1. Introduction

Concrete is a ubiquitous construction material prized for its strength and durability, but its inherent damping capacity is very low. Uncracked ordinary concrete typically exhibits an internal damping ratio on the order of only 0.1–1.0% [

1,

2,

3,

4,

5]. The damping ratio ξ is a dimensionless measure of a material’s ability to dissipate vibrational energy under cyclic or dynamic loading [

6,

7,

8,

9]. The modal properties are vital for the dynamic behavior of structures [

10,

11]. Higher damping allows a structure to absorb more energy and reduces resonant vibrations, directly improving structural response and resilience. Achieving higher intrinsic damping through material design is thus highly desirable for earthquake-resistant buildings, bridge decks, and other structures subjected to dynamic loads [

12,

13,

14].

Recognizing this, researchers have turned to advanced concrete types and mix designs that modify the internal structure to raise damping [

15,

16]. High-Performance Concretes (HPC), typically > 60°MPa strength) and Ultra-High-Performance Concretes (UHPC, often > 150 MPa) achieve an exceptional strength and very low permeability through very low water–cement ratios and optimized aggregate gradations [

17,

18,

19,

20]. Their very dense microstructure (minimal porosity) inherently transmits waves more effectively, which paradoxically tends to lower intrinsic material damping. However, these matrices are often fiber-reinforced or polymer-modified to offset brittleness. For example, UHPC mixes commonly include steel or synthetic fibers to improve post-cracking ductility. The addition of these fibers creates multiple crack-bridging and pull-out interfaces, providing new frictional surfaces for energy dissipation. In practice, Ultra-High-Performance Fiber-Reinforced Concrete (UHPFRC) is valued for absorbing and dissipating high levels of energy under impact or blast loads. Emerging studies have shown that judicious fiber selection in UHPC—such as steel fibers—can produce damping ratios several percentages higher than plain UHPC, enabling these materials to perform effectively in seismic and vibration-sensitive applications [

21,

22]. Engineered Cementitious Composites (ECCs) take this approach further: an ECC is designed for highly distributed cracking using fine aggregates and high volumes of PVA microfibers. The result is a ductile, strain-hardening composite whose numerous micro-cracks and fiber bridges greatly enhance hysteretic energy loss under cyclic loading. Although specific damping measurements for ECCs are limited, the principle is clear—its extremely tight crack widths and fiber pull-out mechanisms provide significant damping compared to ordinary concrete [

21].

Beyond these high-strength mixes, fiber reinforcement of all kinds has been shown broadly to elevate the concrete damping capacity [

23]. Steel fibers, for instance, resist crack opening and induce frictional pull-out, which increase internal hysteretic losses during vibration. One recent study on self-consolidating mixes reported a modest but clear increase in the damping ratio when hooked-end steel fibers were included along with mineral fillers [

24]. Likewise, polymer fibers (such as PVA or polypropylene) improve crack control and post-cracking toughness, so that the material can sustain larger deformations before collapse. In a recycled aggregate concrete study, the inclusion of polymer fibers and air-entraining agents produced higher damping values than plain concrete. In general, any fiber inclusion tends to create additional energy-dissipating pathways (bridge debonding, fiber pull-out friction, and matrix crushing) that augment damping. The volume fraction, aspect ratio, and type of fiber all play a role: optimal fiber contents must balance the benefits of damping with possible reductions in workability or static strength.

Another effective strategy is to modify the aggregate or mix phase to add damping. One approach is rubberization, where natural sand or coarse aggregate is partially replaced with the rubber crumb from recycled tires [

25,

26,

27,

28]. Crumb rubber is highly deformable and viscoelastic; even small amounts can markedly increase damping by introducing soft inclusions that flex and shear under load. Indeed, experiments have shown that adding rubber powder to a fiber-reinforced concrete (for example, PFRC with PVA fibers) significantly boosts the composite’s damping capacity. In one mortar study, replacing a large fraction of aggregate with a lightweight “damping aggregate” (essentially a very elastic filler) raised the damping ratio to roughly three times that of the reference mix. These results underline that viscoelastic aggregate replacements—whether rubber particles, expanded polystyrene beads, or other soft fillers—dramatically enhance energy dissipation. The trade-off is typically reduced stiffness and strength, so practical mix designs seek an optimal balance: enough rubber (often a few percent by volume) to gain damping, but not so much as to compromise the load-bearing performance [

29].

The characteristics of the remaining (non-rubber) aggregate also matter. In general, stiffer, larger aggregates tend to lower damping, because a more rigid skeleton transmits vibrations with less internal friction [

30,

31,

32]. Conversely, lightweight aggregates (e.g., foamed clay, expanded shale, or recycled foams) introduce more internal compliance and can raise the damping ratio. Moreover, well-graded aggregates that fit tightly will reduce the cement paste–aggregate interfacial transition zones, leading to less microcracking and lower damping; looser gradations with more paste can increase damping via more shrinkage cracks. The type (mineralogy, modulus of elasticity) of coarse aggregate can also shift damping: low-modulus aggregates absorb more energy under stress, whereas hard, high-modulus rocks (like basalt or granite) are less dissipative.

Mix design, in a broader sense—not just fibers and aggregates—influences damping as well. Key parameters like the water-to-cementitious ratio, use of supplementary cementitious materials (fly ash, slag, and silica fume), and admixtures can alter the microstructure [

33,

34]. Lower w/c ratios produce denser, stronger cement matrices, which generally reduce intrinsic damping by minimizing micro-cracks [

35,

36]. Adding fine mineral powders (silica fume, metakaolin) can refine the pore structure and also suppress damping capacity (since there is less internal friction). On the other hand, additives that increase porosity or microcracking—such as entrained air or lightweight fillers—enhance damping by providing more slip planes. For example, deliberately introducing air-entraining agents creates microscopic bubbles that can act like tiny springs and dashpots during vibration, modestly raising the damping [

37,

38,

39,

40,

41]. Similarly, plasticizers or polymers that modify the cement paste can increase viscous behavior: polymer-modified concretes (cement–polymer blends or concretes with polymer resin binders) often exhibit much higher damping due to the viscoelastic nature of the polymer phase, although specific values depend strongly on the polymer chemistry and content [

42].

Finally, curing and age act as external factors affecting damping [

43,

44]. As concrete cures and matures, its internal moisture content and pore structure evolve. Well-cured, mature concrete has denser hydration products (C–S–H gel) filling pores, which tend to decrease viscous damping. In other words, the longer and more thorough the curing, the stiffer and less dissipative the matrix becomes. By contrast, younger concrete with a higher water content and incomplete hydration will be softer and more absorbent of energy (higher damping) due to the additional internal friction from fluid movement and plastic zones. Environmental curing conditions (temperature, humidity) likewise influence porosity and microcracking: for example, elevated temperature curing can increase early strength but may also induce micro-cracks that elevate damping. Thus, the curing regime must be considered when comparing damping data, as specimens of the same mix can show different damping ratios if cured under different conditions or tested at different ages [

43,

45].

Mostafaei et al. [

46] provided a comprehensive review of damping mechanisms and dynamic effects in fiber-reinforced concrete; the present study expands the scope to encompass a broader range of advanced concrete types and mix design strategies. While the previous review focused primarily on fiber-based reinforcement and its interaction with dynamic loading, this paper integrates additional damping-enhancing approaches such as polymer modification, rubber powder inclusion, and aggregate tailoring. Furthermore, it critically examines the influence of curing conditions and external environmental factors on the damping performance—areas that were only briefly addressed in earlier work. By synthesizing experimental data and highlighting gaps in standardization, simulation, and long-term durability, this review aims to complement and extend the findings of Mostafaei et al. [

46] and provide a more holistic framework for future research in vibration-resistant concrete technologies.

Concrete’s dynamic behavior and damping ratio depend on an intricate interplay of mix design and material selection. Advanced concretes (HPC, UHPC, and ECC) push the envelope of strength and durability, but achieving sufficient damping often relies on deliberate design—e.g., incorporating fibers or viscoelastic additives. Each factor—from fiber type and volume to rubber content, aggregate selection, binder chemistry, and curing—contributes to the overall energy dissipation. This review will examine these factors in depth, synthesizing recent research to clarify how innovative mix designs and materials can be engineered for improved dynamic dissipation. By understanding the mechanisms of damping in concrete, engineers can better tailor materials and structures to resist vibrations and dynamic loads, ultimately leading to safer and more resilient infrastructure.

2. Effects of Compressive Strength on Concrete Damping Ratio

Concrete, a widely used construction material, is characterized by its fundamental property of compressive strength, which determines its load-bearing capacity. Interestingly, this compressive strength also plays a significant role in influencing the concrete’s damping ratio. This crucial parameter reflects the material’s ability to absorb and dissipate energy when subjected to dynamic loading conditions, such as those encountered in seismic events or impact loading. As the compressive strength of concrete increases, the material’s internal structure undergoes critical changes, with profound implications for its energy dissipation capabilities. In this review, damping ratio values are interpreted primarily using the Half-Power Bandwidth Method unless otherwise noted.

2.1. High Compressive Strength Concrete

Concrete exhibiting higher compressive strength is often characterized by a denser microstructure, primarily due to a significantly reduced number of voids, micro-cracks, and overall porosity within the material. This densification process not only strengthens the concrete matrix by imparting increased stiffness, but it also plays a vital role in enhancing the overall load-bearing capacity of the material. A stiffer concrete matrix is particularly advantageous as it provides a more robust framework for effectively absorbing and dissipating energy. This effectiveness stems from the concrete’s remarkable ability to withstand higher stress levels without succumbing to immediate failure or experiencing excessive deformation [

45,

47].

However, it is essential to recognize that the advantageous increase in stiffness accompanying a high compressive strength in concrete has its trade-offs and potential drawbacks. One notable drawback is the potential reduction in the material’s overall flexibility. As the stiffness of concrete increases, it can lead to a decreased capacity for deformation under stress. The reduced flexibility can negatively impact the concrete’s damping ratio—an important parameter that reflects the material’s ability to absorb and dissipate vibrational energy. A more rigid concrete structure may be less capable of deforming under dynamic loads, resulting in a diminished effectiveness at energy dissipation.

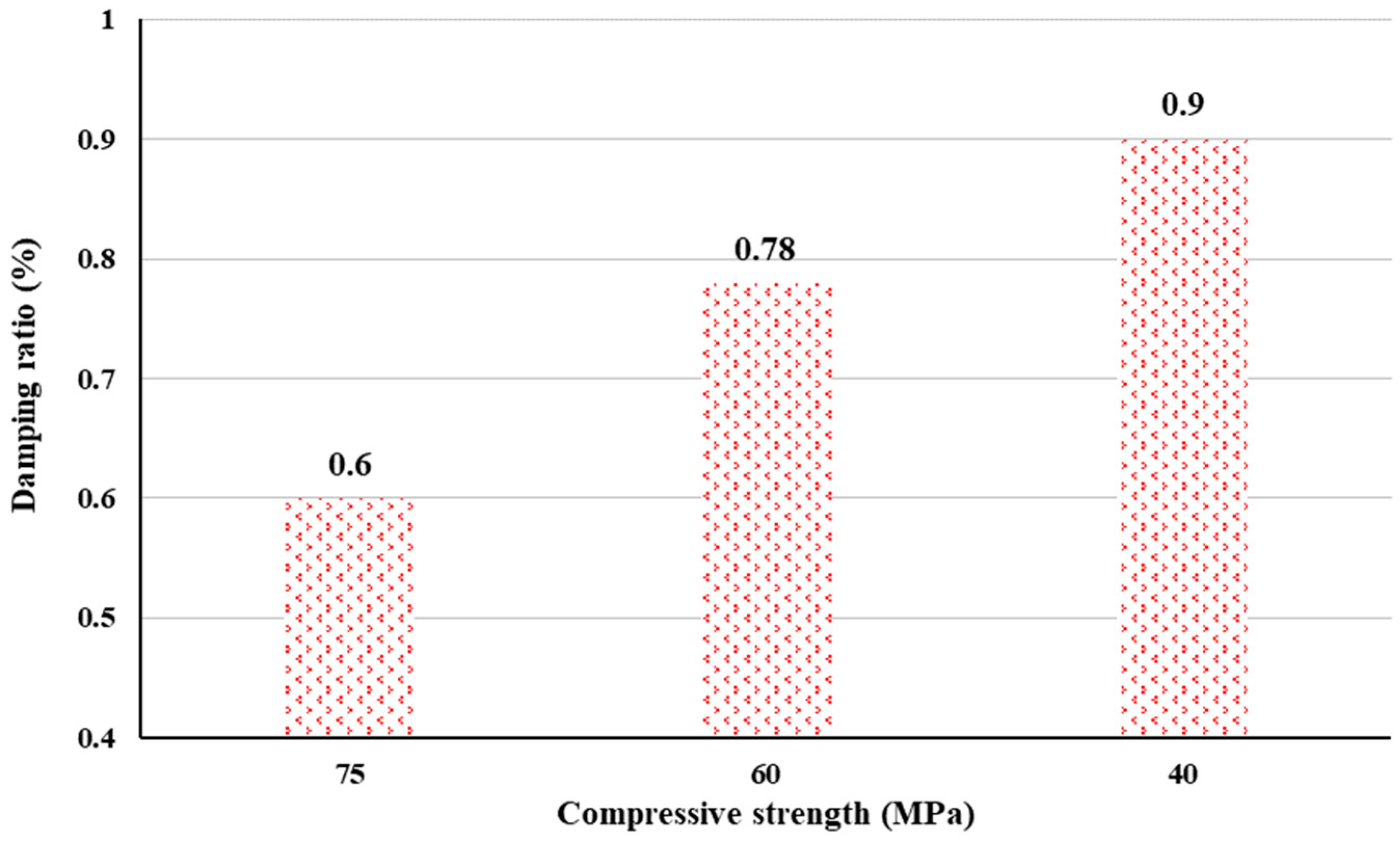

In practical scenarios, when high-strength concrete is subjected to dynamic loads, its increased stiffness may limit the mechanisms through which energy can be effectively absorbed and dissipated. Such limitations can result in a damping performance that is less favorable compared to medium-strength concrete, which tends to offer a more balanced combination of stiffness and flexibility. Empirical studies have provided quantifiable insights into this phenomenon, revealing that as the compressive strength of concrete increases from 40 MPa to 75 MPa, the damping ratio correspondingly decreases from 0.9 to 0.6 (

Figure 1). This trend underscores the nuanced interplay between compressive strength, stiffness, flexibility, and energy dissipation, highlighting the importance of considering these factors when designing concrete structures for specific dynamic loading conditions.

The delicate balance between the enhanced load-bearing capacity and the potential reduction in flexibility associated with high-strength concrete is a crucial consideration for structural engineers. While the increased stiffness can be advantageous in specific applications, it may also limit the material’s ability to effectively dissipate energy under dynamic loads. Understanding this trade-off and the underlying mechanisms is essential for developing concrete mixes and structural designs that optimize the material’s compressive strength and energy dissipation capabilities, ensuring the long-term performance and safety of concrete structures subjected to various loading scenarios.

2.2. Energy Dissipation Mechanisms in High-Strength Concrete

In high-strength concrete, energy dissipation mechanisms are predominantly governed by improved crack resistance and reduced plastic deformation. The dense microstructure leads to fewer micro-cracks, which serve as critical pathways for energy absorption during dynamic loading. In traditional concrete, the presence of micro-cracks allows for energy dissipation through crack propagation and friction, both of which contribute to the damping characteristics of the material. However, the limited avenues for energy absorption in high-strength concrete may result in a more uniform and predictable energy dissipation behavior. Still, they can also restrict the potential for dissipative actions, which is usually beneficial in lower-strength mixes.

As concrete becomes better at resisting cracking under applied stresses, it may rely more on elastic deformation than plastic deformation mechanisms. While this can enhance the immediate load-bearing capacity, it often means that the natural damping capabilities, which rely on the material’s ability to deform plastically, are compromised. This trade-off highlights the complex relationship between compressive strength and damping, necessitating an in-depth understanding of the underlying mechanisms.

2.3. Balancing Compressive Strength and the Damping Ratio

The challenge in concrete design lies in balancing compressive strength and the damping ratio to achieve the optimal performance for specific applications. While increasing compressive strength can significantly enhance certain mechanical properties, such as the load-bearing capacity and durability, it can concurrently hinder energy dissipation capabilities. Designers must consider the intended use of the concrete structure, whether for high-rise buildings, bridges, or pavements, and factor in how varying levels of compressive strength will impact the structure’s response to dynamic loading scenarios.

To address this challenge, innovative design strategies may involve using supplementary materials or additives that can help create a more favorable balance between compressive strength and damping performance. For instance, incorporating fibers, such as polypropylene or steel fibers, into high-strength concrete mixes can enhance energy dissipation despite the matrix’s inherent stiffness. Hybrid approaches that blend high-strength concrete with various other materials can lead to designs that achieve both the required strength and enhanced damping capabilities [

45,

47].

2.4. Balancing Strength and Energy Dissipation: Summaru of Comprehensive Strength Effects on Damping

This review section underscores the intricate relationship between compressive strength, the damping ratio, and energy dissipation mechanisms in concrete. While high compressive strength is often sought for its ability to enhance the load-bearing capacity and structural integrity, it also introduces complexities that can negatively affect the material’s energy dissipation capabilities.

High-strength concrete is characterized by a denser microstructure with fewer voids and micro-cracks, contributing to increased stiffness and improved resistance to deformation under stress. However, this increased stiffness can limit the concrete’s flexibility, resulting in a decreased damping ratio. Empirical studies reveal a clear trend: as compressive strength rises from 40 MPa to 75 MPa, the damping ratio decreases from 0.9 to 0.6. This highlights the trade-off between an enhanced load-bearing capacity and reduced energy dissipation effectiveness.

Furthermore, the energy dissipation mechanisms in high-strength concrete are predominantly influenced by improved crack resistance and a reliance on elastic deformation rather than plastic deformation. While this may enhance immediate strength, it compromises the material’s natural damping capabilities, which typically benefit from plastic deformation.

Achieving an optimal balance between compressive strength and damping performance is crucial for effective concrete design. Structural engineers must carefully consider the concrete’s intended application, whether for high-rise buildings, bridges, or pavements, to ensure that the selected compressive strength aligns with the required energy dissipation characteristics. Innovative design strategies, such as incorporating supplementary materials or fibers, can help bridge the gap between high strength and effective energy dissipation, leading to more resilient and durable concrete structures.

In conclusion, understanding the nuanced interplay between compressive strength and the damping ratio is essential for optimizing concrete performance in dynamic loading scenarios. By acknowledging the trade-offs and exploring hybrid approaches, engineers can develop concrete mixes that meet strength requirements and enhance energy dissipation, ensuring the long-term safety and functionality of concrete structures.

3. Relationship Between Concrete Types and Damping Ratio

Concrete’s damping ratio is a critical parameter that reflects its energy dissipation capability. This capability is vital for performing structures subjected to dynamic loads such as earthquakes, traffic, and wind-induced vibrations. Variations in the damping ratio across different concrete types arise from differences in material composition, structure, and added constituents. Understanding these variations is essential for optimizing material selection for specific applications, particularly in environments characterized by dynamic loading conditions.

3.1. Ordinary Concrete

Ordinary concrete, which typically consists of a standard mix of cement, water, and aggregates, provides basic energy dissipation capabilities but exhibits a lower damping ratio than advanced concrete types. Ordinary concrete’s primary energy dissipation mechanisms include crack propagation and frictional losses at the interfaces between aggregates and the cement paste. While ordinary concrete is widely used due to its simplicity and cost-effectiveness, its performance in dynamic environments is limited. Alternative concrete types may be more appropriate in contexts where enhanced energy dissipation is critical [

48,

49,

50,

51].

3.2. Engineered Cementitious Composites (ECCs)

ECCs represent a significant advancement in concrete technology, characterized by their unique composition and enhanced mechanical properties. These advanced materials are formulated from a carefully selected combination of traditional cement, fine aggregate, and supplementary cementitious materials, which work together to optimize the material’s performance. One of the defining features of an ECC is the incorporation of high volumes of fibers, which play a crucial role in enhancing the ductility of the composite. This enhancement is vital as it allows ECCs to undergo significant deformation under stress without experiencing immediate failure, a behavior that sets it apart from conventional concrete [

52,

53,

54,

55,

56,

57,

58,

59].

The fibers embedded within the ECC matrix contribute to developing multiple crack-bridging mechanisms. These mechanisms facilitate energy absorption and dissipation, enabling the material to manage stress without catastrophic failure effectively. Stress redistribution through these crack-bridging effects improves the tensile strength and significantly enhances the material’s overall toughness. As a result of these properties, ECCs exhibit a remarkably high damping ratio, which is particularly advantageous in seismic zones. In such areas, the ability of an ECC to dissipate energy is crucial for enhancing the structural resilience of buildings and infrastructures, providing them with a greater capacity to withstand dynamic forces induced by earthquakes or other sources of vibration [

52,

53,

54,

55,

56].

ECCs’ superior performance in dynamic loading scenarios can be attributed to their innovative microstructure. This microstructure allows an ECC to undergo large deformations while simultaneously maintaining its load-carrying capacity. Unlike conventional concretes that may fail suddenly under high stress, ECCs’ ability to deform extensively lets them absorb significant amounts of energy, thereby reducing the forces transmitted to the structural elements [

57,

58].

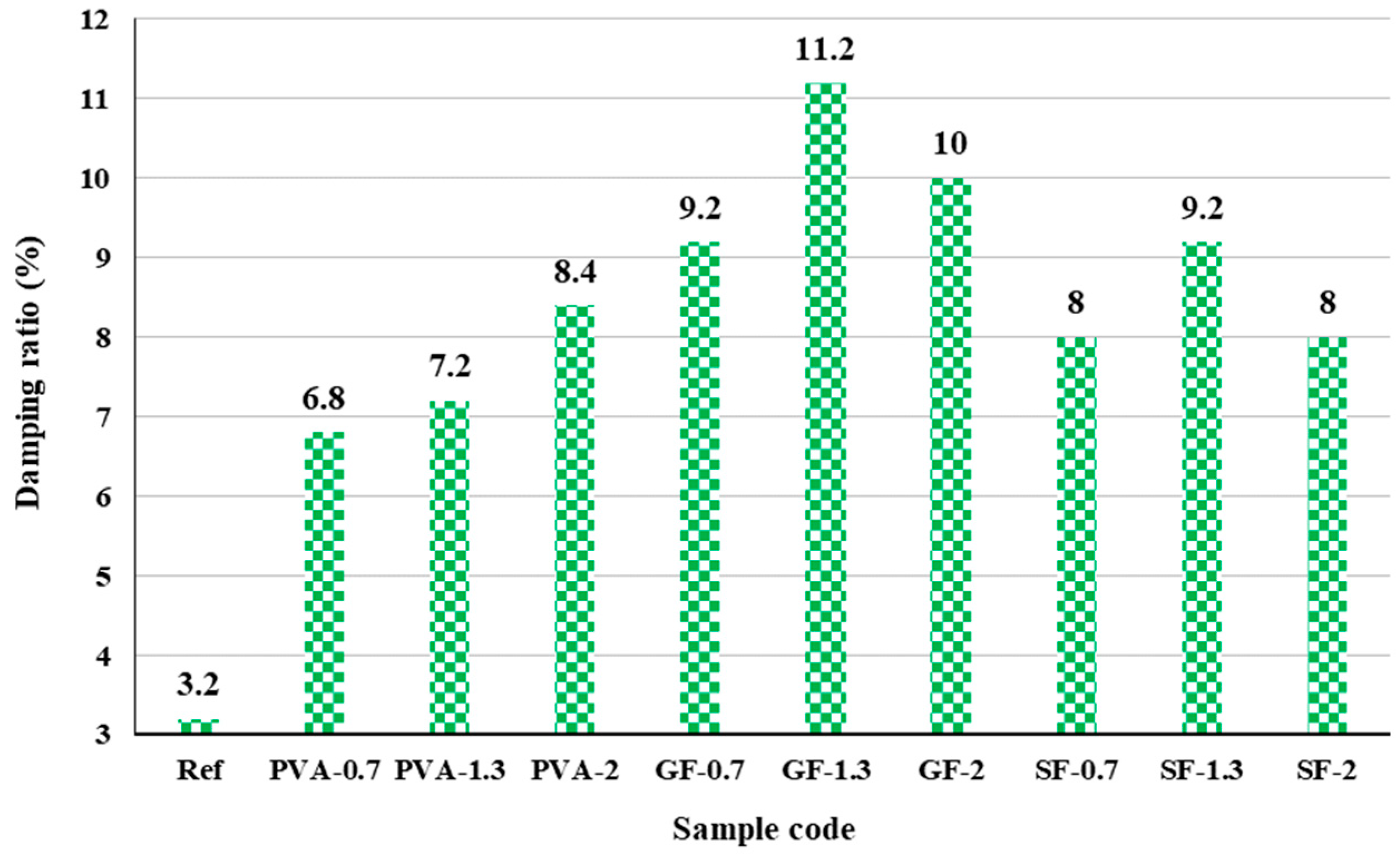

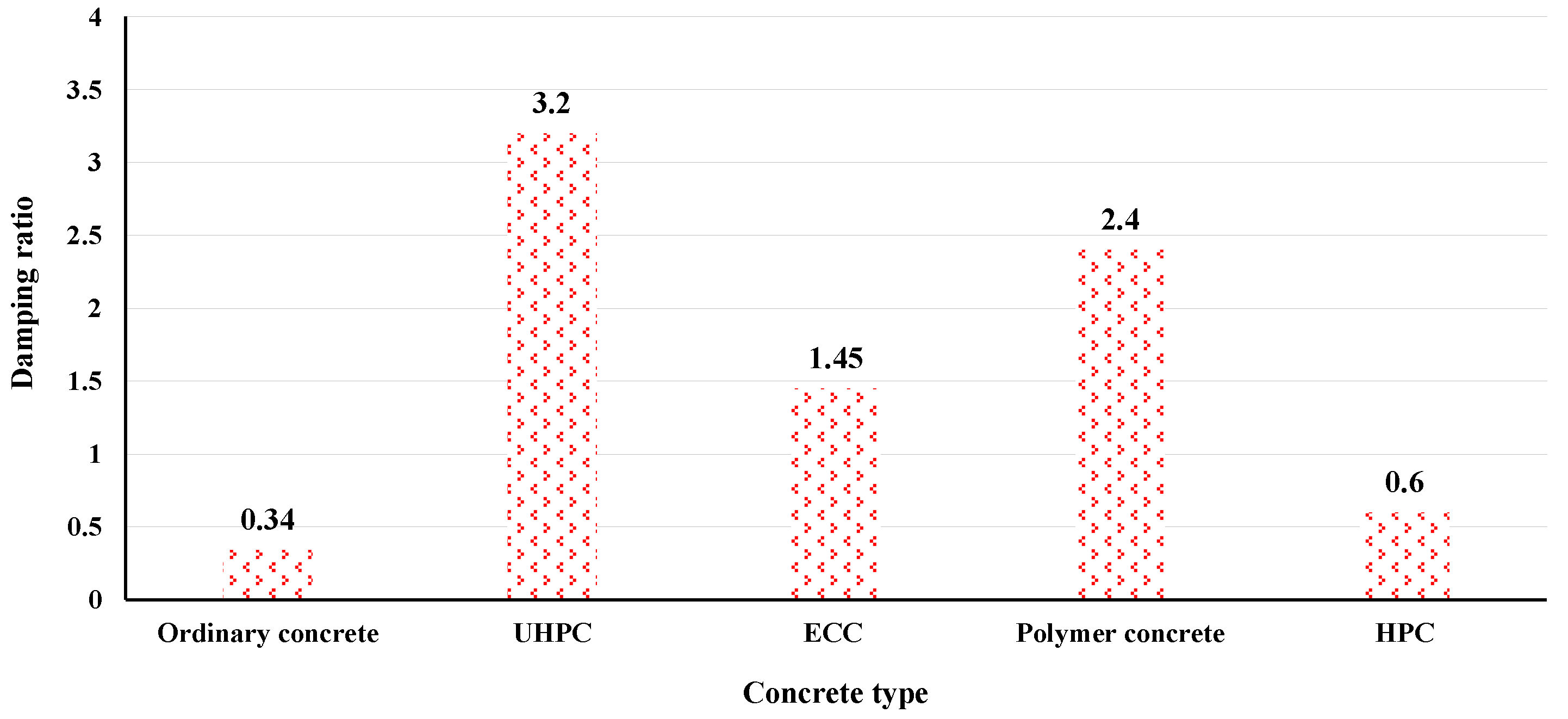

As indicated in

Figure 2, past research highlights a remarkable increase in the damping ratio exhibited by ECCs compared to regular concrete. Specifically, ECCs have been shown to enhance the damping ratio by an impressive 326%, underscoring the material’s exceptional capabilities in energy dissipation. This substantial improvement in the damping performance further reinforces the value of ECCs in applications where energy absorption is critical, such as in the construction of seismic-resistant structures and in infrastructure intended to endure variable and dynamic loading conditions [

59].

In conclusion, the unique attributes of ECCs—derived from their constituent materials and the synergistic effects of their fibrous reinforcement—elevate them to a position of promise in modern engineering applications. Their remarkable ductility, outstanding energy dissipation properties, and resilience against dynamic loads make them a pivotal material for enhancing the durability and safety of structures, particularly in regions prone to seismic activity and other dynamic forces. This advancement in material technology improves structural performance and is vital in designing buildings that can thrive under increasingly rigorous demands associated with contemporary construction practices.

3.3. Ultra-High-Performance Concrete (UHPC)/Ultra-High-Performance Fiber-Reinforced Concrete (UHPFRC)

UHPC is a remarkable advancement in concrete technology, characterized by a highly dense microstructure that significantly elevates its mechanical properties. This density is achieved through a strategic combination of optimized particle packing, which ensures a more efficient use of space within the mix, low water-to-cement ratios that minimize porosity, and the inclusion of supplementary cementitious materials (SCMs) such as silica fume, fly ash, or slag, which results in environmental impacts [

64]. These elements work synergistically to create a concrete matrix with exceptional compressive strength and stiffness, enhancing its energy dissipation characteristics.

The high damping ratio of UHPC is particularly noteworthy; it can be primarily attributed to its ability to confine the formation and propagation of micro-cracks. This confining property leads to the concentration of energy dissipation mechanisms predominantly within the material’s elastic and plastic deformation zones. As a result, when subjected to various loading conditions, UHPC can effectively absorb and dissipate energy, making it an invaluable choice for applications in environments where structures are exposed to high-stress levels and require outstanding durability. Typical applications include the construction of bridges designed to withstand heavy traffic loads, industrial facilities that must endure dynamic operations, and protective structures intended to mitigate the impacts of blasts or extreme weather conditions [

65,

66,

67,

68,

69].

Building upon the established benefits of UHPC, UHPFRC enhances the material’s performance by incorporating various types of fibers, such as steel, glass, or synthetic fibers. This strategic addition significantly boosts the composite’s toughness and crack-bridging capabilities, providing an additional layer of resilience that standard UHPC may not achieve. The presence of these fibers creates alternative energy dissipation pathways within the concrete matrix, thereby increasing the material’s ductility. This trait allows UHPFRC to absorb and dissipate higher amounts of energy before reaching failure, which is critical in applications where unexpected dynamic loads might occur [

67,

68].

The superior damping ratio exhibited by UHPFRC makes it an excellent choice for applications requiring robust vibration control. These can include seismic-resistant structures that must perform under earthquake conditions and infrastructure subjected to dynamic loads from traffic, machinery, or environmental factors such as wind and seismic activities.

In line with previous research efforts, as illustrated in

Figure 3, the incorporation of polyvinyl alcohol (PVA) fibers into UHPC has been shown to improve the damping ratio in comparison to UHPC, which does not utilize fiber reinforcement. PVA fibers are recognized for their high tensile strength, exceptional elastic modulus, and unique ability to enhance the post-cracking behavior of the concrete matrix. Remarkably, by increasing the PVA fiber content up to 2% by volume, the damping ratio of UHPC was enhanced by approximately 6%. This increase can be attributed to several energy dissipation mechanisms facilitated by the PVA fibers, such as fiber pull-out, debonding from the matrix, and the bridging of micro-cracks under stress [

65].

Further investigation into using steel and glass fibers in UHPC also led to notable improvements in the damping ratio, demonstrating that a multi-fiber approach can yield even more benefits. Steel fibers, renowned for their high strength and stiffness, are crucial for effectively controlling cracks’ formation and propagation, enhancing the overall energy dissipation during loading events. In contrast, glass fibers exhibit excellent bonding characteristics with the UHPC matrix, effectively transferring stresses across cracks and enhancing the damping performance.

Research findings indicate that the optimal fiber content for both glass and steel fibers in UHPC was established at 1.3% by volume. This specific addition resulted in a remarkable improvement in the damping ratio, approximately 8% for glass fibers and around 6% for steel fibers, showcasing the efficacy of fiber reinforcement in boosting the material’s performance. Determining these optimal fiber contents reflects a careful balance between maximizing energy dissipation mechanisms and mitigating potential adverse effects on workability and compressive strength that could arise from an excessively high fiber content [

65].

The notable enhancement of the damping ratio in UHPC with the strategic incorporation of various fibers offers significant advantages for applications where effective vibration control and reliable energy dissipation are critical. Such contexts include civil engineering structures subjected to dynamic loads—such as bridges, buildings designed to withstand seismic activity, and foundations for industrial machinery—underscoring the transformative potential of fiber-reinforced UHPC in modern construction.

3.4. High-Performance Concrete (HPC)/High-Performance Fiber-Reinforced Concrete (HPFRC)

HPC is a sophisticated type of concrete engineered to exhibit superior mechanical properties and durability, achieved through the strategic incorporation of SCMs and chemical admixtures [

66,

67,

68,

69]. These enhancements improve the material’s strength and resilience and contribute to a refined microstructure characterized by reduced porosity and improved particle packing. This advanced microstructure facilitates more effective load distribution and minimizes void spaces within the concrete matrix. As a result, HPC demonstrates a modestly higher damping ratio than traditional concrete mixes, an essential attribute for applications that require improved vibration control and energy absorption capabilities.

The mechanisms of energy dissipation in HPC primarily involve the limited formation of micro-cracks and the unique ability of the material to undergo both elastic and plastic deformations when subjected to loading. These processes enable HPC to absorb and dissipate energy effectively while resisting sudden failure. While HPC does not achieve the same high damping ratios as more advanced composites such as ECC or UHPC, it offers a substantially enhanced performance relative to conventional concrete. This combination of properties makes HPC suitable for various structural applications, including elements exposed to varying loads and environmental conditions.

Further enhancing the capabilities of HPC, HPFRC incorporates fibers into the HPC matrix, resulting in noteworthy improvements in both mechanical behavior and energy dissipation capacities [

70]. The addition of fibers plays a critical role in controlling crack propagation, which is essential for enhancing the overall toughness and durability of the concrete. By effectively inhibiting the growth of cracks, the fibers contribute to a more resilient material that can withstand dynamic forces without significant degradation [

71,

72,

73].

Energy dissipation mechanisms in HPFRC are particularly noteworthy, as they primarily stem from fiber debonding, pull-out, and bridging across micro-cracks. These mechanisms collectively enhance the stability of HPFRC during dynamic loading scenarios and allow the composite to absorb and redistribute energy more effectively, reducing the risk of structural failure under repeated stress [

74]. The increased damping ratio associated with HPFRC positions it as a highly suitable material for applications that demand an elevated control of vibrations and resistance to impacts, such as in the construction of pavements, flood-control dikes, and structural components that are likely to encounter high dynamic forces [

75].

Past research has demonstrated significant improvements in the damping ratio associated with HPC, as highlighted in

Figure 3. Specifically, HPC achieves an impressive enhancement of 76% in the damping ratio compared to normal concrete, underscoring its effectiveness as a superior concrete option for applications requiring better energy dissipation and structural performance.

In conclusion, HPC and HPFRC represent significant advancements in concrete technology that address the challenges posed by conventional concrete in demanding applications. Their unique compositions and integrated structural enhancements provide a compelling case for their use in modern engineering, paving the way for more resilient infrastructure to meet the increasing requirements of today’s dynamic and variable environments. The continued exploration and application of these materials promise enhanced structural integrity and greater safety and longevity for the built environment.

3.5. Polymer Concrete

Polymer concrete represents a unique and innovative category that diverges from traditional formulations by utilizing polymeric resins as a binder instead of conventional cement. This fundamental modification in the binding agent redefines the resulting composite material’s mechanical properties and introduces a range of performance enhancements that are particularly beneficial for specialized applications. One of the most significant advantages of using polymeric resins is the improvement in adhesion properties, which results in a stronger bond between the aggregate particles and the matrix. This enhanced adhesion is critical for the longevity and durability of concrete surfaces, particularly in environments where mechanical stresses and chemical exposures are prevalent.

Moreover, using polymer resins significantly enhances the chemical resistance of polymer concrete. Unlike traditional cement-based concrete, polymer concrete maintains its integrity over time, which can be susceptible to degradation from aggressive chemicals or environmental conditions. It is ideal for applications in harsh environments, including chemical processing facilities and wastewater treatment plants. Beyond chemical resistance, modifying the matrix structure afforded by polymeric binders increases the concrete’s overall energy absorption and dissipation properties. This characteristic is vital for applications requiring materials to withstand dynamic loading conditions or high-impact scenarios [

76,

77,

78].

Incorporating polymer resins enables polymer concrete to achieve a notably higher damping ratio than ordinary concrete. This enhanced damping capability is attributed to the inherent properties of the polymer matrix, which allows for greater flexibility and deformation without compromising structural integrity. The resulting material exhibits enhanced ductility and improved crack-bridging capabilities, essential for an effective energy dissipation system. These features allow polymer concrete to deform under stress without experiencing immediate failure, thereby absorbing energy and reducing the transmission of forces through the material.

Due to its distinct properties, polymer concrete is highly effective in various applications subjected to high wear, vibrations, or impacts. Typical uses include flooring systems in industrial settings where heavy machinery operates, precast components designed for load-bearing scenarios, and overlays for existing structures that require reinforcement or resurfacing. Polymer concrete’s versatility and thriving performance metrics make it an attractive choice for many engineering and construction projects [

79,

80].

As presented in

Figure 3, past research demonstrates a staggering increase in the damping ratio associated with polymer concrete, reflecting an impressive enhancement of approximately 605% compared to regular concrete. This remarkable statistic underscores the transformative potential of polymer concrete, highlighting its capability to significantly improve the energy dissipation characteristics crucial for ensuring the resilience and longevity of structures subjected to dynamic loads [

75].

In summary, incorporating polymeric resins in the formulation of polymer concrete marks a pivotal advancement in concrete technology, delivering comprehensive benefits that enhance both its mechanical performance and resilience. By offering superior adhesion, enhanced chemical resistance, and a robust matrix structure conducive to effective energy absorption, polymer concrete emerges as a superior solution for applications demanding heightened durability, flexibility, and resistance to impact. This innovative material’s ongoing exploration and application promise to further redefine performance standards in the concrete industry, particularly in contexts that require superior adaptive capabilities to dynamic stresses and environmental challenges.

3.6. Comparative Evaluation of Concrete Types: Damping Efficiency and Structural Implications

This review section examines the relationship between various concrete types and their corresponding damping ratios, emphasizing the importance of energy dissipation capabilities in structures subjected to dynamic loads such as earthquakes, traffic, and wind. The damping ratio is a critical parameter that reflects a concrete material’s ability to absorb and dissipate energy, which is essential for ensuring the resilience and safety of structures in dynamic environments.

Ordinary concrete is the baseline, providing basic energy dissipation mechanisms through crack propagation and frictional losses. However, its lower damping ratio limits its effectiveness when enhanced energy dissipation is crucial.

In contrast, ECCs demonstrate significant advancements in performance due to their unique composition and high fiber content, resulting in a remarkable 326% increase in the damping ratio compared to ordinary concrete. ECCs’ ability to undergo large deformations without immediate failure makes them particularly advantageous in seismic zones, enhancing structural resilience against dynamic forces.

UHPC and UHPFRC showcase exceptional mechanical properties and energy dissipation capabilities. UHPC’s dense microstructure and ability to confine micro-crack formation contribute to its high damping ratio. At the same time, UHPFRC further improves performance through the incorporation of fibers, which create alternative energy dissipation pathways. Research indicates that the strategic use of fibers can enhance the damping ratio significantly, making these materials suitable for structures exposed to high stress and dynamic loading conditions.

HPC and HPFRC also represent significant advancements over traditional concrete. HPC benefits from reduced porosity and improved particle packing, leading to a modest increase in the damping ratio. The addition of fibers in HPFRC enhances crack control and energy dissipation mechanisms, positioning it as a strong candidate for applications requiring vibration control and resistance to impacts.

Lastly, polymer concrete emerges as a transformative material that utilizes polymeric resins as binders, resulting in superior adhesion, chemical resistance, and energy absorption properties. With an impressive 605% increase in the damping ratio compared to ordinary concrete, polymer concrete is particularly effective in high-wear and high-impact environments.

In conclusion, the choice of concrete type significantly impacts its damping ratio and overall performance under dynamic loading conditions. Advanced concrete formulations such as ECCs, UHPC, HPFRC, and polymer concrete offer substantial improvements in energy dissipation capabilities compared to ordinary concrete. Understanding these differences is crucial for optimizing material selection in engineering applications, ensuring that structures can effectively withstand dynamic forces while maintaining safety and durability. These innovative concrete types’ ongoing development and application promise to enhance infrastructure resilience in increasingly demanding environments.

Table 1 lists the damping ratios of different kinds of concrete.

4. Effects of Replacing Rubber Powder in Concrete on Its Damping Ratio

Incorporating rubber powder into concrete has garnered an increasing interest in civil engineering, particularly regarding its influence on concrete composites’ mechanical properties and durability. One critical aspect affected by the addition of rubber powder is the damping ratio, a parameter that characterizes the energy dissipation behavior of materials under dynamic loading.

4.1. Mechanisms of Damping Enhancement

Rubber particles derived from recycled tires and other sources introduce viscoelastic characteristics into the concrete matrix, significantly influencing damping properties. The viscoelastic nature of rubber allows for better energy absorption when subjected to stress, leading to reduced vibrations and improved performance in earthquake-prone areas or structures subjected to dynamic loads. When rubber powder replaces a portion of the fine aggregate in concrete, various mechanisms contribute to changes in the damping ratio.

Energy Dissipation: The rubber powder is a cushion, absorbing and dissipating energy more effectively than traditional aggregates. This property decreases the amplitude of vibrations in the concrete, which is particularly beneficial for structures requiring enhanced vibration control [

81,

82].

Crack Mitigation: The rubber particles can effectively bridge cracks and prevent their propagation. This functionality supports the energy dissipation mechanism by creating a more ductile failure mode, which is essential in improving concrete structures’ overall stability and longevity [

83,

84].

Altered Microstructure: The presence of rubber powder modifies the concrete’s microstructure. The interfacial transition zone between the rubber and the cement paste may exhibit unique bonding characteristics, influencing the overall acoustic properties and, consequently, the damping ratio [

84,

85].

4.2. Quantitative Evaluations

Several studies have reported the quantitative effects of rubber powder on the damping ratio of concrete. The results indicate that as the proportion of rubber powder increases, the damping ratio also tends to increase, particularly at lower loading frequencies. This enhancement can be attributed to the increased energy dissipation capacity of the rubber component. However, it is essential to identify the optimal content of rubber powder, as excessive amounts may lead to detrimental effects on compressive strength and durability, potentially counteracting the benefits observed in the damping performance [

81,

82,

83,

84,

85].

4.3. Experimental Observations

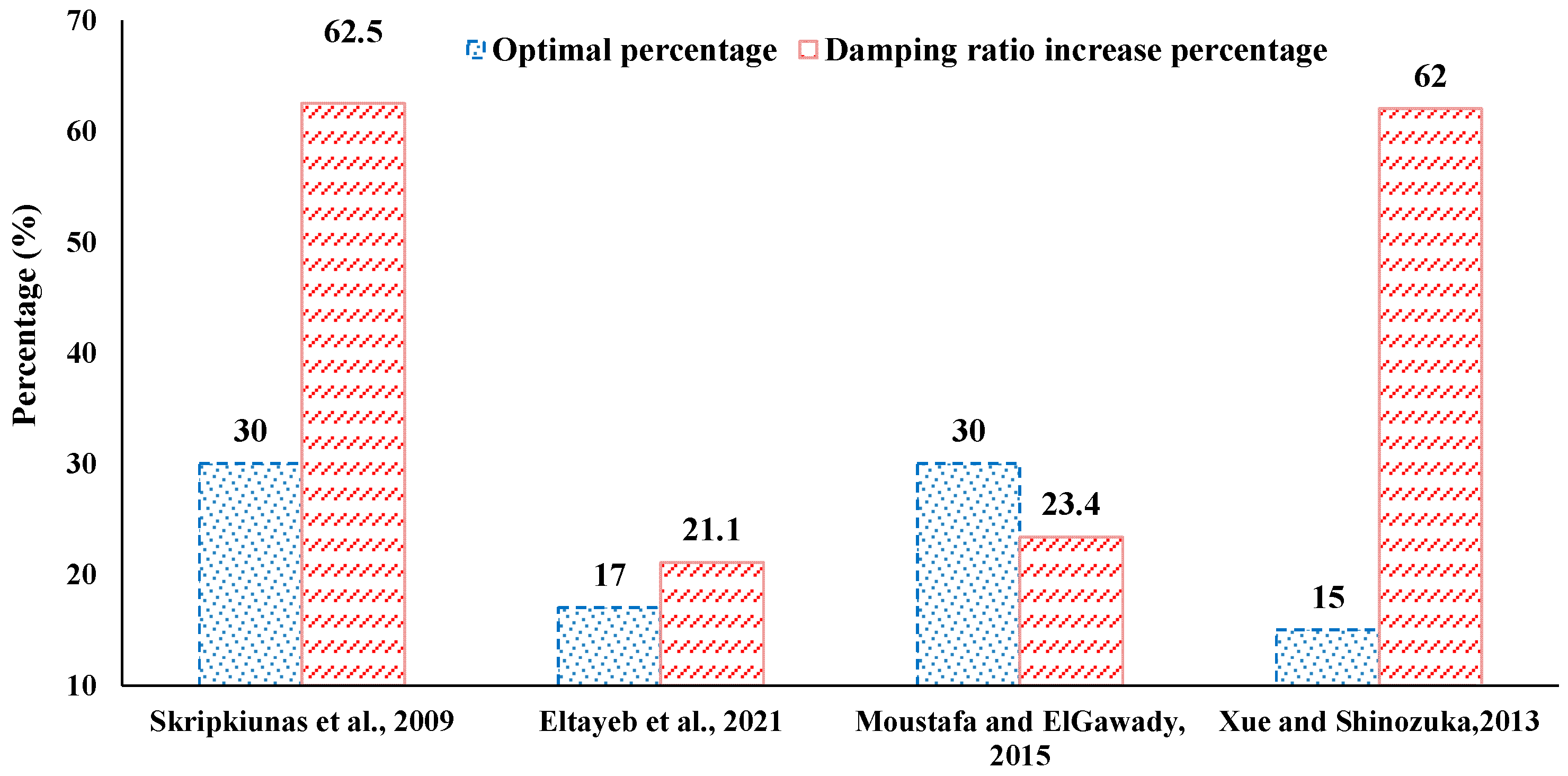

Experimental evaluations involving vibration tests on rubberized concrete specimens have indicated that modifications to the damping ratio directly correlate with the rubber content. For instance, concrete mixtures containing a 10% to 30% replacement of fine aggregates with rubber powder demonstrate significant improvements in damping ratios compared to conventional concrete mixtures (

Figure 4) [

81,

82,

83,

84,

85]. The optimal balance must be evaluated by considering the specific application of the concrete, as enhanced damping characteristics may be more or less crucial depending on the structure’s intended use.

4.4. Optimizing Rubber Powder Content for Enhanced Damping: Mechanisms, Trade-Offs, and Practical Limits

Adding rubber powder to concrete significantly improves its damping ratio—the ability to absorb and dissipate energy under dynamic loads. This enhancement stems from several key mechanisms: The rubber’s viscoelastic nature acts as a cushion, absorbing energy and reducing vibrations; it helps bridge cracks, promoting a more ductile failure; and it alters the concrete’s microstructure, improving the acoustic properties and, consequently, damping.

Quantitative studies show a positive correlation between rubber powder content and the damping ratio, particularly at lower frequencies. However, there is an optimal replacement level; exceeding it can negatively impact compressive strength and durability, undermining the damping benefits. Experiments confirm this relationship, with a 10–30% fine aggregate replacement by rubber powder showing substantial damping ratio improvements. The ideal rubber powder content depends heavily on the specific application, as the need for enhanced damping varies across different structural uses. In short, rubber powder offers a promising way to improve concrete’s damping properties, but careful optimization is crucial for achieving the best balance of performance and durability.

5. Effects of Aggregate Size and Type on Damping Ratio in Concrete

The size and type of aggregates used in concrete significantly influence its mechanical properties, including the damping ratio. Understanding these effects is crucial for optimizing concrete formulations for energy dissipation applications, such as in seismic design and vibration-sensitive structures.

5.1. Aggregate Size

The size of aggregates used in concrete plays a critical role in determining the overall stiffness and flexibility of the composite material. Specifically, smaller aggregates generally form a denser matrix, enhancing the adhesion between the aggregate particles and the surrounding cement paste. This improved bond facilitates a higher level of energy dissipation, making the concrete more effective in responding to dynamic loads. Due to their reduced particle size, research has shown that fine aggregates enhance the damping ratio of concrete mixes. This enhancement can be attributed to the increased contact area between the particles and the frictional interactions within the mixture. Such increased inter-particle bonding not only improves the overall mechanical properties of the concrete but also enhances its viscoelastic characteristics, thereby facilitating better energy absorption during dynamic loading scenarios [

86,

87,

88,

89,

90].

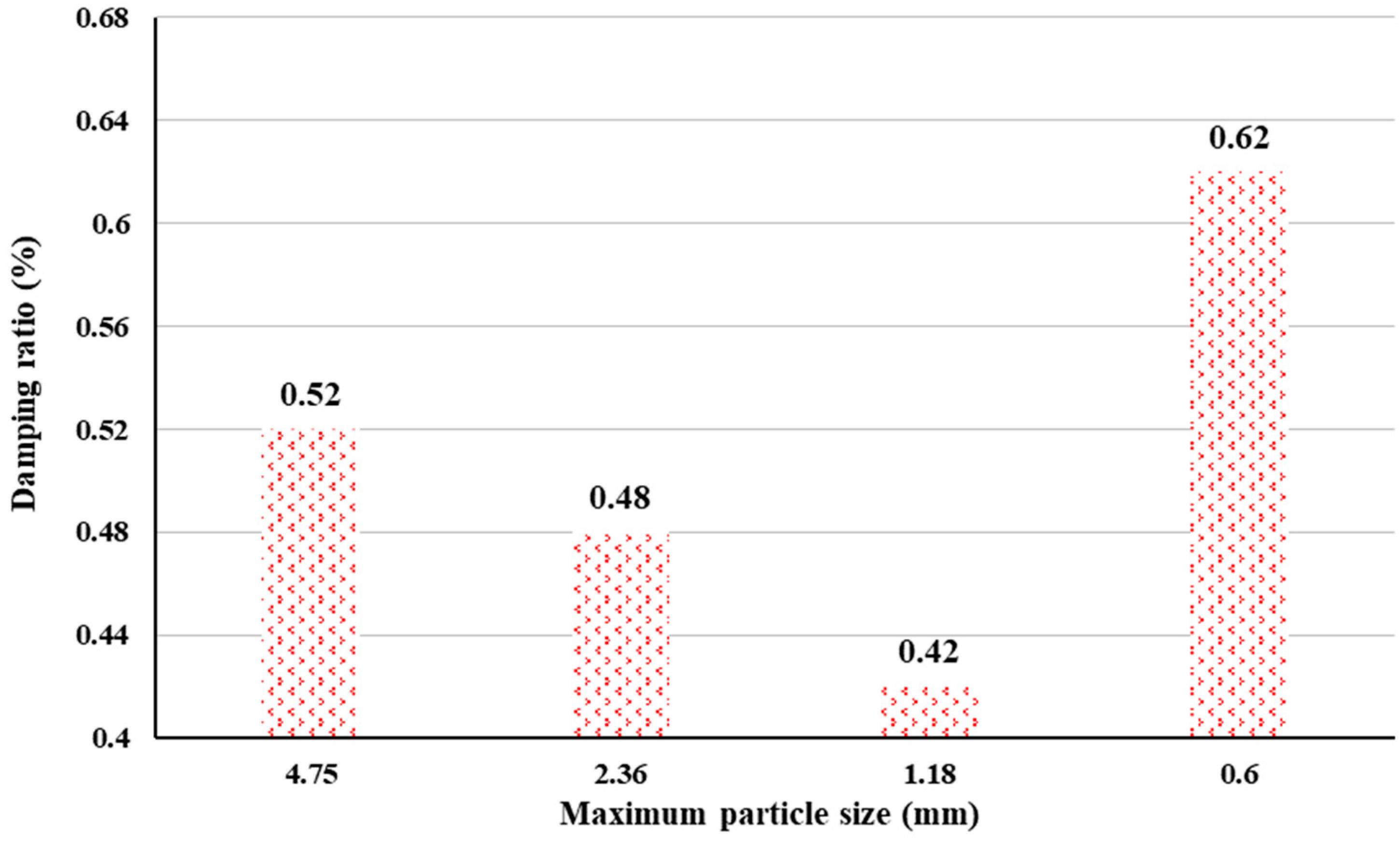

Interestingly, the type of aggregate can significantly influence the impact of size on the damping ratio. For example, it has been observed that reducing the aggregate size from 4.75 mm to 1.18 mm in concrete containing fine glass aggregate leads to a decrease in the damping ratio by approximately 20%. Conversely, when the aggregate size is further reduced to 0.6 mm, the damping ratio experiences an increase of about 20%. These findings underscore the complexity of the relationship between aggregate size and damping behavior, suggesting that the aggregate’s physical and chemical properties must be considered in the concrete mix design (

Figure 5) [

86].

In contrast, using larger aggregates tends to yield lower damping ratios. Including larger particles can create a more rigid framework within the concrete, restricting the material’s ability to deform under applied stress. This rigidity can reduce energy dissipation as the concrete is less capable of absorbing and dissipating energy during dynamic events. Furthermore, the spacing between larger aggregates can lead to zones of weakness within the concrete matrix, further compromising its energy absorption capacity [

86,

87,

88,

89,

90].

Given these dynamics, it is essential to carefully consider the adequacy of aggregate size in concrete design, particularly in applications that necessitate superior damping characteristics. Ultimately, a comprehensive understanding of how aggregate size influences concrete’s mechanical behavior can inform more effective design strategies aimed at enhancing the performance of concrete structures subjected to dynamic loading conditions.

5.2. Aggregate Type

The type of aggregate used can also profoundly impact the damping ratio of concrete. Natural aggregates, such as granite or limestone, exhibit different physical and chemical properties than manufactured or recycled aggregates, such as crushed concrete or glass. Natural aggregates typically provide better particle interlocking and bonding properties, resulting in higher damping ratios. In contrast, some manufactured aggregates might possess a higher porosity or lower density, which can alter the mechanical behavior of concrete under dynamic loading [

31,

91,

92,

93].

Additionally, the mineralogical composition of the aggregates plays a crucial role. For instance, aggregates with high elastic moduli may contribute to increased stiffness but potentially reduce the damping ratio. On the other hand, aggregates with more granular or reactive qualities, such as lightweight aggregates, can improve the composite’s viscoelastic characteristics, leading to better energy absorption and higher damping.

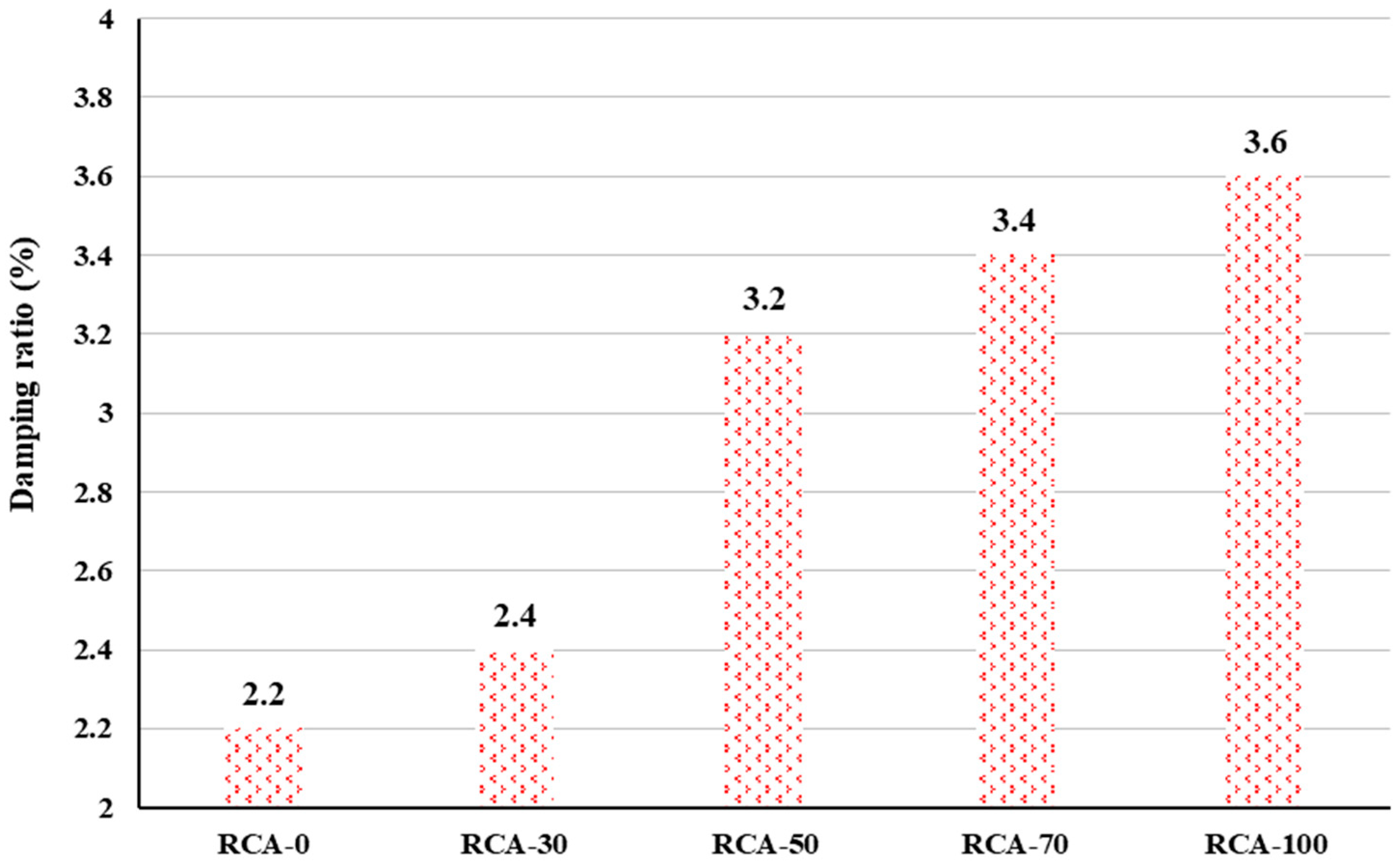

Previous research has consistently demonstrated that the type of aggregate used in concrete significantly influences its damping characteristics, which are critical for understanding the material’s performance under dynamic loading conditions. The choice of aggregate affects not only the mechanical properties of concrete but also its ability to dissipate energy, an essential factor in applications such as seismic design and vibration control [

20]. Notably, studies have shown that when natural aggregates are entirely replaced with recycled aggregates—up to a 100% substitution—there is a substantial increase in the concrete’s damping ratio. Specifically, this replacement results in an impressive increase of approximately 63% in the damping ratio (

Figure 6) [

31]. This enhancement suggests that recycled aggregates, potentially sourced from construction and demolition waste, can provide a more sustainable alternative while simultaneously improving the energy-dissipating capabilities of concrete. Such findings underline the importance of further investigating recycled aggregates’ mechanical and physical properties to optimize their performance in concrete applications and promote sustainable construction practices. Other researchers have conducted investigations revealing that an increase in the replacement percentage of recycled cathode ray tube (CRT) glass with natural sand can reduce the damping ratio of the resulting concrete mix. This finding is significant because it contrasts with the trends observed when natural aggregates are substituted with recycled aggregates more broadly.

The diminished damping ratio with higher proportions of CRT glass can likely be attributed to the inherent physical properties of the glass, such as its lower density and higher brittleness compared to traditional aggregates like natural sand. As the percentage of CRT glass increases, the modified composite may exhibit altered energy dissipation characteristics, which could affect the overall dynamic performance of the concrete. This insight highlights the complex relationship between the type and proportion of aggregate materials and their collective impact on the mechanical behavior of concrete under dynamic loading conditions. Therefore, while the inclusion of recycled materials is generally promoted for sustainability, careful consideration and extensive research are necessary to understand the implications of specific types of recycled aggregates, such as CRT glass, on the performance parameters critical for structural integrity and safety in engineering applications [

86].

5.3. Aggregate Size and Type in Damping Optimization: Summary of Mechanisms and Material Selection Strategies

Aggregate size and type significantly impact concrete’s damping ratio, a crucial factor in applications demanding high energy dissipation (e.g., seismic design). Smaller aggregates generally create denser matrices, improving bonding and energy dissipation. However, the effect is nuanced and depends on aggregate type; some studies show reduced damping with finer aggregates, highlighting the interplay of physical and chemical properties. Larger aggregates tend to reduce damping due to increased rigidity and potential weakness zones in the matrix.

Aggregate type also plays a pivotal role. Natural aggregates typically offer superior interlocking and bonding, leading to higher damping ratios than manufactured or recycled aggregates. Mineralogical composition further complicates this: high-modulus aggregates may increase stiffness but reduce damping, while lightweight aggregates can improve viscoelasticity and damping.

Importantly, replacing natural aggregates with recycled aggregates, such as up to a 100% substitution with construction waste, can surprisingly increase the damping ratio substantially. However, this is not universally true; studies demonstrate that using recycled CRT glass decreases damping due to the glass’s inherent properties.

In conclusion, optimizing concrete’s damping requires careful consideration of both aggregate size and type. While smaller aggregates and recycled aggregates often show promise for enhancing damping, the specific aggregate’s physical and chemical characteristics must be carefully evaluated to ensure improved performance without compromising other critical mechanical properties. Further research is needed to fully understand the complex interplay of these factors and refine material selection for optimal damping in various applications.

6. Effects of Curing Conditions on Damping Ratio in Concrete

Curing plays a pivotal role in the development of concrete’s mechanical and dynamic properties, particularly its ability to dissipate energy under cyclic or vibrational loading. The temperature, humidity, and duration of curing directly affect hydration kinetics, microstructural evolution, and viscoelastic behavior, all of which influence the damping ratio. This section expands the literature base and introduces comparative data to clarify how curing conditions impact the damping performance.

6.1. Temperature Effects

Curing temperature governs the rate of cement hydration and the formation of microstructures.

High temperatures accelerate hydration but may induce shrinkage cracking, thereby reducing the ductility and damping capacity. On the other hand, low temperatures slow hydration, leading to incomplete bonding and a porous matrix, which also lowers damping. Bala and Gupta [

94] found that concrete doped with rubber particles cured at 40 °C exhibited a 15–20% reduction in the damping ratio compared to samples cured at 20 °C due to micro-crack formation.

6.2. Humidity Effects

Relative humidity during curing affects moisture retention and cement paste cohesion.

Low humidity promotes evaporation, resulting in incomplete hydration and weak interfacial bonding. Conversely, high humidity supports full hydration, yielding a denser matrix and improved energy dissipation. Yang et al. [

95] modeled the coupled effects of humidity and temperature on concrete expansion and damping, showing that an RH > 90% during early curing stages led to a 12% increase in the damping ratio compared to an RH < 60%.

6.3. Duration Effects

Curing duration determines the completeness of hydration and long-term stability.

Extended curing (≥28 days) enhances viscoelastic properties and damping performance.

Short curing (<7 days) results in a coarse microstructure and reduced damping capacity. Caronge et al. [

96] demonstrated that PCC mortar cured for 28 days had a 25% higher damping ratio than samples cured for only 7 days. The comparative impact of curing conditions on the damping ratio is listed in

Table 2.

6.4. Trends, Contradictions, and Research Gaps

Trend: Longer curing under moderate temperature and high humidity consistently improves damping.

Contradiction: Some studies report increased damping at elevated temperatures due to accelerated hydration, but this is often offset by microcracking.

Gap: Few studies isolate curing parameters while controlling for mix design and additives, making cross-comparison difficult.

Need: Standardized curing protocols and multi-variable simulation models are essential to predict damping behavior reliably.

6.5. Standardization of Test Conditions in Damping Performance Studies

Despite the growing body of research reporting damping ratio improvements and percentage gains in advanced concrete materials, the lack of standardized test conditions across studies presents a significant barrier to meaningful comparison. Variations in loading frequency, specimen geometry, excitation methods, and measurement techniques can lead to inconsistent or misleading interpretations of the damping performance.

6.6. Key Variables Affecting Damping Comparability

Loading Frequency: Damping behavior is frequency-dependent, especially in viscoelastic materials like polymer concrete. Studies using low-frequency excitation often report higher damping ratios, which may not reflect real-world dynamic conditions.

Specimen Size and Geometry: Differences in mass and stiffness due to specimen dimensions directly influence modal properties and damping calculations. Larger specimens tend to exhibit lower damping due to increased inertia.

Loading Method: Techniques such as cyclic flexural loading, resonant vibration, impact hammer testing, and harmonic excitation each produce distinct dynamic responses. These methods are not interchangeable and must be clearly reported.

Measurement Technique: Common approaches include a logarithmic decrement, half-power bandwidth, and FFT-based signal analysis. Each method has its own sensitivity and limitations, affecting the reported damping values.

Table 3 presents representative experimental conditions in damping studies.

7. Recommendations for Future Research

To improve cross-study comparability and reproducibility:

Adopt standardized specimen dimensions and loading frequencies aligned with real-world structural applications.

Clearly report environmental conditions (e.g., temperature, humidity) that may affect damping behavior.

Use consistent measurement techniques or provide conversion metrics when comparing across methods.

Encourage the development of benchmark testing protocols for damping evaluation in concrete materials.

By addressing these methodological inconsistencies, future studies can contribute to a more coherent understanding of damping performance and facilitate the material selection for vibration-sensitive applications.

7.1. Potential Trade-Offs of Damping-Enhancing Additives in Concrete

While the incorporation of materials such as rubber powder, polymers, and fibers has shown promising improvements in the damping performance, these enhancements often come with compromises in durability, workability, and long-term mechanical properties. A balanced evaluation is essential to ensure that damping benefits do not undermine the structural integrity or service life of concrete elements.

7.2. Durability Concerns

Rubberized Concrete: Inclusion of crumb rubber can reduce compressive strength and increase porosity, leading to a lower resistance to freeze–thaw cycles and chemical attack [

100].

Polymer Concrete: Although polymers improve damping and chemical resistance, they may exhibit poor UV stability and thermal degradation over time [

99].

Fiber-Reinforced Concrete: Excessive fiber content can lead to non-uniform dispersion, creating weak zones and reducing long-term durability [

97].

7.3. Workability Challenges

Rubber and Polymer Additives: These materials often reduce slump and increase viscosity, making concrete difficult to mix, pump, and place without specialized equipment or admixtures [

100].

Fiber Inclusion: High fiber volumes can cause balling and segregation, especially in self-consolidating mixes, affecting surface finish and compaction [

98].

Long-Term Strength and Stability

Rubberized Concrete: Long-term strength development is often compromised due to the low stiffness and poor bonding of rubber particles with the cement matrix [

100].

Polymer-Based Systems: These may exhibit creep and shrinkage under sustained loads, especially in high-temperature environments [

102].

Fiber-Reinforced Systems: While initial crack resistance is improved, long-term hydration and shrinkage behavior can be adversely affected depending on fiber type and dosage [

103].

7.4. Summary and Recommendations

To ensure a holistic performance

Optimize the additive dosage to balance damping and mechanical properties.

Use surface treatments or coupling agents to improve bonding and reduce porosity.

Conduct long-term durability tests under realistic environmental conditions.

Standardize mix design protocols to mitigate workability issues.

By acknowledging these trade-offs, researchers and engineers can make informed decisions when selecting damping-enhancing strategies for specific structural applications.

Effect of Concrete Confinement on Damping Behavior

Concrete confinement is widely recognized for its role in enhancing the ductility, strength, and energy dissipation capacity of structural elements under dynamic loading. However, its influence on the damping ratio—a key parameter for vibration control—has received comparatively less attention in damping-focused reviews. This section highlights the mechanisms, types, and implications of confinement on damping performance.

Mechanisms of Damping Enhancement through Confinement

Confinement improves damping primarily by the following:

Restraining lateral expansion, which delays crack propagation and enhances post-yield behavior.

Increasing energy absorption through hysteretic deformation in confined zones.

Improving strain compatibility between concrete and reinforcement, especially under cyclic loads.

These effects are particularly pronounced in columns, beam-column joints, and retrofit applications subjected to seismic or vibrational forces.

Experimental Insights

Shin and Andrawes [

104] reported that SMA-confined concrete columns exhibited up to 40% higher damping ratios under lateral cyclic loading compared to unconfined specimens.

Zhou et al. [

105] demonstrated that FRP-confined lightweight concrete showed enhanced damping and strain-hardening behavior under axial compression.

Triantafillou et al. [

106] found that TRM confinement improved out-of-plane cyclic damping in URM walls, with damping ratios increasing by 15–25% depending on the textile type and matrix composition.

Research Gaps and Recommendations

Comparative studies across confinement types under standardized dynamic tests are limited.

Long-term performance of confined systems under fatigue and environmental exposure remains underexplored.

Numerical modeling of damping mechanisms in confined concrete—especially for hybrid systems like SMA-FRP—is still in the early stages.

Future research should focus on the following:

Developing multi-scale models to simulate confined concrete damping behavior.

Establishing standardized testing protocols for damping evaluation in confined systems.

Exploring sustainable confinement materials (e.g., basalt fibers, recycled composites) for a cost-effective damping enhancement.

8. Main Challenges and Research Gaps

Despite notable progress in enhancing the damping properties of concrete, several interconnected limitations continue to hinder widespread adoption and optimization. These challenges are summarized below, and each are paired with a targeted future research direction to guide innovation.

Trade-Off Between Damping and Strength

Challenge: Additives such as fibers, rubber particles, and polymers improve damping but may compromise mechanical strength, durability, or workability.

Future Direction: Develop hybrid materials that combine multiple damping mechanisms while preserving structural integrity. Investigate synergistic combinations (e.g., fiber-reinforced rubberized concrete) through experimental and computational methods.

Mixing and Reinforcement Uniformity

Challenge: Achieving consistent dispersion of damping-enhancing additives during mixing remains difficult, leading to performance variability.

Future Direction: Apply machine learning and process modeling to optimize mix design and mixing protocols. Explore real-time monitoring technologies to ensure the uniform distribution of reinforcements.

Influence of External Factors

Challenge: Variability in curing conditions, environmental exposure, and load histories affects damping behavior unpredictably.

Future Direction: Conduct controlled studies on curing regimes (temperature, humidity, and duration) and develop adaptive curing strategies tailored to specific dynamic environments. Integrate environmental sensors for in situ performance tracking.

Lack of Unified Damping Test Standards

Challenge: Diverse testing setups—specimen sizes, loading frequencies, and evaluation methods—limit comparability across studies.

Future Direction: Establish standardized damping test protocols for concrete composites, including benchmark specimen geometries and frequency ranges. Promote international collaboration to harmonize testing frameworks.

Limited Multi-Scale Simulation Research

Challenge: Existing models focus on macro-scale behavior, neglecting meso- and micro-scale interactions that govern damping mechanisms.

Future Direction: Develop multi-scale numerical simulation frameworks that integrate material heterogeneity, interface dynamics, and time-dependent effects. Use AI-assisted modeling to predict the damping behavior under complex loading scenarios.

Lack of Long-Term Performance Evaluation

Challenge: Fatigue behavior, aging effects, and durability under cyclic loading are insufficiently understood for damping-enhanced concretes.

Future Direction: Initiate long-term field studies and accelerated aging tests to assess performance evolution. Incorporate a life-cycle analysis and durability modeling under realistic service conditions.

Cost and Implementation Barriers

Challenge: High production costs and limited scalability of advanced materials restrict practical application.

Future Direction: Prioritize cost-effective and sustainable components, such as recycled aggregates and bio-based polymers. Explore scalable manufacturing techniques and conduct economic feasibility studies to support broader adoption.

9. Conclusions and Future Directions

Concrete structures are increasingly exposed to dynamic loading conditions—seismic events, traffic-induced vibrations, and environmental disturbances—that demand enhanced energy dissipation capabilities. Traditional concrete, with its inherently low damping ratio, often fails to meet these demands. This review has demonstrated that advanced formulations such as ECCs, UHPC, HPC, and polymer concrete offer significant improvements in damping behavior.

Key mix design strategies—including fiber reinforcement, rubber powder incorporation, and aggregate modification—play a pivotal role in enhancing vibrational energy dissipation. Moreover, curing conditions critically influence the microstructural development and damping capacity, underscoring the need for tailored curing protocols.

To address the challenges outlined in

Section 7, future research should pursue the following integrated strategies:

Hybrid Material Development: Combine multiple damping mechanisms to balance energy dissipation with mechanical strength.

Digital Optimization: Use modeling and machine learning to refine mix designs, predict performance, and ensure uniformity.

Standardization and Benchmarking: Create unified testing protocols to enable reliable comparison and validation.

Multi-Scale Simulation: Advance numerical models that capture damping behavior across scales and loading conditions.

Durability and Lifecycle Assessment: Conduct long-term studies to evaluate fatigue resistance and sustainability.

Sustainable Innovation: Embrace eco-friendly materials and scalable production methods to reduce the cost and environmental impact.

By aligning research efforts with these targeted solutions, the field can move toward resilient, adaptive, and economically viable concrete technologies that meet the evolving demands of modern infrastructure. This roadmap not only strengthens the scientific foundation of damping-enhanced concrete but also empowers engineers and researchers to design safer, smarter, and more sustainable structures.