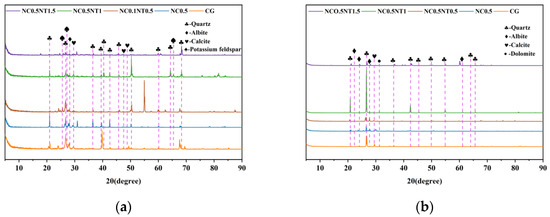

3.5.2. XRD Analysis Results

To discuss the effect of different NT contents on the mineralogical composition of SFRC, five specimens, CG, NC0.5, NC0.5NT0.5, NC0.5NT1, and NC0.5NT1.5, were subjected to XRD tests, and in Figure 9, the results are displayed. The combined SEM and XRD analysis results show that NC does not affect the hydration composition of cement. Rather, its micro aggregate and surface effects promote the production of hydration products C-S-H, which improves the enrichment and directional arrangement properties of interfacial CH from near-planar to spatial arrangement, leading to enhanced mechanical properties of the structure [44,54]. The amount of NT doping affects the peak value of the minerals. The higher the peak, the higher the amount of mineral crystallization [55]. The mineral composition of the five specimens after 7 and 28 days of standard curing remained the same, dominated by quartz, sodium feldspar, and calcite. In the early stage of hydration, calcite can be used as an inert filler to fill the voids between cement particles [56]. From Figure 9a, it can be seen that the addition of 0.5% NC increases the quartz content compared to CG. However, as the NT content increases, the quartz content first increases and then decreases, while the calcite content decreases. In the cement hydration environment, NT has a strong adsorption capacity for Ca2+, affecting the concentration of Ca(OH)2 in the concrete matrix. The reaction of Ca(OH)2 with CO2 produces calcite, and NT changes the amount of Ca(OH)2, which in turn indirectly affects the amount of calcite produced. The adsorption and desorption processes on the quartz surface may be affected by changes in the chemical environment, which in turn can influence the state of quartz and subsequently affect its final content in the hydration products. The specimens maintained for 7 days contained a certain amount of potassium feldspar in addition to quartz, sodium feldspar, and calcite. However, potassium feldspar is only present in the samples with added NC and NT, and the content of potassium feldspar in CG and NC0.5 is almost 0. The content of potassium feldspar gradually decreases with the increase in NT replacement. Figure 9b shows that the content of quartz in NC0.5NT1 increases substantially with the increase of the curing time, while the content of calcite decreases gradually. The crystal structure can affect the hydration reaction rate of cement. The planar structure of calcite is mainly composed of Ca and O atoms, similar to the CaO layers in C-S-H gel. Therefore, calcite can participate in the reaction of calcium carbonate and tricalcium aluminate (C3A), significantly accelerating the hydration process [57].

Figure 9.

XRD analysis of concrete at different ages. ((a) Standard curing for 7 days; (b) standard curing for 28 days).

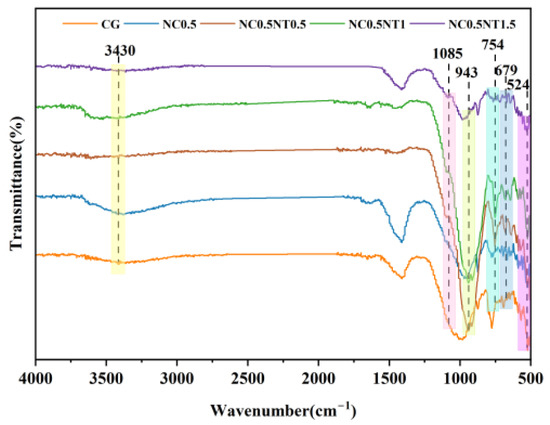

3.5.3. FT-IR Analysis Results

The changes in the absorption peaks of CG, NC0.5, and NC0.5NT after 28 days of standard curing determined according to FT-IR are shown in Figure 10. The analysis results indicate that the changes in the NT substitution amount can alter the ratio and vibration conditions of the functional groups. The stretching vibration of O-H is represented by the absorption peak at 3430 cm−1, The O-H functional groups in water can provide free H+ for the hydration reaction of concrete, accelerating the cement hydration process [58]. At 1085 cm−1, Si-O-Si undergoes an antisymmetric stretching vibration. The fundamental structural unit of the silicate skeleton is the Si-O-Si link, and the composition of the silicate skeleton has a direct impact on the fundamental characteristics of the gel. The Si-O-Si bond can release Si-OH through hydrolysis reactions with alkali activators, and Si-OH can condense with Ca2+ to form C-S-H gel [53,59]. The antisymmetric telescopic vibration absorption peak of Si-O is 943 cm−1, and 754 cm−1 is the symmetric telescopic vibration absorption peak of Si-O. The Si-O bond is formed between silicon atoms through covalent bonds during the gel formation process. It is a crucial component of condensation reactions and the most widely employed chemical bond in silicates and C-S-H gels. With the NT substitution amount increasing, the absorption peak of Si-O in the sample first decreases and then increases, and the degree of Si-O tetrahedra polymerization in the C-S-H gel progressively rises [60]. The stretching vibration absorption peak of O-M (M being a metal element) is 679–523 cm−1.

Figure 10.

The analysis of FT-IR.

4. Conclusions

In this paper, NC and NT were introduced into SFRC to replace cement with different ratios of NC and NT combined. The effects of the changes in the replacement amounts of NC and NT on the mechanical properties, durability, and chemical composition of SFRC were analyzed by various methods. The results revealed the following conclusions:

(1) Different types and ratios of cement substitutes have a greater effect on the mechanical properties of SFRC. The mechanical properties of SFRC at 28 days decreased with increasing NC replacement rate. An optimum replacement of 0.5% increased the compressive strength by 4.0%, flexural strength by 4.1%, and split tensile strength by 11.8%. With the increase of the NT substitution amount, material that has mechanical qualities exhibited a tendency of first rising and then falling. When the replacement rate was 1%, its 28 d compressive strength increased by 4.7%, flexural strength increased by 24.3%, and split tensile strength increased by 16.5%.

(2) The optimized combination of 0.5% replacement of NC and 1% replacement of NT maximally improved the mechanical properties of SFRC and maximally improved the durability properties of concrete. The compressive strength, flexural strength, and split tensile strength of the specimens cured for 28 days were improved by 35.5%, 26.5%, and 16.3%, respectively.

(3) The mechanical properties and durability of SFRC tend to increase and then decrease when the substitution rate of NC and NT exceeds 1%. The mechanical properties and durability of SFRC are greatest when the substitution rate of NC is 0.5% and that of NT is 1%. However, it is lower than the SFRC specimens with a substitution rate of 0.5% for NC and 1% for NT.

(4) The quality of SFRC deteriorates as the number of freeze-thaw cycles rises, although the relative dynamic elastic modulus falls. Compared to CG, the substitution rate of NC is 0.5%, and the substitution rate of NT is 1%. The mass loss of SFRC after 150 freeze–thaw cycles is reduced by 40.6%, and the relative dynamic elastic modulus increases by 7.7%.

(5) The results of microscopic tests, such as SEM and XRD, showed that NC and NT can work synergistically to enhance. Simultaneous replacement of cement using NC and NT can effectively improve the morphology of hydration products, improve the interfacial transition zone and pore structure, and effectively improve the mechanical properties and durability of SFRC.

In summary, it was determined after testing that NC and NT can improve the mechanical properties and durability of SFRC. Optimizing the durability properties of SFRC allows for a reasonable reduction in the size of SFRC numbers or the thickness of the protective layer at the time of design, saving material costs while ensuring structural safety. Optimizing the performance of SFRC also reduces the number of repairs and replacements, lowering overall project costs. Although NT has great potential for application in SFRC, achieving its widespread use still requires overcoming numerous challenges such as dispersion, cost, and compatibility. In the future, to better apply it to engineering practice projects, we will prepare high-performance concrete with stable performance and a wide range of applications. Further determination of the hydration heat and chemically bound water content of cement at different ages is needed to analyze whether the addition of NT to cement-based materials accelerates or delays the hydration process of cement.

Author Contributions

Conceptualization, Y.W., Z.W. and X.Y.(Xin Yang); methodology, Y.W., Z.W. and X.Y.(Xin Yang); software, Y.W., Z.W. and X.Y.(Xilin Yuan); validation, Y.W., Z.W. and X.Y.(Xilin Yuan); formal analysis, Y.W. and X.Y.(Xinlin Yuan); investigation, Y.W. and Z.W.; resources, Z.W.; data curation, Y.W., X.Y.(Xilin Yuan) and X.Y.(Xin Yang); writing—original draft preparation, Y.W. and X.Y.(Xilin Yuan); writing—review and editing, Y.W., Z.W. and X.Y.(Xin Yang); visualization, Y.W. and Z.W.; supervision, Z.W.; project administration, Z.W.; funding acquisition, Z.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Scientific research project under the Guidance Category of Heilongjiang Provincial Key Research and Development Program (GZ20220138); Scientific research project of Heilongjiang Provincial Department of Ecology and Environment (HST2022GF004).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Abreu, F.D.S.; Ribeiro, C.C.; Pinto, J.D.D.S.; Nsumbu, T.M.; Buono, V.T.L. Influence of adding discontinuous and dispersed carbon fiber waste on concrete performance. J. Clean. Prod. 2020, 273, 122920. [Google Scholar] [CrossRef]

- Gong, J.; Ma, Y.; Fu, J.; Hu, J.; Ouyang, X.; Zhang, Z.; Wang, H. Utilization of fibers in ultra-high performance concrete: A review. Compos. Part B Eng. 2022, 241, 109995. [Google Scholar] [CrossRef]

- Zhu, H.; Wu, K.; Li, J.; Chen, G. Effect of synthetic fibers on mechanical proportion of fiber reinforced concrete. J. Tongji Univ. 2017, 44, 1894–1901. [Google Scholar]

- Rajkohila, A.; Chandar, S.P. Assessing the effect of natural fiber on mechanical properties and microstructural characteristics of high strength concrete. Ain Shams Eng. J. 2024, 15, 102666. [Google Scholar] [CrossRef]

- Guo, G. Preparation and mechanical properties of steel fiber reinforced concrete. J. Funct. Mater. 2020, 51, 11165–11170. [Google Scholar]

- Yang, J.-M.; Shin, H.-O.; Yoon, Y.-S.; Mitchell, D. Benefits of blast furnace slag and steel fibers on the static and fatigue performance of prestressed concrete sleepers. Eng. Struct. 2017, 134, 317–333. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, J.; Zhang, J.; Deng, Q.; Xue, Z.; Huang, G.; Huang, X. Influence of steel slag and steel fiber on the mechanical properties, durability, and life cycle assessment of ultra-high performance geopolymer concrete. Constr. Build. Mater. 2024, 441, 137590. [Google Scholar] [CrossRef]

- Xiang, L.; Wang, K. Research and Application of Steel Fiber Reinforced Concrete in Wear-Resistant Pavements in Cold Regions. China Pet. Chem. Stand. Qual. 2012, 32, 235–236. (In Chinese) [Google Scholar]

- Li, J.; Zhang, X.; Li, Z.; Zhang, J.; Shi, Z. Study on flexural toughness of steel fiber reinforced self-compacting lightweight aggregate concrete under freeze-thaw environment. Adv. Eng. Sci. 2024, 1–13. (In Chinese). Available online: http://kns.cnki.net/kcms/detail/51.1773.TB.20240606.1731.008.html (accessed on 24 December 2024).

- Wu, Z.; Shi, C.; Khayat, K.H.; Wan, S. Effects of different nanomaterials on hardening and performance of ultra-high strength concrete (UHSC). Cem. Concr. Compos. 2016, 70, 24–34. [Google Scholar] [CrossRef]

- Fu, Q.; Zhang, Z.; Zhao, X.; Xu, W.; Niu, D. Effect of nano calcium carbonate on hydration characteristics and microstructure of cement-based materials: A review. J. Build. Eng. 2022, 50, 104220. [Google Scholar] [CrossRef]

- Bheel, N.; Chohan, I.M.; Ghoto, A.A.; Abbasi, S.A.; Tag-Eldin, E.M.; Almujibah, H.R.; Ahmad, M.; Benjeddou, O.; Gonzalez-Lezcano, R.A. Synergistic effect of recycling waste coconut shell ash, metakaolin, and calcined clay as supplementary cementitious material on hardened properties and embodied carbon of high strength concrete. Case Stud. Constr. Mater. 2024, 20, e02980. [Google Scholar] [CrossRef]

- Mermerdaş, K.; Gesoğlu, M.; Güneyisi, E.; Özturan, T. Strength development of concretes incorporated with metakaolin and different types of calcined kaolins. Constr. Build. Mater. 2012, 37, 766–774. [Google Scholar] [CrossRef]

- Hu, N.; Tang, E.; Chang, D.; Liu, S.; Chu, X.; Xing, X.; Wang, R.; Liu, X. Modification of CaCO3 nanoparticle by styrene-acrylic polymer emulsion spraying and its application in polypropylene material. Powder Technol. 2021, 394, 83–91. [Google Scholar] [CrossRef]

- Liu, X.; Chen, L.; Liu, A.; Wang, X. Effect of nano-CaCO3 on properties of cement paste. Energy Procedia 2012, 16, 991–996. [Google Scholar] [CrossRef]

- Yao, D.; Liu, J.; Bai, Y. Linkage of multi-scale performances of nano-CaCO3 modified ultra-high performance engineered cementitious composites (UHP-ECC). Constr. Build. Mater. 2020, 234, 117418. [Google Scholar]

- Ming, X.; Ming, X. Influence of Conventional Dispersed Nano-CaCO3 on Performance of Concrete. J. Highw. Transp. Res. Dev. 2019, 36, 25–30. (In Chinese) [Google Scholar]

- Meng, T.; Yu, Y.; Wang, Z. Effect of nano-CaCO3 slurry on the mechanical properties and micro-structure of concrete with and without fly ash. Compos. Part B Eng. 2017, 117, 124–129. [Google Scholar] [CrossRef]

- Huang, Z.; Zu, T. Influence of Nano-CaCO3 on Ultra High Performance Concrete. Bull. Chin. Ceram. Soc. 2013, 32, 1103–1109+25. (In Chinese) [Google Scholar]

- Lothenbach, B.; Le Saout, G.; Gallucci, E.; Scrivener, K. Influence of limestone on the hydration of Portland cements. Cem. Concr. Res. 2008, 38, 848–860. [Google Scholar] [CrossRef]

- Lin, F.; Ren, M.; Wu, H.; Lu, Y.; Huo, M.; Yang, M.; Chen, Z.; Jiang, Z. Fabrication of TiC-graphene dual-reinforced self-lubricating Al matrix hybrid nanocomposites with superior mechanical and tribological properties. Tribol. Int. 2022, 171, 107535. [Google Scholar] [CrossRef]

- Jiang, M.; Li, B.; Chen, X.; Han, T.; Ma, S.; Duan, X.; Du, W.; Lei, Z.; Chen, Y. Enhanced surface finish and reduced porosity of TiC nanoparticles reinforced 2219 aluminum alloy deposit fabricated via oscillating laser-arc hybrid additive manufacturing. J. Manuf. Process. 2024, 120, 414–425. [Google Scholar] [CrossRef]

- Li, W.; Li, Y.; Zhao, Z.; Zheng, Q.; He, P.; Yi, D. Interfacial bonding and wear behavior of macroscopic TiC particulates reinforced iron-based composites fabricated by infiltration casting process. Tribol. Int. 2024, 199, 109991. [Google Scholar] [CrossRef]

- Zheng, Y.; Yan, X.; Qiao, G.; Tang, Y.; Geng, Y.; Shao, Z.; Bai, Q. Enhanced wear resistance of TiC/Ti6Al4V composites through changing TiC morphologies in laser direct energy deposition. Addit. Manuf. 2024, 84, 104134. [Google Scholar] [CrossRef]

- Daneshmand, S.; Sajadi, S.M.; Vini, M.H. A molecular dynamics simulation on corrosion, wear, and mechanical properties of laminated Al/TiC composites. Eng. Anal. Bound. Elem. 2023, 152, 598–607. [Google Scholar] [CrossRef]

- Chen, G.-C.; Li, X. Effect of TiC nano-treating on the fluidity and solidification behavior of aluminum alloy 6063. J. Mater. Process. Technol. 2024, 324, 118241. [Google Scholar] [CrossRef]

- Zheng, T.; Pan, S.; Liu, J.; Moodispaw, M.; Luo, A.A.; Taub, A.I.; Li, X. Study on nano-treating of Al-Mg-Si-Cu alloys with TiC nanoparticles. J. Alloys Compd. 2023, 947, 169405. [Google Scholar] [CrossRef]

- GB/T50081-2019; Standard for Test Methods for Physical and Mechanical Properties of Concrete. China Academy of Building Research: Beijing, China, 2019.

- Yang, X.; Wang, Z.; Wang, X.; Wen, Y.; Du, Y.; Ji, F. Study on Mechanical Properties of Nano-TiC-and Nano-SiO2-Modified Basalt Fiber Concrete. Buildings 2024, 14, 2120. [Google Scholar] [CrossRef]

- Wang, Z.-R.; Li, B.; Liu, H.-B.; Zhang, Y.-X.; Qin, X. Degradation characteristics of graphite tailings cement mortar subjected to freeze-thaw cycles. Constr. Build. Mater. 2020, 234, 117422. [Google Scholar] [CrossRef]

- GB/T50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China Building Industry Press: Beijing, China, 2009.

- Sato, T.; Beaudoin, J.J. Effect of nano-CaCO3 on hydration of cement containing supplementary cementitious materials. Adv. Cem. Res. 2011, 23, 33–43. [Google Scholar] [CrossRef]

- Ge, Z.; Wang, K.; Sun, R.; Huang, D.; Hu, Y. Properties of self-consolidating concrete containing nano-CaCO3. J. Sustain. Cem. Based Mater. 2014, 3, 191–200. [Google Scholar] [CrossRef]

- Gillani, S.T.A.; Hu, K.; Tariq, J.; Song, L.; Zhang, W. Synergistic optimization: A comprehensive life cycle assessment for high-performance concrete with recycled aggregates and Next-Gen nylon waste fibers. Constr. Build. Mater. 2024, 430, 136491. [Google Scholar] [CrossRef]

- Cao, M.; Ming, X.; He, K.; Li, L.; Shen, S. Effect of Macro-, Micro- and Nano-Calcium Carbonate on Properties of Cementitious Composites—A Review. Materials 2019, 12, 781. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Aldulaimi, D.S.; Abdellatief, M.; Youssf, O. Physical, mechanical and durability properties of eco-friendly engineered geopolymer composites. Infrastructures 2024, 9, 191. [Google Scholar] [CrossRef]

- Kenai, S.; Soboyejo, W.; Soboyejo, A. Some engineering properties of limestone concrete. Mater. Manuf. Process. 2004, 19, 949–961. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W.M. Compressive strength and durability of high-volume fly ash concrete reinforced with calcium carbonate nanoparticles—ScienceDirect. In Fillers and Reinforcements for Advanced Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2015; pp. 275–307. [Google Scholar]

- Danying, G.; Liangping, Z.; Gang, C. Compressive stress-strain relationship of fiber and nanosized material reinforced concrete in high temperature. China Civ. Eng. J. 2017, 9, 46–58. [Google Scholar]

- Vance, K.; Aguayo, M.; Oey, T.; Sant, G.; Neithalath, N. Hydration and strength development in ternary portland cement blends containing limestone and fly ash or metakaolin. Cem. Concr. Compos. 2013, 39, 93–103. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Sua-Iam, G.; Makul, N. Effects of calcium carbonate powder on the fresh and hardened properties of self-consolidating concrete incorporating untreated rice husk ash. J. Clean. Prod. 2018, 172 (Pt 3), 3265–3278. [Google Scholar] [CrossRef]

- Tan, Y.; Long, J.; Xiong, W.; Chen, X.; Zhao, B. Effects of polypropylene fibers on the frost resistance of natural sand concrete and machine-made sand concrete. Polymers 2022, 14, 4054. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Multi-scale investigation of microstructure, fiber pullout behavior, and mechanical properties of ultra-high performance concrete with nano-CaCO3 particles. Cem. Concr. Compos. 2018, 86, 255–265. [Google Scholar] [CrossRef]

- Yang, H.S.; Che, Y.J.; Zhang, M. Effect of Nano-CaCO3/Limestone Powder Composite on the Early Age Cement Hydration Products. Key Eng. Mater. 2016, 703, 354–359. [Google Scholar] [CrossRef]

- Eslami, J.; Walbert, C.; Beaucour, A.-L.; Bourges, A.; Noumowe, A. Influence of physical and mechanical properties on the durability of limestone subjected to freeze-thaw cycles. Constr. Build. Mater. 2018, 162, 420–429. [Google Scholar] [CrossRef]

- Xiao, Q.H.; Cao, Z.Y.; Guan, X.; Li, Q.; Liu, X.L. Damage to recycled concrete with different aggregate substitution rates from the coupled action of freeze-thaw cycles and sulfate attack. Constr. Build. Mater. 2019, 221, 74–83. [Google Scholar] [CrossRef]

- Cao, M.; Li, L.; Khan, M. Effect of hybrid fibers, calcium carbonate whisker and coarse sand on mechanical properties of cement-based composites. Mater. De. Construcción 2018, 68, 156. [Google Scholar] [CrossRef]

- Cai, Y.; Hou, P.; Zhou, Z.; Cheng, X. Effects of nano-CaCO3 on the properties of cement paste: Hardening process and shrinkage at different humidity levels. In Proceedings of the International Conference on Durability Concrete Structures, Leeds, UK, 18–20 July 2018. [Google Scholar]

- Sekkal, W.; Zaoui, A. Enhancing the interfacial bond strength of cement nanocomposite with carbonate nanostructure. Compos. Part B Eng. 2017, 124, 111–119. [Google Scholar] [CrossRef]

- Zhang, J.; Diao, B.; Li, Y.D.; Zheng, X.N. Performance Comparison between High Strength Concrete and Ordinary Concrete under Mixed Erosion and Freeze-Thaw Cycling. Adv. Mater. Res. 2011, 163, 1667–1672. [Google Scholar] [CrossRef]

- Wu, S.; Sun, K.; Zhao, H.; Zhang, F. Quantitative Invalidation Characterization of Portland Cement Based on BSE and EDS Analysis. Constr. Build. Mater. 2018, 158, 700–706. [Google Scholar] [CrossRef]

- Hu, K.; Liu, M.; Chen, Y.; Tao, X.; Yu, X.; Zheng, D. Effect and mechanism of accelerated carbonization on the adhesion property of asphalt mixture containing recycled concrete aggregate. Constr. Build. Mater. 2024, 445, 137932. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, K.; Zhang, D.; Zhang, J.; Jiao, Y.; Fang, C.; Tang, W.; Zhao, Z. Durability of geopolymer cementitious materials synergistically stimulated by Ca2+ and Na+. Case Stud. Constr. Mater. 2024, 21, e03514. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W.M.; Barbhuiya, S. Microstructure and Nanoscaled Characterization of HVFA Cement Paste Containing Nano-SiO2 and Nano-CaCO3. J. Mater. Civ. Eng. 2017, 29, 04017063. [Google Scholar] [CrossRef]

- Wu, F.; Liu, X.; Qu, G.; Ning, P.; Jin, C.; Cui, Q.; Ren, Y.; He, M.; Yang, Y.; Li, J. Solidification and stabilization of harmful elements in antimony tailings and synergistic utilization of multiple solid wastes. Cem. Concr. Compos. 2022, 133, 10471. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H.; Ou, Z. A review on use of limestone powder in cement-based materials: Mechanism, hydration and microstructures. Constr. Build. Mater. 2018, 181, 659–672. [Google Scholar] [CrossRef]

- Bentz, D.P.; Ardani, A.; Barrett, T.; Jones, S.Z.; Lootens, D.; Peltz, M.A.; Sato, T.; Stutzman, P.E.; Tanesi, J.; Weiss, W.J. Multi-scale investigation of the performance of limestone in concrete. Constr. Build. Mater. 2015, 75, 1–10. [Google Scholar] [CrossRef]

- Wang, W.; Yuan, Y.; Shi, F.; Li, Q.; Zhao, S.; Wang, J.; Sheng, M.; Wang, Z. Enhancing dispersibility of nanofiller via polymer-modification for preparation of mixed matrix membrane with high CO2 separation performance. J. Membr. Sci. 2023, 683, 121791. [Google Scholar] [CrossRef]

- Quan, P.; Sun, Q.; Xu, Z.; Shi, M.; Gao, Z.; Wang, D.; Liu, D.; Yang, L.; Song, S. Study on the mechanical properties and strength formation mechanism of high-volume graphite tailings concrete. J. Build. Eng. 2024, 84, 108500. [Google Scholar] [CrossRef]

- Liu, H.; Bai, Q.; Ma, H.; Xin, Z.; Deng, S.; Jiang, C. Research on the preparation of eco-economical ultra-high performance concrete utilizing graphite tailings resources. Constr. Build. Mater. 2024, 438, 137102. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).