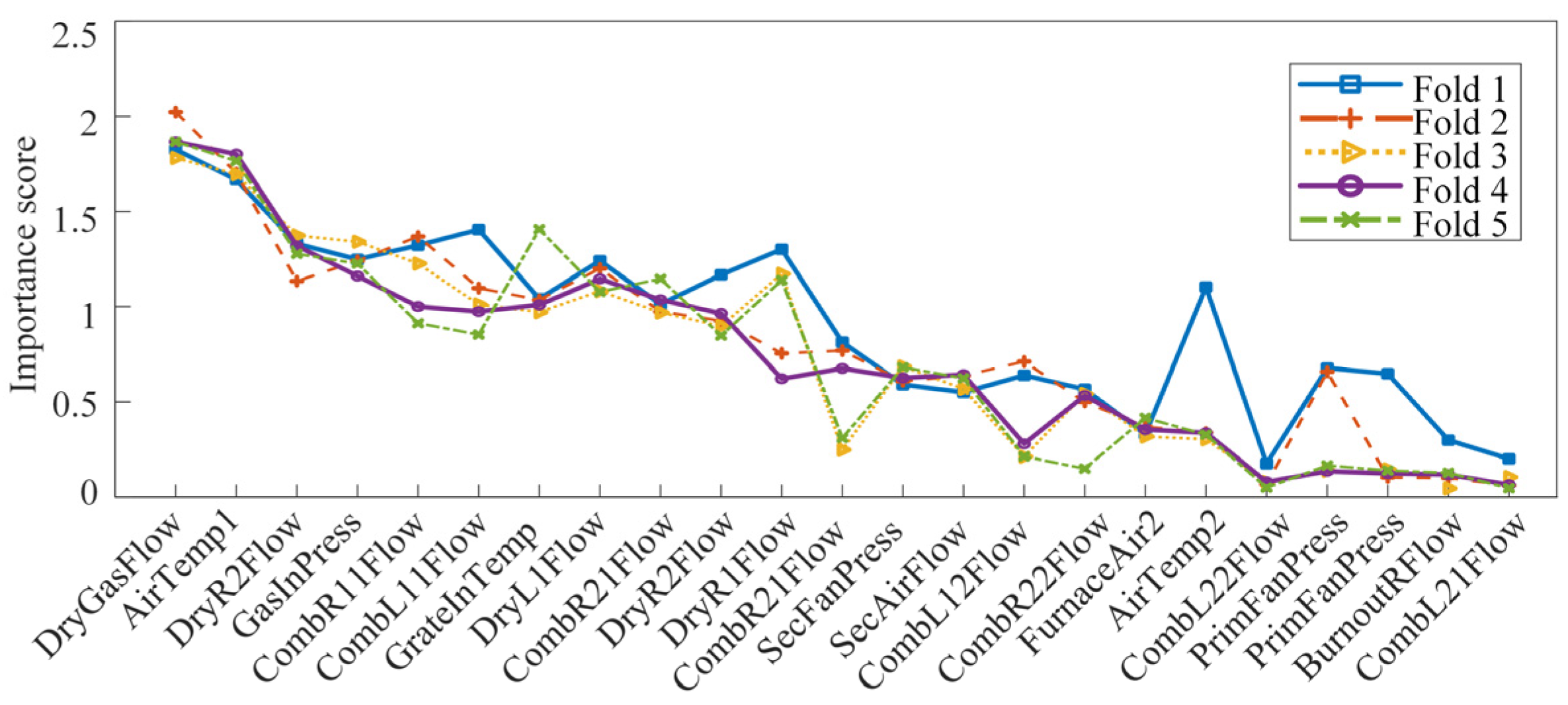

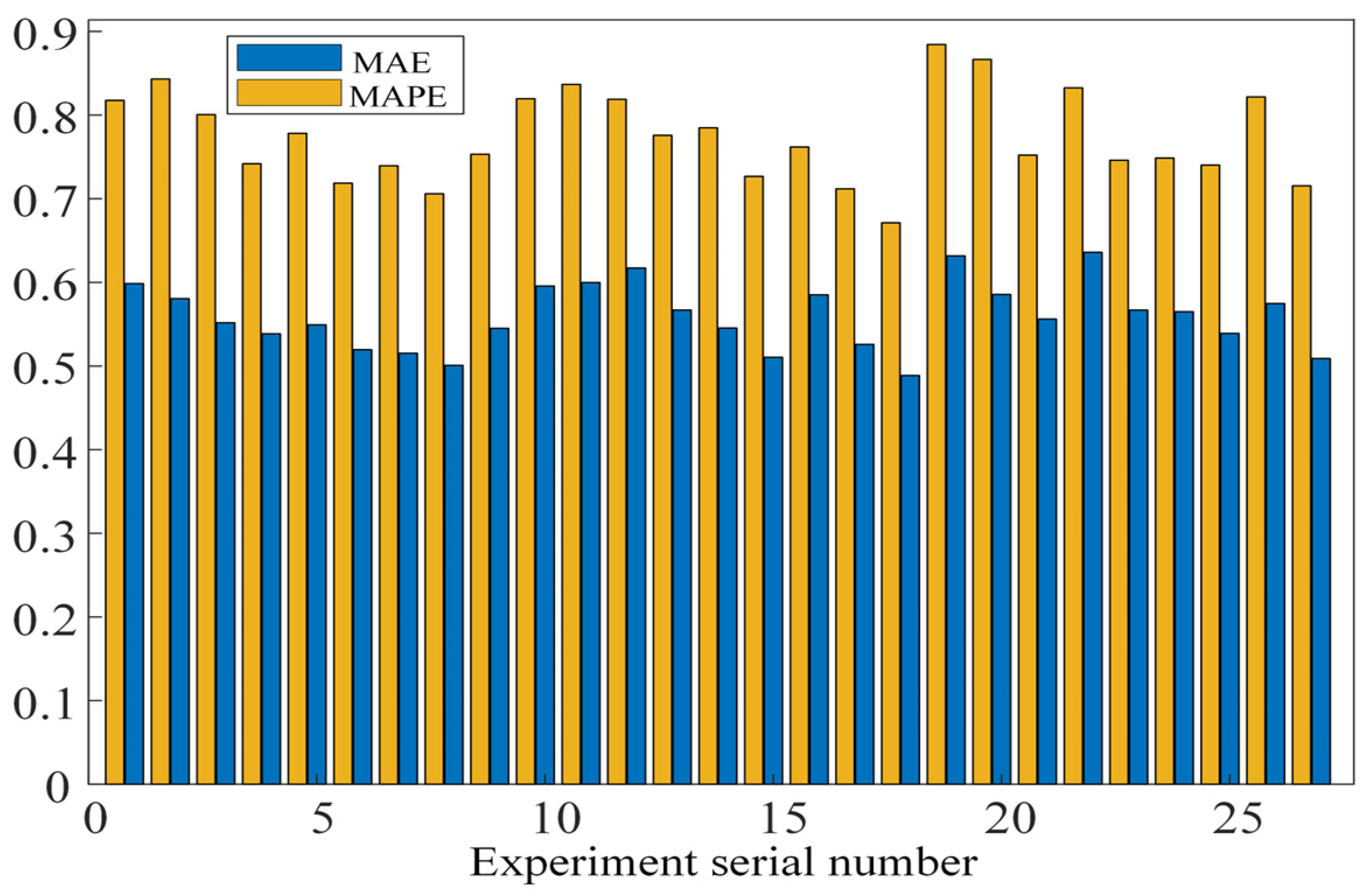

2.2.2. Analysis of Factors Affecting Furnace Temperature

Based on the above combustion process analysis, it can be seen that the furnace temperature is jointly influenced by three key factors: oxygen supply, heat sources, and combustion efficiency. In practice, during the combustion process, the adjustment of furnace temperature relies on regulating operational variables according to the current operating conditions, in order to achieve effective temperature control. The following section further analyzes the influencing factors of furnace temperature.

A higher outlet air temperature of the primary air heater can increase the kinetic energy of oxygen molecules, thereby enhancing their reaction efficiency and promoting more complete combustion. As the air temperature rises, the reaction between oxygen and municipal solid waste becomes faster and more thorough, resulting in greater heat release. Conversely, when the primary air temperature is low, the movement of oxygen molecules slows down, which weakens the combustion reaction, reduces combustion efficiency, and makes it difficult to increase the furnace temperature effectively. In addition, low-temperature air entering the furnace may cause temperature fluctuations and unstable combustion conditions, which can negatively affect the precision of furnace temperature control.

As an auxiliary fuel, biogas provides additional heat to the incineration process. When the biogas flow rate in the drying section increases, it can rapidly release heat, which facilitates the drying and combustion of waste inside the furnace. This effect is particularly significant when the waste has a high moisture content. A higher biogas flow accelerates the evaporation of moisture, improves the combustibility and calorific value of the waste, and enhances the completeness of combustion and total heat release. Meanwhile, increasing the biogas flow rate in the drying section helps raise the furnace temperature, especially during the drying stage. Conversely, a low biogas flow rate may slow down moisture evaporation, leading to poor ignition conditions and unstable furnace temperature.

A higher inlet biogas pressure enhances the injection performance of biogas, allowing it to distribute more evenly within the furnace and mix more thoroughly with the oxygen in the air. This thorough mixing ensures stable combustion reactions, improves the efficiency of oxygen supply, and promotes greater heat release, thereby increasing the furnace temperature. Moreover, higher pressure improves the contact between biogas and solid waste, increasing the chances of reactions between oxygen and combustible components, which enhances combustion efficiency. In contrast, if the biogas pressure is too low, the biogas distribution becomes uneven, and the mixing with oxygen is insufficient. As a result, incomplete combustion may occur, reducing heat release and making it difficult to reach the desired furnace temperature.

An increase in the air flow rate at the Left2 grate in the drying section provides sufficient oxygen for the drying process of solid waste, thereby enhancing oxygen supply during combustion. An appropriate air flow not only facilitates moisture evaporation from the waste but also delivers more oxygen to support complete combustion reactions, leading to an increase in furnace temperature. Conversely, insufficient air flow may result in inadequate oxygen supply, reduced combustion efficiency, and incomplete combustion of combustible components in the waste, ultimately lowering the furnace temperature. Therefore, adjusting the air flow rate is essential to ensure a stable oxygen supply and improve combustion efficiency.

A sufficient inlet air flow in the combustion section ensures an adequate supply of oxygen, which is essential for supporting complete combustion reactions. An appropriate oxygen supply allows combustible substances in the solid waste to fully react, releasing a large amount of heat and thereby increasing the furnace temperature. However, if the inlet air flow is insufficient, the oxygen supply becomes inadequate. As a result, part of the combustible components may not be fully oxidized, leading to incomplete heat release and lower furnace temperature. Therefore, maintaining a proper air flow rate is critical to achieving a stable furnace temperature and ensuring efficient combustion.

- 2.

Low-frequency material distribution variables

The feeder speed directly affects the amount of solid waste fed into the furnace. A higher feeder speed introduces more waste, increasing the availability of combustible materials, which contributes to greater heat release. However, if the feeding rate is too high, the combustion reactions inside the furnace may not be completed in time. This can lead to insufficient oxygen supply, reduced combustion efficiency, and ultimately less heat generation. Therefore, moderately adjusting the feeder speed ensures that enough combustible material is available while avoiding excessive feeding that could limit oxygen availability. This helps maintain stable furnace temperature control.

The grate speed in the combustion section directly affects the contact time between the solid waste and oxygen. A slower grate speed extends the residence time of the waste in the furnace, allowing sufficient interaction with oxygen, which improves combustion efficiency, releases more heat, and promotes an increase in furnace temperature. Conversely, a faster grate speed may shorten the contact time between waste and oxygen, resulting in incomplete combustion, reduced combustion efficiency, and insufficient heat release. This makes it difficult to maintain the furnace temperature at the desired level.

It is evident that the furnace temperature is influenced by several operational variables, such as air distribution and feeding regulation, which affect combustion efficiency, heat release, and oxygen supply. Mechanistic analysis reveals the relationships between these variables and furnace temperature, providing the foundational understanding of the system’s behavior. However, due to the complex interactions and feedback mechanisms among these factors, the relationship is highly nonlinear and difficult to describe accurately with traditional mechanistic models.

In the actual incineration process, variables such as waste composition, calorific value, moisture content, feeder speed, air flow, and fuel type often vary and adjust according to operating conditions. These variations directly or indirectly impact the stability and efficiency of the combustion process, causing fluctuations in furnace temperature. For instance, under high-load conditions, changes in waste input and oxygen supply significantly affect temperature, whereas under low-load conditions, these factors have less impact. The interactions between these variables are time-varying, exhibiting different characteristics at different stages. Additionally, variables like feeder speed and grate speed, which control material transport and flow, influence furnace temperature at low frequencies, while variables such as secondary air heater outlet air temperature and biogas flow regulate combustion at higher frequencies, providing more immediate control.

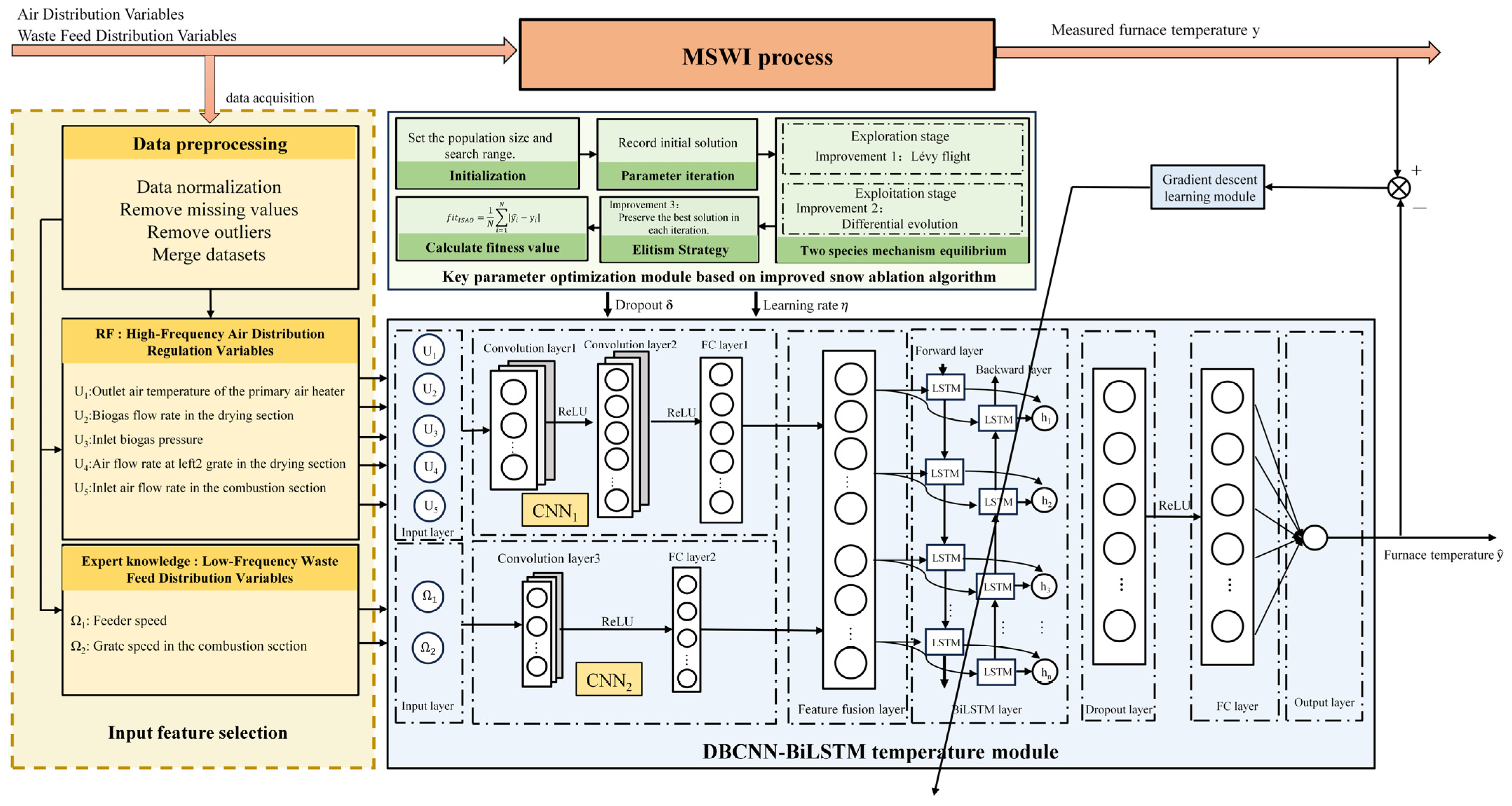

Given the challenges in accurately modeling the highly dynamic and nonlinear relationships, a data-driven approach is employed to complement the mechanistic analysis. The mechanistic insights guide the feature selection process by identifying the most influential variables, which are then incorporated into the data-driven model. This hybrid approach combines the strengths of physical principles with machine learning techniques to better capture the complex, time-varying dynamics that traditional models fail to address. Specifically, the mechanistic analysis informs the design of the model by selecting relevant features, while the data-driven model is used to predict furnace temperature based on these features. The model’s predictions are further validated through physical constraints and system behavior, ensuring consistency with the established mechanistic understanding.

Thus, the integration of mechanistic insights and data-driven methods enhances the model’s robustness, improving its ability to predict furnace temperature under fluctuating and complex operational conditions.

Specifically, the relationship between furnace temperature and its influencing factors can be expressed by Equation (6) and illustrated in

Figure 2. Here,

represents the complex nonlinear relationship between furnace temperature and the influencing factors. U denotes the low-frequency material distribution variables, with

Umin ≤

U ≤

Umax correspond to the outlet air temperature of the primary air heater, biogas flow rate in the drying section, inlet biogas pressure, air flow rate at left2 grate in the drying section, and inlet air flow in the combustion section, respectively.

denotes the high-frequency air distribution variables, with

. Ω

1 and Ω

2 represent the feeder speed and grate speed in the combustion section, respectively.

represents the furnace temperature.

As shown in

Figure 3, the adjustment cycles of Feeder speed (Ω

1) and Grate speed in the combustion section (Ω

2) are significantly longer than those of the other five variables, and their effects on the furnace temperature (y) generally exhibit a time delay. Therefore, Feeder speed (Ω

1) and Grate speed (Ω

2) are defined as low-frequency material distribution variables, while the remaining five variables (Outlet air temperature of the primary air heater (

U1), Biogas flow rate in the drying section (

U2), Inlet biogas pressure (

U3), Air flow rate at left2 grate in the drying section (

U4), and Inlet air flow in the combustion section (

U5)), which can rapidly respond to furnace temperature fluctuations, are defined as high-frequency air distribution regulation variables.