Abstract

Natural disasters are increasing in frequency and intensity, causing escalating humanitarian crises and complex housing challenges globally. Traditional post-disaster housing solutions often fall short, being slow, costly, and ill-adapted to specific community needs. This study addresses these limitations by proposing an innovative, technology-driven model for post-disaster housing that integrates parametric design with 3D printing. The objective is to develop a flexible and adaptable system capable of providing both immediate temporary shelter and evolving permanent housing solutions. In this study, the methodology of the proposed model for post-disaster housing solutions is structured around three main phases: the development of the theoretical framework, the parametric design process, and the implementation phase. In the first phase, a comprehensive literature review and conceptual analyses were conducted to examine the concept of disaster, post-disaster housing approaches, and advanced technologies, thereby establishing the conceptual foundation of the model. In the second phase, parametric modeling was carried out for a modular system using algorithmic design tools such as Grasshopper; the model’s applicability across various scales and its flexibility were analyzed. In the final phase, material selection and digital prototyping of the gridal system were undertaken using 3D printing technology to evaluate the model’s feasibility for rapid on-site production, assembly, and disassembly. The model prioritizes user participation, modularity, and configurability to ensure rapid response and socio-cultural sensitivity. Findings indicate that this integrated approach offers substantial benefits, including accelerated construction, reduced labor and material waste, enhanced design flexibility, and the use of local, sustainable materials. This research highlights the transformative potential of advanced manufacturing in providing resilient, user-centered, and environmentally sustainable post-disaster housing, advocating for governmental financial support to overcome adoption barriers and foster broader implementation.

1. Introduction

Natural disasters inflict profound and escalating damage on communities worldwide, resulting in substantial loss of life and property, and creating urgent, complex housing crises [1]. Recent data from the World Bank (2024) corroborates a significant rise in the socioeconomic repercussions of these events [2]. In 2022 alone, an estimated 186 million individuals were affected globally, with particularly high concentrations in Central Africa (34.56 million), West Africa (32.26 million), East Africa (30.55 million), North Africa (13.20 million), and Southeast Asia (12.72 million) [3]. Earthquakes, in particular, have been devastating. Over the past two decades, they have accounted for approximately 1.5 million fatalities and an estimated $3.5 trillion in global economic losses, according to the Emergency Events Database (EM-DAT). Reconstructing housing in earthquake-affected regions demands substantial resources and protracted timelines [4]. The Federal Emergency Management Agency (FEMA) reports that permanent housing reconstruction post-earthquake can extend up to five years, with even longer durations observed in developing nations [3]. For instance, millions of homes were severely damaged in major events in India (2004), Chile (2010), Nepal (2015), and Indonesia (2019) [5]. Notably, the 1999 Marmara Earthquake in Turkey damaged 66,441 homes, a figure dwarfed by the approximately 830,000 dwellings impacted by the 2023 Kahramanmaraş Earthquake [5]. These statistics starkly highlight the immense impact of disasters on the built environment and the inherent complexities of recovery and reconstruction efforts. Over the past century, there has been a demonstrable increase in both the frequency and intensity of natural disasters. Annual disaster reports averaged 56 in the 1960s, a figure that dramatically surged to 363 between 2012 and 2022 [6]. This escalation is strongly correlated with climate change, global population growth, and the expansion of human settlements into vulnerable coastal areas. An analysis of the same dataset indicates that floods (39%) and storms (31%) were the most prevalent disaster types globally between 1900 and 2022 [6]. This intensifying trend underscores the critical need for innovative and resilient housing solutions to safeguard communities against future catastrophic events.

Disasters inflict profound and multifaceted damage on the built environment and communities, encompassing both tangible material losses and severe emotional distress. The urgency of addressing such impacts, particularly earthquake-induced losses, was a key point of discussion at the COP27 Conference [4]. This urgency is further underscored by international human rights frameworks, specifically Article 11 of both the Universal Declaration of Human Rights and the International Covenant on Economic, Social, and Cultural Rights, which affirms the right to an adequate standard of living, including housing [7]. In the context of post-disaster recovery, it is crucial to differentiate between “shelter” and “housing.” As defined by Quarantelli [8] and Johnson [9], shelter provides immediate, short-term safety and survival, whereas housing represents a comprehensive, long-term living solution that integrates physical, social, and economic infrastructure essential for daily life. Following events such as earthquakes, floods, hurricanes, and volcanic eruptions, the immediate and critical need for safe, healthy, and sustainable housing becomes paramount [2].

Effective post-disaster recovery hinges on developing adaptable housing systems that provide seamless transitions from temporary shelters to permanent residences [10,11]. Traditional “one-size-fits-all” approaches prove inadequate for diverse post-disaster contexts, underscoring the critical need for innovative, technology-driven design methodologies [1,12]. The ongoing digital transformation within the construction industry, specifically the integration of technologies like 3D printing and parametric design, is revolutionizing the development of flexible, rapidly deployable, and sustainable shelter solutions [10]. Three-dimensional printing facilitates the high-precision and rapid production of complex structures, offering significant advantages for both temporary and permanent housing needs [1,12]. This technology is further enhanced by its compatibility with local materials and its alignment with environmental sustainability principles, such as achieving low carbon footprints. For instance, post-earthquake structures in Haiti, fabricated using 3D printing, demonstrated a remarkable 50% cost reduction compared to conventional construction methods, alongside expedited deployment [10]. Concurrently, parametric design emerges as an indispensable tool for post-disaster housing due to its capacity to create structures precisely tailored to user needs and adaptable to diverse environmental conditions [1]. Its inherent flexibility and adaptability enable the provision of highly effective spatial solutions that are closely aligned with the specific requirements of affected populations.

Recent research consistently highlights the transformative potential of 3D printing in both disaster management and the provision of sustainable housing solutions. A key advantage of this technology is its capacity for rapid, localized construction, which significantly reduces material waste and offers increased design flexibility. These attributes are particularly vital for addressing the urgent needs of displaced populations in the aftermath of natural disasters and for mitigating the broader impacts of climate change-related emergencies. Studies by Subramanya and Kermanshachi [10] as well as Waheed and Wahhab [13] have explored the feasibility of 3D-printed housing as temporary and sustainable post-disaster shelters, respectively. Similarly, Rodríguez-Espíndola and Beltagui [14] were early in identifying 3D printing’s potential to resolve operational challenges in disaster management, a theme further developed by Kantaros et al. [1] who integrated it into smart city disaster resilience strategies. Van den Bergh et al. [15] emphasized the ability of Material Extrusion 3D Printing (ME3DP) to deliver climate-resilient housing for low-income communities, while also pointing out critical success factors like social acceptance and the necessity of local expertise. Mistry et al. [16] underscored the substantial benefits of 3D printing, including faster construction times, less material waste, and greater design adaptability. Furthermore, Khan et al. [17] argued that 3D printing can overcome traditional aid logistics by providing swift, localized solutions with fewer resources. Bazli et al. [18] also explored its potential to accelerate construction and reduce costs in remote areas, and Foley [19] investigated its specific applicability in US disaster relief. Collectively, these studies demonstrate that 3D printing offers a highly promising and efficient pathway toward more sustainable and resilient responses to both housing crises and disaster-related challenges.

However, current temporary shelter strategies often prove inadequate for the long-term needs of displaced populations, frequently eroding their sense of spatial belonging and social cohesion [3]. Deficiencies in both the structural and administrative aspects of meeting post-disaster housing demand significantly impede comprehensive recovery processes [2]. Existing housing solutions typically suffer from high production costs, protracted planning and construction timelines, limited flexibility, poor environmental sustainability, and a lack of sensitivity to local needs [1]. This highlights a pressing and unmet demand for low-cost, rapidly deployable, flexible, and durable housing solutions that are specifically tailored to the unique cultural, climatic, and geographical conditions of post-disaster contexts [12]. Addressing this critical need is paramount for fostering resilient communities and ensuring the long-term well-being of disaster-affected populations. While conventional post-disaster housing strategies encompass collective shelters, temporary settlements, rent-assistance programs, and the repair of existing structures, there remains a notable gap in integrated approaches that consider the design of temporary post-disaster housing with opportunities for eventual permanent utilization. Furthermore, the significant potential of advanced technologies in the design of post-disaster housing remains largely underutilized. Specifically, there is a clear absence of design methodologies for post-disaster housing that leverage flexible strategies and advanced technologies for temporary use with an eye toward permanent residency.

This study proposes an innovative, holistic, and technology-driven model aiming to address the fundamental shortcomings of traditional post-disaster shelter solutions. In existing conventional systems, the design process is typically executed through a centralized approach, with limited direct user participation in post-disaster settlement and shelter planning. This hinders the development of sensitive and flexible solutions tailored to the unique needs of disaster victims. In centralized systems, decision-making and design processes are external, leaving users in a passive role only during the implementation phase; this often results in an incomplete fulfillment of social, cultural, and spatial requirements. The proposed model integrates parametric design and 3D printing technologies, enabling direct user involvement in the design process. Thanks to the flexible and modular nature of parametric design, users can actively participate in shelter design, customizing and dynamically adapting the design to their own needs, environmental conditions, and cultural characteristics. This process aligns with participatory design principles and creates an adaptive system capable of meeting rapid post-disaster response requirements while also evolving into long-term, permanent solutions.

The speed, on-site production capability, and material optimization provided by 3D printing technology facilitate the prototyping and implementation of this user-centered design approach. Consequently, prototypes developed with active user participation in disaster-stricken areas can be rapidly and flexibly improved in terms of both geometric form and functionality. The integrated use of parametric design and 3D printing enables a more democratic, inclusive, and sustainable design and implementation process, in contrast to the top-down approaches observed in traditional shelter models.

2. General Concepts

2.1. Understanding Disasters

Disasters, whether originating from natural phenomena or anthropogenic activities, represent severe disruptions that inflict extensive damage across societal, economic, and environmental systems. Natural disasters, such as earthquakes, tsunamis, and hurricanes, typically arise from geological or meteorological processes involving the rapid release of energy within the Earth’s crust or atmosphere, or from large-scale oceanic displacements. Conversely, anthropogenic disasters, including industrial accidents, widespread pollution, nuclear incidents, and armed conflicts, stem from human actions or systemic failures and often involve complex socio-technical processes with profound impacts on societal structures. The inherent unpredictability and multi-dimensional consequences of these events necessitate not only highly efficient emergency response mechanisms but also robust social resilience and comprehensive long-term recovery frameworks. The classification and societal perception of disasters are dynamic and subject to evolution [20]. Generally, disasters can be broadly categorized into two primary types based on their underlying causation:

- I.

- Anthropogenic disasters (man-made) are direct or indirect consequences of human activities, leading to casualties, property destruction, environmental degradation, and societal disruption [21]. These events often arise from human error, negligence, deliberate actions, or technological malfunctions. They can be further categorized as intentional or unintentional. Intentional anthropogenic disasters include warfare, terrorist attacks, and social conflicts [21,22], while unintentional ones encompass events such as nuclear accidents, toxic emissions, dam failures, environmental pollution, and cyberattacks [23]. These disasters can result in substantial human and material losses, significant environmental and socioeconomic damage, and profound disruptions to societal stability [24]. A critical distinction is that, unlike natural disasters, anthropogenic disasters are frequently preventable or their impacts can be substantially mitigated [21].

- II.

- Natural disasters are abrupt and unforeseen occurrences stemming from natural processes that impact physical and social structures across extensive geographical areas [25,26]. They are the result of geological, meteorological, hydrometeorological, and biological hazards that adversely affect human settlements. Common consequences include widespread fatalities, injuries, and damage to livelihoods [27]. Examples include earthquakes, floods, droughts, wildfires, storms, landslides, and tsunamis [23]. These events are characterized by their concentrated spatial and temporal impact, often exceeding societal preparedness measures [28].

2.2. Post-Disaster Housing

Disasters, whether natural or anthropogenic, routinely displace populations, creating an urgent demand for rapid, cost-effective, and sustainable post-disaster housing solutions. Such events are characterized by their sudden onset and the immediate need for intervention. As Barakat [29] and Félix et al. [30] highlight, disasters profoundly disrupt the built environment and urban infrastructure. In these critical situations, the immediate priorities are establishing emergency gathering spaces for safety and creating temporary shelter areas to stabilize conditions and ensure basic living provisions [31]. These temporary settlements serve as interim housing until permanent reconstruction can occur. They commonly utilize prefabricated components to facilitate swift deployment, thereby providing rapid access to secure living environments for affected individuals. The design of these units must prioritize accessibility for vulnerable populations, including the elderly and those with disabilities, and incorporate durable, environmentally friendly materials. Beyond mere physical shelter, post-disaster housing is instrumental in mitigating the physical, social, and economic consequences of disasters and plays a vital role in community reconstruction. The strategies for providing post-disaster housing can be categorized as follows:

- ▪

- Emergency shelters provide immediate, short-term protection following sudden-onset disasters like earthquakes [8,32]. Designed for rapid deployment, these portable structures—typically tents or pneumatic systems—address urgent needs such as safety, warmth, and basic survival until more stable housing options become available [8,33,34].

- ▪

- Temporary shelters address medium-term needs and often include tents, prefabricated units, or containers [35]. They serve displaced populations for six months to three years, offering basic services such as sanitation, food, and medical support, with flexibility and structural adaptability for varying conditions [30,33,36].

- ▪

- Transitional housing bridges temporary shelters and permanent homes, typically used for six months to three years [35]. It includes mobile or prefabricated units with essential domestic spaces [37,38]. Designed for affordability and rapid assembly, it fosters community reintegration and supports recovery efforts post-disaster [35,36,39,40].

- ▪

- Permanent housing delivers long-term, resilient solutions post-disaster [41], requiring infrastructure investment and strategic planning [37]. Funded by governments or NGOs, it promotes psychological stability, economic recovery, and community rebuilding [6]. Its design emphasizes sustainability, disaster resistance, and alignment with local development and land-use policies.

2.3. Integrating Advanced Technologies for the Design of Flexible Post-Disaster Housing Solutions

Natural disasters annually displace millions globally, necessitating the development of effective and sustainable housing solutions to meet immediate shelter needs and support long-term community recovery. This analysis provides a comprehensive overview of post-disaster housing, examining diverse approaches and strategies. The varied nature of disasters, coupled with differing physical, climatic, economic, and socio-cultural contexts, precludes a universal solution. Therefore, effective post-disaster shelter must integrate both rapid, short-term emergency interventions and durable, long-term strategies that foster social integration and environmental sustainability. Consequently, these solutions are typically categorized as “Temporary Shelter Solutions” and “Permanent Housing Solutions.”

However, traditional construction methods are increasingly inadequate for post-disaster housing due to limitations in speed, cost-efficiency, and environmental impact. This has underscored the importance of innovative technologies. Among these, three-dimensional (3D) printing technologies have emerged as a promising alternative for post-disaster reconstruction, offering advantages such as accelerated production, reduced costs, minimized waste, and the potential to utilize sustainable materials. Accordingly, this study evaluates various global housing projects that have successfully implemented 3D printing in post-disaster scenarios, as detailed in Table 1.

Table 1.

Examples of post-disaster housing projects employing 3D printing techniques and their implementing agencies.

The field of post-disaster housing is undergoing continuous evolution, driven by the imperative to deliver not only rapid shelter but also economically sustainable and environmentally conscious solutions. Traditional construction methodologies, characterized by their protracted timelines and inherent inflexibility, are often inadequate in the wake of sudden and widespread disaster-induced destruction. This inadequacy has spurred the development of innovative construction approaches, including prefabricated structures, modular systems, and three-dimensional (3D) printing technologies, which offer adaptable alternatives capable of meeting diverse user needs and accommodating varied local conditions in affected regions. Each of these technologies presents unique advantages in practice while also contending with specific technical and logistical limitations. For example, prefabricated systems significantly expedite assembly, whereas 3D printing technologies enhance production efficiency through their inherent design flexibility and optimized material utilization. However, the practical applicability of these advanced methods is contingent upon more than just technical feasibility. Factors such as high initial costs, restricted material palettes, substantial energy demands, and the requisite for specialized labor can considerably influence their deployment.

Consequently, the strategic integration and selection of technologies for post-disaster housing demands a holistic approach. This approach must not only prioritize technical performance but also critically consider regional needs, overarching sustainability goals, and accessibility. In this context, parametric design methods emerge as a crucial strategic tool. Their ability to work synergistically with various construction technologies enables the development of flexible, scalable, and optimized housing solutions essential for effective post-disaster reconstruction.

2.3.1. Parametric Design

Parametric design represents a sophisticated computational methodology centered on manipulating parameters rather than fixed forms to generate intricate and adaptive designs [51]. This approach fundamentally transforms the design process by enabling decisions to be reversed, revised, and reassessed at any stage, thereby streamlining the evolution of the final product [52]. As articulated by Kolarevic [53], parametric design facilitates the exploration of diverse design scenarios by establishing relational networks among design elements. This interconnectedness ensures that modifications to one component automatically propagate changes throughout the entire system. This inherent consistency across various scales allows for rigorous testing of numerical models and robust comparison between alternatives through precise parameter management, consequently reducing error margins and enhancing designer control. Lawson [54] further reinforces that design is not a linear progression but a solution-oriented endeavor demanding expert judgment.

In stark contrast to conventional digital design tools, which often exhibit limitations in spatial modeling [55], parametric design leverages advanced software such as Maya, Rhino, and Grasshopper. These platforms enable the seamless manipulation of complex geometries and foster interdisciplinary collaboration across architectural, engineering, and industrial design domains [56]. Designers gain the remarkable ability to define intricate relational networks among elements, systematically generating a multitude of forms by altering defined parameters [57]. The parametric design process adheres to a systematic workflow, typically encompassing problem definition, parametric model development, and design evolution. Meredith et al. [58] contend that parametric design is a continuously evolving field with significant untapped potential. The workflow is characterized by sequential steps: comprehending the problem, constructing a parametric model, and developing the design. This structured approach empowers designers to tackle complex problems systematically. The process generally comprises four primary stages [59]:

- I.

- Design and Concept Development, which begins with problem definition and goal setting, followed by the development of the design in a parametric framework.

- II.

- Parametric Modeling and Application, involving the establishment of geometric constraints and rules to construct parametric models.

- III.

- Design Construction and Optimization, which involves generating and refining structural components based on the parametric foundation.

- IV.

- Applications and Contributions of Parametric Design to Architecture, which highlights its benefits such as flexibility, innovation, and sustainability in areas like facade design, performance simulation, and digital fabrication.

In architecture, parametric design enables the creation of complex structures with greater precision, efficiency, and economy by using mathematical algorithms and parameter-based logic. Software like Rhino and visual programming tools like Grasshopper play a significant role in this process. These tools allow the programming of design algorithms and seamless integration with technologies like 3D printers and CNC machines, accelerating the transfer of digital designs into the physical realm.

Utilizing Grasshopper as a Computational Tool for Parametric Design Applications

Grasshopper 3D, a visual programming plugin for Rhino developed by David Rutten, offers a powerful environment for parametric modeling [60]. It allows users to generate intricate geometries and designs without requiring traditional programming expertise, providing an interactive interface where parameters can be adjusted and results visualized in real time. Beyond its core design capabilities, Grasshopper extends its utility to various analytical tasks, including sound analysis, structural analysis, design optimization, and Arduino-based control systems [61]. Its modular component-based approach enables individual adjustment of each element [62]. Furthermore, Grasshopper supports scripting in VB.NET, C#, and Python, facilitating the integration of code-based formulas [63]. According to Cichocka [64], Grasshopper’s global adoption as a leading parametric design platform stems from its robust capacity to integrate numerous plugins, such as Decoding, Anemone, Galapagos, Octopus, and Wallacei, expanding its functionalities significantly. In architectural design, Grasshopper is extensively applied for tasks like geometric form generation and analysis, energy modeling, and material optimization. Its primary advantages include the following:

- I.

- Intuitive Visual Programming: Its visual interface eliminates the need for manual code writing, enhancing accessibility for users across diverse disciplines.

- II.

- Extensive Flexibility: A comprehensive library of functions and plugins provides broad adaptability to various design challenges.

- III.

- Enhanced Efficiency: The platform automates repetitive tasks, considerably accelerating the design process.

Grasshopper’s visual environment makes parametric design more accessible, allowing users from different fields to engage with complex design processes. The tool facilitates interactive simulations, enabling the exploration of design variations through parameter transformations. It also excels at generating sophisticated 3D models through simple iterations, which is particularly beneficial for biomimetic design, translating organic forms into architectural structures [65]. Moreover, its interoperability with other design software, such as Revit, further enhances its utility within integrated design workflows.

2.3.2. Exploring the Principles and Applications of Design Flexibility

Flexibility in the context of design, particularly in architecture, refers to a system’s or object’s inherent capacity to adapt and respond effectively to dynamic conditions or evolving demands. While its precise interpretation can vary across disciplines, the core meaning revolves around the ability to manage change and adjust accordingly. Krishna [66] defines flexibility as a fundamental transformation of the physical configuration of space, encompassing both external and internal modifications. This concept integrates aspects of both form and technique, as exemplified by reconfiguring movable walls or furniture. In housing, flexibility is crucial for long-term usability, occupant satisfaction, and overall sustainability. Flexible dwellings must inherently be able to respond to the evolving needs of their inhabitants, allowing for adaptability and reconfigurability over time. As defined by [67], flexibility in a building denotes its capacity to accommodate changing demands and maximize value throughout its lifecycle. Beyond mere physical alterations, architectural flexibility also encompasses the ability to respond to shifting user requirements and environmental conditions [68].

The contemporary challenges of population growth and evolving risk factors underscore the increasing necessity for flexible and adaptable housing solutions. Parametric design approaches have emerged as a pivotal tool for enhancing the flexibility and adaptability of housing, particularly in post-disaster contexts. These design strategies facilitate the expansion, reconfiguration, or addition of functions to structures using modular components and systems. In post-disaster housing, flexibility is vital for enabling a seamless transition from temporary shelters to permanent homes and for effectively addressing the dynamic needs of disaster-affected populations. Based on the work of Till and Schneider [69], various design and construction strategies are commonly employed to achieve building flexibility, as further illustrated in Table 2.

Table 2.

Strategies for incorporating flexibility in architectural planning and design [67].

In dynamic post-disaster contexts, where user needs and emergency conditions evolve rapidly, flexible shelter strategies are paramount. This necessitates the deployment of mobile and demountable architectural typologies specifically engineered for rapid displacement scenarios and urgent shelter provision. Mobile structures, such as certain prefabricated homes (e.g., the KODA housing system [70]), are typically designed for single-piece transport and are equipped with integrated components that facilitate swift relocation. Shigeru Ban’s innovative project in Onagawa, utilizing stacked shipping containers for multi-story temporary housing, exemplifies this approach [71].

Conversely, demountable structures, like the TECHO house model [70], consist of prefabricated modules that can be efficiently disassembled, transported, and reassembled on-site. A unifying characteristic of both typologies is their inherent modularity, which confers significant spatial flexibility and the capacity to accommodate diverse functional requirements. However, the use of large-scale components in modular systems can introduce logistical challenges during their installation and subsequent disassembly. Despite these potential limitations, the practical efficacy of such systems has been demonstrated by initiatives like the temporary housing provided by the Japanese government in the wake of various disasters [71]. Therefore, from an architectural and logistical standpoint, post-disaster shelter solutions that prioritize rapidity, flexibility, and scalability offer a robust and strategic framework for effectively addressing critical humanitarian housing needs.

The proposed flexible modular housing model was structured based on the strategies outlined in Table 2, which focuses on six fundamental principles of flexible architectural design: amount of space, design for adaptability, generic spaces, service placement, construction techniques, and building layers. These principles were utilized as design inputs during the parametric modeling process, with each strategy translated into spatial and structural attributes through algorithmic definitions. Using a visual algorithm developed in the Grasshopper environment, these flexibility strategies were integrated into the digital design model, resulting in a modular system that can be reconfigured according to user needs. Consequently, flexibility was not only addressed as a theoretical concept but was also embedded as a method within the digital fabrication process.

2.3.3. Three-Dimensional Printing

Three-dimensional (3D) printing, a sub-branch of computer-aided manufacturing (CAM), represents an additive manufacturing process that constructs physical objects layer by layer from digital designs [72]. Unlike traditional subtractive manufacturing methods (e.g., cutting or molding), 3D printing enables the direct fabrication of complex geometries without specialized tooling [73]. This technology has seen widespread adoption across various industrial and individual applications due to its compatibility with a diverse range of materials, including plastics, metals, ceramics, and bio-inks [74]. Developed since the late 1980s to meet market demands for quality, flexibility, cost-efficiency, and speed, 3D printing is not a singular process but rather an umbrella term for multiple distinct technologies that build products and components from the ground up, facilitating intricate surface geometries [73]. Its rapid advancement has been driven by progress in computing power, design software, novel materials, and internet connectivity [75]. The ISO/ASTM 52900 standard offers a comprehensive classification of additive manufacturing (AM) processes [74], detailed in Table 3.

Table 3.

The ISO/ASTM 52900 framework defines seven primary categories for classifying additive manufacturing processes based on their operational principles and material handling approaches [74].

The applications of 3D printing are remarkably diverse, encompassing fields such as architectural design, industrial design, medicine, engineering, education, and research and development. In architecture, 3D printing offers significant advancements. It enables designers to perform full-scale design testing and fabricate highly intricate architectural components. This capability provides crucial benefits, including the validation of design concepts, the early identification of potential structural issues, and a substantial enhancement of project visualization. Consequently, technology has revolutionized architectural design and production by delivering unparalleled design freedom, rapid prototyping, and extensive customization potential. Further advantages of 3D printing in architecture and engineering are detailed in Table 4.

Table 4.

Technological advancements of 3D printing in architecture and engineering applications.

This flexibility, defined as the ability to adapt designs to evolving environmental conditions and diverse user requirements, has become a cornerstone of contemporary architectural practice. By streamlining the fabrication of complex models, 3D printing provides a substantial innovation over labor-intensive and time-consuming traditional modeling methods, thereby increasing both flexibility and repeatability in architectural processes [76].

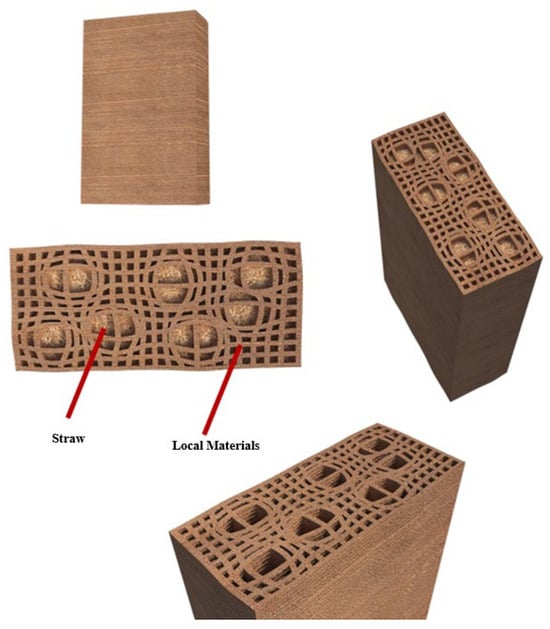

The advantages of 3D printing technology, as outlined in Table 4. Criteria such as design freedom, rapid prototyping, customized structures, cost efficiency, remote production, incorporation of new materials, and environmental sustainability served as key performance indicators throughout the development process. The parametric design process enabled the easy generation of complex geometries, while rapid prototyping allowed for low-cost and timely testing of proposed structures. Furthermore, the use of adobe, locally sourced natural material ensured both environmental sustainability and alignment with regional construction practices. The digital shareability and remote manufacturability of the designs contributed to faster deployment in post-disaster scenarios. This methodological framework thus ensures that the model simultaneously delivers architectural design flexibility and rapid responsiveness to emergency needs.

3. Materials and Methods

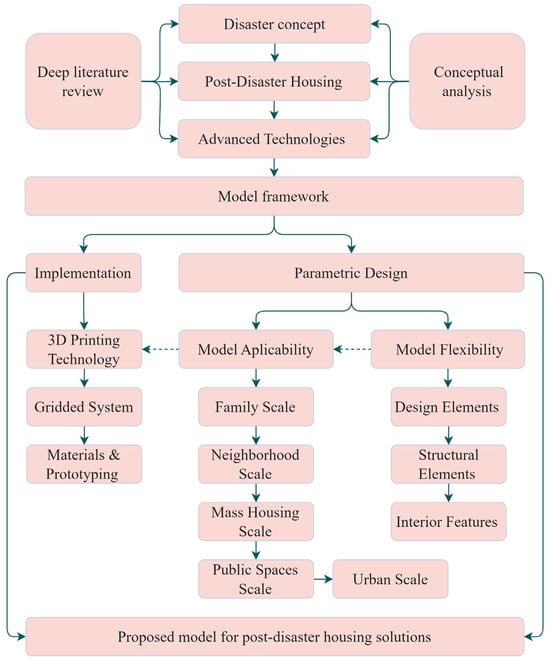

This study proposes an innovative post-disaster housing model that integrates parametric design, three-dimensional (3D) printing technology, and flexible modular systems to respond to the urgent shelter needs arising after disasters. The primary aim of the research is to evaluate the model’s applicability and adaptability across multiple spatial scales. To achieve this, a multi-layered methodological framework was adopted, consisting of three principal phases: (1) theoretical framework development, (2) parametric design process, and (3) implementation and prototyping. The detailed methodology of this study is visually represented in Figure 1.

Figure 1.

Step-by-step methodological framework.

The research began with an extensive literature review and conceptual analysis, focusing on the concepts of disaster, post-disaster shelter strategies, and emerging technologies in architecture and construction. This stage aimed to critically examine the limitations of conventional housing solutions and to identify the potential of algorithmic tools and digital fabrication techniques. The findings informed us of the definition of the problem and the strategic criteria for the proposed model.

In the second phase, a parametric and modular system was developed using Grasshopper, a visual programming plugin for Rhino 3D version 7. The spatial system was based on a standardized 5 × 5 m modular grid, chosen for its scalability and spatial efficiency. The design process involved the following stages:

- ▪

- Problem Definition and Parameter Setting: Post-disaster housing needs were analyzed based on user profiles and disaster scenarios, and corresponding design parameters were defined.

- ▪

- Algorithmic Modeling: Parametric relationships were encoded to dynamically generate spatial, structural, and interior components. The system utilized geometric manipulations (e.g., translation, scaling, rotation) and replication tools (e.g., array, series) to produce a variety of spatial configurations.

- ▪

- Flexibility and Applicability Analysis: The model was tested across different scales from individual housing units to neighborhoods and urban settings. Flexibility was evaluated through design elements, structural systems, and interior layouts.

This design approach allowed for the rapid creation, customization, and optimization of housing units, specifically tailored to user needs and environmental conditions. By leveraging algorithmic scripting with Grasshopper and Python, the system enabled real-time configuration and simulation, ensuring user-driven adaptability throughout the design process. In the context of this study, the term optimization refers to the iterative refinement of spatial layouts and modular configurations based on a set of predefined performance criteria. These criteria included maximizing spatial efficiency within a standardized 5 × 5 m grid, optimizing usability and adaptability through flexible strategies, and minimizing construction complexity to support rapid and holistic post-disaster deployment. Objective functions focused on achieving the best balance between interior usability and external environmental responsiveness, such as thermal comfort and ventilation potential. Constraints were defined by the modular grid itself, structural limitations of adobe-based 3D printing, programmatic requirements of the housing unit, and user-specified preferences for internal spatial arrangements. This parametric strategy not only facilitated the generation of multiple spatial alternatives but also supported design decision-making through continuous simulation and real-time visual feedback, effectively integrating optimization into the early stages of architectural design.

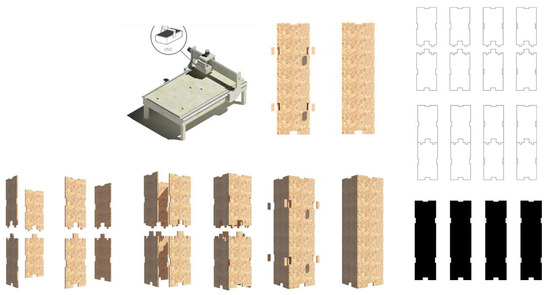

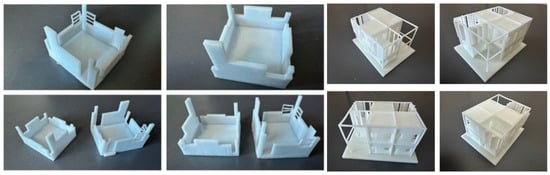

The final stage involved digital fabrication using 3D printing technologies. This included the development of a gridded structural system where modular components were optimized for efficient on-site assembly and disassembly, featuring a “Lego-like” interlocking mechanism to simplify construction and eliminate the need for specialized labor. Material selection prioritized locally available, cost-effective, and environmentally sustainable options like adobe, with choices guided by regional climatic demands to ensure optimal thermal insulation for colder climates and enhanced ventilation for warmer regions. Additionally, rapid prototyping of structural and furniture elements using additive manufacturing validated assembly logic, material performance, and structural stability.

Each modular unit underwent thorough evaluation for its adaptability, sustainability, and resilience. Algorithmic scripts were used to simulate various modular assemblies in different urban and domestic settings. These simulations specifically assessed structural integrity (via CNC-milled OSB panels and timber joinery), interior flexibility (through movable partitions and multifunctional furniture), and urban configuration (using grid-based layouts for scalable neighborhood planning). The integration of Python scripts with Grasshopper further enhanced the system’s spatial logic, optimized modular relationships, and increased configurability across both architectural and urban design scales.

3.1. Framework for the Proposed Flexible Design Model

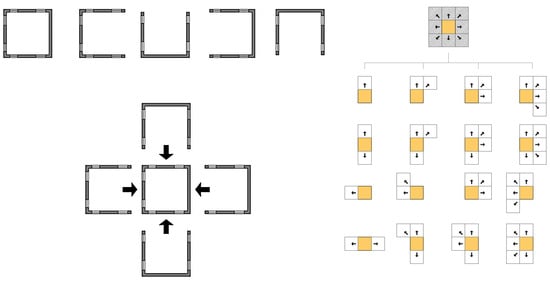

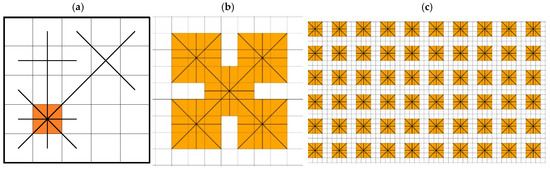

In this study, the square form was selected as the fundamental geometric unit of the proposed modular system due to its historical, architectural, and structural significance. As a symbol of symmetry, balance, and order, the square has played a prominent role in architectural traditions across various cultures from ancient Greek and Roman civilizations to modern architectural practices. Its geometric perfection, defined by four equal sides and right angles, enables seamless modular integration and systematic repetition, making it ideal for scalable and adaptable construction systems.

In post-disaster contexts, where speed, resilience, and adaptability are of paramount importance, the square form offers multiple advantages. Its simplicity facilitates rapid on-site production and assembly, while its modular nature allows for flexible expansion, reconfiguration, and spatial organization. Square modules can be arranged adjacently or diagonally with minimal spatial loss, ensuring maximum efficiency in the use of space. Functionally, a single square unit can accommodate a range of programs—such as bedrooms, kitchens, living areas, or bathrooms—depending on evolving user needs. This flexibility supports user-driven spatial restructuring and enhances both functional and spatial performance.

From an esthetic perspective, the square contributes to the creation of ordered, legible, and visually harmonious spaces, reinforcing users’ psychological comfort and improving the overall quality of living environments. Thus, the square form is not only a structural and constructional convenience, but also a key component of a user-centered, livable, and context-sensitive architectural strategy.

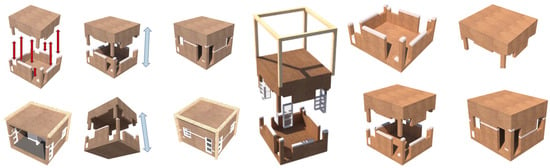

Accordingly, the basic structural units of the proposed model are designed as 5 × 5 m modular blocks. Each wall includes predefined voids for window and door openings, which can be customized according to user preferences and functional requirements. Additionally, wall thicknesses are specified at 40 cm to enhance structural integrity and thermal insulation. These modules can be assembled in various combinations to generate larger configurations suited to diverse usage scenarios, offering a high degree of adaptability in both interior layouts and outdoor spatial organization. As such, the modular system based on the square geometry provides a rapid, scalable, and sustainable architectural solution for post-disaster reconstruction, emphasizing flexibility, efficiency, and user participation. Detailed dimensions and specifications of model illustrated in Figure 2.

Figure 2.

The proposed model includes a structural block plan that enables the flexible and gradual expansion of modular units around the central core.

These basic units can be combined in various configurations to create expanded structures. This flexibility enables the modular system to be easily adapted to functional requirements and spatial arrangements. Thus, the basic units can be interconnected to suit different scenarios and purposes, offering flexibility in the organization of both interior and exterior spaces. While traditional construction methods often focus on producing large-scale and uniform housing, frequently overlooking the diverse needs and preferences of users, the proposed model allows modular blocks to be designed in various sizes and shapes. Furthermore, it enables users to expand or rearrange their living units according to their evolving needs. This modular system facilitates the easy assembly and disassembly of housing units.

In the proposed model, the modular housing system consists of four basic blocks (A, B, C, D). These independent 5 × 5 m modular units offer versatile configurations, allowing for diverse spatial arrangements to meet various user requirements, as depicted in Figure 2. The inherent flexibility of this modular system enables both expansion and rearrangement. Several expansion alternatives, illustrated around a central block, are designed to accommodate a range of living space needs. Table 5 provides a detailed description of these configurations.

Table 5.

Expansion alternatives of modular housing units based on configuration, dimensions, and directionality.

These proposed expansion methodologies underscore the inherent flexibility and adaptability of modular systems in addressing evolving spatial requirements. Each distinct expansion type facilitates the creation of diverse functional zones, thereby enabling users to optimize their living environments according to their specific needs. Table 6 illustrates various combinations and applications of these fundamental structural blocks.

Table 6.

Diverse configurations of blocks and their corresponding functional attributes.

The modular system provides a flexible solution capable of responding rapidly and effectively to users’ changing needs. The ease of assembly and disassembly of blocks offers a significant advantage, especially in emergency situations. Each module is designed to fulfill specific living functions, and users can customize, expand, or reorganize these modules according to their needs. By enabling personalized and flexible living environments, this system allows modular structures to adapt dynamically to evolving living conditions.

This system offers flexibility to expand in four directions around a central block, allowing users to tailor their living spaces according to their requirements. The central block acts as a focal point for expansion, while the modules added around it provide spatial diversity in both horizontal and vertical directions. These configurations enable users to rearrange their living spaces according to personal preferences and changing circumstances. Consequently, the housing units can be dynamically shaped in terms of functionality, comfort, and efficiency, providing a flexible and adaptive living environment.

3.2. Defining Model Flexibility Through Parametric Methods

In architectural design, flexibility refers to the ability of structures to adapt to user needs, environmental conditions, and functional requirements; in this context, parametric design and algorithmic modeling techniques play a critical role. In the proposed model, structural elements are optimized in terms of form and function to enable adaptability to various scenarios. The flexible structural system permits the rearrangement of columns and beams, ensuring durability, reusability, and cost-effectiveness. The flexibility of structural components allows building systems to quickly adapt to changing requirements and environmental conditions. In the proposed model, modular building blocks, exterior walls, openings, and windows can be easily modified and reconfigured according to user needs. Exterior walls are designed according to principles of energy efficiency and sustainability, considering climatic and environmental conditions. Structural systems offer both integrity and functionality through modular and adaptive solutions. Interior spaces are arranged flexibly to enhance user comfort, with partition walls designed to accommodate changing functions. Furniture elements are designed to be multifunctional and user-oriented, enhancing spatial efficiency. Flexibility is also emphasized in the organization of interior spaces, where partition walls can be quickly reconfigured according to user demands. Flexible furniture systems—such as foldable beds and modular furniture—further enhance spatial efficiency, contributing to the creation of functional and adaptive living environments, particularly in post-disaster scenarios.

In addition, the modular block system consists primarily of two main components—base and roof—designed to interlock with each other in a Lego-like geometric configuration. This design approach significantly simplifies the processes of assembly and disassembly, offering major advantages in terms of portability and reconfigurability. The base component rests firmly on the ground to enhance the stability of the structure, while the roof component, with its high load-bearing capacity, allows for the addition of new modules above. Both components are designed to be joined without the need for specialized equipment, enabling rapid intervention and housing setup in emergency situations. Furthermore, the disassembly and reassembly capabilities of the system reinforce its flexibility and adaptive potential, allowing for easy accommodation of various spatial and functional requirements.

3.2.1. Key Design Elements of the Proposed Model

This study introduces a parametric modeling approach leveraging algorithmic techniques to significantly enhance the flexibility of modular block systems. This algorithm facilitates the optimization of building elements using locally sourced materials and enables their customization based on specific user requirements. The algorithm’s core functionalities are structured around three key component types:

- ▪

- Geometric Components: Fundamental units like ‘Rectangle’ and ‘Polygon’ are employed to generate essential building elements such as windows and doors, allowing for diverse shapes and configurations.

- ▪

- Transformation Components: Functions such as ‘Move,’ ‘Rotate,’ and ‘Scale’ are utilized to manipulate the position or size of existing geometries, thereby increasing design adaptability and flexibility.

- ▪

- Duplication Components: Components like ‘Array’ or ‘Series’ enable the systematic replication and distribution of geometries, facilitating the creation of varied and complex wall configurations.

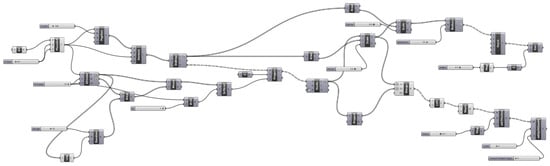

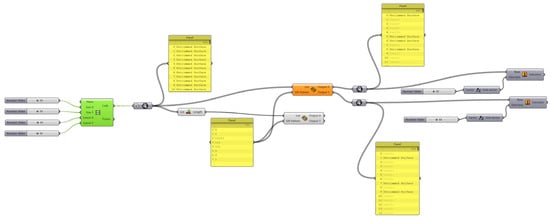

This model establishes a dynamic architectural framework capable of adapting to diverse application scenarios. It allows for the optimization of the form, size, and arrangement of modular blocks through the precise manipulation of parametric variables. As illustrated in Figure 3, the developed algorithm for the modular block system empowers users to readily customize building blocks to meet specific functional requirements.

Figure 3.

The algorithm developed for the design of flexible and modular block systems.

Figure 3 illustrates the Grasshopper-based parametric algorithm developed for generating the spatial configuration of the proposed model. The process begins with the definition of key design parameters such as grid size and density, which are controlled using Number Slider and Panel components. A two-dimensional grid is then generated through a combination of Series, Construct Point, and Rectangular Grid nodes. Spatial filtering is achieved using Dispatch, Cull Pattern, and List Item nodes, allowing the selection of cells that are suitable for placement.

Subsequently, functional units are assigned to the selected cells using stochastic and evaluative methods via components such as Random, Domain, Evaluate, and Remap Numbers. The spatial behavior of these units is then manipulated through transformations including translation, rotation, and scaling using Move, Rotate, and Scale nodes, respectively. In the final stage, the overall form is visualized and materialized in three dimensions using Boundary Surfaces, Extrude, and Custom Preview components.

Developed in Grasshopper, this system facilitates user-centric design in post-disaster housing by enabling the generation of adaptive facade systems, walls, openings, and fenestration. This adaptability allows for optimal performance across diverse climatic and geographical conditions. The system empowers users to customize building designs to meet their specific requirements, thereby promoting the creation of functional and sustainable housing solutions. Its core algorithm dynamically modifies the dimensions, shapes, and other properties of various building elements, adhering to predefined rules and parameters. This is particularly evident in the algorithm’s capability to generate flexible external wall systems, as visually represented in Figure 4.

Figure 4.

Developed algorithm for flexible external wall system design.

The algorithm illustrated in Figure 4 initiates with the definition of fundamental input parameters that guide the overall design process. These parameters, represented by nodes labeled “NUMBER”, control key attributes such as scale, dimensional proportions, and the quantity of repeated elements. For example, values such as NUMBER (1.0), NUMBER (10), and NUMBER (20) indicate base units, iteration counts, or specific dimensional controls within the system. These serve as dynamic input handles, allowing the designer to modify outputs interactively. Following this, geometric construction modules transform the numeric data into spatial components: “POINT” nodes generate coordinates based on input values, while “LINE” constructs linear connections between points. “PLANE” establishes spatial references for orientation and projection, and “EXTRUDE” generates volumetric forms by extending two-dimensional geometries along a specified direction. Together, these modules produce a flexible design structure that responds to parameter changes in real time. Data manipulation nodes such as “LIST ITEM”, “MERGE”, and “FLATTEN TREE” are also employed to efficiently organize, combine, and streamline datasets, which is essential when dealing with large quantities of geometric elements.

In the subsequent stages of the algorithm, mathematical and logical operations enhance design flexibility and computational control. Arithmetic nodes (e.g., ADDITION, SUBTRACTION, MULTIPLICATION) perform quantitative transformations on the input data, enabling the creation of complex proportional relationships. Logical operations like “GREATER THAN” or “LESS THAN” evaluate conditions and drive conditional behaviors in the design logic. The “GENERIC HASH” node, while not fully specified, appears to function as a customizable component—potentially involved in data indexing or the evaluation of unique states during optimization. Analytical modules such as “AREA” calculate surface metrics, while “MASS ADDITION” may indicate cumulative values for performance tracking. The arrangement of nodes in the right-hand section of Figure 4 suggests a feedback mechanism, possibly integrated with an evolutionary solver such as Galapagos. In this setup, the algorithm uses performance indicators (e.g., surface area) as fitness objectives to iteratively adjust input parameters, facilitating an optimization loop that leads to more efficient, adaptive, and performance-driven spatial solutions.

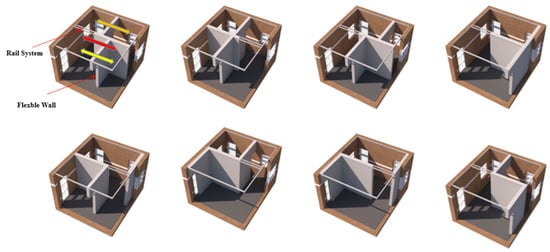

Flexible interiors are defined as spaces that can respond to varying user needs, adapt to environmental changes, and be easily reconfigured. In this respect, this section discusses different types of flexibility in interior layouts and presents practical applications of these approaches. Additionally, it focuses on how flexible interior design can be optimized through the proposed model. Using flexible partition walls and a rail system, the model allows for rapid and efficient spatial reconfiguration based on user needs. The model presents eight different configurations demonstrating the spatial diversity provided by the flexible internal walls and rail system. Each configuration illustrates how the space can be adapted to varying user requirements. Flexible walls can easily slide along the rail system, allowing the internal layout to be modified. This enables spatial arrangements to be rapidly reconfigured in response to changing needs.

In addition, to overcome the current limitations of 3D printers, the modular design approach has been developed to incorporate both base and roof elements within each block, thereby addressing challenges related to height and structural integrity. These modular blocks are designed to remain within the printing volume limits of 3D printers and to interlock during assembly, enabling the creation of larger structures. This approach maintains control over the height of structural components and minimizes the risk of buckling as building height increases. To prevent structural weaknesses such as the rapid reduction in buckling loads with increasing height the segmented and interlocking design of blocks is crucial. Fixed-end structures have lower buckling coefficients compared to free-end structures; thus, the modular system is planned to support structural stability accordingly. The interlocking nature of the blocks not only facilitates easy assembly but also allows for disassembly and reassembly in different locations. This significantly enhances the portability and flexibility of the system. Overall, this modular approach contributes to meeting critical requirements in post-disaster housing applications, including surpassing production constraints, ensuring structural integrity, enabling rapid setup, and supporting reusability.

3.2.2. Structural Elements of the Proposed Model

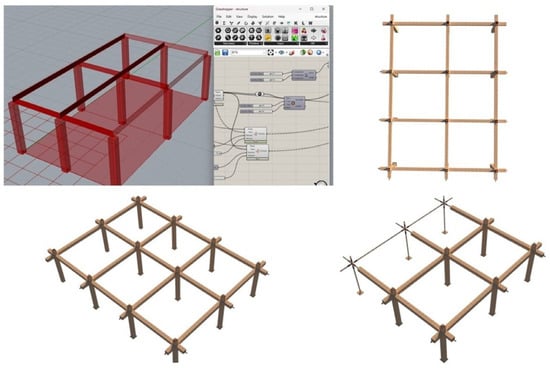

Flexible structural systems are crucial for rapidly and effectively addressing user needs, especially in the design of post-disaster housing. These systems offer adaptability and quick deployment, which are vital in emergency contexts. Algorithmic methods play a pivotal role in optimizing and customizing such systems to meet diverse requirements efficiently. Figure 5 introduces a proposed algorithm that serves as a promising solution for both the design and implementation of these flexible structural systems, ultimately enhancing resilience and responsiveness in disaster recovery efforts.

Figure 5.

Algorithm developed for the design and implementation of the flexible structural system.

As illustrated in Figure 5, this Grasshopper algorithm provides a detailed implementation of parametric modeling principles in the design and application of flexible building systems. The initial phase of the algorithm begins with the definition of numerical inputs via “Number Sliders”, which control key geometric parameters and spatial dimensions. Components such as “Count” determine the number of modules or elements in the system, while “Radius” parameters govern the dimensions of circular or curved components. These adjustable inputs serve as critical control points that allow the design to respond to varying user needs and environmental conditions. Moreover, components like “Divide Length” and “Divide Curve” play a central role by generating evenly spaced division points along curves or lines, thus enabling the dynamic organization of modular panels or framing elements. This operation facilitates scalability and adaptability across multiple configurations and spatial contexts.

In the subsequent stages, the algorithm utilizes these numerical and geometric parameters to generate structural components that ensure flexibility and ease of assembly. The “Offset Curve” component defines the spatial layout and thickness of structural or cladding elements by generating curves at controlled distances from a base geometry. “Boundary Surfaces” nodes create planar surfaces from closed curves, effectively constructing façade panels or structural sheets. Transformation operations such as “Rotate” and “Move” dynamically manipulate the orientation and position of the generated elements, allowing them to adapt to diverse assembly scenarios and site conditions. Collectively, these processes establish a data-driven and optimized design workflow that enables rapid deployment, modular adaptability, and user-specific customization in flexible building systems.

The proposed algorithm represents a major innovation in the design and implementation processes of flexible structural systems. Figure 5 illustrates how the algorithm utilizes parametric design methods to render building components structurally flexible. The algorithm aims to generate the most suitable construction solutions by considering user needs and environmental conditions. In the initial stage, detailed data on user requirements and environmental factors are collected and analyzed. These data are obtained based on users’ living spaces, required functions, and prevailing environmental conditions. Accordingly, design parameters that ensure the system’s flexibility and adaptability are defined and optimized. This process enables the structural system to adapt to diverse usage scenarios and environmental contexts.

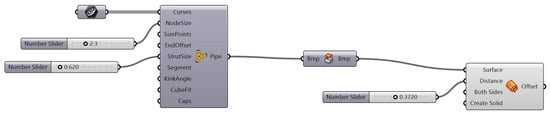

Moreover, the algorithm used in the production of structural components is developed on the Grasshopper platform using parametric modeling and optimization techniques and is aimed at the precise production of joints through CNC milling methods. In the first phase of this process, fundamental design criteria such as dimensions, angle values, and material properties are defined using Number Slider and Panel tools, as illustrated in Figure 6.

Figure 6.

Algorithm used for producing structural component parts.

Each parameter directly affects structural compatibility and stability. Next, geometric modeling tools such as Curves, NodeSize, and EndOffset are used to model the connectors at accurate sizes and angles. These tools play a critical role in optimizing the intersections and joints of modular components. In the final phase of the process, simulations and optimizations, conducted using tools like Surface and Create Solid, test the manufacturability of the parts and aim to validate the physical feasibility of the design.

3.2.3. Interior Features of the Proposed Model

In architectural design, flexibility refers to the organization of interior spaces and features to readily adapt to evolving user needs and functional requirements. This approach prioritizes the creation of reconfigurable and multifunctional environments. Key characteristics of flexible interiors include movable furniture and partitions, spatial diversity, and the capacity for long-term reorganization in response to changing demands. These attributes significantly enhance a space’s sustainability and adaptability, ultimately improving the user experience and extending its functional lifespan. Such flexibility empowers users to seamlessly adjust to shifting lifestyles and technological advancements. The specific flexible interior characteristics integrated into the proposed model are detailed in Figure 7.

Figure 7.

Algorithm developed for the design of furniture and Interior Features.

Furthermore, flexible furniture systems play a crucial role due to their modular and multifunctional nature, enabling easy adaptation and personalization of spaces. They are instrumental in optimizing spatial efficiency, facilitating the creation of both functional and comfortable environments, even within constrained areas. This is particularly pertinent in post-disaster housing, where these systems allow for rapid and effective responses to changing shelter needs, such as converting shared areas into private living spaces over time. In these scenarios, the efficient utilization of limited space is critical for the successful transformation of temporary shelters into more permanent dwellings. The algorithm developed to implement these flexible characteristics is also illustrated in Figure 7.

As depicted in Figure 7, this Grasshopper algorithm addresses core principles of flexibility in architectural design, particularly emphasizing the adaptability of interior layouts and furniture elements to evolving user needs and functional requirements. The initial phase of the algorithm begins with numerical input parameters defined via “Number Sliders,” which control key spatial variables. For instance, “Count” components determine the number of partition elements or modular furniture units, while “Size” and “Length” nodes govern their dimensions and extents. Components such as “Series” and “Construct Point” automate the generation and spatial arrangement of repeating elements such as sliding panels along predefined intervals. These parametric inputs play a critical role in dynamically organizing spatial diversity within interiors, enabling reconfigurable and multifunctional environments. This approach contributes to long-term adaptability and supports the design of sustainable and resilient interior spaces that can respond to future changes in use or occupancy.

The subsequent stages of the algorithm focus on generating flexible furniture systems, particularly in response to challenges observed in post-disaster housing contexts, such as material scarcity and urgent furniture needs. Nodes like “Divide” and “Scale” are employed to proportionally adjust furniture components to align with locally available or low-cost materials. Geometric construction nodes, including “Extrude” and “Boundary Surface,” define the volumetric form of modular furniture units such as storage blocks or seating elements, ensuring they are suitable for fabrication using digital manufacturing methods like 3D printing. Transformation operations such as “Move” and “Rotate” stimulate the flexible positioning of these modules across different configurations, allowing for adaptive spatial arrangements that transform shared spaces into private zones or vice versa. Ultimately, the algorithm provides a data-driven and user-responsive design workflow that enables the creation of compact yet comfortable environments, offering rapid and economical spatial solutions for individuals affected by displacement or disaster.

This algorithm offers a solution to critical problems arising after disasters, such as material loss and the need for furniture. It focuses on the cost-effective use of local and readily available materials and facilitates the production of modular furniture using 3D printers. Thus, it provides rapid and economical solutions for the shelter needs of disaster-affected individuals.

3.3. Implementation of the Proposed Model Using 3D Printing Technology

3D printing technology offers the potential to deliver rapid and effective solutions for post-disaster shelter needs. Thanks to on-site production capabilities, structural components can be quickly fabricated and assembled, reducing logistics costs and time loss. In emergency situations where traditional methods are inadequate, this technology provides sustainable and resilient housing solutions. Three-dimensional printers, which use computer-aided design data to perform additive manufacturing, play a crucial role in disaster management by enhancing the flexibility and durability of buildings.

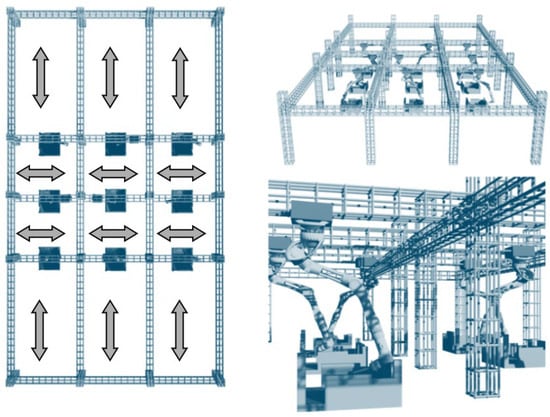

3.3.1. Gridded System

Given the urgent and large-scale nature of post-disaster shelter needs, the proposed gridded system model utilizing 3D printing technology offers an effective alternative for on-site production. The model involves the integration of modular building blocks with 3D printers and the rapid transportation of this technology to disaster areas. Consequently, the use of a gridded system enables the fast and efficient production and assembly of permanent housing units, ensuring timely and effective implementation of post-disaster housing solutions. The combination of 3D printing technology and the gridded system provides fast, cost-effective, and flexible responses to shelter needs. These systems offer significantly faster production than traditional methods, reduce material and transport costs through on-site fabrication, and increase sustainability by minimizing waste. Additionally, their ability to produce customized structures according to specific needs allows for adaptation to a variety of shelter requirements. With successful implementations worldwide, this technology is expected to become a widespread, innovative, and sustainable solution in both disaster management and the general construction sector in the future.

3.3.2. Materials and Prototyping

This section proposes the use of adobe material for the components produced with 3D printers. Adobe is a natural and environmentally friendly construction material made by mixing clay, straw, and water. Its low cost and the easy accessibility of its raw materials make adobe economically advantageous. Abundantly available worldwide, adobe has the potential to offer rapid and cost-effective solutions in post-disaster reconstruction processes. With low energy requirements and a minimal carbon footprint during production, adobe contributes to environmental sustainability. Furthermore, its natural insulation properties enhance energy efficiency by reducing heating and cooling costs. In the proposed model, parametric design and rapid prototyping enable users to easily modify components and visualize prototypes before actual construction. This process offers users greater control and participation, allowing the design to be more accurately aligned with their needs.

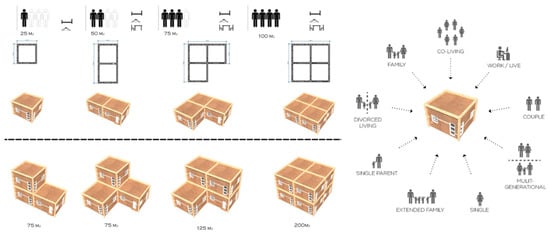

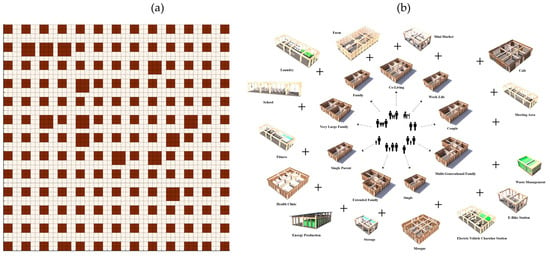

3.4. Applicability of the Proposed Model

In contemporary societies, the rapid transformation of demographic structures and family forms has intensified the need for flexibility and adaptability in post-disaster housing. The proposed model offers modular and expandable building systems that accommodate diverse family sizes and lifestyles. These structures, which can serve the needs of individuals as well as multigenerational families, provide rapid and efficient shelter following disasters. Developed through parametric design and 3D printing technologies, the flexible system can be implemented not only at the individual housing scale but also at neighborhood and mass housing levels. Through the design of housing and public structures that align with socio-economic diversity, it promotes social sustainability.

3.4.1. Application at the Family Scale

Application at the family scale refers to the design and implementation of housing projects tailored to meet the specific needs of individual families. This concept aims to provide flexible and adaptable housing solutions that account for the unique lifestyles, sizes, and requirements of each family. Through modular and customizable structures, families are enabled to easily reconfigure their homes to meet both current and future needs. This approach optimizes the efficient use of physical space while strategically enhancing the quality of life for residents. Therefore, application at the family scale is considered a crucial criterion in the development of sustainable and long-lasting housing solutions. The visual script and parametric definition related to the model’s applicability at this scale are illustrated in Figure 3.

3.4.2. Application at Neighborhood Scale

At the neighborhood scale, the application of 3D printing extends to urban planning and housing design, focusing on creating flexible and adaptable configurations that cater to the unique social, cultural, and economic needs of communities. The proposed model leverages a grid-based system to enhance sustainability, livability, and efficiency within these developments. This grid layout, characterized by perpendicular street intersections, optimizes traffic flow, prioritizes pedestrian and bicycle mobility, and fosters social interaction among residents. Furthermore, it effectively addresses the functional deficiencies of inadequate street designs often termed “stroads” by distributing traffic across smaller, multifunctional streets. The grid system also facilitates efficient rainwater management and is inherently suited for the development of walkable, mixed-use neighborhoods.

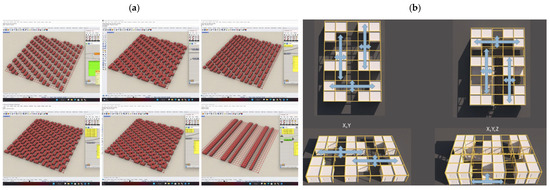

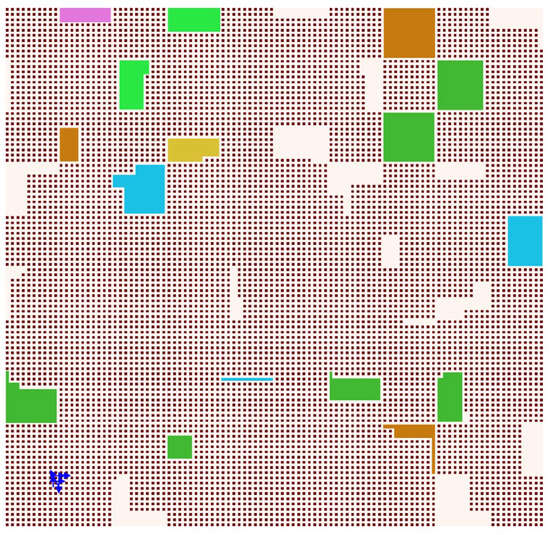

In the context of transit-oriented urbanism, the grid system, despite potential architectural limitations, significantly contributes to environmental sustainability through optimized traffic distribution and robust pedestrian–bicycle infrastructure. Its application at the neighborhood level demonstrably enhances urban planning, offering economically and environmentally sustainable solutions that improve overall quality of life. Figure 8 provides a detailed illustration of the components within a modular system designed for neighborhood-scale application, developed using a parametric approach. The underlying algorithm enables the strategic placement of these modular units within the grid layout, allowing for their effortless repositioning and reconfiguration to meet evolving community needs.

Figure 8.

Algorithm of the modular system at the neighborhood scale.

As illustrated in Figure 8, the algorithm begins with the construction of a grid-based system, where “Number Slider” components control the dimensions and density of cells along the X, Y, and Z axes using “Plane” and “Cells” nodes. This modular grid serves as the foundational spatial framework for the placement of building units and the overall urban structure. The generated surfaces or cells represented as “Untrimmed Surfaces” correspond to potential building plots or development parcels. This spatial organization enables the design of walkable, mixed-use neighborhoods that support sustainable urban strategies such as optimized traffic flow, prioritization of pedestrian and bicycle movement, effective stormwater management, and the spatial integration of diverse functions within a coherent, adaptable urban fabric. In the subsequent phase, the algorithm enables the selective manipulation and reconfiguration of these modular units within the grid structure. List management components such as “List Item” and “Cull Pattern” allow for the filtering, selection, and functional assignment of specific cells, enabling the flexible distribution of housing units, commercial spaces, or green areas according to predefined patterns or dynamic criteria. On the right side of the visual script, additional “Number Sliders” and components like “Factor” and “Base” are used to control transformation operations, particularly “Extrusion” which define the height or volumetric form of the modular building elements. This approach provides a parametric mechanism to modulate architectural diversity and scale within the neighborhood context, supporting a responsive urban design methodology that aligns spatial configuration with both functional needs and sustainability objectives.

The stages of the algorithm include the parametric definition of blocks, determination of their positions, merging them according to specific rules, and listing the resulting combinations. In the Grasshopper environment, each block is defined as a 5 × 5 rectangle using the Rectangle component. As detailed in Table 6, blocks are positioned using the move component; for instance, Block B is placed 3 units to the right of Block A. The positioned blocks are then merged using the Boolean Union component. In the first step, a 5 × 5 grid is generated based on a specific coordinate system, serving as the foundation for block placements. To create an expanded grid in horizontal and vertical planes, the corresponding Grasshopper code is utilized.

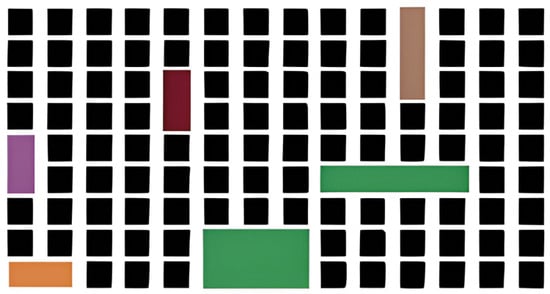

3.4.3. Application at the Mass Housing Scale

Application at the mass housing scale refers to the rapid and cost-effective construction of many housing units in large-scale settlements using standardized modular blocks. The proposed grid-based and modular system enables the creation of housing units of varying sizes and allows for quick adaptation to user needs. Open-plan layouts optimize natural lighting and ventilation, resulting in functional living spaces. The arrangement of modular units in a grid formation facilitates the development of compact, efficient, and sustainable residential areas. Green spaces between buildings and rooftops contribute to environmental sustainability, while pedestrian- and bicycle-friendly streets promote sustainable transportation, reduce traffic congestion, and support healthier lifestyles. The codes of python for the applicability of models on an urban scale are described in Appendix A.

3.4.4. Application at the Public Spaces Scale

Application at the public spaces scale involves the planned placement and management of public services and structures that address the shared needs of the community. Particularly in post-disaster contexts, it becomes crucial to provide not only shelter but also diverse spatial functions that meet social, economic, and environmental demands. In the proposed model, in addition to housing, additional spaces such as farms, markets, cafés, schools, health centers, and energy facilities can also be produced using 3D printing technology. This integration enhances community sustainability and overall quality of life. Within the model, a grid system is generated using the parametric design tool Grasshopper, enabling flexible and modular planning of both housing units and various public spaces at the urban scale. The algorithm developed in the Grasshopper environment with Python scripting optimizes the spatial configuration of residential and public components, offering rapid and effective design and implementation capabilities. This facilitates the adaptation and utilization of modular systems in post-disaster urban areas. Appendix A contains the Python codes developed to test the applicability of the model on the urban scale.

3.4.5. Application on the Urban Scale