1. Introduction

The construction industry generates vast amounts of construction and demolition waste (CDW) each year [

1]. China alone produces an estimated 1.8 billion tons annually (approximately 23% of the global total), followed by Europe (8%), and the United States (7%), with no signs of a declining trend [

2,

3,

4]. Among the various components of CDW, ceramic waste (i.e., bricks, tiles, terracotta fragments) accounts for a substantial share, reaching up to 50% in some cases. Despite this, large-scale and effective recycling strategies for ceramic waste remain limited [

5]. This growing accumulation poses both an environmental challenge and an opportunity. Reusing waste bricks (WBs), for example, can reduce landfill burden, reduce reliance on non-renewable raw materials, and contribute to the mitigation of greenhouse gas emissions [

6,

7]. As a result, interest is growing in circular-economy approaches aimed at valorizing these materials rather than discarding them.

Currently, WB has primarily been used as a recycled aggregate in concrete or mortar. For instance, Zhou et al. [

8] processed waste clay bricks into both powder and coarse particles to manufacture specialized plastering mortars with improved long-term shrinkage and strength. The powder promoted pozzolanic reactions, while the coarser fraction contributed to internal curing effects and increased durability, particularly when combined with styrene-butadiene latex for consistency enhancement. The study emphasized the dual role of WB as both aggregate and reactive filler in mortar systems. Similarly, Raini et al. [

9] incorporated brick powder as a partial replacement for lime and combined it with recycled concrete aggregates (RCAs) to produce eco-friendly lime mortars. The incorporation of 30% brick powder improved compactness and water resistance due to its pozzolanic activity, while the optimized use of RCA reduced density and supported the development of restoration mortars for historic buildings. These findings collectively demonstrate the technical feasibility and sustainability benefits of reusing ceramic waste in mortar formulations, particularly as aggregates or partial binder substitutes. Beyond their use as aggregate, crushed bricks are often employed as substitutes for sand or gravel in non-structural applications such as sub-base layers or low-performance concrete, thereby further extending their reuse potential [

10,

11].

A more advanced and promising strategy has recently emerged: grinding brick waste into a fine powder to partially replace cementitious binders. Several studies have demonstrated that finely ground WB can exhibit pozzolanic activity, especially when the original firing process has produced amorphous silica and alumina. When incorporated into mortar or concrete at replacement levels up to 20%, WB powder can improve compressive and flexural strength by promoting secondary hydration reactions [

5]. Similarly, Guo et al. [

12,

13] showed that using thermally activated red mud powder, rich in aluminosilicates, in alkali-activated systems can achieve compressive strengths up to 33.5 MPa, with improved microstructure and reduced shrinkage, highlighting the broader potential of industrial powders in sustainable binder formulations. These examples point to a growing trend of utilizing industrial and ceramic by-products not only to reduce waste, but to enhance performance characteristics in sustainable construction materials.

This approach not only supports waste valorization, but also contributes to reducing the carbon footprint of construction materials by lowering the demand for high-CO2 binders such as Portland cement.

In one recent study, Chen et al. investigated the use of recycled clay brick powder (RCBP) as supplementary cementitious material in hybrid mortars containing recycled glass and brick aggregates [

14]. The authors demonstrated that replacing 30% of cement with RCBP resulted in a 28-day activity index close to 97%, confirming the material’s pozzolanic reactivity. Although higher substitution levels slightly reduced compressive strength and workability, the study confirmed the feasibility of integrating recycled materials in the formulation of a durable and sustainable mortar. Another study performed by Kilumile et al. [

15] investigated the performance of historical lime-based mortars incorporating recycled burnt clay brick sand and recycled concrete sand as fine aggregates. When compared with a control mortar made with natural river sand, the mortar containing the recycled aggregates showed significantly enhanced mechanical properties. After 28 days, its flexural strength was 300% higher than that of the control mix, while compressive strength followed a similar trend. These findings emphasize the recycled brick aggregates can not only reduce environmental impact, but also enhance mechanical performance, particularly in the context of repair mortars for historical masonry.

More recently, a novel research direction has emerged: using waste brick powder not merely as an aggregate, but as a partial binder replacement in cementitious systems [

16,

17]. This shift in approach underlines the evolving role of ceramic waste in sustainable material formulations. Building upon these promising results, this research explores whether similar benefits can be achieved in gypsum-based mortar. Gypsum is already considered a more environmentally friendly alternative to cement due to its lower calcination temperature (around 150 °C), which results in reduced energy consumption and CO

2 emissions (approximately 820 MJ/t and 100–140 kg CO

2/t, respectively) [

18,

19]. Gypsum mortars have recently regained attention in sustainable construction, not only for restoration purposes but also as a base for eco-friendly plasters incorporating recycled materials [

20,

21]. However, further environmental benefits may be achieved by replacing a portion of gypsum with ceramic waste, thereby combining two sustainability goals: waste reduction and decreased raw material demand.

While many studies have examined the incorporation of CDW as inert filler or reinforcement in gypsum composites, relatively few have explored the direct replacement of gypsum itself with such materials. For example, Beldjilali et al. [

22] demonstrated that WB powder can partially replace gypsum without triggering any significant chemical reactions, while still improving key mechanical properties (flexural, compressive, and adhesion strength), most likely through particle packing and improved microstructure density. Similarly, Naciri et al. [

23] showed that incorporating WB into gypsum-lime mortars can enhance their mechanical behavior both in dry and saturated conditions.

In terms of sustainability, replacing gypsum with WB offer multiple benefits: it reduces energy consumption during binder production, lowers CO2 emissions in the final product, and aligns with circular construction principles by reintegrating ceramic waste into new material cycles. This approach also helps limit raw gypsum extraction and decreases landfill accumulation.

In this context, the present research investigates the use of WB as a partial replacement for gypsum in mortar formulations. Five mixtures were prepared with 0%, 5%, 10%, 20%, and 30% WB by weight. A comprehensive experimental program was conducted to assess setting time, water absorption, compressive and flexural strength, adhesion to limestone substrate, and microstructural analysis (SEM, EDS, XRD). Additionally, the environmental performance of each mixture was assessed based on CO2 emissions and energy demand.

This work proposes an innovative valorization route for ceramic CDW (i.e., waste bricks) and aims to identify the optimal gypsum replacement level that balances mechanical performance and environmental benefit, thereby contributing to the development of eco-efficient mortars suitable for both construction and restoration applications.

2. Materials and Methods

2.1. Materials

The materials used in this study include commercial gypsum (G), construction sand (CS), recycled waste brick powder (WB), and a superplasticizer (SP). The gypsum was a high-fineness commercial product supplied by RIGIPS (Turda, Romania), in compliance with EN 13279-1 [

24]. The sand, supplied by ADE-PLAST (Oradea, Romania), was a quartz-based aggregate, with a density of 2600 kg/m

3 and water absorption of 5.4%.

The waste bricks were sourced from Cemacon (Zalău, Romania), a local supplier of construction demolition waste. After initial coarse crushing, the material was finely ground and sieved to obtain a powder with particles smaller than 1 mm, of which approximately 70% were below 0.25 mm. This particle size distribution was selected to promote filler effects and improve matrix densification. The particle size distribution of sand and waste brick powder is shown in

Figure 1.

In particle size distribution (PSD) analysis, D10, D50, and D90 are key parameters that represent specific particle size percentiles. D10 is the particle size below which 10% of the particles in a sample fall, D50 is the median particle size (50% of particles are smaller, 50% are larger), and D90 is the particle size below which 90% of the particles fall. For sand, we obtain the following data: D10 ≈ 0.18 mm; D50 ≈ 0.45 mm; D90 ≈ 0.85 mm, while for WB, the data are D10 ≈ 0.03 mm; D50 ≈ 0.20 mm; D90 ≈ 0.50 mm.

A polycarboxylate-based superplasticizer (Sika Plastiment BV540 Super, density 1050 kg/m3, Sika AG, Baar, Switzerland) was used to improve workability and ensure consistent flow across all mixtures.

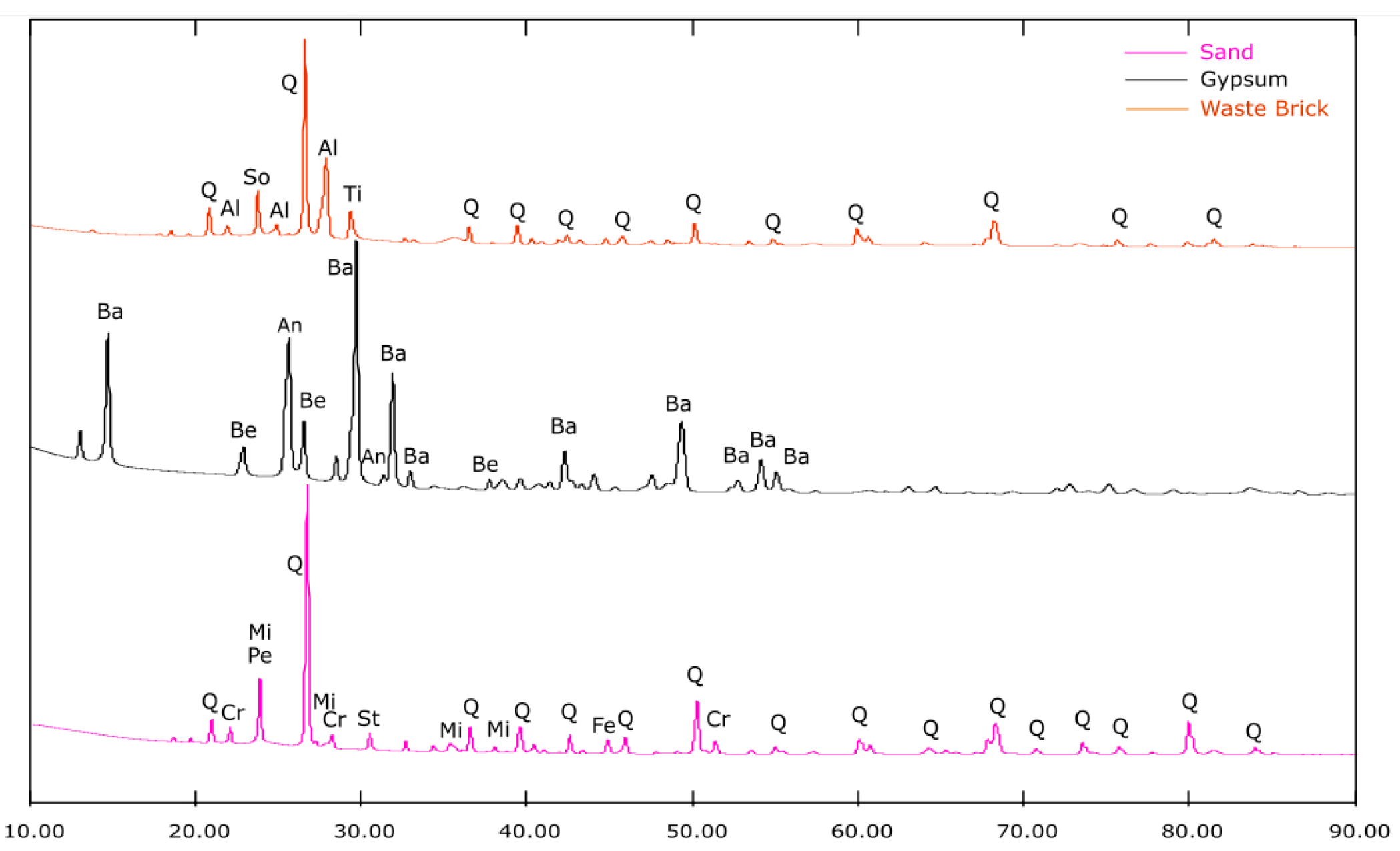

The chemical composition and mineralogical characteristics of the raw materials were analyzed using X-ray fluorescence (XRF) and X-ray diffraction (XRD), respectively.

XRD analysis was performed using a Rigaku Ultima IV X-ray diffractometer (Rigaku Corporation, Tokyo, Japan), equipped with Cu-Kα radiation (λ = 0.15406 nm), at 40 kV and 30 mA. Data were collected over a 2θ range of 5–100° with a step size of 0.0200° and a scanning speed of 1°/min. The instrument, fitted with a NaI detector (count rate limit > 700,000 cps), supports both symmetric and asymmetric geometries, including high-resolution Bragg–Brentano and parallel beam configurations, with a minimum step width of 0.001 mm. Data acquisition and processing were performed using PDXL 2.2 software in conjunction with the ICDD PDF-4+ 2016 database.

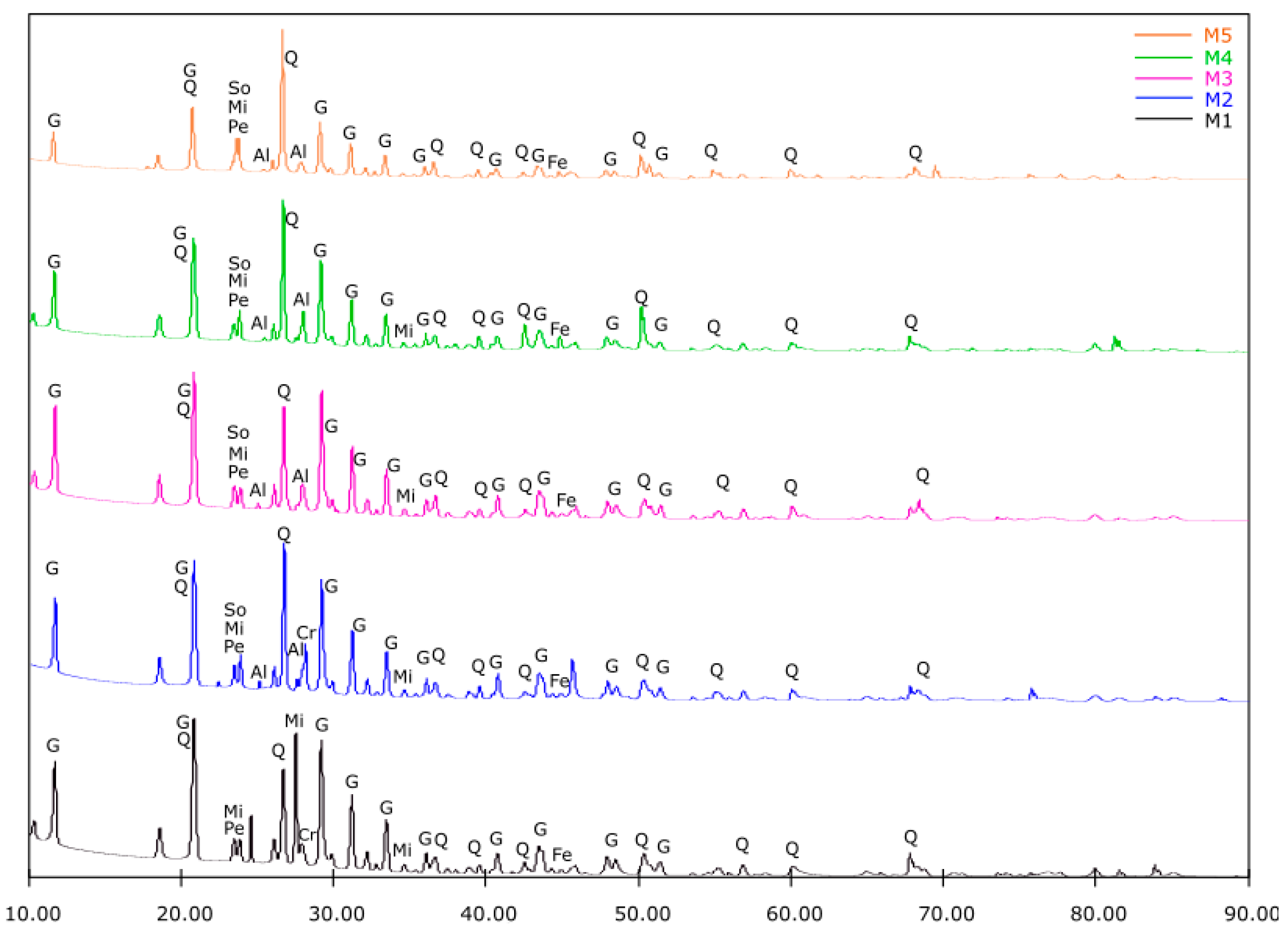

Phase identification was carried out based on standard patterns from the ICDD database, specifically using category S (Star Patterns—extremely high-quality data) and category I (Indexed Patterns—indexed high-quality data). The detection limit of the XRD method is approximately 1%. The XRD patterns of sand, gypsum, and waste brick are shown in

Figure 2.

The main crystalline phases identified include quartz, microcline, petalite, cristobalite, stishovite, and iron in the sand; bassanite as the dominant phase in gypsum, with minor anhydrite and berlinite; and quartz and albite in the WB, along with traces of sodalite and titanium oxide (Ti8O15).

Elemental composition was determined by wavelength-dispersive XRF, using a Rigaku ZSX Primus II spectrometer (Rigaku Corporation, Tokyo, Japan), equipped with an Rh-anode X-ray tube (4.0 kW) and a 30 µm beryllium window, operating under vacuum conditions. Samples were prepared as pressed pellets. The resulting chemical composition, as well as the density and water absorption of each raw material, are presented in

Table 1.

As expected, gypsum exhibited high CaO and SO3 contents, whereas the WB powder showed a significantly higher proportion of SiO2 and lower SO3 content. Notably, WB also demonstrated a much higher water absorption capacity (28.9%) compared to gypsum (2.5%), which is expected to influence both the rheological behavior and mechanical performance of the resulting mortar mixes.

2.2. Mix Design

Five mortar formulations were developed by partially replacing gypsum with waste brick powder (WB) at weight-based substitution levels of 0%, 5%, 10%, 20%, and 30%, identified as M1 through M5, respectively. These levels were selected to represent a range from low (5% and 10%) to high (20% and 30%) incorporation rates, while limiting the number of tested mixtures. The 30% replacement level is commonly reported in the literature as the upper limit for maintaining workability and cohesion, despite notable reductions in mechanical strength [

16]. The 20% level is widely considered a threshold for preserving acceptable performance. Each formulation contained a fixed amount of construction sand and superplasticizer. Water content was adjusted across mixtures to maintain a similar level of workability, with target flow values ranging from 160 to 180 mm, in accordance with EN 1015-3 [

25]. All mixtures were prepared under laboratory conditions.

The component quantities, expressed in kg/m

3, are detailed in

Table 2. It is important to note that the values reported for gypsum content (ranging from 800 to 560 kg/m

3) are not experimental design variables, but rather result from the progressive replacement of gypsum with WB powder (from 0% to 30% by weight). As the gypsum content decreases, the amount of mixing water is also adjusted; however, not proportionally, resulting in an increase in the water-to-gypsum (W/G) ratio from 0.40 to 0.55. The contents of sand and superplasticizer were kept constant across all mixtures to ensure comparability in terms of workability and volume consistency.

2.3. Sample Preparation

All dry components (G, WB, and CS) were first manually premixed and then homogenized in a mechanical mixer. Water and superplasticizer were added gradually, and the final mortar was mixed until uniform consistency was achieved, in accordance with the standard EN 998-1 [

26]. In order to test the mortar samples, nine prismatic specimens (40 × 40 × 160 mm

3) were cast for each mortar formulation according to the European specification 1015-11 [

27].

At first, the molds were filled with the fresh mortar in two roughly equal layers. They were then sealed with a sheet of polyethylene. After 48 h, the samples were demolded and placed in polyethylene bags for an additional five days, maintained at approximately 20 °C and 95% relative humidity. Following this initial curing stage, the specimens were stored under standard laboratory conditions (around 20 °C and 65% relative humidity) for a further 21 days. Although these curing conditions differ from those specified in EN 13279-1 [

24] (which recommends 40 °C), they were chosen to better simulate indoor environmental exposure and to ensure consistency across all tests, including mechanical strength, water absorption, and adhesion.

However, mechanical testing was performed at three different curing intervals: 7, 14, and 28 days. For the adhesion strength tests, three cylindrical samples (50 mm in diameter) were prepared for each mortar formulation and exposure condition, in accordance with EN 1015-12 [

28]. Fresh mortar was applied in 15 mm thick layers onto limestone substrate, chosen due to their use in Romanian historical buildings. The composite specimens were initially covered with polyethylene film and cured for seven days at about 20 °C and 95% relative humidity. After this curing period, the film was removed, and the samples were conditioned in laboratory air (20 °C, 65% RH). A circular cut of 50 mm diameter was then made on each specimen, and a metal disc of the same size was glued to the surface of the mortar to prepare for the pull-off adhesion test.

2.4. Testing Methods

A comprehensive experimental program was carried out to evaluate the physical, mechanical, and microstructural properties of the gypsum-based mortars. Physical performance was assessed through setting time measurement and water absorption by immersion, while mechanical behavior was evaluated via flexural, compressive, and adhesion strength tests. Microstructural characterization included optical microscopy, scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), and X-ray diffraction (XRD).

Setting time was determined using a Vicat apparatus (Vicat SA, Saint-Égrève, France), in accordance with the corresponding standard [

29]. Water absorption by immersion was measured by recording the dry mass of specimens and their mass after 24 h of immersion in distilled water. For this test, half-prisms obtained from the 28-day flexural tests were used. Prior to testing, samples were oven-dried at 50 ± 5 °C until constant mass, in compliance with standard [

30].

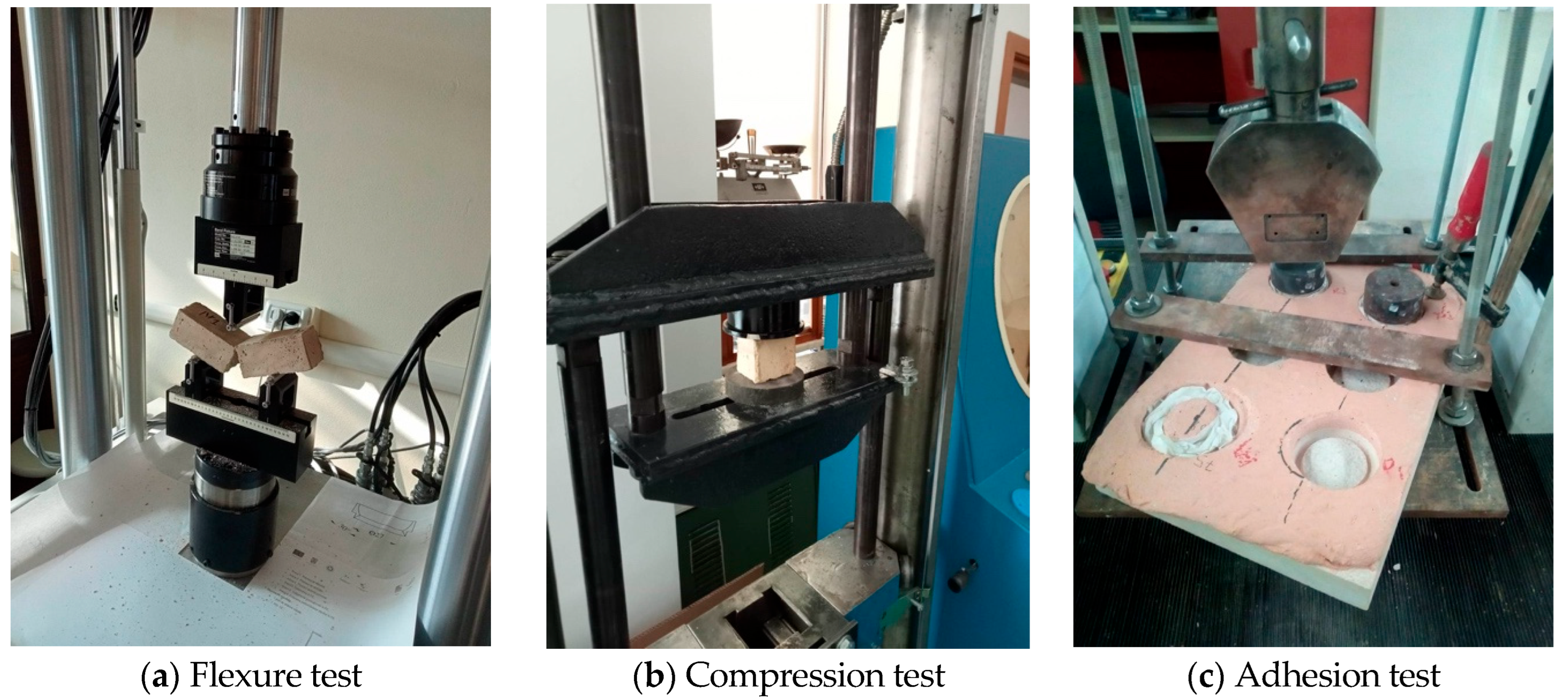

Mechanical strength tests included three-point bending tests on prismatic specimens and compressive strength tests on the fractured halves of the same specimens, performed at 7, 14, and 28 days according to standard [

27]. Testing was performed using an MTS 100 (MTS Systems Corporation, Eden Prairie, MN, USA) loading device with a loading rate of 50 N/s for flexural strength and 2400 N/s for compressive strength. Adhesion strength was assessed by applying two 15 mm thick layers of each mortar formulation onto limestone substrates, chosen due to their common use in Romanian historical buildings [

31,

32]. After 28 days of curing, six circular holes with a diameter of 50 mm were cut from each mortar layer and bonded to metal discs. A perpendicular tensile load was applied until failure, following the procedure outlined in standard [

28]. The equipment used for the mechanical characterization of the samples is shown in

Figure 3.

Optical microscopy was performed with a Novex trinocular microscope (EUROMEX Microscopen B.V., Arnhem, The Netherlands) to examine the surface homogeneity of the mortars. SEM analysis, carried out with an SU-70 microscope (Hitachi, Tokyo, Japan), allowed for detailed observation of the microstructural morphology. The SEM operated at accelerating voltages ranging from 0.1 kV to 30 kV, with magnifications between 30× and 800,000×, and a resolution of 1 nm at 15 kV. EDS was employed for elemental microanalysis, while XRD was used, as previously described, to identify the mineralogical composition of the mortar mixtures.

2.5. Environmental Assessment

The environmental performance of the different mortar formulations was evaluated by estimating the associated CO2 emissions (i.e., Global Warming Potential, GWP) and energy demand, adopting a cradle-to-gate approach. Emission and energy factors were derived from the literature, and the functional unit was set as 1 m3 of hardened mortar, to allow a fair comparison among the mixtures.

The GWP for each mortar mix was calculated using the following Equation (1):

where

mi is the mass (in kg) of component

i per cubic meter of mortar, and

EFi is the emission factor of component

i (expressed in kg CO

2-eq per ton of material). The same formula was applied to estimate the total energy demand, substituting emission factors with energy consumption factors (in MJ/t).

3. Results and Discussion

3.1. Setting Time

The evolution of the setting time of the gypsum mortars as a function of WB content is presented in

Figure 4. The initial and final setting times were measured using the Vicat method and are defined, respectively, as the time from the initial contact between the dry components and water to a penetration depth of the 22 mm, and the time at which the needle no longer sinks into the material.

The reference mortar M1 (i.e., 0% WB) exhibited the longest setting times, with an initial setting of approximately 15 min and a final setting of around 30 min. As the percentage of WB increased, both initial and final setting times progressively decreased. Mortars M4 and M5, containing 20% and 30% WB, respectively, showed initial setting times of less than 10 min and final setting times close to 15 min for M4 and less than 10 min for M5. This trend reflects an almost linear reduction in setting time with increasing WB content. This behavior can be attributed to the high water absorption capacity of the WB particles, as shown in

Table 1. As a result, part of the mixing water is rapidly absorbed by the brick particles, effectively reducing the amount of free water available for gypsum hydration and accelerating the setting process. This interpretation is further supported by microstructural observations (see

Section 3.4), where the presence of voids and porous WB particles was noted, suggesting that the fresh mortar matrix may experience localized water depletion around the brick fragments.

Moreover, the faster setting time may be linked to the reduction in total binder content as gypsum is progressively replaced. While the WB behaves as an inert filler and does not contribute to the hydration reaction, it increases the surface area within the mixture, further promoting localized stiffening [

33,

34]. These effects collectively shorten the interval between the initial and final setting, which drops from 15 min in M1 to less than 6 min in the WB-containing mortars.

It is important to highlight that, despite this acceleration, all the mortars met the standard requirements for setting time according to the standard NBR 13207:1994 [

35], which states that gypsum plasters for coatings must have an initial setting time greater than 10 min and a final setting time greater than 45 min. However, the reduced working time in mixes with higher WB content, which approaches the minimum threshold of the standard [

35], may affect their applicability in construction practices, particularly where extended setting time is required [

36,

37].

3.2. Water Absorption by Immersion

Figure 5 shows the water absorption by immersion of the gypsum mortars at 28 days of curing.

The reference mortar M1, which contains only gypsum as a binder, exhibits an absorption rate of approximately 11%. This value is consistent with the known porous nature of gypsum-based materials, which tend to retain water due to their microcapillary structure and relatively low density [

38].

With the progressive replacement of gypsum by WB, a gradual increase in water absorption is observed. This behavior is attributed to the intrinsic characteristics of the WB, which, according to the material data in

Table 1, has a water absorption capacity of nearly 29%. The high porosity and irregular surface texture of the crushed brick particles enhance the ability of the mortar to absorb and retain water within the matrix. These findings are in line with previous studies on mortars incorporating ceramic waste. For example, Ma et al. [

33] reported a similar trend in cement-based composites, where increasing the content of finely ground waste brick powder led to higher water absorption due to the high internal porosity and irregular surface of the particles. In that study, mortars with 20–30% brick powder showed absorption increases of up to 40% compared to the reference mix. Similarly, Naceri and Hamina [

39] observed that waste brick aggregates increased porosity and capillary absorption in blended mortars, although the mechanical performance remained acceptable under dry conditions.

Furthermore, Scheinherrová et al. [

36] emphasized that the porous and heterogeneous nature of ceramic residues contributes significantly to water retention when incorporated into gypsum- and lime-based matrices. Their study also indicated that while ceramic particles may not participate in hydration reactions, they alter the pore structure in a way that affects both water transport and vapor diffusion within the hardened material.

Regression analysis of the water absorption data yielded the following linear Equation (2):

where absorption is a percentage, WB is expressed as fraction and R

2 = 0.977. The positive slope indicates that increasing the proportion of waste brick leads to a consistent rise in absorption. For every 1% increase in waste brick content, the water absorption increases in the gypsum mortars by approximately 0.353%. This result confirms a strong linear correlation between the waste brick content and the water absorption of gypsum mortar at 28 days, mainly due to the high porosity and absorptivity of the waste material compared to natural sand.

Despite the increase in absorption, the values remain within acceptable limits for non-structural applications, especially in interior environments.

3.3. Mechanical Properties

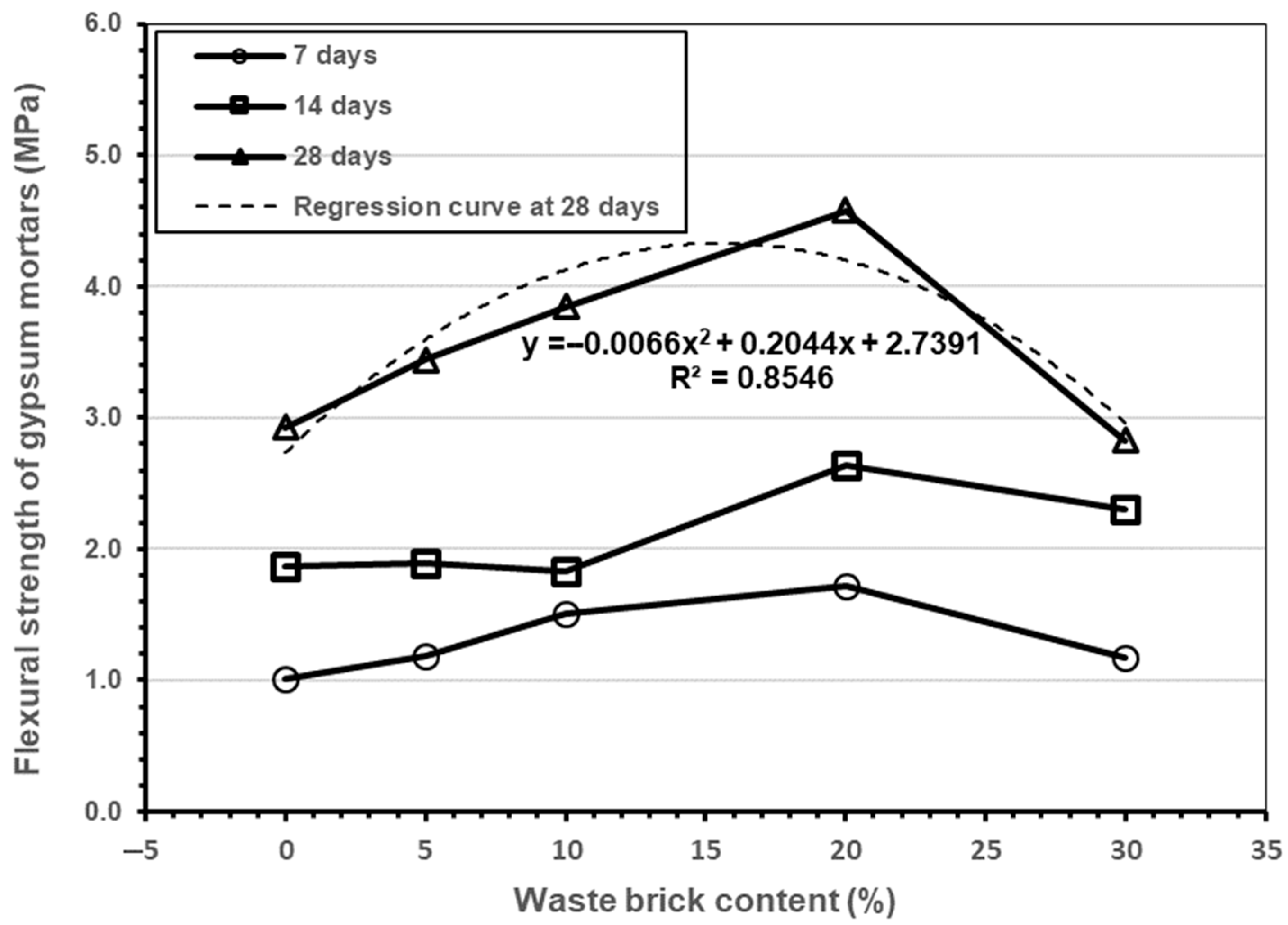

3.3.1. Flexural Strength

The flexural strength of the mortars as a function of WB content and curing time is shown in

Figure 6.

A clear improvement in flexural strength was observed with increasing WB content up to 20%, regardless of curing age. At 7 days, mortar M4 (i.e., 20% of WB) showed an increase of approximately 70% compared to the reference mortar M1; at 14 and 28 days, the gains were around 41% and 56%, respectively. Beyond this replacement level, the performance dropped: M5 (i.e., 30% of WB) showed reduced strength, falling below the 20% optimum but remaining comparable to or slightly above the reference in some cases.

This trend can be attributed to the microstructural effects induced by the addition of WB. As will be discussed in

Section 3.3, the irregular and angular shape of the brick particles may enhance mechanical interlocking within the gypsum matrix, especially when present in moderate amounts. The increased roughness and heterogeneity at the aggregate–matrix interface likely contribute to more efficient stress transfer, thus improving flexural strength.

However, when the WB content exceeds 20%, the decrease in gypsum content reduces the amount of reactive binder, limiting matrix cohesion. Moreover, the high water absorption of WB may lead to localized water deficiencies during setting, hindering the complete formation of gypsum hydration products. This is consistent with the observations in the setting time tests (in

Section 3.1), where faster setting was observed for higher WB contents.

The regression analysis of the data for the 28-day flexural strength shows that the flexural strength increases with waste brick content up to about 15–20%, then decreases beyond that. Therefore, the optimal waste brick content (for the highest 28-day strength) is approximately 17%. The R2 obtained indicates a strong correlation and shows that the regression is a good representation of the actual behavior. The initial increase in strength may be due to improved microstructure as previously mentioned. Beyond about 15–20%, the excessive waste may reduce bonding or increase porosity (waste bricks have high water absorption (28.90%) compared to natural sand), leading to a drop in strength.

Overall, the results indicate that 20% WB replacement offers the best balance between mechanical reinforcement and binder dilution, in agreement with previous research on ceramic waste addition to gypsum composites [

19].

3.3.2. Compressive Strength

The compressive strength results, reported in

Figure 7, show a similar trend to that of flexural strength.

Up to 10% WB, the performance remains close to that of the reference mortar. At 20% WB, a significant improvement is observed: compressive strength increased by approximately 60% at 7 and 14 days and by 33% at 28 days, compared to M1.

This improvement is likely due to a combination of factors. First, the fine brick powder may act as a micro-filler, partially densifying the matrix and reducing voids. Second, the reduced water-to-binder ratio (as reported in

Table 2) may have led to lower initial porosity, as less free water was available for evaporation during curing. Finally, the irregular shape of WB particles may again play a role in enhancing particle packing and stress distribution.

Nevertheless, at 30% WB (i.e., M5), the compressive strength drops, though it remains above the reference mix. This suggests that beyond 20%, the dilution of the binder dominates the mechanical response, and the filler effect of WB is no longer sufficient to compensate for the lack of cohesive phases. These results support the use of up to 20% WB as a sustainable and technically effective partial replacement of gypsum in mortars designed for non-structural applications.

The 28-day compressive strength of gypsum mortar exhibits a parabolic relationship with brick waste content, peaking at approximately 17% replacement. The quadratic regression model (R2 = 0.8279) suggests a significant non-linear trend, where strength first increases and then decreases with higher substitution rates. The initial improvement can be attributed to the fineness of the waste brick powder, helping to fill tiny gaps between particles, which makes the mortar structure more solid and compact. Additionally, the irregular shape of the waste particles likely enhances mechanical interlocking and particle packing, improving stress distribution within the hardened matrix. These effects together promote a denser, more cohesive microstructure.

3.3.3. Adhesion Strength

Figure 8 presents the results of the adhesion strength test. The sample was tested at 28 days, and a progressive decline in the adhesion with increasing WB content was obtained.

Mortar M1 showed the highest adhesion value (i.e., 0.88 MPa), followed by a gradual decline in mortars M2 to M5. At 20% WB (i.e., M4), adhesion was reduced to 0.73 MPa. With 30% WB (i.e., M5), the adhesion dropped significantly below the threshold of 0.57 MPa, typically required for gypsum mortars used in plasters and coatings.

This reduction can be explained by several concurrent effects. As the gypsum content decreases, the volume of binder available to create a cohesive interface with the substrate is reduced. Simultaneously, the increased porosity and water retention introduced by WB, evident in

Section 3.1 and

Section 3.4, may weaken the bond between the mortar and the limestone substrate used for testing.

It is also possible that the faster setting observed in WB-rich mortars (in

Section 3.1) negatively affects adhesion. Rapid loss of workability can limit the quality of contact with the substrate during application, especially when performed manually. For these reasons, maintaining WB content at or below 20% appears to be a reasonable compromise, allowing for improved strength and environmental performance without critically compromising adhesion.

3.4. Microstructural Characterization

A combined optical and scanning electron microscopy (SEM) investigation was conducted to assess the morphology, surface texture, and homogeneity of the mortar samples. Optical microscopy at 20× magnification revealed generally homogeneous and compact surfaces across all formulations, as can be observed in

Figure 9.

Rounded sand particles and irregular fragments of waste brick (WB) were visually identifiable, with an increased coarseness observed in mortars containing higher WB content (i.e., M5). The presence of voids was also noted, likely resulting from entrapped air or excess water during casting. Surface coloration varied noticeably with WB content: the control mortar (M1) appeared light in tone, while mortars M4 and M5 showed a reddish hue due to the ceramic particles.

Optical microscopy revealed that all mortar samples containing waste brick as a partial replacement for gypsum exhibited generally homogeneous and compact surfaces. The microstructure appeared continuous, with minimal surface discontinuities or visible defects. In formulations with higher proportions of waste brick, slight increases in surface roughness and isolated pores were observed, possibly due to the irregular shape and granulometry of the recycled material. However, no significant cracks or delamination zones were detected, indicating good visual cohesion at the microscale. These observations suggest that the incorporation of waste brick did not adversely affect the surface uniformity of the mortar under optical magnification.

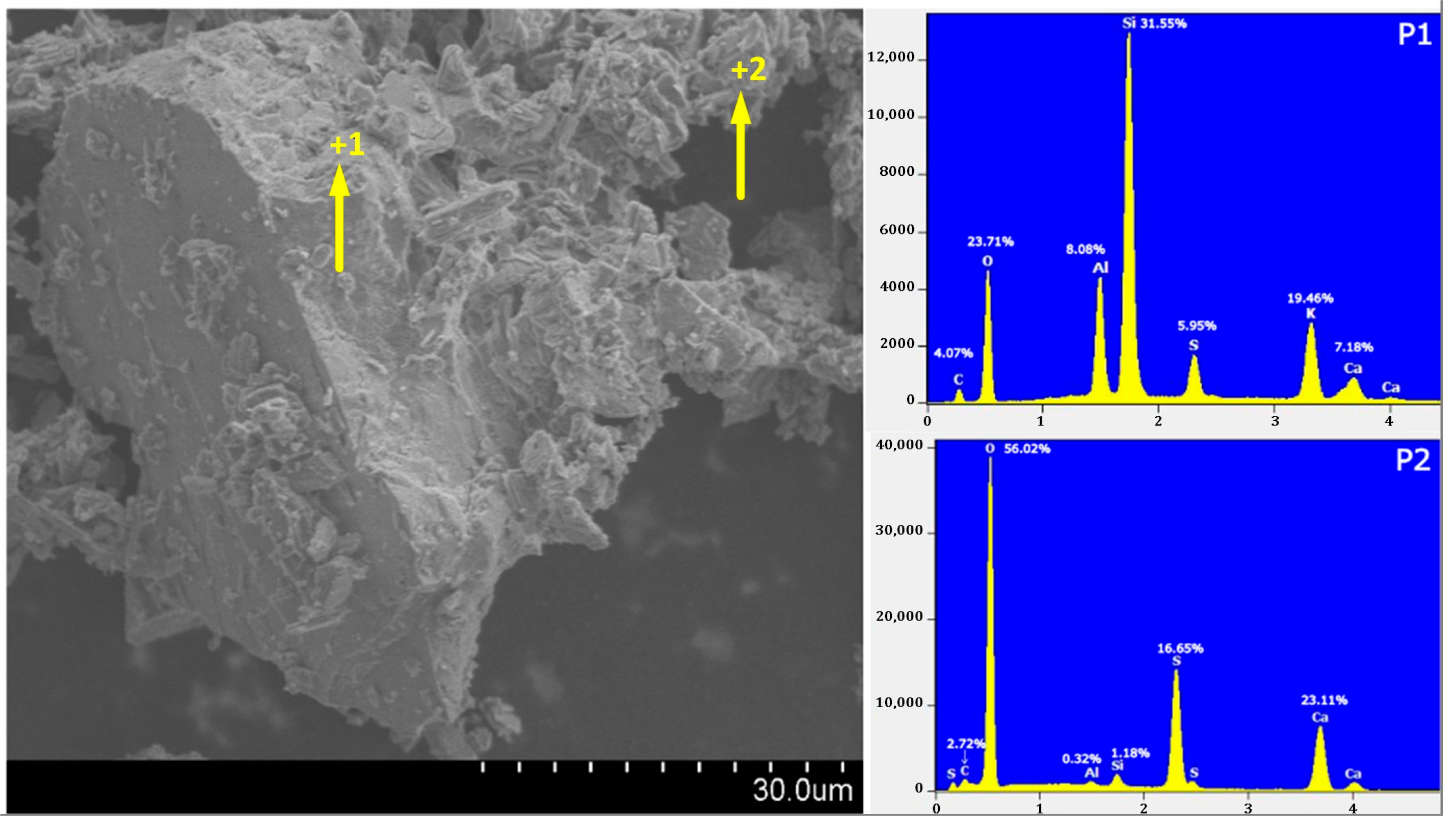

SEM analysis provided higher-resolution insights into the mortar microstructure. In the control sample (i.e., M1), shown in

Figure 10, smooth gypsum crystals and microcline grains from sand were clearly distinguished.

In contrast, the M5 sample exhibited a more heterogeneous morphology, with angular and irregular quartz particles likely originating from either sand or WB, as reported in

Figure 11.

EDS analysis confirmed the elemental composition of selected areas, identifying gypsum (Ca and S) and quartz (Si and O) as the predominant phases. No new crystalline phases were detected in SEM or XRD, indicating that WB acts as an inert filler within the matrix, without undergoing significant chemical interaction with gypsum. These observations are consistent with previous studies [

23,

33,

40].

3.5. X-Ray Diffraction Analysis

X-ray diffraction (XRD) was conducted on the hardened gypsum mortars after 28 days of curing to assess their mineralogical composition, as shown in

Figure 12.

All samples displayed bassanite (G), the primary phase derived from the commercial gypsum binder, especially prominent around 2θ ≈ 14.7°, 25.5°, and 29.7°. As the proportion of waste brick (WB) increases, the intensity of these bassanite peaks progressively decreases, in line with the reduced gypsum content in the mixtures. Quartz (Q) is consistently present in all formulations, showing sharp peaks at 2θ ≈ 20.8°, 26.6°, 36.5°, 39.5°, 50.2°, and 60.0°, originating from both sand and WB. Microcline (Mi) appears primarily between 2θ ≈ 27.3° and 30.0°, and petalite (Pe) is detected in a broader range near 2θ ≈ 22–25°. Traces of iron (Fe) are also present, with peaks observable near 2θ ≈ 44.7°, consistent with the natural sand composition.

In mortars containing waste brick (M2 to M5), additional crystalline phases such as sodalite (So) were detected, around 2θ ≈ 24.5° and 35.0°, reflecting the contribution of ceramic waste. An interesting trend was observed in the distribution of cristobalite (Cr) and albite (Al): cristobalite was clearly present in M1 and marginally in M2, with characteristic peaks near 2θ ≈ 22.0° and 36.1°, but progressively disappeared in mortars with higher WB content. This shift is attributed to the increasing presence of albite, whose diffraction peaks overlap with those of cristobalite, making it the dominant feldspar phase in mixes with 10% WB or more.

The progressive appearance of albite and sodalite, without the formation of new or unexpected phases, suggests that WB behaves as an inert addition at the mineralogical level. This finding is consistent with the SEM-EDS results discussed in

Section 3.4, which revealed no evidence of reaction products or changes in crystal morphology due to the presence of WB. The XRD patterns thus confirm that the incorporation of waste brick does not interfere with the hydration of gypsum, as bassanite remains the predominant phase in all formulations.

From a chemical compatibility standpoint, the coexistence of gypsum-derived and ceramic-derived minerals without new phase formation is favorable for the stability of the material. The inert nature of the WB also contributes to dimensional stability and reduces the risk of deleterious reactions over time. However, this same lack of reactivity implies that the WB does not participate in any pozzolanic or cementitious reactions within the matrix. Although literature has shown that finely ground fired clay bricks can exhibit pozzolanic activity in the presence of calcium-rich binders such as lime or cement, in the case of pure gypsum matrices, the pH and mineral environment are generally not sufficient to activate such behavior [

19,

36,

41].

3.6. Environmental Impact

The environmental performance of the gypsum mortars was assessed by evaluating the Global Warming Potential (GWP, expressed in kg CO2 eq per cubic meter of mortar) and energy demand associated (expressed in MJ/m3) with each formulation, based on a cradle-to-gate approach.

This assessment was performed using the actual compositions of each mortar (M1 to M5, reported in

Table 2) and a functional unit of 1 m

3 of finished product.

Emission and energy factors for the raw materials were sourced from literature and life cycle databases (i.e., Ecoinvent and European Life Cycle Database, ELCD). For natural gypsum, a GWP of 210 kg CO

2 eq/t and an energy demand of 3500 MJ/t were used, based on the ELCD and corroborated by Fořt and Černý [

18]. The contribution of recycled waste brick was estimated using values of 24 kg CO

2 eq/t and 200 MJ/t, reflecting its low environmental impact as a construction and demolition (C&D) by-product [

33,

36,

39]. For construction sand, average values of 10 kg CO

2 eq/t and 200 MJ/t were adopted based on ELCD and supported by Rosado et al. [

42]. The superplasticizer, based on a polyacrylate admixture, was associated with a GWP of 1100 kg CO

2 eq/t and an energy demand of 20,000 MJ/t, as reported by Ecoinvent. Water was considered with minimal impact, using 0.4 kg CO

2 eq/t and 5 MJ/t as average values for tap water (as reported on ELCD).

It is worth noting that some of the energy and emission factors used for WB were obtained from the literature, which already accounts for common life cycle stages such as crushing, sieving, and drying [

36,

43]. However, process-specific variations and on-site conditions are not captured, which represents a limitation of this study. A sensitivity analysis was not carried out, as the purpose of this assessment was to provide a comparative estimate based on standard cradle-to-gate data. Furthermore, the literature data suggest that additional energy requirements for grinding and drying are relatively low (i.e., 5–10 MJ/kg of material), and would not significantly alter the relative environmental trends observed. Nonetheless, this remains a source of uncertainty and should be considered when interpreting the results.

The calculated values of GWP and energy demand for each mortar formulation are reported in

Table 3.

The reference mortar M1, made entirely with natural gypsum as a binder, exhibited the highest GWP value (i.e., 221.80 kg CO2 eq/m3). A progressive reduction was observed with increasing WB content, reaching 176.65 kg CO2 eq/m3 for M5 (i.e., 30% WB), which represents a 20% decrease compared to M1. This improvement is directly linked to the replacement of gypsum, a material requiring high-temperature calcination, with a recycled ceramic filler that demands minimal processing.

Energy demand followed a similar trend, decreasing from 3795.04 MJ/m3 in M1 to 2998.76 MJ/m3 in M5, with a total reduction of approximately 21%. This reflects the lower embodied energy of the WB powder and the lower binder content in the formulations with higher substitution levels.

These results confirm that the partial replacement of gypsum with WB can significantly reduce both the GWP and energy consumption, supporting the development of more sustainable mortars.