Abstract

The construction sector is responsible for over 40% of waste generated in Australia. Construction materials are responsible for around 11% of global carbon dioxide emissions, and a third of these materials can end up wasted on a construction site. Attention in research and industry has been directed towards waste management and recycling, resulting in 78% of construction and demolition waste being diverted from landfill. However, the waste hierarchy emphasises avoiding the generation of waste in the first place. In this paper, the PRISMA approach is used to conduct a systematic review with the objective of identifying waste reduction strategies employed across all stages of projects in the Australian construction industry. Scopus and Web of Science databases were used. The search returned 523 publications which were screened and reviewed; this resulted in 24 relevant publications from 1998 to 2025. Qualitative analysis identifies strategies categorised into five groupings: pre-demolition, design, culture, materials and procurement, and on-site activities. The review finds a distinct focus on strategies within the materials and procurement category. The reviewed literature includes fewer strategies for the avoidance of waste than for any of the other levels of the waste hierarchy, evidencing the need for further focus in this area.

1. Introduction

Societies have developed to produce and consume goods, with waste as the end result, often referred to as a linear economy, in which the processes are simplified as ‘take-make-dispose’ [1]. This linear economy relies on fossil fuels for energy to extract, produce and transport goods, and as raw materials. Indeed, some 45% of global greenhouse gas emissions are associated with the manufacture of products [2]. The construction of buildings involves both the consumption of materials and the production of waste. In Australia, in the financial year 2020–2021, the construction and demolition (C&D) sector was responsible for the production of 29 Mt of waste [3]. This represents 45% of core waste produced in Australia. Waste is produced across the whole lifecycle of a building, including in the design, construction, and maintenance phases, and at the end of life. Whilst waste from the C&D sector has a high recovery rate (78% of waste from the Australian C&D sector was recovered in 2020–2021), recycling and recovery are not a panacea for wastefulness. Indeed, recycling processes often result in both the consumption of energy and a reduction in the use value of materials.

The conceptualisation of waste management has evolved in recent decades, from the 3 Rs (Reduce, Reuse, Recycle) in the 1970s [4], to a six-layer waste hierarchy more recently (e.g., [5]), in which an optimal strategy of avoiding waste was introduced. With increasing awareness of the environmental impacts of producing and consuming goods, calls for a move to a circular economy have been growing (e.g., [2,6]). Within this context, the waste hierarchy has been further reconceptualised as ‘10 Rs’ [1]. Table 1 shows the evolution of strategies first to manage waste, and more recently to contribute to a circular economy.

Table 1.

Evolution of waste management/circularity strategies.

In the context of the circular economy, with the ultimate target of reducing greenhouse gas emissions and minimising the use of resources, Konietzko et al. [8] conceptualised five interrelated strategies for impacting material and energy flows towards circularity: narrow (use less); slow (use longer); close (use again); regenerate (make clean); and inform (use data). Waste reduction strategies that fall into the slow and close categories (using longer and using again) have the potential to create long-term environmental impacts through reductions in material and energy flows. Therefore, whilst waste reduction strategies may be implemented in the short- or medium-term within a construction project, their environmental impact may be experienced in the longer-term.

In Australia, improved construction waste management has historically been incentivised by targets for diversion of waste from landfill, and green building credits for the recycling of waste [9]. However, more recently green rating tools have started to encourage the reuse of buildings and components [10]. In terms of understanding causes of waste within projects, there is an acknowledged lack of detailed data on waste generation at a project level, with typically only waste recovery rates (amount recycled versus sent to landfill) captured [11], which again supports the focus on waste management as opposed to waste avoidance. Concerningly, without considering the value of materials wasted, the management of waste (removal from site and processing) costs the Australian construction industry AUD 2 billion per year [12]. Therefore, finding a solution to reduce the volume of waste produced by the sector has the potential to deliver not only environmental but also economic benefits.

Whilst the 2018 National Waste Policy [13] introduced the principle of avoiding waste, data from the Waste Report 2022 [3] indicates that rather than declining, waste from the C&D sector is growing, with a rise of 39% per capita seen over the past 15 years. In order to curb the excessive growth and address this growing problem, attention needs to be given to how to avoid and minimise construction waste. The aim of this paper is therefore to begin to explore to what extent and how the principles of waste avoidance and minimisation are being translated into the Australian construction industry. This is achieved through a systematic review of the literature, with the following objectives:

To understand the context of waste avoidance/reduction strategies employed in the Australian construction industry, across the whole lifecycle of building projects.

In order to understand how waste avoidance relates to the circular economy, establish the level of the waste hierarchy that each of the waste reduction strategies relates to.

2. Construction Waste Management Background

2.1. Construction Waste Management and Circular Economy

There have been numerous reviews investigating different aspects of the application of circular economy to C&D waste management [14,15,16,17,18,19]. However, there appears to be a lack of focus on waste avoidance and reduction methods when considering the circular economy in the context of the built environment. In one study, only 2 of 45 reviewed papers on circular economy practices in the built environment discussed construction waste reduction [16]. Identified barriers to the implementation of circular economy in the C&D waste management sector include: limited demand for recycled products, lack of data on recycling, and lack of segregation of waste materials [20]. Yang et al. [18] suggest that the construction industry could explore concepts employed in the manufacturing industry, such as remanufacturing, rather than focusing heavily on reuse and recycling.

Geographical differences in the drivers for improved construction waste management to support a circular economy were noted in a review by Alhawamdeh et al. [21]. It was found that in Europe, where there the fundamentals of waste management are well developed, there was in increased focus on regulations and policy, compared to Asia where the focus was on personal factors such as construction skills, experience and behavioural improvement. Oceania, including Australia, was found to closely follow Europe with one exception being a greater need for recycling infrastructure.

A lack of emphasis on waste avoidance also seems to be evident in an analysis of current research trends in C&D waste. Wu et al. [22] identified that whilst the importance of waste minimisation in design is widely accepted, it is not an area that is commonly discussed in the literature. Of the six future research trends involving information technologies identified by Li et al. [23], two related to C&D waste reduction: firstly estimating waste generation at a large scale level, and secondly improving waste minimisation efficiency at the design stage. Whilst recommended methods to reduce construction waste generation exist, a lack of ability to assess the effectiveness of these methods has limited their adoption. Albsoul et al. [24] found that benefits of reducing construction waste spread across all tenets of sustainability—social, environmental and economic—however, the barriers were dominated by legislative and technological barriers.

2.2. Construction Waste Management in Australia

Several notable reviews have highlighted the increase in the literature on the management of construction waste in recent years [22,25,26]. Li et al. [25] found that articles related to C&D waste management displayed slow but steady growth from 2007 to 2016, followed by a sharp increase from 2016 onwards. Australia featured prominently, ranking as the second highest country in terms of frequency of publications. Similarly, Oluleye et al. [15] identified Australia as one of the top 15 countries in terms of volume of research outputs in their review on C&D waste in circular economy research. However, in a more focused analysis investigating articles relating to design for zero waste or design for recycling, Australia contributed only 11 of the 115 publications [27]. Australia was noted as one of the top contributors in a recent review on drivers for construction waste management to support a circular economy, behind China and the UK [21].

In the Australian context, there have been five literature reviews focused on locally based C&D waste management research [28,29,30,31,32]. Previous research has identified barriers to C&D waste management, including a lack of interest/demand from client, attitudes toward material reuse, and lack of training [28] as well as inadequate waste sorting and storage, lack of consistent reporting, and unsupportive regulatory frameworks [31].

One study reviewed waste strategy documents from all jurisdictions in Australia to compare approaches and strategies across the states [32]. This was supported by another study by Zhao et al. [30] who found inconsistencies in legislation across the jurisdictions is leading to cross-jurisdictional waste movement.

Furthermore, Kabirifar et al. [29] found that the construction and demolition phase was ranked as higher priority than planning and design, and that economic factors were most influential in achieving good waste outcomes. They also highlighted that more attention to C&D waste is needed at a national level in Australia, and more emphasis on tools and technologies could assist in developing comprehensive management strategies.

2.3. Construction Waste Management Policy, Legislative and Voluntary Instruments

Literature has highlighted the importance of a policy approach in managing construction and demolition waste [33]. However, it has also been recognised that there are significant jurisdictional differences across Australia that impact the implementation of policies [30,32]. One analysis of the landscape of Australian construction waste management policy [34] describes how the federal policies in Australia, such as the 2019 National Waste Policy Action Plan [35] and the 2018 National Strategy Waste Policy [13] provide only voluntary guidance and aspirational targets for construction waste management, whereas the individual states provide regulations with mandatory targets. However, although these state-based documents may provide mandatory targets, there are inconsistencies between the states, and there is limited guidance provided on the methods to achieve reductions. In addition to mandatory targets for waste reduction, there are other legislative areas which can assist in working towards more sustainable waste management. One such area is sustainable procurement—whereby policy can drive the uptake of recycled waste products as part of a circular economy [36].

2.4. Waste Reduction Strategies

Waste reduction is notably different from waste management. Waste management focuses on the processing of waste from the point at which a material or product transitions from being an asset to being discarded. Whereas waste reduction focuses on the avoidance of materials or products being considered surplus to requirements and being discarded. Waste reduction strategies vary widely, and whilst many international studies have sought to provide summary approaches (e.g., [37,38,39,40]) no single source captures all appropriate strategies, either internationally or for specific contexts. In attempts to simplify the selection of appropriate strategies, some have sought to group or categorise strategies according to a number of methods, including the following:

- Thematic grouping: [26,39,41];

- Life cycle stage of construction: [14,31,37,42];

- Level of the waste management hierarchy addressed: [31,43];

- Associated stakeholders: [28,29,44].

Thematic grouping of the strategies assists in highlighting key areas of focus. Fikri Hasmori et al. [41] reviewed 20 research papers, identifying 54 waste reduction strategies which they assigned to five main categories: human resources; material and equipment; construction methods on site; administration; and regulation. Alhawamdeh and Lee [26] used four categories to classify strategies: on-site waste minimisation practices; technological approaches; legislation; and behavioural approaches. They highlight the potential for changing perceptions, attitudes and behaviours, particularly those of the contractors, to lead to a reduction in waste. This was also reflected in a study by Ajayi et al. [45] who used focus groups and the literature to identify cultural factors that need to be addressed to reduce waste.

Shooshtarian, Maqsood et al. [31] analysed and grouped strategies across eleven stages of project lifecycle: design, manufacturing, procurement, transportation, construction, demolition, reusing, recycling, upcycling, landfilling, and illegal dumping. This comprehensive analysis highlights the need for further study and harmonisation in waste management systems. Similarly, Adams and Hobbs [37] presented a matrix of construction waste management strategies with their relevant project stages and stakeholders involved, as a way of identifying best practice. López Ruiz [14] identified five main lifecycle stages of the sector: preconstruction, construction and renovation, collection and distribution, end-of-life, and material recovery and production. They found that design strategies can provide a waste minimisation approach and facilitate the salvaging of materials at the end-of-life of buildings, but that economic drivers are needed to enhance the market for secondary materials. Additionally, there has been a growing number of studies focusing on methods to design out waste using tools such as Building Information Modelling [46,47].

Although the waste hierarchy is commonly referred to when presenting strategies to address construction waste, there are few studies which connect strategies to levels of the hierarchy addressed. Kabirifar et al. [43] discussed waste management strategies in the context of the waste hierarchy, using the simplified 3R’s. Whilst this previous work captures the importance of addressing reduction as the first priority, strategies relate only to reducing waste through design, and the reuse of recovered materials.

2.5. Research Gaps

Whilst there is evidently a growing interest in construction waste research, with a greater awareness of the scale of the issue, the academic literature to date has focused largely on the theoretical barriers and drivers to broadly addressing construction waste management, rather than on specific practical steps towards improving performance in terms of waste generation. A lack of focus on waste avoidance and reduction was evident, even though it is acknowledged in the waste hierarchy that this should be the top priority. Therefore, the most significant gap in prior research is on identifying and understanding strategies targeting waste avoidance and reduction. The literature has also shown a range of options to categorise waste minimisation strategies, however a consistent comprehensive framework for waste reduction strategies is lacking. This paper aims to address the gap in waste avoidance and reduction research, whilst also using previous studies on categorisation of strategies to inform the framework used to analyse current Australian practice.

3. Methodology

Due to the limited literature on the application of construction waste reduction strategies in the construction industry in Australia, a systematic literature review was conducted to identify all available and valid literature. The Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) method was employed to identify the construction waste reduction strategies applied in the Australian construction industry. In order to mitigate biases in selecting articles, analysing data and reporting research findings, the review was conducted in accordance with the guidelines of the PRISMA protocol [48]. The review was not registered.

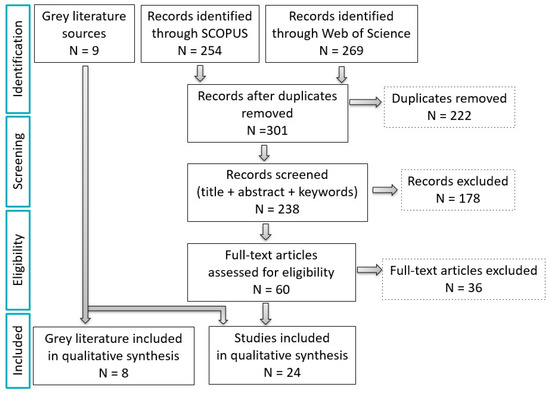

The review was conducted using two of the leading databases for this field of research: Scopus and Web of Science. The same search string was applied in each database, using the phrases: (“Construction waste” OR “Demolition waste” OR “C&D Waste” OR “Construction and demolition waste”) AND (reduc* OR minimi* OR avoid*) AND (Australia). A total of 238 records were screened independently by two researchers (refer to Figure 1), using the online Covidence systematic review management platform [49]. Both the Covidence duplicate filter and manual checking were used to identify and remove duplicates. Articles were screened using the following inclusion criteria:

Figure 1.

PRISMA diagram of literature screening and eligibility assessment process.

- Only empirical studies were included;

- Must include strategies for the reduction of waste;

- Must include Australian case studies or direct reference to the Australian context;

- Must consider construction and/or renovation of buildings.

And the following exclusion criteria:

- Papers that focus solely on the processes of recycling construction waste or on the production of materials using waste were excluded;

- Papers focusing on infrastructure construction projects were excluded;

- Review papers were excluded.

Divergences within the screening process were discussed. Following the initial screening, the full texts of 60 articles were assessed independently by the same two researchers for inclusion within the review. Again, divergences were discussed until consensus was reached.

In addition to the academic literature, relevant grey literature publications were identified through conducting an online search for available public sector and peak industry body documents. This identified 9 documents, one of which was transferred into the academic literature review [50].

A total of twenty-four academic literature and eight grey literature documents were analysed for the review. All 32 articles were reviewed, and all waste reduction strategies were coded using NVivo 12 [51] using an inductive process. The inductive coding approach allowed the qualitative analysis of the papers, through which themes of strategies emerged from the existing body of research as opposed to being predetermined by the researchers [52]. Using this qualitative analysis technique, all construction waste reduction strategies were first identified and coded, before being categorised. A total of 18 waste reduction strategies were identified across the literature.

4. Results and Findings

A brief synopsis of the academic papers and grey literature documents can be found in Table 2 and Table 3, respectively. These tables summarise the focus of the reviewed documents, and the research methods used. Whilst studies and reports were restricted to those considering Australia, it was found that 50% of the academic studies, as well as 50% of grey literature studies used nation-wide data collection or targeting, with the remaining half of the studies focused on individual states. In addition to this, the project type considered (commercial, residential, industrial, etc.) was not mentioned in 54% of the academic studies, with 25% targeting commercial developments, and 17% explicitly mentioning multiple project types. In comparison, in the grey literature, 37.5% of the reports targeted residential developments, with the remaining being applicable to any construction project type.

Table 2.

Academic literature studies included in qualitative analysis.

Table 3.

Grey literature included in the qualitative analysis.

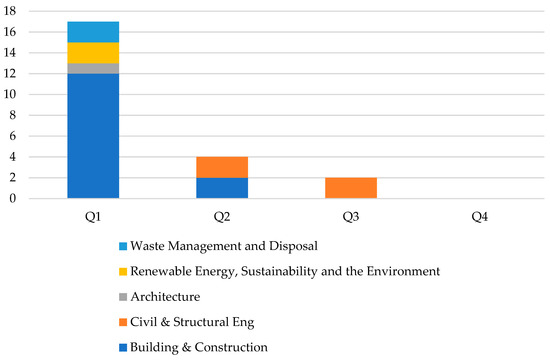

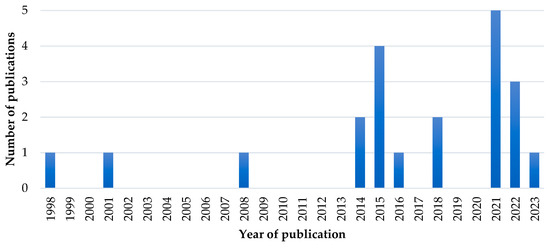

Considering academic rigour, 17 of the 24 academic articles reviewed were published in journals ranked in Q1 for at least one relevant category (Figure 2). Four were published in journals ranked Q2, and two papers were published in Q3 ranked journals. None of the papers were published in journals ranked in the bottom quartile. The year of publication of the selected academic articles ranges from 1998 to 2025, with the majority (17 of the articles) published in the ten-year period to 2025 (Figure 3).

Figure 2.

Journal ranking by quartile and category.

Figure 3.

Number of articles by year of publication.

An analysis of the keywords within the selected academic papers was undertaken using NVivo 13 qualitative data analysis software. ‘Waste’ was the most commonly used keyword amongst the selected academic articles, appearing in 22 of the papers. However, it was never used in isolation, it was instead used in conjunction with other words to form key phrases, including: construction waste, waste management, and waste minimisation. Whilst ‘minimisation’ was the joint third most commonly used word amongst the key words (appearing five times), it was included as a keyword many fewer times than the word ‘management’ (appearing eleven times). In all five instances ‘minimisation’ was used in the phrase ‘waste minimisation’ or ‘construction waste minimisation’. Key phrases including the word ‘design’ appeared six times. Key phrases relating to ‘reuse’ and ‘recycling’ appeared only twice each. The phrase ‘circular economy’ was used five times, and only in papers published since 2022.

Through the inductive coding process, the eighteen identified strategies have been grouped thematically in five categories: pre-demolition; design; culture; materials and procurement; and on-site activities. In Table 4, the strategies are presented in their groupings, together with the number of sources in which they were identified, and the list of references to each strategy. This is disaggregated by body of literature (academic and grey). To highlight the current areas of focus within the literature, the top five waste minimisation strategies by number of references in each body of literature are indicated with shading. The following sub-sections present an analysis of the waste minimisation strategies within their thematic groupings.

Table 4.

Waste avoidance or minimisation strategies highlighted in the literature.

4.1. Pre-Demolition

Standard demolition processes fail to capture the potential value (both financial and environmental) of the materials in existing buildings when compared to alternative approaches such as selective deconstruction [81]. Two academic and two grey literature sources identified pre-demolition audits as a waste minimisation strategy as they encourage maximising the reuse and recycling potential of materials. Pre-demolition audits should provide an inventory of materials that can be reused, recycled or recovered [75], the engagement of a salvage specialist to identify materials with market value is recommended [79]. Li et al. [56] identify the potential of 3D laser scanning and BIM to identify materials or components in existing buildings that could be reused. However, Newaz et al. [69] referred to audits only as a way to encourage waste separation and enable recycling, ultimately targeting reduced landfill costs.

4.2. Design

The category of ‘Design’ includes four strategies identified in the literature: BIM; design for adaptability; design for disassembly; and waste efficient design. Sixteen of the twenty-four academic papers and six of the eight grey literature documents included in the review identified at least one of these design stage strategies.

BIM is conceptualised as either a management tool [59,68]; a planning tool [55,65]; or a design tool [56,62,64]. As a management tool, BIM can enable accurate estimation and material procurement. Digitization of design is thought to provide opportunity to predict waste flows easily which can lead to reductions [73]. However, in their interview study, Jahan et al. [68] found that only 20% of participants were using BIM in their projects to assist with estimation, despite being cognisant of the benefits. For planning, BIM has the potential to enable whole-life-cycle evaluation of materials and components [55,65]. As a design tool, the body of literature has elucidated case studies in which BIM has been used to provide quantitative information about the waste efficiency of different solutions at the design stage, supporting informed design decision making [62,64]. It also provides a collaborative platform to share data, streamline coordination and reduce errors [74]. When it comes to the use of BIM for waste management, the incompatibility of BIM with construction waste management tools has been highlighted as a barrier to industry adoption [68].

There were only three references to design for adaptability in the literature. The Your Home Guide [80] recommends design stage consideration of future adaptation of a home, to avoid it becoming redundant, and thus enable alternate uses as the needs of the household change. In their survey of 140 Australian construction professionals, Udawatta et al. [59] found that design for adaptability was ranked 6th out of twenty-six waste management solutions. It was also highlighted by multiple interview participants that retaining and upgrading existing buildings, or existing building structures can contribute to waste reduction, and designs should consider efficient use of materials be considering durability of building layers [73].

Seven academic papers and four grey literature documents identified design for disassembly as a waste minimisation strategy. Whilst this strategy may not inherently reduce waste at the construction stage, it has the potential to avoid future waste by enabling a subsequent life for materials or components by enabling deconstruction or disassembly for reuse. It emphasises the importance of considering the building’s end-of-life phase during the initial design [73]. Brewer and Mooney [55] advocate for developing practical guidelines on design for disassembly to help construction professionals in the transition to a circular economy. Forghani et al. [63] identified nine technical design principles to enhance reusability of building components, including: avoiding hazardous substances, long lifespan of components; mechanical fixings; and maintaining information about construction methods employed. In an observation of twenty-three case study projects measuring end-of-lease office strip-out waste, Forsythe and Fini [61] concluded that fitout design typically fails to consider disassembly, as only 1.3% of demolished components were found to be reusable. It is recommended that a reusable and adaptable kit-of-parts be adopted to avoid the frequent cycle of fitout demolition [11,61].

The strategy of waste efficient design is amongst the most prevalent strategies within the reviewed literature, with fourteen academic sources and four grey literature sources identifying this strategy. The importance of considering waste efficiency at the early stages of a project is frequently highlighted [56,65,66]. Doust et al. [65] found that 56% of construction organisations surveyed used waste efficient design. However, this contrasts with the findings of Udawatta et al. [59] and Jahan et al. [68], who found that only 31% and 30% of participants (respectively) placed importance on considering waste minimisation principles in design. Hassan and Alashwal [74] highlighted that complex designs can lead to errors, changes in design, inefficiencies and wastage. One study highlighted that design optimisation could lead to greater than 50% reduction in waste generation [62]. Waste efficient design strategies include: designing for standard material sizes; designing for modularisation/prefabrication; avoiding materials that create waste during construction (e.g., swapping roof tiles for metal sheet roofing); design simplification; building less (smaller building); and ensuring design accuracy to avoid errors and modifications.

4.3. Culture

Cultural issues have been identified by previous research as a significant barrier to the effective reduction in construction waste [46]. In the category of ‘Culture’, five strategies for waste minimisation are identified in the reviewed literature: clear communication; contractual requirements; waste reduction culture; waste reduction targets; and training, education and guidance. Fifteen academic papers and all eight grey literature documents reviewed identified at least one of these cultural strategies.

Clear communication was identified by nine academic studies and two grey literature documents. Within construction projects, communication is wide-ranging and diverse in form. Therefore, conceptualisation of this strategy across the literature is varied, ranging from clear, accurate and comprehensive information being provided in drawings and specifications; to regular communication on progress towards waste minimisation targets through toolbox talks on site. Communication responsibilities differ for each of the project stakeholders, with Faniran and Caban [53] highlighting the need for clients to initially establish clear project goals; designers to provide effective and timely communication of the design; and contractors to check specification and drawings for clarity, errors and omissions. Hassan and Alashwal [74] identified that effective communication and coordination were the most influential enablers of designing out waste. In the context of retrofit projects, research has identified the benefit of early involvement of contractors [11,56]. The grey literature sources advocate for engaging with project staff to invite feedback the effectiveness of waste minimisation strategies [75].

The strategy of establishing a waste reduction culture was identified within ten academic papers reviewed, and only one grey literature document. Faniran and Caban [53] identified that only 42% of respondents had organisational waste minimisation policies in place. It appears that this has not improved significantly over the last two decades, with Doust et al. [65] reporting that only 50% of respondents follow a structured approach to design and construction waste minimisation. Furthermore, it is noted that waste management plans are often included in order to tick a box, and are subsequently considered of low importance. The findings of both Shooshtarian et al. [70] and Udawatta et al. [59] support these assertions, with industry culture being ranked as the third most significant barrier to waste minimisation in both studies. The importance of stakeholders as potential agents of change in driving awareness, participation and action is also highlighted [59,66,80]. However, Moreton et al. [60] discuss dissonance regarding responsibility for addressing waste minimisation. Udawatta et al. [58] emphasise the role of the client in establishing a focus on construction waste within a project, noting that this is more prevalent in public sector projects than the broader construction sector.

Ten academic papers and two grey literature sources identified setting waste reduction targets at either the project or organisational level as a waste minimisation strategy. Lingard et al. [54] found that setting targets and providing feedback on progress against these targets was successful in reducing waste to landfill for a case study project. Udawatta et al. [59] also advocate the communication of performance against waste reduction targets in regular toolbox talks. Two papers state the need to establish an industry benchmark and performance targets for C&D waste minimisation in retrofit projects [11,56].

The waste reduction strategy of training, education and guidance is amongst the most prevalent within the reviewed academic literature (identified in 13 academic papers) but only identified in 3 grey literature sources. It has previously been asserted that education and training provide an important foundation for contractors and sub-contractors by raising awareness of the environmental impacts of waste as a pre-cursor to behaviour change [45]. There were contrasting findings regarding the extent of training and education for waste minimisation within the industry. Jahan et al. [68] found that 70% of participants had received education or training on waste minimisation, whereas an earlier study by Moreton et al. [60] found that 65% of participants had received no training. Some sources highlighted the need for on-site training of construction personnel, whereas others stressed the need for all stakeholders (designers, clients, builders, waste management contractors) to develop skills and knowledge in waste minimisation, particularly as it was identified that architects do not perceive any direct benefit of waste minimisation to themselves or their organisation [60]. The survey by Lim et al. [72] found that respondents prioritised the importance of training and education, both in waste management and in design techniques to reduce waste generation.

Both academic and grey literature sources emphasise the need to establish contractual requirements for waste minimisation targets and practices [58,77]. The academic literature focuses on the prequalification of tenderers, based on non-price criteria including waste minimisation [58,59,66]. It should also incorporate clauses relating to waste reduction targets, waste management plan implementation and regular waste monitoring and reporting to foster a shared commitment among stakeholders [73]. The grey literature advocates for ‘green procurement’, noting the potential for the public sector to take the lead in driving demand. The Your Home Guide [80] advises homeowners to ensure waste minimisation and recycling performance clauses are included within project contracts.

4.4. Materials and Procurement

The category of ‘Materials and procurement’ comprises six strategies for waste minimisation—greater than any other category. These are as follows: accurate estimation; material or component reuse; materials handling; prefabrication; supply chain partnerships; and reusable temporary works. Twenty-one academic papers and all eight grey literature documents reviewed identified at least one of these strategies.

Construction projects are time-constrained, complex operations [82]. As a result, the wasteful practice of overestimation of material quantities is often used to avoid delays and losses through incidental damage or cutting to size. The waste minimisation strategy of accurate estimation aims to address this. Jahan et al. [68] recommend the use of BIM to enable accurate estimation, and UQ [79] advocate for making arrangements with suppliers to buyback unused supplies.

Another significant contributor to construction waste is damage to materials during transportation, site handling or storage. Hence, seven sources identified materials handling as a waste minimisation strategy. Appropriate site planning can support effective materials handling, providing laydown areas and safe storage space for materials, as well as planning to schedule material deliveries to align with the project programme [66]. The materials handling strategy also relates to the optimisation of material packaging to ensure adequate protection, while preventing excessive waste [53,65,75,77].

Material or component reuse is hampered by market resistance to the use of recycled materials, due to either cost or quality concerns [58,68,70]. Consequently, a number of sources advocate for public sector and industry support to develop markets for products with recycled content (e.g., [50,77,80]). One survey found the most significant barrier to adopting circularity is an underdeveloped marketplace for reused building materials [71].

Prefabrication has the reputation within the construction industry for being waste efficient, despite limited evidence to support this [83]. Prefabrication as a waste minimisation strategy is suggested by nine academic papers and three grey literature sources. Innovative construction methods such as prefabrication have been found to optimise materials usage and onsite activities which can contribute to waste reduction [74]. Doust et al. [65] report that 56% of respondents adopt forms of prefabricated construction as a waste reduction strategy. In one of the case studies discussed in the literature [67] prefabrication was estimated to result in an 80% reduction in waste, however this result was based on using conventional waste rates not actual data and was largely due to different material specifications and construction techniques.

Supply chain partnerships are amongst the most frequently identified waste minimisation strategies across both bodies of literature (thirteen academic and seven grey literature references). The literature identifies issues in the limited capacity to control the waste management practices of specialist sub-contractors [77]. Doust et al. [65] advocate for an integrated supply chain “to drive efficient material flows” (p. 9). Whilst Crossin et al. [78] promote the extended producer responsibility model, in which suppliers adopt responsibility for their product from production through to recycling/reprocessing. This can also extend to consider digital cataloguing systems to establish material stock information to develop closed loop supply chains for materials at the end of the building’s life [73].

Only two sources identified the waste minimisation strategy of reusable temporary works [65,78]. Doust et al. [65] provide the example of repetitive steel formwork, whereas Crossin et al. [78] developed and implemented methods to reduce the amount of temporary timber bracing in the installation of prefabricated frames.

4.5. On-Site Activities

The category of ‘On-site activities’ comprises just two strategies for waste minimisation. These are: on-site waste segregation and waste management plan. Fifteen academic papers, and six grey literature documents reviewed identified at least one of these on-site waste minimisation strategies.

On-site waste segregation was one of the most frequently identified waste minimisation strategies within the grey literature, highlighted by six of the eight grey literature sources. The benefits of separating waste on-site, in terms of ability to recycle or reuse materials, are well known [55]. Therefore, this strategy is widely endorsed within the literature (e.g., [69,77]). However, the literature also highlighted issues relating to attitudes and behaviours when implementing on-site waste separation [69,78] because many site workers are not used to separating waste.

Development and adoption of a waste management plan is also well described in the literature (fourteen papers and five grey literature sources). However, from the results of their survey, Doust et al. [65] report a concerningly low percentage of projects in which waste management plans are mandated—only 37.5%. This is supported by the findings of Lim et al. [72] who suggested there is a drive to legalise the implementation of waste management plans. The grey literature provides useful guidance for industry on what to include within a waste management plan [5,75]. This guidance also advocates for regular monitoring of how the waste management plan is working, through discussions with site personnel [75].

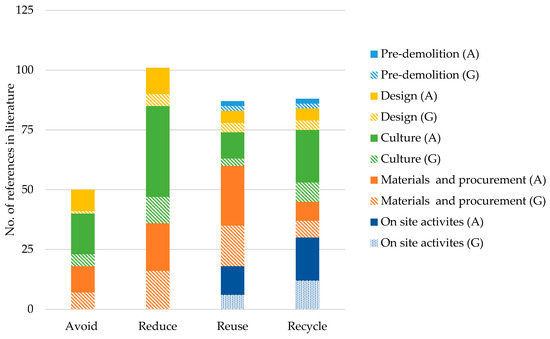

5. Waste Reduction Strategies and the Waste Hierarchy

The prevalence of construction waste reduction strategies is positive; however, preferential attention is needed to the highest levels of the waste hierarchy [13]. Therefore, each of the strategies identified has been assigned to the level of the waste hierarchy being addressed (Table 5). The results of this analysis, coupled with the frequency of their appearance, are visualised in Figure 4.

Table 5.

Hierarchy for each strategy identified.

Figure 4.

Frequency of strategies coded according to the waste hierarchy level addressed.

She et al. [73] previously highlighted the long-term impacts of decisions made at the pre-design stage of a project on potential construction and demolition waste. However, concerningly, there are fewer coded strategies for the avoidance of waste than for any of the other levels of the hierarchy. Nonetheless, given the focus on recycling within the construction industry, the lack of dominance of strategies addressing the ‘Recycle’ level of the waste hierarchy is somewhat positive. The focus on recycling has previously been attributed to drivers, such as green building rating tools [56], in which credits are awarded for diversion of waste from landfill, as opposed to avoidance of waste in the first instance. It should be noted, however, that with a focus on strategies for the avoidance and minimisation of waste, the selection criteria for this review excluded papers whose sole focus was on a single recycled construction material (e.g., the use of recycled aggregate).

In terms of the prevalence of the categories in relation to the levels of the waste hierarchy, the categories of ‘Materials and procurement’ and ‘Culture’ dominate the strategies relating to reducing and avoiding waste. All five categories are represented within the ‘Reuse’ and ‘Recycle’ levels of the waste hierarchy. However, strategies in the category of ‘on-site activities’ are clustered in these two levels of the hierarchy—being absent from the upper two levels of the hierarchy. The category of ‘Design’ is present across all levels of the waste hierarchy, although it is not the dominant grouping of coded strategies in any of the levels of the hierarchy. The ‘Design’ strategies are most prevalent within the ‘Avoid’ and ‘Reduce’ levels of the hierarchy.

Quantitative data in the reviewed studies primarily focuses on perceptions from construction professionals, with only limited studies quantifying the impact of specific strategies on the reduction of waste (the exceptions being [54,62,64,78]). However, the absence of an industry baseline or sector benchmark data on construction waste at a project level is problematic. This lack of data currently prevents meaningful assessment of the efficacy of any of the waste minimisation strategies.

6. Conclusions and Future Work

Through a systematic review of the literature on minimisation of construction waste, this paper has explored how the principles of waste avoidance and minimisation are being employed in the context of the Australian construction industry. This paper aimed to address the gap in the current literature on construction waste management with a specific focus on waste avoidance and reduction. The systematic review identified eighteen construction waste minimisation strategies. These were thematically grouped into five categories: pre-demolition; design; culture; materials and procurement; and on-site activities. It is evident that the largest number of strategies relate to the category of ‘materials and procurement’. Each of these strategies was linked to the level of the waste hierarchy it predominately addressed (avoid, reduce, reuse, recycle)—which demonstrated a significant lack of focus within the literature on strategies targeting the avoidance of waste. Waste reduction strategies at the higher end of the waste hierarchy have significant potential to contribute to the transition of the construction industry towards a circular economy through slowing and closing loops.

The body of literature reviewed in this paper demonstrates that many strategies for the minimisation of construction waste exist, and that these strategies have been employed or tested within the construction and renovation of buildings in the Australian context. Reflecting on the national level waste data, which shows increasing waste per capita from the construction sector, it is purported that these strategies are not yet being employed at a meaningful scale within the construction industry. There was a distinct lack of quantitative data available in the literature to support any assessment on the effectiveness of the strategies at achieving a reduction or avoidance of waste, which hinders the ability to make justifiable recommendations for action. The dearth of strategies related to culture or design in the grey literature is perhaps indicative of a lack of drive from the government to enact change.

This review provides a comprehensive inventory of the waste reduction strategies that have been employed within the Australian construction buildings sector. However, there is a clear need for quantitative data on construction waste generation across the sector as a foundation for catalysing change. There is a need for data at the sector level and also in relation to specific building types. This data will allow benchmarking to be established within the construction sector, providing nuance in relation to waste generation within different project types and scales. Once benchmarking data is available, it will then be possible to analyse the efficacy of different waste reduction strategies or combinations of strategies, and to quantify their impacts on construction waste generation. In the absence of this kind of data, neither benchmarking of projects nor quantification of the impact of waste reduction strategies is possible at the time of writing. Additionally, there is a lack of data available on the implementation of waste reduction strategies, and how this is influenced by project or construction types, various stakeholders involved or regulatory and economic factors.

Future research work should target the following areas:

- Investigating the quantification and characterisation of construction waste from the sites of various building types—both project types (residential, commercial, etc.) as well as construction types (such as timber framed, steel framed, cladding type) to provide benchmarking data.

- Quantitative assessment of the impact of waste minimisation strategies in various contexts.

- In-depth analysis of the barriers and drivers of waste minimisation strategies for different project types (commercial, residential, industrial, etc.).

- Investigation into the interaction of stakeholders with strategies to highlight the most effective ones to be implemented by various stakeholders.

- Based on all of the above information, developing a prioritisation of the waste reduction strategies to target a balance between effectiveness and ease of implementation.

Author Contributions

The research this paper is based on—and the writing of the paper has been—a collaboration between the two authors. E.H. and L.K. have contributed equally to the conceptualization; methodology; analysis; data curation; writing—original draft preparation; writing—review and editing; and project administration. L.K. was responsible for funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the University of Wollongong through the Prioritising Early Research Leaders Fellowship scheme.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The authors would like to acknowledge funding support from the University of Wollongong through the Prioritising Early Research Leaders Fellowship scheme.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cramer, J. Building a Circular Future Ten Takeaways for Global Changemakers; Amsterdam Economic Board: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Ellen Macarthur Foundation. Completing the Picture: How the Circular Economy Tackles Climate Change. Available online: www.ellenmacarthurfoundation.org/publications (accessed on 21 June 2025).

- Pickin, J.; Wardle, C.; O-Farrell, K.; Stovell, L. National Waste Report 2022; Blue Environment Pty Ltd.: Melbourne, Australia, 2023. [Google Scholar]

- Wilcox, B. Reduce. Reuse. And Then, When All Else Fails, Recycle. Available online: https://news.climate.columbia.edu/2022/02/25/reduce-reuse-and-then-when-all-else-fails-recycle/ (accessed on 21 June 2025).

- NSW Environment Protection Authority. Construction and Demolition Waste: A Management Toolkit. 2020. Available online: https://www.epa.nsw.gov.au/sites/default/files/20p2392-construction-demolition-waste-management-toolkit.pdf (accessed on 21 June 2025).

- United Nations Climate Change, Shifting to a Circular Economy Essential to Achieving Paris Agreement Goals|UNFCCC. Available online: https://unfccc.int/news/shifting-to-a-circular-economy-essential-to-achieving-paris-agreement-goals (accessed on 28 February 2023).

- Building Commission NSW and University of Wollongong, How to Reduce Construction Waste and Improve Productivity—store.training.tafensw.edu.au. Available online: https://store.training.tafensw.edu.au/product/how-to-reduce-construction-waste-and-improve-productivity/ (accessed on 21 July 2025).

- Konietzko, J.; Bocken, N.; Hultink, E.J. A tool to analyze, ideate and develop circular innovation ecosystems. Sustainability 2020, 12, 417. [Google Scholar] [CrossRef]

- Ratnasabapathy, S.; Perera, S.; Alashwal, A. Assessment of Waste Generation and Diversion Rates in Residential Construction Projects in Australia Modeling Drivers and Barriers to Adopting Risk Management Practices in Malaysian Small Construction Projects View project Liquid Waste Management in the C. In Proceedings of the CIB World Building Congress, Hong Kong SAR, China, 17–21 June 2019. [Google Scholar]

- GBCA. A Practical Guide to Upfront Carbon Reductions: For New Buildings and Major Refurbishments. Available online: https://new.gbca.org.au/news/gbca-media-releases/reducing-upfront-carbon-at-scale/ (accessed on 21 June 2025).

- Li, M.; Yang, J. Analysis of interrelationships between critical waste factors in office building retrofit projects using interpretive structural modelling. Int. J. Constr. Manag. 2014, 14, 15–27. [Google Scholar] [CrossRef][Green Version]

- Australian Bureau of Statistics. Waste Account, Australia, Experimental Estimates, ABS. Available online: https://www.abs.gov.au/statistics/environment/environmental-management/waste-account-australia-experimental-estimates/latest-release (accessed on 21 June 2025).

- Australian Government. National Waste Policy 2018: Less Waste, More Resources. Available online: https://www.dcceew.gov.au/environment/protection/waste/publications/national-waste-policy-2018 (accessed on 21 June 2025).

- López Ruiz, L.A.; Roca Ramón, X.; Gassó Domingo, S. The circular economy in the construction and demolition waste sector—A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Oluleye, B.I.; Chan, D.W.M.; Saka, A.B.; Olawumi, T.O. Circular economy research on building construction and demolition waste: A review of current trends and future research directions. J. Clean. Prod. 2022, 357, 131927. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Bilal, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R. Current state and barriers to the circular economy in the building sector: Towards a mitigation framework. J. Clean. Prod. 2020, 276, 123250. [Google Scholar] [CrossRef]

- Yang, Y.; Guan, J.; Nwaogu, J.M.; Chan, A.P.C.; Chi, H.-L.; Luk, C.W.H. Attaining higher levels of circularity in construction: Scientometric review and cross-industry exploration. J. Clean. Prod. 2022, 375, 133934. [Google Scholar] [CrossRef]

- Mhatre, P.; Gedam, V.; Unnikrishnan, S.; Verma, S. Circular economy in built environment—Literature review and theory development. J. Build. Eng. 2021, 35, 101995. [Google Scholar] [CrossRef]

- Cristiano, S.; Ghisellini, P.; D’Ambrosio, G.; Xue, J.; Nesticò, A.; Gonella, F.; Ulgiati, S. Construction and demolition waste in the Metropolitan City of Naples, Italy: State of the art, circular design, and sustainable planning opportunities. J. Clean. Prod. 2021, 293, 125856. [Google Scholar] [CrossRef]

- Alhawamdeh, M.; Ferriz-Papi, J.A.; Lee, A. Examining the Drivers to Support Improved Construction and Demolition Waste Management for a Circular Economy: A Comprehensive Review Using a Systematic Approach. Sustainability 2024, 16, 6014. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Status quo and future directions of construction and demolition waste research: A critical review. J. Clean. Prod. 2019, 240, 118163. [Google Scholar] [CrossRef]

- Li, C.Z.; Zhao, Y.; Xiao, B.; Yu, B.; Tam, V.W.; Chen, Z.; Ya, Y. Research trend of the application of information technologies in construction and demolition waste management. J. Clean. Prod. 2020, 263, 121458. [Google Scholar] [CrossRef]

- Albsoul, H.; Doan, D.T.; Aigwi, I.E.; GhaffarianHoseini, A. A review of extant literature and recent trends in residential construction waste reduction. Waste Manag. Res. 2025, 43, 322–338. [Google Scholar] [CrossRef]

- Li, Y.; Li, M.; Sang, P. A bibliometric review of studies on construction and demolition waste management by using CiteSpace. Energy Build. 2022, 258, 111822. [Google Scholar] [CrossRef]

- Alhawamdeh, M.; Lee, A. Construction Waste Minimization: A Narrative Review. Int. J. Environ. Sustain. 2021, 18, 1–33. [Google Scholar] [CrossRef]

- Zaman, A.; Ruiz, A.M.C.; Shooshtarian, S.; Ryley, T.; Caldera, S.; Maqsood, T. Development of the Circular Economy Design Guidelines for the Australian Built Environment Sector. Sustainability 2023, 15, 2500. [Google Scholar] [CrossRef]

- Park, J.; Tucker, R. Overcoming barriers to the reuse of construction waste material in Australia: A review of the literature. Int. J. Constr. Manag. 2017, 17, 228–237. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.C.; Tam, V.W.Y. Effective construction and demolition waste management assessment through waste management hierarchy; a case of Australian large construction companies. J. Clean. Prod. 2021, 312, 127790. [Google Scholar] [CrossRef]

- Zhao, X.; Webber, R.; Kalutara, P.; Browne, W.; Pienaar, J. Construction and demolition waste management in Australia: A mini-review. Waste Manag. Res. 2022, 40, 34–46. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Maqsood, T.; Caldera, S.; Ryley, T. Transformation towards a circular economy in the Australian construction and demolition waste management system. Sustain. Prod. Consum. 2022, 30, 89–106. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Maqsood, T.; Wong, P.S.P.; Yang, R.J.; Khalfan, M. Review of waste strategy documents in Australia: Analysis of strategies for construction and demolition waste. Int. J. Environ. Technol. Manag. 2020, 23, 1–21. [Google Scholar] [CrossRef]

- Shahid, M.U.; Ali, M. Enablers and Policy Framework for Construction Waste Minimization Under Circular Economy: Stakeholder Perspectives. Sustainability 2025, 17, 4129. [Google Scholar] [CrossRef]

- Dilogini, R.A.A.; Karunasena, G.; Udawatta, N.; Liu, C. Are Australian Construction and Demolition Waste Management Research Efforts Coherent with Policy Targets? In Global Net Zero Carbon Practices in Construction; Domingo, N., Senarathne, S., Wilkinson, S., Perera, S., Eds.; Springer Nature: Singapore, 2025; pp. 135–153. [Google Scholar] [CrossRef]

- Department of Climate Change, Energy, the Environment and Water (DCCEEW). National Waste Policy Action Plan 2019. 2019. Available online: https://www.dcceew.gov.au/environment/protection/waste/publications/national-waste-policy-action-plan (accessed on 27 July 2025).

- Shooshtarian, S.; Maqsood, T.; Wong, P.S.P.; Bettini, L. Application of Sustainable Procurement Policy to Improve the Circularity of Construction and Demolition Waste Resources in Australia. Mater. Circ. Econ. 2022, 4, 27. [Google Scholar] [CrossRef]

- Adams, K.; Hobbs, G. Material Resource Efficiency in Construction: Supporting a Circular Economy (FB 85); BRE Electronic Publications: Watford, UK, 2017. [Google Scholar]

- US EPA. Best Practices for Reducing, Reusing, and Recycling Construction and Demolition Materials|US EPA. United States Environmental Protection Agency. Available online: https://www.epa.gov/smm/best-practices-reducing-reusing-and-recycling-construction-and-demolition-materials (accessed on 1 March 2023).

- Osmani, M. Construction Waste. In Waste; Letcher, T.M., Vallero, D.A., Eds.; Academic Press: Boston, MA, USA, 2011; pp. 207–218. [Google Scholar] [CrossRef]

- Zero Waste Scotland. Best Practice Guide to Improving Waste Management on Construction Sites. Available online: https://www.zerowastescotland.org.uk/resources/improving-waste-management-construction-sites (accessed on 21 June 2025).

- Fikri Hasmori, M.; Zin, A.F.M.; Nagapan, S.; Deraman, R.; Abas, N.; Yunus, R.; Klufallah, M. The on-site waste minimization practices for construction waste. IOP Conf. Ser. Mater. Sci. Eng. 2020, 713, 012038. [Google Scholar] [CrossRef]

- Esa, M.R.; Halog, A.; Rigamonti, L. Strategies for minimizing construction and demolition wastes in Malaysia. Resour. Conserv. Recycl. 2017, 120, 219–229. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W.Y. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Zhao, X.B. Stakeholder-Associated Factors Influencing Construction and Demolition Waste Management: A Systematic Review. Buildings 2021, 11, 149. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Kadiri, K.O. Reducing waste to landfill: A need for cultural change in the UK construction industry. J. Build. Eng. 2016, 5, 185–193. [Google Scholar] [CrossRef]

- Meshref, A.N.; Elkasaby, E.A.F.A.; Farid, A.A.K.M. Reducing construction waste in the construction life cycle of industrial projects during design phase by using system dynamics. J. Build. Eng. 2023, 69, 106302. [Google Scholar] [CrossRef]

- Bilal, M.; Oyedele, L.O.; Akinade, O.O.; Delgado, J.M.D.; Akanbi, L.A.; Ajayi, A.O.; Younis, M.S. Design optimisation using convex programming: Towards waste-efficient building designs. J. Build. Eng. 2019, 23, 231–240. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, 71. [Google Scholar] [CrossRef]

- Covidence. Covidence—Better Systematic Review Management. Available online: https://www.covidence.org/ (accessed on 25 May 2023).

- Zou, P.; Hardy, R.; Yang, R. Barriers to Building and Construction Waste Reduction, Reuse and Recycling: A case study of the Australian Capital Region. In Building Today—Saving Tomorrow: Sustainability in Construction and Deconstruction Conference Proceedings; Unitec Institute of Technology: Auckland, New Zealand, 2015; pp. 27–35. [Google Scholar]

- Lumivero. NVivo—Lumivero. Available online: https://lumivero.com/products/nvivo/ (accessed on 25 May 2023).

- Skjott Linneberg, M.; Korsgaard, S. Coding qualitative data: A synthesis guiding the novice. Qual. Res. J. 2019, 19, 259–270. [Google Scholar] [CrossRef]

- Faniran, O.O.; Caban, G. Minimizing waste on construction project sites. Eng. Constr. Arch. Manag. 1998, 5, 182–188. [Google Scholar] [CrossRef]

- Lingard, H.; Gilbert, G.; Graham, P. Improving solid waste reduction and recycling performance using goal setting and feedback. Constr. Manag. Econ. 2001, 19, 809–817. [Google Scholar] [CrossRef]

- Brewer, G.; Mooney, J. A best practice policy for recycling and reuse in building. Proc. Inst. Civ. Eng. Eng. Sustain. 2008, 161, 173–180. [Google Scholar] [CrossRef]

- Li, M.; Yang, J. Critical factors for waste management in office building retrofit projects in Australia. Resour. Conserv. Recycl. 2014, 93, 85–98. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Zeng, S.X.; Le, K.N. Green evaluation systems for project sustainability. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2015, 168, 177–185. [Google Scholar] [CrossRef]

- Udawatta, N.; Zuo, J.; Chiveralls, K.; Zillante, G. Attitudinal and behavioural approaches to improving waste management on construction projects in Australia: Benefits and limitations. Int. J. Constr. Manag. 2015, 15, 137–147. [Google Scholar] [CrossRef]

- Udawatta, N.; Zuo, J.; Chiveralls, K.; Zillante, G. Improving waste management in construction projects: An Australian study. Resour. Conserv. Recycl. 2015, 101, 73–83. [Google Scholar] [CrossRef]

- Moreton, A.; Coffey, V.; Sadiqi, Z. Training for reduction of design waste. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2016, 169, 123–130. [Google Scholar] [CrossRef]

- Forsythe, P.; Fini, A.A.F. Quantifying demolition fitout waste from Australian office buildings. Facilities 2018, 36, 600–617. [Google Scholar] [CrossRef]

- Moussavi Nadoushani, Z.S.; Hammad, A.W.A.; Xiao, J.; Akbarnezhad, A. Minimizing cutting wastes of reinforcing steel bars through optimizing lap splicing within reinforced concrete elements. Constr. Build. Mater. 2018, 185, 600–608. [Google Scholar] [CrossRef]

- Forghani, R.; Sher, W.; Kanjanabootra, S. Critical technical design principles for maximizing the reuse of building components. Int. J. Constr. Manag. 2021, 23, 1187–1195. [Google Scholar] [CrossRef]

- Haeusler, M.H.; Gardner, N.; Yu, D.K.; Oh, C.; Huang, B. (Computationally) designing out waste: Developing a computational design workflow for minimising construction and demolition waste in early-stage architectural design. Int. J. Arch. Comput. 2021, 19, 594–611. [Google Scholar] [CrossRef]

- Doust, K.; Battista, G.; Rundle, P. Front-end construction waste minimization strategies. Aust. J. Civ. Eng. 2021, 19, 1–11. [Google Scholar] [CrossRef]

- Al-Hamadani, S.; Egbelakin, T.; Sher, W.; Von Meding, J. Drivers of applying ecological modernization to construction waste minimization in New South Wales construction industry. Constr. Econ. Build. 2021, 21, 80–104. [Google Scholar] [CrossRef]

- Loizou, L.; Barati, K.; Shen, X.; Li, B. Quantifying advantages of modular construction: Waste generation. Buildings 2021, 11, 622. [Google Scholar] [CrossRef]

- Jahan, I.; Zhang, G.; Bhuiyan, M.; Navaratnam, S.; Shi, L. Experts’ Perceptions of the Management and Minimisation of Waste in the Australian Construction Industry. Sustainability 2022, 14, 11319. [Google Scholar] [CrossRef]

- Newaz, M.T.; Davis, P.; Sher, W.; Simon, L. Factors affecting construction waste management streams in Australia. Int. J. Constr. Manag. 2022, 22, 2625–2633. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Caldera, S.; Maqsood, T.; Ryley, T.; Khalfan, M. An investigation into challenges and opportunities in the Australian construction and demolition waste management system. Eng. Constr. Arch. Manag. 2022, 29, 4313–4330. [Google Scholar] [CrossRef]

- Amarasinghe, I.; Hong, Y.; Stewart, R.A. Visualising a framework for enhancing material circularity in building construction projects: Drivers, barriers, and strategies. Build. Environ. 2024, 253, 111359. [Google Scholar] [CrossRef]

- Lim, B.T.H.; Oo, B.L.; McLeod, C.; Yang, P. Institutional and Actor Network Perspectives of Waste Management in Australia: Is the Construction Industry Prepared for a Circular Economy? Sustainability 2024, 16, 617. [Google Scholar] [CrossRef]

- She, Y.; Udawatta, N.; Liu, C.; Tokede, O. Circular Economy-Related Strategies to Minimise Construction and Demolition Waste Generation in Australian Construction Projects. Buildings 2024, 14, 2487. [Google Scholar] [CrossRef]

- Hassan, N.M.; Alashwal, A. Developing a model for the implementation of designing out waste in construction. Arch. Eng. Des. Manag. 2025, 21, 154–170. [Google Scholar] [CrossRef]

- WALGA (Western Australian Local Government Association). Construction Waste Management Plan Guidelines: A resource for Western Australian Local Government, Developers, Property Owners and Builders; Western Australian Local Government Association: West Perth, Australia, 2014. [Google Scholar]

- MBAV. The Resource Efficient Builder: A Simple Guide to Reducing Waste; Master Builders Association of Victoria: Melbourne, Australia, 2004. [Google Scholar]

- Hyder Consulting. Construction and Demolition Waste Status Report—Management of Construction and Demolition Waste in Australia. 2011. Available online: https://www.dcceew.gov.au/environment/protection/waste/publications/construction-and-demolition-waste-status-report (accessed on 21 June 2025).

- Crossin, E.; Hedayati, M.; Clune, S. Waste Avoidance and Reuse Strategies for Residential Buildings in Australia; RMIT University Centre for Design and Society: Melbourne, Australian, 2014. [Google Scholar]

- University of Queensland. Construction & Demolition Waste Reduction Guideline. 2016. Available online: https://sustainability.uq.edu.au/files/9576/Gde_ConstrnDemoWaste.pdf (accessed on 21 June 2025).

- Australian Government. Your Home: Australia’s Guide to Environmentally Sustainable Homes; Waste Minimisation. 2023. Available online: https://www.yourhome.gov.au/materials/waste-minimisation (accessed on 21 June 2025).

- Shooshtarian, S.; Maqsood, T.; Wong, P.S.P.; Khalfan, M.; Yang, R.J. Extended Producer Responsibility in the Australian Construction Industry. Sustainability 2021, 13, 620. [Google Scholar] [CrossRef]

- Böhme, T.; Escribano, A.; Heffernan, E.E.; Beazley, S. Causes and mitigation for declining productivity in the Australian mid-rise residential construction sector. Built Environ. Proj. Asset Manag. 2018, 8, 253–266. [Google Scholar] [CrossRef]

- López-Guerrero, R.E.; Vera, S.; Carpio, M. A quantitative and qualitative evaluation of the sustainability of industrialised building systems: A bibliographic review and analysis of case studies. Renew. Sustain. Energy Rev. 2022, 157, 112034. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).