Environmental Impact of Building Drainage Systems: Analysis of Embodied Carbon Emissions in Terms of Code-Based Design

Abstract

1. Introduction

2. Embodied Carbon Emissions of BDS

2.1. Materials Used in BDS

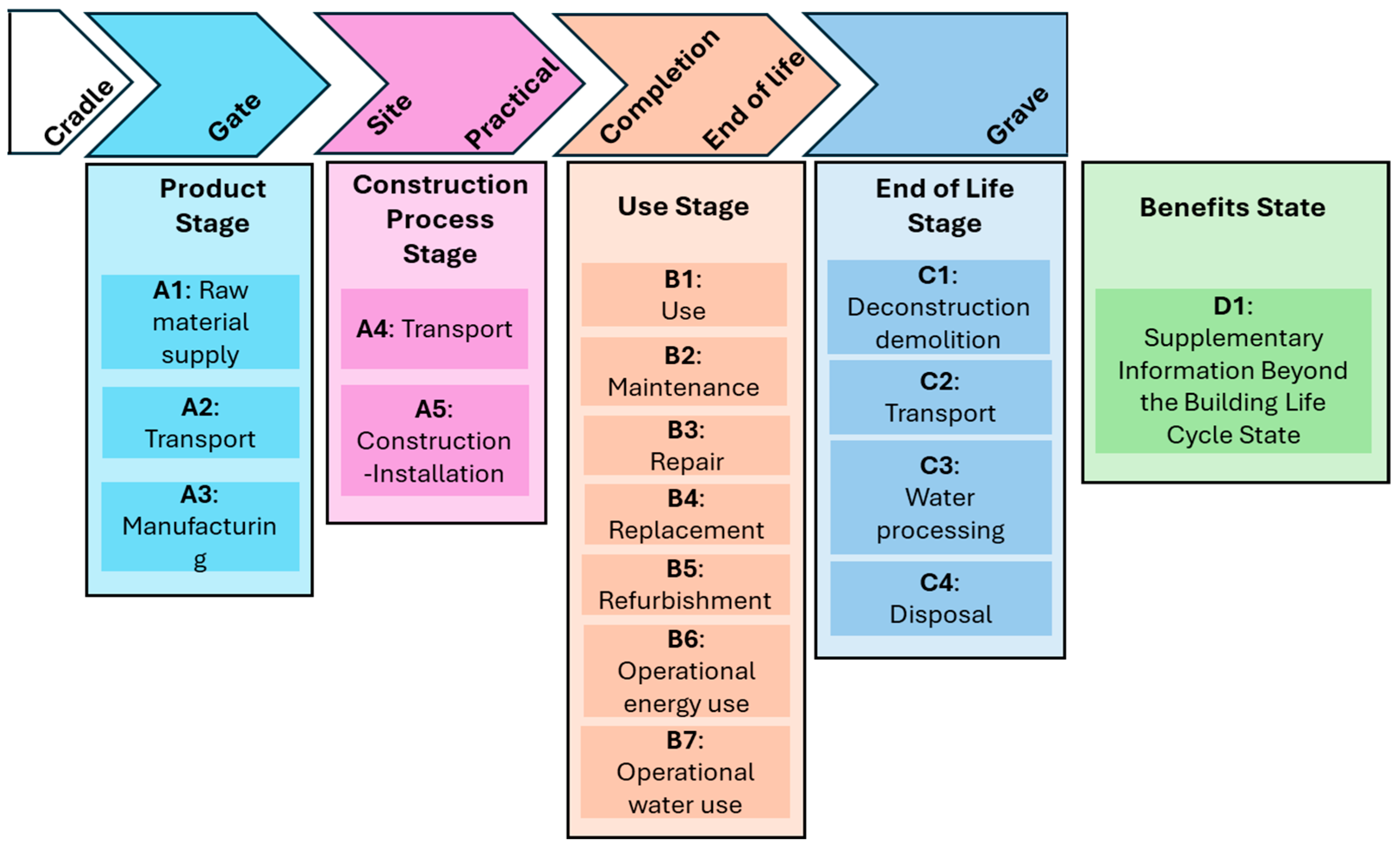

2.2. Boundary Conditions and Life Cycle Stages

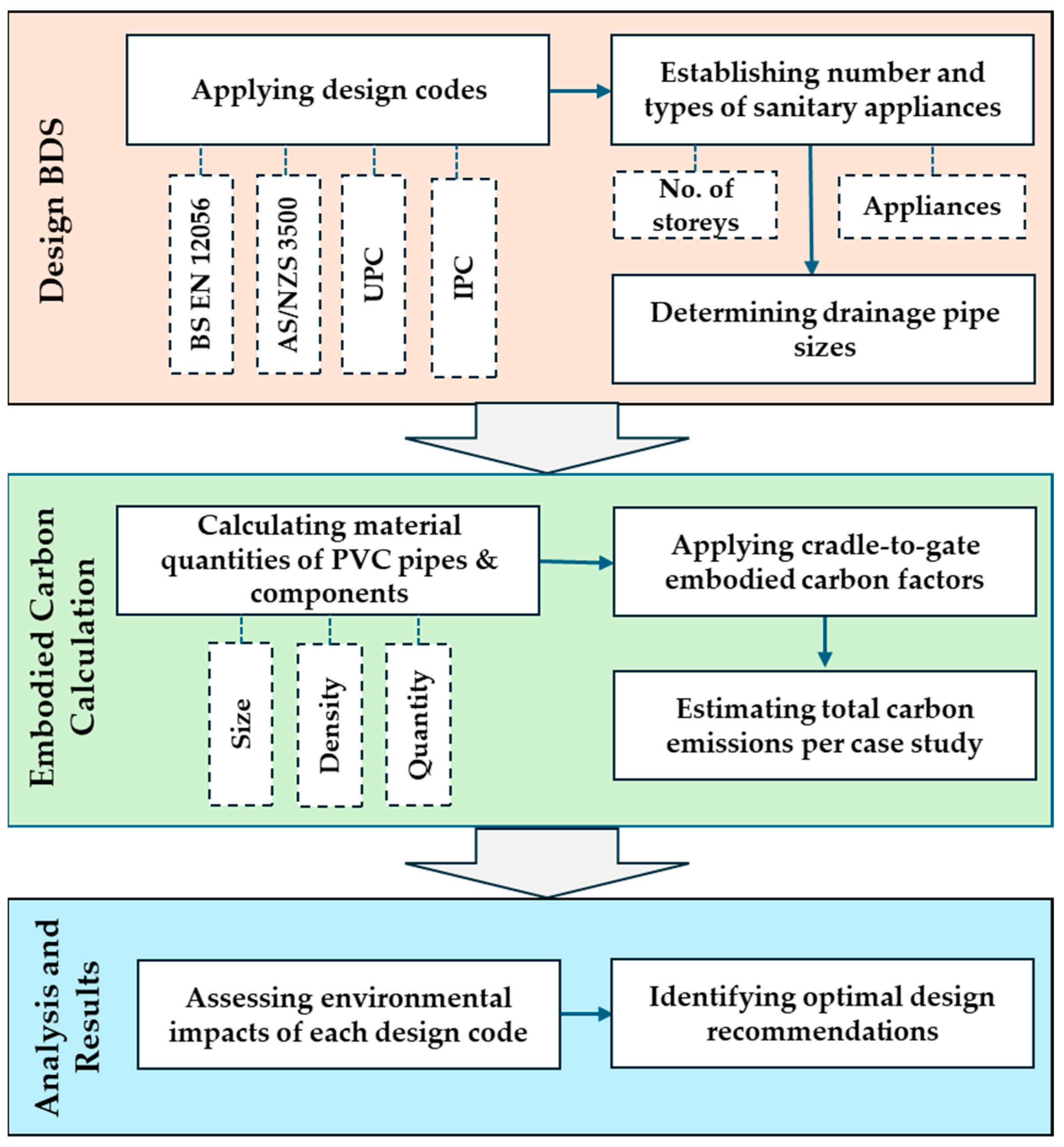

3. Methodology

3.1. Design Codes for BDS

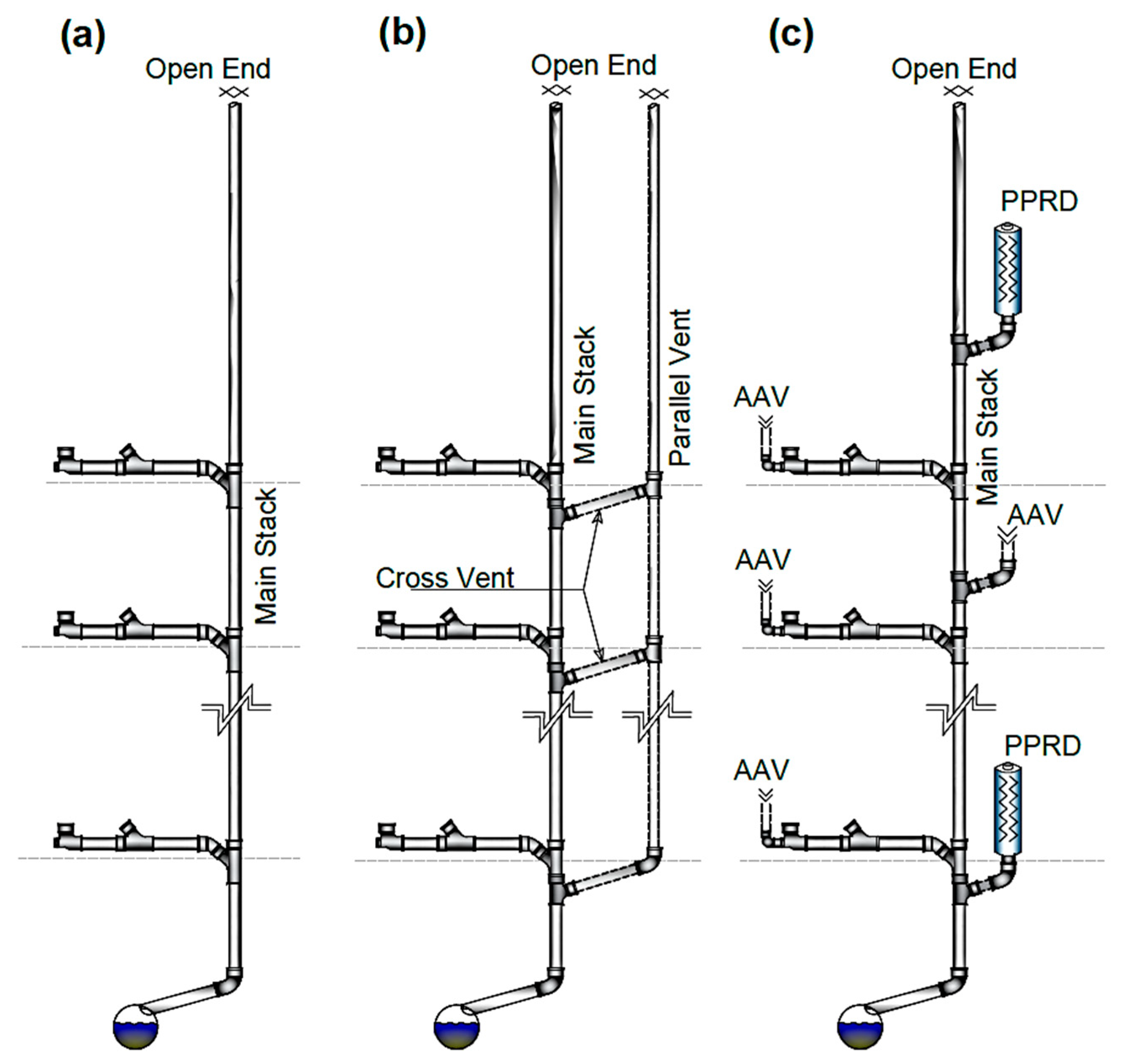

- (i)

- The European Standard BS EN 12056 incorporates four system configurations covering different design practices across Europe: System I (German, Swiss, and Austrian practice), System II (Scandinavian practice), System III (UK), and System IV (French). The code offers different configurations for pressure regulation including primary ventilated stacks (PVS), secondary ventilated stacks (SVS) [24]. This code uses discharge units (DU) to estimate wastewater discharge loading in litres per second (L/s) to determine pipe sizes. It notably incorporates frequency factors (K) ranging from 0.5 to 1.2 depending on building usage. This frequency factor influences the final wastewater discharge loading which is then used to select appropriate pipework sizes [39]. Additionally, the standard highlights two types of drainage junctions: swept and square, which influence system efficiency and flow management [40].

- (ii)

- The AS/NZS 3500 standard is a joint initiative by the Australian and New Zealand National Plumbing and Drainage Code and Technical Committee WS-014 [25]. Pipe sizing under this code is based on the total number of Fixture Units (FUs). Group FU values are recommended for combined sanitary appliances in a single room. Building height is also taken into account, with different FU values recommended for buildings above or below four storeys. A relief vent is mandatory whenever there is one or more floors of vertical separation between the highest and lowest branch connections.

- (iii)

- The Uniform Plumbing Code (UPC) is one of the most widely implemented standards in the United States. It was developed by the International Association of Plumbing and Mechanical Officials (IAPMO). The UPC employs the FU concept to size drainage systems, categorised FUs into private, public and assembly. Regarding relief vent, the UPC mandates that any drainage stack extending ten or more storeys above the building drain or another horizontal drain must include a parallel vent stack. For pipe sizing, the code considers both the total FUs and the pipe length [26].

- (iv)

- The International Plumbing Code (IPC), published by the International Code Council (ICC) in the USA, presents a comprehensive regulatory framework for designing and installing plumbing systems in residential, commercial, and industrial buildings. Similarly to the UPC, the IPC employs the fixture unit method to determine pipe sizes and requires venting where five or more branch intervals are located above a horizontal offset. The code also recommends the use of group FU values for combined sanitary appliances and considers pipe length as a factor in vent pipe sizing [27].

3.2. Establishing Number and Types of Sanitary Appliances

3.3. Determining the Size of Drainage Pipes

3.4. Pipe Sizing Recommendations and Material Quantities

3.5. Estimation of Embodied Carbon Emissions

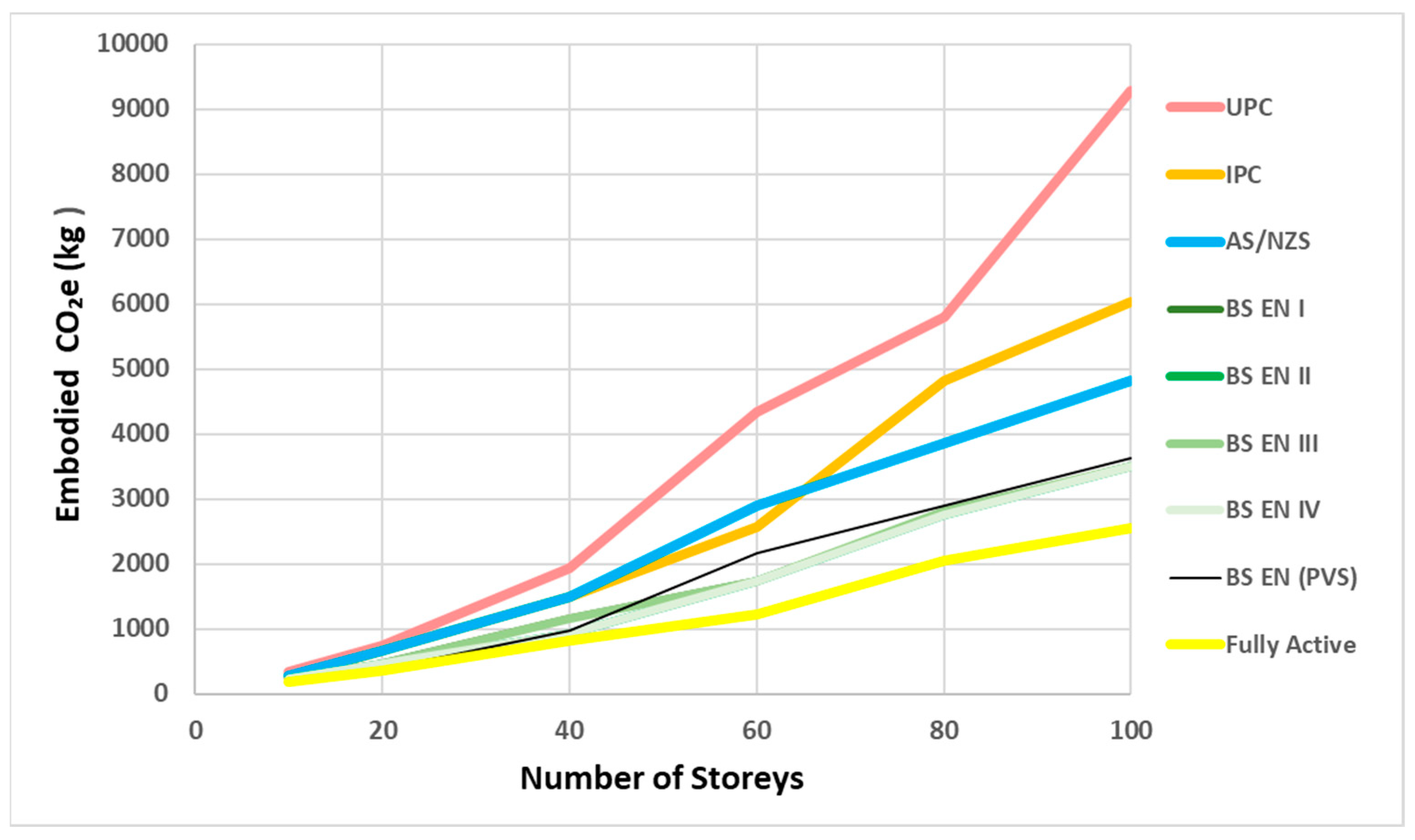

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, B.; Xing, K.; Rameezdeen, R. Exploring Embodied Carbon Comparison in Lightweight Building Structure Frames: A Case Study. Sustainability 2023, 15, 15167. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Building Materials and the Climate: Constructing A New Future; United Nations Environment Programme: Nairobi, Kenya, 2023. [Google Scholar]

- Patil, M. What Do Circular Strategies Mean for Current HVAC Systems in Utility Buildings? Master’s Thesis, Delft University, Delft, The Netherlands, 2023. [Google Scholar]

- Rios, F.C. Beyond Recycling: Design for Diassembly, Reuse and Circular Economy in the Built Environment. Ph.D. Thesis, Drexel University, Philadelphia, PA, USA, 2018. [Google Scholar]

- Theißen, S.; Höper, J.; Drzymalla, J.; Wimmer, R.; Markova, S.; Meins-Becker, A.; Lambertz, M. Using Open BIM and IFC to Enable a Comprehensive Consideration of Building Services within a Whole-Building LCA. Sustainability 2020, 12, 5644. [Google Scholar] [CrossRef]

- Ostojic, S.; Traverso, M. Application of Life Cycle Sustainability Assessment in the Automotive Sector–A Systematic Literature Review. Sustain. Prod. Consum. 2024, 47, 105–127. [Google Scholar] [CrossRef]

- Itanola, M.; Griffiths, P.; Motawa, I. Closing the Loop in Building Services: A Systematic Review of Circular Economy Applications. Build. Serv. Eng. Res. Technol. 2024, 46, 293–315. [Google Scholar] [CrossRef]

- FAO Land and Water. Available online: http://www.fao.org/land-water/water/en/ (accessed on 26 April 2021).

- Huang, M.; Simonen, K.L.; Ditto, J. Life Cycle Assessment of Mechanical, Electrical and Plumbing in Commercial Office Buildings; The Carbon Leadership Forum: Seattle, WA, USA, 2019. [Google Scholar]

- Xiong, J.; Zhu, J.; He, Y.; Ren, S.; Huang, W.; Lu, F. The Application of Life Cycle Assessment for the Optimization of Pipe Materials of Building Water Supply and Drainage System. Sustain. Cities Soc. 2020, 60, 102267. [Google Scholar] [CrossRef]

- Simion, I.M.; Pennellini, S.; Awere, E.; Rosatti, A.; Bonoli, A. Enhancing Sustainability in Italian Water Supply Pipes through Life Cycle Analysis. Sustainability 2024, 16, 2685. [Google Scholar] [CrossRef]

- Nguyen, L.K.; Na, S.; Hsuan, Y.G.; Spatari, S. Uncertainty in the Life Cycle Greenhouse Gas Emissions and Costs of HDPE Pipe Alternatives. Resour. Conserv. Recycl. 2020, 154, 104602. [Google Scholar] [CrossRef]

- Chohan, I.M.; Ahmad, A.; Sallih, N.; Bheel, N.; Ali, M.; Deifalla, A.F. A Review on Life Cycle Assessment of Different Pipeline Materials. Results Eng. 2023, 19, 101325. [Google Scholar] [CrossRef]

- Istrate, I.R.; Juan, R.; Martin-Gamboa, M.; Domínguez, C.; García-Muñoz, R.A.; Dufour, J. Environmental Life Cycle Assessment of the Incorporation of Recycled High-Density Polyethylene to Polyethylene Pipe Grade Resins. J. Clean. Prod. 2021, 319, 128580. [Google Scholar] [CrossRef]

- Du, F.; Woods, G.J.; Kang, D.; Lansey, K.E.; Arnold, R.G. Life Cycle Analysis for Water and Wastewater Pipe Materials. J. Environ. Eng. 2013, 139, 703–711. [Google Scholar] [CrossRef]

- Kang, M.; Wei, J.; Yuan, J.; Guo, J.; Zhang, Y.; Hang, J.; Qu, Y.; Qian, H.; Zhuang, Y.; Chen, X.; et al. Probable Evidence of Fecal Aerosol Transmission of SARS-CoV-2 in a High-Rise Building. Ann. Intern. Med. 2020, 173, 974–980. [Google Scholar] [CrossRef]

- Cheng, C.L.; Lin, Y.Y. CFD Numerical Simulation in Building Drainage Stacks as an Infection Pathway of COVID-19. Int. J. Environ. Res. Public Health 2022, 19, 7475. [Google Scholar] [CrossRef]

- Xue, Y.; Stewart, C.; Kelly, D.; Campbell, D.; Gormley, M. Two-Phase Annular Flow in Vertical Pipes: A Critical Review of Current Research Techniques and Progress. Water 2022, 14, 3496. [Google Scholar] [CrossRef]

- Wong, L.T.; Mui, K.W.; Cheng, C.L.; Leung, P.H.M. Time-Variant Positive Air Pressure in Drainage Stacks as a Pathogen Transmission Pathway of COVID-19. Int. J. Environ. Res. Public Health 2021, 18, 6068. [Google Scholar] [CrossRef]

- Gormley, M. SARS-CoV-2: The Growing Case for Potential Transmission in a Building via Wastewater Plumbing Systems. Ann. Intern. Med. 2020, 173, 1020–1021. [Google Scholar] [CrossRef]

- Wang, Q.; Lin, Z.; Niu, J.; Choi, G.K.; Fung, J.C.H.; Lau, A.K.H.; Louie, P.; Leung, K.K.M.; Huang, J.; Cheng, P.; et al. Spread of SARS-CoV-2 Aerosols via Two Connected Drainage Stacks in a High-Rise Housing Outbreak of COVID-19. J. Hazard. Mater. 2022, 430, 128475. [Google Scholar] [CrossRef]

- Sharif, K.; Gormley, M. Integrating the Design of Tall Building, Wastewater Drainage Systems into the Public Sewer Network: A Review of the Current State of the Art. Water 2021, 13, 3242. [Google Scholar] [CrossRef]

- Gormley, M.; Campbell, D.P. The Transport of Discrete Solids in above Ground near Horizontal Drainage Pipes: A Wave Speed Dependent Model. Build. Environ. 2006, 41, 534–547. [Google Scholar] [CrossRef]

- BS EN 12056-2; Gravity Drainage Systems inside Buildings. Sanitary Pipework, Layout and Calculatioin. BSI Knowledge: London, UK, 2000.

- AS/NZS 3500.2; Plumbing and Drainage, Part 2: Sanitary Plumbing and Drainage. SA/SNZ: Sydney, Australia, 2003.

- UPC Uniform Plumbing Code TM; International Association of Plumbing Mechanical Officials: Ontario, CA, USA, 2003; ISBN 9094724111.

- International Code Council. International Plumbing Code IPC; ICC: Washington, DC, USA, 2003. [Google Scholar]

- Pomponi, F.; Moncaster, A. Scrutinising Embodied Carbon in Buildings: The next Performance Gap Made Manifest. Renew. Sustain. Energy Rev. 2018, 81, 2431–2442. [Google Scholar] [CrossRef]

- Lewandowski, K.; Katarzyna, S. A Brief Review of Poly(Vinyl Chloride) (PVC) Recycling. Polymers 2022, 14, 3035. [Google Scholar] [CrossRef] [PubMed]

- Martins, J.D.N.; Freire, E.; Hemadipour, H. Applications and Market of PVC for Piping Industry. Polimeros 2009, 19, 58–62. [Google Scholar] [CrossRef]

- Vahidi, E.; Jin, E.; Das, M.; Singh, M.; Zhao, F. Comparative Life Cycle Analysis of Materials in Wastewater Piping Systems. Procedia Eng. 2015, 118, 1177–1188. [Google Scholar] [CrossRef]

- Alsadi, A. Evaluation of Carbon Footprint During the Life-Cycle of Four Different Pipe Materials. Ph.D. Thesis, Louisiana Tech University, Ruston, LA, USA, 2019. [Google Scholar]

- BS EN15804; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. BSI Knowledge: London, UK, 2021.

- BS EN 15978:2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. BSI Knowledge: London, UK, 2012.

- Harnot, L.; George, C.B. TM65 Embodied Carbon in Building Services: A Calculation Methodology; CIBSE: London, UK, 2021. [Google Scholar]

- Hunter, R.B. Building Materials and Structures. Plumbing Manual; National Bureau of Standards: Washington, DC, USA, 1940. [Google Scholar]

- Kragh, J.; Rose, J.; Buhl, L.S. The Risks of Oversizing Domestic Water Piping–Measurement of Peak Flows in Multistory Residential Buildings. Build. Serv. Eng. Res. Technol. 2025, 46, 361–374. [Google Scholar] [CrossRef]

- Gormley, M.; Mohammed, S.; Kelly, D.A.; Campbell, D.P. Application and Validation of AIRNET in Simulating Building Drainage Systems for Tall Buildings. Buildings 2025, 15, 1725. [Google Scholar] [CrossRef]

- The Institute of Plumbing. Plumbing Engineering Services Design Guide; Chartered Institute of Plumbing and Heating Engineering (CIPHE): Hornchurch, UK, 2002; ISBN 1871956404. [Google Scholar]

- Swaffield, J.; Gormley, M.; Wright, G.; McDougall, I. Transient Free Surface Flows in Building Drainage Systems; Swales & Willis Ltd.: Exeter, UK, 2015; ISBN 9780203845769. [Google Scholar]

- BS EN 1329-1-2020; Plastics Piping Systems for Soil and Waste Discharge (Low and High Temperature) Within the Building Structure—Unplasticized Poly(Vinyl Chloride) (PVC-U). BSI Knowledge: London, UK, 2020.

- Circular Ecology Embodied Carbon—The ICE Database. Available online: https://circularecology.com/embodied-carbon-footprint-database.html (accessed on 19 August 2025).

- Hammond, G.; Jones, C. Embodied Carbon: The Inventory of Carbon and Energy (ICE); BSRIA: Bracknell, UK, 2011. [Google Scholar]

- Uni-Bell PVC Pipe Association l. Environmental Product Declaration; NSF International: Ann Arbor, MI, USA, 2023; Available online: https://www.uni-bell.org/Portals/0/ResourceFile/environmental-product-declaration-2023.pdf (accessed on 5 July 2025).

- Aliaxis Technical Services. Positive Air Pressure Attenuator (PAPA)–Best Practice Guide. 2017. Available online: https://www.emea-international.aliaxis.com/en/brands/studor/studor-products/productdetails/studor-p-a-p-a-861881 (accessed on 10 June 2025).

| Property | Value | Unit |

|---|---|---|

| Density | 1380 | kg/m3 |

| Young’s modulus | 2900–3300 | MPa |

| Tensile strength | 50–80 | MPa |

| Elongation@break | 20–40% | - |

| Impact strength | 2–5 | kJ/m2 |

| Glass temperature | 87 | °C |

| Melting point | 212 | °C |

| Vicat temperature | 85 | °C |

| Heat transfer coefficient | 0.16 | W/m.K |

| Linear expansion coefficient | 8.10–5 | /K |

| Specific heat | 0.9 | kJ/(kg·K) |

| Water absorption | 0.04–0.4 | - |

| Sanitary Appliances | Discharge Units | Fixture Units | |||||

|---|---|---|---|---|---|---|---|

| BS EN 12056 | AS/NZS | IPC | UPC | ||||

| I | II | III | IV | ||||

| Hand wash basin | 0.5 | 0.3 | 0.3 | 0.3 | 1 | 1 | 1 |

| Bath | 0.8 | 0.6 | 1.3 | 0.5 | 4 | 2 | 2 |

| Shower | 0.6 | 0.4 | 0.4 | 0.4 | 2 | 2 | 2 |

| WC | 2 | 1.8 | 1.7 | 2 | 4 | 3 | 3 |

| Kitchen sink | 0.8 | 0.6 | 1.3 | 0.5 | 3 | 2 | 2 |

| Washing machine | 0.8 | 0.6 | 0.6 | 0.5 | 5 | 2 | 3 |

| Dishwasher machine | 0.8 | 0.6 | 0.2 | 0.5 | 3 | 2 | 2 |

| Total (per apartment) | 6.3 | 4.9 | 5.8 | 4.7 | 22 | 14 | 15 |

| No. of Floors | Type of System | Stack/Vent | Size of Pipe DN in mm | ||||||

|---|---|---|---|---|---|---|---|---|---|

| BS EN 12056 | AS/NZS | IPC | UPC | ||||||

| I | II | III | IV | ||||||

| 10 | PVS | Stack | 100 | 100 | 100 | 100 | - | - | - |

| SVS | Stack | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| Vent | 50 | 50 | 50 | 50 | 80 | 75 | 100 | ||

| 20 | PVS | Stack | 125 | 100 | 125 | 100 | - | - | - |

| SVS | Stack | 100 | 100 | 100 | 100 | 100 | 100 | 125 | |

| Vent | 50 | 50 | 50 | 50 | 100 | 100 | 125 | ||

| 40 | PVS | Stack | 150 | 125 | 150 | 125 | - | - | - |

| SVS | Stack | 125 | 100 | 125 | 100 | 125 | 125 | 150 | |

| Vent | 70 | 50 | 70 | 50 | 125 | 125 | 150 | ||

| 60 | PVS | Stack | 150 | 150 | 150 | 150 | - | - | - |

| SVS | Stack | 125 | 125 | 125 | 125 | 150 | 125 | 200 | |

| Vent | 70 | 70 | 70 | 70 | 150 * | 150 * | 200 | ||

| 80 | PVS | Stack | 150 | 150 | 150 | 150 | - | - | - |

| SVS | Stack | 150 | 125 | 150 | 125 | 150 | 150 | 200 * | |

| Vent | 80 | 70 | 80 | 70 | 150 * | 200 * | 200 * | ||

| 100 | PVS | Stack | 200 | 150 | 150 | 150 | - | - | - |

| SVS | Stack | 150 | 150 | 150 | 150 | 150 | 150 | 250 * | |

| Vent | 80 | 80 | 80 | 80 | 150 * | 200 * | 200 * | ||

| PVC Pipe | Wall Thickness | Weight | Weight | |

|---|---|---|---|---|

| Dia. (in) | Dia. (mm) | mm | kg/m | kg/unit |

| 2 | 50 | 3.25 | 0.341 | - |

| 3 | 75 | 3.25 | 0.517 | - |

| 4 | 100 | 3.5 | 0.821 | - |

| 5 | 125 | 3.5 | 0.935 | - |

| 6 | 150 | 4.3 | 1.471 | - |

| 8 | 200 | 5.25 | 2.245 | - |

| 10 | 250 | 6.65 | 3.554 | - |

| 12 | 300 | 8.3 | 5.257 | - |

| PPRD | - | - | 3.2 | |

| AAV | - | - | 0.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, S.; Gormley, M.; Kelly, D.A. Environmental Impact of Building Drainage Systems: Analysis of Embodied Carbon Emissions in Terms of Code-Based Design. Sustainability 2025, 17, 8207. https://doi.org/10.3390/su17188207

Mohammed S, Gormley M, Kelly DA. Environmental Impact of Building Drainage Systems: Analysis of Embodied Carbon Emissions in Terms of Code-Based Design. Sustainability. 2025; 17(18):8207. https://doi.org/10.3390/su17188207

Chicago/Turabian StyleMohammed, Sarwar, Michael Gormley, and David A. Kelly. 2025. "Environmental Impact of Building Drainage Systems: Analysis of Embodied Carbon Emissions in Terms of Code-Based Design" Sustainability 17, no. 18: 8207. https://doi.org/10.3390/su17188207

APA StyleMohammed, S., Gormley, M., & Kelly, D. A. (2025). Environmental Impact of Building Drainage Systems: Analysis of Embodied Carbon Emissions in Terms of Code-Based Design. Sustainability, 17(18), 8207. https://doi.org/10.3390/su17188207