Circular Economy in the Construction Sector in Materials, Processes, and Case Studies: Research Review

Abstract

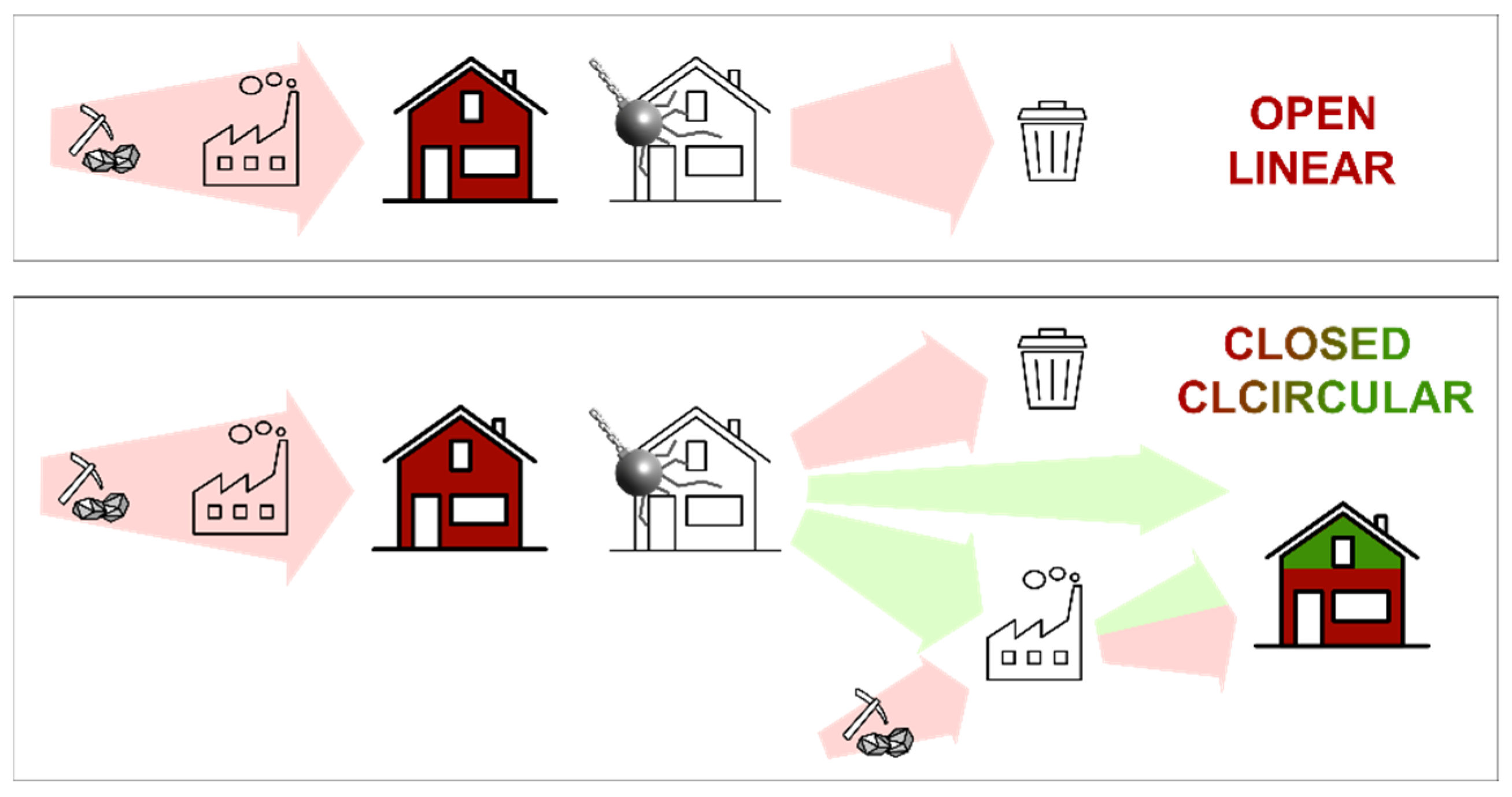

1. Introduction

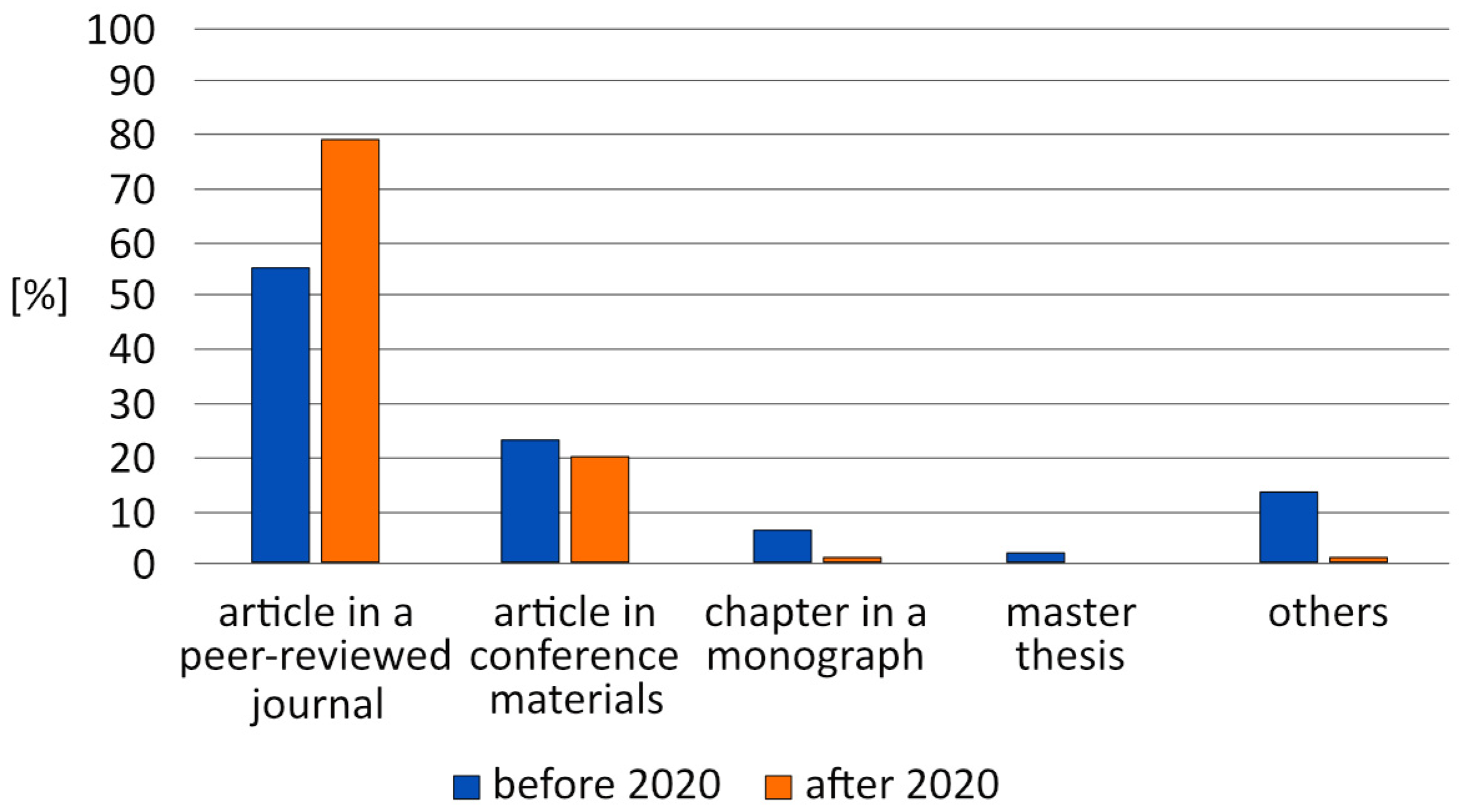

2. Materials and Methods

- Economic and environmental value of material recovery in demolition–25 articles were selected,

- Recycled building materials: quality and durability analysis–24 articles were selected,

- Legal framework for the reuse of demolished materials in Europe–25 articles were selected.

- Building materials produced using recycling and reuse of building materials from demolition, methods of their recovery,

- Methods for assessing the quality of recycled materials and their properties,

- Use of digital technology in the design process, especially in assessing the life cycle of a building,

- Examples of implementing recycling technologies for the production of building materials or the use of demolition elements,

- Circular economy in the field of construction in the aspect of building materials, as well as processing and design processes,

- European context in the aspect of the regulatory framework.

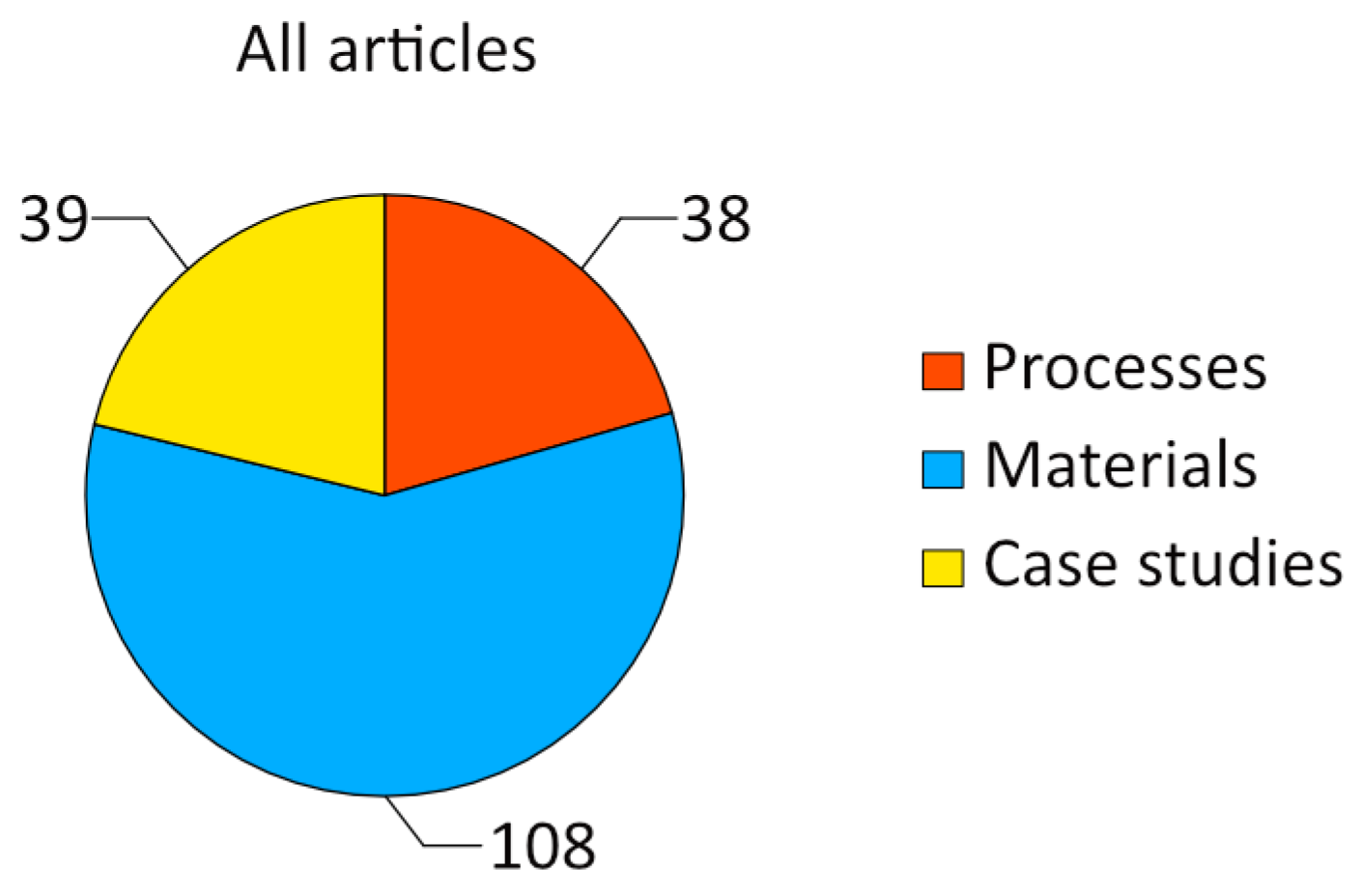

- Design processes, such as design for assembly DfD (and reuse), BIM data management, or construction and demolition waste (CDW) management,

- Material processing, when a manufactured component is reused or recycled to obtain a new one;

- Case studies, with practical applications of the circular economy and secondary use of materials.

3. Results

3.1. Materials

3.2. Processes

3.3. Case Studies

4. Discussion

5. Conclusions

- Currently, many building materials are recycled, including concrete, wood, glass, steel, and plastics.

- A definite advantage is seen in concrete research, which creates a gap between the other materials. Many of them are being used as concrete fillers, greatly expanding the possibilities of obtaining concrete with favourable environmental properties.

- In the case of steel and wood, the main limitations are the original properties of these materials, which, over time, highlight their defects. Prevention and technological advances would make it possible to prevent corrosion.

- Prevention and technological advances would make it possible to prevent fungi and pests in the case of wood, which is also used in other areas, such as the furniture or finishing market.

- A need to create a database of demolition materials with information on their parameters.

- Various solutions are proposed, but all have in common centralisation and access for a large group of potential recipients.

- The potential for reusing building materials can be increased through the use of digital support tools such as databases, material passports, and BIM technologies, which enable data collection and analysis. Integrating artificial intelligence can significantly increase the efficiency of processes in a circular economy.

- It would be beneficial to develop and improve new applications and plug-ins for various software to collect, analyse, and share information on building materials that will be suitable for reuse.

- The inclusion of AI tools in the analysis of large amounts of data may also have great potential.

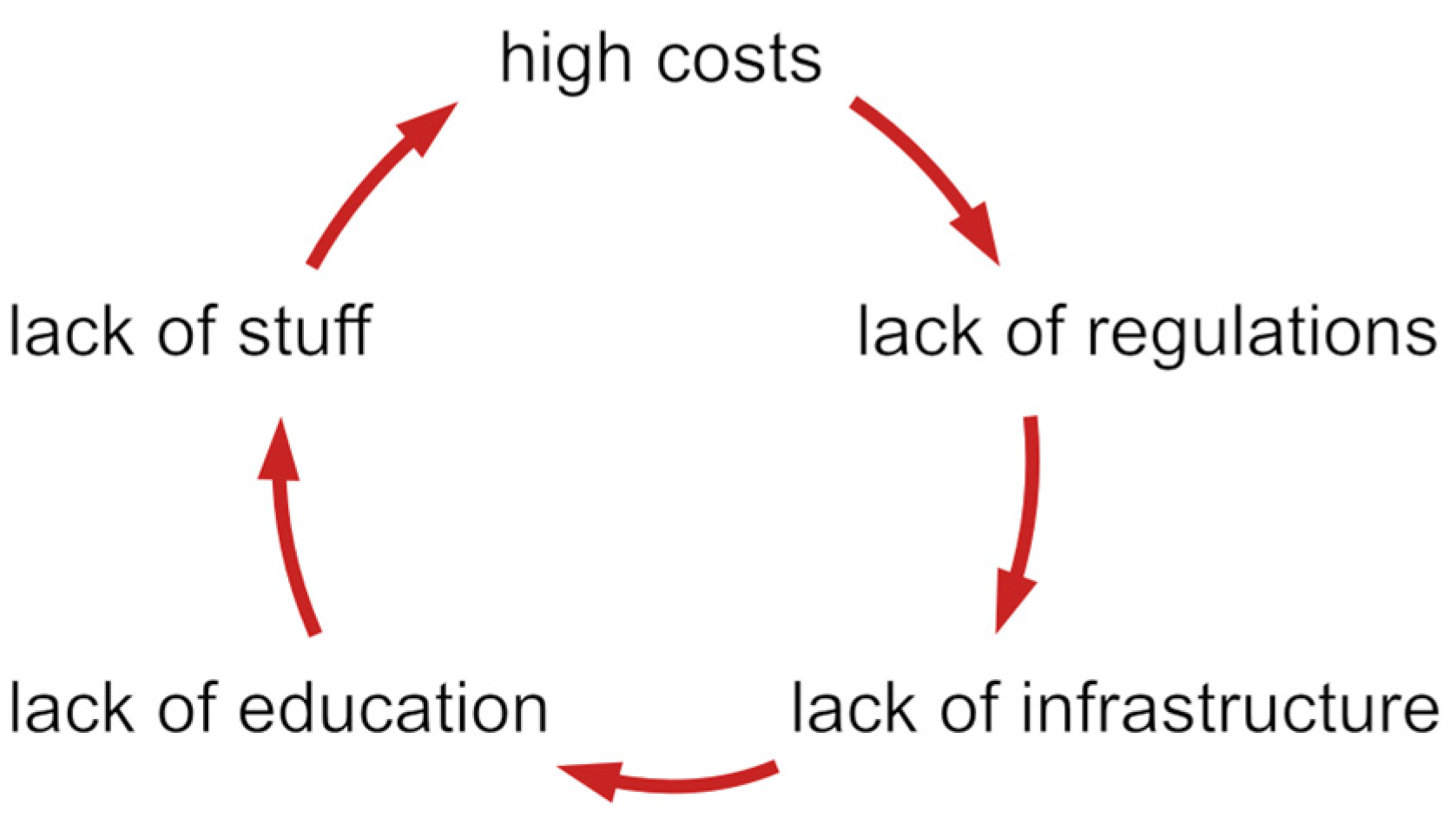

- The lack of standardised regulations and limited LCA tools hinders the assessment of CO2 emissions in construction and the comparison of results. Legislative action and the development of professional education in collaboration with companies implementing new circular economy technologies are needed.

- Due to the large variety of processes in different countries, standardisation of regulations may be difficult, but there is room for joint action to develop standards, optimisation, and good practices that, if tested on a small scale, could be implemented in other countries.

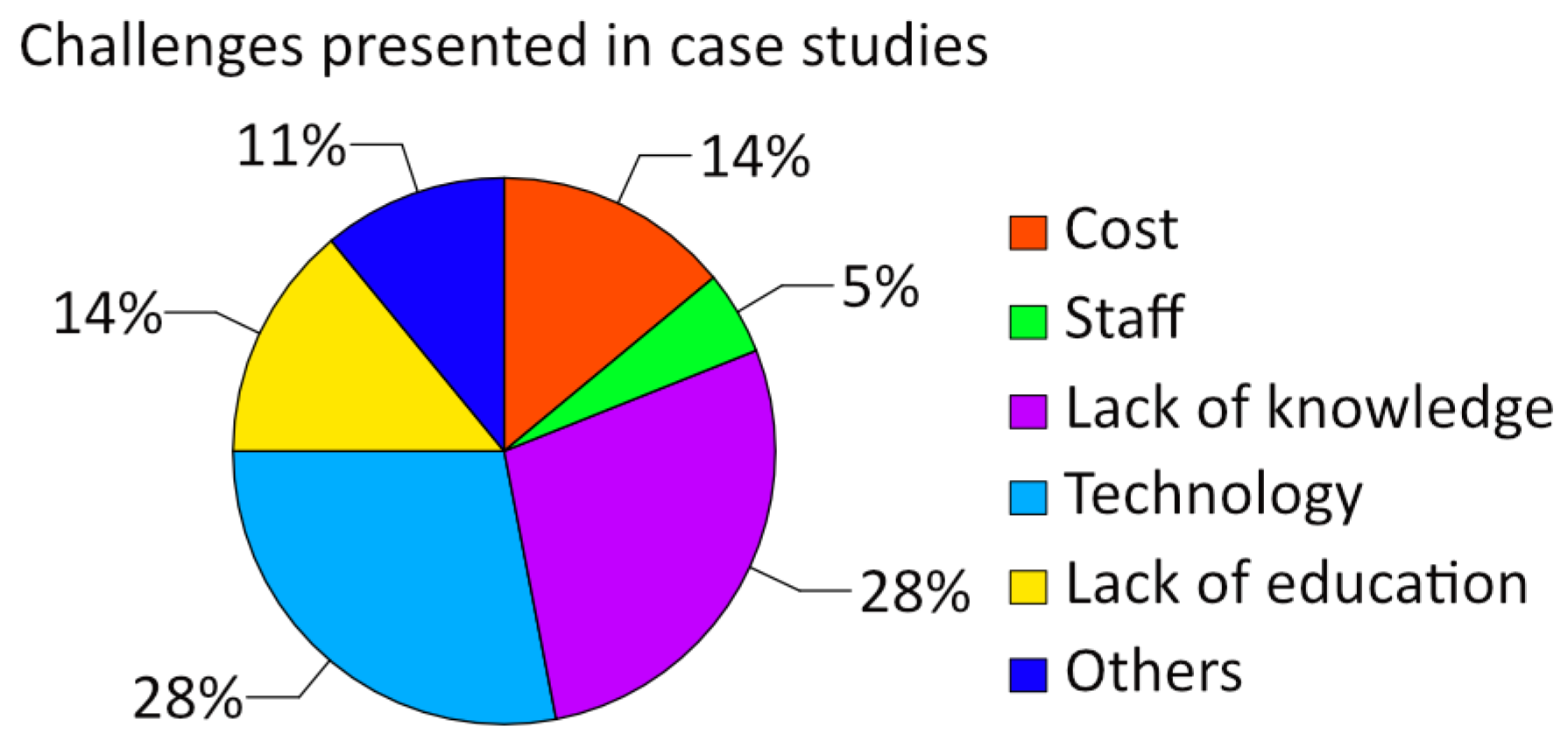

- Reusing building components is a sustainable solution that can reduce the environmental impact of construction, but its implementation is hampered by technological, economic, and organisational barriers.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| LCA | Life Cycle Analysis |

| GWP | Global Warning Potential |

| CDW | Construction and Demolition Waste |

| DfD&R | Design for Disassembly and Reuse |

| OSB | Oriented Strand Board |

| GIS | Geographic Information System |

| BIM | Building Information Modelling |

| AI | Artificial Intelligence |

References

- Hamilton, I.; Kennard, H.; Rapf, O.; Kockat, J.; Zuhaib, S.; Toth, Z.; Barrett, M.; Milne, C.; Delmastro, C.; Monschauer; et al. The Global Status Report for Buildings and Construction; United Nations Environment Programme: Nairobi, Kenya, 2022; ISBN 978-92-807-3984-8. [Google Scholar]

- Véliz, K.D.; Busco, C.; Walters, J.P.; Esparza, C. Circular Economy for Construction and Demolition Waste in the Santiago Metropolitan Region of Chile: A Delphi Analysis. Sustainability 2025, 17, 1057. [Google Scholar] [CrossRef]

- Nadazdi, A.; Naunovic, Z.; Ivanisevic, N. Circular Economy in Construction and Demolition Waste Management in the Western Balkans: A Sustainability Assessment Framework. Sustainability 2022, 14, 871. [Google Scholar] [CrossRef]

- Godina, M.; Gowler, P.; Rose, C.M.; Wiegand, E.; Mills, H.F.; Koronaki, A.; Ramage, M.H.; Shah, D.U. Strategies for Salvaging and Repurposing Timber Elements from Existing Buildings in the UK. J. Clean. Prod. 2025, 489, 144629. [Google Scholar] [CrossRef]

- Gnatiuk, L.; Novik, H.; Melnyk, M. Recycling and Upcycling in Construction. Theory Pract. Des. 2022, 25, 130–139. [Google Scholar] [CrossRef]

- Kralj, D.; Markič, M. Building Materials Reuse and Recycle. WSEAS Trans. Environ. Dev. 2008, 4, 409–418. [Google Scholar]

- Webb, R.S.; Thomson, D.S.; Kelly, J.R. Building Services Component Reuse: A Response to the Need for Adaptability. Build. Serv. Eng. Res. Technol. 2000, 21, 91–97. [Google Scholar] [CrossRef]

- Turku, I.; Keskisaari, A.; Kärki, T.; Puurtinen, A.; Marttila, P. Characterization of Wood Plastic Composites Manufactured from Recycled Plastic Blends. Compos. Struct. 2016, 161, 469–476. [Google Scholar] [CrossRef]

- Bertin, I.; Lebrun, F.; Braham, N.; Le Roy, R. Construction, Deconstruction, Reuse of the Structural Elements: The Circular Economy to Reach Zero Carbon. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012020. [Google Scholar] [CrossRef]

- Pecur, I.B.; Štirmer, N.; Milovanovic, B. Durability Properties of Recycled Aggregate Concrete. In Proceedings of the RILEM International Workshop on Performance-Based Specification and Control of Concrete Durability, Zagreb, Croatia, 11–13 June 2014; pp. 191–198, ISBN 978-2-35158-135-3. [Google Scholar]

- De Luca, P.; Carbone, I.; Nagy, J.B. Green Building Materials: A Review of State of the Art Studies of Innovative Materials. J. Green. Build. 2017, 12, 141–161. [Google Scholar] [CrossRef]

- Pierluca, V.; Noemi, A.; Di Gregorio, F.; Umberto, A. Life Cycle Assessment of the End-of-Life Phase of a Residential Building. Waste Manag. 2017, 60, 311–321. [Google Scholar] [CrossRef]

- Francesconi, L. New Building Materials in Structural Engineering: Structural Concretes Made with Coarse and Fine Recycled Aggregates. Ph.D. Thesis, University of Cagliari, Cagliari, Italy, 2012. [Google Scholar]

- Kasai, Y.; Kawamura, M.; Zhou, J. Production Process and Bending/Compressive Strength of Wood-Chip Concrete with Demolished-Timber. J. Struct. Constr. Eng. (Trans. AIJ) 1995, 60, 1–10. [Google Scholar] [CrossRef][Green Version]

- Posi, P.; Foytong, P.; Thongjapo, P.; Thamultree, N.; Boontee, P.; Kasemsiri, P.; Cao, T.; Chindaprasirt, P. Preliminary Study of Pressed Lightweight Geopolymer Block Using Fly Ash, Portland Cement and Recycled Lightweight Concrete. Key Eng. Mater. 2016, 718, 184–190. [Google Scholar] [CrossRef]

- Pangdaeng, S.; Phoo-ngernkham, T.; Sata, V.; Chindaprasirt, P. Influence of Curing Conditions on Properties of High Calcium Fly Ash Geopolymer Containing Portland Cement as Additive. Mater. Des. 2014, 53, 269–274. [Google Scholar] [CrossRef]

- Layachi, B.; Nourredine, A.; Laurent, M.; Raoul, J. Propriétés Mécaniques et Durabilité Des Bétons à Base de Graviers et s Ables Recyclés Issus de Béton de Démolition. In Proceedings of the Deuxième Conférence Internationale Francophone Nouveaux Matériaux et Durabilité, Douai, France, 16–17 November 2015; hal-01366521. Available online: https://hal.science/hal-01366521v1/document (accessed on 26 March 2025).

- Xanthos, M.; Dey, S.K.; Mitra, S.; Yilmazer, U.; Feng, C. Prototypes for Building Applications Based on Thermoplastic Composites Containing Mixed Waste Plastics. Polym. Compos. 2002, 23, 153–163. [Google Scholar] [CrossRef]

- Keskisaari, A.; Kärki, T. Raw Material Potential of Recyclable Materials for Fiber Composites: A Review Study. J. Mater. Cycles Waste Manag. 2016, 19, 1136–1143. [Google Scholar] [CrossRef]

- de Brito, J.; Goncalves, A.P.; dos Santos, R.R. Recycled Concrete Production. Multiple Recycling of Concrete Coarse Aggregates. Rev. Ing. De Constr. 2006, 21, 33–40. [Google Scholar]

- Purnell, P.; Dunster, A. 20-Recycling of Concrete. In Management, Recycling and Reuse of Waste Composites; Woodhead Publishing Series in Composites Science and Engineering; Goodship, V., Ed.; Woodhead Publishing: Cambridge, UK, 2010; pp. 569–591. ISBN 978-1-84569-462-3. [Google Scholar]

- De Venny, A.S. Recycling of Demolished Masonry Rubble. Ph.D. Thesis, Napier University, Napier, New Zealand, 1999. Available online: https://napier-repository.worktribe.com/output/281000/recycling-of-demolished-masonry-rubble (accessed on 28 March 2025).

- Charytonowicz, J.; Skowroński, M. Reuse of Building Materials. Procedia Manuf. 2015, 3, 1633–1637. [Google Scholar] [CrossRef]

- Joseph, P.; Tretsiakova-McNally, S. Sustainable Non-Metallic Building Materials. Sustainability 2010, 2, 400–427. [Google Scholar] [CrossRef]

- Durmisevic, E.; Beurskens, P.R.; Adrosevic, R.; Westerdijk, R. Systemic View on Reuse Potential of Building Elements, Components and Systems: Comprehensive Framework for Assessing Reuse Potential of Buil Ding Elements. In Proceedings of the International HISER Conference on Advances in Recycling and Management of Construction and Demolition Waste, Delft, The Netherlands, 21–23 June 2017. [Google Scholar]

- Briga-Sá, A.; Nascimento, D.; Teixeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile Waste as an Alternative Thermal Insulation Building Material Solution. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar] [CrossRef]

- Guy, B. The Optimization of Building Deconstruction for Department of Defense Facilities: Ft. McClellan Deconstruction Project. J. Green. Build. 2006, 1, 102–122. [Google Scholar] [CrossRef]

- Keskisaari, A.; Kärki, T. The Use of Waste Materials in Wood-Plastic Composites and Their Impact on the Profitability of the Product. Resour. Conserv. Recycl. 2018, 134, 257–261. [Google Scholar] [CrossRef]

- Bojan, M.; Marina, B.; Ivana, B.P.; Nina, Š. Use of Recycled Aggregate Concrete for Energy Efficient Buildings. 3rd R.N. In Proceedings of the Raikar Memorial International Conference and Gettu-Kodur International Symposium on Advances in Science and Technology of Concrete, Mumbai, India, 14–15 December 2018. [Google Scholar]

- Hobbs, G.; Adams, K. Reuse of Building Products and Materials—Barriers and Opportunities. In Proceedings of the International HISER Conference on Advances in Recycling and Management of Construction and Demolition Waste, Delft, The Netherlands, 21–23 June 2017. [Google Scholar]

- Keskisaari, A.; Kärki, T. Utilization of Industrial Wastes from Mining and Packaging Industries in Wood-Plastic Composites. J. Polym. Env. 2018, 26, 1504–1510. [Google Scholar] [CrossRef]

- Bouslamti, A.; Irle, M.A.; Salvador, V.; Bondu, M.; Hulo, S.; Caron, B. Why Simulate a Sample of Recycled Wood? Maderas Cienc. tecnol. 2012, 14, 145–153. [Google Scholar] [CrossRef]

- Ankur, G. Accelerating Circularity in Built-Environment through ‘Active-Procurem Ent’: An Aggregated Assessment Framework to Make Sustainable Choices w Hile Using Secondary Material at Early Design Phase. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2019. Available online: https://resolver.tudelft.nl/uuid:6bdb4827-82f5-43c7-aba9-79c0db9e6ef5 (accessed on 8 April 2025).

- Lantz, S.F.; Falk, R.H.; Feasibility of Recycling Timber from Military Industrial Buildings. Use of Recycled Wood and Paper in Building Applications. Available online: https://www.fpl.fs.usda.gov/documnts/pdf1997/lantz97a.pdf (accessed on 25 March 2025).

- Zaman, A.; Arnott, J.; Mclntyre, B.K.; Hannon, J. Resource Harvesting through a Systematic Deconstruction of the Residential House: A Case Study of the ‘Whole House Reuse’ Project in Christc Hurch, New Zealand. Sustainability 2018, 10, 3430. [Google Scholar] [CrossRef]

- Brütting, J.; De Wolf, C.; Fivet, C. The Reuse of Load-Bearing Components. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012025. [Google Scholar] [CrossRef]

- Yeung, J.; Walbridge, S.; Haas, C.; Saari, R. Understanding the Total Life Cycle Cost Implications of Reusing Structural Steel. Env. Syst. Decis. 2017, 37, 101–120. [Google Scholar] [CrossRef]

- Sigrid Nordby, A. Barriers and Opportunities to Reuse of Building Materials in the Norwegian Construction Sector. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012061. [Google Scholar] [CrossRef]

- Bertin, I.; Ferraille, A.; Laratte, B.; Roy, R. Design for Reuse (DfReu) Applied to Buildings; Anticipate Disassembly for the End-of-Life (EoL), in Order to Preserve Resources. In Proceedings of the Eco Design 2019 International Symposium, Yokohama, Japan, 25–27 November 2019. [Google Scholar] [CrossRef]

- Serwanja, E.; Sheidaei, M. Evaluation of Recycling & Reuse of Building Materials from Demolition: Cost Feasibility and Environmental Impact Assessment. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2016. Available online: https://odr.chalmers.se/server/api/core/bitstreams/4851b7c5-6a7e-4d98-958f-f3d18fad944d/content (accessed on 20 March 2025).

- Murray, R. Construction and Demolition Waste in Western Australia: A Case Study on Best Practice Demolition. Licentiate Thesis, Murdoch University, Perth, Australia, 2019. [Google Scholar]

- Pantini, S.; Rigamonti, L. Is Selective Demolition Always a Sustainable Choice? Waste Manag. 2019, 103, 169–176. [Google Scholar] [CrossRef]

- Hebel, D.E.; Wisniewska, M.H.; Heisel, F. Building from Waste: Recovered Materials in Architecture and Construction; DE GRUYTER: Berlin/Heidelberg, Germany, 2014; ISBN 978-3-03821-584-4. [Google Scholar]

- Debacker, W.; Manshoven, S.; Peters, M.; Ribeiro, A.; Weerdt, R.Y. Circular Economy and Design for Change within the Built Environment: P Reparing the Transition. In Proceedings of the International HISER Conference on Advances in Recycling and Management of Construction and Demolition Waste, Delft, The Netherland, 21–23 June 2017; Available online: https://www.bamb2020.eu/wp-content/uploads/2017/07/Circular-economy-and-design-for-change-within-the-built-environment_prep....pdf (accessed on 15 March 2025).

- Pecur, I.B.; Strimer, N.; Milovanovic, B. Innovative Prefabricated System with Recycled CDW for New and Renovation of Existing Buildings. In Proceedings of the Advances in Civil, Environmental, and Materials Research (ACEM14), Busan, Republic of Korea, 24–28 August 2014; Available online: https://www.academia.edu/68484370/Innovative_prefabricated_system_with_recycled_CDW_for_new_and_renovation_of_existing_buildings (accessed on 16 March 2025).

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Kellenberger, D.; Althaus, H.-J. Relevance of Simplifications in LCA of Building Components. Build. Environ. 2009, 44, 818–825. [Google Scholar] [CrossRef]

- Lassandro, P. Deconstruction Case Study in Southern Italy: Economic and Environmental Assessment. In Proceedings of the 11th Rinker International Conference, Gainesville, FL, USA, 7–10 May 2003; Available online: https://www.irbnet.de/daten/iconda/CIB860.pdf (accessed on 20 March 2025).

- Keskisaari, A.; Butylina, S.; Kärki, T. Use of Construction and Demolition Wastes as Mineral Fillers in Hybrid Wood-Polymer Composites. J. Appl. Polym. Sci. 2016, 133, 43412. [Google Scholar] [CrossRef]

- Forsythe, P. Drivers of Housing Demolition Decision Making and the Impact on Timber Waste Management. Constr. Econ. Build. 2011, 11, 1–14. [Google Scholar] [CrossRef]

- Altamura, P.; Baiani, S. Superuse and Upcycling through Design: Approaches and Tools. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012014. [Google Scholar] [CrossRef]

- Stokke, D.D. Micro and Macromorphology of Recycled Fiber and Wood. MRS Online Proc. Libr. 1992, 266, 47–63. [Google Scholar] [CrossRef]

- Alotaibi, S.; Martinez-Vazquez, P.; Baniotopoulos, C. Advancing Circular Economy in Construction Mega-Projects: Awareness, Key Enablers, and Benefits—Case Study of the Kingdom of Saudi Arabia. Buildings 2024, 14, 2215. [Google Scholar] [CrossRef]

- Amudjie, J.; Agyekum, K.; Adinyira, E.; Amos-Abanyie, S.; Kumah, V.M.A. Awareness and Practice of the Principles of Circular Economy among Built Environment Professionals. Built Environ. Proj. Asset Manag. 2023, 13, 140–156. [Google Scholar] [CrossRef]

- Gebremariam, A.T.; Vahidi, A.; Di Maio, F.; Moreno-Juez, J.; Vegas-Ramiro, I.; Łagosz, A.; Mróz, R.; Rem, P. Comprehensive Study on the Most Sustainable Concrete Design Made of Recycled Concrete, Glass and Mineral Wool from C&D Wastes. Constr. Build. Mater. 2021, 273, 121697. [Google Scholar] [CrossRef]

- Dosho, Y. Contributions of Concrete Recycling Technology toward Sustainable Development: Standards and Technologies Related to Recycled Aggregate Concrete in Japan. J. Mater. Eng. Struct. 2020, 7, 525–549. [Google Scholar]

- Silva, S.; Evangelista, L.; de Brito, J. Durability and Shrinkage Performance of Concrete Made with Coarse Mult I-Recycled Concrete Aggregates. Constr. Build. Mater. 2021, 272, 121645. [Google Scholar] [CrossRef]

- Drochytka, R.; Dufek, Z.; Michalčíková, M.; Hodul, J. Study of Possibilities of Using Special Types of Building and Demolition Waste in Civil Engineering. Period. Polytech. Civ. Eng. 2020, 64, 304–314. [Google Scholar] [CrossRef]

- Sheikh Hassani, M.; Matos, J.C.; Zhang, Y.X.; Teixeira, E. Concrete Production with Domestic and Industrial Wastewaters—A Literature Review. Struct. Concr. 2023, 24, 5582–5599. [Google Scholar] [CrossRef]

- Hasan, E. Feasibility of Recycling Concrete Construction Waste in Environmental and Economic Sides. FES J. Eng. Sci. 2021, 11, 20–30. [Google Scholar] [CrossRef]

- Skocek, J.; Ouzia, A.; Vargas Serrano, E.; Pato, N. Recycled Sand and Aggregates for Structural Concrete: Toward the Indus Trial Production of High-Quality Recycled Materials with Low Water Absorption. Sustainability 2024, 16, 814. [Google Scholar] [CrossRef]

- Nielsen-Roine, K.; Meyboom, A. Seven Generations for Wood. In Proceedings of the 112th ACSA Annual Meeting Proceedings, Disruptors on the Edge, Vancouver, BC, Canada, 14–16 March 2024. [Google Scholar] [CrossRef]

- Dias, S.; Tadeu, A.; Almeida, J.; Humbert, P.; António, J.; de Brito, J.; Pinhão, P. Physical, Mechanical, and Durability Properties of Concrete Containing Wood Chips and Sawdust: An Experimental Approach. Buildings 2022, 12, 1277. [Google Scholar] [CrossRef]

- Ren, X. Application and Performance Evaluation of Recycled Building Materials in Civil Engineering. Appl. Comput. Eng. 2024, 78, 1–9. [Google Scholar] [CrossRef]

- Findik, F.; Findik, F. Civil Engineering Materials. Herit. Sustain. Dev. 2021, 3, 154–172. [Google Scholar] [CrossRef]

- Ribeiro, L.S.; Stolz, C.M.; Amario, M.; Silva, A.L.N.D.; Haddad, A.N. Use of Post-Consumer Plastics in the Production of Wood-Plastic Composites for Building Components: A Systematic Review. Energies 2023, 16, 6549. [Google Scholar] [CrossRef]

- Egonzalez, R.; Stephens, M.T.; Toma, C.; Dowdell, D. The Estimated Carbon Cost of Concrete Building Demolitions following the Canterbury Earthquake Sequence. Earthq. Spectra 2022, 38, 1615–1635. [Google Scholar] [CrossRef]

- Stepien, A.; Wojarska-Gniady, P. Recycling in Construction—Characteristics of Composite and Recycled Materials Used in Structural Elements of Buildings. Energy Clean Technol. 2023, 23, 61–70. [Google Scholar] [CrossRef]

- Lamba, P.; Kaur, D.P.; Raj, S.; Sorout, J. Recycling/Reuse of Plastic Waste as Construction Material for Sustainable Development: A Review. Env. Sci. Pollut. Res. 2022, 29, 86156–86179. [Google Scholar] [CrossRef]

- Ulewicz, M. Recycled Materials for Concrete and Other Composites. Materials 2021, 14, 2279. [Google Scholar] [CrossRef]

- Ulewicz, M. Recycled Materials in Civil Engineering Application. Materials 2023, 16, 7075. [Google Scholar] [CrossRef]

- Gabryś, K. Dynamic Shear Properties of Recycled Combustion Slag, a Sustainable Material, in Road Construction. Sustainability 2025, 17, 926. [Google Scholar] [CrossRef]

- Haas, M.; Galler, R.; Scibile, L.; Benedikt, M. Waste or Valuable Resource—A Critical European Review on Re-Using an d Managing Tunnel Excavation Material. Resour. Conserv. Recycl. 2020, 162, 105048. [Google Scholar] [CrossRef]

- Almokdad, M.; Zentar, R. Characterization of Recycled Dredged Sediments: Toward Circular Economy in Road Construction. Constr. Build. Mater. 2023, 402, 132974. [Google Scholar] [CrossRef]

- Si, W.; Zhang, B.; Zhang, X.; Xia, W.; Cheng, X.; Luo, X.; Hu, Y. Maximizing the Circularity of Asphalt Pavements by Improving the RAP Content in Recycled Asphalt Mixtures. Constr. Build. Mater. 2024, 438, 137316. [Google Scholar] [CrossRef]

- Ilma, J. Economic Feasibility of Reusing Structural Components: How to Quantitatively Assess the Economic Feasibility of Reusing Structural Componen Ts from Existing Buildings into New Construction? Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2020. Available online: https://resolver.tudelft.nl/uuid:e17e92e0-9b3e-4e70-8b93-5f77ccbe1154 (accessed on 30 July 2025).

- Küpfer, C.; Bastien-Masse, M.; Devènes, J.; Fivet, C. Environmental and Economic Analysis of New Construction Techniques Reusing Existing Concrete Elements: Two Case Studies. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012013. [Google Scholar] [CrossRef]

- Dervishaj, A.; Fonsati, A.; Hernández Vargas, J.; Gudmundsson, K. Modelling Precast Concrete for a Circular Economy in the Built Environment. In Proceedings of the 41st Conference on Education and Research in Computer Aided Architectural Design in Europe (eCAADe 2023), Graz, Austria, 20–22 September 2023; 2, pp. 177–186. [Google Scholar]

- Charlotte, L.; Eberhardt, M.; Birgisdottir, H. Building the Future Using the Existing Building Stock: The Environmental Potential of Reuse. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012020. [Google Scholar] [CrossRef]

- Ahmed, K.S.; Rana, L.R. Fresh and Hardened Properties of Concrete Containing Recycled Waste Glass: A Review. J. Build. Eng. 2023, 70, 106327. [Google Scholar] [CrossRef]

- Anwar, M.K.; Zhu, X.; Gilabert, F.A.; Siddiq, M.U. Recycling and Optimum Utilization of CRT Glass as Building Materials: An Application of Low CO2 Based Circular Economy for Sustainable Construction. Constr. Build. Mater. 2024, 453, 138798. [Google Scholar] [CrossRef]

- Gopalakrishna, B.; Pasla, D. Durability Performance of Recycled Aggregate Geopolymer Concrete Incor Porating Fly Ash and Ground Granulated Blast Furnace Slag. J. Mater. Civ. Eng. 2024, 36, 4. [Google Scholar] [CrossRef]

- Sultana, A. Impact of Multiple Recycling on the Strength of Coarse Aggregate. Civ. Eng. Beyond Limits 2020, 2, 12–15. [Google Scholar] [CrossRef]

- Shamass, R.; Rispoli, O.; Limbachiya, V.; Kovacs, R. Mechanical and Environmental Impact of Using Blast Burnace Slag, Silica Fume and Recycled Aggregate in Concrete. Soc. Sci. Res. Netw. Case Stud. Constr. Mater. 2023, 18. [Google Scholar] [CrossRef]

- Shamass, R.; Rispoli, O.; Limbachiya, V.; Kovacs, R. Mechanical and GWP Assessment of Concrete Using Blast Furnace Slag, Si Lica Fume and Recycled Aggregate. Case Stud. Constr. Mater. 2023, 18, e02164. [Google Scholar] [CrossRef]

- Soldati, L.; Bacciocchi, M.; Tarantino, A.M. Mechanical Characterization of Sustainable Mortars with Recycled Aggre Gates from Construction and Demolition Wastes: An Experimental Investigation. Materials 2024, 17, 5409. [Google Scholar] [CrossRef] [PubMed]

- Borg, R.P.; Cuenca, E.; Garofalo, R.; Schillani, F.; Nasner, M.L.; Ferrara, L. Performance Assessment of Ultra-High Durability Concrete Produced From Recycled Ultra-High Durability Concrete. Front. Built Environ. 2021, 7, 1–22. [Google Scholar] [CrossRef]

- Louzi, N.; Alzoubi, H.M.; El, M.; Ghazal, T.M.; Alshurideh, M.; Kukunuru, S. Psychological Health and Environmental Effect of Using Green Recycled Amassed Concrete on Construction. J. Reatt. Ther. Dev. Divers. 2022, 5, 163–175. [Google Scholar]

- De Andrade Salgado, F.; De Andrade Silva, F. Recycled Aggregates from Construction and Demolition Waste towards an Application on Structural Concrete: A Review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Rahmani, A.A.; Chemrouk, M.; Ammar-Boudjelal, A. Rheological, Physico-Mechanical and Durability Properties of Multi-Rec Ycled Concrete. Adv. Concr. Constr. 2020, 9, 9–22. [Google Scholar] [CrossRef]

- Marathe, S.; Shetty, T.S.; Mithun, B.M.; Ranjith, A. Strength and Durability Studies on Air Cured Alkali Activated Pavement Quality Concrete Mixes Incorporating Recycled Aggregates. Case Stud. Constr. Mater. 2021, 15, e00732. [Google Scholar] [CrossRef]

- Ghernouti, Y.; Rabehi, B.; Mansour, S.M. Study of the Mechanical Properties and the Durability of Concrete Base d on Recycled Wastes Aggregates. Eurasia Proc. Sci. Technol. Eng. Math. 2024, 32, 463–475. [Google Scholar] [CrossRef]

- Venkrbec, V.; Klanšek, U. Suitability of Recycled Concrete Aggregates from Precast Panel Buildin Gs Deconstructed at Expired Lifespan for Structural Use. J. Clean. Prod. 2020, 247, 119593. [Google Scholar] [CrossRef]

- Gerhardsson, H.; Lindholm, C.L.; Andersson, J.; Kronberg, A.; Wennesjö, M.; Shadram, F. Transitioning the Swedish Building Sector toward Reuse and Circularity. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 042036. [Google Scholar] [CrossRef]

- Vaishnavi Devi, S.; Gausikan, R.; Chithambaranathan, S.; Wilfred Jeffrey, J. Utilization of Recycled Aggregate of Construction and Demolition Waste as a Sustainable Material. Mater. Today Proc. 2021, 45, 6649–6654. [Google Scholar] [CrossRef]

- Rakhshan, K.; Morel, J.-C.; Alaka, H.; Charef, R. Components Reuse in the Building Sector—A Systematic Review. Waste Manag. Res. 2020, 38, 347–370. [Google Scholar] [CrossRef]

- Rosca, B. Eco-Friendly Lightweight Aggregate Concrete of Structural Grade Made with Recycled Brick Aggregate Containing Expanded Polystyrene Beads. Sustainability 2025, 17, 3050. [Google Scholar] [CrossRef]

- Mostert, C.; Weber, C.; Bringezu, S. Modelling and Simulation of Building Material Flows: Assessing the Potential for Concrete Recycling in the German Construction Sector. Recycling 2022, 7, 13. [Google Scholar] [CrossRef]

- Kul, A.; Ozcelikci, E.; Furkan Ozel, B.; Yildirim, G.; Ashour, A. Adapting Construction and Demolition Waste to Circular Building Materials and Evaluation of Life Cycle Environmental Impacts. In Proceedings of the 16th International Conference on Durability of Building Materials and Components, Beijing, China, 10–13 October 2023. [Google Scholar] [CrossRef]

- Cruze, D.; Sah, C.; Manikanta, N.; Mandal, D.K.; Jha, A.K.; Solomon, A.A. Axial Compressive Behavior of Recycled Aggregate Concrete Steel Composite Columns. Res. Eng. Struct. Mat. 2024, 10, 1155–1171. [Google Scholar] [CrossRef]

- Morón, A.; Ferrández, D.; Saiz, P.; Morón, C. Experimental Study with Cement Mortars Made with Recycled Concrete Aggregate and Reinforced with Aramid Fibers. Appl. Sci. 2021, 11, 7791. [Google Scholar] [CrossRef]

- Zeng, L.; Wu, L.; Li, B.; Fang, S.; Samih Mohamed, H.; Fang, Z.; Yuan, H. Recycled Aggregate Concrete-Filled Steel Tube Columns with Small-Diameter Circular FRP-Confined Sea-Sand Concrete Cores: Conceptual and Experimental Investigations. Constr. Build. Mater. 2023, 401, 132853. [Google Scholar] [CrossRef]

- Grigorjev, V.; Azenha, M.; De Belie, N. Towards Sustainable Masonry Construction Through Natural Aggregate Replacement by Fine Recycled Aggregates in Cement–Lime Mortars. Sustainability 2025, 17, 1269. [Google Scholar] [CrossRef]

- Slánský, B.; Zelinka, P.; Čermák, J. Unique and Innovative Technology for Sustainable and Efficient Structural Concrete Made of 100% Recycled Aggregate from CDW. Acta Polytech. CTU Proc. 2022, 33, 564–570. [Google Scholar] [CrossRef]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular Economy in the Building and Construction Sector: A Scientific Evolution Analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Mojica, A.; Serrano-Ruiz, J.C.; Andres, B.; De La Torre, R. A Conceptual Framework for the Upcycling Supply Chain in the Wood Sector. Sustainability 2025, 17, 1006. [Google Scholar] [CrossRef]

- Kauniste, M.; Just, A.; Tuhkanen, E.; Kalamees, T. Assessment on Strength and Stiffness Properties of Aged Structural Timber. J. Sustain. Arch. Civ. Eng. 2024, 34, 62–74. [Google Scholar] [CrossRef]

- Sanadi, A.R.; Guna, V.; Hoysal, R.V.; Krishna, A.; Deepika, S.; Mohan, C.B.; Reddy, N. MAPP Compatibilized Recycled Woodchips Reinforced Polypropylene Composites with Exceptionally High Strength and Stability. Waste Biomass Valor 2024, 15, 301–312. [Google Scholar] [CrossRef]

- Santos, F.L.D.L.; Santos, H.F.; Costa, L.L.; Lima, V.S.; Cunha, R.D.A.; César, S.F. Mass Timber as a Tool to Sustainable Construction: A Review. Rev. De Gestão Soc. E Ambient. 2025, 19, e011329. [Google Scholar] [CrossRef]

- Jonathan, C.; Onyoni, J. A Feasible Circularity Model for Construction Wood Wastes in Developing Countries: The Case of Kenya and Nigeria. J. Circ. Econ. 2025, 3, 1–24. [Google Scholar] [CrossRef]

- Ottenhaus, L.-M.; Yan, Z.; Brandner, R.; Leardini, P.; Fink, G.; Jockwer, R. Design for Adaptability, Disassembly and Reuse—A Review of Reversible Timber Connection Systems. Constr. Build. Mater. 2023, 400, 132823. [Google Scholar] [CrossRef]

- Finch, G.; Marriage, G.; Pelosi, A.; Gjerde, M. Building Envelope Systems for the Circular Economy; Evaluation Parameters, Current Performance and Key Challenges. Sustain. Cities Soc. 2021, 64, 102561. [Google Scholar] [CrossRef]

- Ahn, N.; Bjarvin, C.; Riggio, M.; Muszynski, L.; Schimleck, L.; Pestana, C.; Dodoo, A.; Puettmann, M. Envisioning Mass Timber Buildings for Circularity: Life Cycle Assessment of a Mass Timber Building with Different End-Of-Life (Eol) and Post-Eol Options. In Proceedings of the 13th World Conference on Timber Engineering (WCTE 2023), Oslo, Norway, 19–22 June 2023; pp. 3581–3587. Available online: https://www.diva-portal.org/smash/record.jsf?pid=diva2%3A1814216&dswid=-5750 (accessed on 25 March 2025).

- Fadai, A.; Stephan, D. Ecological Performance of Reusable Load-Bearing Constructions. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012123. [Google Scholar] [CrossRef]

- Ramírez, C.P.; Barriguete, A.V.; Muñoz, J.G.; Merino, M.D.R.; Serrano, P.D.S. Ecofibers for the Reinforcement of Cement Mortars for Coating Promoting the Circular Economy. Sustainability 2020, 12, 2835. [Google Scholar] [CrossRef]

- Pichlmeier, F.; Lindner, S. Reuse Potential of Building Services in Building Relocation. IOP Conf. Ser. Earth Environ. Sci. 2024, 1363, 012050. [Google Scholar] [CrossRef]

- Goh, K.C.; Kurniawan, T.A.; Goh, H.H.; Zhang, D.; Jiang, M.; Dai, W.; Khan, M.I.; Othman, M.H.D.; Aziz, F.; Anouzla, A.; et al. Harvesting Valuable Elements from Solar Panels as Alternative Construction Materials: A New Approach of Waste Valorization and Recycling in Circular Economy for Building Climate Resilience. Sustain. Mater. Technol. 2024, 41, e01030. [Google Scholar] [CrossRef]

- Patil, H. Study of Waste Material for Concrete Brick Construction. Int. J. Res. Appl. Sci. Eng. Technol. 2024, 12, 424–428. [Google Scholar] [CrossRef]

- Bhooshan, S.; Dell’Endice, A.; Ranaudo, F.; Van Mele, T.; Block, P. Unreinforced Concrete Masonry for Circular Construction. Arch. Intell. 2024, 3, 7. [Google Scholar] [CrossRef]

- Kancheva, Y.D.; Zaharieva, R.A. End-of-Life Options for Ceramic Masonry Units—Environmental and Performance-Based Perspective. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1276, 012002. [Google Scholar] [CrossRef]

- Malaiškienė, J.; Škamat, J.; Kudžma, A.; Boris, R.; Bačinskas, D. The Impact of Differently Prepared Mixed Plastic Waste Granules on the Structure and Properties of Concrete. Sustainability 2025, 17, 1052. [Google Scholar] [CrossRef]

- Villegas Pilay, Y.E.; Bravo Carrasco, A.R.; Cruz Ronquillo, S.I. Circular Economy Model for Reuse of Plastic in Eco-Efficient Production of Building Materials. J. Bus. Entrep. Stud. 2023, 7, 9–26. [Google Scholar] [CrossRef]

- Horvath, M.; Bollen, P.; Pardoen, T.; Trachte, S. Evaluation of the Properties of a New Circular Building Composite Material to Upcycle Building Wastes. J. Phys. Conf. Ser. 2023, 2600, 192018. [Google Scholar] [CrossRef]

- Turk, J.; Urbanc, J.; Mladenovič, A.; Pavlin, A.; Oprčkal, P.; Fifer Bizjak, K.; Likar, B.; Brodnik, M.; Mali, N. Construction of lysimeters for researching the leaching of potentially toxic elements from building materials. Geologija 2020, 63, 271–280. [Google Scholar] [CrossRef]

- Bendix, P.; Achenbach, H.; Weißhaupt, P.; Eckert, D.; Oehme, I.; Berg, H. Circular Economy for Durable Products and Materials: The Recycling of Plastic Building Products in Germany—Status Quo, Potentials and Recommendations. J. Mater. Cycles Waste Manag. 2022, 24, 1432–1443. [Google Scholar] [CrossRef]

- Pietrzak, A.; Ulewicz, M.; Kozień, E.; Pietraszek, J. Application of a Mixture of Fly Ash and Solid Waste from Gas Treatment from Municipal Solid Waste Incineration in Cement Mortar. Materials 2025, 18, 481. [Google Scholar] [CrossRef]

- Zhang, Z.; Lei, Y.; Liew, J.Y.R.; Liu, M.; Wong, G.; Du, H. Embodied Carbon Saving Potential of Using Recycled Materials as Cement Substitute in Singapore’s Buildings. npj Mater. Sustain. 2024, 2, 27. [Google Scholar] [CrossRef]

- Patel, P.; Patel, A. Use of Sustainable Green Materials in Construction of Green Buildings for Sustainable Development. IOP Conf. Ser. Earth Environ. Sci. 2021, 785, 012009. [Google Scholar] [CrossRef]

- Ulfat, W.; Mohyuddin, A.; Amjad, M.; Kurniawan, T.A.; Mujahid, B.; Nadeem, S.; Javed, M.; Amjad, A.; Ashraf, A.Q.; Othman, M.H.D.; et al. Reuse of Buffing Dust-Laden Tanning Waste Hybridized with Poly- Styrene for Fabrication of Thermal Insulation Materials. Sustainability 2023, 15, 1958. [Google Scholar] [CrossRef]

- Hegyi, A.; Bulacu, C.; Szilagyi, H.; Lăzărescu, A.-V.; Colbu, D.E.; Sandu, M. Waste Management in the Context of the Development of Sustainable Thermal Insulation Products for the Construction Sector. Int. J. Conserv. Sci. 2021, 12, 225–236. [Google Scholar]

- Bertin, I.; Mesnil, R.; Jaeger, J.-M.; Feraille, A.; Le Roy, R. A BIM-Based Framework and Databank for Reusing Load-Bearing Structural Elements. Sustainability 2020, 12, 3147. [Google Scholar] [CrossRef]

- Ruggiero, R.; Cognoli, R.; Cocco, P.L. From Debris to the Data Set (DEDA) a Digital Application for the Upcycling of Waste Wood Material in Post Disaster Areas. In Architecture and Design for Industry 4.0; Barberio, M., Colella, M., Figliola, A., Battisti, A., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2024; pp. 807–835. ISBN 978-3-031-36921-6. [Google Scholar]

- Petojević, Z.; Nadaždi, A.; Isailović, D.; Višnjevac, N. An Integrated Solution for Increased Circularity in Buildings: A Method. In Digital Transformation and Sustainable Development in Project Management, Proceedings of the 6th IPMA SENET Project Management Conference, Zagreb, Croatia, 12 September 2023; Mladen, V., Golomejić, V., Rebeka, D., Eds.; Građevinski fakultet Sveučilišta u Zagrebu: Zagreb, Croatia, 2023; pp. 259–272. [Google Scholar] [CrossRef]

- Gillott, C.; Mihkelson, W.; Lanau, M.; Cheshire, D.; Densley Tingley, D. Developing Regenerate: A Circular Economy Engagement Tool for the Assessment of New and Existing Buildings. J. Ind. Ecol. 2023, 27, 423–435. [Google Scholar] [CrossRef]

- Piccardo, C.; Alam, A.; Hughes, M. The Potential Contribution of Wood in Green Building Certifications: Prospects in Sustainable Residential Buildings. Arch. Res. Finl. 2021, 5, 130–146. [Google Scholar] [CrossRef]

- Jayasinghe, L.B.; Waldmann, D. Development of a BIM-Based Web Tool as a Material and Component Bank for a Sustainable Construction Industry. Sustainability 2020, 12, 1766. [Google Scholar] [CrossRef]

- Cardoso, A.; Salomé, R. Matter by Design. How Can Circular Economy Play a Role in Building Green Efficient and Sustainable through Innovative Use of Mediterranean Materials. In Sustainable Construction in the Era of the Fourth Industrial Revolution, Proceedings of the AHFE (2024) International Conference, Nice, France, 22–27 July 2024; Aigbavboa, C., Oke, E., Thwala, W., Eds.; AHFE International: Orlando, FL, USA, 2024; Volume 149. [Google Scholar] [CrossRef]

- Göswein, V.; Carvalho, S.; Cerqueira, C.; Lorena, A. Circular Material Passports for Buildings—Providing a Robust Methodology for Promoting Circular Buildings. IOP Conf. Ser. Earth Environ. Sci. 2022, 1122, 012049. [Google Scholar] [CrossRef]

- Meglin, R.; Kytzia, S.; Habert, G. Regional Circular Economy of Building Materials: Environmental and Economic Assessment Combining Material Flow Analysis, Input-Output Analyses, and Life Cycle Assessment. J. Ind. Ecol. 2022, 26, 562–576. [Google Scholar] [CrossRef]

- Saka, A.; Taiwo, R.; Saka, N.; Oluleye, B.; Akanbi, L. Integrated BIM and Machine Learning System for Circularity Prediction of Construction Demolition Waste. arXiv arXiv:2407.14847, 2024. [CrossRef]

- Spišáková, M.; Mandičák, T.; Mésároš, P.; Špak, M. Waste Management in a Sustainable Circular Economy as a Part of Design of Construction. Appl. Sci. 2022, 12, 4553. [Google Scholar] [CrossRef]

- Zhao, Z. Research on Building Deconstruction Based on BIM Technology. Theor. Nat. Sci. 2023, 14, 18–26. [Google Scholar] [CrossRef]

- Hubmann, G.; Van Maaren, V. Circular Material Systems: Anticipating Whole-System Design in Architecture and Construction. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012002. [Google Scholar] [CrossRef]

- Cosma, I.; Petre, I.; Stalidi, C.; Suciu, G.; Dănilă, A. An Interactive Visualization Tool for Circular Economy and Building Materials Recovery. In Proceedings of the 2024 IEEE 30th International Symposium for Design and Technology in Electronic Packaging (SIITME), Sibiu, Romania, 16–18 October 2024; pp. 251–254. [Google Scholar] [CrossRef]

- Bhadane, P.; Nemade, P.D. Assessment of Circular Economy and Reduction of Embodied Carbon Drive for Sustainable Construction. Int. J. Adv. Res. 2022, 10, 357–365. [Google Scholar] [CrossRef]

- Antunes, A.; Martins, R.; Silvestre, J.D.; Do Carmo, R.; Costa, H.; Júlio, E.; Pedroso, P. Environmental Impacts and Benefits of the End-of-Life of Building Materials: Database to Support Decision Making and Contribute to Circularity. Sustainability 2021, 13, 12659. [Google Scholar] [CrossRef]

- Li, A.; Guo, C.; Gu, J.; Hu, Y.; Luo, Z.; Yin, X. Promoting Circular Economy of the Building Industry by the Use of Straw Bales: A Review. Buildings 2024, 14, 1337. [Google Scholar] [CrossRef]

- Pešta, J.; Trubina, N.; Schulzová, K.; Vlasatá, B.; Pavlů, T. Streamlining Demolition Processes: A Material Cadaster-Based Digitalization and Automation of Predemolition Audit. IOP Conf. Ser. Earth Environ. Sci. 2024, 1402, 012041. [Google Scholar] [CrossRef]

- Fereydooni Eftekhari, A.; Khodabakhshian, A.; Re Cecconi, F.; Daniotti, B. Improving Circularity in Construction Through a BIM-Based Waste Management Framework. IOP Conf. Ser. Earth Environ. Sci. 2024, 1363, 012042. [Google Scholar] [CrossRef]

- Tharaka Dharmasiri Pathberiyage, N.; Delzendeh, E.; Cheung, F.; Mateo Garcia, M. A Conceptual Model for Assessing Circularity Potential of Building Materials at the Product Manufacturing Stage. In Proceedings of the 16th International Conference on Durability of Building Materials and Components; XVI International Conference on Durability of Building Materials and Components, Beijing, China, 10–13 October 2023. [Google Scholar] [CrossRef]

- Zubair, M.U.; Ali, M.; Khan, M.A.; Khan, A.; Hassan, M.U.; Tanoli, W.A. BIM- and GIS-Based Life-Cycle-Assessment Framework for Enhancing Eco Efficiency and Sustainability in the Construction Sector. Buildings 2024, 14, 360. [Google Scholar] [CrossRef]

- Morganti, L.; Demutti, M.; Fotoglou, I.; Coscia, E.A.; Perillo, P.; Pracucci, A. Integrated Platform-Based Tool to Improve Life Cycle Management and Circularity of Building Envelope Components. Buildings 2023, 13, 2630. [Google Scholar] [CrossRef]

- Ibe, C.N.; Serbescu, A.; Hossain, M.; Ibe, I.I. Optimizing Circular Economy Practices in Construction: A Systematic Review of Material Management Strategies. Built Environ. Proj. Asset Manag. 2025, 1–16. [Google Scholar] [CrossRef]

- Kaewunruen, S.; O’Nell, C.; Sengsri, P. Digital Twin-Driven Strategic Demolition Plan for Circular Asset Management of Bridge Infrastructures. Sci. Rep. 2025, 15, 10554. [Google Scholar] [CrossRef] [PubMed]

- Feng, H.; Chen, Q.; García De Soto, B.; Arashpour, M. Using BIM and LCA to Evaluate Material Circularity: Contributions to Building Design Improvements. In Proceedings of the 39th ISARC, Bogotá, Colombia, 15 July 2022; pp. 9–16. [Google Scholar] [CrossRef]

- Guerriero, A.; Busio, F.; Saidani, M.; Boje, C.; Mack, N. Combining Building Information Model and Life Cycle Assessment for Def Ining Circular Economy Strategies. Sustainability 2024, 16, 4561. [Google Scholar] [CrossRef]

- Ferronato, N.; Sirpa, R.C.F.; Lizarazu, E.G.G.; Conti, F.; Torretta, V. Construction and Demolition Waste Recycling in Developing Cities: Mana Gement and Cost Analysis. Environ. Sci. Pollut. Res. 2022, 30, 24377–24397. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, A.O.; Oyedele, L.O.; Salami, R.O. Deep Learning Model for Demolition Waste Prediction in a Circular Economy. J. Clean. Prod. 2020, 274, 122843. [Google Scholar] [CrossRef]

- Vashishth, R.; Goel, M. Impact of Circular Economy in Construction Sector: Review of Current Trends and Future Research Direction. Sust. Agric. Food Environ. Res. 2023, 11, 1–13. [Google Scholar] [CrossRef]

- Vásquez-Cabrera, A.; Montes, M.V.; Llatas, C. The Incorporation of Recycled Aggregate Concrete as a Strategy to Enhance the Circular Performance of Residential Building Structures in Spain. Appl. Sci. 2025, 15, 3265. [Google Scholar] [CrossRef]

- Činčikaitė, R. Assessment of Sustainable Waste Management: A Case Study in Lithuania. Sustainability 2024, 17, 120. [Google Scholar] [CrossRef]

- Stuetzer, M.A.D.; Essig, N.; Kustermann, A. Sustainable Practices in Construction: Exposing the Potential of Waste as a Resource. IOP Conf. Ser. Earth Environ. Sci. 2024, 1402, 2–15. [Google Scholar] [CrossRef]

- Tanthanawiwat, K.; Gheewala, S.; Nilsalab, P.; Schoch, M.; Silalertruksa, T. Environmental Sustainability and Cost Performances of Construction and Demolition Waste Management Scenarios: A Case Study of Timber and Con Crete Houses in Thailand. J. Clean. Prod. 2024, 436, 140652. [Google Scholar] [CrossRef]

- Unegbu, H.C.O.; Yawas, D.S.; Dan-asabe, B.; Alabi, A.A. Optimizing Waste Management Strategies for Sustainable Construction: Assessing the Implementation of Circular Economy Principles in Nigeria. J. Ilm. Teknol. Dan Rekayasa 2024, 29, 276–301. [Google Scholar] [CrossRef]

- Marek, M.; Krejza, Z. Sustainable Building: Circular Economy as a Key Factor for Cost Reduction. E3S Web Conf. 2024, 550, 01009. [Google Scholar] [CrossRef]

- Behúnová, A.; Mandičák, T.; Behún, M.; Mésároš, P. The Building Information Modelling Through Information Technology and Impacts on Selected Circular Economy Performance Indicators of Construction Projects. Mob. Netw. Appl. 2024, 29, 506–515. [Google Scholar] [CrossRef]

- Gordon, M.; Batallé, A.; De Wolf, C.; Sollazzo, A.; Dubor, A.; Wang, T. Automating Building Element Detection for Deconstruction Planning and Material Reuse: A Case Study. Autom. Constr. 2023, 146, 104697. [Google Scholar] [CrossRef]

- Heisel, F.; McGranahan, J.; Lucas, A.; Cohen, D.; Stone, G. Carbon, Economics, and Labor: A Case Study of Deconstruction’s Relative Costs and Benefits Compared to Demolition. J. Phys. Conf. Ser. 2023, 2600, 192003. [Google Scholar] [CrossRef]

- Behún, M.; Behúnová, A. Advanced Innovation Technology of BIM in a Circular Economy. Appl. Sci. 2023, 13, 7989. [Google Scholar] [CrossRef]

- Stricker, E.; Angst, M.; Brandi, G.; Buser, B.; Sonderegger, A. Case Study K.118—The Reuse of Building Components in Winterthur, Switzerland. J. Phys. Conf. Ser. 2023, 2600, 192008. [Google Scholar] [CrossRef]

- Rybak-Niedziółka, K.; Starzyk, A.; Łacek, P.; Mazur, Ł.; Myszka, I.; Stefańska, A.; Kurcjusz, M.; Nowysz, A.; Langie, K. Use of Waste Building Materials in Architecture and Urban Planning—A Review of Selected Examples. Sustainability 2023, 15, 5047. [Google Scholar] [CrossRef]

- Çetin, S.; Raghu, D.; Honic, M.; Straub, A.; Gruis, V. Data Requirements and Availabilities for Material Passports: A Digital Ly Enabled Framework for Improving the Circularity of Existing Buildings. Sustain. Prod. Consum. 2023, 40, 422–437. [Google Scholar] [CrossRef]

- Di Ruocco, G.; Melella, R.; Sabatano, L. Timber Buildings Deconstruction as a Design Solution toward Near Zero CO2e Emissions. Buildings 2023, 13, 157. [Google Scholar] [CrossRef]

- Rune, A.; Ravn, A.; Ryberg, M. Environmental Benefits of Applying Selective Demolition to Buildings: A Case Study of the Reuse of Façade Steel Cladding. Front. Mater. 2024, 11, 1337843. [Google Scholar] [CrossRef]

- Christensen, T.B.; Johansen, M.R.; Buchard, M.V.; Glarborg, C.N. Closing the Material Loops for Construction and Demolition Waste: The Circular Economy on the Island Bornholm, Denmark. Resources, Conservation & Recycling. Adv. Eng. Constr. Archit. Manag. 2024, 31, 430–454. [Google Scholar] [CrossRef]

- Lione, R.; Fiandaca, O.; Minutoli, F.; Cernaro, A.; Manuel Palmero, L. The disused precious stone elements are not CDWaste. A digital management chain to save them. Riv. Tema 2022, 8, 44–55. [Google Scholar] [CrossRef]

- Larsen, V.G.; Tollin, N.; Antoniucci, V.; Birkved, M.; Sattrup, P.A.; Holmboe, T.; Marella, G. Filling the Gaps Circular Transition of Affordable Housing in Denmark. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012078. [Google Scholar] [CrossRef]

- Han Hoang, N.; Ishigaki, T.; Watari, T.; Yamada, M.; Kawamoto, K. Current State of Building Demolition and Potential for Selective Disma Ntling in Vietnam. Waste Manag. 2022, 149, 218–227. [Google Scholar] [CrossRef] [PubMed]

- Piccardo, C.; Hughes, M. Design Strategies to Increase the Reuse of Wood Materials in Buildings: Lessons from Architectural Practice. J. Clean. Prod. 2022, 368, 133083. [Google Scholar] [CrossRef]

- Çetin, S.; Gruis, V.; Straub, A. Digitalization for a Circular Economy in the Building Industry: Multiple Case Study of Dutch Housing Organizations. Resour. Conserv. Recycl. Adv. 2022, 15, 1–24. [Google Scholar] [CrossRef]

- Sandberg, E.; Fufa, S.M.; Knoth, K.; Eberhardt, L.C.M. Ombruk av bygningsdeler—læringspunkter fra forbildeprosjekter i Norg e, Danmark og Belgia. Prakt. Okon. Finans. 2022, 38, 23–46. [Google Scholar] [CrossRef]

- Superti, V.; Forman, T.V.; Houmani, C. Recycling Thermal Insulation Materials: A Case Study on More Circular Management of Expanded Polystyrene and Stonewool in Switzerland and Research Agenda. Resources 2021, 10, 104. [Google Scholar] [CrossRef]

- Küpfer, C.; Bertola, N.; Brütting, J.; Fivet, C. Decision Framework to Balance Environmental, Technical, Logistical, and Economic Criteria When Designing Structures with Reused Components. Front. Sustain. 2021, 2, 689877. [Google Scholar] [CrossRef]

- Lachat, A.; Mantalovas, K.; Desbois, T.; Yazoghil-Marzouk, O.; Colas, A.; Di Mino, G.; Feraille, A. From Buildings’ End of Life to Aggregate Recycling under a Circular Ec Onomic Perspective: A Comparative Life Cycle Assessment Case Study. Sustainability 2021, 13, 9625. [Google Scholar] [CrossRef]

- Sprecher, B.; Verhagen, T.J.; Sauer, M.L.; Baars, M.; Heintz, J.; Fishman, T. Material Intensity Database for the Dutch Building Stock: Towards Big Data in Material Stock Analysis. J. Ind. Ecol. 2021, 26, 272–280. [Google Scholar] [CrossRef]

- Francart, N.; Malmqvist, T. Investigation of Maintenance and Replacement of Materials in Building LCA. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 032027. [Google Scholar] [CrossRef]

- Xing, K.; Kim, K.P.; Ness, D. Cloud-BIM Enabled Cyber-Physical Data and Service Platforms for Building Component Reuse. Sustainability 2020, 12, 10329. [Google Scholar] [CrossRef]

- De Wolf, C.; Hoxha, E.; Fivet, C. Comparison of Environmental Assessment Methods When Reusing Building Components: A Case Study. Sustain. Cities Soc. 2020, 61, 102322. [Google Scholar] [CrossRef]

- Gharehbaghi, K.; Rahmani, F.; Paterno, D. Sustainable Concrete in Transportation Infrastructure: Australian Case Studies. IOP Conf. Ser. Mater. Sci. Eng. 2020, 829, 012001. [Google Scholar] [CrossRef]

- The European Green Deal—European Commission. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/story-von-der-leyen-commission/european-green-deal_en (accessed on 24 June 2025).

| Material | Reuse Method | Reuse Potential | Challenges | Environmental Benefits | Regulations/ Documents |

|---|---|---|---|---|---|

| Concrete | Deconstruction aggregate as an ingredient of new concrete mixture and subconstruction under roads [70,72,73,74,75] | High | Variability of quantity and material contamination [70,72,73,74,75] | Reduced usage of natural aggregate [70,72,73,74,75] | EN 206+A2, ISO 14040 [74,75] |

| Prefabricates or entire elements from recycling [68,76,77,78,79] | High | Measurement adaptation, transport [68,76,77,78,79] | Reduced energy and water usage due to the production process [68,76,77,78,79] | UE CDW Protocol [68,76,77,78,79] | |

| Addiction to fragmented glass and mineral wool [55,80,81] | Medium | Reactivity and alcaic properties of glass [55,80,81] | Reduction of cement demand [55,80,81] | Standards for glass waste [81] | |

| Usage of Slag and Recycled Aggregate [56,57,60,61,67,70,71,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105] | Medium | Difficulties in standardisation [56,57,60,61,67,70,71,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105] | Reduction of CO2 emission, reduction of new material production, reduction in the usage of natural aggregate [56,57,60,61,67,70,71,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105] | ISO 14025, environmental declaration [56,57,60,61,67,70,71,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105] | |

| Wood | Upcycling in the furniture and construction sector [62,66,71,106,107,108,109,110,111] | High | Getting old of the material, damages [62,66,71,106,107,108,109,110,111] | Reduction of CO2 emission [62,66,71,106,107,108,109,110,111] | Local law of forest market [62,66,71,106,107,108,109,110,111] |

| Usage as an aggregate or concrete filling [71,109,112,113] | High | Fire resistance, durability [71,109,112,113] | Reduction of new material production [71,109,112,113] | ISO-Tree classification [71] | |

| Usage and strengthening of OSB and composites [62,113] | Medium | Different quality of the waste material [62,113] | Reduction of structure weight, lower CO2 emission [62,113] | Fire safety standards [113] | |

| Steel | Recycle and reuse fibres [70,76,102,114] | High | Separation fibres [70,76,102,114] | Replacement new materials [70,76,102,114] | - |

| Reuse entire elements (beam, column, rebar) [64,65,100] | High | Different quality of reused material [64,65,100] | Reuse produces less pollution than new material [64,65,100] | LCA according to ISO [100] | |

| Glass | Usage as concrete aggregate and subingredient [56,80,115] | Medium | Risk of alcaic reaction, cracks [56,80] | Reduction of natural sand demand [56,80] | Glass recycling standards [56,80] |

| Upcycling to decorative elements or solar panels [58,93,116,117] | Low | Difficulties in recovering glass panels [58,93,116,117] | Usage waste materials without producing new ones [58,93,116,117] | National recycling regulations [58,93,116,117] | |

| Brick | Selective deconstruction and reuse [97,118] | Medium | Hight fragility, necessity of mortar removal [97,118] | Reduction of waste [97,118] | Local standards [97,118] |

| Crushing into sub-construction or aggregate [97,101,118,119,120] | Low | Low structural value after recycling [97,101,118,119,120] | Reduce the space needed to store materials [97,101,118,119,120] | UE Waste Framework Directive [97,101,118,119,120] | |

| Plastic composites | Strengthening WPC, boards, addition [66,69,121,122,123,124,125] | Medium | UV stability, ageing [66,69,121,122,123,124,125] | Limitation of new plastic production [66,69,121,122,123,124,125] | EU directives on plastics [66,69,121,122,123,124,125] |

| Fly ash | Addition to cement and geopolymers [58,82,126] | High | Different quality and pollutions [58,82,126] | Increase in the use of clinker [58,82,126] | EN 450-1, local cement standards [58,82,126] |

| Blast furnace slag | Substitutive of cement [82,84,85,127] | High | Standardisation, availability [82,84,85] | Reduction in CO2 emission due to concrete production [82,84,85] | ISO 14025 [82,84,85] |

| Plastics | Aggregate or a wall filling [122,125,128,129,130] | Medium | cohesion, toxicity [122,125,128,129,130] | Reduction of pollution emission [122,125,128,129,130] | Packaging Waste Directive [122,125,128,129,130] |

| Tool | Number of Articles | Main Recommendations | References to Material or Location |

|---|---|---|---|

| Lack of regulations and knowledge/regulations/trainings/guidelines/methodology/consistence of supply chain/implementation strategies/deconstruction strategies | 8 | Attention was drawn to the lack of regulations and knowledge about the possibilities of reusing materials and also recommendations for new regulations [131] High conservative requirements influence to decrease the amount of waste [132] Propose methodology for quantitative description of the amount of waste during the design process and key effective factor [132]. Pay attention to the necessity of connecting the supply chain for information flow [133]. Analyse the possibilities of implementing a circular economy [134,135]. Pay attention to the necessity of training in civil engineering [136] and prepare training materials [137]. | Mediterranean region [134] |

| Materials Bank/Shared Platform/Collection Map | 11 | Propose to extend the practice to a national scale to take advantage of the nationwide resource of elements [131] Recommendation of the shared platform [138,139,140,141,142,143,144,145] Revit software (BIM) plug-in and materials bank [147] | Wood, steel [138] Concrete, steel [143] Luxemburg/Europe [138] |

| Passport of the material | 3 | Proposal to create platform collecting information about the platform of the material [133] Necessity of labelling materials and implement certificates [136,147] | - |

| BIM/applications/plug-ins/parametric design/ | 13 | Define materials in connection with BIM to create LCA [131,132,142,145,147,148,149,150,151] BIM as information transfer [133]. Tool for the design of usage to collect [146], process, and classify data [152,153]. | Wood, concrete prefabricate, steel [149] Asphalt [151] Bridge infrastructure [132] |

| Optimalization/geographic information system/influence on simplification and selective analysis on the result of LCA/avoid double counting benefits/multi-criteria analysis/LCA/estimation tool | 5 | Pay attention to the danger of double counting benefits [141]—it may influence the result. Propose a system of classification of criteria to measure the effectiveness of the circular economy [153] and use multicriteria analysis [154] Notice that GIS might help optimise the waste transport route [150,155] | Wood [154] |

| Cost/profit | 2 | Pay attention that reconstruction increases the cost of the investment, but also might be a new income source for civil engineering companies [156] The cost of deconstruction increases twice if the waste is collected selectively, especially on the beginning cost increase, which is estimated at a level of 60% [135]. | Plastic, concrete, steel, wood [156] |

| AI | 1 | Propose to use AI to estimate the amount of deconstruction materials [157] | United Kingdom [157] |

| Design for deconstruction | 2 | Design for the idea of deconstruction [158,159] or adaptation might increase the material reuse factor | Steel [159] Sri Lanka [159] |

| Title | Year | Method of Reuse or Recycling | Results | Environment Benefits | Challenges |

|---|---|---|---|---|---|

| The Incorporation of Recycled Aggregate Concrete as a Strategy to Enhance the Circular Performance of Residential Building Structures in Spain [160] | 2025 | Application of recycled concrete in housing buildings in Spain | Replacing traditional materials with Recycled Aggregate Concrete enhances the circular performance of the structure by 10.81%. | Reduce of the natural sources | Need for an examination of the properties of recycled concrete |

| Assessment of Sustainable Waste Management: A Case Study in Lithuania [161] | 2024 | Management of waste in circular economy | Increase in environmental protection (According to the global waste index in 2022, Lithuania ranked 16th up from 23rd place). | Decrease in the amount of waste | The need to reduce materials usage through effective waste management |

| Sustainable Practices in Construction: Exposing the Potential of Waste as a Resource [162] | Identification of Good Waste Practices in Sustainable Engineering | Project Elementum demonstrated that accurate identification and segregation of materials enables the recovery of large quantities of clean materials (~1.94 million kg). | Reduce the amount of waste and increase social awareness | Lack of social awareness and need for education | |

| Environmental Sustainability and Cost Performances of Construction and Demolition Waste Management Scenarios: A Case Study of Timber and Con Crete Houses in Thailand [163] | Comparison of different scenarios in waste management | The 100% recycling scenario resulted in 124% and 166–169% reductions of the mineral resource scarcity impact as compared to the conventional CDW management for the concrete and timber houses, respectively. | Optimalization recycling processes | Limited technological resource | |

| Optimizing Waste Management Strategies for Sustainable Construction: Assessing the Implementation of Circular Economy Principles in Nigeria [164] | Circular economy implementation rules in Nigeria | Without comprehensive reforms, selective demolition and high-quality recycling can bring significant environmental (18 Mkg CO2 eq savings) and social benefits (~1000 new jobs), although costs may limit the scale. | Waste reduction, promotion of sustainability | Lack of infrastructure and awareness, need for education | |

| Sustainable Building: Circular Economy as a Key Factor for Cost Reduction [165] | Key factor of circular economy in civil engineering | A 26% of companies plan to expand in the field of recycling or green technologies. | Waste reduction, reduction of materials, saving of the materials | Need of education and change approach | |

| Advancing Circular Economy in Construction Mega-Projects: Awareness, Key Enablers, and Benefits —Case Study of the Kingdom of Saudi Arabia [53] | Survey of stakeholder awareness of the circular economy | A 70% of respondents demonstrated general awareness of the Circular Economy concept, but only 35% were able to identify specific CE strategies used in mega-projects. | Growing public awareness of the circular economy | Lack coherence in standardization, need of education | |

| The Building Information Modelling Through Information Technology and Impacts on Selected Circular Economy Performance Indicators of Construction Projects [166] | 2023 | Use of BIM in the classification of circular economy factors | Increase in quality in life cycle management by using BIM technology (described positive influence). | Increase of effectiveness in resource use, waste reduction | Need for integration with existing systems |

| Automating Building Element Detection for Deconstruction Planning and Material Reuse: A Case Study [167] | Semi-automatic planning of deconstruction by BIM scanning | Process development by planning deconstruction for reuse by identification of elements with 85–90% effectiveness. | Increase in the usage potential and identification of materials | Need for technology development and integration with existing industry | |

| Carbon, Economics, and Labor: A Case Study of Deconstruction’s Relative Costs and Benefits Compared to Demolition [168] | Comparison of deconstruction and demolition | Deconstruction may be more expensive, but it offers environmental and social benefits (lack of quantifiable results). | CO2 reduction | Hight costs and time consumption in deconstruction in comparison to demolish | |

| Advanced Innovation Technology of BIM in a Circular Economy [169] | Integration of BIM tools with circular economy rules | Control of components and life-cycle management (creating sustainable components library). | Optimalization in materials usage, increase of the materials reuse | Lack of interoperation BIM systems, need of standardisation | |

| The Reuse of Building Components in Winterthur, Switzerland [170] | Reuse components | Successfully usage of components (41% of materials might be used again, 60% reduction of embodied carbon in comparison to building with new materials). | Savings in materials, reduction of CO2 | Complicated logistics in the collection and storage of components | |

| Use of Waste Building Materials in Architecture and Urban Planning—A Review of Selected Examples [171] | Review of examples in waste usage in urban planning | Presenting projects which include reused materials (The dominant material categories plastics (72), metals (79) and glass (49) are the most frequently studied in the context of architecture and urban planning). | Decrease in waste materials, promotion of reuse and recycling | Limited availability of recycled materials, need for properties examination | |

| Data Requirements and Availabilities for Material Passports: A Digital Ly Enabled Framework for Improving the Circularity of Existing Buildings [172] | Study the rules for material passports in existing buildings | Thirty-eight respondents were surveyed, which allowed us to identify the basic set of data necessary for a complete MP for existing buildings, including material specifications, technical condition, waste management, and economic and environmental aspects. | Facilitation of reuse of materials and circularity | Collect and manage data | |

| Timber Buildings Deconstruction as a Design Solution toward Near Zero CO2e Emissions [176] | Deconstruction of wood buildings as a solution to reduce CO2 emission | The potential of reconstruction in reducing emission (The cradle-to-grave emissions of wood-based materials (CLT/glulam) in an office building are 80–99% lower than in a traditional steel and reinforced concrete structure). | Emission reduction. promotion of sustainability | Need for knowledge and development of technology | |

| Awareness and practice of the principles of circular economy among built environment professionals [54] | Survey on awareness of the circular economy | Moderate level of awareness of the six main principles of circular economy (described). | Promoting the idea of a circular economy among people involved in construction | Need of standardisation. | |

| Environmental Benefits of Applying Selective Demolition to Buildings: A Case Study of the Reuse of Façade Steel Cladding [174] | 2022 | Selective demolition with the purpose of reusing steel facades | Environmental benefits across the full cladding life cycle, the average environmental impact scores across all impact categories were 40% lower for the selective scenario compared to the conventional baseline scenario. | CO2 emission re duction | High cost |

| Closing the Material Loops for Construction and Demolition Waste: The Circular Economy on the Island Bornholm, Denmark [175] | Create a closed circle in production and consumption | Bricks proved to be a key category: their reuse can be achieved without large expenditures, often with the effect of significant material recovery. | Reduce waste amounts, promote local circularity | Need for education, infrastructure barriers | |

| The disused precious stone elements are not CDWaste. A digital management chain to save them [176] | Digital management of recovery materials | Development of the recovery and reuse management chain (described). | Save the cultural legacy | Lack of digital standardisation | |

| Filling the Gaps Circular Transition of Affordable Housing in Denmark [177] | Implementing of circular economy in house buildings | Examples of implementation | Waste reduction | Limited financial resources | |

| Current State of Building Demolition and Potential for Selective Dismantling in Vietnam [178] | Evaluation of current demolition practices and the potential for selective deconstruction | The average rate of reuse/ recycling was as low as 3%. | Waste reduction, recovery of materials | Lack of awareness and technology limits | |

| Design Strategies to Increase the Reuse of Wood Materials in Buildings: Lessons from Architectural Practice [179] | Design strategies to increase timber reusing | Identification of effective practices (described). | Restrictions on tree falling | Limited access to recycled materials | |

| Digitalization for a Circular Economy in the Building Industry: Multiple-Case Study of Dutch Housing Organizations [180] | Digital implementation in circular economy | Circular facilitation management (described). | Increase the effectiveness of resource usage | Integration of systems | |

| Ombruk av bygningsdeler–læringspunkter fra forbildeprosjekter i Norg e, Danmark og Belgia [181] | Analysis of components reuse in Norway, Denmark and Belgium | Identification of success factors and barriers in reuse (described). | CO2 and waste reduction | Lack of documentation, differences in regulations | |

| Recycling Thermal Insulation Materials: A Case Study on More Circular Management of Expanded Polystyrene and Stonewool in Switzerland and Research Agenda [185] | 2021 | Recycling of thermal insulation materials | Strategies for wool and EPS recycling and reuse (1.5% of this material was recycled). | Reduce nonbiodegradable materials | Difficulties in separating materials, lack of infrastructure |

| Decision Framework to Balance Environmental, Technical, Logistical, and Economic Criteria When Designing Structures With Reused Components [183] | Creating rules including various criteria in designing recycled components | Clearer decision making (described). | Decrease of new materials usage | The complexity of multi-criteria assessment | |

| From Buildings’ End of Life to Aggregate Recycling under a Circular Economic Perspective: A Comparative Life Cycle Assessment Case Study [184] | Life cycle analysis of recycled aggregate after usage | Comparison of various recycling methods (transportation and selective deconstruction). | Reduce the use of natural sources | Transportation and processing costs | |

| Material Intensity Database for the Dutch Building Stock: Towards Big Data in Material Stock Analysis [185] | Database creation | Database of deconstruction buildings (described). | Increase the quality of recycling planning. | Various types and materials of buildings, need for standardisation | |

| Investigation of Maintenance and Replacement of Materials in Building LCA [186] | 2020 | Study of the impact of maintenance and replacement of materials on the life cycle analysis | Variations in service lives of materials can cause uncertainties on GWP for the whole building of 10–20%. | Increase in durability and waste reduction | Difficulties in modelling and prediction |

| Cloud-BIM Enabled Cyber-Physical Data and Service Platforms for Building Component Reuse [187] | Identifying and managing components using cloud-BIM | Enabling real-time identification, evaluation, and exchange of components. | Increase in component life cycle management | Need of standardization | |

| Comparison of Environmental Assessment Methods When Reusing Building Components: A Case Study [188] | Comparison of environmental assessment methods | Values of GWP per GFA vary in the ratio of one to two (increase of 94 kgCO2 eq/m2). When considering the first life cycle and of one to three (increase of 115 kgCO2 eq/m2) for the last life cycle. | Enabling of method choice | Need for standardisation | |

| Sustainable Concrete in Transportation Infrastructure: Australian Case Studies [189] | Sustainable concrete usage in transportation infrastructure | Examples of concrete usage (less than 10% recycled material in road construction). | Reduction of CO2 emission | Limited availability of recycled materials, need for research |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krajewska, A.; Siewczyńska, M. Circular Economy in the Construction Sector in Materials, Processes, and Case Studies: Research Review. Sustainability 2025, 17, 7029. https://doi.org/10.3390/su17157029

Krajewska A, Siewczyńska M. Circular Economy in the Construction Sector in Materials, Processes, and Case Studies: Research Review. Sustainability. 2025; 17(15):7029. https://doi.org/10.3390/su17157029

Chicago/Turabian StyleKrajewska, Alicja, and Monika Siewczyńska. 2025. "Circular Economy in the Construction Sector in Materials, Processes, and Case Studies: Research Review" Sustainability 17, no. 15: 7029. https://doi.org/10.3390/su17157029

APA StyleKrajewska, A., & Siewczyńska, M. (2025). Circular Economy in the Construction Sector in Materials, Processes, and Case Studies: Research Review. Sustainability, 17(15), 7029. https://doi.org/10.3390/su17157029