Assessment of the Post-Thermal Performance of Concrete Modified with Treated and Untreated Crumb Rubber

Abstract

1. Introduction

2. Materials and Methods

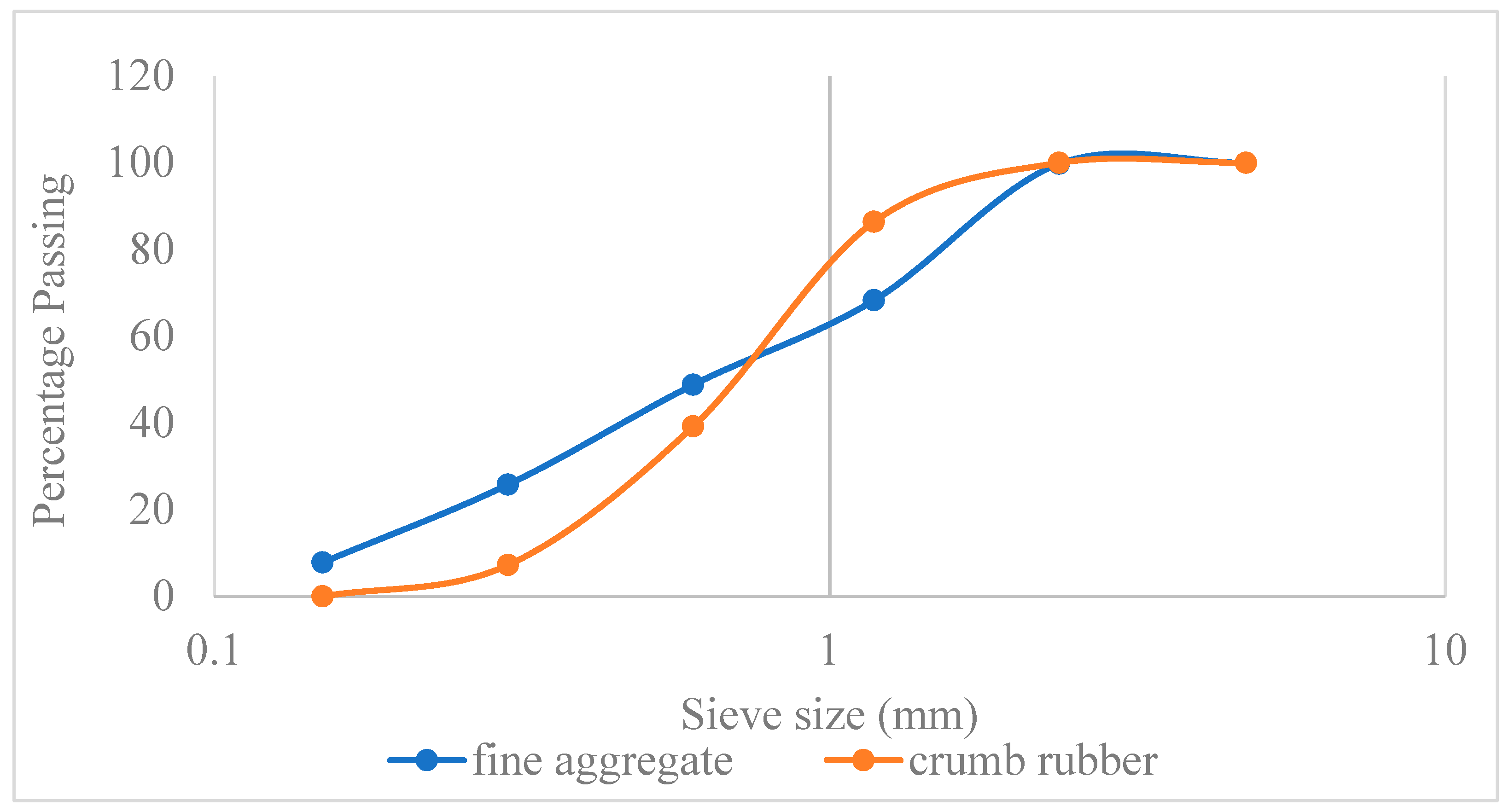

2.1. Materials

2.2. Treatment of Crumb Rubber

2.3. Mix Proportion and Methods

3. Results and Discussion

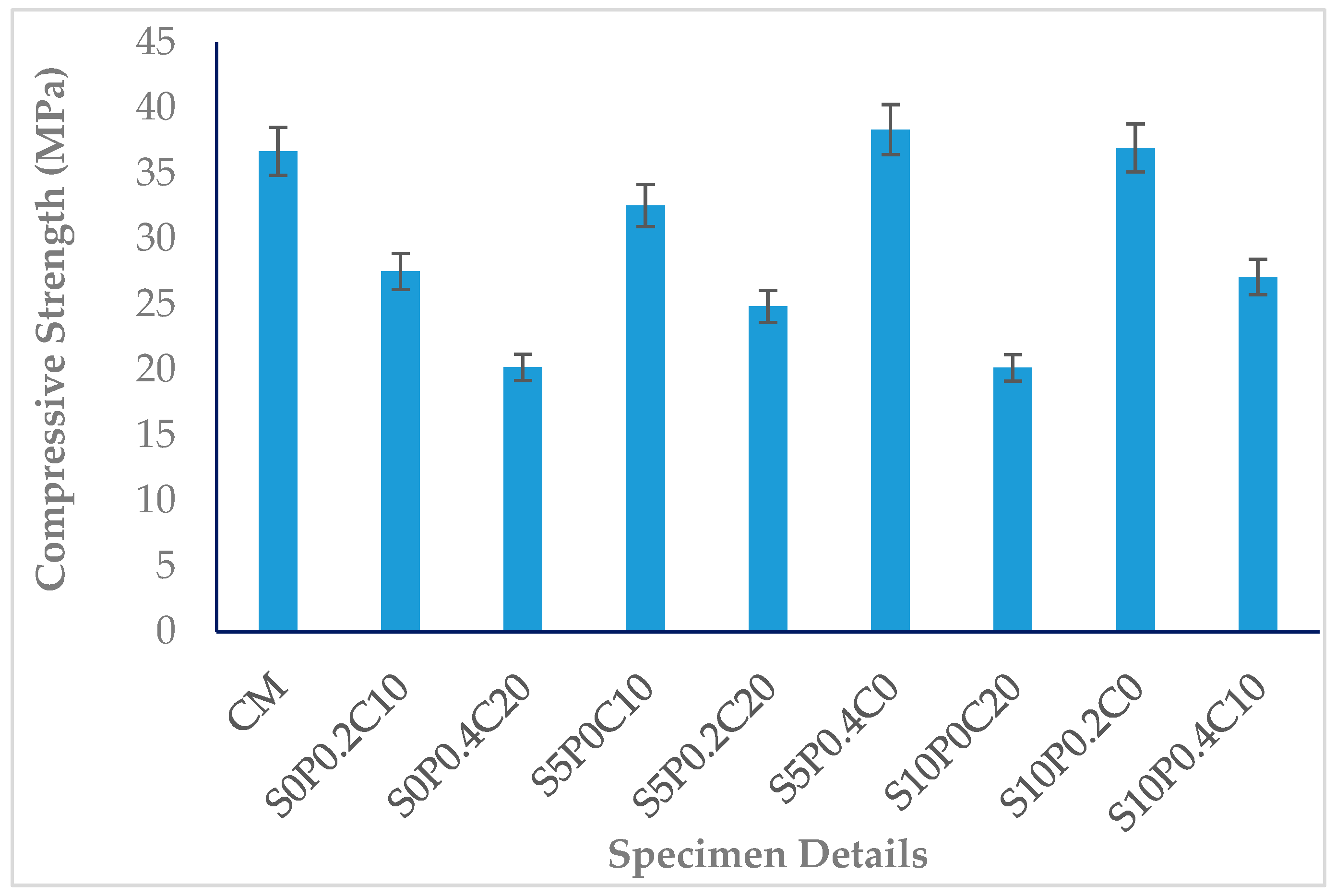

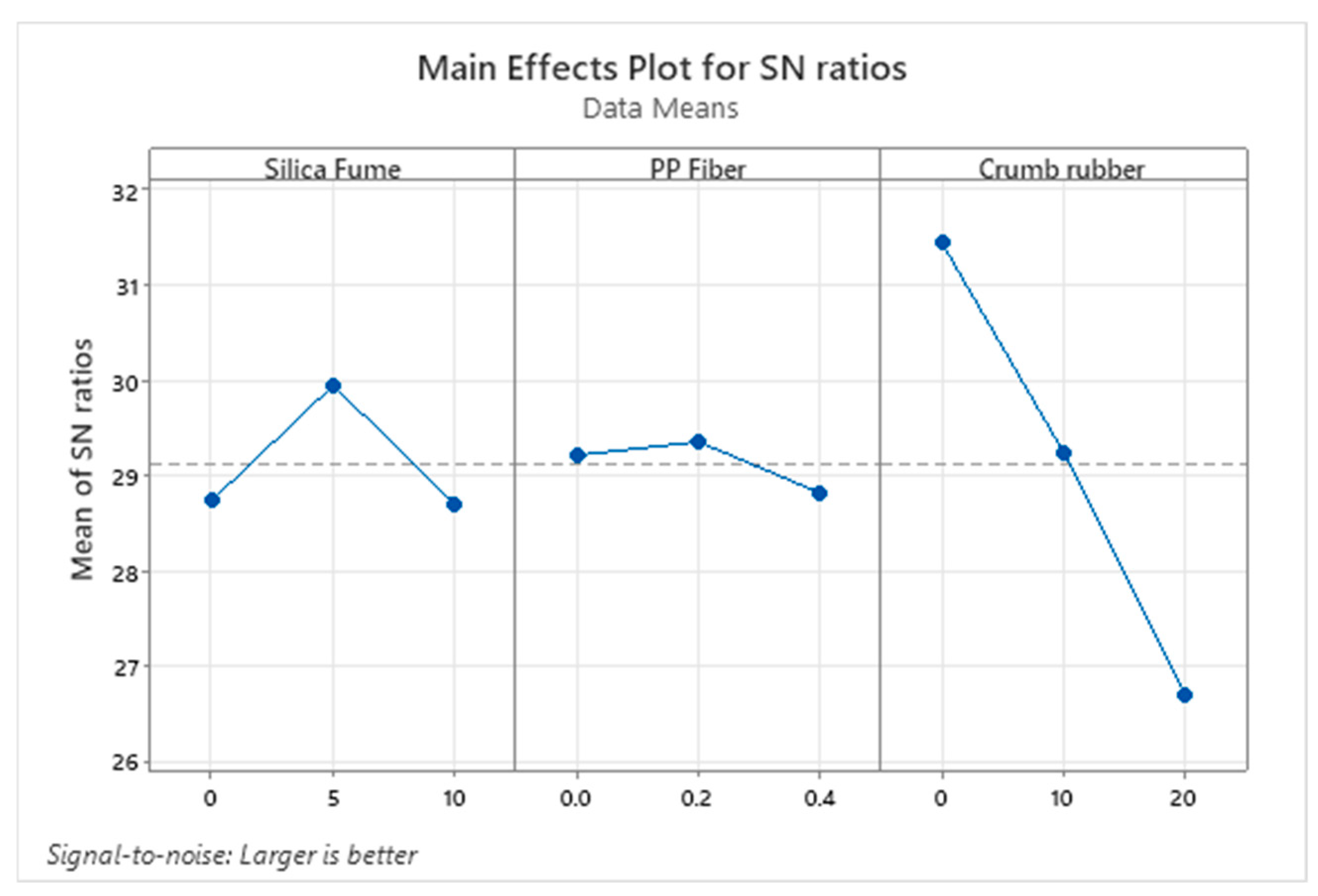

Optimum Mix Combination

4. Experimental Studies–Optimum Mix Combination

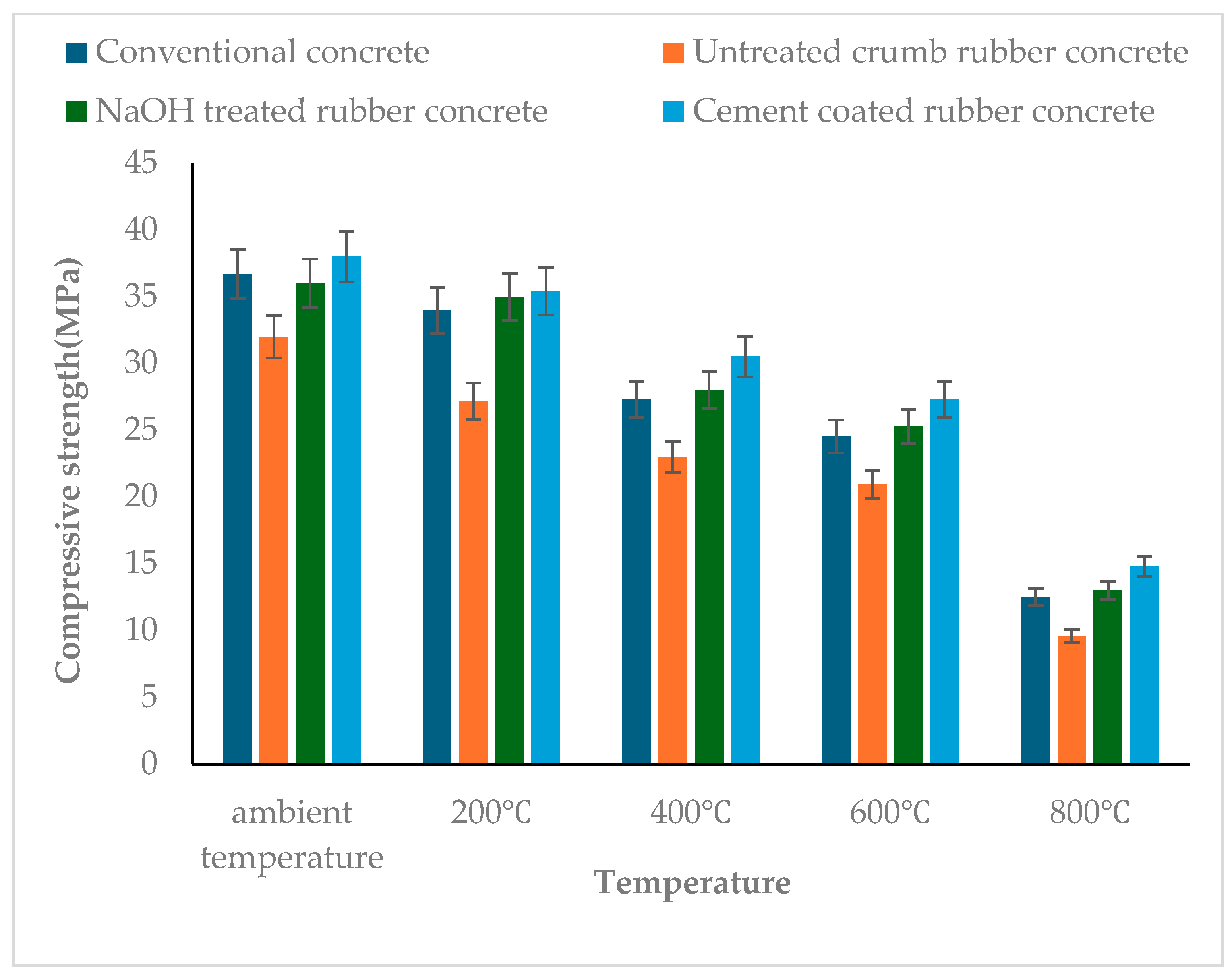

4.1. Compressive Strength

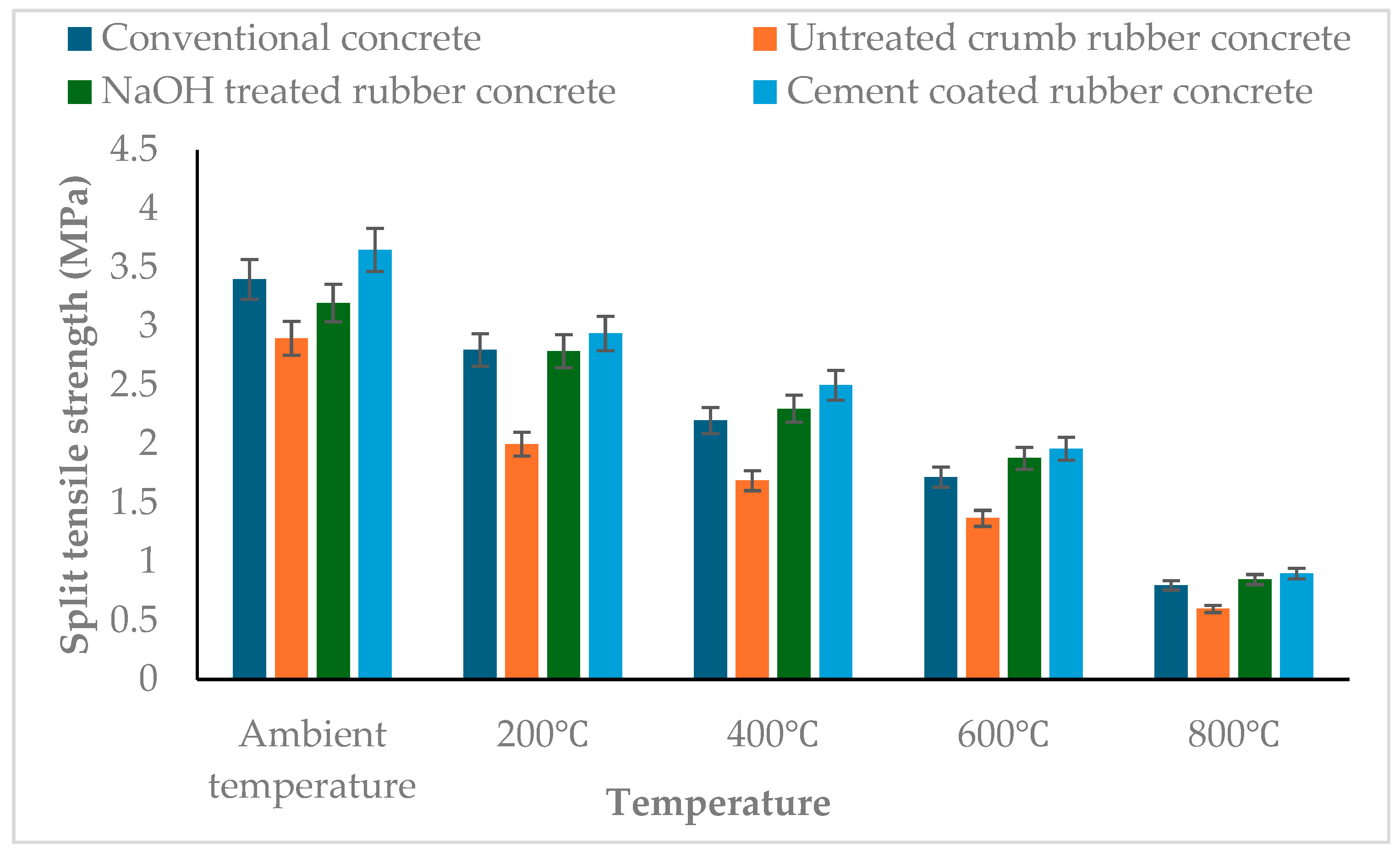

4.2. Split Tensile Strength

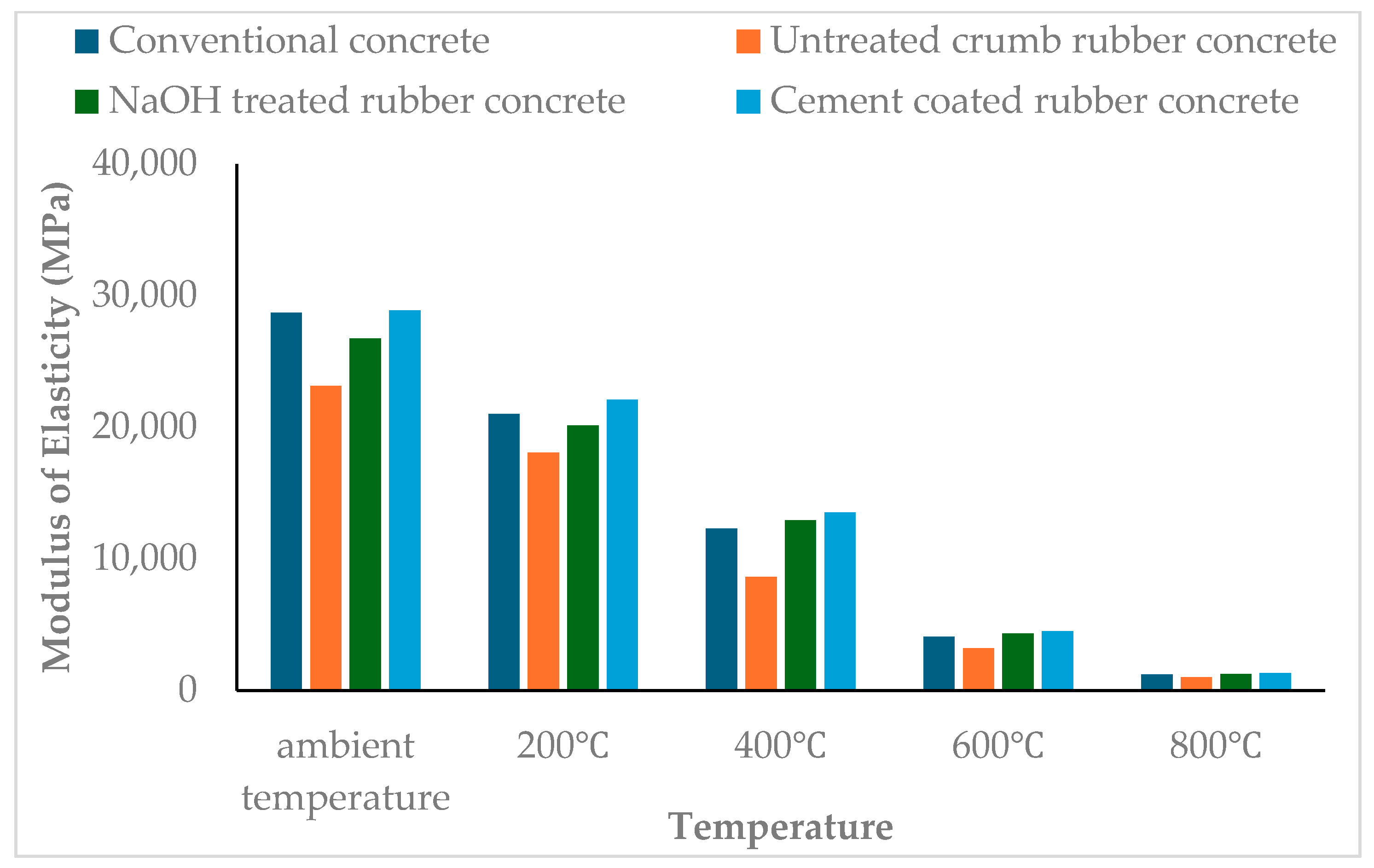

4.3. Modulus of Elasticity

4.4. Ultra Sonic Pulse Velocity (UPV) Test

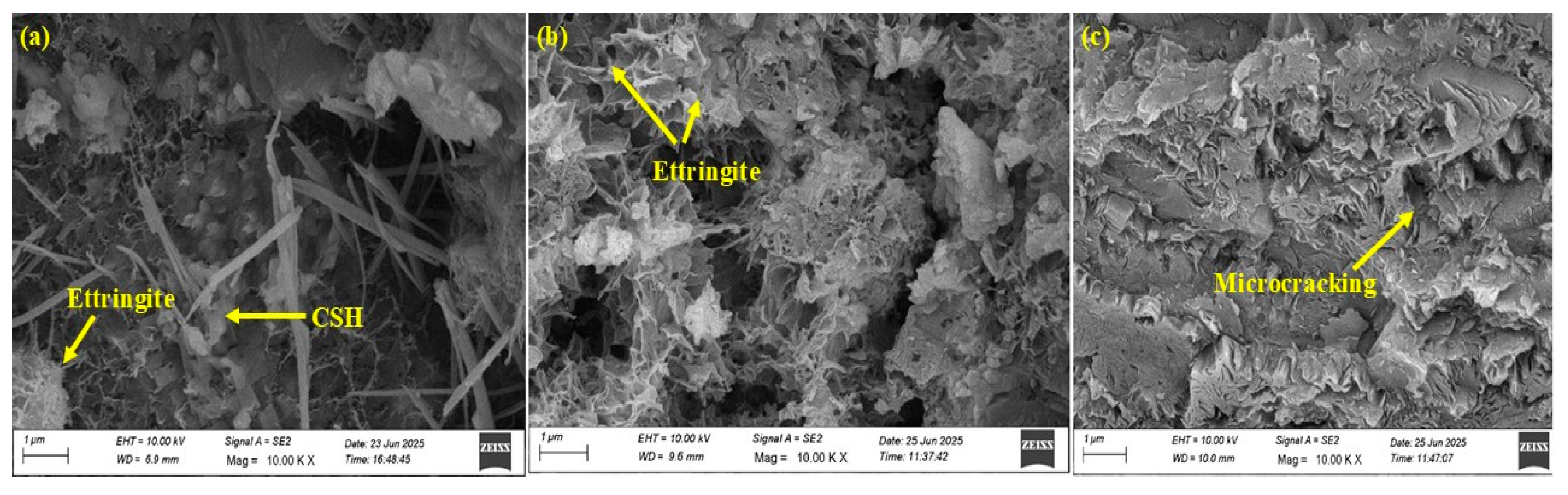

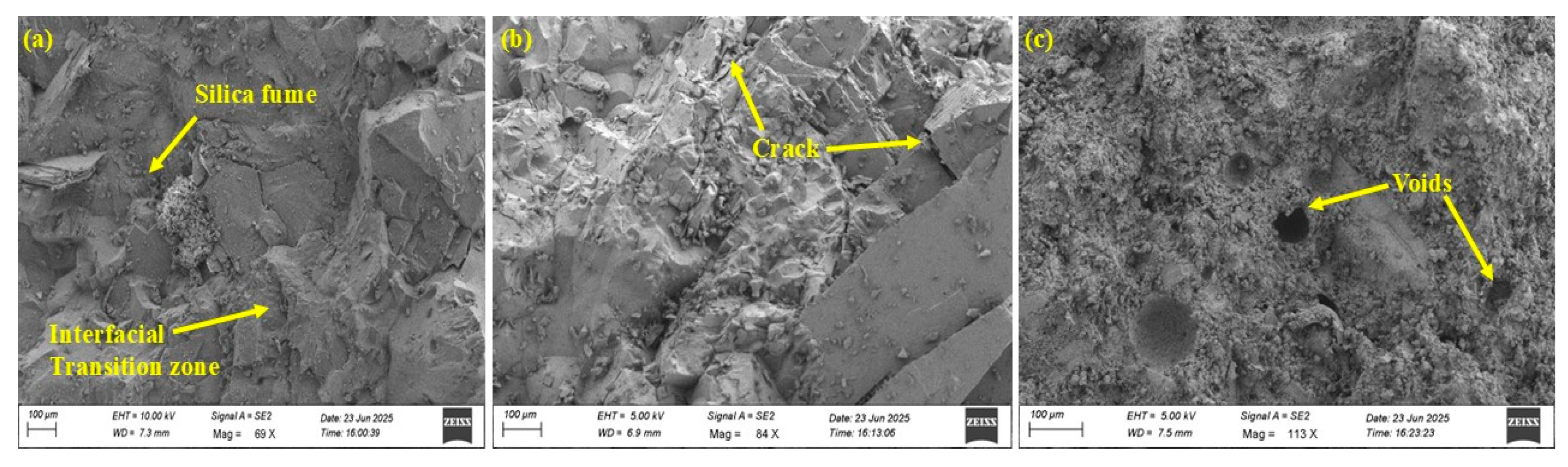

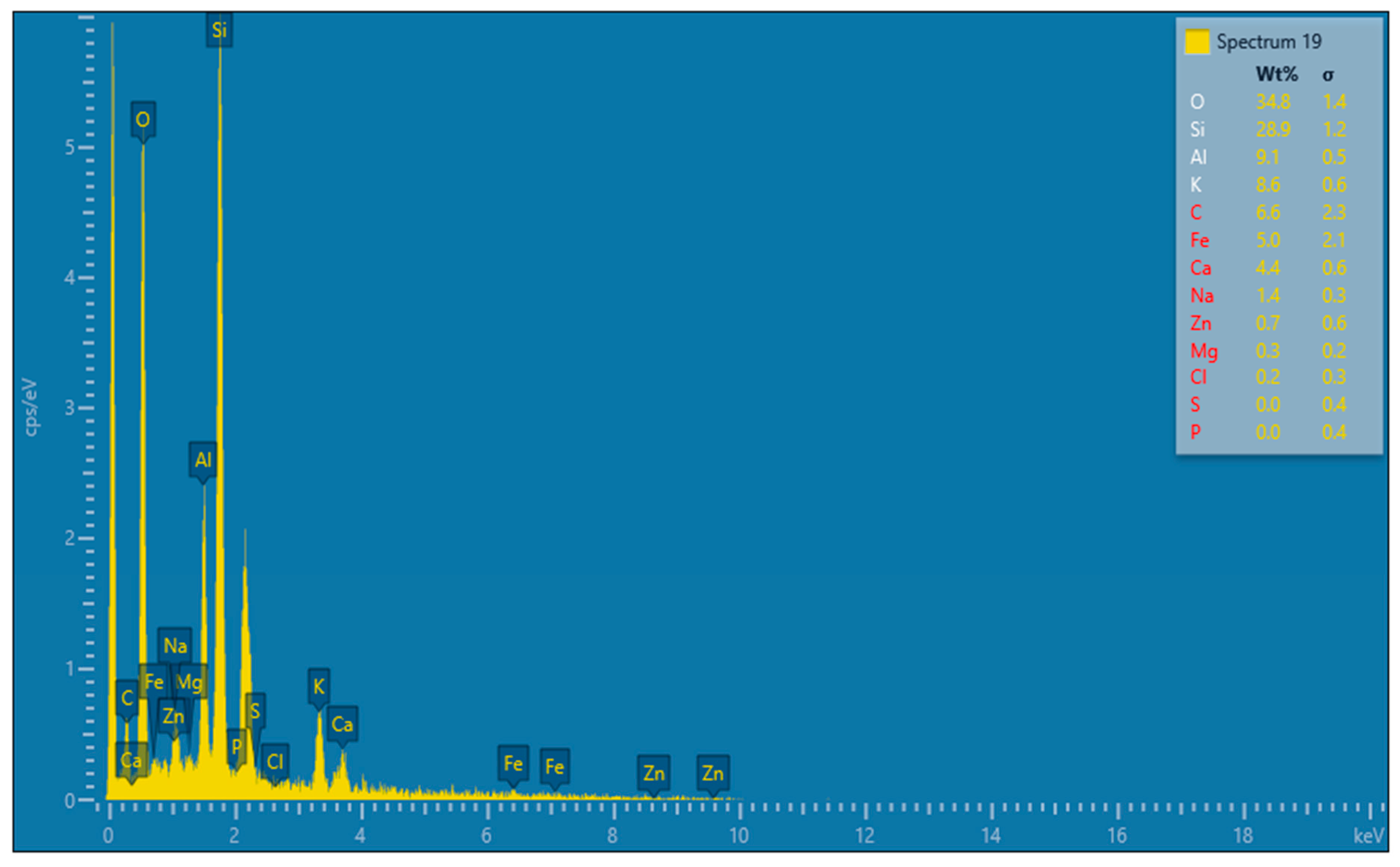

4.5. Microstructural Analysis

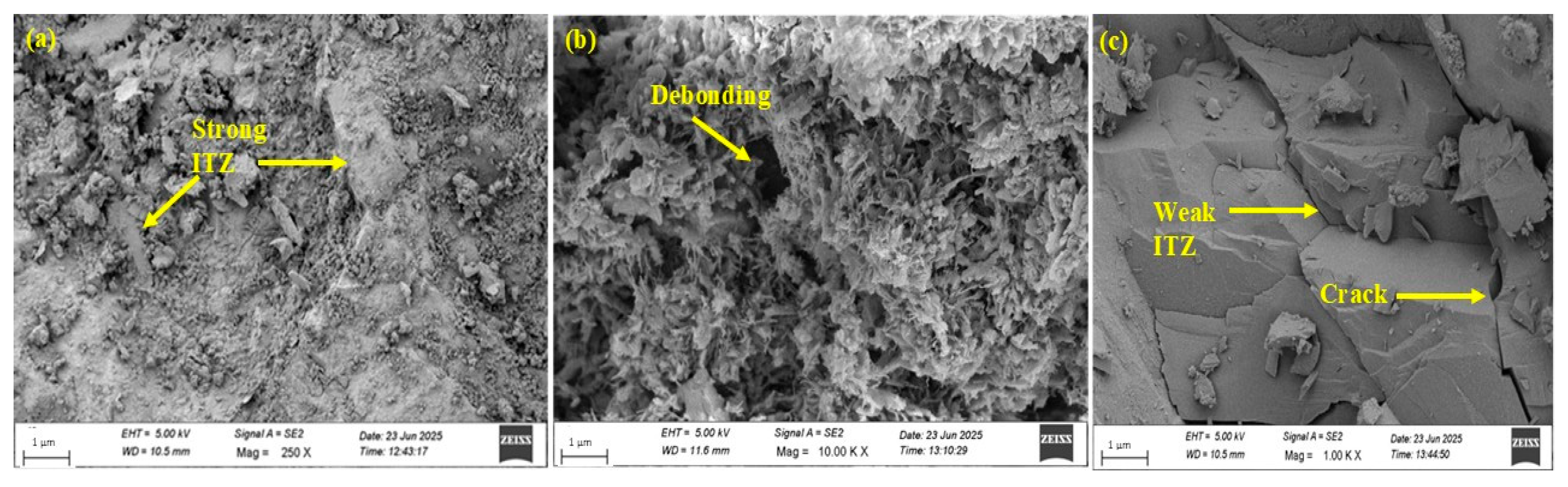

4.5.1. Control Mix Concrete

4.5.2. Untreated Rubber Mix Concrete

4.5.3. NaOH-Treated Rubber Mix Concrete

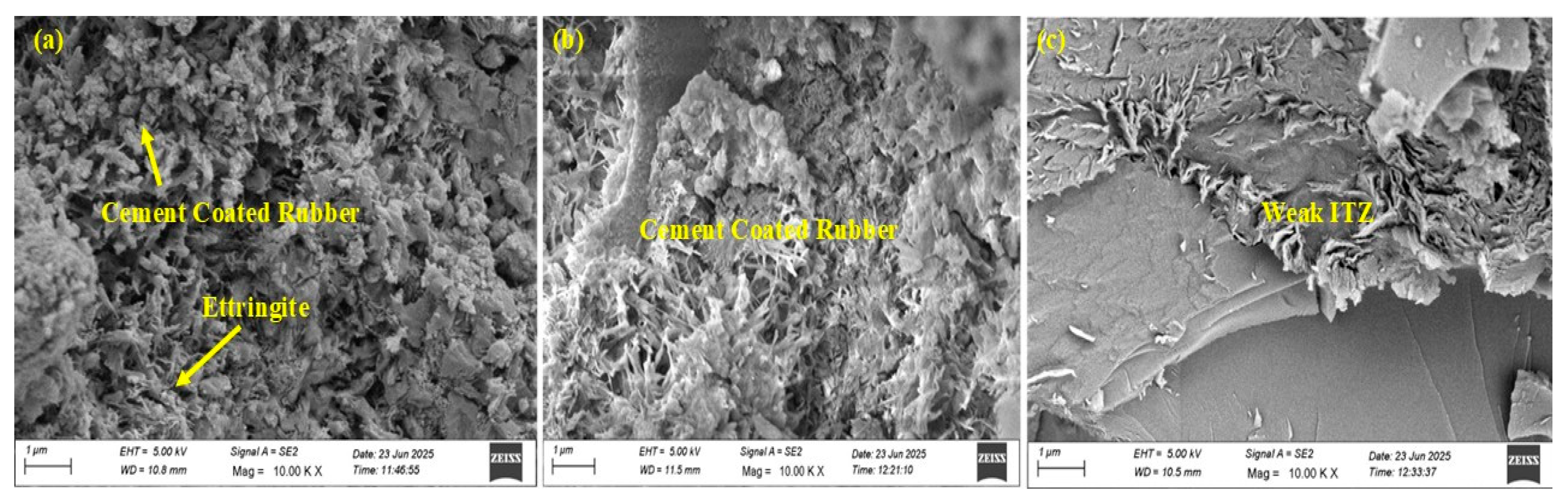

4.5.4. Cement-Coated Rubber Mix Concrete

5. Conclusions

- Loss in strength occurs as crumb rubber percentage increases.

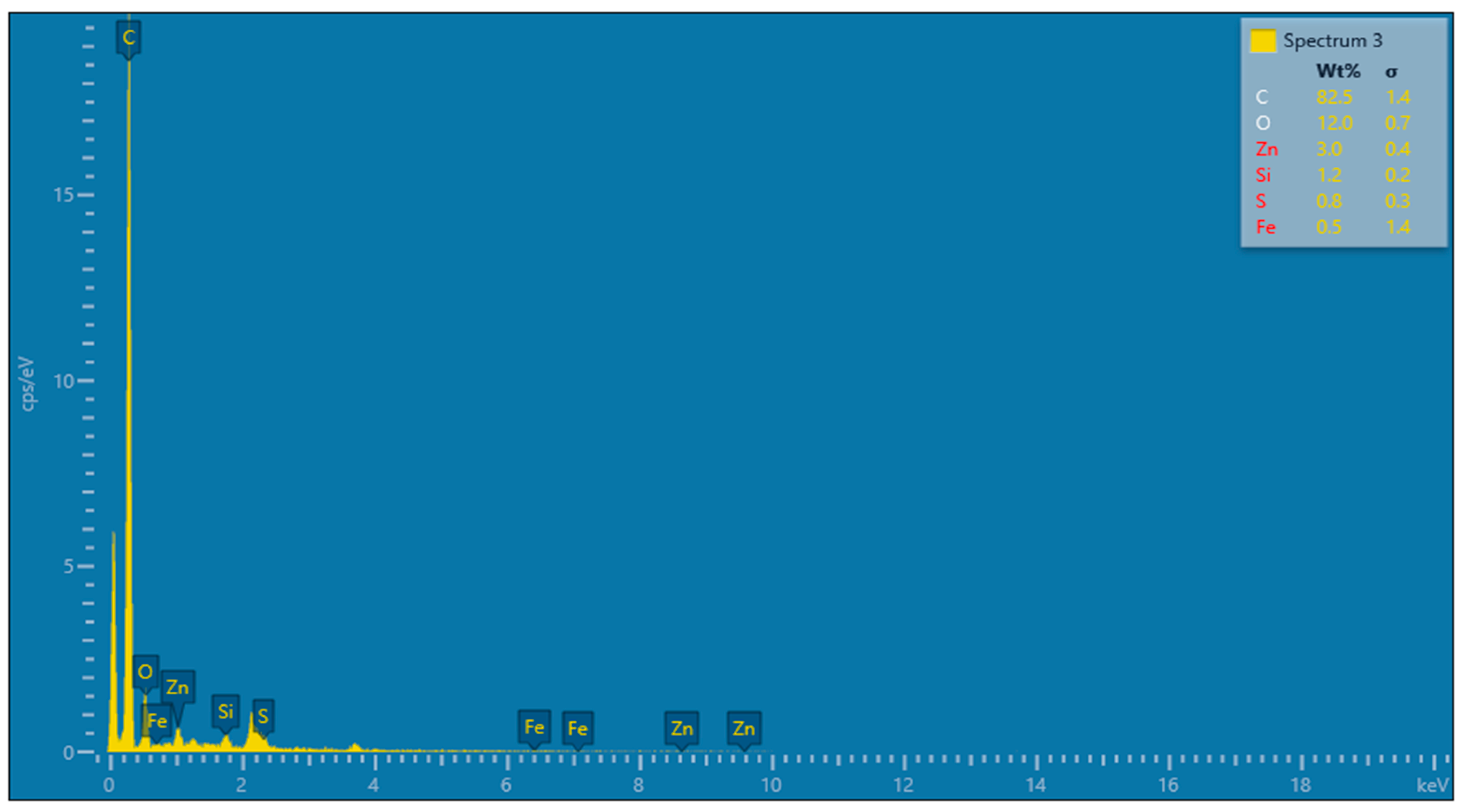

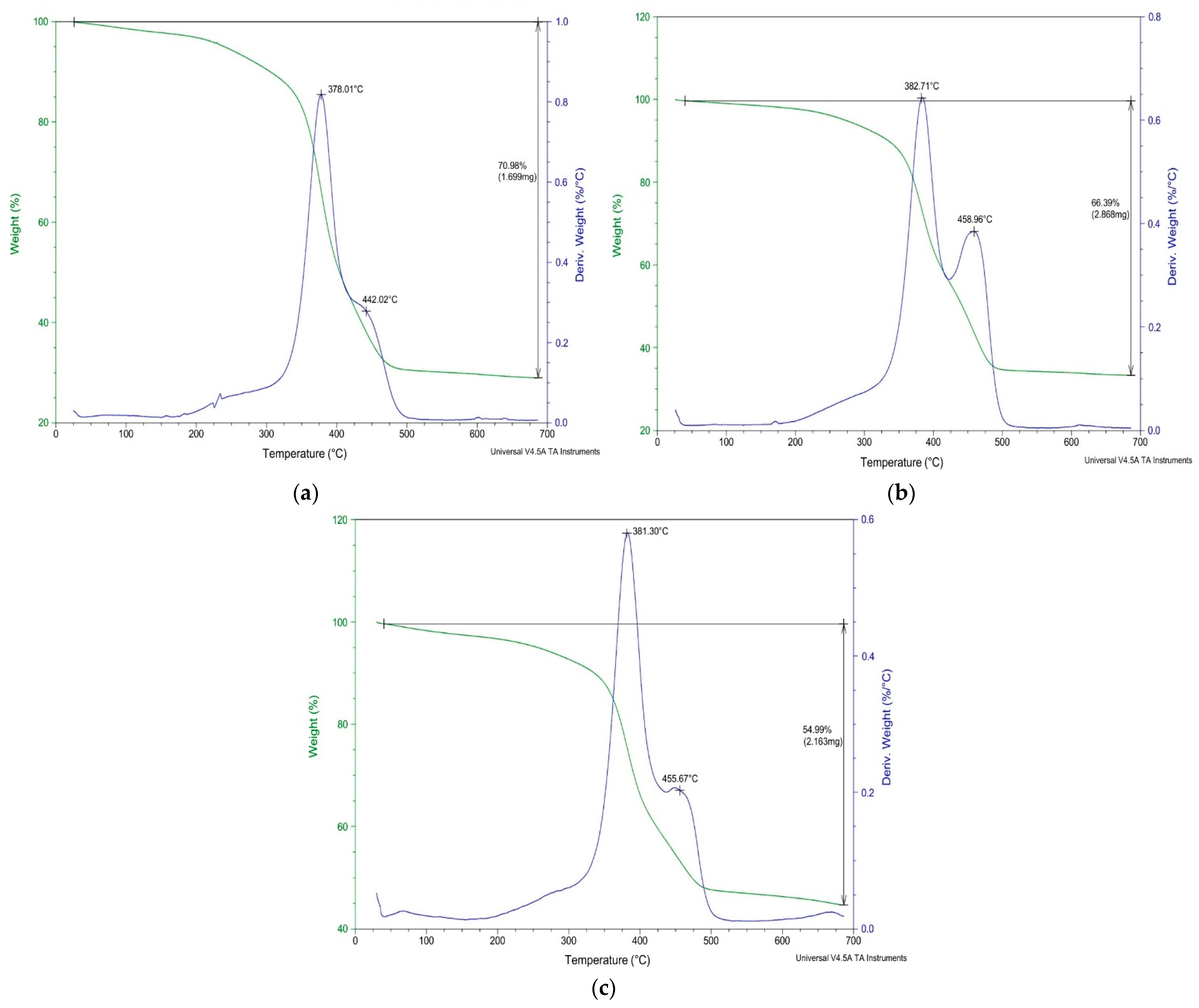

- SEM analysis of treated CR indicated better surface morphology and bonding compared to untreated rubber particles. TGA confirmed major degradation of CR between 300 and 475 °C and shows the better thermal stability of treated CR concrete.

- From 200 °C to 800 °C, the compressive strength loss is 7.5–65.84% for the control mix, whereas for the rubberized concrete it was in the range of 15.12 to 70.06%, 2.83 to 63.88%, and 6.84 to 61.05% for untreated, NaOH-treated, and cement-coated crumb rubber concrete, which is due to the dehydration of concrete due to the evaporation of water from the hydrated concrete, as well as the decomposition of CR.

- Split tensile strength dropped more rapidly than compressive strength under heat, especially for rubberized concrete. From temperatures of 200 °C to 800 °C, the split tensile strength value was decreased in the range of 17.64 to 76.47% for the control mix, whereas for the rubberized concrete it was in the range of 31.03 to 79.31%. But the treated CR concrete shows a comparatively better performance in the range of 7 to 71.66% for NaOH-treated and 19.45 to 75.34% for cement-coated concrete, respectively.

- The modulus of elasticity was lower in rubberized mixes due to the flexible nature of CR. But the treatment improved the performance compared to untreated CR concrete. UPV values also decreased at higher temperatures due to the degradation of PP fiber and CR, which reduces the compactness of the specimen.

- The microstructural characterization studies confirm the better performance of the treated CR compared to untreated CR at elevated temperatures.

- Based on the test results, it is observed that cement-coated CR offers the best thermal and structural performance under elevated temperatures compared to all other combinations. Cement coating outperforms NaOH treatment at high temperatures, likely due to enhanced thermal shielding and stronger interface with the cement paste. NaOH treatment provides improvement over untreated rubber but is slightly less effective than cement coating at high temperatures. Also, the combined use of silica fume and PP fibers enhances early-stage crack resistance and vapor pressure relief, contributing to better fire performance. Thus, it can be inferred that rubberized concrete with treated CR incorporated with admixtures is promising for structural applications and moderate-load structural applications, especially when treated and optimized.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alsharari, F. Utilization of Industrial, Agricultural, and Construction Waste in Cementitious Composites: A Comprehensive Review of their Impact on Concrete Properties and Sustainable Construction Practices. Mater. Today Sustain. 2025, 29, 101080. [Google Scholar] [CrossRef]

- Olaiya, B.C.; Lawan, M.M.; Olonade, K.A.; Segun, O.O. An overview of the use and process for enhancing the pozzolanic performance of industrial and agricultural wastes in concrete. Discov. Appl. Sci. 2025, 7, 164. [Google Scholar] [CrossRef]

- Gowri, R.; Anand, K.B. Utilization of fly ash and ultrafine GGBS for higher strength foam concrete. In Proceedings of the IOP Conference Series: Materials Science and Engineering, International Conference on Advances in Materials and Manufacturing Applications (IConAMMA-2017), Bengaluru, India, 17–19 August 2017; IOP Publishing: Bristol, UK, 2018; Volume 310, p. 012070. [Google Scholar] [CrossRef]

- George, E.S.; Hari, R.; Madhavan, M.K. Performance assessment of blended self-compacting concrete with ferrochrome slag as fine aggregate using functional ANOVA. J. Build. Eng. 2024, 89, 109390. [Google Scholar] [CrossRef]

- Assiamah, S.; Agyeman, S.; Adinkrah-Appiah, K.; Danso, H. Utilization of sawdust ash as cement replacement for landcrete interlocking blocks production and mortarless construction. Case Stud. Constr. Mater. 2022, 16, e00945. [Google Scholar] [CrossRef]

- Mohan, H.T.; Jayanarayanan, K.; Mini, K. A sustainable approach for the utilization of PPE biomedical waste in the construction sector. Eng. Sci. Technol. Int. J. 2022, 32, 101060. [Google Scholar] [CrossRef]

- Chandni, T.J.; Anand, K.B. Utilization of recycled waste as filler in foam concrete. J. Build. Eng. 2018, 19, 154–160. [Google Scholar] [CrossRef]

- Vijayan, V.; Shukla, S.K.; Mini, K.M. Slurry infiltrated low-quality construction and demolition coarse aggregate waste in concrete–a sustainable construction. Mater. Res. Express 2024, 11, 085505. [Google Scholar] [CrossRef]

- Ma, Z.; Wu, Y.; Fang, K.; Zhang, Y.; Wang, C. Developing fully recycled alkali-activated mortar made with waste concrete fines as a substitute for both binder and sand: Multi-properties evaluation. Constr. Build. Mater. 2025, 477, 141323. [Google Scholar] [CrossRef]

- Ma, Z.; Wu, Y.; Wang, B.; Liang, C.; Zhang, Y.; Wang, C. Understanding the micro-characteristics and mechanical behavior of more sustainable UHP-ECC with both recycled aggregate and recycled powder from concrete waste. J. Build. Eng. 2025, 112, 113705. [Google Scholar] [CrossRef]

- Assaggaf, R.A.; Ali, M.R.; Al-Dulaijan, S.U.; Maslehuddin, M. Properties of concrete with untreated and treated crumb rubber—A review. J. Mater. Res. Technol. 2021, 11, 1753–1798. [Google Scholar] [CrossRef]

- Eissa, M.; Habib, A.; AL Houri, A.; Alibrahim, B. Recent efforts on investigating the effects of recycled rubber content on the mechanical properties of structural concrete. Discov. Civ. Eng. 2024, 1, 16. [Google Scholar] [CrossRef]

- Siddique, R.; Naik, T.R. Properties of concrete containing scrap-tire rubber–an overview. Waste Manag. 2004, 24, 563–569. [Google Scholar] [CrossRef]

- Fadiel, A.A.M.; Abu-Lebdeh, T.; Munteanu, I.S.; Niculae, E.; Petrescu, F.I.T. Mechanical properties of rubberized concrete at elevated temperatures. J. Compos. Sci. 2023, 7, 283. [Google Scholar] [CrossRef]

- Assaggaf, R.A.; Al-Dulaijan, S.U.; Maslehuddin, M.; Al-Amoudi, O.S.B.; Ahmad, S.; Ibrahim, M. Effect of different treatments of crumb rubber on the durability characteristics of rubberized concrete. Constr. Build. Mater. 2022, 318, 126030. [Google Scholar] [CrossRef]

- Mousavimehr, M.; Nematzadeh, M. Predicting post-fire behavior of crumb rubber aggregate concrete. Constr. Build. Mater. 2019, 229, 116834. [Google Scholar] [CrossRef]

- Kevin, B.; Sarker, P.K.; Madhavan, M.K. Performance assessment and microstructural characterization of combined surface, chemical and polymer treated crumb rubber concrete. Sci. Rep. 2025, 15, 15853. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.; Dai, Q.; Si, R.; Sun, X.; Lu, C. Evaluation of properties and performance of rubber-modified concrete for recycling of waste scrap tire. J. Clean. Prod. 2017, 148, 681–689. [Google Scholar] [CrossRef]

- Ren, F.; Mo, J.; Wang, Q.; Ho, J.C.M. Crumb rubber as partial replacement for fine aggregate in concrete: An overview. Constr. Build. Mater. 2022, 343, 128049. [Google Scholar] [CrossRef]

- Khaloo, A.R.; Dehestani, M.; Rahmatabadi, P. Mechanical properties of concrete containing a high volume of tire–rubber particles. Waste Manag. 2008, 28, 2472–2482. [Google Scholar] [CrossRef] [PubMed]

- Abd-Elaal, E.-S.; Araby, S.; Mills, J.E.; Youssf, O.; Roychand, R.; Ma, X.; Zhuge, Y.; Gravina, R.J. Novel approach to improve crumb rubber concrete strength using thermal treatment. Constr. Build. Mater. 2019, 229, 116901. [Google Scholar] [CrossRef]

- Neeraja, R.; Jayakrishnan, P.; Mini, K.M. Experimental and statistical investigation on structural feasibility of admixture based foam concrete with hexagonal wire mesh reinforcement. J. Build. Eng. 2023, 80, 107967. [Google Scholar] [CrossRef]

- IS 516 (Part 1/Section 1); Hardened Concrete Methods of Test: Part 1 Testing of Strength of Hardened Concrete. Section 1 Compressive, Flexural and Split Tensile Strength (First Revision). Bureau of Indian Standards: New Delhi, India, 2021.

- IS 456:2000 (Reaffirmed 2005); Plain and Reinforced Concrete -Code of Practice (Fourth Revision). Bureau of Indian Standards: New Delhi, India, 2000.

- Hertz, K.D. Concrete strength for fire safety design. Mag. Concr. Res. 2005, 57, 445–453. [Google Scholar] [CrossRef]

- Arioz, O. Effects of elevated temperatures on properties of concrete. Fire Saf. J. 2007, 42, 516–522. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Khoshnaw, G.; İpEk, S. Investigating properties of pervious concretes containing waste tire rubbers. Constr. Build. Mater. 2014, 63, 206–213. [Google Scholar] [CrossRef]

- Yesilata, B.; Isıker, Y.; Turgut, P. Thermal insulation enhancement in concretes by adding waste PET and rubber pieces. Constr. Build. Mater. 2009, 23, 1878–1882. [Google Scholar] [CrossRef]

- Gupta, T.; Chaudhary, S.; Sharma, R.K. Mechanical and durability properties of waste rubber fiber concrete with and without silica fume. J. Clean. Prod. 2016, 112, 702–711. [Google Scholar] [CrossRef]

- Cruz, C.R. Elastic Properties of Concrete at High Temperatures; No. 191; Portland Cement Association: Washington, DC, USA, 1966. [Google Scholar]

- Georgali, B.; Tsakiridis, P.E. Microstructure of fire-damaged concrete. A case study. Cem. Concr. Compos. 2005, 27, 255–259. [Google Scholar] [CrossRef]

- IS 516 (Part 5):2021; Hardened Concrete—Methods of Test: Part 5 Non-Destructive Testing of Concrete (First Revision). Bureau of Indian Standards: New Delhi, India, 2021.

| Cement (kg/m3) | Water (kg/m3) | Coarse Aggregate (kg/m3) | Fine Aggregate (kg/m3) | Crumb Rubber | W/C Ratio | |

|---|---|---|---|---|---|---|

| CM | 447 | 204 | 1119 | 610 | 0 | 0.45 |

| Variable Parameters | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Silica fume (%) | 0 | 5 | 10 |

| PP fiber (%) | 0 | 0.2 | 0.4 |

| Crumb rubber (%) | 0 | 10 | 20 |

| Sample Name | Silica Fume (%) | PP Fiber (%) | Crumb Rubber (%) |

|---|---|---|---|

| CM | 0 | 0 | 0 |

| S0P0.2C10 | 0 | 0.2 | 10 |

| S0P0.4C20 | 0 | 0.4 | 20 |

| S5P0C10 | 5 | 0 | 10 |

| S5P0.2C20 | 5 | 0.2 | 20 |

| S5P0.4C0 | 5 | 0.4 | 0 |

| S10P0C20 | 10 | 0 | 20 |

| S10P0.2C0 | 10 | 0.2 | 0 |

| S10P0.4C10 | 10 | 0.4 | 10 |

| Source | Degree of Freedom | Sequential Sum of Squares | Contribution | Adjusted Sum of Squares | Adjusted Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Silica fume | 2 | 29.042 | 7.27% | 29.042 | 14.521 | 12.14 | 0.076 |

| PP fiber | 2 | 3.062 | 0.77% | 3.062 | 1.531 | 1.28 | 0.439 |

| Crumb rubber | 2 | 365.158 | 91.37% | 365.158 | 182.579 | 152.62 | 0.007 |

| Error | 2 | 2.393 | 0.60% | 2.393 | 1.196 | ||

| Total | 8 | 399.654 | 100.00% |

| Parameter | Silica Fume | Crumb Rubber | PP Fiber |

|---|---|---|---|

| Compressive strength | 5% | 10% | 0.2% |

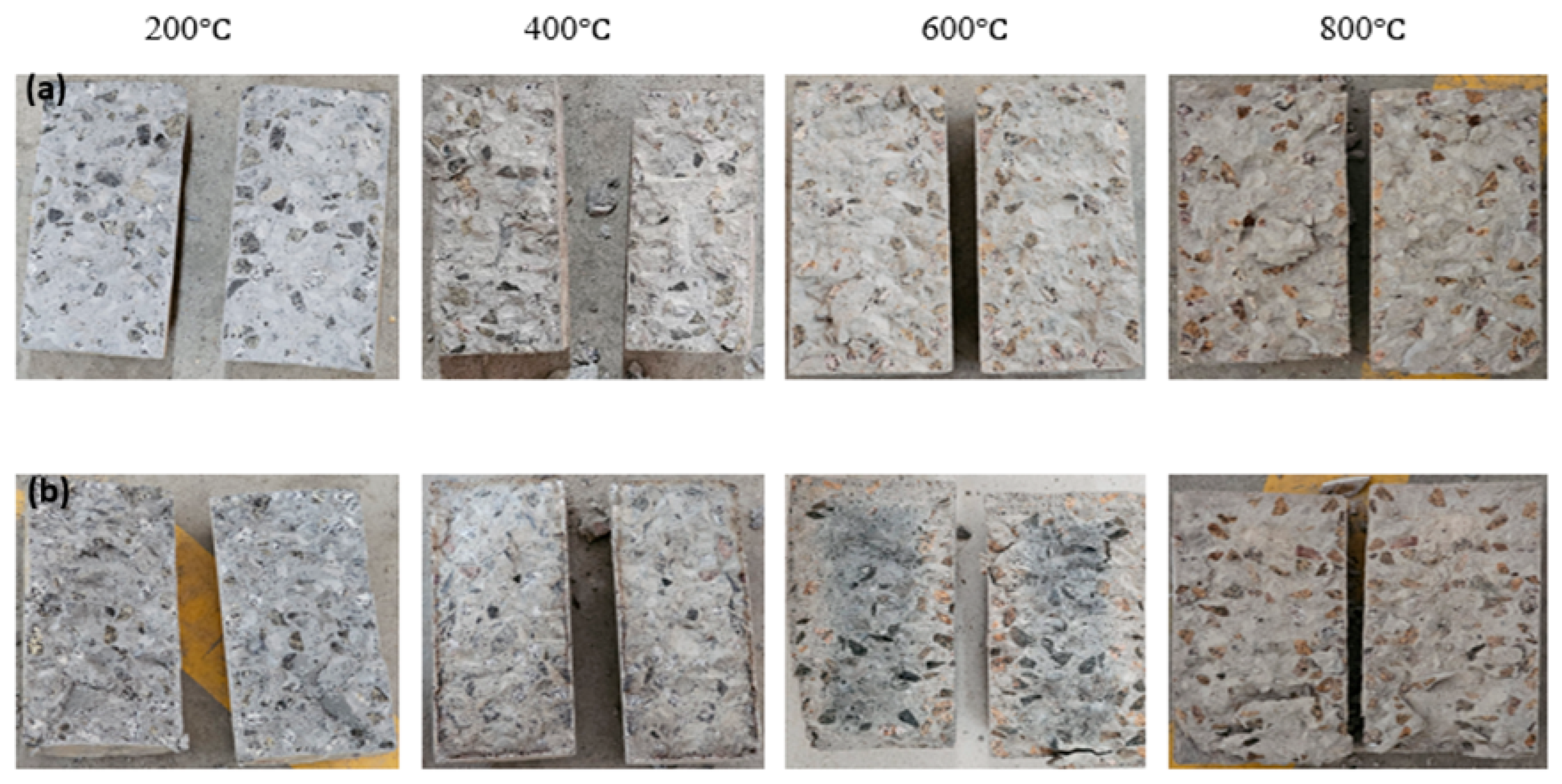

| Temperature | Conventional Concrete | Untreated CR Concrete | NaOH-Treated CR Concrete | Cement-Coated CR Concrete |

|---|---|---|---|---|

| Ambient | Cube is intact with cracks on both edges. | Intact with minor cracks on edges, due to the influence of silica fume and PP fibre. | Intact with minimum surface cracks. | Intact and clean surface with minor cracks. |

| 200 °C | Spalling of concrete starts from the surface with visibly smaller cracks on faces. Chemically bound water starts losing at ~105 °C. | Surface was relatively intact, with lesser cracks than the normal concrete; may be due to the influence of silica fume and PP fibre present. Rubber softens but remains, internal flexibility can reduce cracking. PP fibre melts and provide voids, for vapor to escape. | Minor surface cracking is observed. Rubber begins softening; PP fibres may start melting. Spalling present at edges. | Minor cracks, cube remains intact. Rubber softens but coating provides thermal buffer. Spalling present at edges. Surface appears slightly lighter, maybe due to moisture loss. |

| 400 °C | Visible deterioration on the surface and cracks observed with degradation on the edges. | Spalling of surface concrete starts along with cracking. Rubber starts decomposing, produces voids. | Increased surface cracking with reduced spalling, due to NaOH treatment, compared to rubberized concrete; some edge degradation. Rubber partially decomposes, internal void formation. | Slight surface cracking, still cohesive. Cement coating delays rubber decomposition; matrix remains stronger. Surface appear slightly lighter, maybe due to moisture loss. |

| 600 °C | Severe cracking with broken surface. Decomposition of calcium hydroxide (~400–500 °C). Becomes brittle, and structural integrity deteriorates quickly above 400 °C. | Rubber burns off, leaving large internal voids, reducing strength. Similar deprivation to normal concrete with more discoloration and flakiness. | Surface chipping, moderate cracking, and visible spalling. Degraded rubber and melted fibres leave voids; strength deteriorates. Better performance than untreated cube at same temperature. | Moderate cracking, but cube shape well retained. Surface appear slightly lighter, maybe due to moisture loss. |

| 800 °C | Almost complete disintegration with a major loss of material. Complete disintegration of the cement matrix. | Severe crumbling due to absence of rubber and collapse of weakened matrix. Wide surface damage along with charring, as the crumb rubber and PP fibre have completely burned out and left voids. | Severe damage, edge collapse. Crumb rubber fully degraded; thermal stress and internal voids caused collapse. Some cohesion compared to untreated crumb rubber concrete. Coating protects rubber longer; helps maintain some post-fire compressive strength. | Significant damage, but some cohesion in structure remains. Coating protects rubber longer; helps to maintain some post-fire compressive strength. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Joshi, B.; Jayanarayanan, K.; Madhavan, M.K. Assessment of the Post-Thermal Performance of Concrete Modified with Treated and Untreated Crumb Rubber. Sustainability 2025, 17, 8599. https://doi.org/10.3390/su17198599

Joshi B, Jayanarayanan K, Madhavan MK. Assessment of the Post-Thermal Performance of Concrete Modified with Treated and Untreated Crumb Rubber. Sustainability. 2025; 17(19):8599. https://doi.org/10.3390/su17198599

Chicago/Turabian StyleJoshi, Barun, Karingamanna Jayanarayanan, and Mini K. Madhavan. 2025. "Assessment of the Post-Thermal Performance of Concrete Modified with Treated and Untreated Crumb Rubber" Sustainability 17, no. 19: 8599. https://doi.org/10.3390/su17198599

APA StyleJoshi, B., Jayanarayanan, K., & Madhavan, M. K. (2025). Assessment of the Post-Thermal Performance of Concrete Modified with Treated and Untreated Crumb Rubber. Sustainability, 17(19), 8599. https://doi.org/10.3390/su17198599