Effect of Pre-Treatment on the Pressing Yield and Quality of Grape Juice Obtained from Grapes Grown in Poland

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

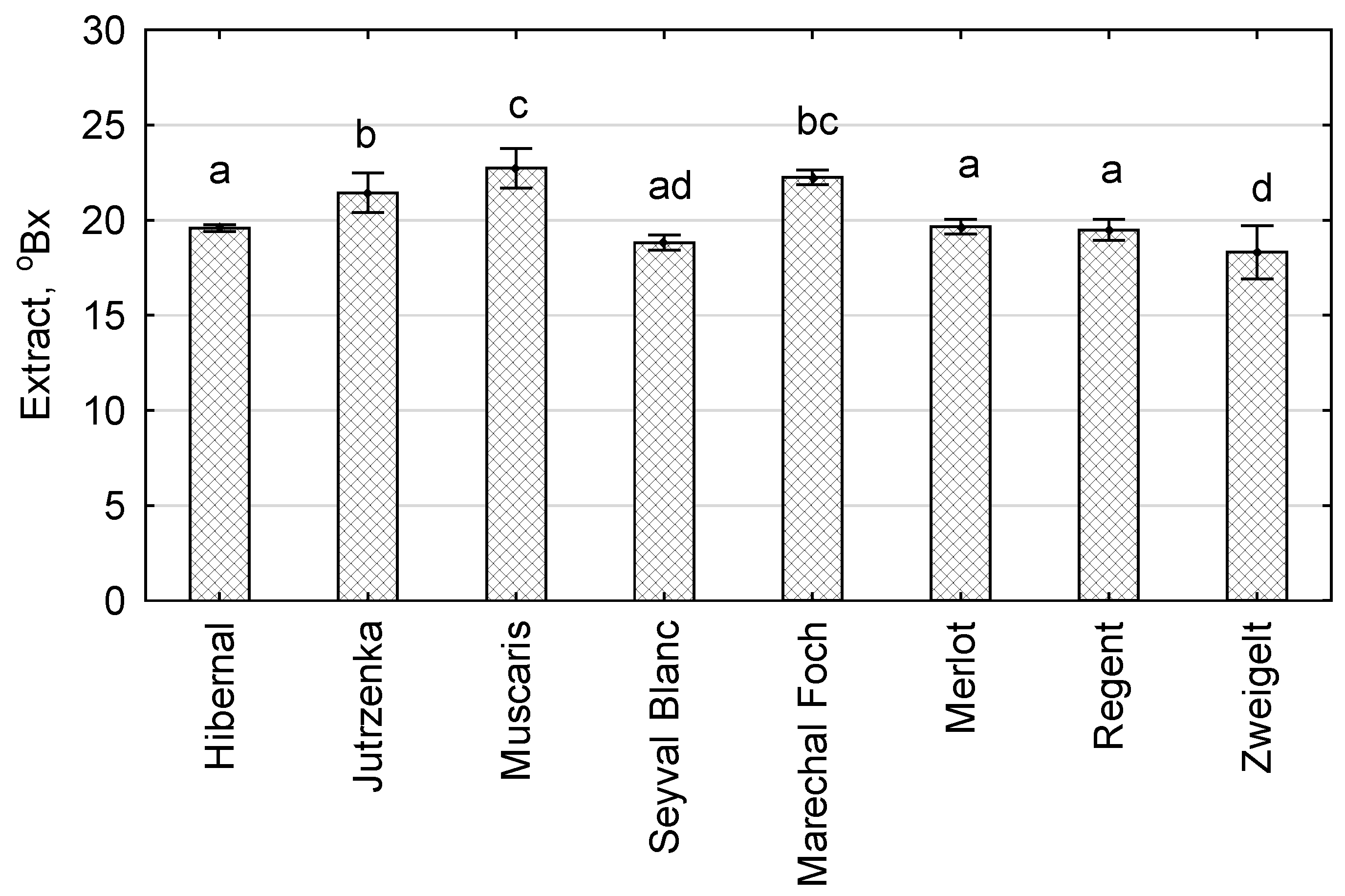

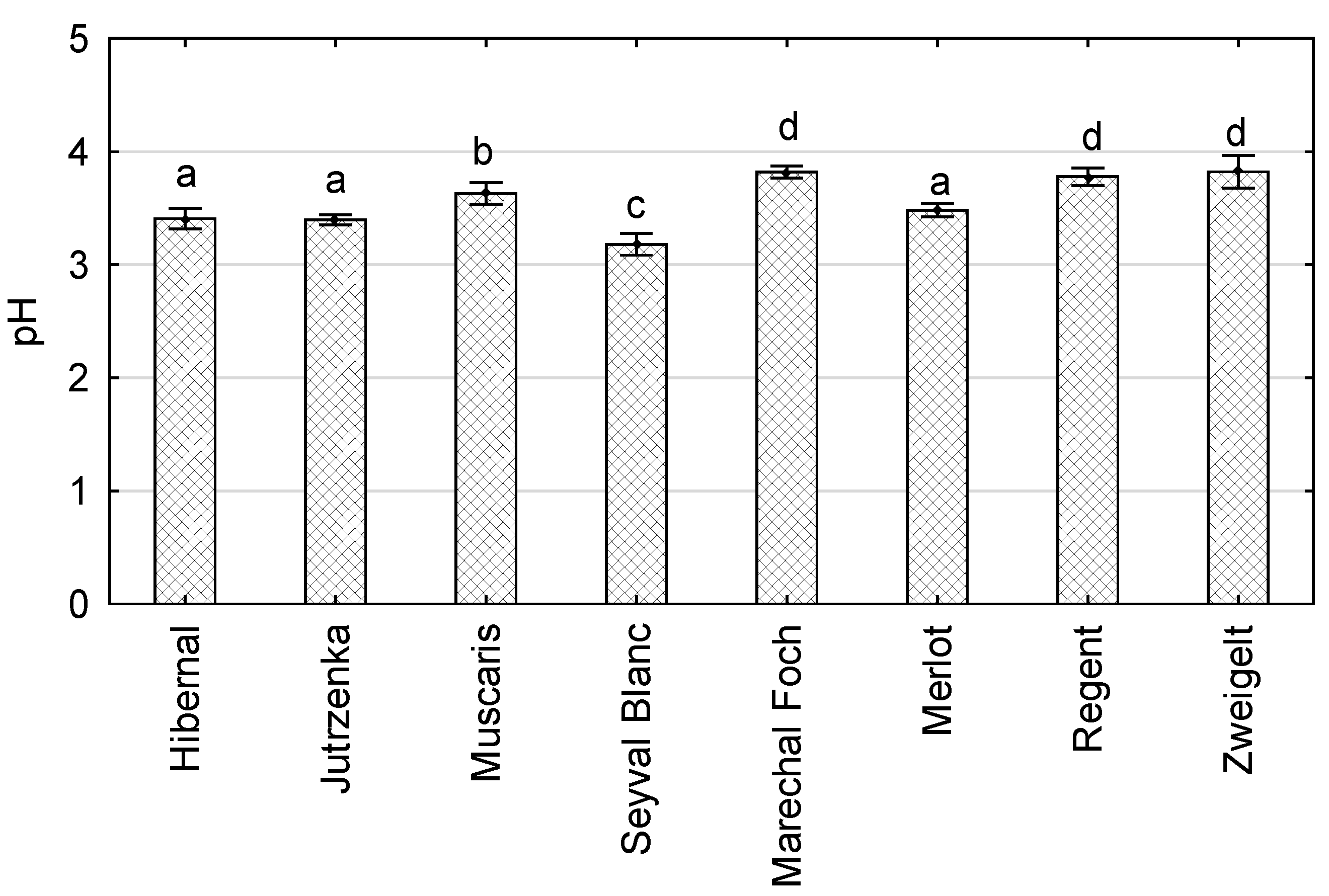

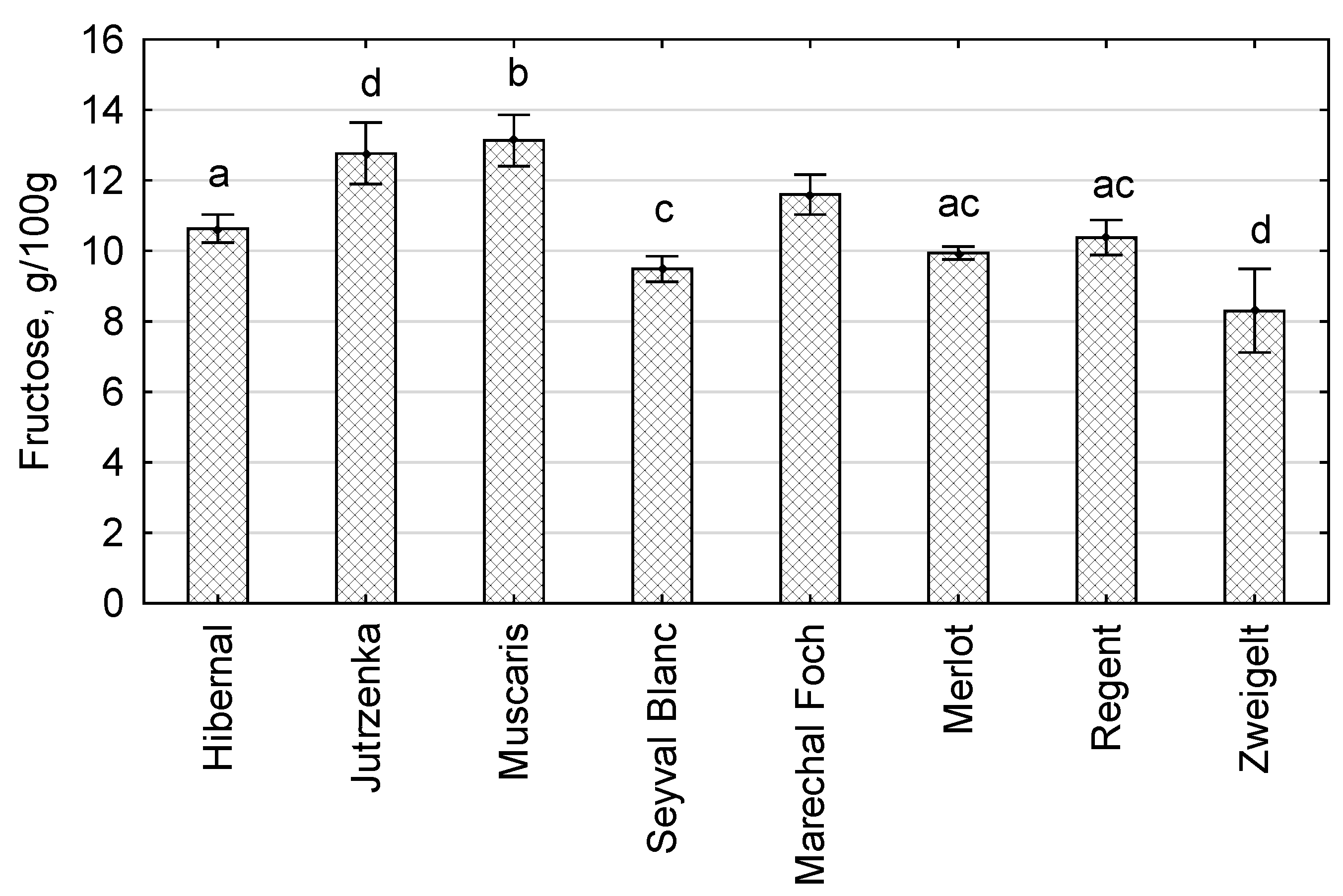

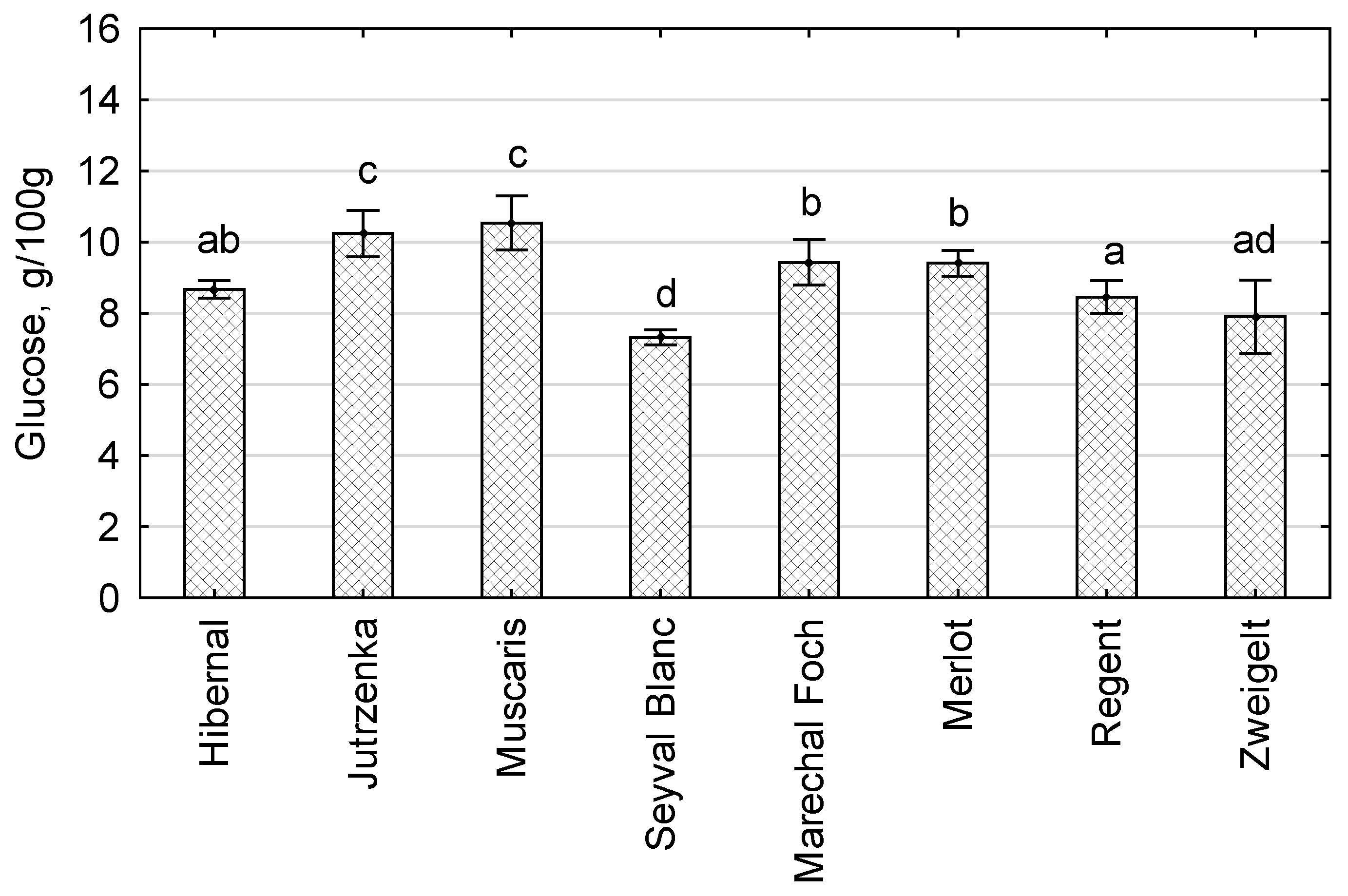

3.1. Effect of the Varietal Characteristics of the Grapes on the Pressing Yield and Quality of the Obtained Juice

3.2. Effect of Pre-Treatment of Grapes on the Pressing Yield and Quality of the Obtained Juice

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| C | Control |

| E | Enzymatic pre-treatment |

| F | Thermal pre-treatment |

References

- El Kersh, D.; Ghada, H.; Marwa, D.; Farag, M. A Comprehensive Review on Grape Juice Beverage in Context to Its Processing and Composition with Future Perspectives to Maximize Its Value. Food Bioprocess Technol. 2023, 16, 1–23. [Google Scholar] [CrossRef]

- Granato, D.; Carrapeiro, M.M.; Fogliano, V.; Van Ruth, S.M. Effects of geographical origin, varietal and farming system on the chemical composition and functional properties of purple grape juices: A review. Trends Food Sci. Technol. 2016, 52, 31–48. [Google Scholar] [CrossRef]

- Gonzalez, C.; Bendaali, Y.; Vaquero, C.; Escott, C.; del Fresno, J.M.; Loira, I.; Bañuelos, M.A.; Palomero, F.; López, C.; Lepe, J.A.S.; et al. Use of red grape juice (concentrated and treated by UHPH) as a base to produce isotonic drinks. In Proceedings of the 44th World Congress of Vine and Wine, BIO Web of Conferences, Cádiz/Jerez, Spain, 5–9 June 2023; p. 02024. [Google Scholar] [CrossRef]

- Rizzon, L.A.; Miele, A. Analytical characteristics and discrimination of Brazilian commercial grape juice, nectar, and beverage. Food Sci. Technol. 2012, 32, 93–97. [Google Scholar] [CrossRef]

- Cory, H.; Passarelli, S.; Szeto, J.; Tamez, M.; Mattei, J. The Role of Polyphenols in Human Health and Food Systems: A Mini-Review. Front. Nutr. 2018, 5, 87. [Google Scholar] [CrossRef]

- Cosme, F.; Pinto, T.; Vilela, A. Phenolic compounds and antioxidant activity in grape juices: A chemical and sensory view. Beverages 2018, 4, 22. [Google Scholar] [CrossRef]

- Dumas, V.; Saurin, N.; Destrac, I.A.; Dedet, S.; Veyret, M.; Marchal, C.; Ojeda, H.; Van Leeuwen, C.; Duchêne, E. Influence of grape juice extraction methods on basic analytical parameters. Vitis 2000, 59, 77–83. [Google Scholar] [CrossRef]

- Shanshiashvili, G.; Baviera, M.; Fracassetti, D. Exploring grape pressing for sparkling wine production: A comprehensive literature review on physicochemical parameters and technological applications. Appl. Food Res. 2024, 4, 100454. [Google Scholar] [CrossRef]

- Kobus, Z.; Nadulski, R.; Wilczyński, K.; Kozak, M.; Guz, T.; Rydzak, L. Effect of the black chokeberry (Aronia melanocarpa (Michx.) Elliott) juice acquisition method on the content of polyphenols and antioxidant activity. PLoS ONE 2019, 4, e0219585. [Google Scholar] [CrossRef]

- Nadulski, R.; Masłowski, A.; Mazurek, A.; Sobczak, P.; Szmigielski, M.; Żukiewicz-Sobczak, W.; Niedziółka, I.; Mazur, J. Vitamin C and lutein content of northern highbush blueberry (Vaccinium corymbosum L.) juice processed using freezing and thawing. J. Food Meas. Charact. 2019, 13, 2521–2528. [Google Scholar] [CrossRef]

- Nadulski, R.; Skwarcz, J.; Sujak, A.; Kobus, Z.; Zawiślak, K.; Stój, A.; Wyrostek, J. Effect of pre-treatment on pressing efficiency and properties of rhubarb (Rheum rhaponticum L.) juice. J. Food Eng. 2015, 166, 370–376. [Google Scholar] [CrossRef]

- Wrolstad, R.E.; Wightman, J.D. Glycosidase activity of enzyme preparations used in fruit juice processing. Food Technol. 1994, 48, 90, 92–94, 96, 98. [Google Scholar]

- Wightman, J.D.; Wrolstad, R.E. Beta-glucosidase activity in juice processing enzymes based on anthocyanin analysis. J. Food Sci. 1996, 61, 544–547. [Google Scholar] [CrossRef]

- Sun, D.-W. Handbook of Frozen Food Processing and Packaging, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2011; p. 960. [Google Scholar]

- Nadulski, R.; Kobus, Z.; Wilczyński, K.; Zawiślak, K.; Grochowicz, J.; Guz, T. Application of freezing and thawing in apple (Malus domestica) juice extraction. J. Food Sci. 2016, 81, E2718–E2725. [Google Scholar] [CrossRef] [PubMed]

- PN-EN 1132:1999; Soki Owocowe i Warzywne—Oznaczanie pH (Fruit and Vegetable Juices—Determination of the pH-Value). Polish Committee for Standardization: Warsaw, Poland, 2013.

- PN-90/A-75101/02:1990; Przetwory Owocowe i Warzywne. Przygotowanie Próbek i Metody Badań Fizykochemicznych. Oznaczenie Zawartości Ekstraktu Ogólnego. Polish Committee for Standardization: Warsaw, Poland, 2013.

- PN-EN 1131:1999; Soki Owocowe i Warzywne—Oznaczanie Gęstości Względnej (Fruit and Vegetable Juices—Determination of the Relative Density). Polish Committee for Standardization: Warsaw, Poland, 2013.

- PN-EN 12630:2002; Soki Owocowe i Warzywne—Oznaczanie Zawartości Glukozy, Fruktozy, Sorbitolu i Sacharozy—Metoda Wysokosprawnej Chromatografii Cieczowej (Fruit and Vegetable Juices—Determination of Glucose, Fructose, Sorbitol and Sucrose Contents—Method Using High Performance Liquid Chromatography). Polish Committee for Standardization: Warsaw, Poland, 2013.

- Statistica, version 12; StatSoft Inc.: Tulsa, OK, USA, 2014.

- Aerny, J.; Dupraz, P.; Brückner, D. Influence du mode d’extraction du moût sur sa composition lors des contrôles de maturité du raisin. Rev. Suisse Vitic. Arboric. Hortic. 2000, 32, 239–243. [Google Scholar]

- Ferreira-Lima, N.; Burin, V.; Caliari, V.; Bordignon-Luiz, M. Impact of pressing conditions on phenolic composition, radical scavenging activity and glutathione content of Brazilian Vitis vinifera white wines and evolution during bottle ageing. Food Bioprocess Technol. 2016, 9, 944–957. [Google Scholar] [CrossRef]

- Silva, M.J.R.; Paiva, A.P.M.; Pimentel Juniora, A.; Sánchez, C.A.P.C.; Callili, D.; Mourab, M.F.; Leonel, S.; Antonio, M. Yield performance of new juice grape varieties grafted onto different rootstocks under tropical conditions. Sci. Hort. 2018, 241, 194–200. [Google Scholar] [CrossRef]

- Krośniak, M.; Gąstoł, M.; Banach, P.; Pytel, A. Wybrane parametry jakościowe winogron uprawianych w Polsce południowej ŻYWNOŚĆ. Nauka. Technologia. Jakość 2009, 4, 116–121. [Google Scholar]

- Nardello, I.C.; Bender, A.; Caliari, V.; Kulkamp de Souza, A.L.; Malgarim, M.B. Quality of juices from different grape cultivars obtained by distinct extraction systems. Cienc. Tec. Vitivinic. 2021, 36, 163–172. [Google Scholar] [CrossRef]

- Ide, W.; Sabando, C.; Castaño, J.; Pettinelli, N.; Bustos, R.; Linares, A.; Mora, L.; Müller, N.; Pascual, G.; Rodríguez-Llamazares, S. Grape (Vitis vinifera L. cv. País) Juices Obtained by Steam Extraction. Processes 2021, 9, 1670. [Google Scholar] [CrossRef]

- Yamamoto, L.Y.; Assis, A.M.; Roberto, S.R.; Bovolenta, Y.R.; Nixford, S.L.; García-Romero, E.; Gómez-Alonso, S.; Hermanoín-Gutiérrez, I. Application of abscisic acid (S -ABA) to cv. Isabel grapes (Vitis vinifera × Vitis labrusca) for color improvement: Effects on color, phenolic composition and antioxidant capacity of their grape juice. Food Res. Int. 2015, 77, 572–583. [Google Scholar] [CrossRef]

- Fongaro, C.; Cavagnolli, N.I.; Spada, P.K.W.D.S. Evaluation of physicochemical parameters of grape juices produced in the Serra Gaúcha. In Proceedings of the 39th World Congress of Vine and Win, BIO Web of Conferences, Bento Gonçalves, Brazil, 24–28 October 2016; p. 01008. [Google Scholar] [CrossRef]

- Jediyi, H.; Naamani, K.; Elkoch, A.; Lemjiber, N. Changes in grapes composition during ripening of five Vitis vinifera L varieties as related to Tephritidae and Drosophilidae infestations. Physiol. Mol. Biol. Plants. 2019, 25, 1407–1418. [Google Scholar] [CrossRef]

- Souza Prado, D.; Pereira Fernandes, J.L.; Gomes de Oliveira, L.; Farias Lima Guedes, T.J.; da Silva Padilha, C.V.; dos Santos Lima, M. Physicochemical stability of grape juice produced on industrial scale by different commercial enzyme preparations. Int. Food Res. J. 2019, 26, 67–74. [Google Scholar]

- Błaszczyk, J.; Krzywonos, M. Analysis of properties grape musts and wines on the example of vineyard from Dolny Śląsk. In Research Papers of Wrocław University of Economics; Wydawnictwo Uniwersytetu Ekonomicznego we Wrocławiu: Wrocław, Poland, 2015; pp. 9–18. [Google Scholar]

- Mota, R.V.; Glória, M.B.A.; Souza, B.; Peregrino, I.; Pimentel, R.; Dias, F.; Souza, L.; Souza, A.; Murillo, R. Bioactive compounds and juice quality from selected grape cultivars. Crop Prod. Manag. Bragantia 2018, 77, 62–73. [Google Scholar] [CrossRef]

- Haight, K.G.; Gump, B.H. The Use of Macerating Enzymes in Grape Juice Processing. Am. J. Enol. Vitic. 1994, 45, 113–116. [Google Scholar] [CrossRef]

- Chevalier, D.; Le Bai, A.; Ghoul, M. Freezing and ice crystals formed in cylindrical food model: Part I. Freezing at atmospheric pressure. J. Food Eng. 2000, 46, 277–285. [Google Scholar] [CrossRef]

- Zuritz, C.A.; Muñoz Puntes, E.; Mathey, H.H.; Pérez, E.H.; Gascón, A.; Rubio, L.A.; Carullo, C.A.; Chernikoff, R.E.; Cabeza, M.S. Density, viscosity and coefficient of thermal expansion of clear grape juice at different soluble solid concentrations and temperatures. J. Food Eng. 2005, 71, 143–149. [Google Scholar] [CrossRef]

- Barnaba, C.; Dellacassa, E.; Nicolini, G.; Giacomelli, M.; Villegas, T.M.; Nardina, T.; Larcher, R. Targeted and untargeted high resolution mass approach for a putative profiling of glycosylated simple phenols in hybrid grapes. Food Res. Int. 2017, 98, 20–33. [Google Scholar] [CrossRef]

- Jovanović-Cvetković, T.; Grbić, R.; Starčević, D.; Milašin, M. Technological characteristics of interspecific hybrids Bronner, Muscaris and Morava in Banja Luka region. J. Agric. Food Environ. Sci. 2022, 76, 57–67. [Google Scholar] [CrossRef]

| White Grapes | Red Grapes | |

|---|---|---|

| Yield, % | 56.07 ± 6.48 a | 59.45 ± 4.31 b |

| Extract, °Bx | 20.66 ± 1.72 a | 19.93 ± 1.65 b |

| pH | 3,41 ± 0.18 a | 3.73 ± 0.17 b |

| Density, g/cm3 | 1.035 ± 0.023 a | 1.041 ± 0.028 a |

| Fructose, g/100 g | 11.51 ± 1.64 a | 10.05 ± 1.38 b |

| Glucose, g/100 g | 9.19 ± 1.41 a | 8.81 ± 0.92 b |

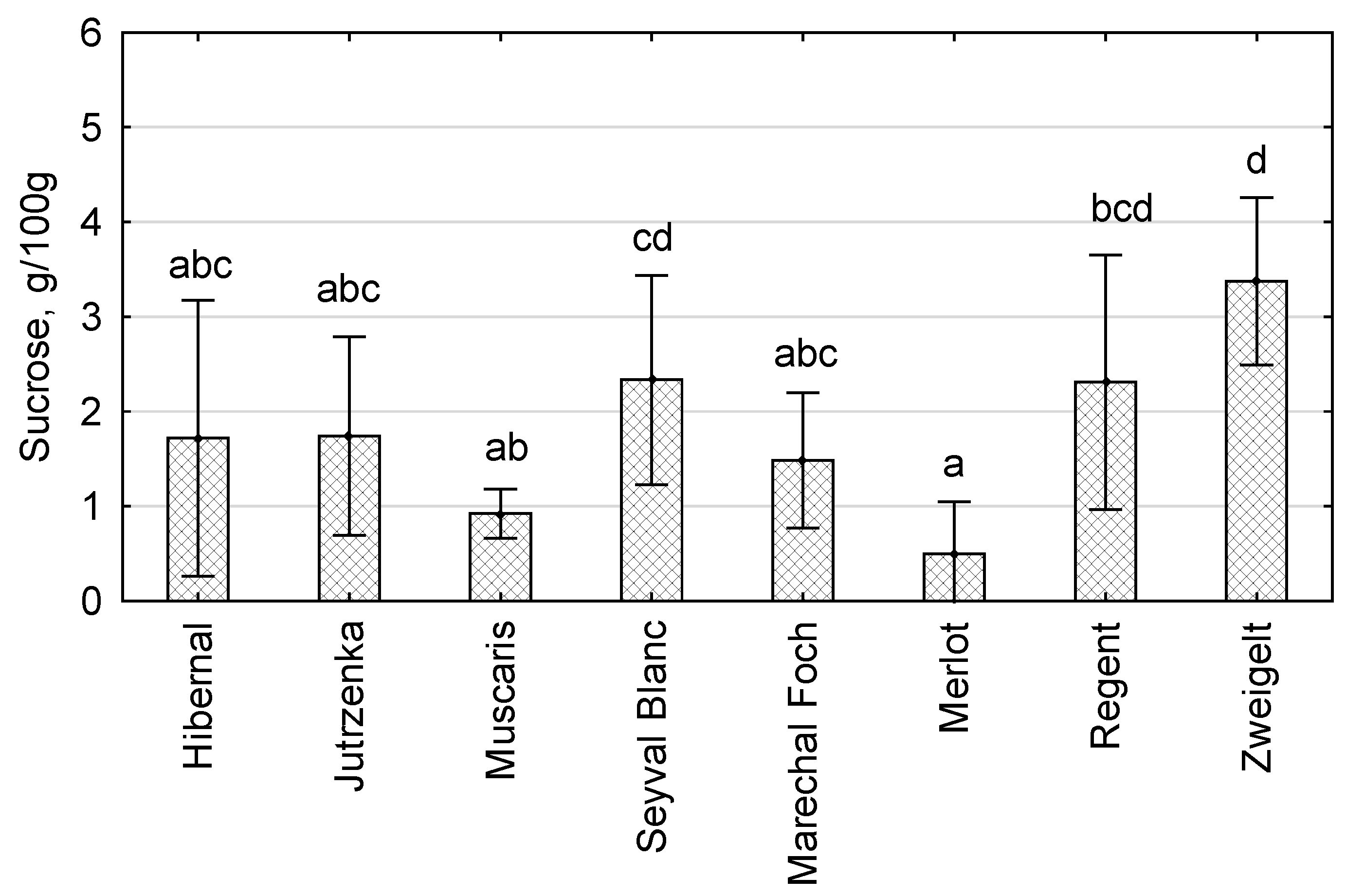

| Sucrose, g/100 g | 1.68 ± 1.13 a | 1.92 ± 1.39 a |

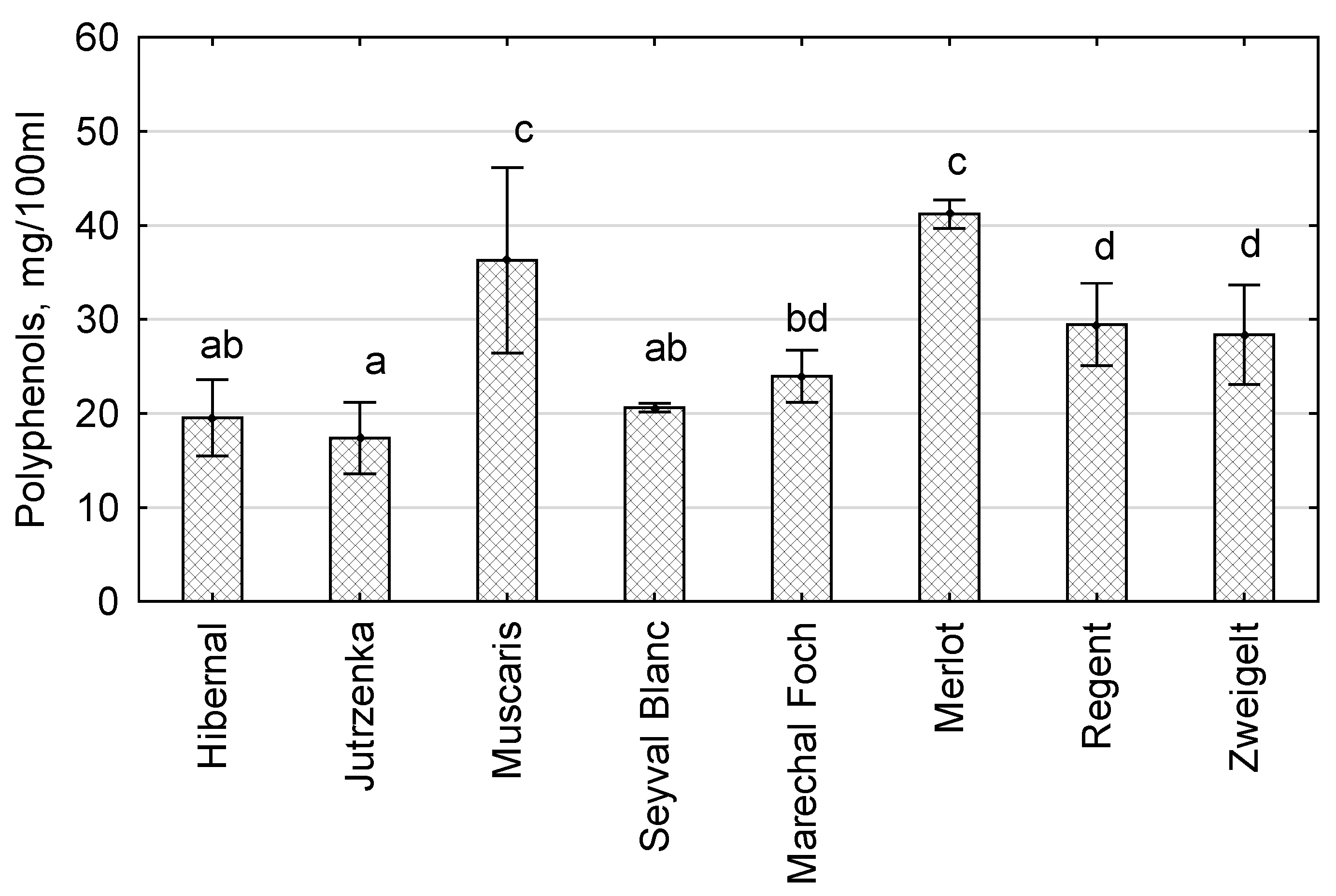

| Polyphenol, mg/100 mL | 23.45 ± 9.34 a | 30.75 ± 7.42 b |

| Ash, % | 0.39 ± 0.07 a | 0.41 ± 0.08 a |

| Color | Variety | Control (C) | Enzymatic Pre-Treatment (E) | Thermal Pre-Treatment (F) |

|---|---|---|---|---|

| White grapes | Jutrzenka | 58.99 ± 0.76 a | 63.81 ± 0.01 b | 47.84 ± 0.86 c |

| Hibernal | 54.74 ± 0.32 a | 57.07 ± 0.68 a | 59.46 ± 1.16 b | |

| Muscaris | 49.53 ± 2.75 ab | 51.79 ± 0.91 a | 45.03 ± 1.39 b | |

| Seyval Blanc | 58.48 ± 1.16 a | 67.58 ± 1.15 b | 58.58 ± 1.12 c | |

| Red grapes | Marechal Foch | 63.39 ± 0.75 a | 66.54 ± 1.04 a | 58.87 ± 1.99 b |

| Merlot | 54.31 ± 1.69 a | 56.53 ± 1.45 ab | 52.92 ± 0.38 b | |

| Regent | 54.39 ± 1.81 a | 60.82 ± 1.09 b | 62.34 ± 1.07 b | |

| Zweigelt | 58.24 ± 2.26 a | 62.62 ± 0.64 b | 62.38 ± 1.55 b |

| Color | Variety | Control (C) | Enzymatic Pre-Treatment (E) | Thermal Pre-Treatment (F) |

|---|---|---|---|---|

| White grapes | Jutrzenka | 20.80 ± 0.43 a | 20.77 ± 0.06 a | 22.80 ± 0.10 b |

| Hibernal | 19.63 ± 0.23 a | 19.57 ± 0.06 a | 19.60 ± 0.27 a | |

| Muscaris | 22.77 ± 1.96 a | 22.37 ± 0.06 a | 23.10 ± 0.27 a | |

| Seyval Blanc | 18.43 ± 0.35 a | 19.17 ± 0.25 b | 18.90 ± 0.20 ab | |

| Red grapes | Marechal Foch | 22.13 ± 0.41 a | 22.63 ± 0.21 a | 22.01 ± 0.27 a |

| Merlot | 20.01 ± 0.36 a | 19.73 ± 0.15 b | 19.27 ± 0.23 ab | |

| Regent | 18.97 ± 0.61 a | 20.01 ± 0.20 b | 19.51 ± 0.10 ab | |

| Zweigelt | 19.23 ± 0.15 a | 19.27 ± 0.15 a | 16.47 ± 0.25 b |

| Color | Variety | Control (C) | Enzymatic Pre-Treatment (E) | Thermal Pre-Treatment (F) |

|---|---|---|---|---|

| White grapes | Jutrzenka | 3.46 ± 0.03 ab | 3.29 ± 0.02 a | 3.48 ± 0.04 b |

| Hibernal | 3.45 ± 0.03 a | 3.29 ± 0.02 b | 3.40 ± 0.04 a | |

| Muscaris | 3.66 ± 0.03 a | 3.51 ± 0.03 b | 3.72 ± 0.01 a | |

| Seyval Blanc | 3.11 ± 0.02 a | 3.13 ± 0.01 a | 3.31 ± 0.02 b | |

| Red grapes | Marechal Foch | 3.87 ± 0.04 a | 3.83 ± 0.01 a | 3.75 ± 0.01 b |

| Merlot | 3.46 ± 0.01 a | 3.43 ± 0.02 b | 3.56 ± 0.01 c | |

| Regent | 3.68 ± 0.02 a | 3.81 ± 0.02 b | 3.85 ± 0.01 b | |

| Zweigelt | 3.74 ± 0.01 a | 3.71 ± 0.03 a | 4.01 ± 0.04 b |

| Color | Variety | Control (C) | Enzymatic Pre-Treatment (E) | Thermal Pre-Treatment (F) |

|---|---|---|---|---|

| White grapes | Jutrzenka | 1.073 ± 0.009 a | 1.026 ± 0.005 b | 1.027 ± 0.007 b |

| Hibernal | 1.062 ± 0.006 a | 1.007 ± 1.003 b | 1.021 ± 0.016 b | |

| Muscaris | 1.055 ± 0.008 a | 1.044 ± 0.006 a | 1.008 ± 0.004 b | |

| Seyval Blanc | 1.054 ± 0.004 a | 1.043 ± 0.006 a | 1.006 ± 0.004 b | |

| Red grapes | Marechal Foch | 1.077 ± 0.001 a | 1.043 ± 0.008 b | 1.007 ± 0.002 c |

| Merlot | 1.062 ± 0.003 a | 1.021 ± 0.005 b | 1.006 ± 0.003 c | |

| Regent | 1.051 ± 0.012 a | 1.087 ± 0.007 b | 1.015 ± 0.006 c | |

| Zweigelt | 1.059 ± 0.014 a | 1.046 ± 0.007 a | 1.014 ± 0.011 b |

| Color | Variety | Control (C) | Enzymatic Pre-Treatment (E) | Thermal Pre-Treatment (F) |

|---|---|---|---|---|

| White grapes | Jutrzenka | 13.72 ± 0.27 a | 11.81 ± 0.35 b | 12.81 ± 0.38 c |

| Hibernal | 11.01 ± 0.22 a | 10.21 ± 0.20 b | 10.71 ± 0.21 a | |

| Muscaris | 12.81 ± 0.26 a | 12.62 ± 0.38 a | 14.01 ± 0.42 b | |

| Seyval Blanc | 9.65 ± 0.29 a | 9.71 ± 0.19 a | 9.11 ± 0.77 a | |

| Red grapes | Marechal Foch | 11.01 ± 0.33 a | 12.12 ± 0.36 b | 11.7 ± 0.35 ab |

| Merlot | 9.99 ± 0.21 a | 9.97 ± 0.20 a | 9.85 ± 0.20 a | |

| Regent | 9.94 ± 0.30 a | 10.91 ± 0.33 b | 10.31 ± 0.31 ab | |

| Zweigelt | 6.76 ± 0.14 a | 9.33 ± 0.19 b | 8.81 ± 0.18 c |

| Color | Variety | Control (C) | Enzymatic Pre-Treatment (E) | Thermal Pre-Treatment (F) |

|---|---|---|---|---|

| White grapes | Jutrzenka | 10.81 ± 0.32 a | 9.54 ± 0.38 b | 10.41 ± 0.42 a |

| Hibernal | 8.54 ± 0.25 a | 8.75 ± 0.26 a | 8.74 ± 0.26 a | |

| Muscaris | 10.21 ± 0.31 a | 9.93 ± 0.20 a | 11.52 ± 0.23 b | |

| Seyval Blanc | 7.32 ± 0.22 a | 7.44 ± 0.22 a | 7.22 ± 0.22 a | |

| Red grapes | Marechal Foch | 8.66 ± 0.26 a | 9.99 ± 0.30 b | 9.65 ± 0.19 b |

| Merlot | 9.18 ± 0.28 a | 9.28 ± 0.28 a | 9.77 ± 0.29 a | |

| Regent | 7.94 ± 0.24 a | 8.88 ± 0.27 b | 8.81 ± 0.26 b | |

| Zweigelt | 6.56 ± 0.20 a | 8.67 ± 0.26 b | 8.48 ± 0.26 b |

| Color | Variety | Control (C) | Enzymatic Pre-Treatment (E) | Thermal Pre-Treatment (F) |

|---|---|---|---|---|

| White grapes | Jutrzenka | 0.82 ± 0.02 a | 1.29 ± 0.03 b | 3.11 ± 0.06 c |

| Hibernal | 0.73 ± 0.02 a | 0.77 ± 0.02 a | 3.66 ± 0.07 b | |

| Muscaris | 1.26 ± 0.04 a | 0.81 ± 0.02 | 0.70 ± 0,01 c | |

| Seyval Blanc | 3.61 ± 0.07 a | 1.05 ± 0.04 b | 2.35 ± 0.05 c | |

| Red grapes | Marechal Foch | 0.56 ± 0.01 a | 1.75 ± 0.04 b | 2.14 ± 0.06 c |

| Merlot | 0.12 ± 0.00 a | 0.15 ± 0.01 a | 1.23 ± 0.04 b | |

| Regent | 2.83 ± 0.06 a | 3.53 ± 0.07 b | 0.57 ± 0.01 c | |

| Zweigelt | 2.22 ± 0.07 a | 3.77 ± 0.11 b | 4.13 ± 0.12 c |

| Color | Variety | Control (C) | Enzymatic Pre-Treatment (E) | Thermal Pre-Treatment (F) |

|---|---|---|---|---|

| White grapes | Jutrzenka | 13.15 ± 0.26 a | 17.09 ± 0.51 b | 21.88 ± 0.66 c |

| Hibernal | 16.76 ± 0.34 a | 16.92 ± 0.34 a | 24.91 ± 0.49 b | |

| Muscaris | 29.41 ± 0.59 a | 30.11 ± 0.91 b | 49.39 ± 1.48 c | |

| Seyval Blanc | 20.57 ± 0.62 a | 20.45 ± 0.41 a | 20.81 ± 0.42 a | |

| Red grapes | Marechal Foch | 27.55 ± 0.55 a | 21.56 ± 0.43 b | 22.74 ± 0.68 b |

| Merlot | 40.64 ± 1.22 a | 42.64 ± 1.28 a | 40.36 ± 1.21 a | |

| Regent | 25.75 ± 0.52 a | 35.19 ± 0.71 b | 27.42 ± 0.55 c | |

| Zweigelt | 21.41 ± 0.64 a | 32.48 ± 0.97 b | 31.21 ± 0.94 b |

| Color | Variety | Control (C) | Enzymatic Pre-Treatment (E) | Thermal Pre-Treatment (F) |

|---|---|---|---|---|

| White grapes | Jutrzenka | 0.291 ± 0.006 a | 0.351 ± 0.007 b | 0.362 ± 0.006 b |

| Hibernal | 0.314 ± 0.006 a | 0.391 ± 0.008 b | 0.441 ± 0.009 c | |

| Muscaris | 0.442 ± 0.013 a | 0.412 ± 0.012 b | 0.392 ± 0.012 c | |

| Seyval Blanc | 0.562 ± 0.017 a | 0.361 ± 0.011 b | 0.343 ± 0.010 b | |

| Red grapes | Marechal Foch | 0.473 ± 0.014 a | 0.562 ± 0.017 b | 0.371 ± 0.011 c |

| Merlot | 0.432 ± 0.009 a | 0.372 ± 0.007 b | 0.333 ± 0.007 c | |

| Regent | 0.353 ± 0.011 a | 0.362 ± 0.011 a | 0.473 ± 0.014 b | |

| Zweigelt | 0.273 ± 0.005 a | 0.423 ± 0.008 b | 0.472 ± 0.009 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nadulski, R.; Sobczak, P.; Mazur, J.; Łysiak, G. Effect of Pre-Treatment on the Pressing Yield and Quality of Grape Juice Obtained from Grapes Grown in Poland. Sustainability 2025, 17, 7010. https://doi.org/10.3390/su17157010

Nadulski R, Sobczak P, Mazur J, Łysiak G. Effect of Pre-Treatment on the Pressing Yield and Quality of Grape Juice Obtained from Grapes Grown in Poland. Sustainability. 2025; 17(15):7010. https://doi.org/10.3390/su17157010

Chicago/Turabian StyleNadulski, Rafał, Paweł Sobczak, Jacek Mazur, and Grzegorz Łysiak. 2025. "Effect of Pre-Treatment on the Pressing Yield and Quality of Grape Juice Obtained from Grapes Grown in Poland" Sustainability 17, no. 15: 7010. https://doi.org/10.3390/su17157010

APA StyleNadulski, R., Sobczak, P., Mazur, J., & Łysiak, G. (2025). Effect of Pre-Treatment on the Pressing Yield and Quality of Grape Juice Obtained from Grapes Grown in Poland. Sustainability, 17(15), 7010. https://doi.org/10.3390/su17157010