Abstract

Packaging configurations have variable environmental impacts, making it essential to assess changes over time, particularly for high-impact food categories such as dairy. This study examined yoghurt packaging in Australia between 2013 and 2023, focusing on sustainability implications. Analyses of products from major retailers (n = 315 in 2013; n = 454 in 2023) assessed (i) the number and type of packaging configurations, (ii) prevalence of serving and pack sizes, and (iii) packaging features affecting food waste. Packaging types were classified by container and film composition. The number of configuration categories increased from 16 to 19, reflecting greater diversity in packaging solutions. Nearly half of single-serve products in both years featured resealable packaging, despite being intended for one-time consumption, suggesting potential over-packaging. The rise in pouch packaging raises concerns about reduced emptiability, which may contribute to increased food waste. These findings demonstrate how packaging changes over the decade have introduced sustainability trade-offs. Monitoring such changes can inform strategies to reduce waste and improve the environmental performance of packaging solutions for environmentally intensive products, such as yoghurts.

1. Introduction

The global food system plays a significant role in contributing to climate change, accounting for nearly 30% of total greenhouse gas emissions worldwide [1]. These emissions are generated throughout the entire food supply chain, encompassing activities such as agricultural production, food processing, transportation and distribution, consumption, and the management of food waste [1,2,3]. In recent years, the shift toward urban living has led to a growing preference for convenient, ready-to-eat food products [4]. This trend has fuelled a marked increase in the consumption of packaged foods [5]. As a result, food packaging has come under increasing scrutiny due to the environmental burdens associated with both its production and its end-of-life disposal [6,7,8].

Food packaging plays a vital role in safeguarding food safety, enhancing accessibility, and extending shelf life [9]. Global consumption of packaged foods has increased rapidly, with the market projected to reach USD 3.4 trillion by 2030, growing at an annual rate of 5%. This expansion is primarily driven by packaging innovations that enhance convenience and distribution efficiency [10]. The growing global population and accompanying increasing demand for food are key drivers of the expanding food packaging market [7]. The growing reliance on packaging, particularly single-use types, has attracted increasing attention due to its potential environmental consequences [11,12,13].

Food packaging is associated with both direct and indirect environmental impacts. Direct impacts relate to the negative effects of packaging production and disposal of packaging materials, and include resource depletion, pollution from manufacturing, litter generation, landfill accumulation, energy consumption, and greenhouse gas (GHG) emissions throughout the packaging lifecycle [14,15]. Concerns over the direct negative environmental impact of food packaging have led to a focus on the development of eco-friendly materials, such as recycled or biodegradable materials, and innovative packaging technologies, including smart packaging [16,17].

However, food packaging is also associated with indirect impacts, both positive and negative, including the effects on food waste, which is spoiled, damaged, or unconsumed food that is disposed of during the retail and consumer stages of the food system [18,19]. It is estimated that 931 million tonnes of food waste were produced globally in 2019, with 61% attributable to household waste [20]. Food waste is estimated to account for around 10% of global GHG emissions [20], a major concern reflected in Sustainable Development Goal (SDG) 12.3: “By 2030, halve per capita global food waste at the retail and consumer levels” [21]. Therefore, it is crucial to assess food packaging not only for its direct environmental impact but also for its broader role in influencing food waste, which is a key factor in building more sustainable and resilient food [15,22,23].

Positive indirect effects of food packaging can stem from packaging functions that mitigate food waste by facilitating transportation and storage through containment of food, extend shelf life through preservation, and enable apportionment of food to suit varied consumer needs [13,24]. Life cycle assessments (LCAs), a methodology used to evaluate the environmental impacts of products and processes throughout their entire life cycle [25,26], have demonstrated that in certain instances the environmental benefits of reduced food waste due to packaging outweigh the direct negative impacts of the packaging itself. For example, plastic wrapping on cucumbers has been shown to be able to prevent 4.9 times more GHG emissions from food waste than the emissions produced from the production and disposal processes of the plastic packaging [27].

Negative indirect consequences of food packaging can arise from food waste caused by ineffective packaging design. Packaging sizing is a packaging characteristic that can increase food waste [28,29]. For example, larger pack sizes may lead to greater waste if consumers discard the products prematurely due to safety concerns [29]. Different packaging types (e.g., tubs vs. bottles) can affect emptiability and increase food waste if consumers are unable to easily access food [8,28,30,31]. Therefore, it is critical that packaging design is optimised to reduce food waste [32].

Food product characteristics can also affect the amount of packaging-related food waste produced. For example, foods that adhere more to packaging, such as yoghurts, have variable residual food waste with different packaging types [33,34]. Furthermore, the impacts associated with the same quantity of food waste can vary depending on the food category. Animal-derived food products such as dairy food and meat products are associated with high environmental impacts [35,36]. The dairy industry is the fifth-largest consumer of energy within the manufacturing sector, and it has been shown that dairy-based food waste can be associated with higher environmental impacts compared to packaging [35]. Dairy yoghurt in particular has emerged as a category of concern due to its notable environmental footprint [35]. This is especially relevant given that global sales of yoghurt have shown steady growth and are projected to continue at a compound annual growth rate of 7% from 2025 to 2030 [37]. These considerations, combined with the increasing research demonstrating the influence of packaging on yoghurt food waste [30,31,38,39], dairy yoghurt packaging is an important category to monitor over time.

Despite growing recognition of the role packaging plays in food waste, there remains a lack of understanding of how packaging characteristics evolve within specific food categories and how these changes may influence food waste outcomes. Understanding how packaging configurations have changed over time in the yoghurt category can provide valuable insights into opportunities for reducing packaging-related food waste and improving sustainability outcomes. The objective of the present study was to provide insights into packaging developments in the Australian yoghurt market and potential implications for packaging sustainability and food waste. The specific aims were to examine trends between 2013 and 2023 in (i) the number and type of packaging configurations for yoghurt products sold in major Australian retail outlets, (ii) the prevalence of different serving and pack sizes, and (iii) resealability and emptiability features of observed products (characteristics that serve as indicators of potential impacts of packaging on food waste).

2. Methods

The FoodSwitch database was accessed to analyse data for this study. The database, developed and managed by The George Institute for Global Health, consists of images obtained by data collectors who visit supermarkets annually to take photographs of food products sold in major Australian grocery chains [40]. The FoodSwitch database is extensive, reflecting around 90% of packaged foods available for sale in Australia [41]. Barcode information is used to exclude any duplicate entries, ensuring only unique products are included. The data for dairy yoghurt products sold in 2013 (4 stores, n = 315 products) and 2023 (9 stores, n = 454 products) were accessed from the database. The selection of the data collection period of 2013 to 2023 was due to 2023 being the most recent date of data collection at the time of writing and 2013 being one decade prior to that. The difference in the number of stores between the two time points reflects the expansion of FoodSwitch data collection activities over time to include an additional supermarket chain and more stores within existing chains. All stores visited in both years were part of Australia’s major supermarket chains, which dominate the national grocery market, ensuring that the products captured were broadly representative of the Australian yoghurt market [42]. A longitudinal analysis was impractical due to the highly manual nature of image analysis. Therefore, this study employed a repeated cross-sectional design to determine the prevalence of yoghurt packaging [43].

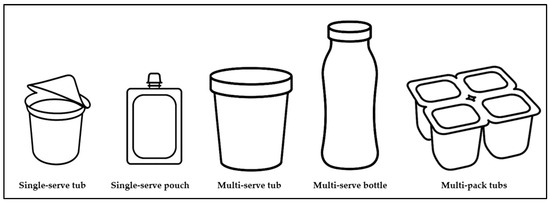

The images were interrogated to classify packaging configurations according to their container type (tub, pouch, or bottle), and size (single-serve, multi-serve, and multi-tub packs). Figure 1 shows images of yoghurt packaging configurations, which were generated using an AI-based image creation tool (Microsoft Copilot 2025) to represent container types and sizes visually. These images were created solely for explanatory purposes and do not depict specific commercial products.

Figure 1.

Yoghurt packaging configurations by container type and size.

The configurations were further classified according to the presence and composition of film (plastic, paper, foil, or various combinations of these materials that form multilayer films). Heat-shrink wrap seals used to secure lids were classified as plastic film seals. In cases where the film was not visible or identifiable, the product was categorised as ‘film presence or composition unknown’. Servings per package were calculated based on an adult serving size of 200 g as defined by the Australian Dietary Guidelines (ADGs) [44], with all products ≤200 g classified as single-serve. The adult serving size was applied due to the inability to reliably differentiate between products intended for consumption by adults versus children. Where relevant, differences in the prevalence of packaging characteristics between 2013 and 2023 were assessed using two-sample proportion tests in Stata version 19.0.

3. Results

The number of packaging configuration categories increased from 16 to 19 between 2013 and 2023 (see Table 1). The three new configurations included (i) single-serve tubs with transparent lids and multilayer films, (ii) multi-serve tubs with transparent lids and multilayer films, and (iii) multi-pack tubs with plastic lids and plastic film seal.

Table 1.

Yoghurt packaging configurations in 2013 and 2023.

3.1. Trends in Packaging Configurations Between 2013 and 2023

There was a clear shift in dominant packaging type from multi-serve to single-serve products between the two time points. In 2013, multi-serve tubs were the most prevalent configuration, with 24% featuring opaque/transparent lids (film presence/composition unknown) and 22% featuring transparent lids with foil films. By 2023, single-serve formats emerged as the dominant configuration, with single-serve tubs with foil films representing 21% of all products and pouches with large plastic lids accounting for 20%. Multi-serve tubs with transparent lids and foil films experienced a significant decrease from 22% in 2013 to 9% in 2023, while multi-serve tubs with plastic lids and unknown films saw a significant drop from 24% to 18%. Multi-pack tubs with paperboard sleeves and unknown film remained relatively consistent, representing 12% of assessed products in 2013 and 10% in 2023.

Yoghurt packaging container types were analysed to examine potential emptiability performance by comparing the prevalence of tubs (typically better emptiability performance) vs. pouches and bottles (typically lower emptiability) (see Table 1). While tubs remained the most common packaging type in both 2013 and 2023, their prevalence fell by 11 percentage points, dropping from 86% of all products in 2013 to 75% in 2023. The proportion of pouches rose by 11 percentage points from 13% in 2013 to 24% in 2023. Bottles remained the least-prevalent packaging type at 1% in both 2013 and 2023.

3.2. Frequencies and Trends Observed for Serving Sizes Between 2013 and 2023

The prevalence of single containers with ≤1 serve (i.e., ≤200 g) rose significantly from 2013 to 2023 (36% to 53%), and this was the dominant packaging type for both years (see Table 2). There was a significant increase in the prevalence of single containers with >3–≤4 serves from 5% to 11%. By comparison, single containers with >1–≤2 serves (10% in 2013 vs. 2% in 2023) and >2–≤3 serves (13% in 2013 vs. 5% in 2023) both fell by 8 percentage points, which was also significant.

Table 2.

Yoghurt product serving sizes in 2013 and 2023.

3.3. Resealability

The resealability of yoghurt packaging was evaluated to estimate potential impact on food waste and contribution to direct environmental impact (i.e., overuse of packaging materials). Table 3 and Table 4 show the presence of resealability features (e.g., plastic lids, caps) for each serving size range in 2013 and 2023, respectively.

Table 3.

Resealability of yoghurt packaging configurations categorised by serving size (2013).

Table 4.

Resealability of yoghurt packaging configurations categorised by serving size (2023).

Products containing ≤1 serves were predominantly packaged in configurations that included resealability features. All single containers with ≤0.5 serves in both 2013 and 2023 were pouches with lids. Products containing >0.5–≤1 serves with resealability features comprised nearly half of all products within the single-serve category in both years (47% in 2013 and 49% in 2023). There was a slight increase in the prevalence of non-resealable configurations for single containers with multiple serves (2% in 2013 to 4% in 2023).

4. Discussion

4.1. Trends in Prevalence and Type of Packaging Configurations

While several studies have demonstrated a link between characteristics such as emptiability in different packaging configurations and varying levels of packaging-related food waste [39,45], research examining the prevalence of these different packaging configurations is lacking. This paper contributes new evidence by documenting changes in the number and types of yoghurt packaging configurations in the Australian market between 2013 and 2023. The observed increase in the number of packaging configurations is aligned with previous research highlighting the food industry’s response to evolving consumer demands and advancements in packaging technologies [46]. However, the widening range of configurations may be suboptimal in terms of the indirect impacts associated with packaging-related food waste. For example, the observed shift towards pouches may have consequences on the residual food waste produced by varying emptiability performance.

4.2. Influence of Pack Size on Potential Food Waste

The identified changes in prevalence of different serving and pack sizes for yoghurt products provide insights into possible implications for packaging-related food waste. The increased prevalence of single containers with ≤1 serve may potentially be due to an increasing demand for portion-controlled packaged food products [47]. From a sustainability perspective, this can be viewed as a desirable trend due to the fact that providing a range of pack sizes allows households to select appropriate portions, minimising food waste [18,48,49]. Therefore, smaller pack sizes present an advantage in preventing food from being wasted due to unconsumed excess [29].

Despite the benefit of reducing food waste, smaller pack sizes are associated with a notable trade-off. Smaller products have higher packaging-to-food ratios (i.e., higher packaging intensity) [50], which increases the direct environmental impacts of the packaging materials [39]. Some research has shown that increased packaging intensity can be desirable where the consequent reduction in food waste achieves a net decrease in the total environmental burden [51,52]. However, further research is crucial to determine if the benefit of minimising food waste definitively outweighs the environmental impacts of increased packaging intensity.

4.3. Potential Impacts of Packaging Configuration Trends on Emptiability

This study examined the apparent emptiability of the observed packaging configurations as an indicator of potential impacts on packaging-related food waste. Designing packaging configurations that provide good emptiability is important to enable consumers to fully access and consume the products, thereby minimising food waste [8,30]. Notably, packaging features (e.g., container shape and the size of container openings) have been found to influence the emptiability of products such as yoghurts that demonstrate a higher degree of adherence to the internal surfaces of packaging [30]. In a Swedish study, consumers preferred yoghurt tubs over cartons because they could more easily see and access residual food [49].

However, there is also an increased demand for more convenient and portable packaging formats [53], which potentially explains the increased prevalence of pouches and to a lesser extent, bottles identified in the present study. This change points to a potential deterioration of packaging emptiability across the yoghurt market segment, possibly with an associated increase in food waste. To better understand the environmental impacts of the observed increase in the prevalence of pouches and bottles, future research should quantify and compare their emptiability against other packaging types.

4.4. Apparent Resealability

Resealability enables consumers to store unfinished food while ensuring that the food stays fresh and safe for consumption for longer periods [48]. This makes resealability an important packaging characteristic for minimising food waste, particularly in packaging configurations containing multiple serves [23,54]. Despite this potential benefit, the observed resealability features on around half of the products intended for consumption in a single sitting can be considered an excessive use of packaging material. Further research on consumer interaction with resealability features in such products is needed to determine if the amount of food waste saved supports the increased use of packaging materials.

Conversely, although small, the observed increase in the use of single-tub products containing more than a single serving but lacking resealable features might contribute to increased food waste if consumers are unable to appropriately store unconsumed portions, potentially leading to spoilage and subsequent disposal [55]. Therefore, the lack of resealability features in this case could inadvertently increase packaging-related food waste and thereby the overall environmental impact of the packaging. This highlights a potential area where packaging design could be better improved to support consumers in minimising food waste.

5. Study Limitations

The most notable limitation of this study was the inability to determine the material and presence of plastic or foil films, which in some cases limited packaging material identification and categorisation. Additionally, not all food waste types were included in the analyses. For example, the influence of packaging on food waste due to potential spillage during transport from retail outlets to households was not included in the scope of this study. To more comprehensively understand the environmental impacts of packaging-related food waste, future research should incorporate evaluations of direct impacts by including the physical assessment of packaging materials and expand analysis to other food product categories and food waste types (e.g., spillage caused due to poor packaging design).

Another limitation was the need to calculate the number of serves based on the serving size defined for adults because of a lack of definitive information about the intended consumer segment for each product. Additionally, the data available for 2013 and 2023 were sourced from different numbers and ranges of stores, resulting in varying sample sizes and potentially limiting the comparability of the product ranges. To address these limitations, future research could identify products targeted at specific consumer segments (e.g., children) to apply different serving size thresholds and cover a broader range of outlets using consistent data collection protocols to enhance the comparability and generalisability of the findings. Lastly, these results do not necessarily reflect broader purchasing and consumption patterns across Australia, as the data were confined to products available for sale. Future research could explore purchasing behaviours alongside packaging characteristics to better understand how packaging influences consumer choices and environmental outcomes.

6. Conclusions

Overall, this study presents a novel contribution through the use of a unique dataset to identify emerging patterns in food packaging within a product category that carries significant environmental consequences. This analysis of yoghurt packaging trends reveals several key observations related to the prevalence of various packaging types of yoghurt products sold in major Australian retail stores. The apparent shift to smaller serving sizes and single-serve containers necessitates careful consideration of the associated environmental impacts. While smaller pack sizes can mitigate food waste by avoiding unconsumed portions, they could potentially result in higher packaging intensities, raising concerns about increased packaging waste. Furthermore, while resealability is an important food waste prevention characteristic of packaging, the increased adoption of this packaging function for single-serve portions raises questions about the potential for over-packaging. The dominance of tubs as the most prevalent packaging type over the 10-year period suggests a preference for packaging configurations that facilitate better emptiability; however, the increasing prevalence of pouches, and to a lesser extent bottles, necessitates research into how the emptiability characteristics of these packaging configurations influence consumer behaviours and subsequent impacts on food waste. Although intermediate data points were not analysed, the comparison between 2013 and 2023 provides a decade-long snapshot of packaging evolution, offering insight into long-term shifts in packaging practices and their potential sustainability implications.

Overall, these findings highlight the diverse and changing packaging landscape of dairy yoghurt products. If current trends continue, packaging practices in the yoghurt market may evolve in ways that present challenges in achieving SDG 12.3, which aims to halve per capita global food waste at retail and consumer levels by 2030. This underscores the urgent need to develop evidence-based policies that incentivise the food industry to adopt more environmentally sustainable packaging solutions that are optimised to reduce food waste. Future research should compare the life-cycle environmental impacts of packaging material waste and eco-design principles of yoghurt packaging formats, as well as the characteristics of packaging that influence food waste. Additionally, interdisciplinary studies that integrate consumer behaviour, packaging design, and waste management systems will be critical to inform policy frameworks that balance convenience, food waste reduction, and environmental sustainability. Lastly, this study also provides a benchmark for future investigations within the yoghurt product packaging category.

Author Contributions

S.H.: conceptualisation, data curation, formal analysis, methodology, writing—original draft. S.P.: conceptualisation, supervision, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by National Health and Medical Research Council grant number 2006620. Author Simone Pettigrew is funded by a NHMRC fellowship (grant number 2034602).

Data Availability Statement

Requests to access the data can be directed to foodswitch@georgeinstitute.org.au, however restrictions to the availability of these data may apply.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Crippa, M.; Solazzo, E.; Guizzardi, D.; Monforti-Ferrario, F.; Tubiello, F.N.; Leip, A. Food systems are responsible for a third of global anthropogenic GHG emissions. Nat. Food 2021, 2, 198–209. [Google Scholar] [CrossRef]

- Liu, T.C.; Wu, Y.C.; Chau, C.F. An Overview of Carbon Emission Mitigation in the Food Industry: Efforts, Challenges, and Opportunities. Processes 2023, 11, 1993. [Google Scholar] [CrossRef]

- Poore, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef]

- de Bruin, S.; Dengerink, J.; van Vliet, J. Urbanisation as driver of food system transformation and opportunities for rural livelihoods. Food Secur. 2021, 13, 781–798. [Google Scholar] [CrossRef] [PubMed]

- Knorr, D.; Khoo, C.S.H.; Augustin, M.A. Food for an Urban Planet: Challenges and Research Opportunities. Front. Nutr. 2018, 4, 73. [Google Scholar] [CrossRef]

- Deshwal, G.K.; Panjagari, N.R.; Alam, T. An overview of paper and paper based food packaging materials: Health safety and environmental concerns. J. Food Sci. Technol. 2019, 56, 4391–4403. [Google Scholar] [CrossRef]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. An overview of plastic waste generation and management in food packaging industries. Recycling 2021, 6, 12. [Google Scholar] [CrossRef]

- Wohner, B.; Gabriel, V.H.; Krenn, B.; Krauter, V.; Tacker, M. Environmental and economic assessment of food-packaging systems with a focus on food waste. Case study on tomato ketchup. Sci. Total Environ. 2020, 738, 139846. [Google Scholar] [CrossRef]

- Ibrahim, I.D.; Hamam, Y.; Sadiku, E.R.; Ndambuki, J.M.; Kupolati, W.K.; Jamiru, T.; Eze, A.A.; Snyman, J. Need for Sustainable Packaging: An Overview. Polymers 2022, 14, 4430. [Google Scholar] [CrossRef] [PubMed]

- Kan, M.; Miller, S.A. Environmental impacts of plastic packaging of food products. Resour. Conserv. Recycl. 2022, 180, 106156. [Google Scholar] [CrossRef]

- Norton, V.; Oloyede, O.O.; Lignou, S.; Wang, Q.J.; Vásquez, G.; Alexi, N. Understanding consumers’ sustainability knowledge and behaviour towards food packaging to develop tailored consumer-centric engagement campaigns: A Greece and the United Kingdom perspective. J. Clean. Prod. 2023, 408, 137169. [Google Scholar] [CrossRef]

- Omolayo, Y.; Feingold, B.J.; Neff, R.A.; Romeiko, X.X. Life cycle assessment of food loss and waste in the food supply chain. Resour. Conserv. Recycl. 2021, 164, 105119. [Google Scholar] [CrossRef]

- Otto, S.; Strenger, M.; Maier-Nöth, A.; Schmid, M. Food packaging and sustainability—Consumer perception vs. correlated scientific facts: A review. J. Clean. Prod. 2021, 298, 126733. [Google Scholar] [CrossRef]

- Langley, S.; Phan-Le, N.T.; Brennan, L.; Parker, L.; Jackson, M.; Francis, C.; Lockrey, S.; Verghese, K.; Alessi, N. The good, the bad, and the ugly: Food packaging and consumers. Sustainability 2021, 13, 12409. [Google Scholar] [CrossRef]

- Molina-Besch, K.; Wikström, F.; Williams, H. The environmental impact of packaging in food supply chains—Does life cycle assessment of food provide the full picture? Int. J. Life Cycle Assess. 2019, 24, 37–50. [Google Scholar] [CrossRef]

- Song, J.; Kay, M.; Coles, R. Bioplastics. In Food and Beverage Packaging Technology; John Wiley & Sons, Ltd.: Chichester, UK, 2011; pp. 295–319. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/9781444392180.ch11 (accessed on 13 October 2023).

- Song, J.H.; Murphy, R.J.; Narayan, R.; Davies, G.B.H. Biodegradable and compostable alternatives to conventional plastics. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2127–2139. [Google Scholar] [CrossRef]

- Verghese, K.; Lewis, H.; Lockrey, S.; Williams, H. Packaging’s role in minimizing food loss and waste across the supply chain. Packag. Technol. Sci. 2015, 28, 603–620. [Google Scholar] [CrossRef]

- Vittuari, M.; Garcia Herrero, L.; Masotti, M.; Iori, E.; Caldeira, C.; Qian, Z.; Bruns, H.; van Herpen, E.; Obersteiner, G.; Kaptan, G.; et al. How to reduce consumer food waste at household level: A literature review on drivers and levers for behavioural change. Sustain. Prod. Consum. 2023, 38, 104–114. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Food Waste Index Report 2021. Available online: http://www.unep.org/resources/report/unep-food-waste-index-report-2021 (accessed on 17 October 2023).

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. Available online: https://sdgs.un.org/publications/transforming-our-world-2030-agenda-sustainable-development-17981 (accessed on 6 March 2025).

- Licciardello, F. Packaging, blessing in disguise. Review on its diverse contribution to food sustainability. Trends Food Sci. Technol. 2017, 65, 32–39. [Google Scholar] [CrossRef]

- Pauer, E.; Wohner, B.; Heinrich, V.; Tacker, M. Assessing the environmental sustainability of food packaging: An extended life cycle assessment including packaging-related food losses and waste and circularity assessment. Sustainability 2019, 11, 925. [Google Scholar] [CrossRef]

- Yokokawa, N.; Kikuchi-Uehara, E.; Amasawa, E.; Sugiyama, H.; Hirao, M. Environmental analysis of packaging-derived changes in food production and consumer behavior. J. Ind. Ecol. 2019, 23, 1253–1263. [Google Scholar] [CrossRef]

- Hauschild, M.Z. Introduction to LCA methodology. In Life Cycle Assessment: Theory and Practice; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer: Cham, Switzerland, 2018; pp. 59–66. [Google Scholar] [CrossRef]

- Herrero, M.; Laca, A.; Díaz, M. Chapter 15—Life cycle assessment focusing on food industry wastes. In Food Industry Wastes; Kosseva, M.R., Webb, C., Eds.; Academic Press: San Diego, CA, USA, 2013; pp. 265–280. Available online: https://www.sciencedirect.com/science/article/pii/B9780123919212000159 (accessed on 2 August 2023).

- Shrivastava, C.; Crenna, E.; Schudel, S.; Shoji, K.; Onwude, D.; Hischier, R.; Defraeye, T. To Wrap or to Not Wrap Cucumbers? Front. Sustain. Food Syst. 2022, 6, 750199. [Google Scholar] [CrossRef]

- Doğdu, G.; Pekdemir, T.; Lakestani, S.; Karabörk, Ş.; Çavuş, O. Hidden realities: Food waste from servings in mini size packaging. Waste Manag. 2024, 173, 141–151. [Google Scholar] [CrossRef]

- Wilson, N.L.W.; Rickard, B.J.; Saputo, R.; Ho, S.T. Food waste: The role of date labels, package size, and product category. Food Qual. Prefer. 2017, 55, 35–44. [Google Scholar] [CrossRef]

- Klein, M.; Werner, C.; Tacker, M.; Apprich, S. Influence of Packaging Design on Technical Emptiability of Dairy Products and Implications on Sustainability Through Food Waste Reduction. Sustainability 2024, 16, 6335. [Google Scholar] [CrossRef]

- Wohner, B.; Schwarzinger, N.; Gürlich, U.; Heinrich, V.; Tacker, M. Technical emptiability of dairy product packaging and its environmental implications in Austria. PeerJ 2019, 7, e7578. [Google Scholar] [CrossRef] [PubMed]

- Wikström, F.; Verghese, K.; Auras, R.; Olsson, A.; Williams, H.; Wever, R.; Grönman, K.; Pettersen, M.K.; Møller, H.; Soukka, R. Packaging strategies that save food: A research agenda for 2030. J. Ind. Ecol. 2019, 23, 532–540. [Google Scholar] [CrossRef]

- González-García, S.; Castanheira, É.G.; Dias, A.C.; Arroja, L. Environmental life cycle assessment of a dairy product: The yoghurt. Int. J. Life Cycle Assess. 2013, 18, 796–811. [Google Scholar] [CrossRef]

- Wikström, F.; Williams, H. Potential environmental gains from reducing food losses through development of new packaging—A life-cycle model. Packag. Technol. Sci. 2010, 23, 403–411. [Google Scholar] [CrossRef]

- Feil, A.A.; Schreiber, D.; Haetinger, C.; Haberkamp, Â.M.; Kist, J.I.; Rempel, C.; Maehler, A.E.; Gomes, M.C.; da Silva, G.R. Sustainability in the dairy industry: A systematic literature review. Environ. Sci. Pollut. Res. 2020, 27, 33527–33542. [Google Scholar] [CrossRef]

- Gaines, A.M.; Davies, T.; Shahid, M.; Taylor, F.; Wu, J.H.; Hadjikakou, M.; Pettigrew, S.; Seferidi, P.; Neal, B. A novel approach to estimate product-specific greenhouse gas emissions for 23,550 Australian packaged foods and beverages. J. Clean. Prod. 2023, 425, 138816. [Google Scholar] [CrossRef]

- Statista. Yogurt—Worldwide|Statista Market Forecast. Available online: https://www.statista.com/outlook/cmo/food/dairy-products-eggs/yogurt/worldwide (accessed on 11 February 2025).

- Hemachandra, S.; Hadjikakou, M.; Pettigrew, S. A scoping review of food packaging life cycle assessments that account for packaging-related food waste. Int. J. Life Cycle Assess. 2024, 29, 1899–1915. [Google Scholar] [CrossRef]

- Kostic, D.; Hoffmann, U.; Fürtauer, S.; Fell, T.; Yilmaz, C.; Burth, D.; Sängerlaub, S. Packaging Weight, Filling Ratio and Filling Efficiency of Yogurt and Relevant Packagings Depending on Commercial Packaging Design, Material, Packaging Type and Filling Quantity. Dairy 2022, 3, 668–692. [Google Scholar] [CrossRef]

- Dunford, E.; Trevena, H.; Goodsell, C.; Ng, K.H.; Webster, J.; Millis, A.; Goldstein, S.; Hugueniot, O.; Neal, B. FoodSwitch: A Mobile Phone App to Enable Consumers to Make Healthier Food Choices and Crowdsourcing of National Food Composition Data. JMIR MHealth UHealth 2014, 2, e3230. [Google Scholar] [CrossRef] [PubMed]

- Shah, P.; Geyik, Ö.; Archibald, C.L.; Hadjikakou, M. Sustainable food choices require product-specific environmental footprints: The case of packaged food in Australia. Sustain. Prod. Consum. 2024, 49, 362–371. [Google Scholar] [CrossRef]

- Australian Competition and Consumer Commission (ACCC). Supermarkets Inquiry. Available online: https://www.accc.gov.au/system/files/supermarkets-inquiry_1.pdf (accessed on 28 August 2025).

- Teti, D.M. Handbook of Research Methods in Developmental Science; John Wiley & Sons: Hoboken, NJ, USA, 2008; p. 583. [Google Scholar]

- Australian Government Department of Health and Aged Care. The Australian Dietary Guidelines. Available online: https://www.health.gov.au/resources/publications/the-australian-dietary-guidelines?language=en (accessed on 21 October 2024).

- Köck, B.; Spatt, P.; Archodoulaki, V.M.; Mihalyi-Schneider, B. Life cycle inventory data generation for yogurt packaging in Austria. Clean Environ. Syst. 2025, 17, 100271. [Google Scholar] [CrossRef]

- Chakori, S.; Aziz, A.A.; Smith, C.; Dargusch, P. Untangling the underlying drivers of the use of single-use food packaging. Ecol. Econ. 2021, 185, 107063. [Google Scholar] [CrossRef]

- Fraser, A. The influence of package design on consumer purchase intent. In Packaging for Nonthermal Processing of Food; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2018; pp. 225–249. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/9781119126881.ch10 (accessed on 19 December 2024).

- Chan, R.B.Y. A review of packaging-related studies in the context of household food waste: Drivers, solutions and avenues for future research. Packag. Technol. Sci. 2022, 35, 3–51. [Google Scholar]

- Wikström, F.; Williams, H.; Trischler, J.; Rowe, Z. The importance of packaging functions for food waste of different products in households. Sustainability 2019, 11, 2641. [Google Scholar] [CrossRef]

- Marsh, K.; Bugusu, B. Food packaging roles, materials, and environmental issues. J. Food Sci. 2007, 72, R39–R55. [Google Scholar] [CrossRef]

- Heller, M.C.; Selke, S.E.M.; Keoleian, G.A. Mapping the influence of food waste in food packaging environmental performance assessments. J. Ind. Ecol. 2019, 23, 480–495. [Google Scholar] [CrossRef]

- Uhlig, E.; Sadzik, A.; Strenger, M.; Schneider, A.M.; Schmid, M. Food wastage along the global food supply chain and the impact of food packaging. J. Consum. Prot. Food Saf. 2025, 20, 5–17. [Google Scholar] [CrossRef]

- Francis, D.V.; Dahiya, D.; Gokhale, T.; Nigam, P.S. Sustainable packaging materials for fermented probiotic dairy or non-dairy food and beverage products: Challenges and innovations. AIMS Microbiol. 2024, 10, 320–339. [Google Scholar] [CrossRef] [PubMed]

- Licciardello, F.; Piergiovanni, L. Packaging and food sustainability. In The Interaction of Food Industry and Environment; Galanakis, C., Ed.; Academic Press: San Diego, CA, USA, 2020; pp. 191–222. Available online: https://www.sciencedirect.com/science/article/pii/B9780128164495000060 (accessed on 20 December 2024).

- Pascall, M.A.; DeAngelo, K.; Richards, J.; Arensberg, M.B. Role and Importance of Functional Food Packaging in Specialized Products for Vulnerable Populations: Implications for Innovation and Policy Development for Sustainability. Foods 2022, 11, 3043. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).