Sustainable Stabilization of Clay Soil Using Lime and Oryza sativa-Waste-Derived Dried Solid Digestate

Abstract

1. Introduction

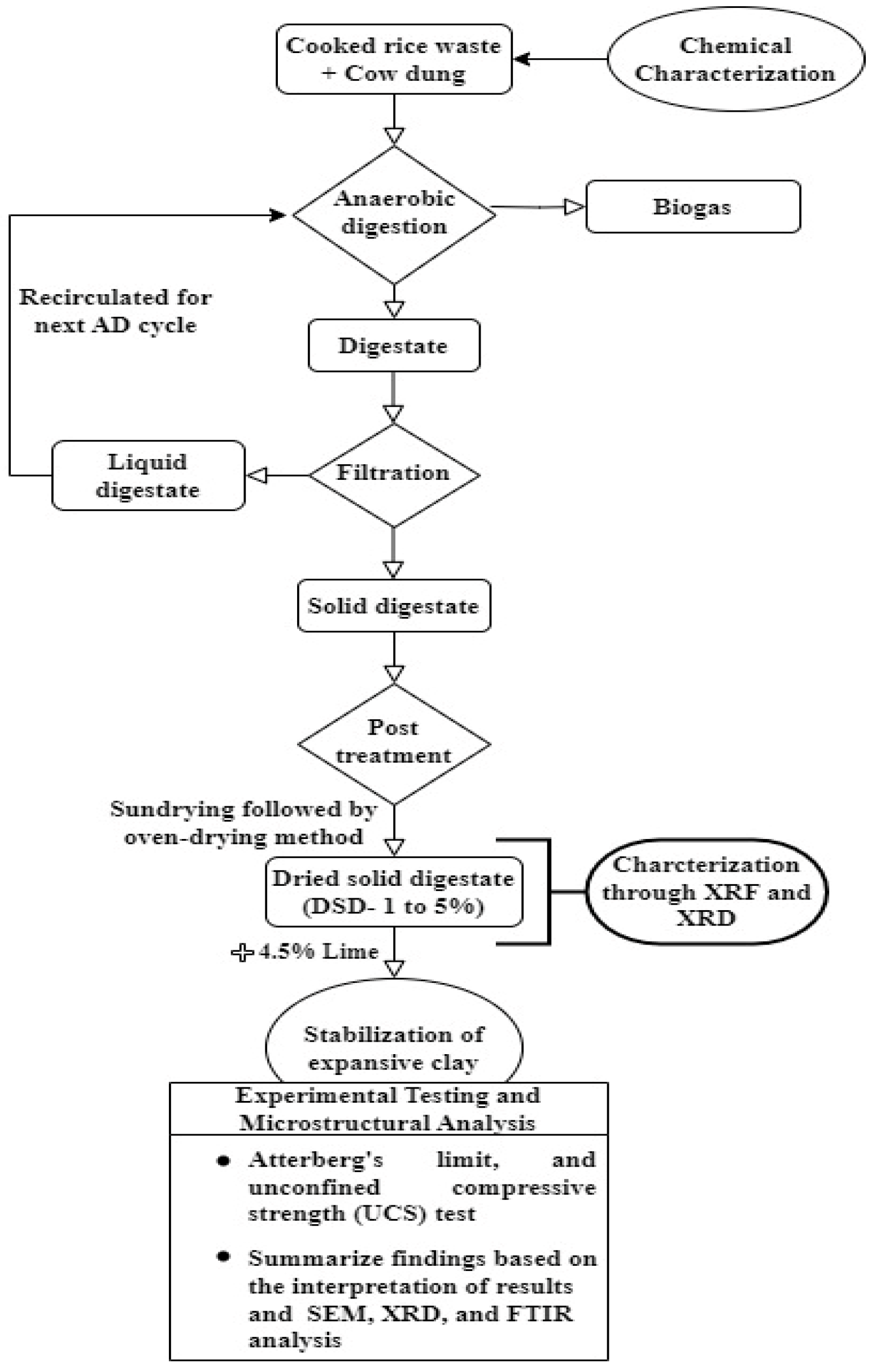

2. Materials and Methods

2.1. Substrate and Inoculum

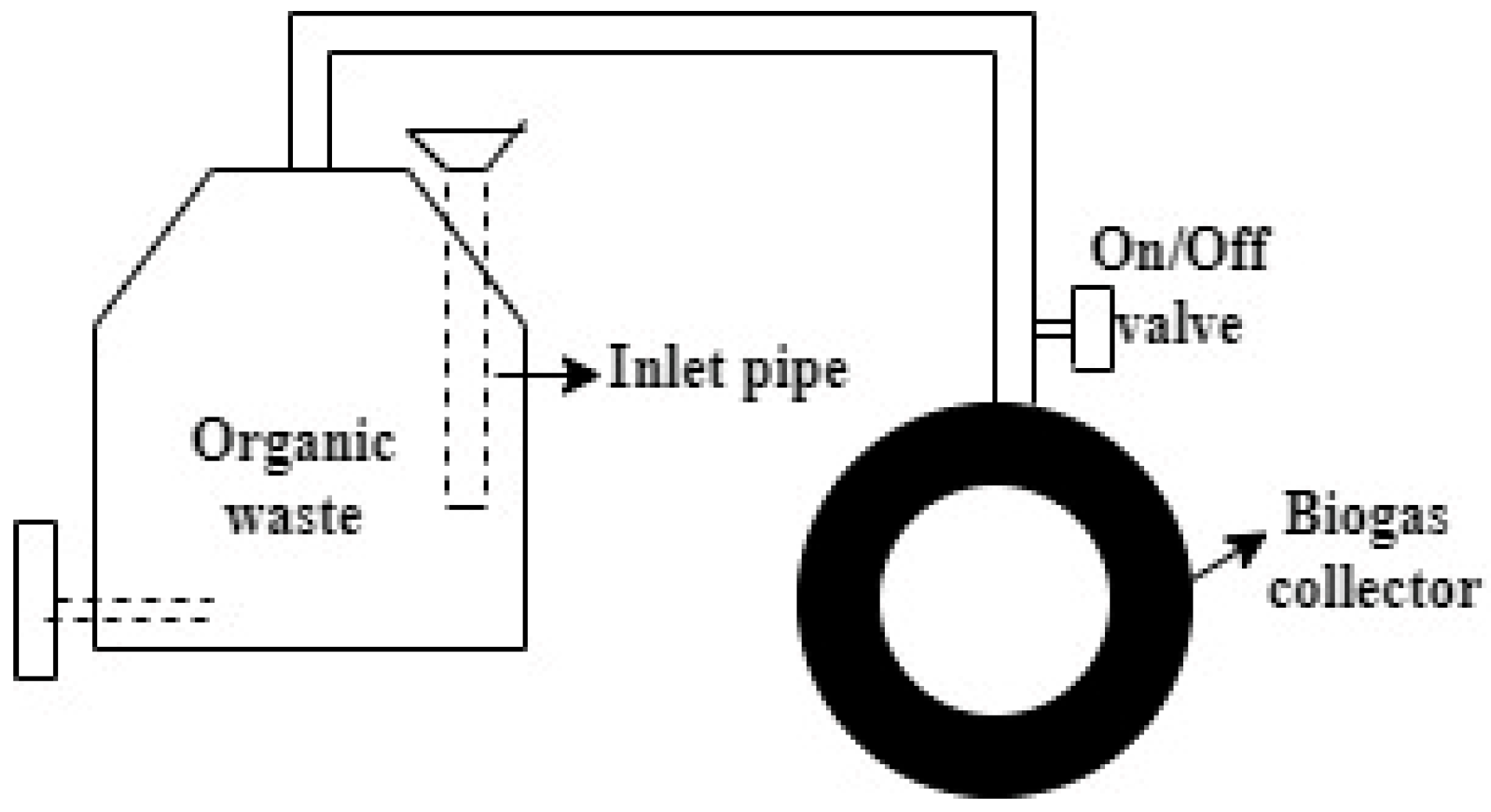

2.2. Experimental Setup and Procedure

2.3. Soil Stabilization

3. Results and Discussions

3.1. Characterization of Feed and Digestate

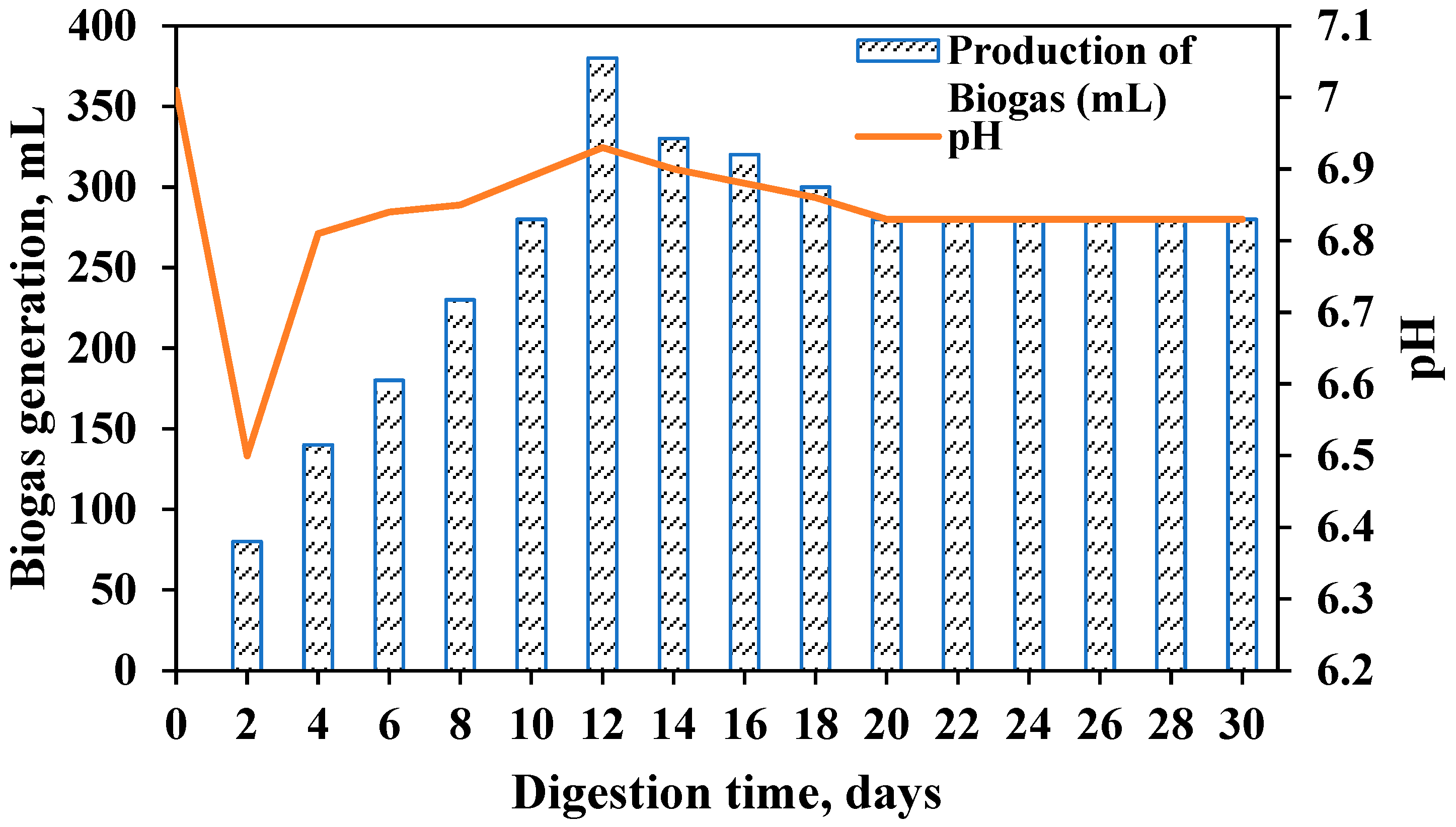

3.2. Biogas Production from a Small-Scale Digester and pH Effect

3.3. Characterization and Application of Solid Residue Digestate

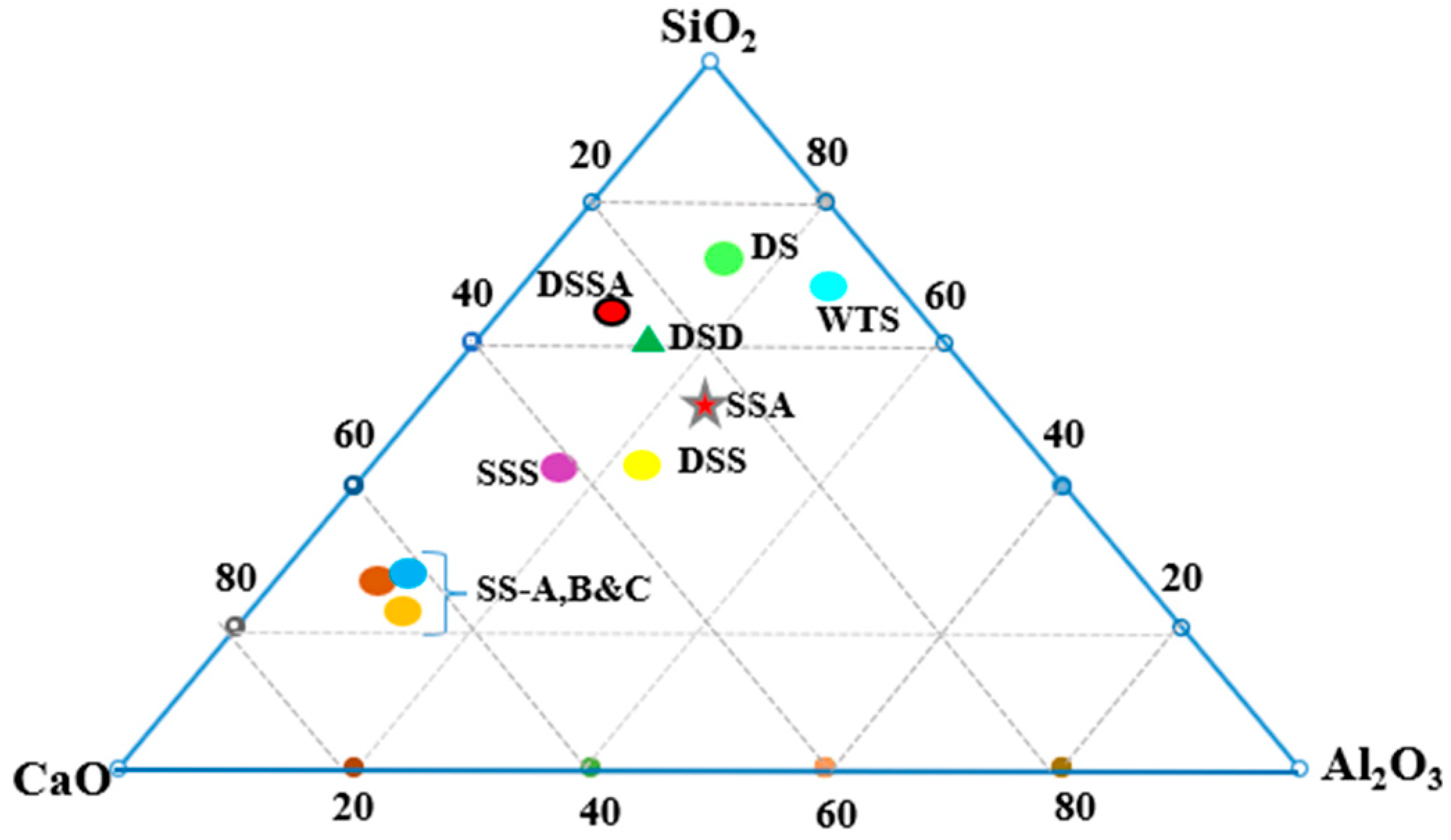

3.3.1. Chemical Composition and Mineralogical Study of Dried Solid Digestate

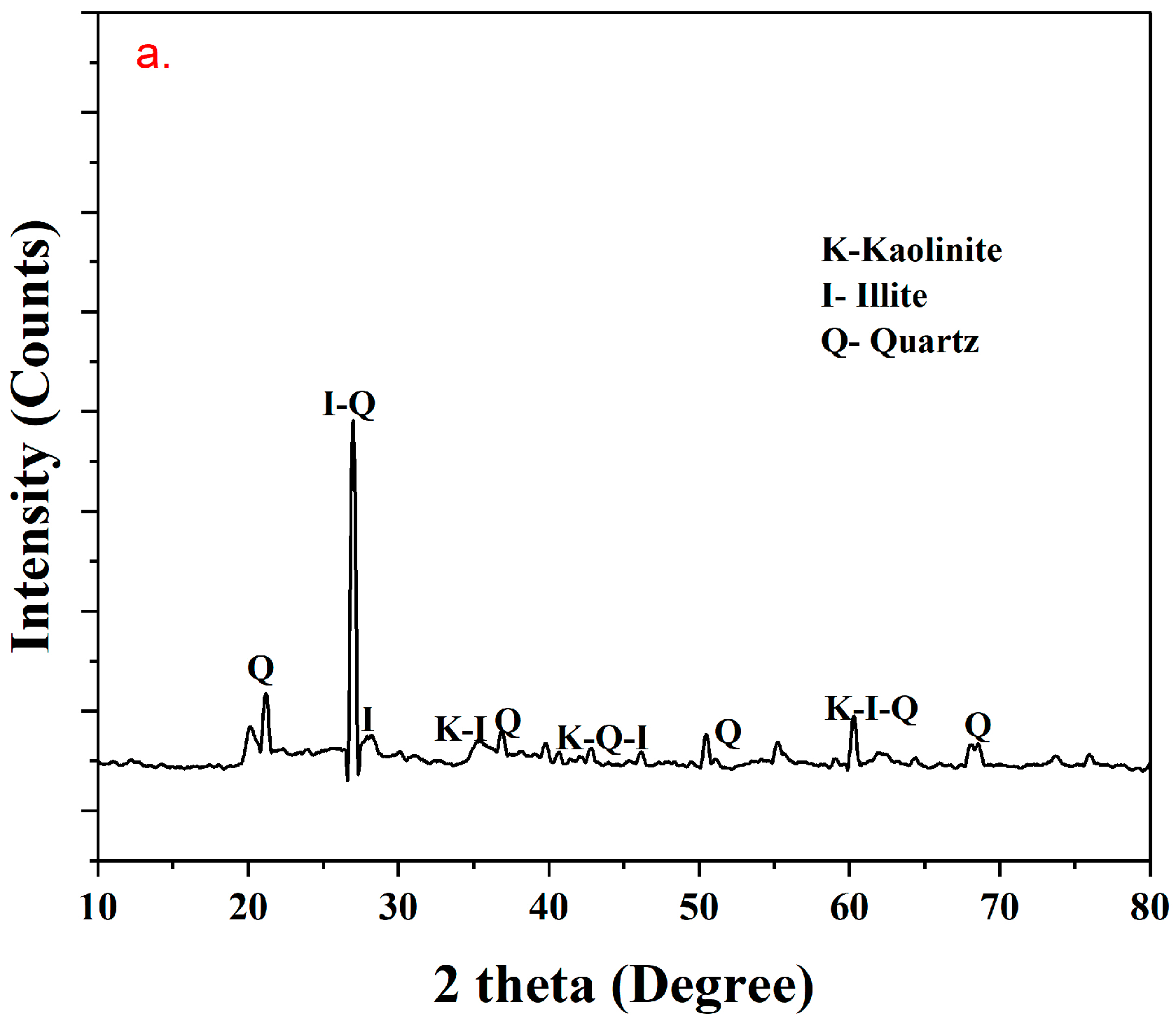

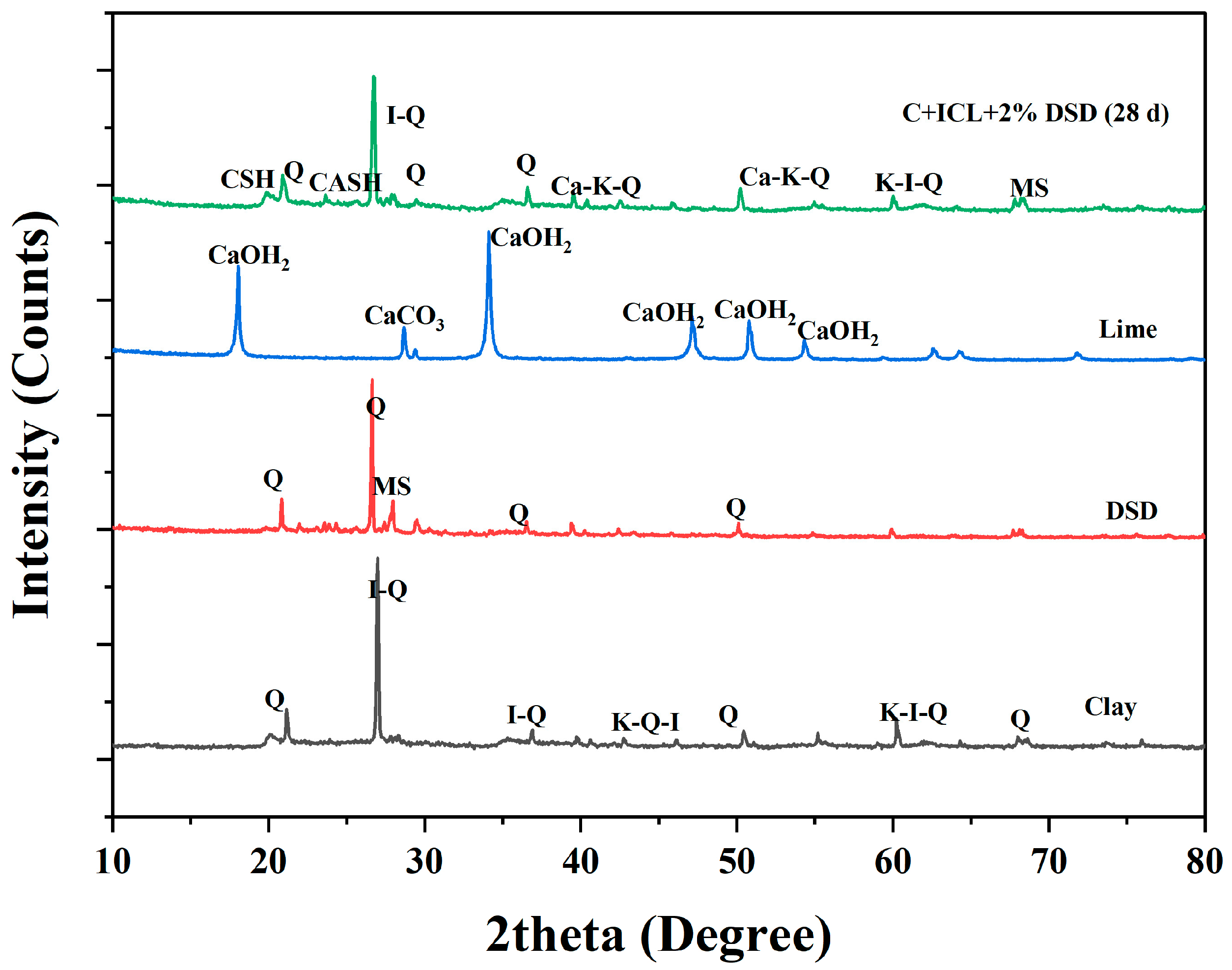

3.3.2. XRD Analysis of DSD

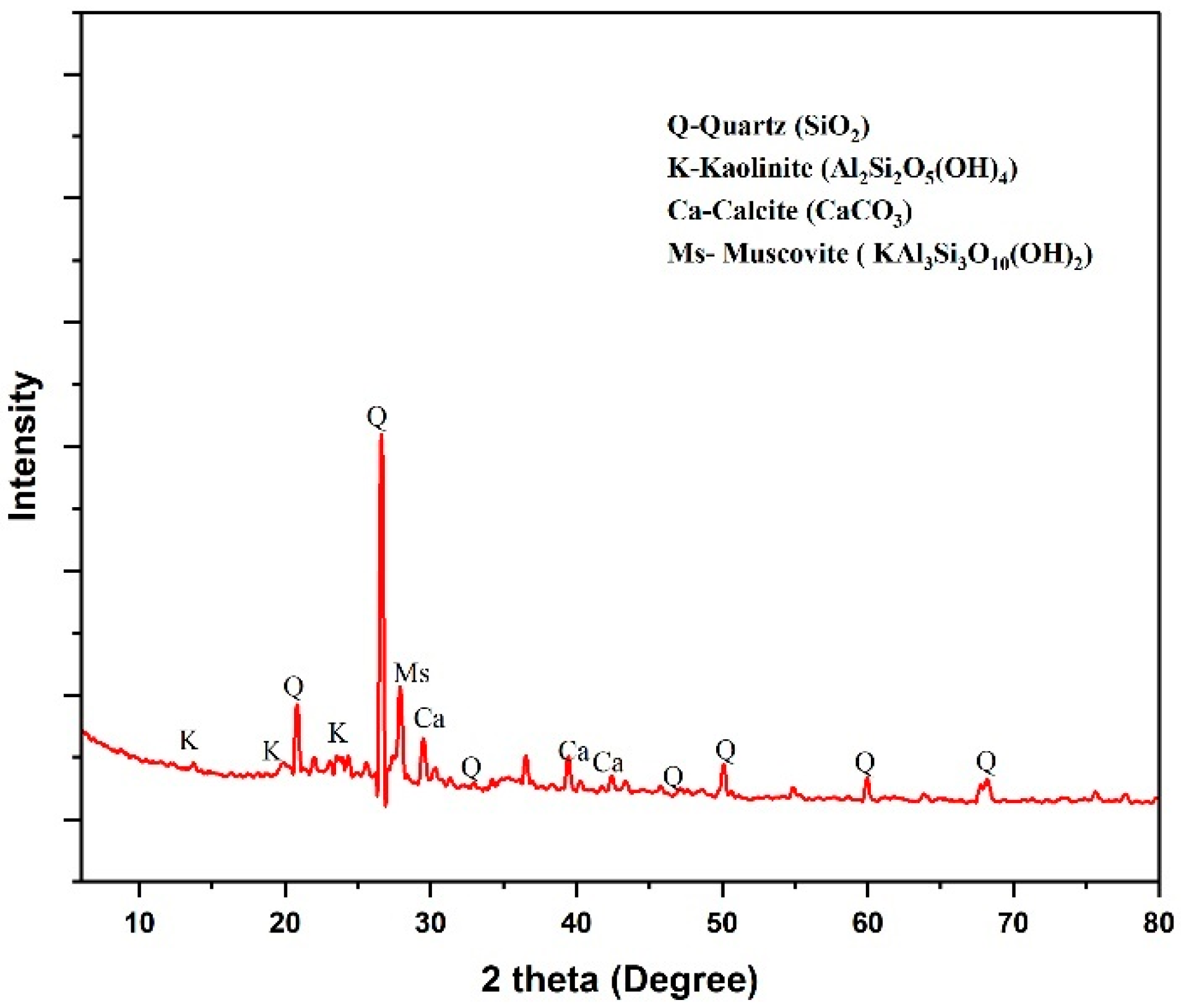

3.4. Characterization of Clayey Soil (Chemical, Engineering, and Mineralogical Aspects)

3.5. Impact of Additives on Plasticity Index, Compaction, and Strength of Clay

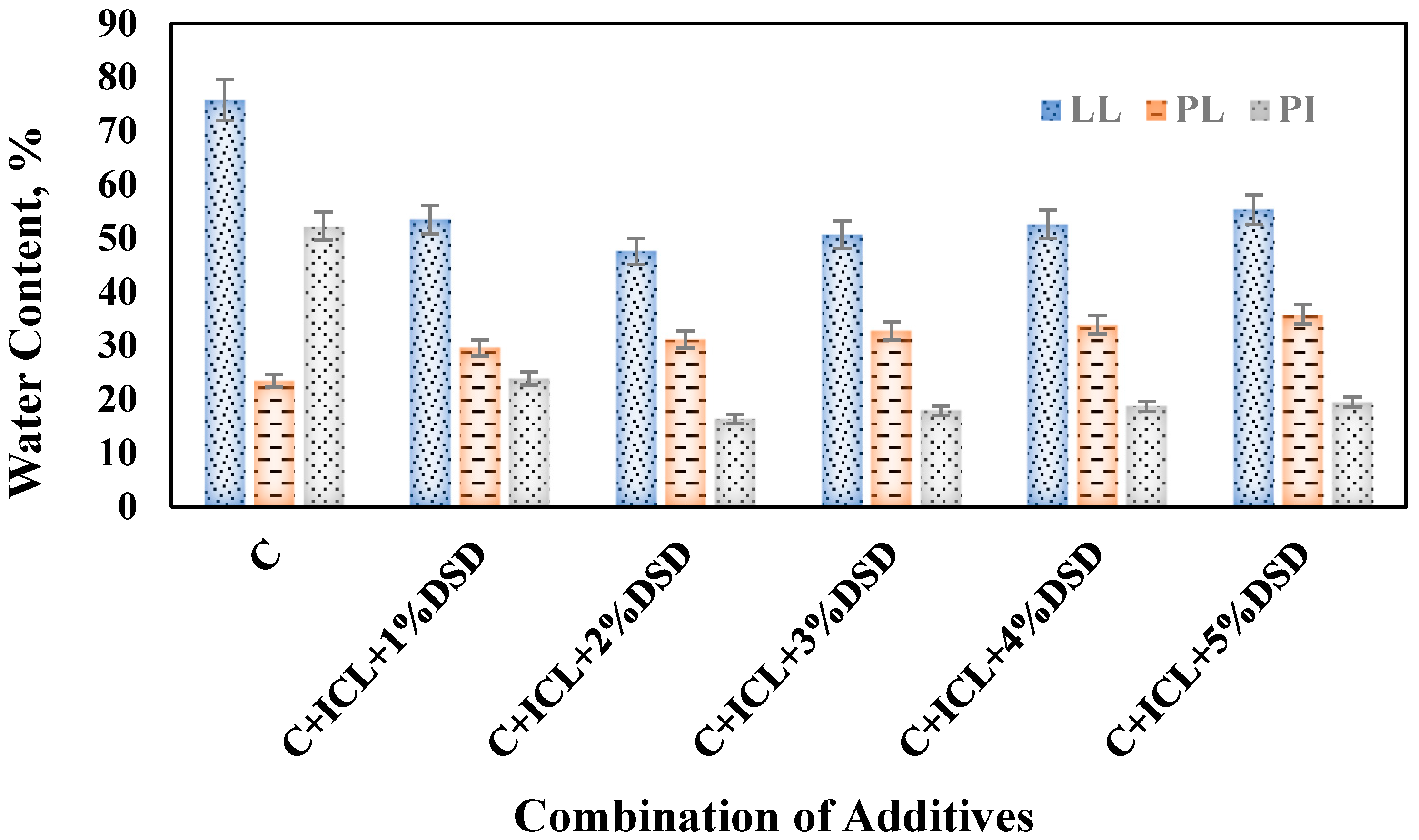

3.5.1. Atterberg’s Limits

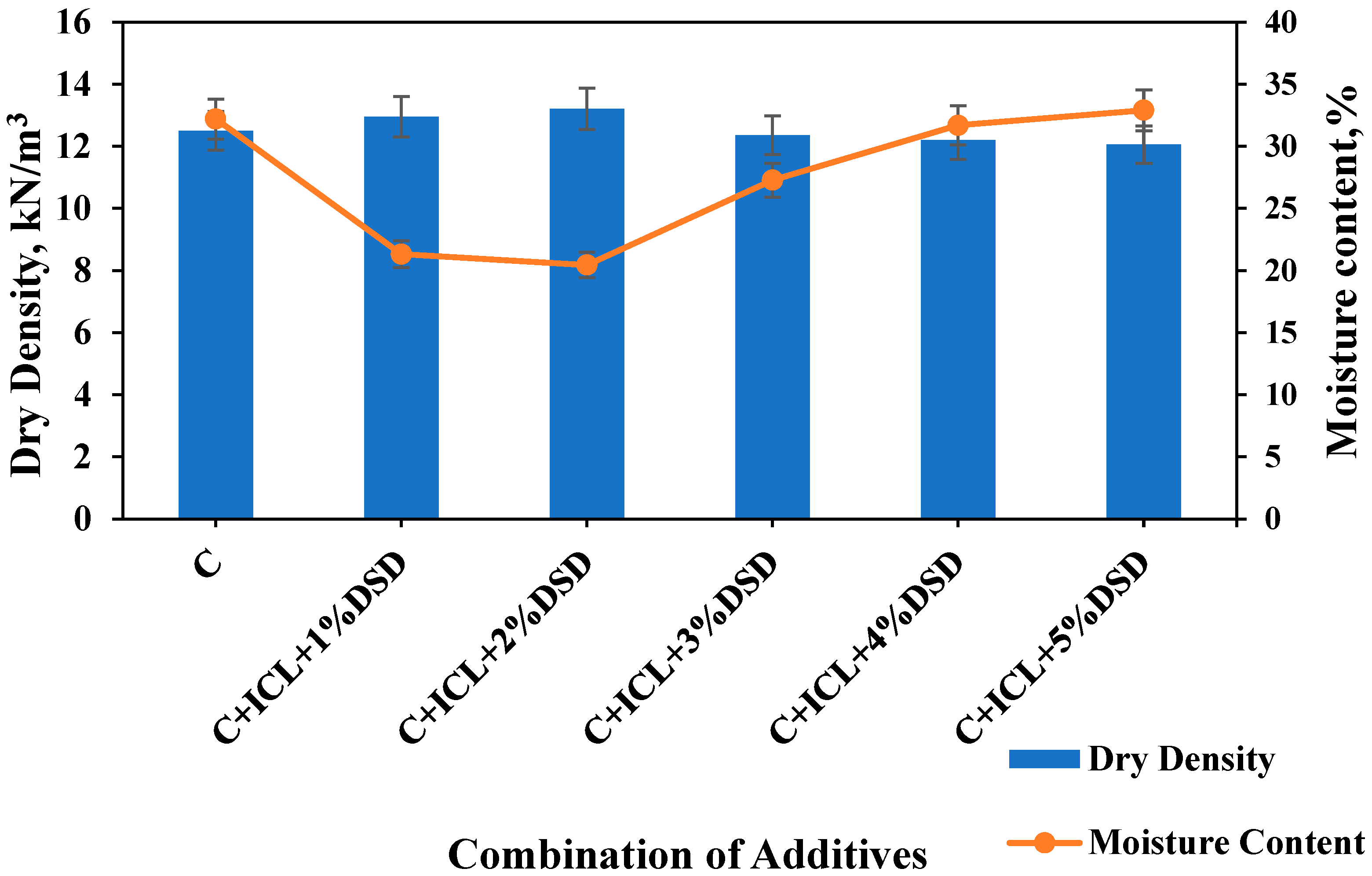

3.5.2. Compaction Characteristics

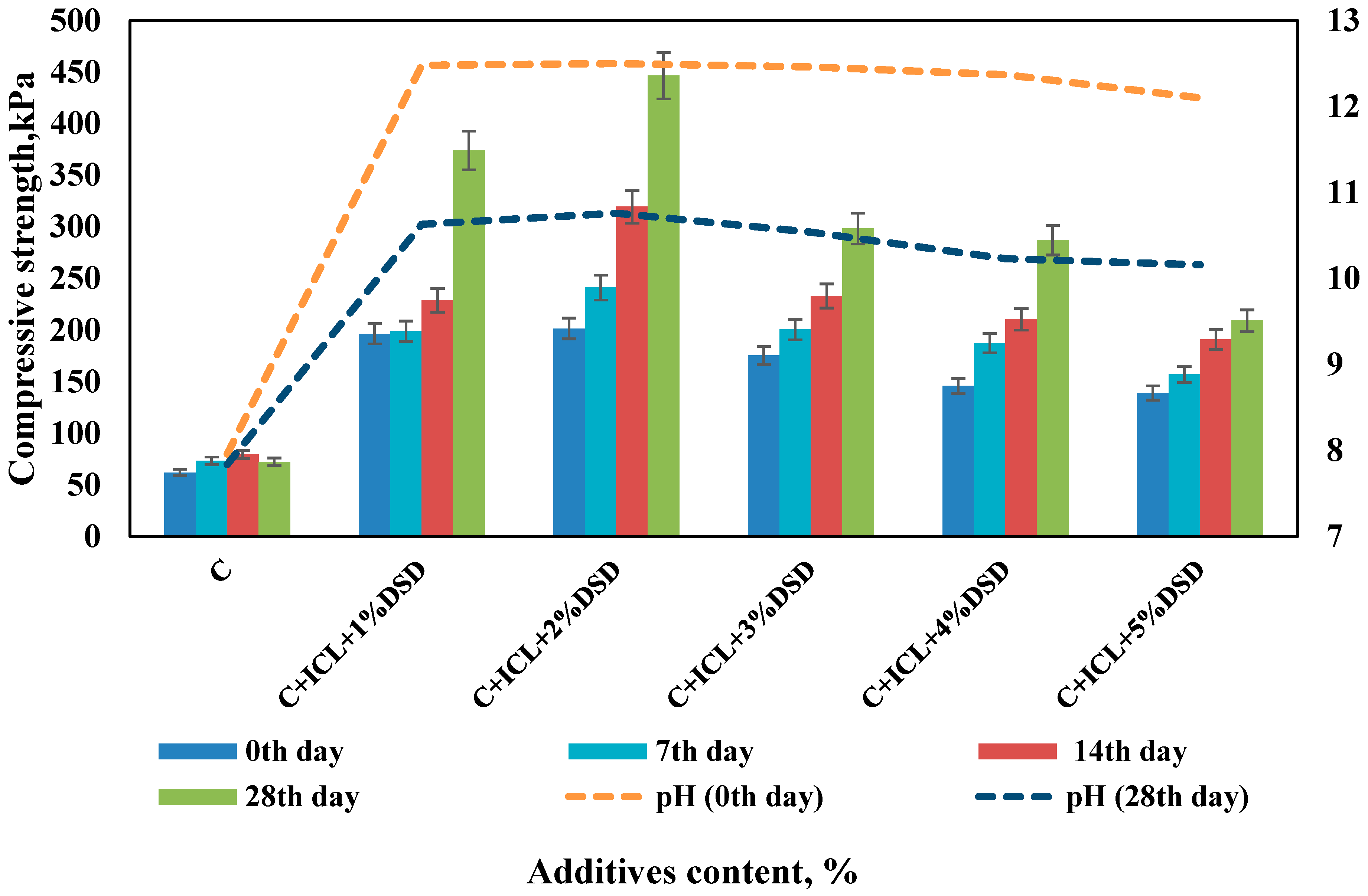

3.5.3. Compressive Strength of Clay

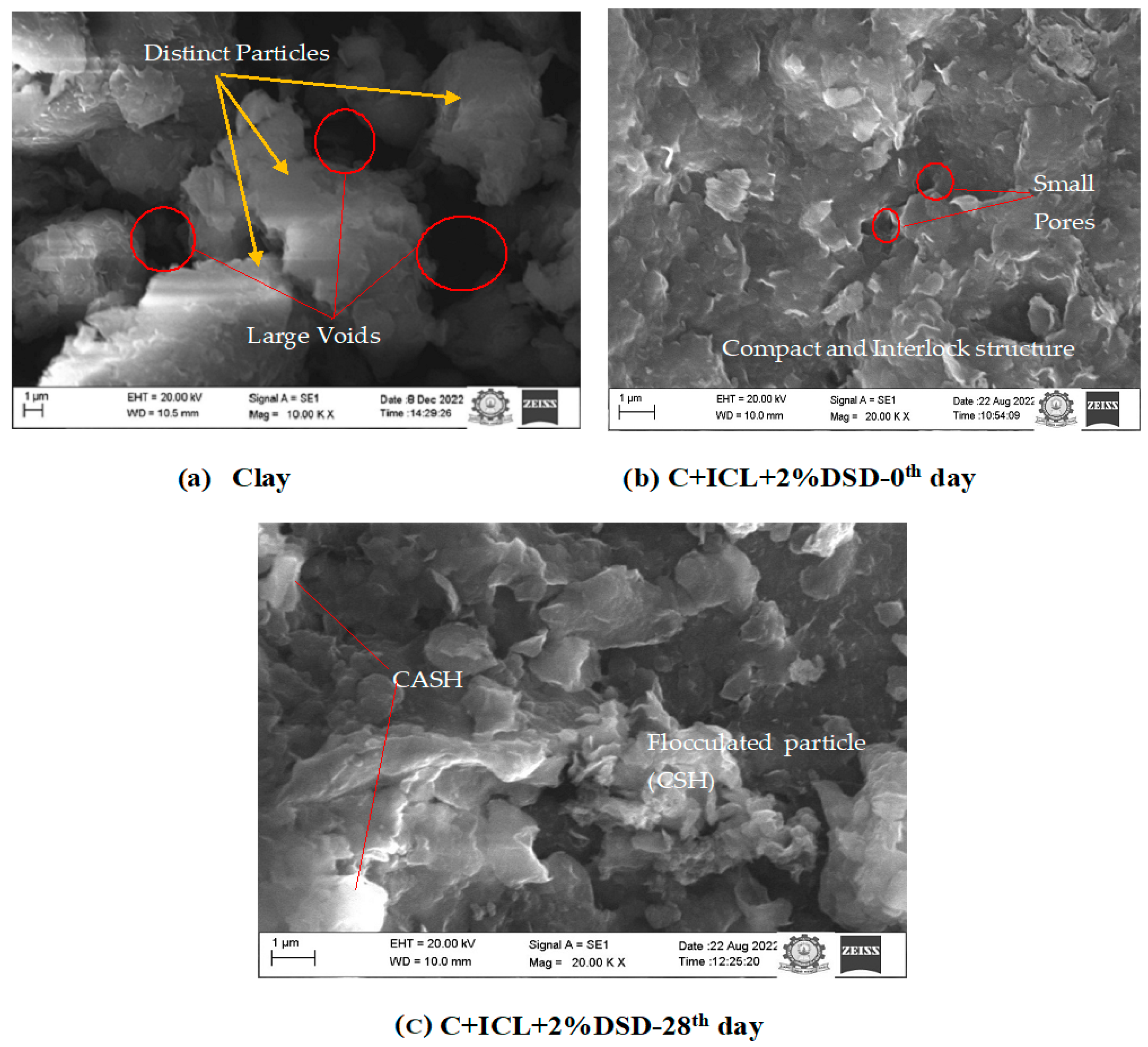

3.6. Microscopic Analysis of Stabilized Clay

3.6.1. SEM and EDS

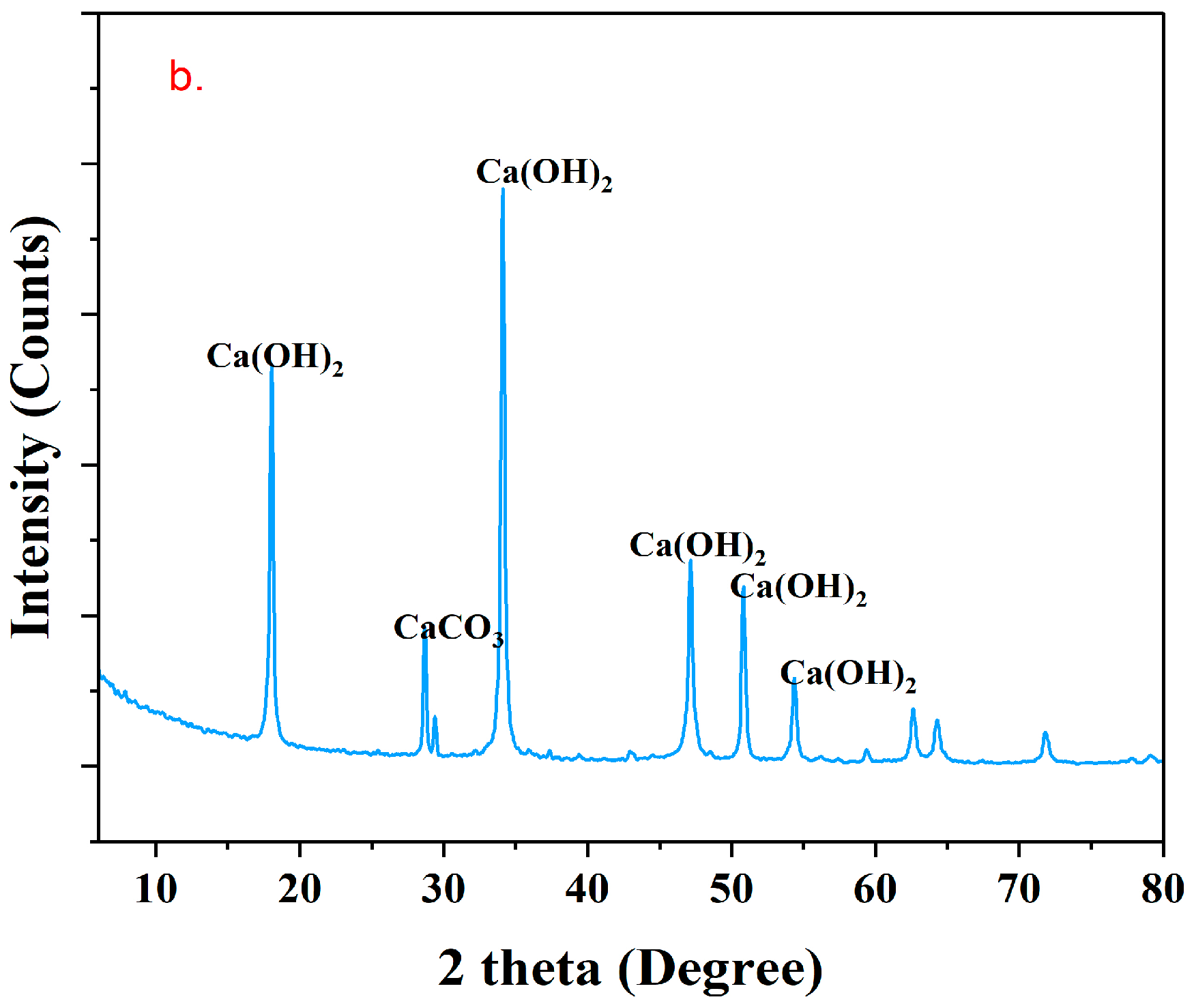

3.6.2. XRD

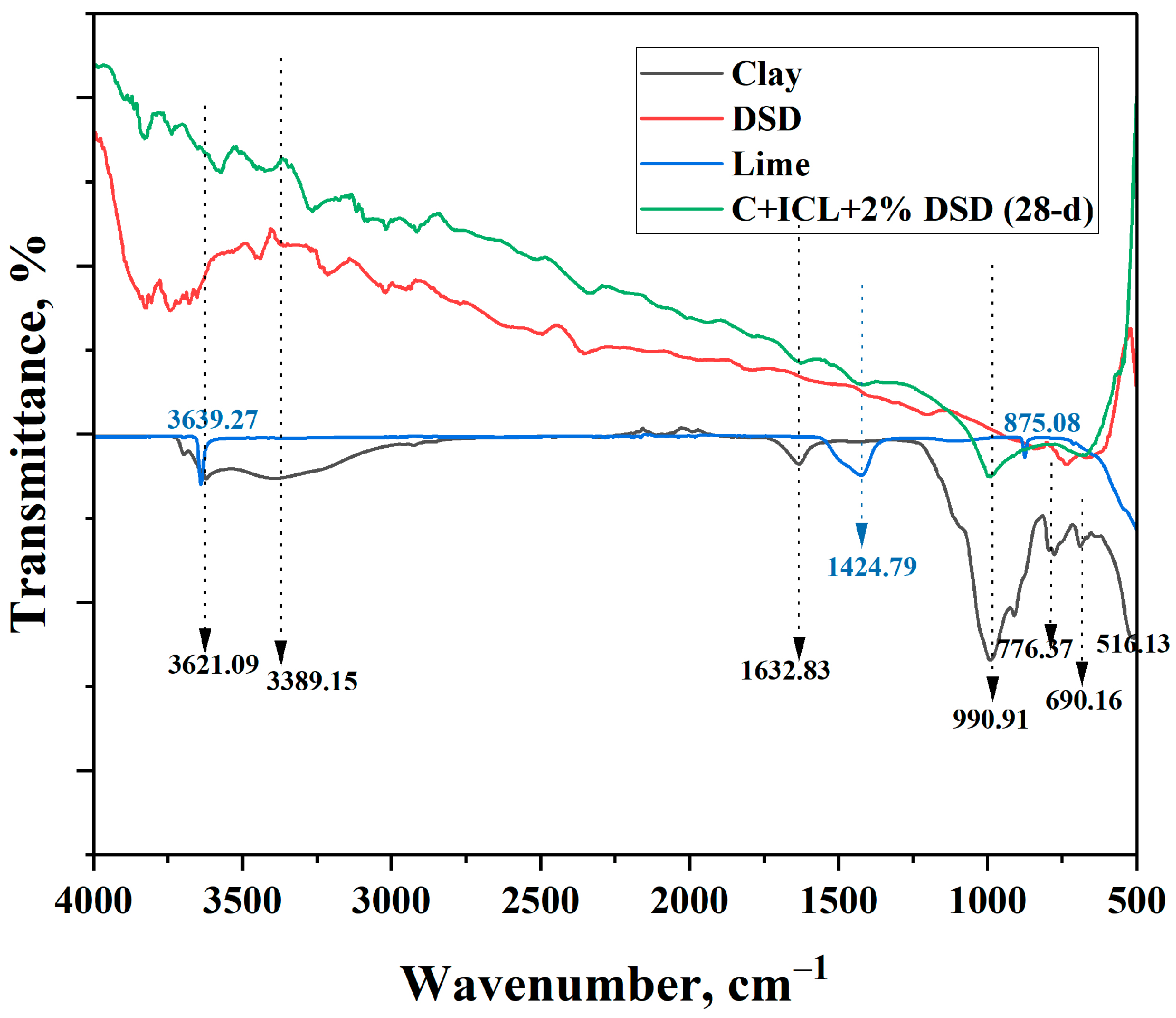

3.6.3. FTIR Analysis

4. Conclusions

- The optimum blend, comprising 4.5% lime and 2% DSD in clay, increased unconfined compressive strength (UCS) from 72.43% to 446.5% and reduced the plasticity index from 52.3% to 11.4% after 28-day curing.

- An innovative feature of this research is the use of DSD produced from cooked rice waste as a sustainable, non-traditional stabilizer, contributing to waste recycling and reducing reliance on conventional chemical stabilizers.

- The stabilization process is driven by lime hydration and carbonation reactions that form calcium carbonate. At the same time, DSD provides reactive minerals that promote ion exchange and pozzolanic reactions, thereby enhancing soil structure and cohesion.

- Microstructural studies using XRD, SEM, and FTIR techniques confirmed the formation of particle agglomeration and flocculation, as well as the development of cementitious materials such as CSH, which supports the observed improvements in soil strength.

- These findings underscore the potential of incorporating waste-based materials in sustainable soil improvement strategies for geotechnical applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wilson, D.C.; Velis, C.A. Waste management—Still a global challenge in the 21st century: An evidence-based call for action. Waste Manag. Res. 2015, 33, 1049–1051. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Smith, S.R.; Fowler, G.; Velis, C.; Kumar, S.J.; Arya, S.; Rena; Kumar, R.; Cheeseman, C. Challenges and opportunities associated with waste management in India. R. Soc. Open Sci. 2017, 4, 160764. [Google Scholar] [CrossRef]

- Mrosso, R.; Mecha, A.C.; Kiplagat, J. Characterization of kitchen and municipal organic waste for biogas production: Effect of parameters. Heliyon 2023, 9, e16360. [Google Scholar] [CrossRef]

- Breitenmoser, L.; Gross, T.; Huesch, R.; Rau, J.; Dhar, H.; Kumar, S.; Hugi, C.; Wintgens, T. Anaerobic digestion of biowastes in India: Opportunities, challenges and research needs. J. Environ. Manage. 2019, 236, 396–412. [Google Scholar] [CrossRef]

- Zamri, M.F.M.A.; Hasmady, S.; Akhiar, A.; Ideris, F.; Shamsuddin, A.H.; Mofijur, M.; Fattah, I.M.R.; Mahlia, T.M.I. A comprehensive review on anaerobic digestion of organic fraction of municipal solid waste. Renew. Sustain. Energy Rev. 2021, 137, 110637. [Google Scholar] [CrossRef]

- Moya, D.; Aldás, C.; López, G.; Kaparaju, P. Municipal solid waste as a valuable renewable energy resource: A worldwide opportunity of energy recovery by using Waste-To-Energy Technologies. Energy Procedia 2017, 134, 286–295. [Google Scholar] [CrossRef]

- Singh, C.K.; Kumar, A.; Roy, S.S. Quantitative analysis of the methane gas emissions from municipal solid waste in India. Sci. Rep. 2018, 8, 2913. [Google Scholar] [CrossRef]

- Lu, J.; Xu, S. Post-treatment of food waste digestate towards land application: A review. J. Clean. Prod. 2021, 303, 127033. [Google Scholar] [CrossRef]

- Barbara, L.; Amaury, P.-M.; Estela, G.-Y.; Christian, G.F.; Karel, D.-S.; Gerardo, J.R.-M. Anaerobic digestate management, environmental impacts, and techno-economic challenges. Waste Manag. 2022, 140, 14–30. [Google Scholar] [CrossRef]

- Tambone, F.; Orzi, V.; D’Imporzano, G.; Adani, F. Solid and liquid fractionation of digestate: Mass balance, chemical characterization, and agronomic and environmental value. Bioresour. Technol. 2017, 243, 1251–1256. [Google Scholar] [CrossRef]

- Fernández-Bayo, J.D.; Achmon, Y.; Harrold, D.R.; McCurry, D.G.; Hernandez, K.; Dahlquist-Willard, R.M.; Stapleton, J.J.; VanderGheynst, J.S.; Simmons, C.W. Assessment of Two Solid Anaerobic Digestate Soil Amendments for Effects on Soil Quality and Biosolarization Efficacy. J. Agric. Food Chem. 2017, 65, 3434–3442. [Google Scholar] [CrossRef] [PubMed]

- Monlau, F.; Sambusiti, C.; Ficara, E.; Aboulkas, A.; Barakat, A.; Carrère, H. New opportunities for agricultural digestate valorization: Current situation and perspectives. Energy Environ. Sci. 2015, 8, 2600–2621. [Google Scholar] [CrossRef]

- Peng, W.; Pivato, A. Sustainable Management of Digestate from the Organic Fraction of Municipal Solid Waste and Food Waste Under the Concepts of Back to Earth Alternatives and Circular Economy. Waste Biomass Valorization 2019, 10, 465–481. [Google Scholar] [CrossRef]

- Czekała, W. Solid Fraction of Digestate from Biogas Plant as a Material for Pellets Production. Energies 2021, 14, 5034. [Google Scholar] [CrossRef]

- Ekielski, A.; Żelaziński, T.; Mishra, P.K.; Skudlarski, J. Properties of Biocomposites Produced with Thermoplastic Starch and Digestate: Physicochemical and Mechanical Characteristics. Materials 2021, 14, 6092. [Google Scholar] [CrossRef]

- Tasaki, K. Chemical-free recovery of crude protein from livestock manure digestate solid by thermal hydrolysis. Bioresour. Bioprocess. 2021, 8, 60. [Google Scholar] [CrossRef]

- Tambone, F.; Genevini, P.; D’Imporzano, G.; Adani, F. Assessing amendment properties of digestate by studying the organic matter composition and the degree of biological stability during the anaerobic digestion of the organic fraction of MSW. Bioresour. Technol. 2009, 100, 3140–3142. [Google Scholar] [CrossRef]

- Beggio, G.; Peng, W.; Lü, F.; Cerasaro, A.; Bonato, T.; Pivato, A. Chemically Enhanced Solid–Liquid Separation of Digestate: Suspended Solids Removal and Effects on Environmental Quality of Separated Fractions. Waste Biomass Valorization 2022, 13, 1029–1041. [Google Scholar] [CrossRef]

- Li, L.-J.; You, M.-Y.; Shi, H.-A.; Ding, X.-L.; Qiao, Y.-F.; Han, X.-Z. Soil CO2 emissions from a cultivated Mollisol: Effects of organic amendments, soil temperature, and moisture. Eur. J. Soil Biol. 2013, 55, 83–90. [Google Scholar] [CrossRef]

- Dietrich, C.C.; Rahaman, M.A.; Robles-Aguilar, A.A.; Latif, S.; Intani, K.; Müller, J.; Jablonowski, N.D. Nutrient Loaded Biochar Doubled Biomass Production in Juvenile Maize Plants (Zea mays L.). Agronomy 2020, 10, 567. [Google Scholar] [CrossRef]

- Liberti, F.; Pistolesi, V.; Mouftahi, M.; Hidouri, N.; Bartocci, P.; Massoli, S.; Zampilli, M.; Fantozzi, F. An Incubation System to Enhance Biogas and Methane Production: A Case Study of an Existing Biogas Plant in Umbria, Italy. Processes 2019, 7, 925. [Google Scholar] [CrossRef]

- Qiao, Y.; Zhang, S.; Quan, C.; Gao, N.; Johnston, C.; Wu, C. One-pot synthesis of digestate-derived biochar for carbon dioxide capture. Fuel 2020, 279, 118525. [Google Scholar] [CrossRef]

- Fu, D.; Chen, Z.; Xia, D.; Shen, L.; Wang, Y.; Li, Q. A novel solid digestate-derived biochar-Cu NP composite activating H2O2 system for simultaneous adsorption and degradation of tetracycline. Environ. Pollut. 2017, 221, 301–310. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, F.; Shen, X.; Yi, W.; Li, Z.; Li, Y.; Tian, C. Comparison study on fuel properties of hydrochars produced from corn stalk and corn stalk digestate. Energy 2018, 165, 527–536. [Google Scholar] [CrossRef]

- Zhang, J.J.; Fan, H.X.; Dai, X.H.; Yuan, S.J. Digested sludge-derived three-dimensional hierarchical porous carbon for high-performance supercapacitor electrode. R. Soc. Open Sci. 2018, 5, 172456. [Google Scholar] [CrossRef]

- Zhong, Y.; Ruan, Z.; Zhong, Y.; Archer, S.; Liu, Y.; Liao, W. A self-sustaining advanced lignocellulosic biofuel production by integration of anaerobic digestion and aerobic fungal fermentation. Bioresour. Technol. 2015, 179, 173–179. [Google Scholar] [CrossRef]

- Biswas, R.; Ahring, B.K.; Uellendahl, H. Improving biogas yields using an innovative concept for conversion of the fiber fraction of manure. Water Sci. Technol. 2012, 66, 1751–1758. [Google Scholar] [CrossRef] [PubMed]

- Nagarajan, D.; Lee, D.J.; Chang, J.S. Integration of anaerobic digestion and microalgal cultivation for digestate bioremediation and biogas upgrading. Bioresour. Technol. 2019, 290, 121804. [Google Scholar] [CrossRef]

- Mattoso, A.P.; Cunha, S.; Aguiar, J.; Duarte, A.; Lemos, H. Valorization of Water Treatment Sludge for Applications in the Construction Industry: A Review. Materials 2024, 17, 1824. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2017; Volume 23. [Google Scholar]

- IS 2720-4; Methods of Test for Soils, Part 4: Grain Size Analysis. Bureau of Indian Standard: New Delhi, India, 1985.

- IS 2720-5; Methods of Test for Soils, Part 5: Determination of Liquid and Plastic Limit. Bureau of Indian Standard: New Delhi, India, 1985.

- IS 2720-8; Methods of Test for Soils, Part 8: Determination of Water Content-Dry Density Relation Using Heavy Compaction. Bureau of Indian Standard: New Delhi, India, 2006.

- IS 2720-10; Methods of Test for Soils, Part 10: Determination of Unconfined Compressive Strength. Bureau of Indian Standards: New Delhi, Indian, 1991.

- Arunthathi, S.; Sivapriya, S.V.; Balaji, D. Strength, mineralogical and microstructural studies on clayey soil stabilized by bio-stabilized waste ash with lime. J. Mater. Cycles Waste Manag. 2023, 25, 3625–3637. [Google Scholar] [CrossRef]

- Sridharan, A.; Sivapullaiah, P.V. Mini compaction test apparatus for fine grained soils. Geotech. Test. J. 2005, 28, 240–246. [Google Scholar] [CrossRef]

- Emmanuel Pax, M.; Muzenda, E.; Lekgoba, T. Effect of co-digestion of food waste and cow dung on biogas yield. E3S Web Conf. 2020, 181, 01005. [Google Scholar] [CrossRef]

- Zhai, N.; Zhang, T.; Yin, D.; Yang, G.; Wang, X.; Ren, G.; Feng, Y. Effect of initial pH on anaerobic co-digestion of kitchen waste and cow manure. Waste Manag. 2015, 38, 126. [Google Scholar] [CrossRef]

- Zhang, R.; El-Mashad, H.M.; Hartman, K.; Wang, F.; Liu, G.; Choate, C.; Gamble, P. Characterization of food waste as feedstock for anaerobic digestion. Bioresour. Technol. 2007, 98, 929–935. [Google Scholar] [CrossRef]

- Yu, M.; Wu, C.; Wang, Q.; Sun, X.; Ren, Y.; Li, Y.-Y. Ethanol prefermentation of food waste in sequencing batch methane fermentation for improved buffering capacity and microbial community analysis. Bioresour. Technol. 2018, 248, 187–193. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.-J.; Kobayashi, T.; Li, Y.-Y.; Xu, K.-Q. Comparison of single-stage and temperature-phased two-stage anaerobic digestion of oily food waste. Energy Convers. Manag. 2015, 106, 1174–1182. [Google Scholar] [CrossRef]

- Kuruti, K.; Begum, S.; Ahuja, S.; Anupoju, G.R.; Juntupally, S.; Gandu, B.; Ahuja, D.K. Exploitation of rapid acidification phenomena of food waste in reducing the hydraulic retention time (HRT) of high rate anaerobic digester without conceding on biogas yield. Bioresour. Technol. 2017, 226, 65–72. [Google Scholar] [CrossRef]

- Lin, L.; Xu, F.; Ge, X.; Li, Y. Improving the sustainability of organic waste management practices in the food-energy-water nexus: A comparative review of anaerobic digestion and composting. Renew. Sustain. Energy Rev. 2018, 89, 151–167. [Google Scholar] [CrossRef]

- He, K.; Liu, Y.; Tian, L.; He, W.; Cheng, Q. Review in anaerobic digestion of food waste. Heliyon 2024, 10, e28200. [Google Scholar] [CrossRef] [PubMed]

- Selvam, A.; Ilamathi, P.M.K.; Udayakumar, M.; Murugesan, K.; Banu, J.R.; Khanna, Y.; Wong, J. Food Waste Properties. Curr. Dev. Biotechnol. Bioeng. 2021, 19, 11–41. [Google Scholar] [CrossRef]

- Fardous, M.R.; Nasrin, M.S.; Shakil, M.E.; Islam, M.S.; Hoque, M.A.; Islam, M.N. Cow Urine for Enhancement of Biogas Production and Fertilizer Quality of Biogas Slurry. J. Sci. Res. 2020, 12, 135–144. [Google Scholar] [CrossRef]

- Torres-Climent, A.; Martin-Mata, J.; Marhuenda-Egea, F.; Moral, R.; Barber, X.; Perez-Murcia, M.D.; Paredes, C. Composting of the Solid Phase of Digestate from Biogas Production: Optimization of the Moisture, C/N Ratio, and pH Conditions. Commun. Soil Sci. Plant Anal. 2015, 46, 197–207. [Google Scholar] [CrossRef]

- Dhungana, B.; Lohani, S.P.; Marsolek, M. Anaerobic Co-Digestion of Food Waste with Livestock Manure at Ambient Temperature: A Biogas Based Circular Economy and Sustainable Development Goals. Sustainability 2022, 14, 3307. [Google Scholar] [CrossRef]

- Kesharwani, N.; Bajpai, S. Batch anaerobic co-digestion of food waste and sludge: A multi criteria decision modelling (MCDM) approach. SN Appl. Sci. 2020, 2, 1467. [Google Scholar] [CrossRef]

- Ojewumi, M.E.; Ogele, P.C.; Oyekunle, D.T.; Omoleye, J.A.; Taiwo, S.O.; Obafemi, Y.D. Co-digestion of cow dung with organic kitchen waste to produce biogas using Pseudomonas aeruginosa. J. Phys. Conf. Ser. 2019, 1299, 012011. [Google Scholar] [CrossRef]

- Malik, W.; Mohan, C.; Annachhatre, A.P. Community based biogas plant utilizing food waste and cow dung. Mater. Today Proc. 2020, 28, 1910–1915. [Google Scholar] [CrossRef]

- Hilmi, N.A.M.; Zakarya, I.A.; Gunny, A.A.N.; Izhar, T.N.T.; Zaaba, S.K.; Samah, M.F.; Daud, Z.A.A.M.; Beson, M.R.C. Co-digestion of food waste with cow dung by anaerobic digestion for biogas production. IOP Conf. Ser. Earth Environ. Sci. 2023, 1135, 012034. [Google Scholar] [CrossRef]

- Chakraborty, D.; Karthikeyan, O.P.; Selvam, A.; Wong, J.W.C. Co-digestion of food waste and chemically enhanced primary treated sludge in a continuous stirred tank reactor. Biomass Bioenergy 2018, 111, 232–240. [Google Scholar] [CrossRef]

- Okewale, A.O.; Adesina, O.A. Evaluation of biogas production from co-digestion of pig dung, water hyacinth and poultry droppings. Waste Dispos. Sustain. Energy 2019, 1, 271–277. [Google Scholar] [CrossRef]

- Sharma, D.; Mahajan, R.; Baghel, V.; Bansal, S.; Ahuja, V.; Goel, G. Simultaneous Production of Biogas and Electricity from Anaerobic Digestion of Pine Needles: Sustainable Energy and Waste Management. BioTech 2024, 13, 35. [Google Scholar] [CrossRef]

- Jameel, M.K.; Mustafa, M.A.; Ahmed, H.S.; Mohammed, A.j.; Ghazy, H.; Shakir, M.N.; Lawas, A.M.; Mohammed, S.k.; Idan, A.H.; Mahmoud, Z.H.; et al. Biogas: Production, properties, applications, economic and challenges: A review. Results Chem. 2024, 7, 101549. [Google Scholar] [CrossRef]

- Uusitalo, V.; Havukainen, J.; Kapustina, V.; Soukka, R.; Horttanainen, M. Greenhouse gas emissions of biomethane for transport: Uncertainties and allocation methods. Energy Fuels 2014, 28, 1901–1910. [Google Scholar] [CrossRef]

- Ahern, E.P.; Deane, P.; Persson, T.; Ó Gallachóir, B.; Murphy, J.D. A perspective on the potential role of renewable gas in a smart energy island system. Renew. Energy 2015, 78, 648–656. [Google Scholar] [CrossRef]

- Hossain, M.S.; Karim, T.u.; Onik, M.H.; Kumar, D.; Rahman, M.A.; Yousuf, A.; Uddin, M.R. Impact of temperature, inoculum flow pattern, inoculum type, and their ratio on dry anaerobic digestion for biogas production. Sci. Rep. 2022, 12, 6162. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.A.; Shahazi, R.; Nova, S.N.B.; Uddin, M.R.; Hossain, M.S.; Yousuf, A. Biogas production from anaerobic co-digestion using kitchen waste and poultry manure as substrate—Part 1: Substrate ratio and effect of temperature. Biomass Convers. Biorefinery 2023, 13, 6635–6645. [Google Scholar] [CrossRef] [PubMed]

- Baştabak, B.; Koçar, G. A review of the biogas digestate in agricultural framework. J. Mater. Cycles Waste Manag. 2020, 22, 1318–1327. [Google Scholar] [CrossRef]

- Salamat, R.; Scaar, H.; Weigler, F.; Berg, W.; Mellmann, J. Drying of biogas digestate: A review with a focus on available drying techniques, drying kinetics, and gaseous emission behavior. Dry. Technol. 2022, 40, 5–29. [Google Scholar] [CrossRef]

- Pulvirenti, A.; Ronga, D.; Zaghi, M.; Tomasselli, A.R.; Mannella, L.; Pecchioni, N. Pelleting is a successful method to eliminate the presence of Clostridium spp. from the digestate of biogas plants. Biomass Bioenergy 2015, 81, 479–482. [Google Scholar] [CrossRef]

- Michele, P.; Giuliana, D.; Carlo, M.; Sergio, S.; Fabrizio, A. Optimization of solid state anaerobic digestion of the OFMSW by digestate recirculation: A new approach. Waste Manag. 2015, 35, 111–118. [Google Scholar] [CrossRef]

- Vouk, D.; Serdar, M.; Nakić, D.; Anić-Vučinić, A. Use of sludge generated at WWTP in the production of cement mortar and concrete. Gradjevinar 2016, 68, 199–210. [Google Scholar] [CrossRef]

- Montero, M.A.; Jordán, M.M.; Hernández-Crespo, M.S.; Sanfeliu, T. The use of sewage sludge and marble residues in the manufacture of ceramic tile bodies. Appl. Clay Sci. 2009, 46, 404–408. [Google Scholar] [CrossRef]

- Qi, Y.; Yue, Q.; Han, S.; Yue, M.; Gao, B.; Yu, H.; Shao, T. Preparation and mechanism of ultra-lightweight ceramics produced from sewage sludge. J. Hazard. Mater. 2010, 176, 76–84. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, L.; Yin, Y.; Liang, X.; Li, A. The recycling of incinerated sewage sludge ash as a raw material for CaO–Al2O3–SiO2–P2O5 glass-ceramic production. Environ. Technol. 2015, 36, 1098–1103. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Jia, L.T.; Mei, H.; Cui, Q.; Zhang, P.G.; Sun, Z.M. Fabrication, microstructure and properties of bricks fired from lake sediment, cinder and sewage sludge. Constr. Build. Mater. 2016, 121, 154–160. [Google Scholar] [CrossRef]

- Dhir, R.K.; Ghataora, G.S.; Lynn, C.J. Sewage Sludge Ash Characteristics. Sustain. Constr. Mater. 2017, 69–110. [Google Scholar] [CrossRef]

- Na, W. Production of sludge ceramsite from sewage sludge, municipal solid waste incineration fly ash and clay. Nat. Environ. Pollut. Technol. 2015, 14, 153–156. [Google Scholar]

- Chang, Z.; Long, G.; Zhou, J.L.; Ma, C. Valorization of sewage sludge in the fabrication of construction and building materials: A review. Resour. Conserv. Recycl. 2020, 154, 104606. [Google Scholar] [CrossRef]

- Ali, M.B.; Dahhou, M.; Benzaouak, A. Kinetic Study of Urban Sludge Using Iso-conversional Kinetic Analysis. NanoWorld J. 2023, 9, 419–424. [Google Scholar] [CrossRef]

- Fan, H.; Li, L.; Li, Z.; Shang, S. Structure of Sewage Sludge-Clay Multiscale Composite Particles to Control the Mechanism of SO2 and H2S Gas Release. Materials 2022, 15, 1855. [Google Scholar] [CrossRef] [PubMed]

- Zat, T.; Bandieira, M.; Sattler, N.; Segadães, A.M.; Cruz, R.C.D.; Mohamad, G.; Rodríguez, E.D. Potential re-use of sewage sludge as a raw material in the production of eco-friendly bricks. J. Environ. Manag. 2021, 297, 113238. [Google Scholar] [CrossRef] [PubMed]

- El-Deen, S.E.A.S.; Zhang, F. Synthesis of Sludge@Carbon Nanocomposite for the Recovery of as (V) from Wastewater. Procedia Environ. Sci. 2012, 16, 378–390. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Guney Olgun, C.; Firoozi, A.A.; Baghini, M.S. Fundamentals of soil stabilization. Int. J. Geo-Eng. 2017, 8, 26. [Google Scholar] [CrossRef]

- Behnood, A. Soil and clay stabilization with calcium- and non-calcium-based additives: A state-of-the-art review of challenges, approaches and techniques. Transp. Geotech. 2018, 17, 14–32. [Google Scholar] [CrossRef]

- Sendilvadivelu, A.; Vijayasimhan, S.; Dhandapani, B.; Shabir, S. Exploring the impact of temperature in valorising digestate as a strength enhancer of the expansive soil. Bull. Mater. Sci. 2025, 48, 36. [Google Scholar] [CrossRef]

- Gonzalez, J.; Sargent, P.; Ennis, C. Sewage treatment sludge biochar activated blast furnace slag as a low carbon binder for soft soil stabilisation. J. Clean. Prod. 2021, 311, 127553. [Google Scholar] [CrossRef]

- Malkawi, D.A.; Rabab’ah, S.R.; AlSyouf, M.M.; Aldeeky, H. Utilizing expansive soil treated with phosphogypsum and lime in pavement construction. Results Eng. 2023, 19, 101256. [Google Scholar] [CrossRef]

- Cheng, Y.; Huang, X. Effect of Mineral Additives on the Behavior of an Expansive Soil for Use in Highway Subgrade Soils. Appl. Sci. 2019, 9, 30. [Google Scholar] [CrossRef]

- Supandi, S.; Zakaria, Z.; Sukiyah, E.; Sudradjat, A. The Influence of Kaolinite-Illite toward mechanical properties of Claystone. Open Geosci. 2019, 11, 440–446. [Google Scholar] [CrossRef]

- Özkan, İ.; Yenginar, Y. Improvement of high plasticity clay by using filter sludge. Konya J. Eng. Sci. 2023, 11, 973–985. [Google Scholar] [CrossRef]

- Zaini, M.S.I.; Hasan, M.; Almuaythir, S.; Hyodo, M. Experimental investigations on physico-mechanical properties of kaolinite clay soil stabilized at optimum silica fume content using clamshell ash and lime. Sci. Rep. 2024, 14, 10995. [Google Scholar] [CrossRef]

- Taki, K.; Choudhary, S.; Gupta, S.; Kumar, M. Enhancement of geotechnical properties of municipal sewage sludge for sustainable utilization as engineering construction material. J. Clean. Prod. 2020, 251, 119723. [Google Scholar] [CrossRef]

- Shabanzadeh, H.; Àtrchian, M.R. Failure envelope and strength of dispersive clay/sewage sludge ash/lime. Sādhanā 2024, 49, 285. [Google Scholar] [CrossRef]

- Noorzad, R.; Motevalian, S. Improvement of Clayey Soil with Lime and Industrial Sludge. Geotech. Geol. Eng. 2018, 36, 2957–2966. [Google Scholar] [CrossRef]

- Umar, I.H.; Lin, H.; Ibrahim, A.S. Laboratory Testing and Analysis of Clay Soil Stabilization Using Waste Marble Powder. Appl. Sci. 2023, 13, 9274. [Google Scholar] [CrossRef]

- Alrubaye, A.J.; Hasan, M.; Fattah, M.Y. Stabilization of soft kaolin clay with silica fume and lime. Int. J. Geotech. Eng. 2017, 11, 90–96. [Google Scholar] [CrossRef]

- James, J.; Singh, B.; Ramachandran, H.K.; Sreenivasan, R.; Shafi, Y. Sustainable Management of Sugarcane Press Mud Waste as a Ternary Additive in Cement-Lime Stabilization of an Expansive Soil. Present Environ. Sustain. Dev. 2022, 2, 81–94. [Google Scholar] [CrossRef]

- James, J.; Pandian, P.K. Geoenvironmental application of sugarcane press mud in lime stabilisation of an expansive soil: A preliminary report. Aust. J. Civ. Eng. 2016, 14, 114–122. [Google Scholar] [CrossRef]

- Çetin, M.Y.; Bağrıaçık, B.; Annagür, H.M.; Topoliński, S. Improvement of Geotechnical Properties of Clayey Soil Using Biopolymer and Ferrochromium Slag Additives. Polymers 2024, 16, 1306. [Google Scholar] [CrossRef] [PubMed]

- Debnath, A.; Saha, S.; Chattaraj, R. Stabilization of Clayey Soil with Marble Dust. In Recent Developments in Sustainable Infrastructure; Springer: Singapore, 2021; pp. 175–183. [Google Scholar] [CrossRef]

- Baĝrıaçık, B.; Güner, E.D. An Experimental Investigation of Reinforcement Thickness of Improved Clay Soil with Drinking Water Treatment Sludge as an Additive. KSCE J. Civ. Eng. 2020, 24, 3619–3627. [Google Scholar] [CrossRef]

- Modarres, A.; Nosoudy, Y.M. Clay stabilization using coal waste and lime-Technical and environmental impacts. Appl. Clay Sci. 2015, 116–117, 281–288. [Google Scholar] [CrossRef]

- Saeed, K.K.A.; Kassim, K.A.; Yunus, N.Z.M. Characterization of Hydrated Lime-Stabilized Brown Kaolin Clay. Int. J. Eng. Res. Technol. 2013, 2, 3722–3727. [Google Scholar]

- Vakili, A.H.; Kaedi, M.; Mokhberi, M.; bin Selamat, M.R.; Salimi, M. Treatment of highly dispersive clay by lignosulfonate addition and electroosmosis application. Appl. Clay Sci. 2018, 152, 1–8. [Google Scholar] [CrossRef]

- Obijole, O.A.; Gitari, M.W.; Ndungu, P.G.; Samie, A. Mechanochemically Activated Aluminosilicate Clay Soils and their Application for Defluoridation and Pathogen Removal from Groundwater. Int. J. Environ. Res. Public Health 2019, 16, 654. [Google Scholar] [CrossRef] [PubMed]

- Madejová, J.; Komadel, P. Baseline Studies of the Clay Minerals Society Source Clays: Infrared Methods. Clays Clay Miner. 2001, 49, 410–432. [Google Scholar] [CrossRef]

- Dhar, S.; Hussain, M. The strength and microstructural behavior of lime stabilized subgrade soil in road construction. Int. J. Geotech. Eng. 2021, 15, 471–483. [Google Scholar] [CrossRef]

| Chemical Characterization | Feed | |

|---|---|---|

| Cooked Rice Waste | Cow Dung | |

| Moisture content (%) | 77.95 ± 0.3 | 80.58 ± 0.2 |

| pH | 5.47 | 6.75 |

| TS (%) | 22.01 ± 0.4 | 19.41 ± 0.1 |

| VS (%) | 19.39 ± 0.1 | 15.24 ± 0.2 |

| VS/TS | 87.93 | 78.52 |

| Carbon (%) | 45.56 | 38.47 |

| Nitrogen (%) | 1.328 | 2.14 |

| C/N ratio | 34.31 | 17.98 |

| Elements in Oxide Form | SiO2 | Al2O3 | CaO | Fe2O3 | K2O | SO3 | P2O5 | TiO2 | MnO | Cr2O3 |

|---|---|---|---|---|---|---|---|---|---|---|

| DSD, Wt.% | 40.99 | 10.96 | 14.77 | 13.01 | 8.24 | 4.44 | 3.38 | 1.11 | 0.20 | 0.15 |

| Clay, Wt.% | 66.00 | 20.00 | 1.70 | 8.80 | 1.80 | 0.12 | - | 1.32 | 0.11 | - |

| Element | Clayey Soil | Stabilized Clay (2% DSD + 4.5% Lime) | ||

|---|---|---|---|---|

| Weight % | Atomic % | Weight % | Atomic % | |

| C | 13.0 | 21.2 | 11.1 | 18.2 |

| O | 45.3 | 55.4 | 45.1 | 55.4 |

| Si | 16.3 | 11.4 | 17.4 | 12.2 |

| Al | 5.8 | 4.2 | 7.2 | 5.3 |

| Ca | 1.2 | 0.6 | 11.9 | 5.8 |

| Mn | 1.8 | 0.6 | - | - |

| K | 0.8 | 0.4 | 1.1 | 0.9 |

| Fe | 14.0 | 4.9 | 5.4 | 1.8 |

| Ti | 0.4 | 0.2 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sendilvadivelu, A.; Dhandapani, B.; Vijayasimhan, S.; Pauldurai Kalaiselvi, S.P. Sustainable Stabilization of Clay Soil Using Lime and Oryza sativa-Waste-Derived Dried Solid Digestate. Sustainability 2025, 17, 8447. https://doi.org/10.3390/su17188447

Sendilvadivelu A, Dhandapani B, Vijayasimhan S, Pauldurai Kalaiselvi SP. Sustainable Stabilization of Clay Soil Using Lime and Oryza sativa-Waste-Derived Dried Solid Digestate. Sustainability. 2025; 17(18):8447. https://doi.org/10.3390/su17188447

Chicago/Turabian StyleSendilvadivelu, Arunthathi, Balaji Dhandapani, Sivapriya Vijayasimhan, and Surya Prakash Pauldurai Kalaiselvi. 2025. "Sustainable Stabilization of Clay Soil Using Lime and Oryza sativa-Waste-Derived Dried Solid Digestate" Sustainability 17, no. 18: 8447. https://doi.org/10.3390/su17188447

APA StyleSendilvadivelu, A., Dhandapani, B., Vijayasimhan, S., & Pauldurai Kalaiselvi, S. P. (2025). Sustainable Stabilization of Clay Soil Using Lime and Oryza sativa-Waste-Derived Dried Solid Digestate. Sustainability, 17(18), 8447. https://doi.org/10.3390/su17188447