Towards a Low-Carbon Future: Evaluating 3D Printing’s Alignment with Sustainable Development Goal 13

Abstract

1. Introduction

1.1. Overview of Sustainable Development Goals

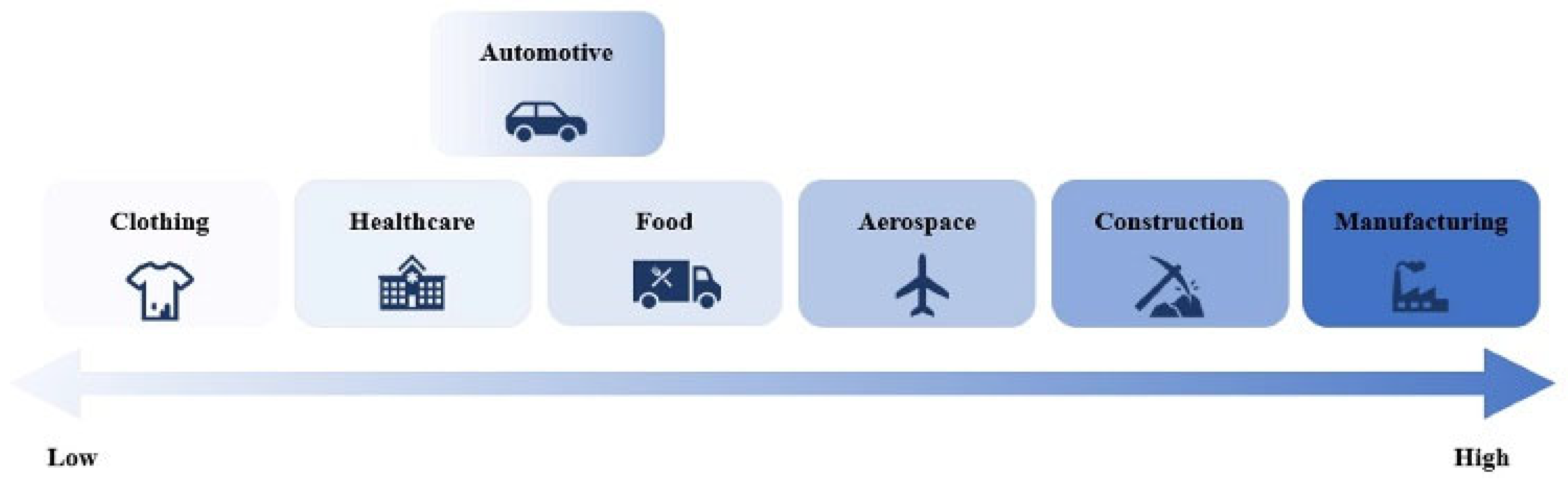

1.2. Integration of SDGs and 3D Printing in Previous Literature

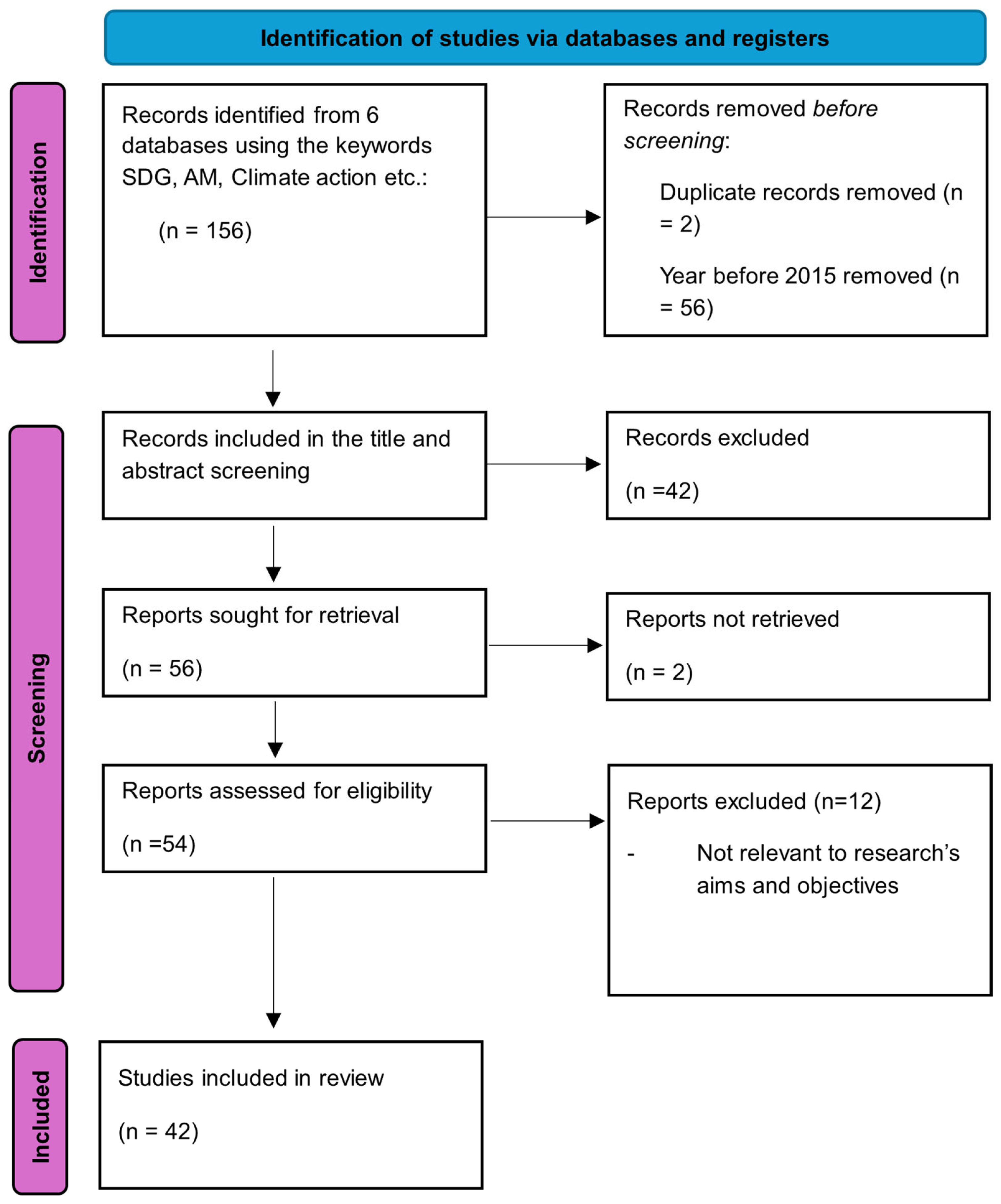

2. Methodology

2.1. Search and Data Collection

2.2. Eligibility for Inclusion and Exclusion of Studies

- Studies after the year 2015;

- Studies that looked at correlating SDGs with additive manufacturing;

- Studies pointing out the technological, economic, social and environmental advancements in AM;

- Studies that addressed 3D printing as a means to combat climate action;

- Case studies that demonstrated the viability of AM towards achieving SDGs;

- Publications available in full-text format.

- Papers that did not address any target or subtargets of SDG 13 through 3D printing;

- Papers without any quantifiable data;

- Papers that did not meet the aims and objectives of this study;

- Studies not available in full-text format.

2.3. Descriptive Analysis of Included Studies

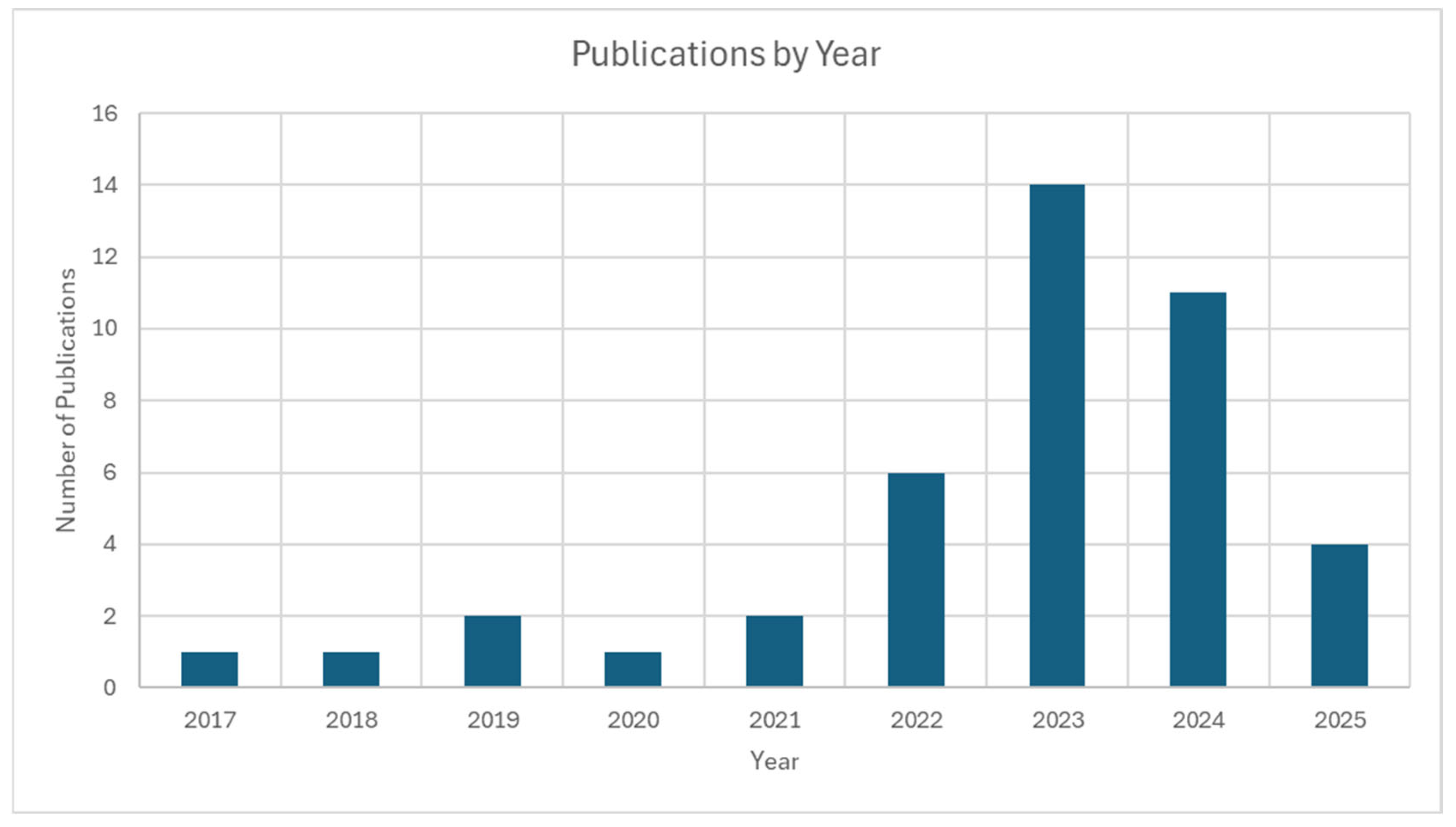

2.3.1. Publication by Year

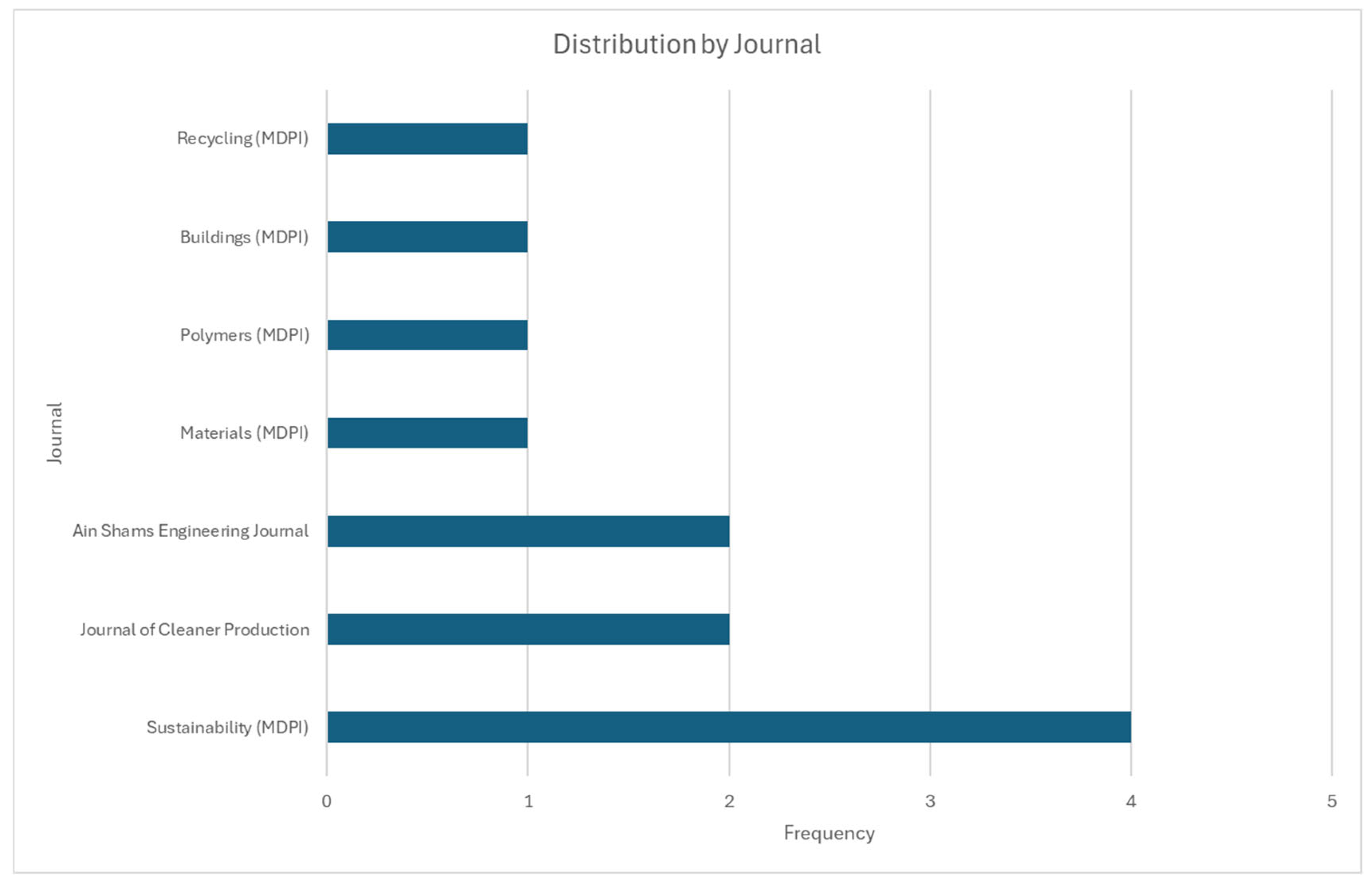

2.3.2. Distribution of Research Journals

2.4. Data Analysis Techniques and Framework

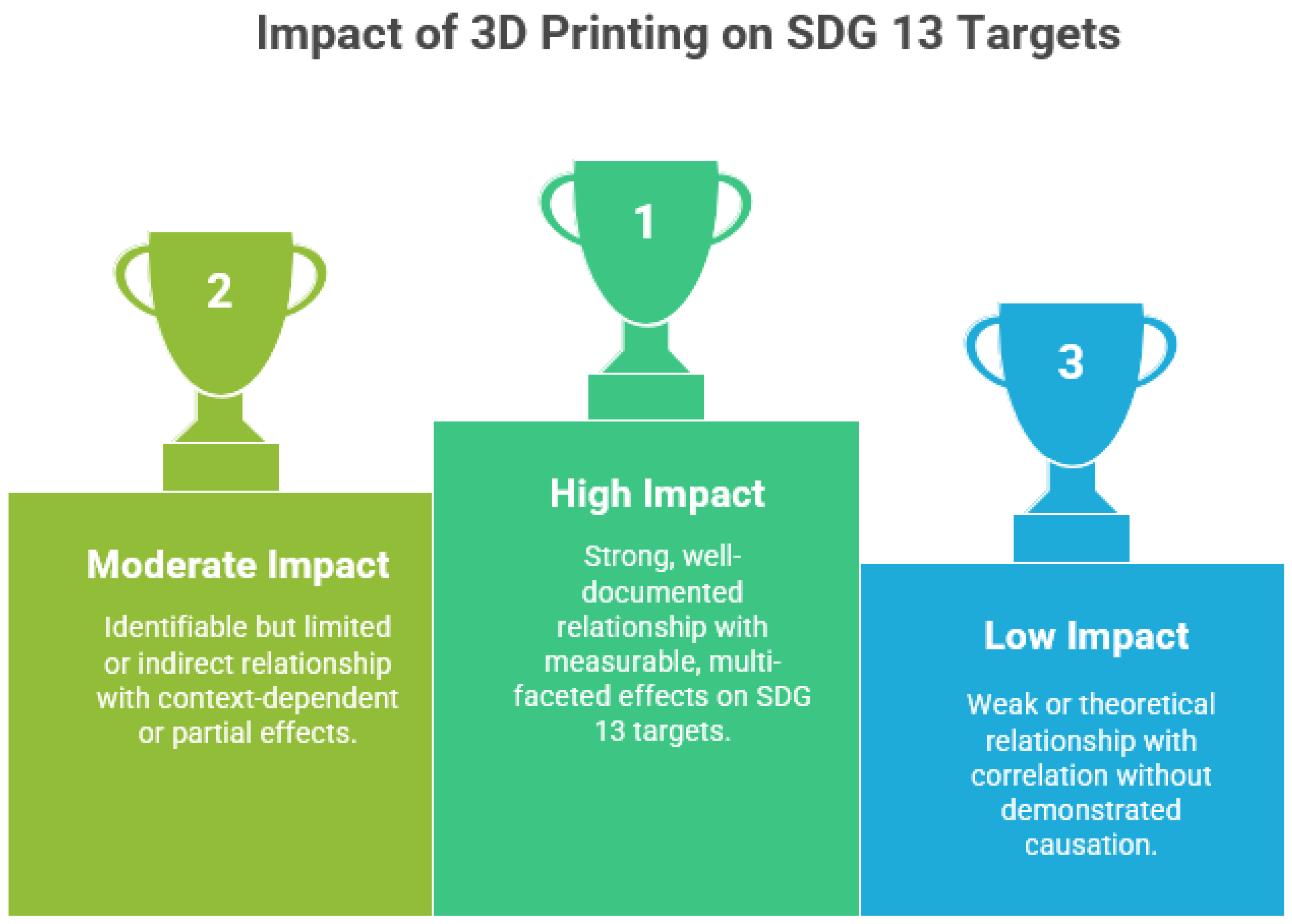

- a.

- High Impact: There is a significant relationship between SDG 13 and 3D printing, which is backed up through multiple studies. The effects of 3D printing on SDG 13 demonstrate measurable effects and are seen to influence at least two subcategories of SDG 13.

- ○

- Strong, well-documented relationship. The category corresponds where multiple studies provide robust evidence demonstrating that 3D printing directly contributes to achieving specific targets under SDG 13.

- ○

- Measurable, multi-faceted effects. The positive impact is quantifiable (e.g., reduced greenhouse gas (GHG) emissions and enhanced resilience) and influences at least two distinct aspects of SDG 13 targets.

- b.

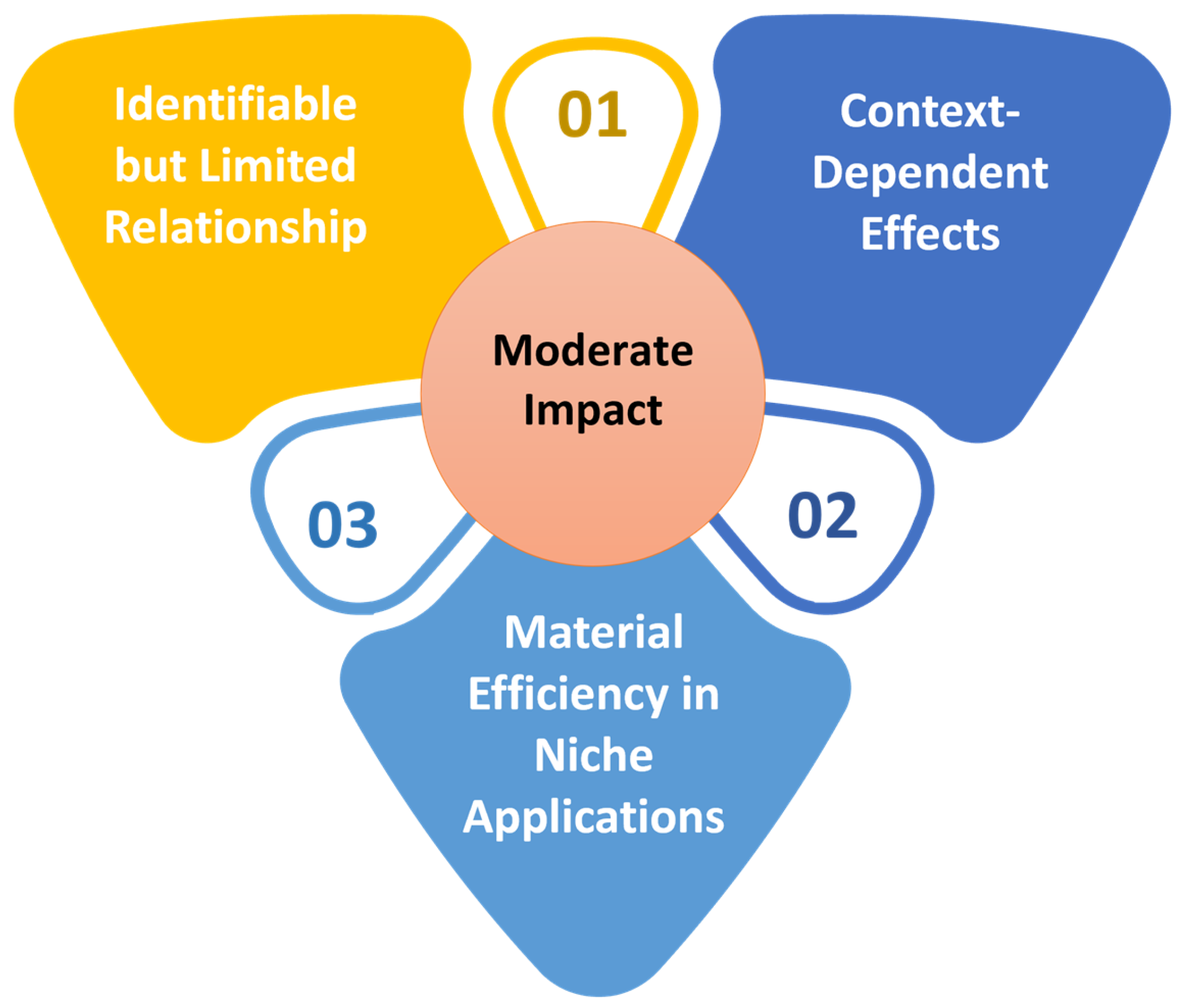

- Moderate Impact: In this category, the relationship between SDG 13 and 3D printing is not substantial and only has a relative effect when looked at from a narrower domain.

- ○

- Identifiable but limited or indirect relationship. Evidence suggests a potential link or indirect contribution of 3D printing to SDG 13.

- ○

- Context-dependent or partial effects. The positive impact is observed primarily in specific applications, sectors or under certain conditions. The evidence may be less comprehensive or more theoretical.

- c.

- Low Impact: Here, there is no direct cause–effect relationship between the two. However, correlation is observed in certain domains.

- ○

- Weak or theoretical relationship. A plausible connection exists based on general principles, but there is little to no empirical evidence directly linking 3D printing practices to progress on SDG 13 targets.

- ○

- Correlation without demonstrated causation. Observations might align with SDG 13 goals, but no studies demonstrate 3D printing as a cause of climate action outcomes.

3. Analysis and Discussion

3.1. Impact of 3D Printing on SDG 13

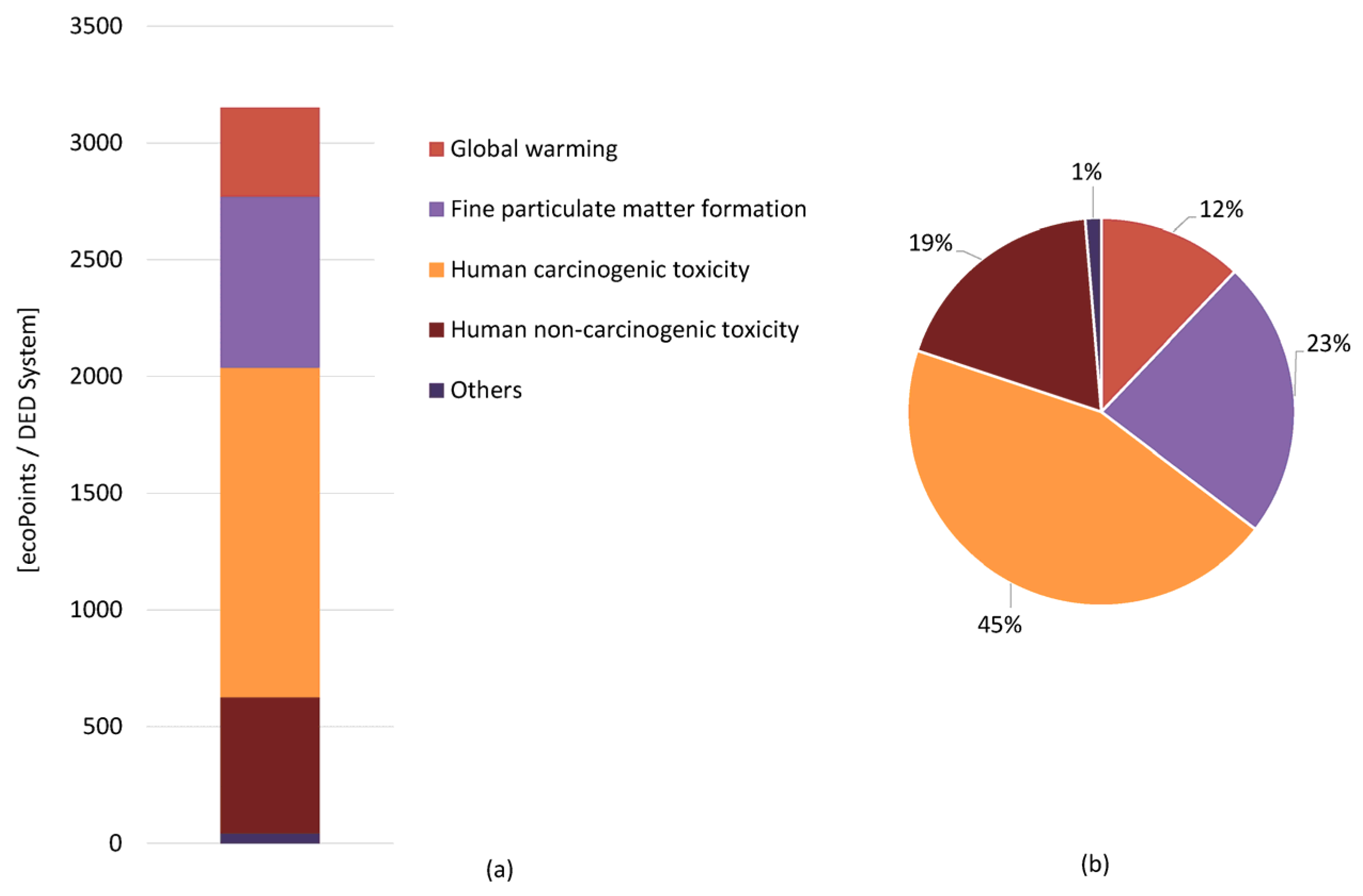

3.1.1. Reduction in GHGs Through Sustainable Additive Manufacturing

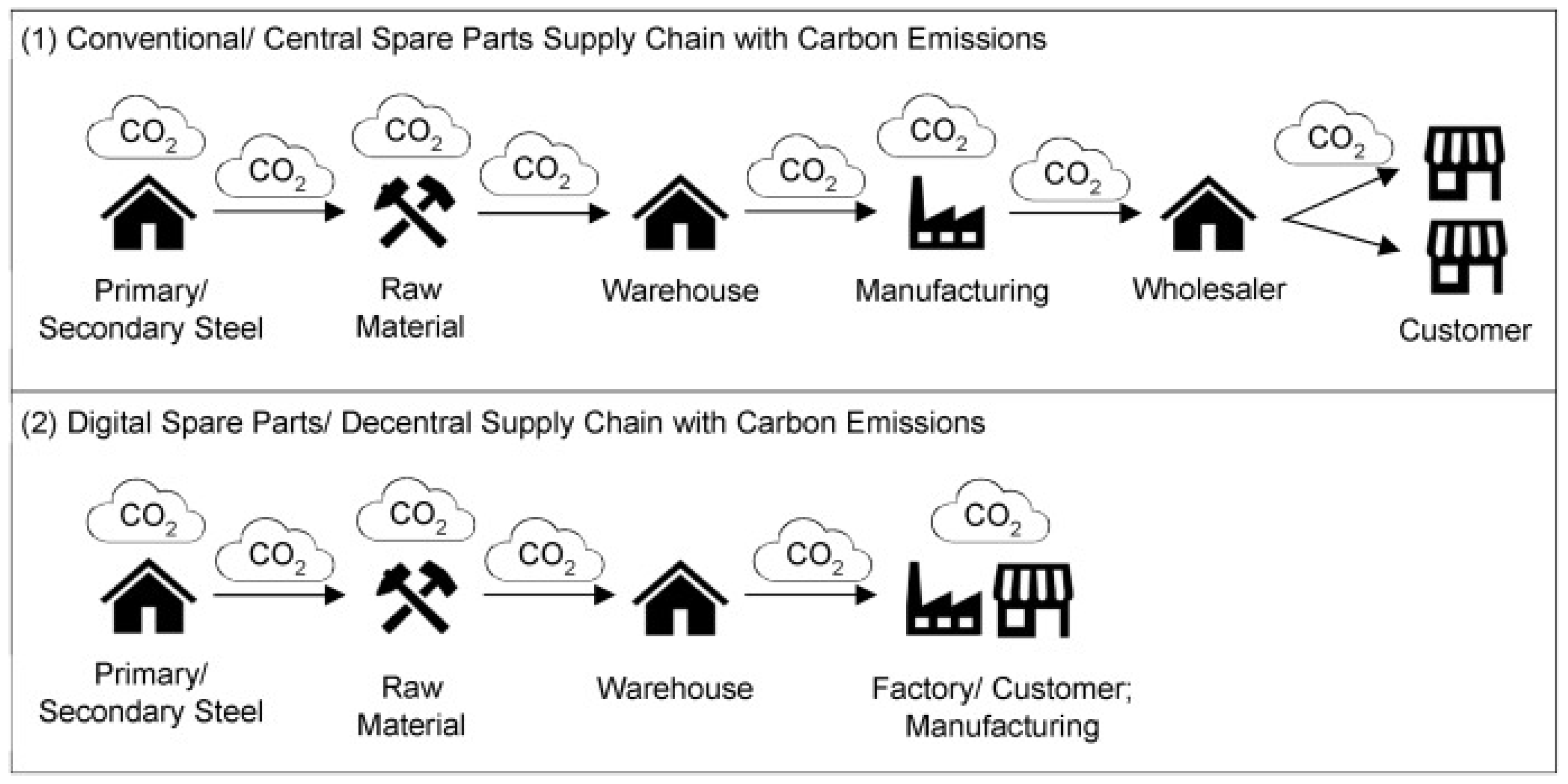

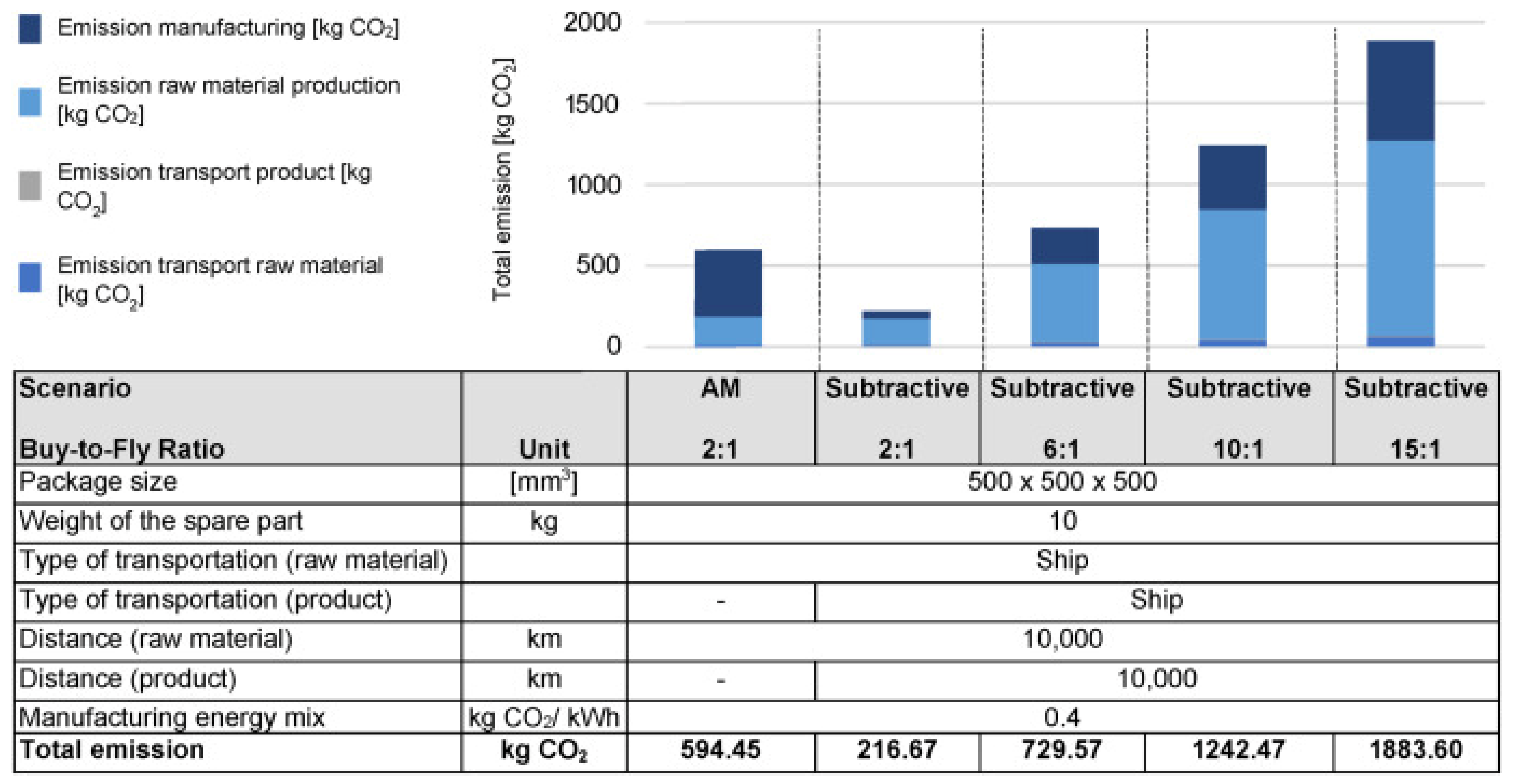

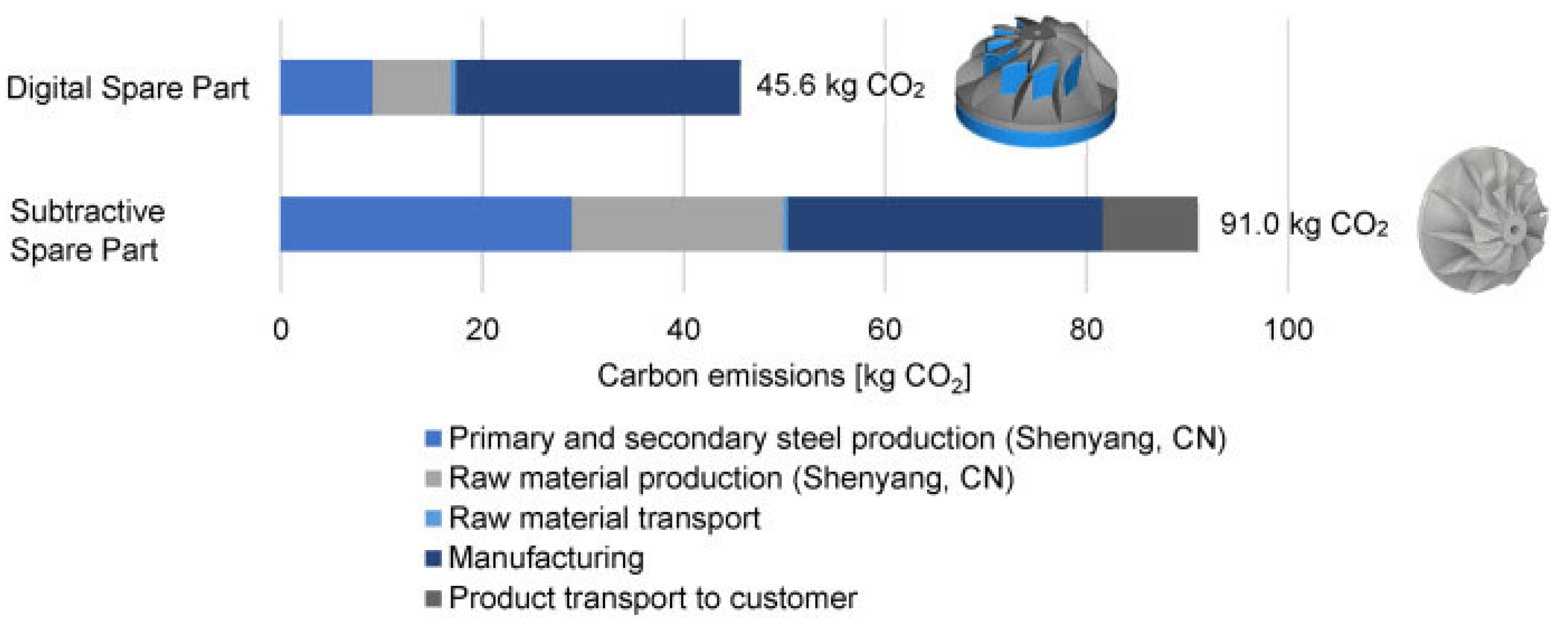

3.1.2. Localized Manufacturing and Reduced Logistics Emissions

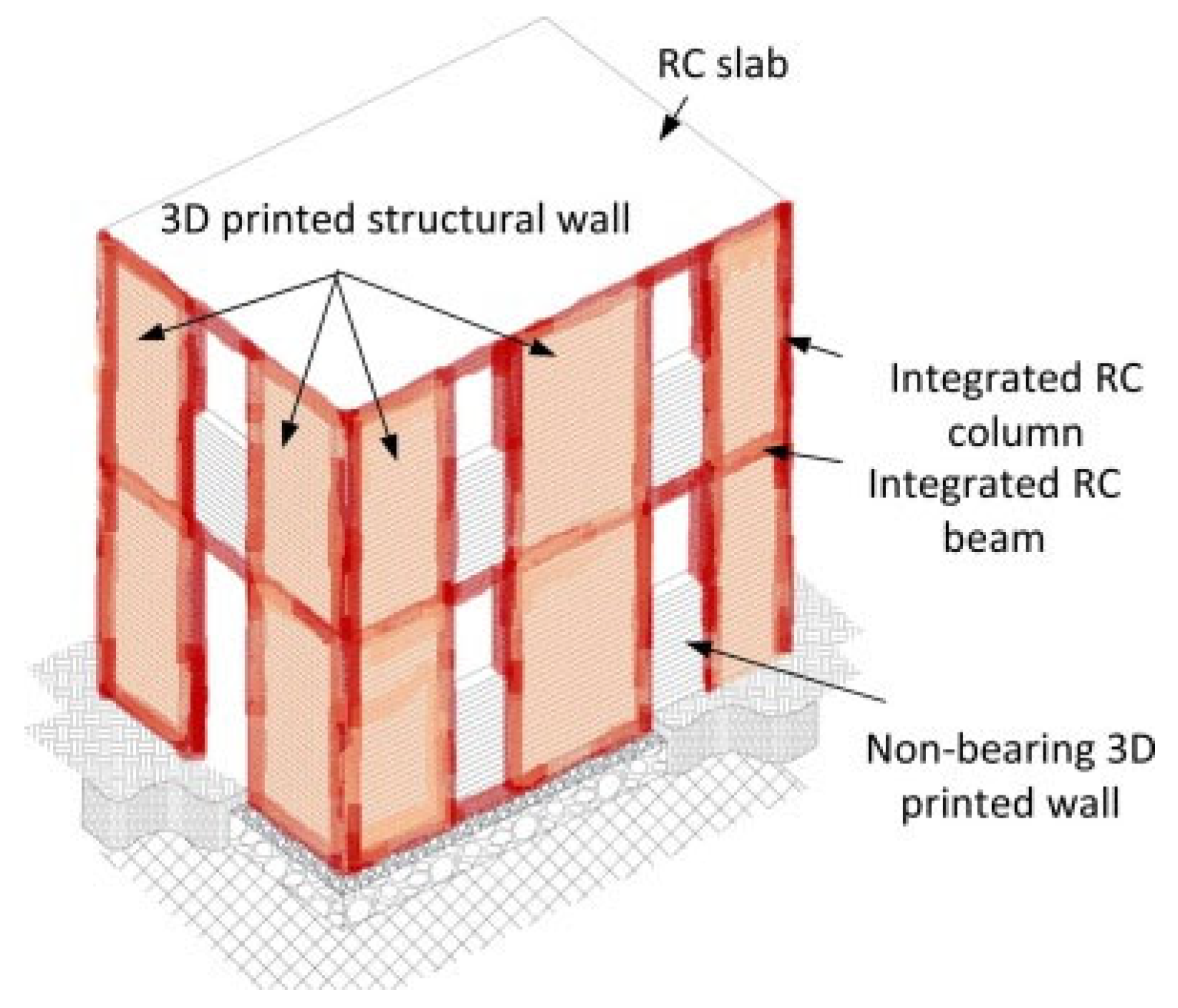

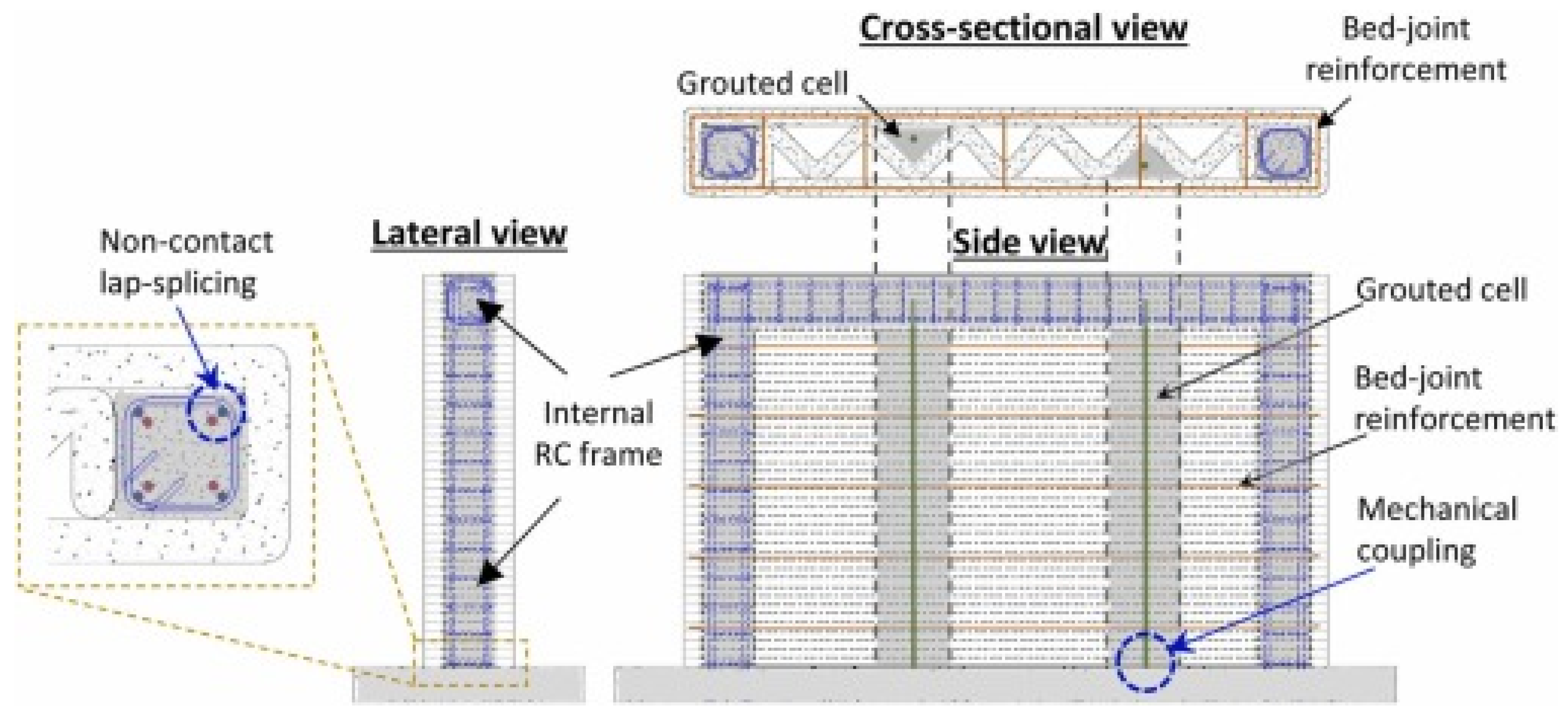

3.1.3. Resilient Infrastructure to Combat Climate-Related Hazards

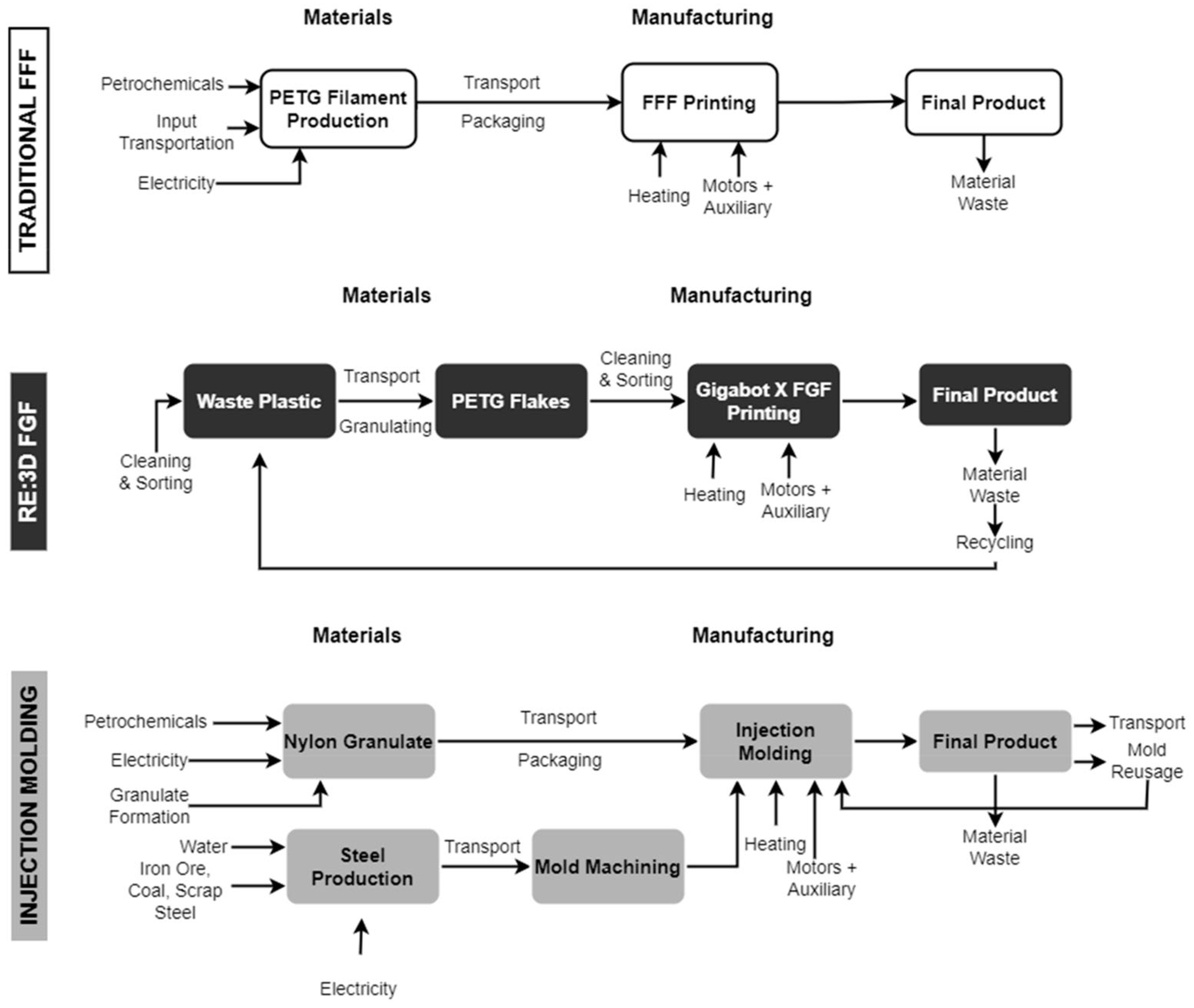

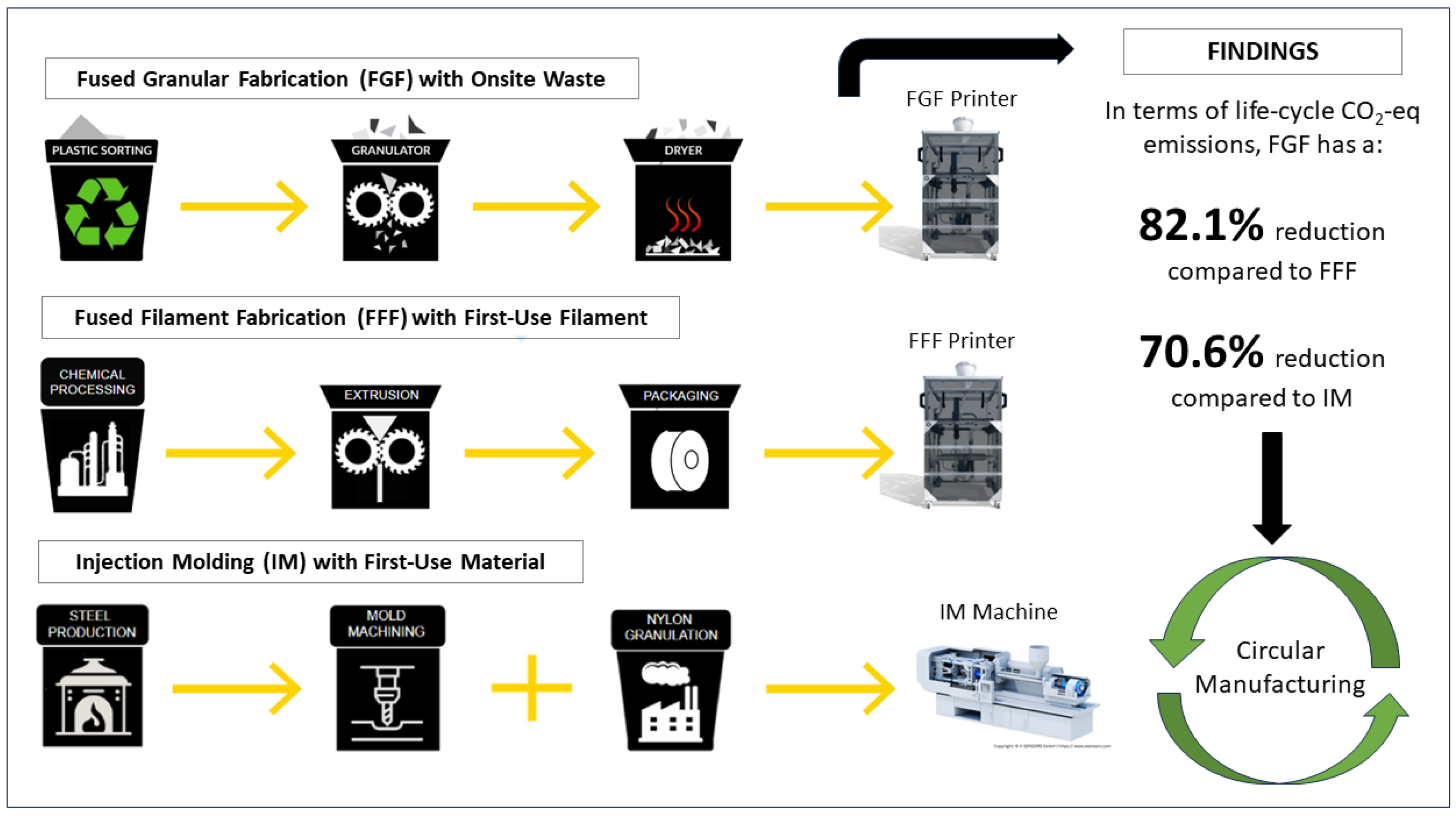

3.1.4. Circular Economy

3.1.5. Extension of Product Lifecycles

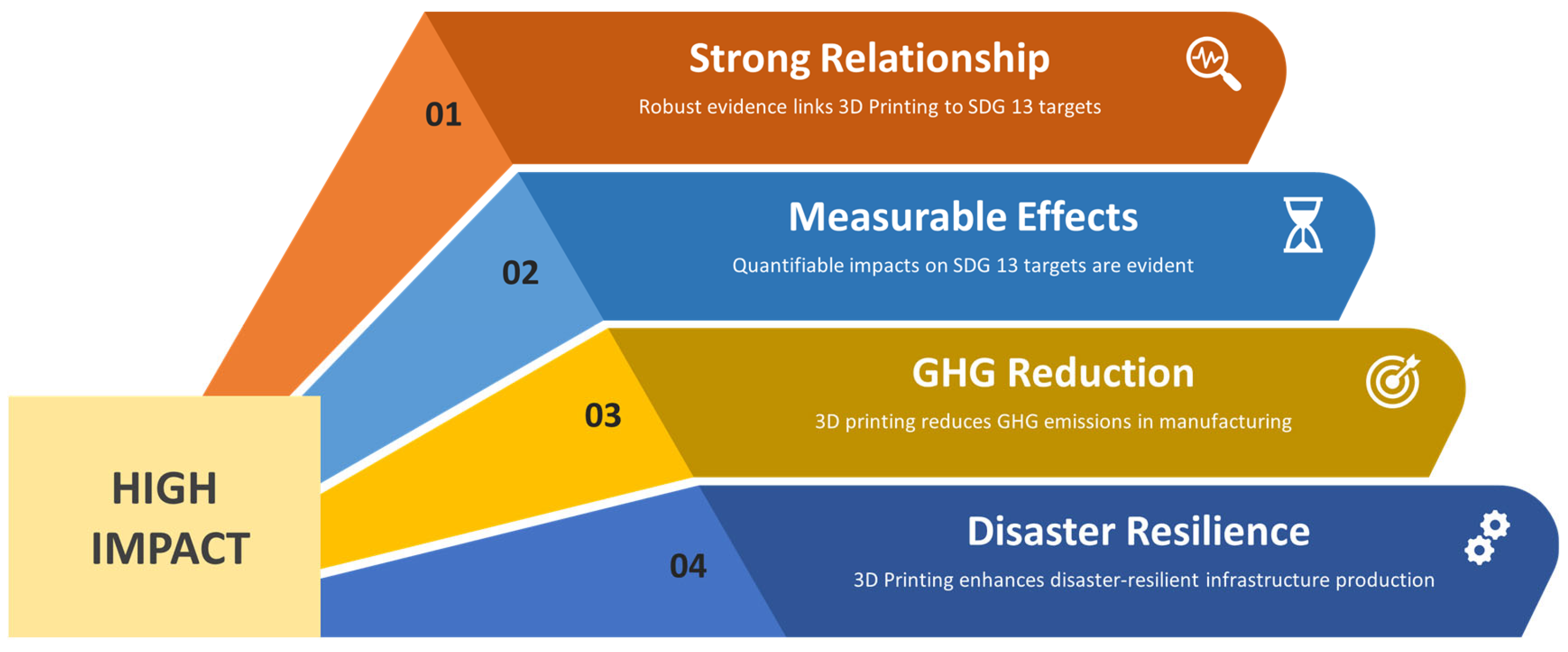

3.2. Synthesis of Findings

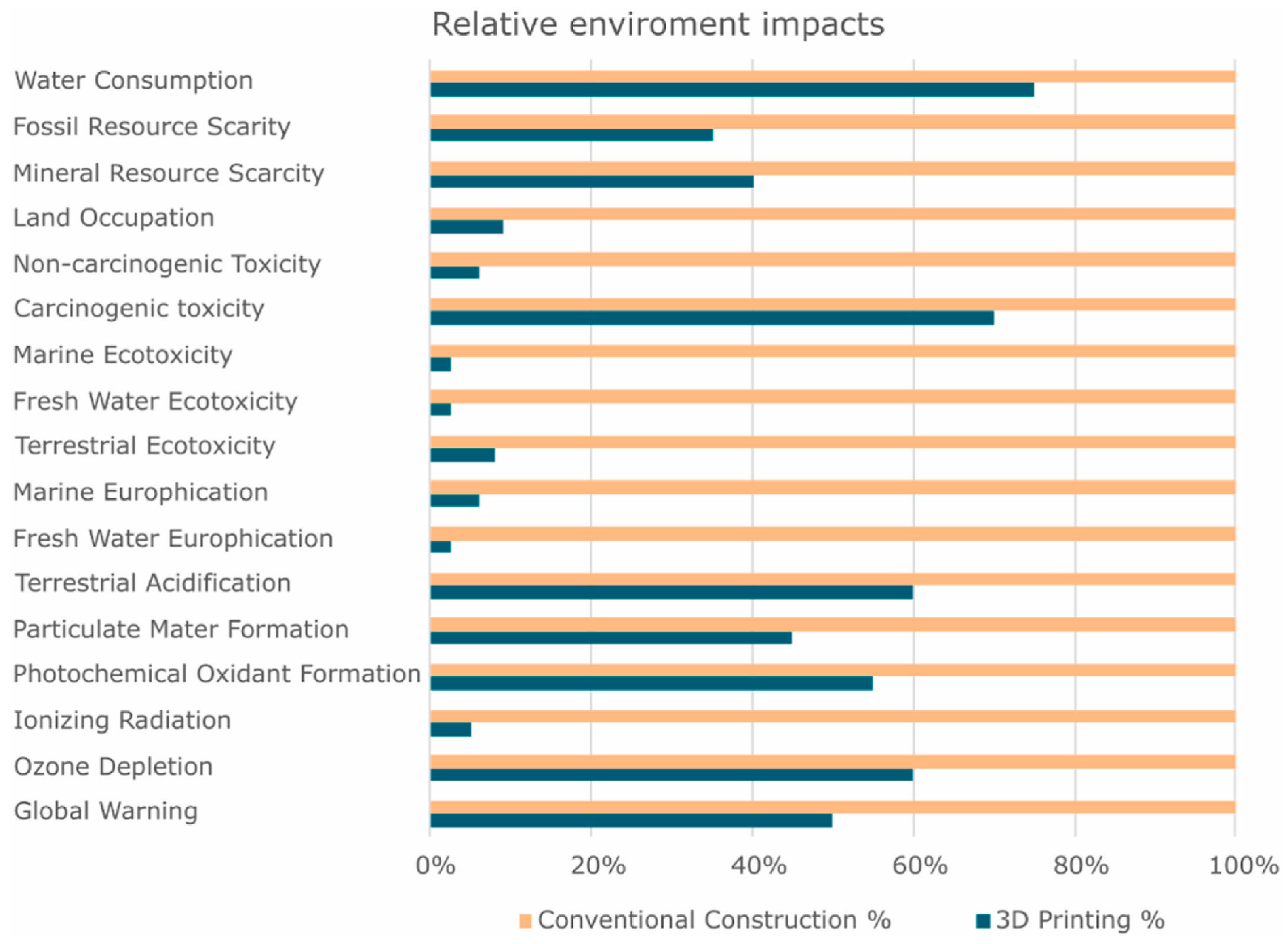

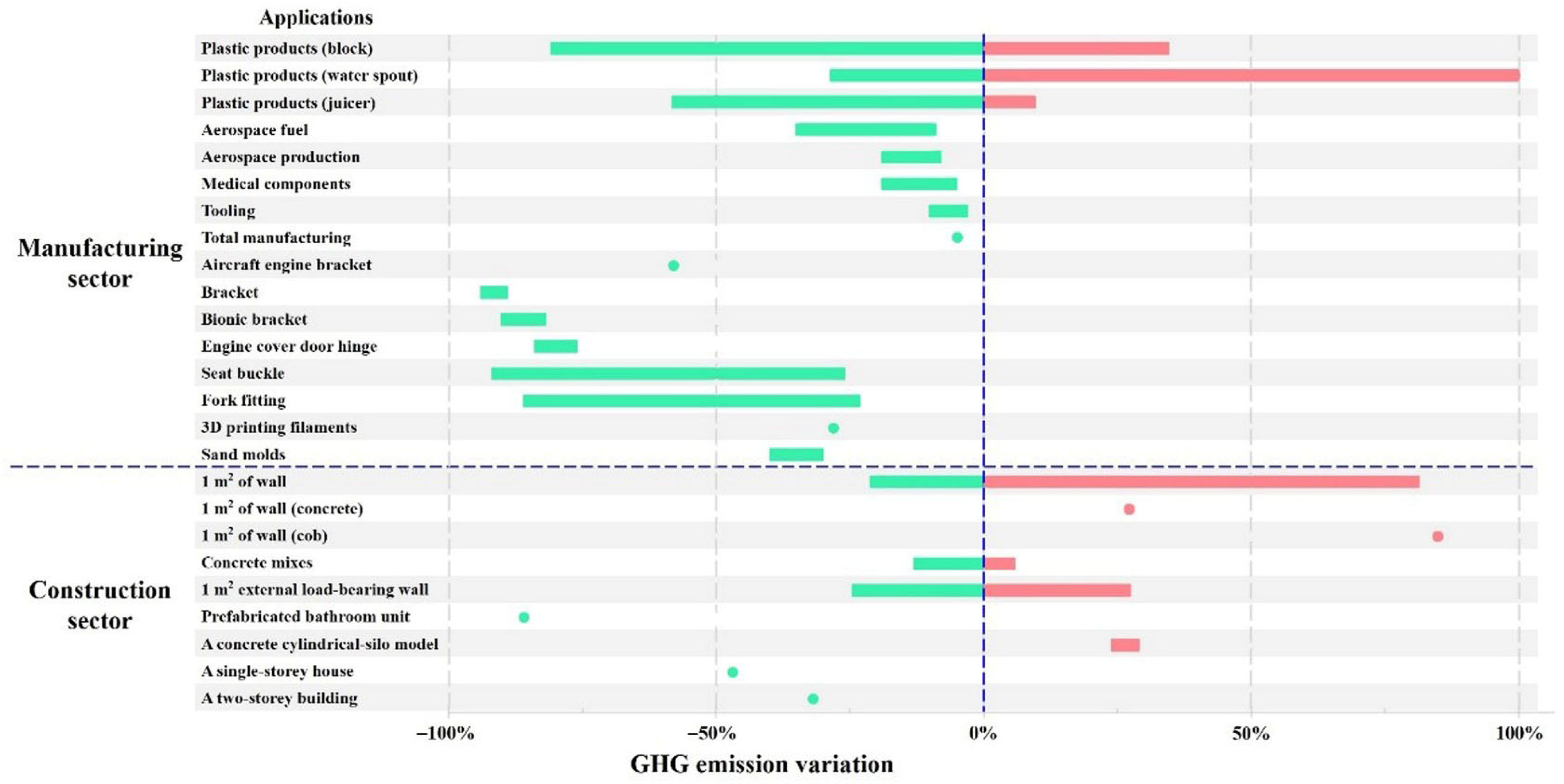

- Environmental Impact: Three-dimensional printing technology is seen to have a positive impact towards the environment through many applications. In regard to SDG 13, this technology has the potential to address issues such as GHG emissions and to support climate-resilient policies. The studies in the above sections used LCA to study the impact of 3D-printed products from “cradle-to-grave” and observed positive impacts on the environment when compared to conventional manufacturing methods.

- Socio-technical Impact: The impact that 3D printing has on the socio-technical front is seen with regard to decentralized production, aligning with SDG 13.1 and SDG 13.2. Increasing the resilience towards climate-related hazards and the implementation of such measures within policies are crucial for 3D printing to have a lasting socio-technical impact for upcoming generations. Based on these assessment markers, qualitative analysis was performed on the five above-mentioned impacts of 3D printing on SDG 13. These impacts will be categorized as low, moderate or high based on the information obtained from the existing literature. Qualitative analysis of the same was performed and is visualized in Figure 23. It can be concluded that the environmental impact is greatly affected by the reduction in GHGs through sustainable manufacturing, localized manufacturing and the circular economy. Localized manufacturing, resilient structures and the extension of product lifecycles are the factors that have a great impact on the socio-technical front. The effects of causation for each SDG 13 targets through 3D printing impacts are analyzed briefly below based on the literature analyzed.

- Reduction in GHGs through Sustainable Additive Manufacturing: Sustainable additive manufacturing was seen to have a very high environmental impact due to its direct involvement in the reduction in GHGs. The studies analyzed showed great reductions in GHG emissions when AM was used to manufacture and repair parts as opposed to using conventional methods. In fact, the CO2eq emissions that come just from material wastage in subtractive manufacturing are 1.5 tons, while the total CO2eq footprint of 3D printing is a mere 0.8 tons [33]. However, on the socio-technical front, there is only a moderate impact on the reduction in GHGs, arising from the fact that this is fairly limited to advanced sectors. Seeing the potential of AM, there is a need to translate this potential towards low-tech manufacturing sectors in the near future.

- Localized Manufacturing: Localized manufacturing or the decentralization of 3D printing technology has a high environmental and socio-technical impact on SDG 13 targets. Studies have shown that decentralizing the technology reduces GHGs that arise from logistics and transport. Moreover, this factor has a direct impact towards SDG 13.1, as it allows for quick and rapid response in strengthening the resilience to climate-related hazards, thus reducing the overreliance on global supply chains.

- Climate-Resilient Infrastructure: Use of AM to facilitate climate-resilient infrastructure has a high impact on the socio-technical impact, as it enables the rapid deployment of temporary or permanent structures in times of climate-related hazards. This positive impact is also directly related to the added advantage of localized manufacturing. However, with regard to environmental impacts, it is seen that using AM for climate-resilient infrastructure only has a moderate influence. Though AM is seen as an advanced technology to build rapid structures, the GHG savings are highly dependent on the type of core material used, structural complexity and energy use. Thus, a moderate impact is asserted, as this method still shows a reduction in GHG emissions when tested out on small-scale applications.

- Circular Economy: The environmental benefits arising from the concept of the circular economy are high, as it would facilitate lower emissions, thus directly supporting SDG 13 targets. However, as mentioned above, the literature shows that this is not easily feasible due to multiple complexities that arise within the process chains. The potential to reuse and recycle certain plastic materials is highly affected through high contamination levels, and using more iterative processes to achieve this will effectively lead to higher GHG emissions. Thus, the circular economy only demonstrates a low influence with regard to the socio-technical impact on SDG 13.

- Extension of Product Lifecycles: Three-dimensional printing’s potential to repair objects at a rapid pace with minimal material has delivered a high influence on the environmental impacts. The need to manufacture whole replacement parts for moderate damage is being eliminated through AM. Though the literature shows certain frameworks being established for repair with AM, there still needs to be more regulations and policies that facilitate a foolproof repair system through AM. Thus, the socio-technical impact is seen to be moderate in this case.

3.3. Practical Relevance and Economic Impacts for Industry

3.4. Use of Emerging Technologies in Additive Manufacturing to Support Climate Action (SDG 13)

3.5. Challenges in Implementing AM for Supporting Climate Action (SDG 13)

4. Conclusions and Future Research

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mobarak, M.H.; Islam, A.; Hossain, N.; Al Mahmud, Z.; Rayhan, T.; Nishi, N.J.; Chowdhury, M.A. Recent advances of additive manufacturing in implant fabrication—A review. Appl. Surf. Sci. Adv. 2023, 18, 100462. [Google Scholar] [CrossRef]

- BS EN ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. British Standards Institute: London, UK, 2021.

- Zhang, J.; Jung, Y.G. Additive Manufacturing: Materials, Processes, Quantifications and Applications; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Kanishka, K.; Acherjee, B. Revolutionizing manufacturing: A comprehensive overview of additive manufacturing processes, materials, developments, and challenges. J. Manuf. Process. 2023, 107, 574–619. [Google Scholar] [CrossRef]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive manufacturing processes: Selective laser melting, electron beam melting and binder jetting-selection guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [PubMed]

- Prashar, G.; Vasudev, H.; Bhuddhi, D. Additive manufacturing: Expanding 3D printing horizon in industry 4.0. Int. J. Interact. Des. Manuf. 2023, 17, 2221–2235. [Google Scholar] [CrossRef]

- Hegab, H.; Khanna, N.; Monib, N.; Salem, A. Design for sustainable additive manufacturing: A review. Sustain. Mater. Technol. 2023, 35, e00576. [Google Scholar] [CrossRef]

- Reeves, P. Additive Manufacturing—A Supply Chain Wide Response to Economic Uncertainty and Environmental Sustainability; Econolyst Ltd.: Derbyshire, UK, 2009. [Google Scholar]

- Henderson, K.; Loreau, M. A model of Sustainable Development Goals: Challenges and opportunities in promoting human well-being and environmental sustainability. Ecol. Modell. 2023, 475, 110164. [Google Scholar] [CrossRef]

- Mishra, M.; Desul, S.; Santos, C.A.G.; Mishra, S.K.; Kamal, A.H.M.; Goswami, S.; Kalumba, A.M.; Biswal, R.; da Silva, R.M.; dos Santos, C.A.C.; et al. A bibliometric analysis of sustainable development goals (SDGs): A review of progress, challenges, and opportunities. Environ. Dev. Sustain. 2024, 26, 11101–11143. [Google Scholar] [CrossRef]

- Sorooshian, S. The sustainable development goals of the United Nations: A comparative midterm research review. J. Clean. Prod. 2024, 453, 142272. [Google Scholar] [CrossRef]

- Ghosh, P.; Chakravarty, T. Sustainable Development Goals: Challenges, Opportunities, and the Way Forward; Springer: Cham, Switzerland, 2023; pp. 235–241. [Google Scholar]

- Setó-Pamies, D.; Papaoikonomou, E. Sustainable Development Goals: A Powerful Framework for Embedding Ethics, CSR, and Sustainability in Management Education. Sustainability 2020, 12, 1762. [Google Scholar] [CrossRef]

- United Nations. The 17 Goals | Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 9 September 2025).

- Yamaguchi, N.U.; Bernardino, E.G.; Ferreira, M.E.C.; de Lima, B.P.; Pascotini, M.R.; Yamaguchi, M.U. Sustainable development goals: A bibliometric analysis of literature reviews. Environ. Sci. Pollut. Res. 2023, 30, 5502–5515. [Google Scholar] [CrossRef]

- Muth, J.; Klunker, A.; Völlmecke, C. Putting 3D printing to good use—Additive Manufacturing and the Sustainable Development Goals. Front. Sustain. 2023, 4, 1196228. [Google Scholar] [CrossRef]

- Balubaid, M.; Alsaadi, N. Achieving Sustainability in Manufacturing through Additive Manufacturing: An Analysis of Its Enablers. Sustainability 2023, 15, 9504. [Google Scholar] [CrossRef]

- Alami, A.H.; Olabi, A.G.; Alashkar, A.; Alasad, S.; Aljaghoub, H.; Rezk, H.; Abdelkareem, M.A. Additive manufacturing in the aerospace and automotive industries: Recent trends and role in achieving sustainable development goals. Ain Shams Eng. J. 2023, 14, 102516. [Google Scholar] [CrossRef]

- Alami, A.H.; Mahmoud, M.; Aljaghoub, H.; Mdallal, A.; Abdelkareem, M.A.; Kamarudin, S.K.; Olabi, A.G. Progress in 3D printing in wind energy and its role in achieving sustainability. Int. J. Thermofluids 2023, 20, 100496. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Hasaballah, M.; Pervaiz, S. An Exploration of 3D Printing’s Contribution to Responsible Consumption and Production (SDG 12). In Proceedings of the ASME 2024 International Mechanical Engineering Congress and Exposition, Portland, OR, USA, 17–21 November 2024. [Google Scholar] [CrossRef]

- United Nations. SDG 13 Indicators. 2021. Available online: https://unstats.un.org/sdgs/report/2021/goal-13/ (accessed on 10 June 2025).

- Küfeoğlu, S. SDG-13: Climate Action; Springer: Cham, Switzerland, 2022; pp. 429–451. [Google Scholar]

- Alami, A.H.; Olabi, A.G.; Khuri, S.; Aljaghoub, H.; Alasad, S.; Ramadan, M.; Abdelkareem, M.A. 3D printing in the food industry: Recent progress and role in achieving sustainable development goals. Ain Shams Eng. J. 2024, 15, 102386. [Google Scholar] [CrossRef]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development | Department of Economic and Social Affairs. 2015. Available online: https://sdgs.un.org/publications/transforming-our-world-2030-agenda-sustainable-development-17981 (accessed on 11 June 2025).

- Belkhir, L.; Elmeligi, A. Carbon footprint of the global pharmaceutical industry and relative impact of its major players. J. Clean. Prod. 2019, 214, 185–194. [Google Scholar] [CrossRef]

- Achleitner, L.; Frank, A.-C.; Mesef, O.; Satzer, P. The future of single-use plastics in life science: Sterile printing of PLA reduces greenhouse gas emissions by 80% and enables carbon neutrality. Green Technol. Sustain. 2025, 3, 100132. [Google Scholar] [CrossRef]

- London, M.B.; Lewis, G.M.; Keoleian, G.A. Life Cycle Greenhouse Gas Implications of Multi Jet Fusion Additive Manufacturing. ACS Sustain. Chem. Eng. 2020, 8, 15595–15602. [Google Scholar] [CrossRef]

- Oladunni, O.J.; Lee, C.K.M.; Ibrahim, I.D.; Olanrewaju, O.A. Advances in sustainable additive manufacturing: A systematic review for construction industry to mitigate greenhouse gas emissions. Front. Built Environ. 2025, 11, 1535626. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, T.; Guo, X.; Ling, D.; Hu, L.; Jiang, G. The potential of 3D printing in facilitating carbon neutrality. J. Environ. Sci. 2023, 130, 85–91. [Google Scholar] [CrossRef]

- The National. 3D-printed ‘green’ villa in Sharjah cuts building and maintenance costs. The National, 4 December 2021. [Google Scholar]

- Flor-Unda, O.; Toapanta, C.; Fuentes, M.; Rivera, M. Additive manufacturing Technologies: Advances for the construction industry. Heliyon 2025, 11, e43568. [Google Scholar] [CrossRef]

- Dzogbewu, T.C.; de Beer, D.J. The role of PGMs in decarbonizing the atmosphere: Additive manufacturing in perspective. Manuf. Rev. 2024, 11, 16. [Google Scholar] [CrossRef]

- Saltagianni, N.; Lagodimos, A.; Chountalas, P.; Georgakellos, D. 3D Printing Technologies for Enhancing Sustainability in Supply Chains. Qual. Success 2025, 26, 23–33. [Google Scholar] [CrossRef]

- Woldesilassiea, T.L.; Lemu, H.G.; Gutema, E.M. Impacts of Adopting Additive Manufacturing Process on Supply Chain: Systematic Literature Review. Logistics 2024, 8, 3. [Google Scholar] [CrossRef]

- Rupp, M.; Buck, M.; Klink, R.; Merkel, M.; Harrison, D.K. Additive manufacturing of steel for digital spare parts—A perspective on carbon emissions for decentral production. Clean. Environ. Syst. 2022, 4, 100069. [Google Scholar] [CrossRef]

- ADNOC. ADNOC Gas Using 3D Printing to Manufacture Critical Replacement Components on Demand—Gas. 9 October 2024. Available online: https://www.adnocgas.ae/en/news-and-media/press-releases/2024/adnoc-gas-using-3d-printing (accessed on 7 September 2025).

- Zawya. 3DXB Group welcomes 2025 with renewed commitment to sustainable construction. Informed Infrastructure, 25 January 2025. [Google Scholar]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Leveraging 3D Printing for Resilient Disaster Management in Smart Cities. Smart Cities 2024, 7, 3705–3726. [Google Scholar] [CrossRef]

- NYCEDC. Industrial and Manufacturing. Available online: https://edc.nyc/industry/industrial-and-manufacturing (accessed on 13 June 2025).

- Subramanya, K.; Kermanshachi, S. Exploring Utilization of the 3D Printed Housing as Post-Disaster Temporary Shelter for Displaced People. In Construction Research Congress; American Society of Civil Engineers: Reston, VA, USA, 2022; pp. 594–605. [Google Scholar] [CrossRef]

- Alim Khan, S.; Al Rashid, A.; Muhammad, J.; Ali, F.; Koc, M. 3D Printing Technology for Rapid Response to Climate Change: Challenges and Emergency Needs. Intell. Sustain. Manuf. 2024, 1, 10004. [Google Scholar] [CrossRef]

- Dörrie, R.; Laghi, V.; Arrè, L.; Kienbaum, G.; Babovic, N.; Hack, N.; Kloft, H. Combined Additive Manufacturing Techniques for Adaptive Coastline Protection Structures. Buildings 2022, 12, 1806. [Google Scholar] [CrossRef]

- Florida International University. Researchers Are Testing a Textured Seawall Designed to Hold Back Water and Create a Home for Marine Organisms | FIU News—Florida International University. 16 April 2025. Available online: https://news.fiu.edu/2025/miami-researchers-are-testing-a-textured-seawall-designed-to-hold-back-water-and-create-a-home-for-marine-organisms (accessed on 7 September 2025).

- Aghajani Delavar, M.; Chen, H.; Sideris, P. Analysis and design of 3D printed reinforced concrete walls under in-plane quasi-static loading. Eng. Struct. 2024, 303, 117535. [Google Scholar] [CrossRef]

- Zhu, C.; Li, T.; Mohideen, M.M.; Hu, P.; Gupta, R.; Ramakrishna, S.; Liu, Y. Realization of circular economy of 3D printed plastics: A review. Polymers 2021, 13, 744. [Google Scholar] [CrossRef]

- Bilal, E.; Glazer, Y.R.; Sassaman, D.M.; Seepersad, C.C.; Webber, M.E. Circularity: Understanding the Environmental Tradeoffs of Additive Manufacturing with Waste Plastics. Recycling 2024, 9, 72. [Google Scholar] [CrossRef]

- Chowdhury, H. Circular Economy Integration in Additive Manufacturing. Preprints, 2023. [Google Scholar] [CrossRef]

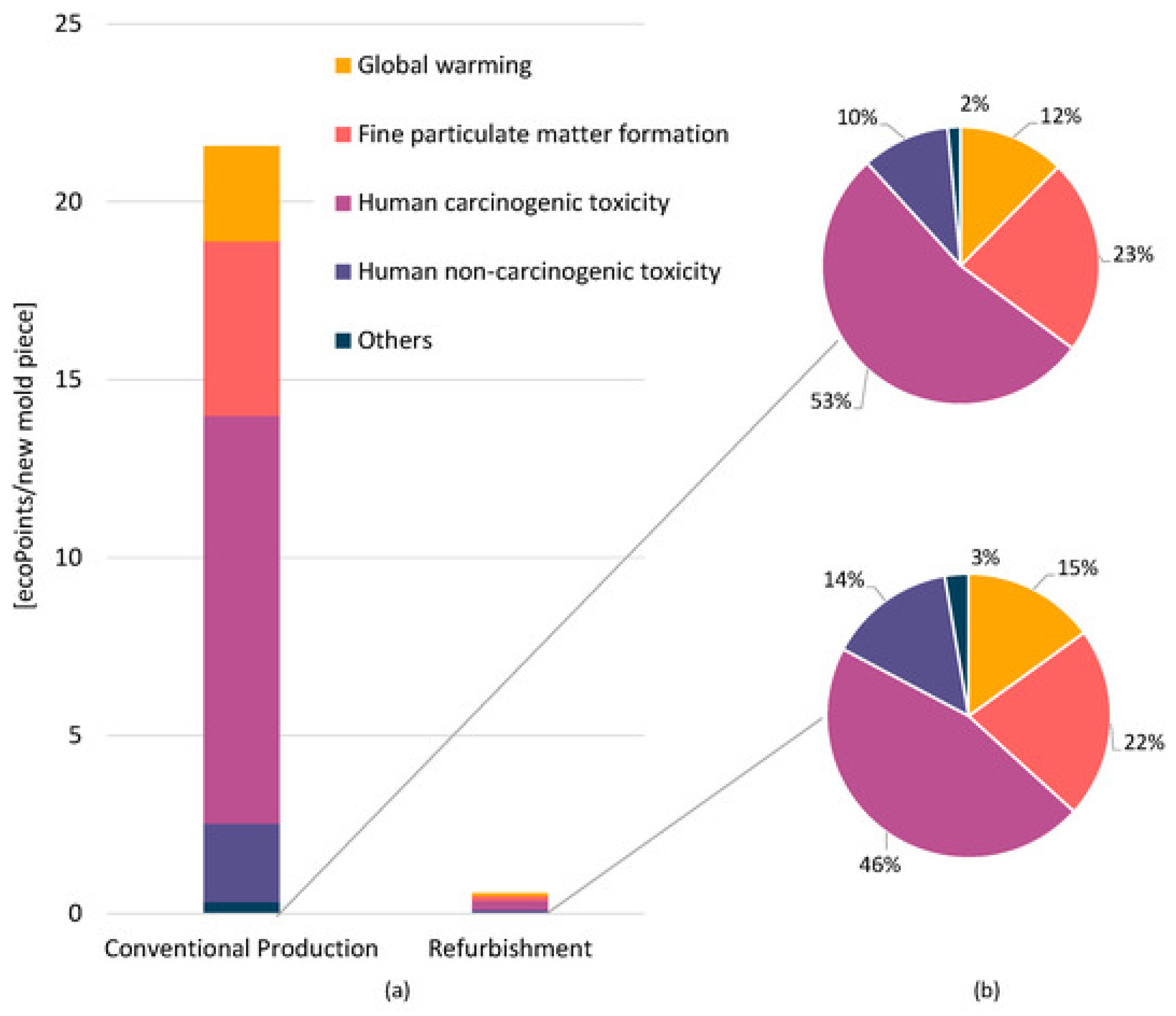

- Gouveia, J.R.; Pinto, S.M.; Campos, S.; Matos, J.R.; Sobral, J.; Esteves, S.; Oliveira, L. Life Cycle Assessment and Cost Analysis of Additive Manufacturing Repair Processes in the Mold Industry. Sustainability 2022, 14, 2105. [Google Scholar] [CrossRef]

- Gouveia, J.R.; Pinto, S.M.; Campos, S.; Matos, J.R.; Costa, C.; Dutra, T.A.; Esteves, S.; Oliveira, L. Life Cycle Assessment of a Circularity Case Study Using Additive Manufacturing. Sustainability 2022, 14, 9557. [Google Scholar] [CrossRef]

- Kim, H.; Cha, M.; Kim, B.C.; Lee, I.; Mun, D. Maintenance Framework for Repairing Partially Damaged Parts Using 3D Printing. Int. J. Precis. Eng. Manuf. 2019, 20, 1451–1464. [Google Scholar] [CrossRef]

- Prasad, G.; Arunav, H.; Dwight, S.; Ghosh, M.B.; Jayadev, A.; Nair, D.I. Advancing Sustainable Practices in Additive Manufacturing: A Comprehensive Review on Material Waste Recyclability. Sustainability 2024, 16, 10246. [Google Scholar] [CrossRef]

- Peron, M.; Panza, L.; Demiralay, E.; Talluri, S. Additive Manufacturing for Spare Parts Management: Is Decentralized Production Always Environmentally Preferable? IEEE Trans. Eng. Manag. 2025, 72, 634–650. [Google Scholar] [CrossRef]

- Abdalla, H.; Fattah, K.P.; Abdallah, M.; Tamimi, A.K. Environmental Footprint and Economics of a Full-Scale 3D-Printed House. Sustainability 2021, 13, 11978. [Google Scholar] [CrossRef]

- Dias, M.; Pragana, J.P.M.; Ferreira, B.; Ribeiro, I.; Silva, C.M.A. Economic and Environmental Potential of Wire-Arc Additive Manufacturing. Sustainability 2022, 14, 5197. [Google Scholar] [CrossRef]

- Singh, N.; Colangelo, F.; Farina, I. Sustainable Non-Conventional Concrete 3D Printing—A Review. Sustainability 2023, 15, 10121. [Google Scholar] [CrossRef]

- Mohammad, M.; Masad, E.; Al-Ghamdi, S.G. 3D Concrete Printing Sustainability: A Comparative Life Cycle Assessment of Four Construction Method Scenarios. Buildings 2020, 10, 245. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Ruan, S.; Wong, T.N.; Tan, M.J.; Yeong, K.L.O.; Qian, S. Comparative economic, environmental and productivity assessment of a concrete bathroom unit fabricated through 3D printing and a precast approach. J. Clean. Prod. 2020, 261, 121245. [Google Scholar] [CrossRef]

- Shehbaz, W.; Peng, Q. Evaluation of Machine Learning Models for Enhancing Sustainability in Additive Manufacturing. Technologies 2025, 13, 228. [Google Scholar] [CrossRef]

- Khan, I.; Al Rashid, A.; Koç, M. Integration of machine learning and digital twin in additive manufacturing of polymeric-based materials and products. Prog. Addit. Manuf. 2025, 1–53. [Google Scholar] [CrossRef]

- Rojek, I.; Kopowski, J.; Lewandowski, J.; Mikołajewski, D. Use of Machine Learning to Improve Additive Manufacturing Processes. Appl. Sci. 2024, 14, 6730. [Google Scholar] [CrossRef]

- John, J.S.; Pervaiz, S. Structural Integrity Assessment of Stainless Steel Fabricated by GMAW-Assisted Wire Arc Additive Manufacturing. Technologies 2025, 13, 392. [Google Scholar] [CrossRef]

- Liu, W.; Liu, X.; Liu, Y.; Wang, J.; Evans, S.; Yang, M. Unpacking Additive Manufacturing Challenges and Opportunities in Moving towards Sustainability: An Exploratory Study. Sustainability 2023, 15, 3827. [Google Scholar] [CrossRef]

- Arteaga Irene, Y.J.; Chan, W.K.V. Additive Manufacturing Global Challenges in the Industry 4.0 Era; Springer: Cham, Switzerland, 2021; pp. 316–336. [Google Scholar]

- Kawalkar, R.; Dubey, H.K.; Lokhande, S.P. A review for advancements in standardization for additive manufacturing. Mater. Today Proc. 2022, 50, 1983–1990. [Google Scholar] [CrossRef]

- Ďurfina, M.; Babaei, N.; Vanovčanová, Z.; Feranc, J.; Horváth, V.; Vašková, I.; Kruželák, J.; Tomanová, K.; Plavec, R. Bio-Based Polyhydroxyalkanoate (PHA) Blends for 3D Printing: Rheological, Mechanical, Biocompatibility, and Biodegradation Properties. Polymers 2025, 17, 1477. [Google Scholar] [CrossRef]

- Tănase, M.; Portoacă, A.I.; Diniță, A.; Brănoiu, G.; Zamfir, F.; Sirbu, E.-E.; Călin, C. Optimizing Mechanical Properties of Recycled 3D-Printed PLA Parts for Sustainable Packaging Solutions Using Experimental Analysis and Machine Learning. Polymers 2024, 16, 3268. [Google Scholar] [CrossRef]

- Goal 13: Climate Action—The Global Goals. Available online: https://www.globalgoals.org/goals/13-climate-action/ (accessed on 14 June 2025).

| SDG Number | Sustainable Development Goal | Main Target |

|---|---|---|

| 1 | No Poverty | End poverty in all its forms everywhere |

| 2 | Zero Hunger | End hunger while achieving food security and promoting sustainable agriculture |

| 3 | Good Health and Well-being | Ensure healthy lives and promote well-being for all at all ages |

| 4 | Quality Education | Ensure inclusive and equitable quality education and promote lifelong learning opportunities for all |

| 5 | Gender Equality | Achieve gender equality and empower all women and girls |

| 6 | Clean Water and Sanitation | Ensure availability and sustainable management of water and sanitation for all |

| 7 | Affordable and Clean Energy | Ensure access to affordable, reliable and modern energy for all |

| 8 | Decent Work and Economic Growth | Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all |

| 9 | Industry, Innovation and Infrastructure | Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation |

| 10 | Reduced Inequalities | Reduce inequality within and among countries |

| 11 | Sustainable Cities and Communities | Make cities and human settlements inclusive, safe, resilient and sustainable |

| 12 | Responsible Consumption and Production | Ensure sustainable consumption and production patterns |

| 13 | Climate Action | Take urgent action to combat climate change and its impacts |

| 14 | Life Below Water | Conserve and sustainably use the oceans, seas and marine resources for sustainable development |

| 15 | Life on Land | Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification and halt and reverse land degradation and halt biodiversity loss |

| 16 | Peace, Justice and Strong Institutions | Promote peaceful and inclusive societies for sustainable development, provide access to justice for all and build effective, accountable and inclusive institutions at all levels |

| 17 | Partnership for the Goals | Strengthen the means of implementation and revitalize the Global Partnership for Sustainable Development |

| 3D Printing Technology | Key Finding | SDG 13 Impact |

|---|---|---|

| Material Jet Fusion (MJF) [28] | LCD controller made through the injection molding process resulted in 244–460 kg of CO2eq emissions, as it also considers the emissions resulting from required tooling production. On the other hand, the same product made through the MJF process resulted in 27.4 kg of CO2eq emissions. | Lower GHG emissions. Energy efficient at medium production volumes. |

| Directed Energy Deposition (DED) [49,50] | This technology can be used for repairing small-scale damages rather than replacing the part. | Extends the lifecycle of the part. GHG emissions associated with replacement part manufacturing are eliminated. |

| 3D Concrete Printing [29] | Used for constructing buildings at a rapid pace. | Rapidly build resilient infrastructure in times of climate-related hazards and natural disasters. Lower material wastage. |

| Study/Source | Practical Implication | Breakthrough in Comparison with Traditional Manufacturing Methods |

|---|---|---|

| Ref. [29] Advances in sustainable additive manufacturing: a systematic review for construction industry to mitigate greenhouse gas emissions | 3D Concrete Printing | 90% reduction in material waste. GHG emission reduction of 80%. |

| Ref. [39] Leveraging 3D Printing for Resilient Disaster Management in Smart Cities | Contour Crafting | Construct buildings with robotic arms at a rapid pace. Build resilient shelters at high speeds during natural disasters. |

| Ref. [35] Impacts of Adopting Additive Manufacturing Process on Supply Chain: Systematic Literature Review | Part Assembly | Consolidating and manufacturing several components into one assembled structure will reduce GHG emissions through reduced global logistical activities. The long global logistics network can be decoupled through this technology, and the decentralized network will support shorter lead times. |

| Ref. [50] Life Cycle Assessment of a Circularity Case Study Using Additive Manufacturing | Repair of Damaged Part | There is a 98% reduction in environmental damage when DED technology is used to repair a small mold rather than manufacturing a new one using conventional production techniques. |

| Ref. [41] Exploring Utilization of the 3D Printed Housing as Post-Disaster Temporary Shelter for Displaced People | 3D Printing of Houses in Climate Induced Emergency Situations | Subramanya et al. also looked into 3DP for printing houses for people displaced from their houses during a natural disaster, and saw the potential especially with regard to its reduced build time, high safety and low transportation logistics. |

| Ref. [42] 3D Printing Technology for Rapid Response to Climate Change: Challenges and Emergency Needs | 3D Printing of Infrastructure in Climate Induced Emergency Situations | 3D printing can be used to build emergency infrastructure such as bridges to facilitate rapid mobilization. Bridges such as the Striatus bridge in Venice and Dutch bridge in Amsterdam were 3D-printed, and they demonstrated robustness during day-to-day operations. |

| [43] Combined Additive Manufacturing Techniques for Adaptive Coastline Protection Structures | Coastline Protection Structures to Combat Sea Level Rising | 3DP can be used to build coastline protection structures (CPSs) that can combat sea level rise due to climate change while preserving the aquatic ecosystem and ecology. |

| Ref. [33] The role of PGMs in decarbonizing the atmosphere: additive manufacturing in perspective | Aerospace Industry | AM for manufacturing turbine blades for Boeing 787 resulted in 80% lower carbon emissions, 50% lower noise reduction while attaining an improvement in propelling efficiency by 50%. |

| Real Life Application/Use Case Study | Additive Manufacturing Emissions | Conventional Manufacturing Emissions |

|---|---|---|

| UAE Green House [31] | 608.55 kg CO2eq | 1154.2 kg CO2eq |

| Manufacturing a Complex Pump Impeller [36] | 45.6 kg CO2eq | 91 kg CO2eq |

| Manufacturing Molds [49] | 2.62 kg CO2eq | 10.95 kg CO2eq |

| Manufacturing a Small-Scale Stool [47] | 37.4 kg CO2eq | 125.5 kg CO2eq |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

John, J.S.; Pervaiz, S. Towards a Low-Carbon Future: Evaluating 3D Printing’s Alignment with Sustainable Development Goal 13. Sustainability 2025, 17, 8837. https://doi.org/10.3390/su17198837

John JS, Pervaiz S. Towards a Low-Carbon Future: Evaluating 3D Printing’s Alignment with Sustainable Development Goal 13. Sustainability. 2025; 17(19):8837. https://doi.org/10.3390/su17198837

Chicago/Turabian StyleJohn, Joel Sam, and Salman Pervaiz. 2025. "Towards a Low-Carbon Future: Evaluating 3D Printing’s Alignment with Sustainable Development Goal 13" Sustainability 17, no. 19: 8837. https://doi.org/10.3390/su17198837

APA StyleJohn, J. S., & Pervaiz, S. (2025). Towards a Low-Carbon Future: Evaluating 3D Printing’s Alignment with Sustainable Development Goal 13. Sustainability, 17(19), 8837. https://doi.org/10.3390/su17198837