1. Introduction

With the rapid development of e-commerce and the acceleration of urbanization, the demand for urban freight has shown explosive growth, especially the number and frequency of last-mile delivery have increased significantly [

1,

2]. This stage, as the most complex and challenging link in the logistics distribution chain, is not only related to service quality and customer satisfaction but also directly affects urban traffic congestion, energy consumption, and carbon emissions [

3,

4]. According to statistics, urban logistics transportation has accounted for more than 40% of urban road traffic flow and contributed up to 30% of urban traffic carbon emissions [

5]. This not only aggravates environmental pollution and energy pressure but also places increased requirements on urban sustainable development strategies. Therefore, the development of an efficient, green, and low-carbon urban logistics system has become an important issue faced by major cities around the world.

In this context, as a key infrastructure and functional node of the urban logistics system, the scientific site selection of logistics centers is crucial to optimizing the distribution network, improving transportation efficiency, and reducing operating costs and environmental burdens [

6,

7]. The reasonable site selection of logistics centers can not only shorten the distribution distance and alleviate road traffic pressure but can also promote the agglomeration of logistics industries and the efficient use of land resources. However, in metropolitan areas with limited land resources and huge traffic pressure, traditional logistics centers are mostly located on the edge of the city, often with problems such as long distance, slow response, and untimely delivery, which makes it difficult to meet the increasingly diversified and efficient delivery needs. In this context, how to reasonably lay out logistics centers in the core area or near the core area of the city has become a key issue that needs to be studied and solved urgently.

In recent years, with the rise of the concept of urban stock space reuse, the site selection scheme of urban logistics centers based on the transformation of public infrastructure such as subway vehicle bases and old factories has begun to attract attention from academia and practitioners. This type of scheme has significant advantages in alleviating the contradiction between land supply and demand, improving urban logistics efficiency, and promoting sustainable development. However, systematic research on this type of new site selection scheme is still relatively limited. The existing literature mostly focuses on the optimization of new logistics parks or traditional site selection in suburban areas, but lacks theoretical frameworks and empirical analysis for the site selection of logistics centers against the background of stock space reuse [

6,

8,

9,

10]. In addition, in terms of methodology, most studies use a single evaluation method and rarely combine qualitative and quantitative indicators for comprehensive evaluation, which makes it difficult to fully reflect the demands of complex stakeholders in the city and the multi-dimensional characteristics of site selection decisions.

Therefore, this study focuses on the Seoul metropolitan area and proposes a multi-criteria decision analysis framework that integrates the Analytic Hierarchy Process (AHP) and the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) to systematically identify and evaluate the reuse of subway vehicle bases as a key factor in the site selection of urban logistics centers and to rank and compare different site selection options. This framework covers multiple dimensions such as geographical location, economic benefits, social acceptance, and environmental impact and aims to provide a scientific and systematic site selection reference for government decision-makers, urban planners, and logistics companies to support Seoul and other metropolises in promoting the practical exploration of sustainable logistics system construction.

This research is structured as follows: the second part reviews the relevant research on the location selection of logistics centers; the third part introduces the current situation of the Korean logistics market and the background of urban logistics development; the fourth part elaborates on the evaluation framework and research methods proposed in this study; the fifth part presents the results of empirical analysis; the sixth part is the discussion part, which analyzes the theoretical and practical significance of the research results and compares them with existing research; and the seventh part summarizes the main findings of the study and proposes directions and suggestions for future research.

2. Literature Review

The concept of the ‘location problem’, initially articulated by Owen and Daskin in 1998 [

11] and expanded by Farahani and Hekmatfar in 2009 [

12], focuses on the strategic placement of infrastructure such as facilities or logistics centers within a designated area. This decision-making process integrates the preferences of the stakeholders with the constraints inherent to the environment. Given its broad applicability, the location problem spans a variety of site types and facility categories. Researchers investigating the optimal siting of logistics centers have utilized a range of methodologies and criteria to navigate and resolve this complex problem.

Various methodologies and decision-making frameworks have been utilized by researchers to address the challenges of selecting locations for logistics centers. Notably, Erkayman et al. [

13] utilized a fuzzy TOPSIS methodology for determining the most suitable logistics center locations in Eastern Anatolia, Turkey. This method is particularly valuable for its integration of fuzzy logic, which adeptly manages the uncertainty and imprecision commonly present in real-world problems. By incorporating elements like linguistic variables and fuzzy numbers, fuzzy TOPSIS offers a dynamic and realistic framework for evaluating possible sites for logistics centers, enhancing the decision-making process in complex scenarios. Żak and Węgliński [

14] developed a novel two-phase methodology that employs the Multiple Criteria Decision Making/Analysis (MCDM/A) framework to enhance regional logistics assessments. This method initiates with a macro-analysis to filter potential regions, followed by a meticulous multiple criteria evaluation of specific sites within these regions using the Electre III/IV technique. Renowned for its robustness, the Electre III/IV method excels in addressing complex scenarios characterized by numerous, and sometimes conflicting, decision criteria, offering a thorough and nuanced evaluation of logistics capabilities.

Uyanık et al. [

15] executed an extensive review of the literature, organizing prior studies by the models and criteria they utilized. This survey not only provided a comprehensive summary of the field but also revealed existing trends and gaps, underlining the dynamic development of methodologies in logistics center site selection. Their findings advocate for regular updates and refinements of evaluation models to align with evolving logistics and environmental landscapes. Simultaneously, the process of selecting locations for logistics centers requires the detailed consideration of both qualitative and quantitative factors. Highlighting this, Erkayman et al. [

13] focused on elements such as the proximity to production hubs, commercial centers, and major transportation links, including highways, railways, airports, and seaports. Their research underscored the critical role that connectivity and accessibility play in boosting the operational efficiency and overall effectiveness of logistics centers.

Different scholars have applied a variety of methods and frameworks in the study of logistics center location selection. Relevant representative studies have been summarized in

Table 1.

Table 1 lists the authors, years, methods, and facility types of the studies to help readers understand the current status of the research.

While these studies offer valuable methodological contributions, several gaps remain. First, few studies incorporate infrastructure reuse (e.g., public or idle facilities) into site selection models. Second, empirical applications targeting dense metropolitan regions with space constraints, such as Seoul, are relatively limited. Third, although last-mile delivery has emerged as a critical component of urban logistics, it is rarely central to existing site evaluation frameworks. To address these gaps, this study proposes an integrated AHP-TOPSIS framework tailored to evaluate the suitability of repurposing subway vehicle bases as urban logistics centers. By considering a broad set of criteria, this approach aims to provide a more holistic and context-specific method for urban logistics infrastructure planning.

3. Korean Logistics Market

3.1. Urban Logistics Development

According to the World Bank Logistics Performance Index (LPI), the global competitiveness of South Korea’s logistics industry has been continuously improving in recent years. The changes in South Korea’s global LPI ranking are shown in

Table 2.

Table 2 shows the trend of South Korea’s ranking changes from 2014 to 2023. Between 2014 and 2023, South Korea’s ranking improved from 21st to 17th place, reflecting advancements in performance and efficiency on a global scale. This positive trend suggests that South Korea has effectively addressed various factors contributing to logistics performance, including infrastructure quality, logistics competence, shipment procedures, tracking and tracing, timeliness, and international shipments. Such improvements have considerable implications for South Korea’s competitiveness in international trade and its appeal to investors in logistics-related sectors.

Urbanization, technological advancements, and evolving consumer behaviors have driven substantial changes in urban logistics development in South Korea [

3,

28]. With a growing population in urban areas, particularly in megacities like Seoul and Busan, there is an increasing demand for efficient and sustainable urban logistics solutions.

The rise of e-commerce has also significantly impacted logistics [

29]. Changing consumer habits have led to a surge in online retail transactions, necessitating the development of urban logistics infrastructure to manage increased parcel volumes and ensure timely, reliable delivery. Consequently, South Korea has seen the growth of urban fulfillment centers, micro-warehouses, and automated parcel delivery systems to meet the increasing demand for e-commerce logistics services.

Generally, the development of urban logistics in South Korea showcases a dynamic landscape marked by technological innovation, shifting consumer preferences, and a strong emphasis on sustainability [

30,

31]. As urban areas continue to grow, effective collaboration among logistics stakeholders will be essential to address emerging challenges and capitalize on opportunities to enhance efficiency and sustainability. The continued improvement in logistics performance, as reflected in the World Bank LPI rankings, highlights South Korea’s commitment to advancing its logistics industry and reinforcing its position in the global market.

3.2. Logistics Facilities in Seoul Metropolitan Area

The Seoul Metropolitan Area, situated in northwest Korea, spans approximately 605.2 km2. This region includes Seoul, Incheon Metropolitan City, cities in Gyeonggi Province, and Cheonan and Asan in South Chungcheong Province, as well as Chuncheon in Gangwon Province. As Korea’s economic, political, residential, and cultural hub, the area plays a central role in the country’s activities. Logistics centers in this region are predominantly located in the southeastern part, which benefits from excellent highway connectivity. The central expressway, connecting Busan Port with southeastern Seoul, serves as a crucial logistics hub and distribution point, significantly enhancing the efficiency of goods movement within and beyond the region.

The Seoul Metropolitan Government, reliant on national funding, aligns its planning projects with national priorities, reflecting both regional and national strategic goals. Despite economic challenges, the strategic significance of the area has prompted many logistics facilities to relocate closer to Seoul to optimize operations in response to evolving market demands. The rapid expansion of the internet and the high population density in urban areas have revolutionized the retail sector. E-commerce, fueled by advanced online sales models and direct distribution methods, has significantly grown, expanding the logistics market in the Seoul Metropolitan Area and underscoring its importance as a logistics hub.

The COVID-19 pandemic accelerated the shift towards online shopping, with a marked increase in orders for food, daily necessities, and medical supplies. This surge highlighted the essential role of last-mile delivery and logistics facilities in meeting the growing demand for timely and efficient deliveries. The pandemic emphasized the need for a well-integrated logistics infrastructure capable of handling increased online order volumes and ensuring robust supply chain resilience.

Given Seoul’s high population density, developing sustainable and advanced logistics systems that align with national and regional plans is crucial [

1,

32]. Efforts are underway to create an urban logistics ecosystem, with a focus on evaluating and selecting logistics centers near subway stations. Aligning logistics planning with urban development goals is vital for achieving sustainable growth and efficient urban logistics networks.

To address the rising logistics demand while reducing traffic congestion and air pollution, the Seoul Metropolitan Government has introduced an innovative business model. This model repurposes vehicle bases near subway stations into logistics hubs, transforming these areas into global business districts. This approach aims to alleviate road congestion, decrease pollution, and ensure the safety of logistics operations within the city center.

Following the success of this pilot project, the Korean Ministry of Land, Infrastructure, and Transport launched the ‘Life-Logistics Development Agenda’ in September 2020. This agenda aims to establish public subway stations as logistics hubs, with a target of increasing such hubs to ten by 2025. Additionally, existing logistics plans, including cargo containers at subway stations and passenger deliveries from the city center to the airport, continue to expand, further integrating logistics into urban infrastructure.

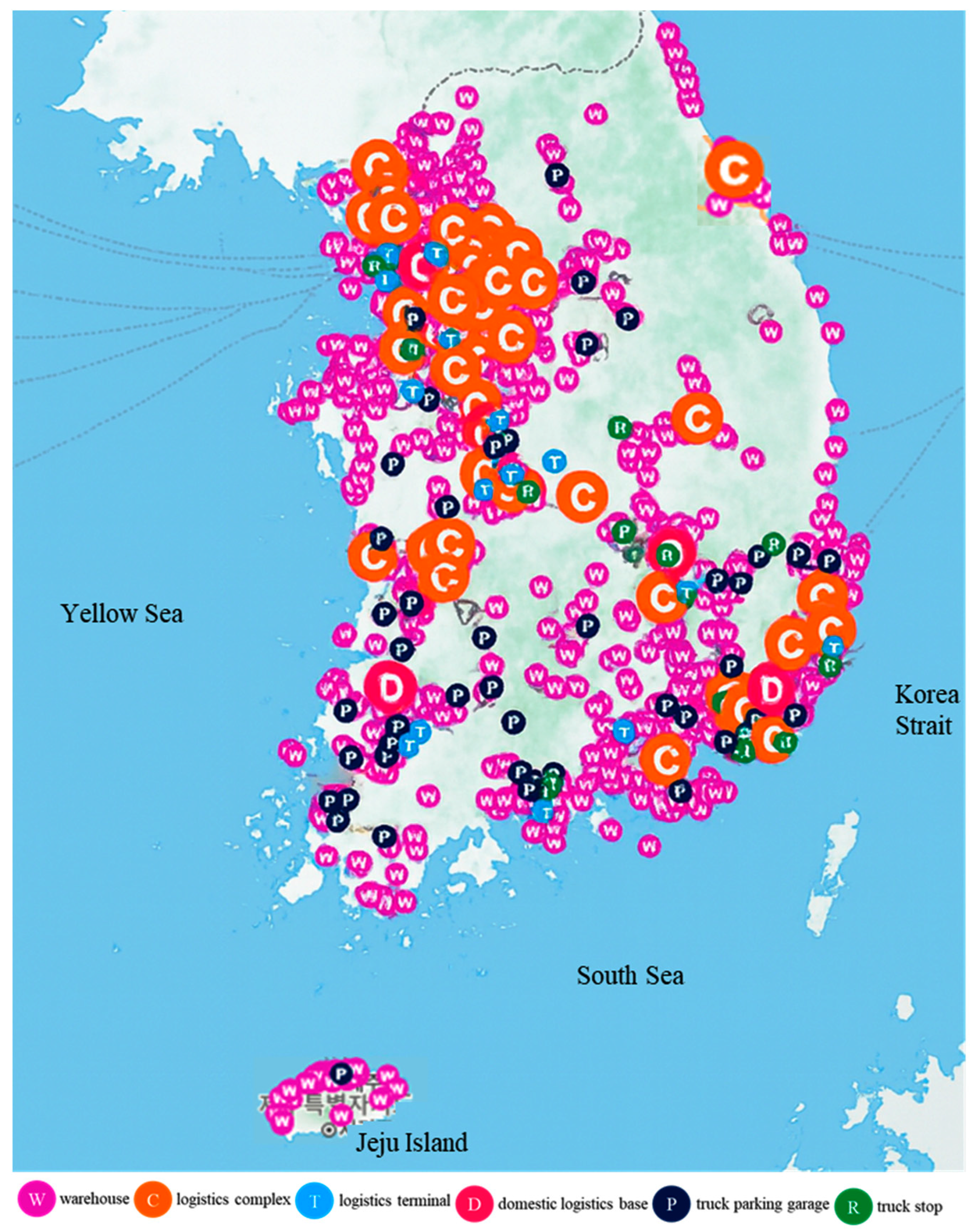

Figure 1 shows the geographical distribution of major logistics infrastructure (such as logistics parks, warehouses, parking lots, etc.) across the country. It can be seen that logistics resources are highly concentrated in the southeast of the Seoul metropolitan area, forming a regional logistics core area. This phenomenon further highlights the shortage of logistics land in the central area of Seoul and the complexity of site selection.

In general, although the current logistics infrastructure of the Seoul metropolitan area is well laid out, it still faces problems such as tight logistics space in the central city, slow distribution response, and heavy road traffic pressure. Especially in the city center and its surrounding areas, traditional logistics centers are unable to meet the rapid development of e-commerce distribution needs in a timely manner due to the lack of available land and long construction period. Therefore, the reuse of existing urban public spaces such as subway vehicle bases has become an attractive innovative site selection solution. Based on this realistic background, this study focuses on how to scientifically evaluate and rank the feasibility of subway vehicle bases as the site selection of urban logistics centers to support Seoul in achieving efficient, low-carbon, and sustainable urban logistics goals.

This study closely combines the reuse of subway vehicle bases with the problem of urban logistics site selection and quantitatively compares different site selection solutions through a multi-criteria decision analysis method. This solution not only meets the actual needs of Seoul’s existing land resource utilization but also echoes the government’s policy direction on building a comprehensive logistics hub, alleviating traffic pressure, and promoting sustainable urban development.

4. Evaluation System

4.1. Research Objects

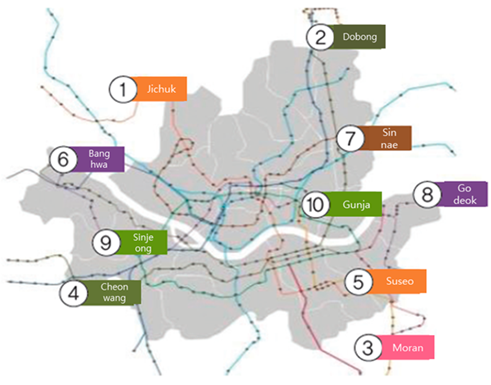

In response to the surge in logistics demand, the government is developing logistics centers utilizing idle spaces in subway vehicle bases across the Seoul Metropolitan Subway and its surrounding areas. Given this context, this study has selected ten subway vehicle bases as the focal points of research. These locations have been chosen for their potential to serve as effective logistics centers due to their strategic placement and available infrastructure. This study aims to evaluate these sites to determine their suitability for logistics operations based on various criteria.

Table 3 briefly shows the names and areas of the 10 candidate subway vehicle bases. A schematic diagram of their location distribution is also included in the table. This information provides a basic reference for subsequent site selection evaluation.

4.2. Evaluation Criteria

The selection of suitable locations for urban logistics centers involves a multidimensional evaluation process, given the complex interplay between infrastructure characteristics, spatial accessibility, socio-environmental considerations, and stakeholder dynamics. In this study, a hierarchical evaluation framework is established to assess the feasibility of repurposing subway vehicle bases into logistics hubs within the Seoul Metropolitan Area. The framework consists of four major categories, namely facility, geographical, environmental, and social factors, and is further divided into fifteen sub-criteria, as shown in

Table 4. These evaluation criteria were developed through a review of the literature and refined based on expert consultations to ensure their contextual relevance and practical applicability.

4.3. Methodology

4.3.1. Analytic Hierarchy Process (AHP)

In this research, the initial analytical approach involves the AHP, an established MCDM tool that is particularly effective for addressing complex scenarios with multiple decision criteria and possible outcomes [

23,

24,

27]. Originating from the work of Thomas L. Saaty in the 1970s [

33,

34,

35], the AHP framework supports decision-makers in a detailed evaluation and comparison of varying criteria and alternatives. This process is instrumental in deriving a decision that is both optimal and informed, suited especially for contexts where decisions are heavily based on subjective judgment. The AHP provides a methodical structure for such assessments, consisting of the following steps to calculate and analyze decision-making elements

Step 1: Establishing the hierarchy: The decision problem is first decomposed into a hierarchical structure, which simplifies the complexity of the decision-making process. This hierarchy generally includes three levels:

Goal Level: This level specifies the overall objective of the decision.

Criteria Level: This level contains the key criteria necessary to achieve the goal.

Alternatives Level: This level includes various options or alternatives available for selection.

Step 2: Constructing pairwise comparison matrices: Decision-makers play a central role in this step, as they are required to provide their assessments on the relative importance of each pair of factors. The process begins with the decision-makers comparing each pair of criteria, one at a time, using a predefined scale.

In the AHP method, the experts’ relative importance judgments are based on a standard 9-point scale. The scale definition for pairwise comparisons is shown in

Table 5.

Table 5 helps to standardize the evaluation process and ensure the consistency of the judgment results.

Step 3: Calculating weights: After establishing the pairwise comparison matrices, the subsequent phase involves deriving the weights for each criterion and alternative. This calculation involves extracting the eigenvector from the judgment matrices, specifically the one corresponding to the highest eigenvalue. This vector forms the priority vector or weights, reflecting the relative importance assigned by the decision-maker to each factor. These weights are then normalized to ensure their total equals one.

Step 4: To verify the reliability of the decision-maker’s judgments, a consistency check is carried out on the matrices. This check involves calculating the consistency ratio (CR), which is determined by comparing the consistency index (CI) of the matrix against the random index (RI). A CR of 0.1 or below is generally acceptable, indicating a coherent judgment set. If the CR exceeds this limit, it suggests potential inconsistencies in the judgments, requiring the decision-maker to re-evaluate and adjust the comparisons.

In the pairwise comparison process, the matrix A is used for decisions, and the maximum eigenvalue from this matrix, denoted as

, plays a critical role. For indexes ranging from 1 to n, the CI is derived to measure the degree of consistency in the pairwise comparisons. The CI is pivotal for assessing the reliability of the judgments provided.

The final step in the evaluation process involves calculating the CR. According to Saaty [

33], a CR value below 0.1 is indicative of a consistent and reliable judgment matrix, thereby validating the suitability of the derived weights for decision-making. This threshold confirms that the judgments made in the pairwise comparisons are both coherent and acceptable. The formulation of CR is as follows:

In the consistency evaluation process, RI represents the average random index, which is determined for matrices of varying orders, typically from 1 to 10. This value is crucial for assessing the consistency of the decision matrix. The specific RI values for these matrix orders can be referenced from the table provided by Saaty in 1980 [

34], which aids in ensuring the reliability of the pairwise comparison judgments (see

Table 6).

Step 5: Comprehensive evaluation: Based on the weights assigned to each criterion and alternative, a comprehensive evaluation is conducted to determine the optimal alternative. This typically involves multiplying the weights of each factor by its scores across alternatives and then summing the weighted scores to obtain a comprehensive score. The alternative with the highest comprehensive score is chosen as the optimal selection.

4.3.2. Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS)

Developed by Hwang and Yoon in 1981 [

36], the TOPSIS method is an acclaimed approach widely used in MCDM scenarios. Its adoption across various disciplines is largely due to its effective framework that methodically evaluates and ranks alternatives based on their closeness to the ideal solution [

24]. This method facilitates clear and logical decision-making processes, enhancing the reliability of the results in complex evaluations.

Step 1: Normalization: Initiating the TOPSIS process involves the normalization of the decision matrix, which includes the performance scores of alternatives across various criteria. The purpose of normalization is to equalize the scales of the criteria, standardizing values typically between 0 and 1. This step ensures that each criterion contributes equally to the overall evaluation. The normalized values, denoted as

, are computed as follows:

In this formula, j = 1, 2, 3, … J. i = 1, 2, 3, … n.

Step 2: Weighting: In this phase of the TOPSIS method, weights are allocated to each criterion to signify their importance as per the decision-maker’s preferences. The assignment of these weights can be carried out through different approaches, including the AHP, expert evaluations, or statistical methods. These weights are then applied to the normalized scores, resulting in weighted normalized values, represented as

, calculated through the following formula:

where

is the weight of the

attribute or criterion and

.

Step 3: Ideal Solution Determination: Following the normalization and weighting of the decision matrix, this step involves identifying the Positive Ideal Solution (PIS) and the Negative Ideal Solution (NIS). The PIS is defined by the highest values for each criterion across all options, highlighting the most desirable characteristics. In contrast, the NIS is characterized by the lowest values for each criterion, indicating the least desirable outcomes. The process for calculating both the PIS and NIS is based on the following mathematical formulations:

In this framework, denotes the set of benefit criteria, where higher values are preferable, and indicates the set of cost criteria, where lower values are more favorable.

Step 4: Distance Calculation: This step involves computing the Euclidean distances from each alternative to both the PIS and the NIS. This measurement provides a quantitative assessment of each alternative’s performance relative to the ideal and least favorable conditions. The calculated distances accurately reflect how closely each option approaches the ideal state while distancing from the least desired outcomes. The formula for determining these separations is structured as follows:

In this formula, represents the distance from alternative i to the PIS, while denotes the distance from alternative i to the NIS. The term refers to the normalized and weighted value of alternative i with respect to criterion j and n stands for the total number of criteria considered in the evaluation.

Step 5: Similarity Score Calculation: In this final step, the similarity score is determined by evaluating how close each alternative is to the PIS. This score is a direct indicator used for ranking the alternatives, where a higher similarity score suggests that an alternative is nearer to the ideal solution, making it more favorable. The specific formula used to compute the similarity score is as follows:

where

is the similarity score of alternative j. Alternatives with higher similarity scores are considered closer to the ideal solution and are ranked higher.

Step 6: Ranking: The final ranking of alternatives based on their similarity scores allows decision-makers to quickly identify the best option. By considering both the proximity to the ideal solution and the distance from the worst case, TOPSIS ensures a balanced evaluation that takes into account all relevant criteria.

This study selected the AHP and TOPSIS methods because they can take into account both expert knowledge judgment and objective data analysis and are suitable for multi-dimensional and multi-standard urban logistics center site selection problems. At the same time, they can provide decision-makers with a clear and systematic basis for sorting options and are highly operational in practice.

5. Measurement and Evaluation

5.1. Identification of Indicators

Identifying the right indicators is a crucial phase in determining suitable locations for urban logistics centers. These indicators form the basis for evaluating the potential of sites. Through a detailed review of academic research and industry practices, a thorough process was established to select and validate these indicators. This extensive review shed light on commonly used methodologies and critical performance metrics in the site selection for urban logistics centers. The chosen indicators are categorized as either positive or negative (see

Table 7). For example, positive indicators might include the number of access lanes, the extent of available space, and closeness to urban centers; negative indicators could cover aspects like traffic density, proximity to major logistics nodes, and the distance from key highways.

5.2. Data Collection

In order to better analyze TOPSIS, this study collected specific data for each criterion, as described in

Table 8 below. Specifically, the collected data include the number of lanes on the main road adjacent to the candidate site, the length of the road from the main road to the candidate site, available site area, proximity to urban centers, average distance to major logistics complexes, distance to the nearest highway interchange, daily traffic volume, surrounding population density, feasibility of workforce supply, and so on. Through detailed data collection, the accuracy and reliability of the TOPSIS method in evaluating logistics center candidate sites are ensured.

5.3. Relative Weights of Decision Criteria

At the outset of the evaluation, the AHP was utilized to assign relative weights to the decision criteria. This process included a detailed application of AHP that involved pairwise comparisons and expert evaluations to determine the importance of each criterion relative to the overall goals of the evaluation. The assigned weights, as shown in

Table 9, provide a quantitative measure of each criterion’s significance within its category. These weights are instrumental throughout the evaluation, guiding both the analytical and decision-making phases to pinpoint the most suitable locations for urban logistics centers.

In the site selection process for urban logistics centers, geographical factors emerge as the most influential, with a weight of 0.498. This underscores the critical importance of location, transportation accessibility, and topography. Facility factors, with a weight of 0.215, also play a significant role, though to a lesser extent. These considerations include the available site area, existing building structures, and facility amenities. Social factors, weighted at 0.171, also impact the evaluation, encompassing aspects like population density, workforce availability, and community dynamics. Lastly, environmental factors, with a weight of 0.116, though less critical, remain important. These include traffic congestion, environmental quality, and sustainability initiatives.

Moreover, the AHP analysis reveals that proximity to urban centers is the most significant criterion, with a weight of 0.252. This highlights the importance of locating logistics centers near urban hubs for optimal access to transportation networks, customer markets, and a ready labor pool, thereby enhancing logistics operations. The distance to major logistics facilities and highways, both with a weight of 0.148, ranks second. These factors are crucial for connectivity, reducing transportation costs, and improving operational efficiency. The availability of the site area, with a weight of 0.109, ensures sufficient space for necessary infrastructure and operations. The demand from logistics companies to move into a location, weighted at 0.086, reflects the site’s attractiveness and the benefits it offers to potential operators, such as operational advantages and market opportunities.

Moderately important is the level of traffic congestion, weighted at 0.059, as high congestion can lead to delays and increased costs. The degree of cooperation from local governments, with a weight of 0.048, is also significant since supportive authorities can facilitate smoother development and operations. Traffic flow on access routes, weighted at 0.041, emphasizes the need for efficient and timely transportation. The extent of complaints from local residents, with a weight of 0.034, indicates potential community resistance and operational challenges. Surrounding population density, weighted at 0.030, reflects labor availability and market opportunities but can also pose challenges like increased traffic and potential opposition.

The number of lanes on adjacent roads, with a weight of 0.028, affects access and transportation efficiency. The feasibility of workforce supply, with the lowest weight of 0.019, ensures adequate staffing for efficient operations. The AHP results highlight that proximity to urban centers and the distance to major logistics facilities and highways are the most influential factors in site selection. These factors are crucial for logistics efficiency and accessibility. Other factors, while less critical, are essential for a comprehensive evaluation of potential sites for logistics centers.

5.4. Performance Ratings of Candidates

Following the AHP analysis, the TOPSIS methodology was employed to provide a comprehensive evaluation of the candidate sites for urban logistics centers. This method integrates the weighted importance of various criteria derived from the AHP calculations, enabling a nuanced and multidimensional assessment of each site’s suitability. The TOPSIS analysis ensures that the selection process accounts for the complex interplay of multiple factors, ultimately aiding in informed and balanced decision-making.

The evaluation criteria encompass a wide range of factors that are critical to the performance and efficiency of logistics centers. These include facility factors, such as the number and width of lanes on adjacent roads and the available site area; geographical factors, like proximity to urban centers and distance to major logistics facilities; environmental factors, including the level of traffic congestion and surrounding population density; and social factors, such as the demand from logistics companies to move in and the extent of complaints from local residents. The weights assigned to these criteria, as determined through the AHP, guided the overall assessment and ensured that the most significant factors were prioritized in the final evaluation.

By employing the TOPSIS methodology, each candidate site was systematically evaluated against the identified criteria and subcategories. This approach involves comparing each site’s performance to both the ideal and the worst possible solutions, providing a relative performance score that reflects how closely each site aligns with the optimal conditions. The resulting performance ratings for each site, as detailed in

Table 10, offer a clear and actionable ranking of the candidate locations.

The TOPSIS results revealed that Sinnae subway vehicle base is the most suitable site for an urban logistics center, with a performance score of 0.168, securing the top rank. The high ranking of Sinnae suggests that its strategic location, robust infrastructure, and accessibility are critical factors that contribute to its suitability as a logistics center. In addition, Sinnae’s proximity to major transportation hubs and urban centers likely plays a significant role in reducing transportation distances and times, which is crucial for efficient last-mile deliveries. Furthermore, the availability of ample site area and supportive local government policies may also enhance its attractiveness as a logistics hub.

Godeok subway vehicle base follows closely with a score of 0.145, indicating its strong potential as a logistics hub, particularly in terms of geographical and facility factors. Cheonwang subway vehicle base ranking third with a score of 0.138, also demonstrates significant suitability, benefitting from its strategic location and infrastructure. Godeok and Cheonwang, while slightly lower in ranking, still show strong potential due to similar factors. Their locations likely offer good connectivity to key transport routes and sufficient infrastructure to support logistics operations. However, specific areas for improvement, such as traffic congestion management and workforce supply, could further enhance their suitability.

Gunja, with a score of 0.132, and Dobong, scoring 0.114, complete the top five, highlighting their relative strengths in meeting the logistical and operational needs. Banghwa, Moran, and Suseo, with scores of 0.099, 0.076, and 0.068, respectively, present moderate suitability, suggesting that while they have certain strengths, there are areas requiring improvement to enhance their overall performance as logistics centers. Sinjeong and Jichuk, scoring 0.040 and 0.021, respectively, are ranked lowest. These sites may face significant challenges in meeting the comprehensive criteria evaluated, indicating the need for considerable development and infrastructure enhancements to be considered viable options.

The lower rankings of Banghwa, Moran, Suseo, Sinjeong, and Jichuk highlight the need for targeted interventions to address their deficiencies. For instance, enhancing road infrastructure, mitigating traffic congestion, and increasing cooperation from local governments could significantly improve their rankings. These sites might also benefit from investments in technology and automation to boost operational efficiency.

6. Discussion

From a theoretical perspective, this paper expands the perspective of urban logistics facility site selection research and fills the gap in systematic research on the site selection context of reuse of urban stock public space. Most existing studies focus on the traditional site selection of new logistics parks or urban fringe areas and rarely consider the possibility of transforming existing public infrastructure (such as subway vehicle bases) into logistics nodes. By introducing the comprehensive multi-criteria decision-making framework of AHP-TOPSIS, this paper not only achieves quantitative weight assignment and comprehensive ranking but also shows how to balance operational efficiency, environmental impact, and social acceptance among multi-dimensional indicators, providing a new theoretical model and analysis paradigm for the optimization of urban logistics infrastructure.

From a practical application perspective, the research results of this paper provide highly operational decision-making support for Seoul and other high-density cities to promote the construction of sustainable urban logistics networks under the background of limited resources. In particular, the conclusion that proximity to urban centers and close to the main roads and logistics hubs have significant weights in site selection revealed in this paper provides priority suggestions for the government to carry out facility transformation based on existing land. In addition, combining social acceptance factors such as population density and resident complaints can also help improve policy coordination and social coordination efficiency during project implementation. The index system and method proposed in this study can be directly used in practical decision-making in other cities at the stage of site selection, transformation, and evaluation.

Compared with previous studies, this paper has three differentiated characteristics: first, the site selection background is special. It is based on the perspective of urban stock space redevelopment and focuses on the systematic evaluation of facility reuse, which is rare in site selection research; second, the evaluation indicators take into account multiple dimensions such as operation, environment, and society, highlighting soft factors such as public acceptance and willingness to cooperate, and expanding the traditional research dimensions that focus on cost and traffic accessibility; third, the method integrates AHP and TOPSIS, which not only absorbs the subjective weight of expert judgment but also retains the objective ranking logic based on data and improves the applicability and practicability of the method. Therefore, this study not only supplements the empirical cases in the field of site selection but also promotes the application boundary of multi-criteria methods in the study of urban sustainable infrastructure.

In summary, the main contribution of this paper is to construct a systematic, multi-dimensional, and transferable site selection evaluation framework for urban logistics centers, which is suitable for the urban background of land shortage and strong environmental protection demands and responds to the current policy orientation of the dual goals of green logistics and sustainable development. For the general readers, this article not only provides an empirical research model that can be directly referenced but also provides migration paths and implementation ideas for other cities with similar backgrounds (such as Tokyo, Hong Kong, etc.). Therefore, the research in this article has strong universality and practical reference value, especially for stakeholders such as urban planners, policymakers, and logistics operators, and it can provide high information gain and practical inspiration.

7. Conclusions

This study explored the strategic site selection of urban logistics centers by repurposing subway vehicle bases in the Seoul Metropolitan Area. In response to growing last-mile delivery demands and the need for sustainable urban freight solutions, we proposed a comprehensive multi-criteria evaluation framework that integrates both the AHP and the TOPSIS. The evaluation system incorporated fifteen sub-criteria under four major categories: facility, geographical, environmental, and social factors.

In applying the AHP methodology, the importance weights for each category and subcategory were calculated. Geographical factors emerged as the most significant, with a weight of 0.498, reflecting the critical importance of location in logistics operations. Facility factors, social factors, and environmental factors followed, with weights of 0.215, 0.171, and 0.116, respectively. The subcategory weights highlighted the paramount importance of proximity to urban centers (0.252), distance to major logistics facilities (0.148), and distance to highways (0.148).

Subsequently, the TOPSIS method enabled the ranking of candidate sites based on their performance across the identified criteria. The results revealed Sinnae as the top candidate, followed closely by Godeok and Cheonwang. This ranking provides valuable insights for policymakers and logistics planners seeking to make informed decisions about infrastructure development.

Based on the findings, several policy and planning recommendations can be proposed to enhance the effectiveness and efficiency of urban logistics facilities. Firstly, strategic investment in infrastructure is essential, particularly in high-ranking areas like Sinnae. Prioritizing investments in transportation infrastructure can further enhance connectivity and reduce congestion. This includes expanding road networks, improving public transport links, and upgrading existing facilities to support efficient logistics operations. Such infrastructure improvements will not only streamline logistics activities but also boost the overall economic vitality of the region.

Secondly, fostering stronger cooperation between logistics companies and local governments is crucial. Encouraging local government support through policies and incentives can create more favorable conditions for logistics operations. Streamlined permitting processes and support for infrastructure development can significantly ease the logistical challenges faced by companies. Additionally, integrating advanced logistics technologies such as real-time tracking systems, automated sorting, and delivery vehicles can enhance efficiency and reduce operational costs. These technological advancements will make even lower-ranking sites more competitive and attractive to logistics companies.

Finally, environmental considerations, workforce development, and community engagement are vital components of a sustainable logistics strategy. Implementing green logistics practices, such as using electric or hybrid vehicles and optimizing delivery routes, can minimize the environmental impact of logistics operations. Addressing workforce supply issues by partnering with educational institutions to train logistics professionals can create a skilled workforce, enhancing the operational efficiency of logistics centers. Engaging with local communities through public consultations and transparent communication can address their concerns and mitigate negative impacts such as noise and traffic congestion. By incorporating these recommendations, urban logistics facilities can become more efficient, sustainable, and community-friendly.

The results of this study have important implications for urban logistics planning practices. By reusing subway vehicle bases as logistics centers, Seoul can effectively improve the resilience and sustainability of the urban logistics system under the background of tight land resources. The study shows that high-ranking candidate sites such as Sinnae and Godeok have significant advantages in terms of geographical location and traffic accessibility, which provides data support and decision-making reference for policymakers in infrastructure investment and urban renewal.

In addition, the multi-criteria decision-making framework proposed in this study is not only applicable to Seoul but also can provide reference for other metropolises facing similar spatial and traffic challenges. For example, cities such as Tokyo and Hong Kong also face problems such as limited land and high environmental pressure when developing urban logistics facilities. The methods and indicator system of this study can act as a useful reference for these cities.

Nevertheless, this study also has certain limitations. First, the data used in the evaluation process are mainly static data, and dynamic factors such as real-time traffic flow, environmental impact, or social equity have not been included. Second, the consideration of logistics enterprise needs and residents’ attitudes in the study mainly relies on expert opinions. In the future, more extensive questionnaires or big data analysis can be used to improve the representativeness of the conclusions.

Future research can further optimize the existing framework, such as introducing GIS spatial analysis technology, fuzzy logic methods, or dynamic evaluation models based on real-time data to improve the scientificity and practicality of site selection analysis. At the same time, applying the framework to different cities or different types of logistics facilities will help verify its universality and robustness.