Abstract

Life cycle assessment (LCA) is a standardized tool (ISO 14040) used to evaluate the environmental impacts of products and processes across their entire life cycle, from raw material extraction to end-of-life disposal or recycling. It has become particularly important in the context of engineering materials, where sustainability considerations are critical. Despite challenges such as data quality limitations, variations in system boundary definitions, and methodological inconsistencies, LCA remains an essential tool for assessing and improving product sustainability. This work presents a foundational overview of LCA principles and describes a systematic, step-by-step procedure for its effective application. Additionally, this article revisits the fundamental concepts of carbon footprint (CF) analysis as a complementary tool for quantifying greenhouse gas emissions associated with products and activities. CF analysis underscores the necessity of adopting low-carbon materials and manufacturing processes to minimize embodied energy and reduce environmental emissions. Low-carbon materials are characterized by attributes such as being lightweight, recyclable, renewable, bio-based, locally sourced, and safe for public health. Their development balances the reduction of raw material and resource consumption during production, with increasing product performance, recyclability, and service life, reflecting a cradle-to-cradle, circular economy approach. The integration of LCA and CF methodologies provides an integral framework for assessing environmental performance and supports decision-making processes aligned with global sustainability targets.

1. Introduction

Life cycle analysis (LCA) is indeed a managerial concept whose roots could be traced back to the 1960s [1,2]. However, over time, LCA has gained importance, owing to the increase in anti-environmental engineering and scientific practices, resulting in the uncontrolled acquisition of non-renewable and precious natural resources. The worldwide acknowledgement of the LCA concept led to the formation of an International Standard ‘ISO-14040’ that serves as framework and defines LCA as follows [3]:

“A technique for collecting information relevant to a products’ environmental aspects and impacts by considering each and every impact associated with all stages of a process from cradle-to-grave, including materials processing, manufacture, distribution, use, repair, maintenance, and disposal or recycling.”

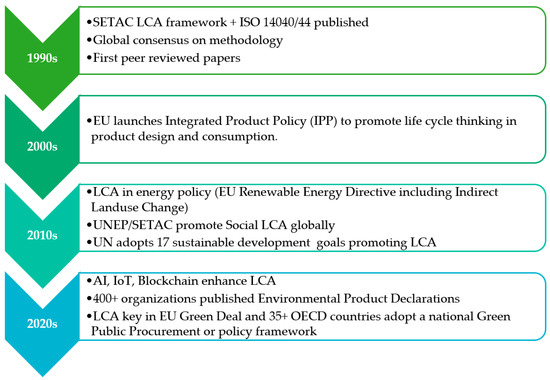

Besides ISO-14040, the LCA concept has also been defined by the Society of Environmental Toxicology and Chemistry (SETAC) in its “Code of Practice” [1]. In addition, several organizations from around the world have been involved in the development of LCA using different types of analytic approaches. However, regardless of the success rate of the approaches, there are several nonspecific complications in performing LCA. These include poor quality data, weak reasons or procedures for establishing boundary constraints, and the existence of diverse principles when comparing environmental factors without any common objective [4]. Indeed, the propagation of LCA tools, alongside the growing perceived market opportunities of LCA tools, as depicted in Figure 1 [5], have become a key problem, as different studies focus on different datasets and methods. Therefore, it was of utmost importance to standardize the LCA methods through a consensus approach and, fortunately, in 2002 the United Nations Environment Program (UNEP), in association with SETAC, has launched the Life Cycle Initiative (LCI) [6]. The LCI brought new robustness into LCA tools for evaluating materials, products, and systems. In 2011, SETAC founded the LCA Global Coordinating Group (GCG) as a communication center among the regional advisory committees, including Europe, North America, and the other three geographic units of SETAC (Latin America, Asia-Pacific, and Africa) [7]. The United States Environmental Protection Agency (USEPA) published an article entitled, Life cycle assessment: Principles and practice, to summarize the general LCA methodologies and life cycle impact assessment (LCIA) tools in 2006 [8]. LCA is now widely recognized as an important tool for assessing the sustainability of products and systems in relation to the United Nations’ Sustainable Development Goals (SDGs) set in 2015 [9]. However, despite growing adoption and methodological refinement, practical implementation of LCA continues to face critical challenges. These include the labor-intensive nature of life cycle inventory (LCI) data collection, persistent data gaps, particularly in toxicity-related impact categories, and uncertainties surrounding the reliability and relevance of external data sources [10]. To address these limitations, enhancements such as coupling Geographic Information Systems (GISs) with LCA have been implemented to support biomass energy projects through resource potential assessment, supply chain optimization, and site planning [11]. Additionally, emerging digital technologies, such as Artificial Intelligence (AI), the Internet of Things (IoT), and Blockchain offer promising solutions by enabling real-time data acquisition, enhanced model integration, and improved transparency, thereby strengthening the reliability, efficiency, and scalability of LCA [10].

Figure 1.

Trajectories and drivers of LCA development [12,13,14,15]. Adapted from [5], licensed under CC BY 4.0.

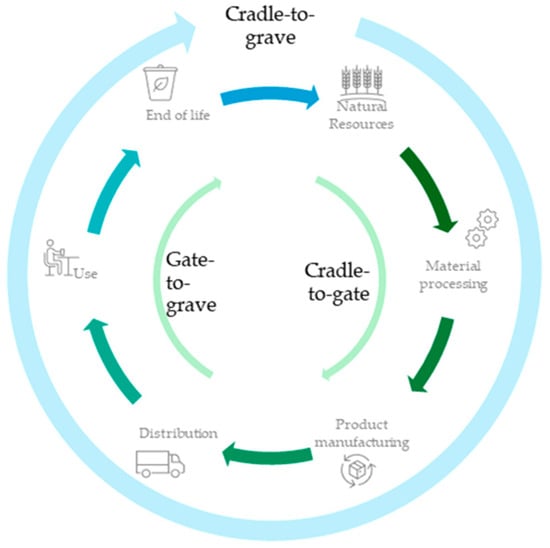

This commentary provides a foundational overview of LCA and carbon footprint (CF) analyses, detailing key concepts, application stages, and the quantification of greenhouse gas (GHG) emissions. It should be noted that the purpose of this article is to revisit and clarify foundational concepts related to LCA and CF analyses. Given the growing environmental concerns and increasing application of LCA across diverse fields, there is value in reinforcing a clear and accessible understanding of these core principles. By doing so, the article aims to support more consistent and effective implementation of LCA and CF practices across various sectors. Thus, the main purpose of this article is to clarify the distinctions between different LCA approaches and to highlight their importance in sustainability assessment and decision-making. To support this, Figure 2 illustrates the “cradle-to-grave” concept central to LCA. It can be seen that the LCA of any engineering goods consists of different phases through its lifecycle, such as [16].

Figure 2.

Cradle-to-grave life cycle of engineering goods. Adapted from [16] with permissions from Elsevier via CCC RightsLink.

- Resources: these are the valuable elements of nature, including water, energy, and raw materials, which are utilized in the production of engineering materials.

- Material processing: it involves a series of transformation steps through which the natural resources have been converted to produce the desired form of engineering materials.

- Product manufacturing: Once the raw material becomes available, the manufacturing of a physical entity starts in response to the end-user implications. The qualitative performance and yield of any manufacturing process rely on the efficacy of the adopted manufacturing technique.

- Distribution: it involves the distribution of the produced goods and services from the manufacturing units to the consumers.

- Use: Once the manufactured products are delivered to customers, they start to provide the required services.

- End of Life: every product has a definite span of service life, after which it needs to be discarded.

The definitions of the terminologies mentioned above often seem too generic; however, each stage of the “cradle-to-grave” cycle generates enormous hazardous elements in the environment and, therefore, it is reasonable to question which way is the most sustainable. Indeed, LCA helps in searching for and defining the most sustainable option by using a set of predefined rules and policies. The following are the key benefits of LCA analysis [17]:

- It helps to promote sustainable design and re-design of products and processes;

- It leads to reduced overall environmental impacts and the decreased use and release of non-renewable or toxic materials;

- It identifies key materials and processes within the products’ life cycles;

- It assesses the full benefits and costs of a product or process;

- It compares the various possible alternatives;

- It recognizes inefficient or significant changes in the life cycle phases;

- It goes beyond the concept of ‘use’.

The application of LCA is never an easy process, owing to the wide range of process parameters involved at each stage of Figure 2. Therefore, it becomes necessary for the applicant to consider only the most impactful parameters and to set-up constraints and boundaries for the problem at hand. Figure 3 shows the various hurdles while employing LCA.

Figure 3.

Hurdles in applying LCA [18].

There are two main types of LCA: attributional LCA (ALCA), which assesses the global impact share of a product’s life cycle based on defined system boundaries, and consequential LCA (CLCA), which evaluates how environmental impacts change as a consequence of a decision and aligns with consequential ethics and future-oriented sustainability goals [19,20]. A comparison of ALCA and CLCA is presented in Table 1. Nevertheless, a consistent approach for consequential LCA has not yet been established [21]; thus, the expansion and evolution of LCA face four main categories of developmental challenges:

Table 1.

Comparison of attributional and consequential LCA [19,22,23].

- Mechanisms and models;

- Gaps in data and knowledge;

- Incorporating temporal and dynamic components;

- Comparability limitations originating from different scenarios and system boundaries.

2. Application of LCA

Life cycle thinking (LCT) is one of the most qualitative discussions for identifying stages of the life cycle and potential environmental impacts. The application of LCA starts with the “Conceptual LCA (c-LCA)” for assessing the environmental aspects based on a limited and usually qualitative inventory. The c-LCA serves to evaluate [24] the basis for adopting a green marketing strategy, examine how the product compares to competing alternatives, and identify specific environmental advantages or disadvantages across relevant impact categories.

The verdicts about green-marketing and product development do not generally require a critical analysis, but rather foundation knowledge on the relative advantages, disadvantages, and uncertainties of the product. In this process, the outcomes of c-LCA can be presented using qualitative statements, outlining which components or materials have the largest environmental impacts and why. However, limitations in the inventory can occur in the form of omissions of one or more of the phases in the life cycle. A c-LCA may help a decision maker identify products possessing competitive advantages and reduced environmental impacts. Subsequent application of a detailed LCA fulfils the requirements of a standard and can be used for public information. The LCA takes a systems approach to evaluate the environmental consequences of a particular product, process, or activity from “cradle-to-grave” [25].

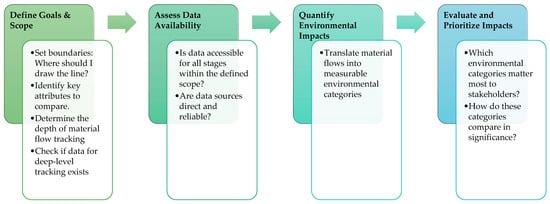

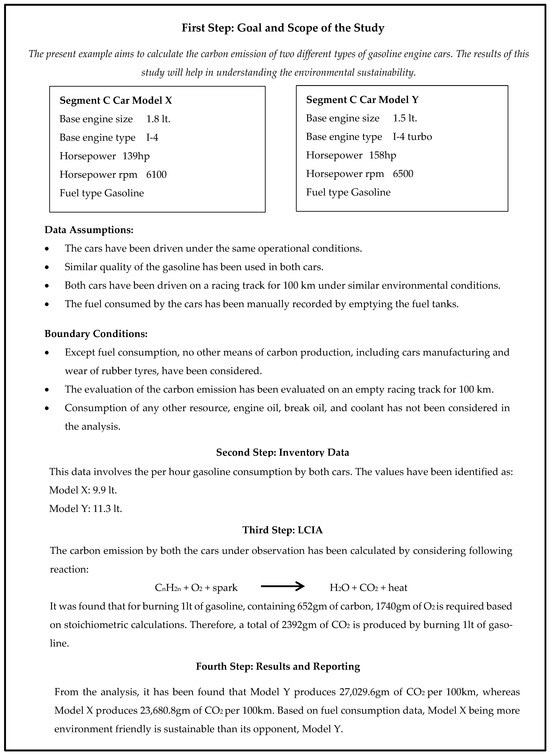

By considering the entire life cycle of a product, from its extraction and processing of raw materials, manufacturing, and transportation, to final disposal, LCA is used to systematically assess the impact of each component process. Figure 4 illustrates the simplified application of LCA. Ideally, a complete LCA would include four separate but interrelated components, as shown in Figure 5.

Figure 4.

Simplified application of LCA.

Figure 5.

The steps for conducting an LCA.

2.1. Goal and Scope Definition

According to the ISO-14040 standard [3], the first phase of an LCA is to define the goal and scope of the problem. It is of high importance that the goal and scope should have clear definitions and consistency, underlining the intended application.

- Goal: It is the intended application of the LCA study, such as marketing, product development, product improvement, strategic planning, etc. The specific objective of the study significantly influences the design and extent of its scope.

- Scope: While defining the scope of LCA, it is essential to characterize the process under observation. At this stage, various assumptions are identified, and the methodological approach used to model the product system is specified. In particular, the following factors strengthen the reliability, efficiency, and scalability of LCA execution:

- ○

- Function of the product (functional unit);

- ○

- Reference flow;

- ○

- System description;

- ○

- System boundaries, which can take several forms [26,27]:

- ▪

- Cradle-to-grave: covers all life cycle stages, from raw material extraction, production, and transportation, through to the use phase and end-of-life treatment.

- ▪

- Cradle-to-gate: includes processes from raw material extraction up to the point where the product leaves the production facility (gate of the factory).

- ▪

- Gate-to-grave: focuses on the downstream processes, starting from the product’s use phase to its end-of-life.

- ▪

- Gate-to-gate: limits the analysis of environmental impacts to the production phase only.

- ○

- Allocation procedures;

- ○

- Impact categories and the impact assessment method;

- ○

- Data requirements;

- ○

- Data assumptions;

- ○

- Limitations;

- ○

- Data quality requirements;

- ○

- Peer review requirements;

- ○

- Reporting type.

2.2. Life Cycle Inventory

The second phase of a LCA is the life cycle inventory (LCI) analysis, which entails the systematic collection and quantification of all relevant inputs and outputs associated with a product system across its life cycle. It includes data collection and the accumulation of the data in a life cycle inventory (LCI) table. Indeed, this phase is the most work-intensive and time-consuming due to the need for comprehensive quantitative and qualitative data across all unit processes in the system, but IoT technologies can streamline this process by enabling automated, real-time data collection [10]. Furthermore, digital tools and software such as SimaPro and OpenLCA facilitate the management, modelling, and analysis of inventory data by providing extensive databases and structured workflows, thereby enhancing accuracy and efficiency in the LCI phase [28,29]. The inventory data typically consists of the following categories: energy inputs, raw material inputs, ancillary inputs, physical inputs, products and co-products, waste outputs, emissions to air, water, and soil, as well as other relevant environmental aspects [30].

Prior to conducting the life cycle inventory (LCI) analysis, several preparatory steps must be carried out. First, data validation must be performed to ensure the reliability of collected data, typically through mass or energy balance checks. Next, the validated data should be assigned to the appropriate unit processes within the system model. Finally, all data must be normalized to the functional unit, enabling meaningful comparisons and consistent interpretation of results across the system boundaries.

2.3. Life Cycle Impact Assessment

The life cycle impact assessment (LCIA) finds and evaluates the volume and implication of the possible environmental impacts arising from the inputs and outputs quantified during the LCA. In this phase, inputs and outputs are first assigned to relevant impact categories, and their potential effects are quantified using characterization factors. The assessment should consider not only ecological and human health impacts, but also social, cultural, and economic dimensions [31].

- Impact assessment methods: Several methodologies are available for conducting life cycle impact assessment (LCIA), including TRACI and CML [32,33]. The tool for the Reduction and Assessment of Chemical and other Environmental Impacts (TRACIs) was developed by the U.S. Environmental Protection Agency (EPA) and is both a methodology and a software tool that is predominantly used in the United States. CML is a methodological framework that focuses on assessing a range of environmental impact categories based on emissions to the environment. The CML approach involves a structured process of classification, characterization, and normalization. Impact categories such as global warming potential and ozone layer depletion are assessed using characterization factors derived from IPCC data.

- Selection of Impact Categories: The selection of the impact categories should align with the goal and scope of the LCA study. Selected categories must comprehensively reflect the environmental effects of the product system under analysis. Justification for the selection of impact categories and the chosen assessment methodology should be clearly documented during the goal and scope definition phase.

- Classification: The output from the life cycle inventory (LCI) phase typically includes numerous emissions. Upon selecting relevant impact categories, each emission is assigned to one or more categories based on its environmental relevance. Substances that contribute to multiple environmental effects must be allocated accordingly. For example, carbon dioxide (CO2) and methane (CH4) are both assigned to the global warming potential category, while nitrogen oxides (NOx) may contribute to both eutrophication and acidification categories.

- Characterization: Characterization involves the quantification of potential environmental impacts associated with the assigned impact categories. This process includes applying characterization factors to the LCI results, which convert emissions into a common unit of impact within each category. For instance, emissions influencing human health and acidification are evaluated in parallel, with the environmental flows distributed across both impact mechanisms based on their relative contribution.

- Optional elements of an LCA: The optional components of an LCA, such as normalization, grouping, evaluation, and weighting, are employed to enhance the interpretation and communication of LCIA results [34,35]. While not mandatory, these steps can support clearer insights into the relative importance of impact categories. To minimize the risk of errors, the implementation of these elements must be transparently documented.

- ♦

- Normalization: it expresses the magnitude of the impact indicator results relative to a reference value.

- ♦

- Grouping: it involves the sorting and ranking of the impact categories. The impact categories could also be ranked in a given hierarchy, for example, as high, medium, and low priority. The ranking is based on value-based choices.

- ♦

- Weighting: It assigns relative importance to different impact categories to facilitate comparison.

2.4. Interpretation and Reporting

The final phase of the LCA is often addressed as the interpretation stage, which assesses the results and significance from the previous stages in relation to the originally defined goal and scope [33,36]. This phase comprises the following three primary steps:

- Identification of significant issues: The identification of significant issues serves as the foundation for the evaluation step. It involves analyzing the extensive data collected within the constraints of available time and resources to determine which elements, such as energy consumption, major material flows, waste generation, and emissions, have the most substantial influence on the overall results.

- Evaluation: The aim of the evaluation is to enhance the level of reliability of the LCA study. It includes

- ♦

- Completeness check;

- ♦

- Sensitivity check;

- ♦

- Consistency check.

Conclusions, recommendations, and reporting: Based on the outcomes of the study, certain conclusions are drawn, which help in making recommendations and preparing the reports. The conclusive results of the LCA study should be presented in a comprehensive report that communicates the findings in a clear, transparent, and systematically organized manner. The reporting of the results should be consistent with the goal and scope definition.

3. Carbon Footprints: Basics

The term “Carbon Footprints (CF)” is generally used for describing the total amount of carbon dioxide (CO2) and other GHG emissions by an individual or industry [37]. Individual and industrial activities such as energy use in homes and factories, transportation, manufacturing, food production, public services, and the consumption of goods, contribute to GHG emissions and thus result in a carbon footprint [38,39]. Carbon footprints can be calculated by evaluating emissions across the entire life cycle of a product. For organizations, the complete carbon footprint includes a wide range of emissions, from direct fuel use to indirect sources, such as employee commuting and supply chain activities. To ensure consistency and comparability in quantification and reporting, several internationally recognized standards are available. These standards include ISO 14064 [40], which guides GHG accounting at the organizational level; ISO 14067 [41] and PAS 2050 [42], which provide frameworks for calculating product-level carbon footprints based on life cycle assessment; and the GHG Protocol, a widely used framework for both corporate and product carbon footprint accounting [43]. Indeed, it is important to quantify the entire range of hazardous emissions while calculating an organization’s CF. GHG emissions can be classified into three main scopes [44]:

Direct emissions resulting from activities the organization controls: This includes the direct emissions from the combustion of fuels and the generation of CO2 emissions. Furthermore, some organizations directly emit GHG; for instance, the manufacturing of some chemicals produces methane (CH4), while the use of fertilizers leads to nitrous oxide (N2O).

Emissions from the use of electricity: This includes the general use of electricity for lighting and running industrial equipment. This further includes the indirect emissions of the GHG during the generation of electricity.

Indirect emissions from products and services: This type of emission results from the outsourced products or services, which affect the CF. For instance, a company that manufactures a product is indirectly responsible for the carbon that is emitted in the preparation and transport of raw materials. Therefore, it is clear that the production of a full-fledged CF covers all three types of emissions. Despite emerging international standards, not every organization follows the same approach for calculating their CF.

The CF analysis has provided important findings, which have helped to shape climate policy [45]. Detailed insights into key consumption categories have contributed to more targeted policymaking, informed the development of product policies, and supported public procurement strategies focused on reducing emissions. A significant share of the quickly cumulative emissions in middle-income countries assists in satisfying the consumption in rich countries. Nowadays, the problems of global warming and environmental pollution have become major concerns among economists and environmentalists. In particular, GHG emissions are considered to be the main contributor causing global warming [46], with the consumption of fossil fuels being the prime cause of these emissions. Ultimately, this prompted many countries to adopt sustainable measures, aimed at reducing fossil fuel consumption by promoting renewable energy sources. However, in some developing countries, progress toward these commitments may be partly attributed to the outsourcing of emissions-intensive production to other regions. [47]. This has resulted in the displacement of the polluting industries and businesses to the developing countries, thereby shifting the source of CO2 emissions from developed to developing countries. Though international agreements are of utmost importance in tackling climate change, the local industries always play an important role in introducing and implementing national policies to decrease emissions. For instance, we consume an abundant stock of food produced in foreign countries despite the reduction in territorial emissions; consumption-based emissions can upsurge, as territorial emissions do not take into account the emissions from imported goods [48,49].

3.1. Concepts of CF

The origin of CF can be traced back to as a subset of “ecological footprint” proposed by Wackernagel and Rees, 1998 [50]. The “ecological footprint” refers to the biologically productive land and sea area required to endure human population. According to this concept, CF refers to the land area required to integrate the entire CO2 produced by a human during its lifetime. With the passage of time, as the issue of global warming took a worldwide prominence, the use of CF has become quite common. The concept of CF has been in use for several decades, but it was known differently because life cycle impacts the category indicator of global warming potential. Thus, the present form of CF can be viewed as a hybrid, conceptually serving as a global warming potential indicator. Besides its extensive, constructive, and communal reputation as an indicator of influence of an entity towards global warming, there are misperceptions about what it exactly means due to the limited scientific literature available on this subject. Other associated terms, used as synonyms of CF, are embodied carbon, carbon content, embedded carbon, carbon flows, virtual carbon, GHG footprint, and climate footprint [51,52]. Recently, a new term, “climate footprint” was proposed as a comprehensive GHG indicator. However, it demands extensive methods for CF calculation [53]. There is a lack of consistency in the selection of direct and embodied emissions, making it challenging to account for all potential emission sources. As a result, most studies report only direct or first-order indirect emissions. Despite the methodological differences, carbon footprint (CF) is commonly expressed in terms of CO2-equivalent (CO2-e) mass, based on a 100-year global warming potential. Therefore, the term ‘carbon footprint’ is often more accurately described as ‘carbon weight’ or ‘carbon mass’ [54]. Thus, CF can be defined as the quantity of GHGs expressed in terms of CO2-e emitted into the atmosphere by an individual, organization, process, product, or event from within a specified boundary.

3.2. Importance of Policies in CF

Having acknowledged the emissions, the important sources can be identified, and areas for emission reductions and efficiency improvements can be developed. This offers the opportunity for eco-friendly innovations and cost savings. Reporting CFs to third parties or disclosing them publicly is often driven by regulatory requirements, participation in carbon trading schemes, corporate social responsibility initiatives, or efforts to enhance brand reputation. Legislative actions have been considered to quantify and reduce the CF of cities and organizations. The United States has made it mandatory to keep a track record of the emissions from firms and companies under ‘Consolidated Appropriations Act of 2008’ [55]. Additionally, the state of California has imposed caps on GHG emissions from major industries and has restricted the import of non-conventional vehicular fuels unless their carbon footprint is lower than that of petroleum-based fuels [56,57]. The UK Government, through the Low-Carbon Transition Plan, 2009 prompts households to participate towards constructing a low-carbon future. The EU has strengthened its climate action agenda by implementing the European Climate Law, aiming to achieve climate neutrality by 2050 through legally binding emission reduction targets and expanded carbon pricing mechanisms [58]. Most of such attempts have been observed to reduce emissions via buying carbon credits or other control measures. Besides policy matters, CF tracking has an enormous importance for businesses. The business world has anticipated a carbon-constrained economy in the near future. Therefore, the rush to compute the CF and to cut-down the emissions has begun, globally, to have a competitive advantage. In a survey [59], it was found that 44% of the consumers favored purchasing products that provided information about their CF, while 43% were willing to pay more for the products with relatively low CF. Thus, the corporate sector has responded in a significant manner because of the growing awareness regarding climate change. A substantial concern has grown among individuals and organizations over their accountability for contributing to the emissions of GHGs. This has led to a surge in personal CF facilities, particularly in developed countries [60,61].

3.3. Low-Carbon Materials

Owing to the alarming threat of global warming, many nations across the world have started practicing with a range of low-carbon materials. The following are some of the examples [62]:

- Berlin has rolled out various climate change moderation and adaptation programs largely focused on promoting energy awareness, inspiring energy efficient house-hold construction and transportation practices.

- The Greater London Authority addressed the problem of rising energy consumption in the 2004 London Plan and Mayor’s Energy Strategy. For more than 20 years, these policies have helped avoid roughly 252,000 tons CO2 per annum [63].

- More than a decade ago, about 80 cities and towns started low-carbon community planning and construction, including Denmark, Norway, Iceland, Finland, UK, France, and Germany.

- In North America, there exist numerous low-carbon communities, and it is expected that Asia and the South Pacific area would be the next region to take such initiatives [62].

As of now, China is going through a major urbanized process that will continue till 2050. This will induce a massive source of embodied energy producing CF from large infrastructures, buildings, transportation systems, and daily urban household life. Therefore, it is important for China to take initiative on practicing and implying low-carbon materials through a set of strategy and technology toolkit that fit into its conditions.

The escalating problems associated with GHGs, limited reserves of fossil fuels and increasing comprehension regarding the advantages of sustainable development prompted society, and the increased awareness of the benefits of sustainable development have motivated governments and industry to adopt low-carbon materials within the framework of the circular economy [64]. These low-carbon materials possess reduced CF, decreased embodied energy, and carbon with enhanced recyclability, which conserve the product’s functional requirements. The development and utilization of low-carbon material, on one hand, will ensure an environment that is conducive towards health and prosperity while on the other hand preserving resources for future generations. The efficient development of low-carbon materials necessitates innovative steps in modifying the chemistry of materials, adopting intelligent design of products, implementing low-energy intensive processing, dynamic supply chain management, non-polluting product distribution and novel end-of-life treatments. The overarching aim is to enhance the circularity of materials and their corresponding products. Life cycle analysis and circularity measurement tools are generally employed to assess the low-carbon intensity of materials.

3.3.1. The Idea of Embodied Energy

The notion of embodied energy is related to an integral part of the total energy required to develop a product and/or run a process. Numerous studies have attempted to define the embodied energy of a material. The definition that encompasses their viewpoints is the energy that is expended for the procurement, transportation, and processing of raw materials; conversion into useable products; and the energy consumed in their end-of-life disposal treatments. The embodied energy of a material accounts for the operating energy required during the service life of the product [65]. A somewhat quantitative definition was provided by Ashby, 2009 [66], which states that embodied energy is the energy utilized in developing 1 kg of a material from its precursor in a production unit. Considering the abovementioned definitions, embodied energy can be related to the overall energy consumption, which correlates with the carbon footprint (whose definition is provided in Section 3) as Carbon footprint ≅ 0.08 × energy consumption [65].

The increase in GHG, the depletion of fossil fuel reserves, and the heightened recognition of the advantages associated with sustainable development have led governments and society to promote the use of low-carbon materials within the framework of a circular economy. These materials are characterized by reduced carbon footprints and embodied energy, enhanced recyclability, and the ability to meet functional performance requirements. To achieve this, it is essential to understand the characteristics of raw materials, their potential for recycling or safe disposal, and the overall environmental impact of the product. Particularly, the recyclability of a material or product is critical for reducing energy consumption and resource use over the long term. Furthermore, efforts to lower the embodied energy of materials and products must not compromise their performance or economic value. Ideally, the development of materials and products with low embodied energy should also enhance their functional properties, thereby encouraging stakeholders to adopt and promote them within economically sustainable markets.

3.3.2. The Case of Low-Carbon Materials

Low-carbon materials are those that possess low-carbon footprint, thereby being more environmentally friendly. There exist several attributes of low-carbon materials, some of which include lightweight, recyclable, possibility for remanufacturing, exhibiting concurrent long service life and low maintenance, ethically and locally sourced, renewable and bio-based, and non-hazardous to public health. The core aim of the aforementioned facets of low-carbon materials is to lower the overall carbon footprint from cradle to end-of-life and beyond. Interestingly, the word “reduction” has a key responsibility in the development of low-carbon materials. The entire process, from procurement to disposal, should be performed with a “reduced” mentality. The initial phase of the material development includes lowering the amount of raw materials used, decreasing the use of resources (e.g., water, electricity) during manufacturing, lowering emissions, reducing waste (non-hazardous) generation. However, the word “increased” has a dominant role in the service life and disposal of low-carbon materials.

The utilization of low-carbon materials should enhance product performance and safety while increasing the efficiency by which it can be recycled, remanufactured, or composted. In essence, the creation of low-carbon materials is a paradigm for the circular economy that promotes the use of renewable energies along with bio-refinery models and a low-carbon economy.

Some strategies are available that can aid in the development of low-carbon materials. The first is the sustainable selection of raw material, which ideally should be available in the vicinity to reduce energy consumed by transport and logistics. Others include the increment of recycle constituent in a product, plastics designed for rapid composting, adoption and utilization of renewable energies whenever possible, saving energy by lowering the weights of products and vehicles, and effective remanufacturing and recycling of plastics, solid and electronic wastes. Advanced porous materials have also been identified as promising candidates for CO2 capture and other environmental applications, offering complementary approaches to low-carbon material development [67].

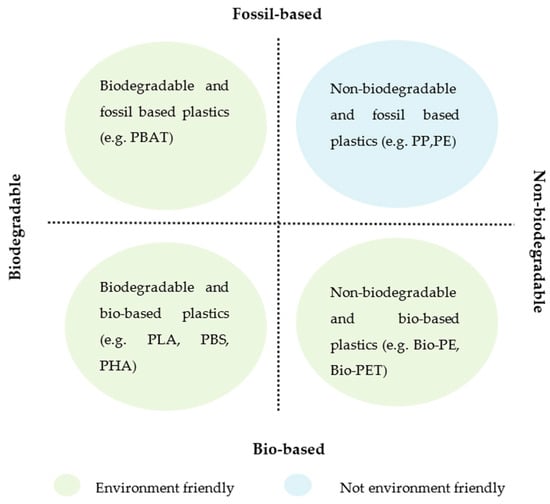

Although the polymer/plastics age was at its zenith in the 1940s, many of today’s products have continued to include plastics in their construction. In order to promote sustainable development, most of the societies around the world are adopting a bio-based circular economy. This necessitates the extensive application of bio-resources; however, the focus should be to procure them from waste-based sources (forestry, agricultural and municipal wastes) which will not compete with arable land. Therefore, the development of high-performing materials is the cornerstone for building a sustainable bio-based industry. Many different types of plastics can be developed from biomass-based sources for e.g., poly (lactic acid)/PLA from corn, bio-polyethylene/Bio-PE from sugar cane, gluten from wheat, etc. These bioplastics can be a new class of materials having a new chemical structure or analogous to synthetic plastics but derived from a natural resource. Bioplastics serve a pivotal role as renewable alternatives to conventional plastics, with potential applications in food packaging, consumer products, automotive components, construction materials and biomedical devices [68,69]. It is important to understand that not all bioplastics are biodegradable (e.g., bio-PE is made from bio-based sources but do not degrade in the natural environment). However, some like PLA are both bio-based and biodegradable. Interestingly, some fossil-based plastics are biodegradable, e.g., polybutylene adipate terephthalate (PBAT). Therefore, the biodegradability of plastic is determined by its chemical structure and not by its precursor. This concept is illustrated in Figure 6.

Figure 6.

Biodegradability of plastics: PHA = polyhydroxyalkanoates; PBS = poly (1,4-butylene succinate); PET = polyethylene terephthalate; PP = polypropylene; PE = polyethylene; PBAT = polybutylene adipate terephthalate.

It is interesting to note that a study by Ashby, 2015 [70] revealed that numerous bioplastics such as PLA, bio-PE/PP have similar embodied energies as the fossil-based counterparts (e.g., polypropylene, polyethylene, etc.). On the other hand, the carbon footprint of bioplastics is not significantly lower than the petroleum-derived ones. The only advantage of bioplastics is that some (Figure 6) are biodegradable, thus disintegrating into the natural world in the form of harmless constituents. Understanding their end-of-life behavior is essential when assessing environmental benefits, as not all bioplastics degrade readily. Although often used interchangeably, the terms biodegradable and compostable describe different processes: biodegradable plastics break down via microbial activity, while compostable plastics, a subset of biodegradable materials, decompose under controlled composting conditions without leaving toxic residues [71], thus better aligning with circular waste management approaches [72]. The improved biodegradability of certain bioplastics provides important end-of-life benefits, significantly reducing environmental impact, particularly in sectors dominated by single-use plastics, such as disposable surgical face masks, medical gowns, compostable cutlery, coffee pods etc. [69]. One potential candidate for low-carbon material is wheat gluten bioplastic, which is a co/by-product of cereal processing industries. This bioplastic does not compete with the land on which food crops are grown; in fact, the increasing prevalence of gluten intolerance (i.e., celiac disease) and, consequently, lowered production of wheat-based consumables create motivation for producing renewable plastic products from this industrial side-stream [73]. Some studies point to the fact that materials derived from biomass (e.g., bamboo) can be considered to have negative embodied carbon because they absorb environmental CO2 needed for their growth, thereby proving possession of negative carbon footprint [74]. Hence, the use of biomass for low-carbon materials is appropriate to drive sustainable development. Not only can the use of biomass replace fossil fuels, but these biofuels are carbon-neutral or negative in nature. Moreover, biomass utilization only recycles the mobile carbon without affecting the fixed carbon. The combustion of biomass-based fuels is significantly cleaner, owing to the trace amounts of sulfur, nitrogen, and heavy metals in them. In summary, materials derived from renewable and waste-based sources offer a viable pathway to reducing GHG emissions while improving resource efficiency and end-of-life performance. Their integration into material systems is essential for climate mitigation and the transition toward a sustainable, circular economy.

4. Conclusions

The fundamental concepts related to life cycle assessment (LCA), a widely recognized tool for evaluating the sustainability of products and systems, have been discussed in this work. The four key phases of LCA; goal and scope definition, life cycle inventory (LCI), life cycle impact assessment (LCIA), and interpretation and reporting, have been detailed to provide a structured understanding of its implementation. While LCA delivers a broad assessment of environmental impacts across a product’s life cycle, carbon footprint (CF) analysis specifically targets GHG emissions. The development and implementation of low-carbon materials aims to reduce the overall carbon footprint from cradle to end-of-life and beyond. The effectiveness of both LCA and CF relies on addressing ongoing challenges related to data quality and transparency, which can be mitigated through the adoption of emerging digital technologies. Artificial Intelligence (AI), the Internet of Things (IoT), and Blockchain present valuable opportunities to improve the accuracy, clarity, and real-time data integration within LCA frameworks.

Author Contributions

Conceptualization, E.K., I.S.P. and O.D.; writing—original draft preparation, E.K., I.S.P. and O.D.; writing—review and editing, E.K., I.S.P. and O.D.; visualization, E.K., I.S.P. and O.D.; supervision, O.D.; project administration, O.D.; funding acquisition, O.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by FORMAS, Grant number 2022–00676.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to the preliminary nature of the analysis.

Acknowledgments

Sunpreet Singh of Lovely Professional University is acknowledged for his assistance in creating Figure 4 in the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of this study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Bjørn, A.; Owsianiak, M.; Molin, C.; Hauschild, M.Z. LCA History. In Life Cycle Assessment; Springer: Cham, Switzerland, 2017; pp. 17–30. [Google Scholar] [CrossRef]

- Hunt, R.G.; Franklin, W.E.; Hunt, R.G. LCA—How it came about. Int. J. Life Cycle Assess. 1996, 1, 4–7. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- El-Haggar, S.; Samaha, A. Sustainable Rural Community. In Roadmap for Global Sustainability—Rise of the Green Communities; Springer: Cham, Switzerland, 2019; pp. 103–120. [Google Scholar]

- McManus, M.C.; Taylor, C.M. The changing nature of life cycle assessment. Biomass Bioenergy 2015, 82, 13–26. [Google Scholar] [CrossRef] [PubMed]

- You, S.; Wang, X. On the Carbon Abatement Potential and Economic Viability of Biochar Production Systems: Cost-Benefit and Life Cycle Assessment. In Biochar from Biomass and Waste; Elsevier: Amsterdam, The Netherlands, 2019; pp. 385–408. [Google Scholar]

- Klöpffer, W. Background and Future Prospects in Life Cycle Assessment; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Curran, M.A. Life Cycle Assessment Handbook: A Guide for Environmentally Sustainable Products; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Hannouf, M.B.; Padilla-Rivera, A.; Assefa, G.; Gates, I. Methodological framework to find links between life cycle sustainability assessment categories and the UN Sustainable Development Goals based on literature. J. Ind. Ecol. 2023, 27, 707–725. [Google Scholar] [CrossRef]

- Popowicz, M.; Katzer, N.J.; Kettele, M.; Schöggl, J.; Baumgartner, R.J. Digital technologies for life cycle assessment: A review and integrated combination framework. Int. J. Life Cycle Assess. 2025, 30, 405–428. [Google Scholar] [CrossRef]

- Liu, M.; Zhu, G.; Tian, Y. The historical evolution and research trends of life cycle assessment. Green Carbon 2024, 2, 425–437. [Google Scholar] [CrossRef]

- Harnessing Public Procurement for the Green Transition. Available online: https://www.oecd.org/en/publications/harnessing-public-procurement-for-the-green-transition_e551f448-en.html (accessed on 12 August 2025).

- Climate Action. Available online: https://www.un.org/sustainabledevelopment/climate-action/ (accessed on 14 May 2025).

- The European Green Deal Striving to Be the First Climate-Neutral Continent. Available online: https://ec.europa.eu/newsroom/know4pol/items/664852 (accessed on 14 May 2025).

- EPD in Figures. Available online: https://www.environdec.com/all-about-epds/epd-figures (accessed on 14 May 2025).

- Brusseau, M.L. Sustainable development and other solutions to pollution and global change. In Environmental and Pollution Science; Academic Press: Cambridge, MA, USA, 2019; pp. 585–603. [Google Scholar]

- Smith, L.; Ibn-Mohammed, T.; Koh, L.; Reaney, I.M. Life cycle assessment of functional materials and devices: Opportunities, challenges, and current and future trends. J. Am. Ceram. Soc. 2019, 102, 7037–7064. [Google Scholar] [CrossRef]

- van der Giesen, C.; Cucurachi, S.; Guinée, J.; Kramer, G.J.; Tukker, A. A critical view on the current application of LCA for new technologies and recommendations for improved practice. J. Clean. Prod. 2020, 259, 120904. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Schaubroeck, T. Relevance of attributional and consequential life cycle assessment for society and decision support. Front. Sustain. 2023, 4, 1063583. [Google Scholar] [CrossRef]

- Ekvall, T.; Weidema, B.P. System boundaries and input data in consequential life cycle inventory analysis. Int. J. Life Cycle Assess. 2004, 9, 161–171. [Google Scholar] [CrossRef]

- Ekvall, T. Attributional and Consequential Life Cycle Assessment. In Sustainability Assessment at the 21st Century; Bastante-Ceca, M.J., Ed.; InTech: Dubai, United Arab Emirates, 2020; p. 42. [Google Scholar] [CrossRef]

- Ekvall, T.; Azapagic, A.; Finnveden, G.; Rydberg, T.; Weidema, B.P. Alessandra Zamagni Attributional and consequential LCA in the ILCD handbook. Int. J. Life Cycle Assess. 2016, 21, 293–296. [Google Scholar] [CrossRef]

- Assessment, L.C. A Guide to Approaches, Experiences and Information Sources; European Environmental Agency: Copenhagen, Denmark, 1998. [Google Scholar]

- Svoboda, S. Note on life cycle analysis. In Environmental Management: Readings and Cases; Sage: Los Angeles, CA, USA, 1999; pp. 217–227. [Google Scholar]

- Willers, C.D.; Rodrigues, L.B. Critical evaluation of Brazilian life cycle assessment studies. Int. J. Life Cycle Assess. 2014, 19, 144–152. [Google Scholar] [CrossRef]

- Li, T.; Zhang, H.; Liu, Z.; Ke, Q.; Alting, L. System boundary identification method for life cycle assessment. Int. J. Life Cycle Assess. 2014, 19, 646–660. [Google Scholar] [CrossRef]

- Silva, D.; Nunes, A.; Moris, V.; Piekarski, C.; Rodrigues, T. How Important is the LCA Software Tool You Choose Comparative Results from GaBi, openLCA, SimaPro and Umberto. 2017. Available online: https://www.researchgate.net/publication/318217178_How_important_is_the_LCA_software_tool_you_choose_Comparative_results_from_GaBi_openLCA_SimaPro_and_Umberto (accessed on 12 August 2025).

- Kiemel, S.; Rietdorf, C.; Schutzbach, M.; Miehe, R. How to Simplify Life Cycle Assessment for Industrial Applications—A Comprehensive Review. Sustainability 2022, 14, 15704. [Google Scholar] [CrossRef]

- Fatta, D.; Moll, S.; Tsotsos, D. Assessment of Information Related to Waste and Material Flows; EEA: Copenhagen, Denmark, 2003. [Google Scholar]

- Guinée, J.; Heijungs, R. Introduction to life cycle assessment. In Sustainable Supply Chains; Springer: Berlin/Heidelberg, Germany, 2017; pp. 15–41. [Google Scholar]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.; Hischier, R.; Doka, G.; Bauer, C.; Dones, R.; Nemecek, T.; Hellweg, S.; Humbert, S.; et al. Implementation of Life Cycle Impact Assessment Methods. Data v2.0 (2007). Ecoinvent Report No. 3. 2025. Available online: https://inis.iaea.org/records/zywe4-z1149 (accessed on 12 August 2025).

- Hauschild, M.Z.; Rosenbaum, R.; Olsen, S.I. Life Cycle Assessment; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Roesch, A.; Sala, S.; Jungbluth, N. Normalization and weighting: The open challenge in LCA. Int. J. Life Cycle Assess. 2020, 25, 1859–1865. [Google Scholar] [CrossRef]

- Prado, V.; Cinelli, M.; Ter Haar, S.F.; Ravikumar, D.; Heijungs, R.; Guinée, J.; Seager, T.P. Sensitivity to weighting in life cycle impact assessment (LCIA). Int. J. Life Cycle Assess. 2020, 25, 2393–2406. [Google Scholar] [CrossRef]

- Laurent, A.; Weidema, B.P.; Bare, J.; Liao, X.; Maia de Souza, D.; Pizzol, M.; Sala, S.; Schreiber, H.; Thonemann, N.; Verones, F. Methodological review and detailed guidance for thelife cycle interpretation phase. J. Ind. Ecol. 2020, 24, 986–1003. [Google Scholar] [CrossRef]

- Decisions, C. Carbon Footprinting: An Introduction for Organizations; The Carbon Trust: London, UK, 2007. [Google Scholar]

- Fantozzi, F. Carbon Footprint as a Tool to Limit Greenhouse Gas Emissions. In Greenhouse Gases; InTech: Dubai, United Arab Emirates, 2016. [Google Scholar] [CrossRef]

- Panagiotopoulou, V.C.; Stavropoulos, P.; Chryssolouris, G. A critical review on the environmental impact of manufacturing: A holistic perspective. Int. J. Adv. Manuf. Technol. 2022, 118, 603–625. [Google Scholar] [CrossRef]

- ISO 14064-1:2018; Greenhouse Gases—Part 1: Specification with Guidance at the Organization Level for Quantification and Reporting of Greenhouse Gas Emissions and Removals. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 14067:2018; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. International Organization for Standardization: Geneva, Switzerland, 2018.

- PAS 2050:2011; Specification for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services. British Standards Institution: London, UK, 2011.

- Yu, F.; Yuan, Q.; Sheng, X.; Liu, M.; Chen, L.; Yuan, X.; Zhang, D.; Dai, S.; Hou, Z.; Wang, Q.; et al. Understanding carbon footprint: An evaluation criterion for achieving sustainable development. Chin. J. Popul. Resour. Environ. (Online) 2024, 22, 367–375. [Google Scholar] [CrossRef]

- Wiedmann, T.; Chen, G.; Owen, A.; Lenzen, M.; Doust, M.; Barrett, J.; Steele, K. Three-scope carbon emission inventories of global cities. J. Ind. Ecol. 2021, 25, 735–750. [Google Scholar] [CrossRef]

- Wiedmann, T. A review of recent multi-region input–output models used for consumption-based emission and resource accounting. Ecol. Econ. 2009, 69, 211–222. [Google Scholar] [CrossRef]

- Fodha, M.; Zaghdoud, O. Economic growth and pollutant emissions in Tunisia: An empirical analysis of the environmental Kuznets curve. Energy Policy 2010, 38, 1150–1156. [Google Scholar] [CrossRef]

- Lau, L.S.; Choong, C.K.; Eng, Y.K. Investigation of the environmental Kuznets curve for carbon emissions in Malaysia: Do foreign direct investment and trade matter? Energy Policy 2014, 68, 490–497. [Google Scholar] [CrossRef]

- Pablo-Romero, M.D.; Sánchez-Braza, A. The changing of the relationships between carbon footprints and final demand: Panel data evidence for 40 major countries. Energy Econ. 2017, 61, 8–20. [Google Scholar] [CrossRef]

- Nissinen, A.; Salo, M. Consumption Choices to Decrease Personal Carbon Footprints of Finns; Suomen Ympäristökeskus (SYKE): Helsinki, Finland, 2017. [Google Scholar]

- Wackernagel, M.; Rees, W. Our Ecological Footprint: Reducing Human Impact on the Earth; New Society Publishers: Gabriola, BC, Canada, 1998. [Google Scholar]

- Wiedinmyer, C.; Neff, J.C. Estimates of CO2 from fires in the United States: Implications for carbon management. Carbon Balance Manag. 2007, 2, 10. [Google Scholar] [CrossRef]

- Peters, G.P. Carbon footprints and embodied carbon at multiple scales. Curr. Opin. Environ. Sustain. 2010, 2, 245–250. [Google Scholar] [CrossRef]

- Eshel, G.; Martin, P.A. Diet, energy, and global warming. Earth Interact. 2006, 10, 1–7. [Google Scholar] [CrossRef]

- Jarvis, P. Never mind the footprint, get the mass right. Nature 2007, 446, 24. [Google Scholar] [CrossRef]

- Rich, D. Designing a US Greenhouse Gas Emissions Registry. 2008. Available online: http://pdf.wri.org/designing_a_us_ghg_emissions_registry.pdf#:~:text=Designing%20a%20U.S.%20Greenhouse%20Gas,Emissions%20Registry&text=This%20section%20outlines%20a%20few,U.S.%20greenhouse%20gas%20emissions%20registry (accessed on 12 August 2025).

- Courchene, T.J.; Allan, J.R. Climate change: The case for a carbon tariff/tax. Policy Options Montr. 2008, 29, 59. [Google Scholar]

- Kossoy, A.; Ambrosi, P. State and Trends of the Carbon Market. 2010. Available online: https://openknowledge.worldbank.org/server/api/core/bitstreams/01a3c66a-9d45-5b9e-a4ef-731bc6fb2f3d/content (accessed on 12 August 2025).

- European Climate Law. Available online: https://climate.ec.europa.eu/eu-action/european-climate-law_en (accessed on 27 May 2025).

- Pandey, D.; Agrawal, M.; Pandey, J.S. Carbon footprint: Current methods of estimation. Environ. Monit. Assess. 2011, 178, 135–160. [Google Scholar] [CrossRef]

- Padgett, J.P.; Steinemann, A.C.; Clarke, J.H.; Vandenbergh, M.P. A comparison of carbon calculators. Environ. Impact Assess. Rev. 2008, 28, 106–115. [Google Scholar] [CrossRef]

- Kenny, T.; Gray, N.F. Comparative performance of six carbon footprint models for use in Ireland. Environ. Impact Assess. Rev. 2009, 29, 1–6. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, G.Q.; Feng, J.; Wu, Y. Delivering a low-carbon community in China: Technology vs. strategy? Habitat. Int. 2013, 37, 130–137. [Google Scholar] [CrossRef]

- Day, T.; Ogumka, P.; Jones, P. Monitoring the London Plan: Energy Policies-Phase 3. 2009. Available online: https://www.london.gov.uk/media/77221/download (accessed on 12 August 2025).

- Ramakrishna, S.; Pervaiz, M.; Tjong, J.; Ghisellini, P.; Sain, M.M. Low-Carbon Materials: Genesis, Thoughts, Case Study, and Perspectives. Circ. Econ. Sust. 2022, 2, 649–664. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Fernández, A.I. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials and the Environment: Eco-Informed Material Choice; Butterworth-Heinemann: Oxford, UK, 2009. [Google Scholar]

- Schaubroeck, T.; Schaubroeck, S.; Heijungs, R.; Zamagni, A.; Brandão, M.; Benetto, E. Attributional & Consequential Life Cycle Assessment: Definitions, Conceptual Characteristics and Modelling Restrictions. Sustainability 2021, 13, 7386. [Google Scholar] [CrossRef]

- Oberti, I.; Paciello, A. Bioplastic as a Substitute for Plastic in Construction Industry. Encyclopedia 2022, 2, 1408–1420. [Google Scholar] [CrossRef]

- Nanda, S.; Patra, B.R.; Patel, R.; Bakos, J.; Dalai, A.K. Innovations in applications and prospects of bioplastics and biopolymers: A review. Environ. Chem. Lett. 2022, 20, 379–395. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials and Sustainable Development; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Nizamuddin, S.; Baloch, A.J.; Chen, C.; Arif, M.; Mubarak, N.M. Bio-based plastics, biodegradable plastics, and compostable plastics: Biodegradation mechanism, biodegradability standards and environmental stratagem. Int. Biodeterior. Biodegrad. 2024, 195, 105887. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; AbdulGhani, A. Sustainability of biodegradable plastics: New problem or solution to solve the global plastic pollution? Curr. Res. Green. Sustain. Chem. 2022, 5, 100273. [Google Scholar] [CrossRef]

- Patil, R.A.; Seal, S.; Ramakrishna, S. Circular Economy, Sustainability and Business Opportunities. 2020. Available online: https://www.europeanbusinessreview.com/circular-economy-sustainability-and-business-opportunities/ (accessed on 12 August 2025).

- Das, O.; Kim, N.K.; Sarmah, A.K.; Bhattacharyya, D. Development of waste based biochar/wool hybrid biocomposites: Flammability characteristics and mechanical properties. J. Clean. Prod. 2017, 144, 79–89. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).