A Techno-Economic Analysis of Integrating an Urban Biorefinery Process Within a Wastewater Treatment Plant to Produce Sustainable Wood Adhesives

Abstract

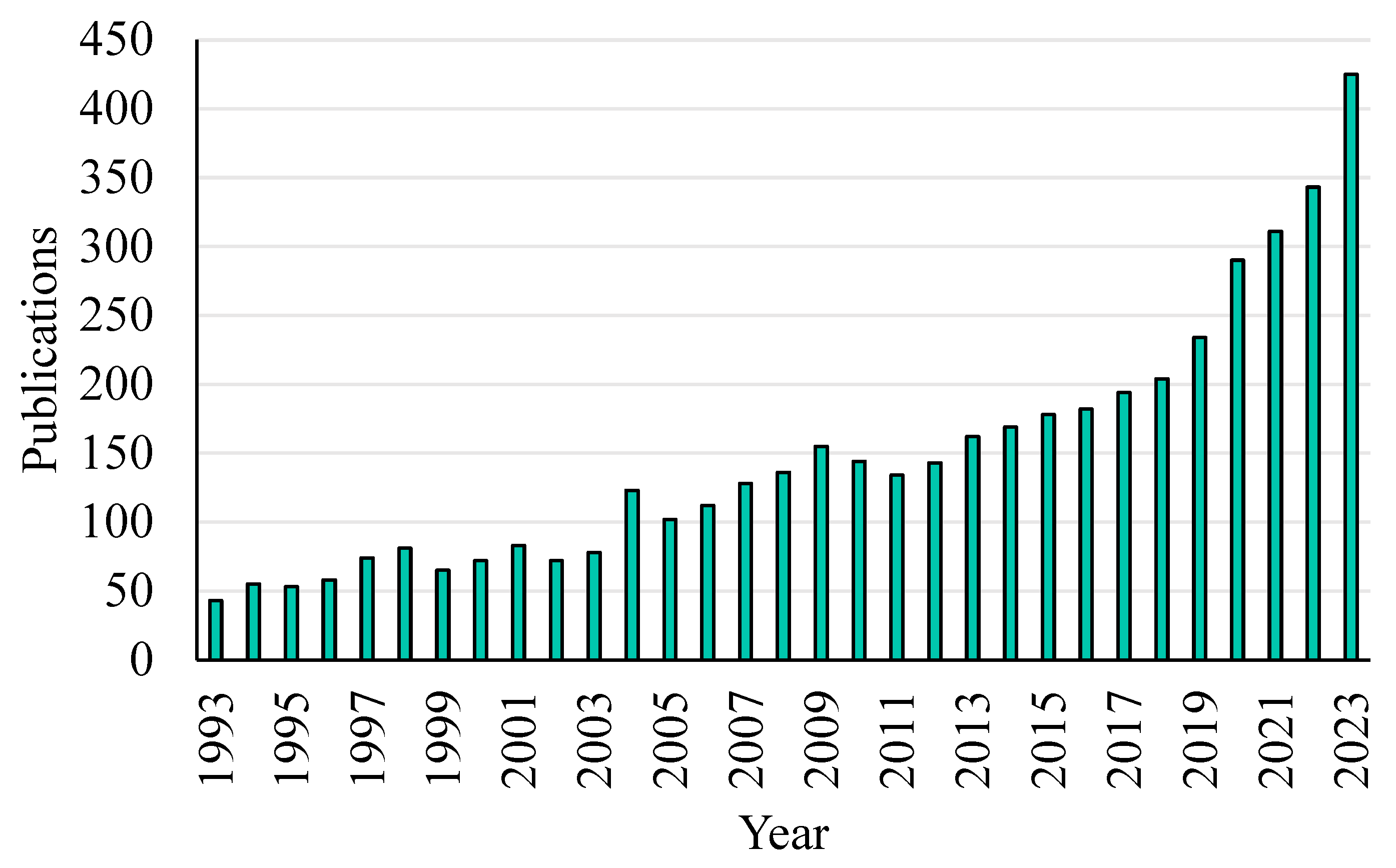

1. Introduction

- Develop models for 10 MGD WWTP operations producing DB adhesives with and without DSF protein blending and estimate associated costs.

- Size, design, and estimate the required process equipment for WWTP integrated adhesive biorefinery models utilizing Aspen Cost Estimator V12.

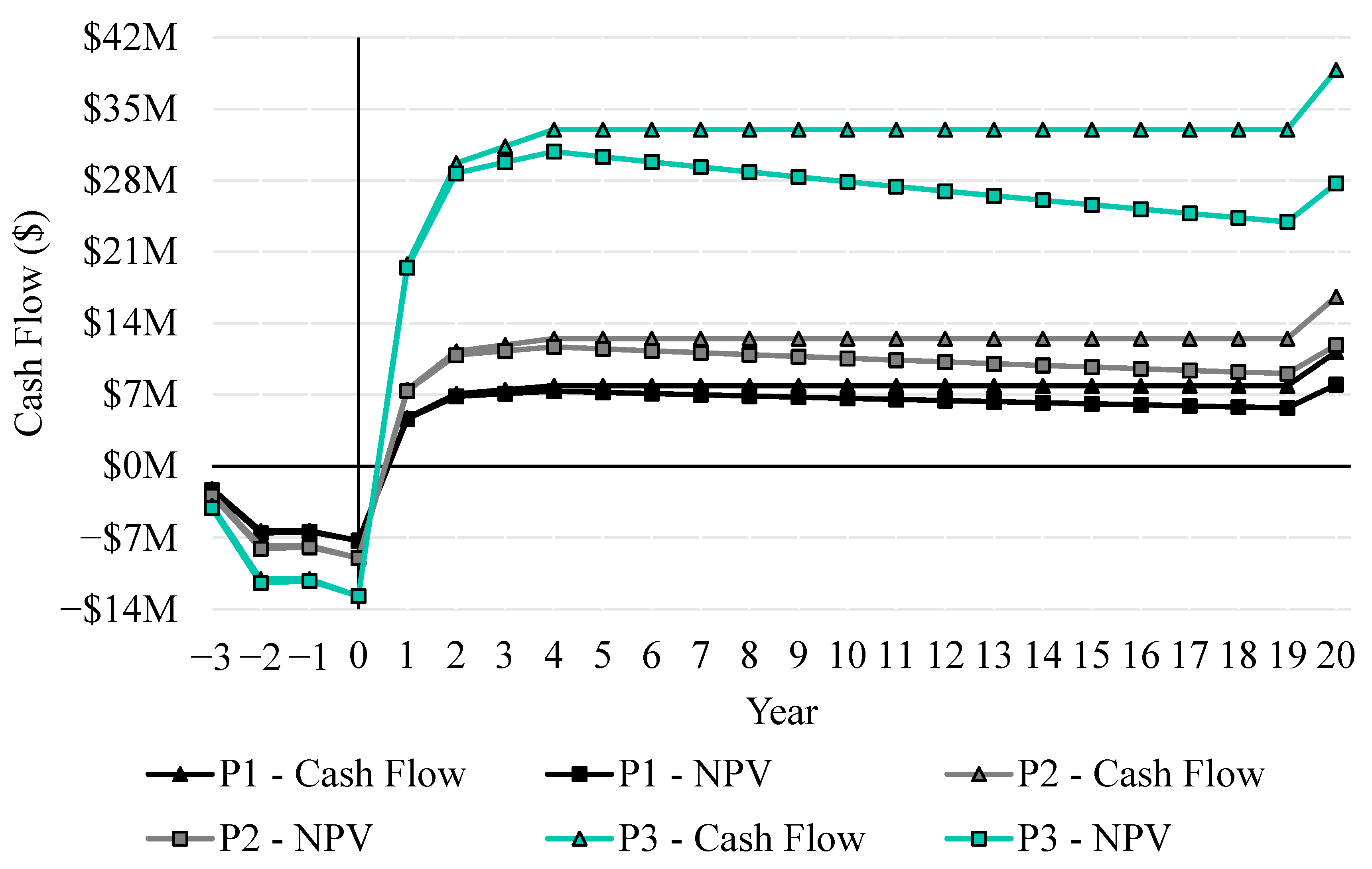

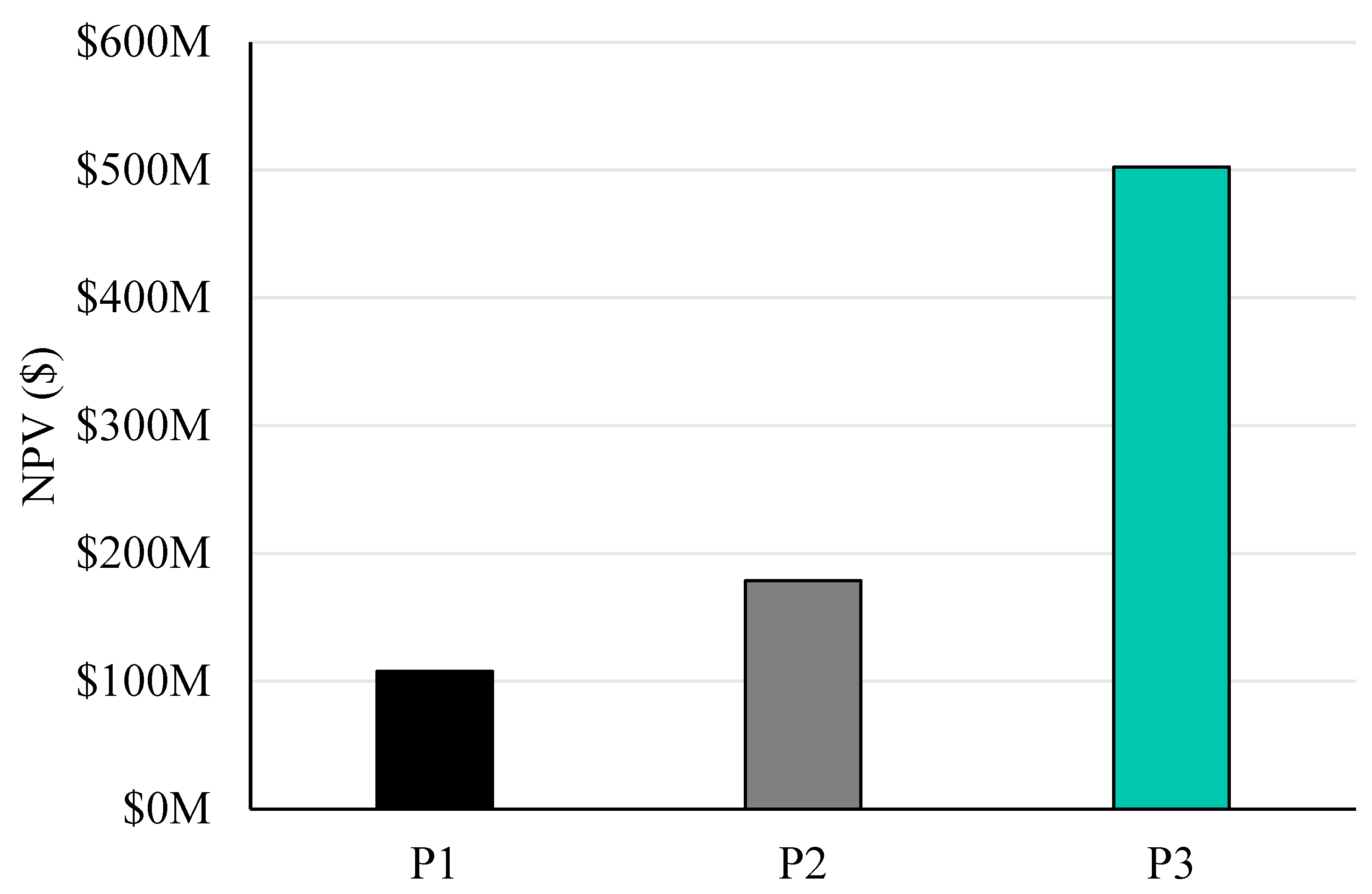

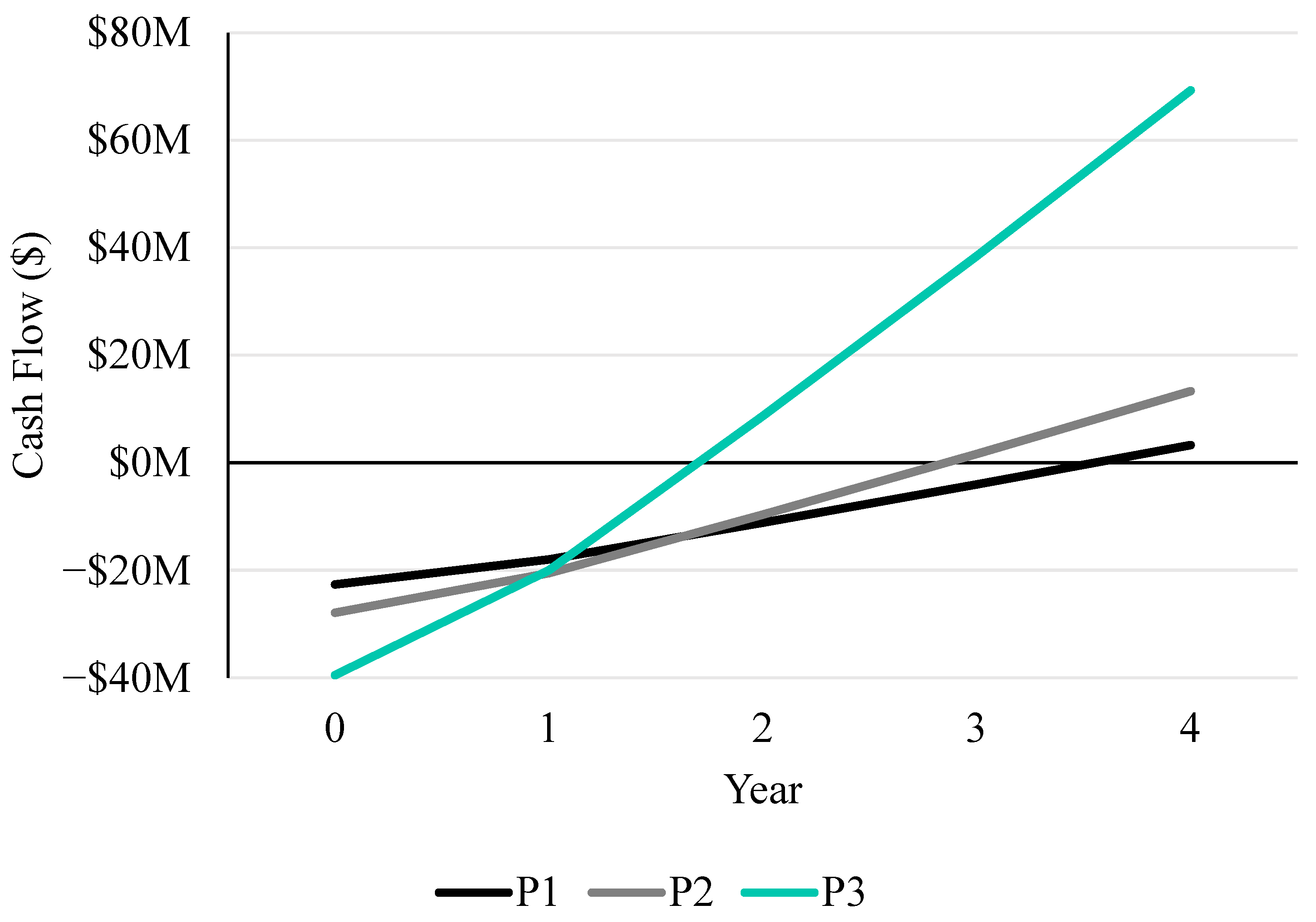

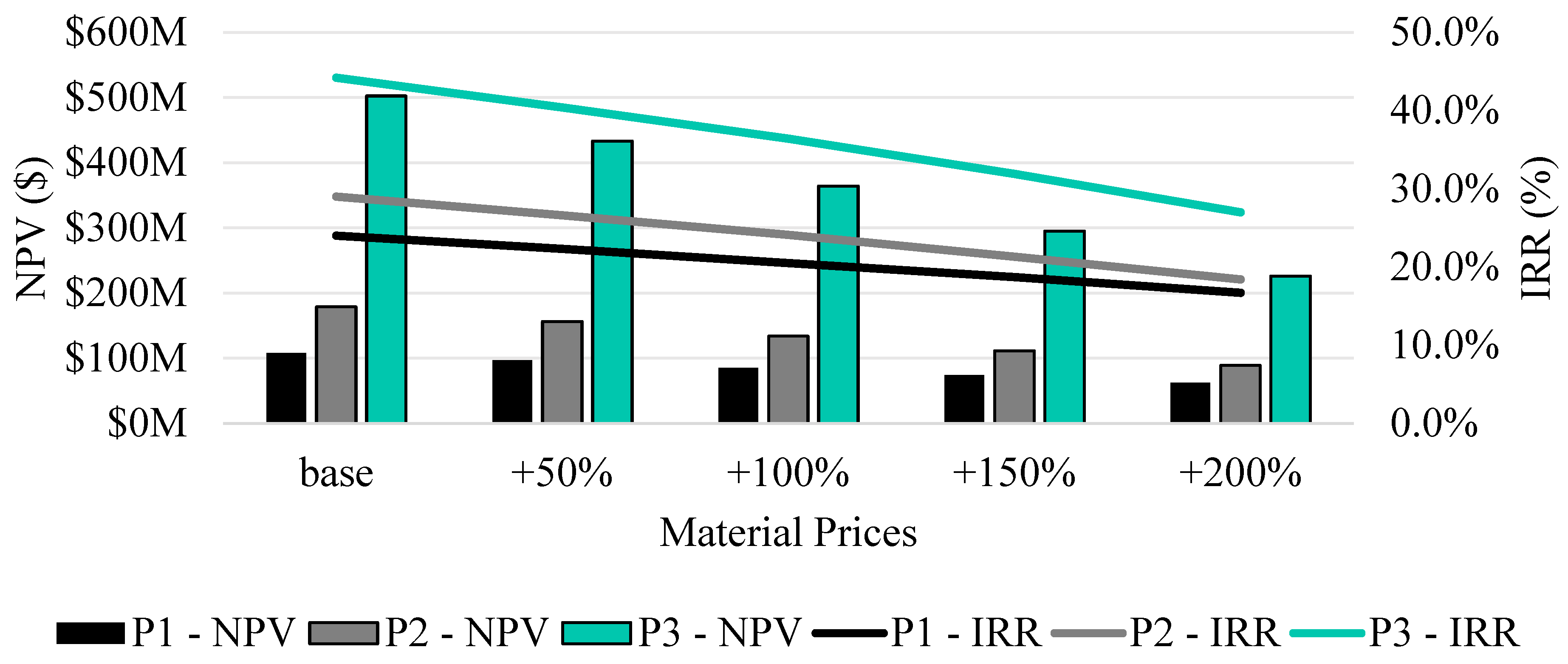

- Apply economic formulas to evaluate 20-year plant life for net present value (NPV) and discounted cash flow rate of return/internal rate of return (IRR) to obtain the modeled process’s economic capability.

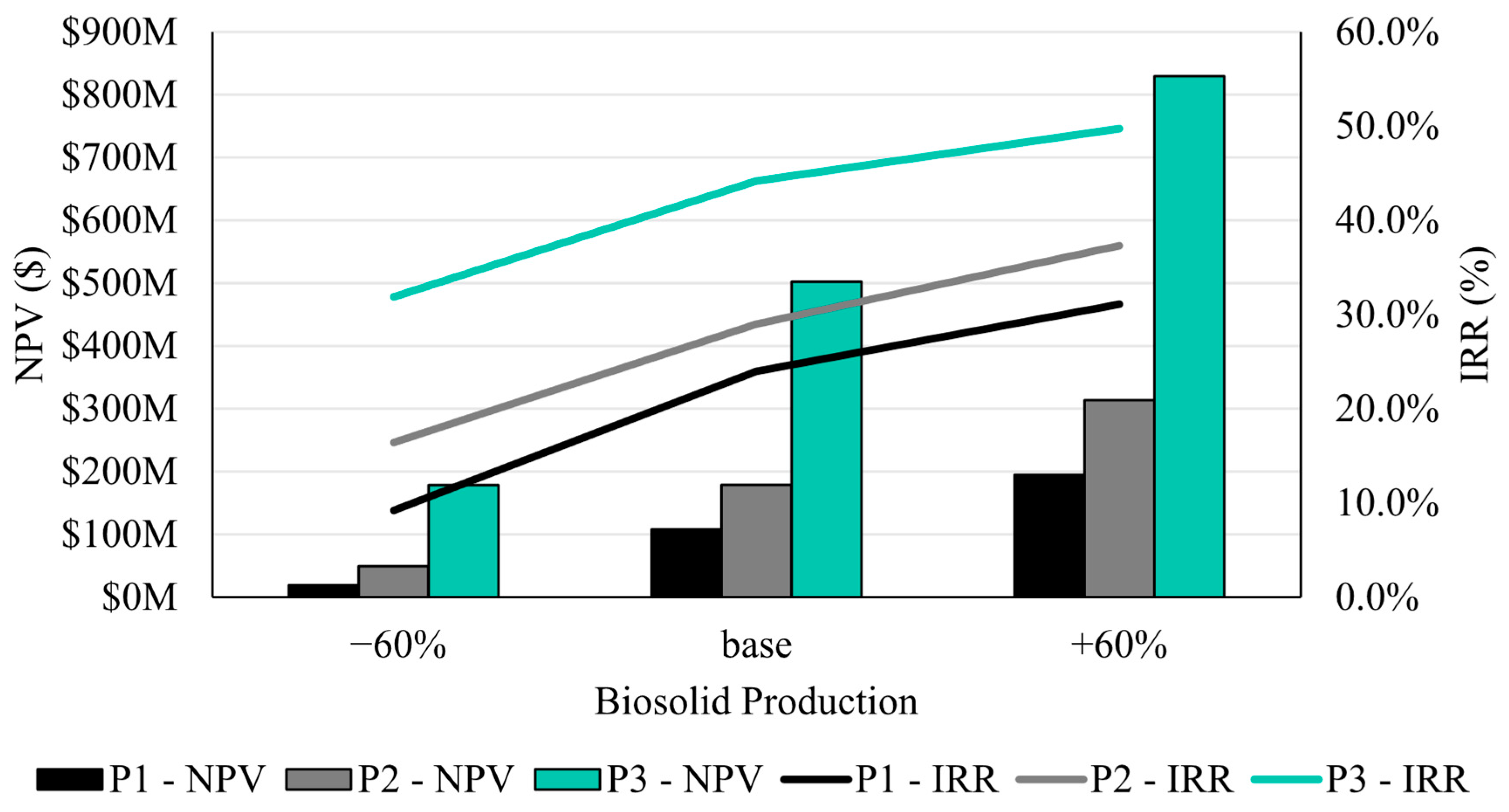

- Conduct sensitivity analyses on critical process parameters to test the robustness of the models.

2. Methods and Development

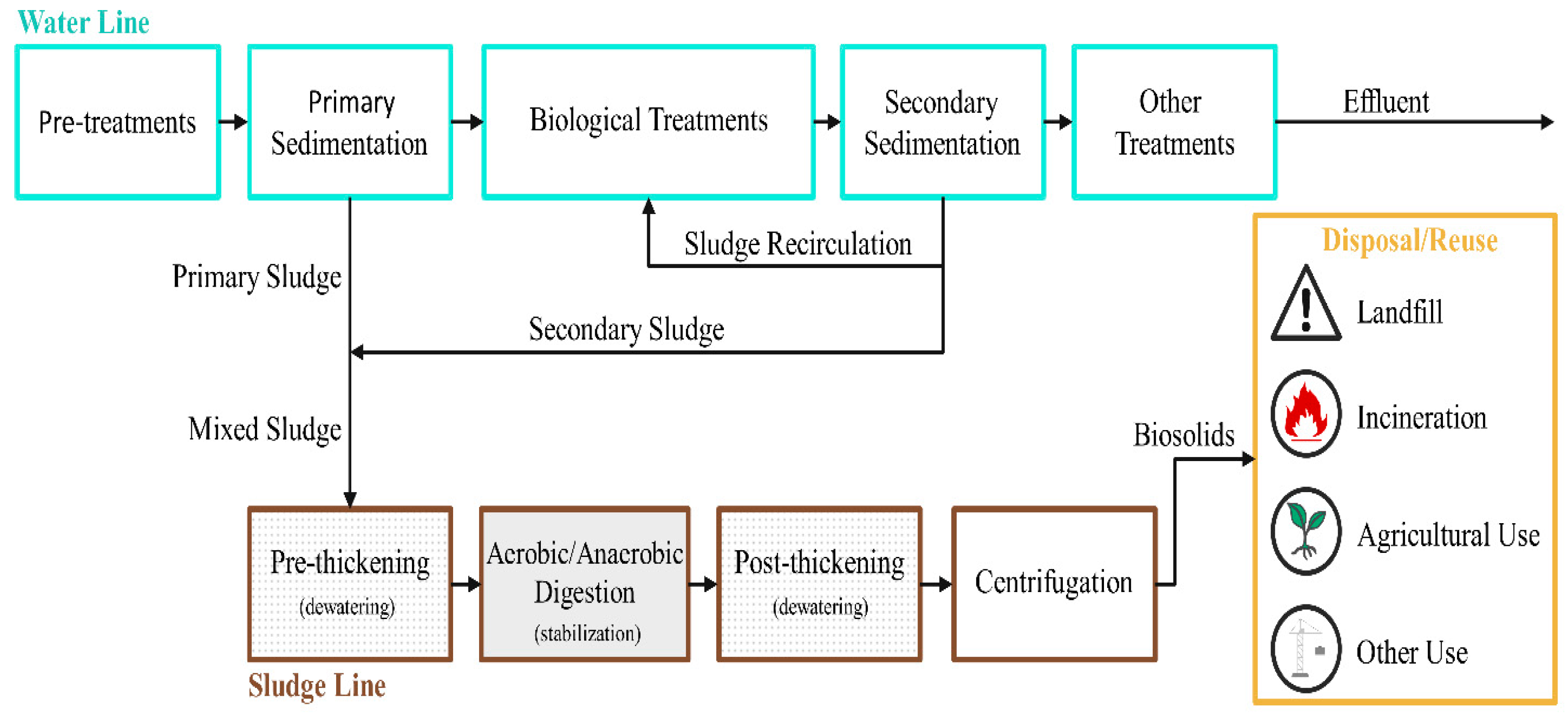

2.1. Biosolid Production Calculations

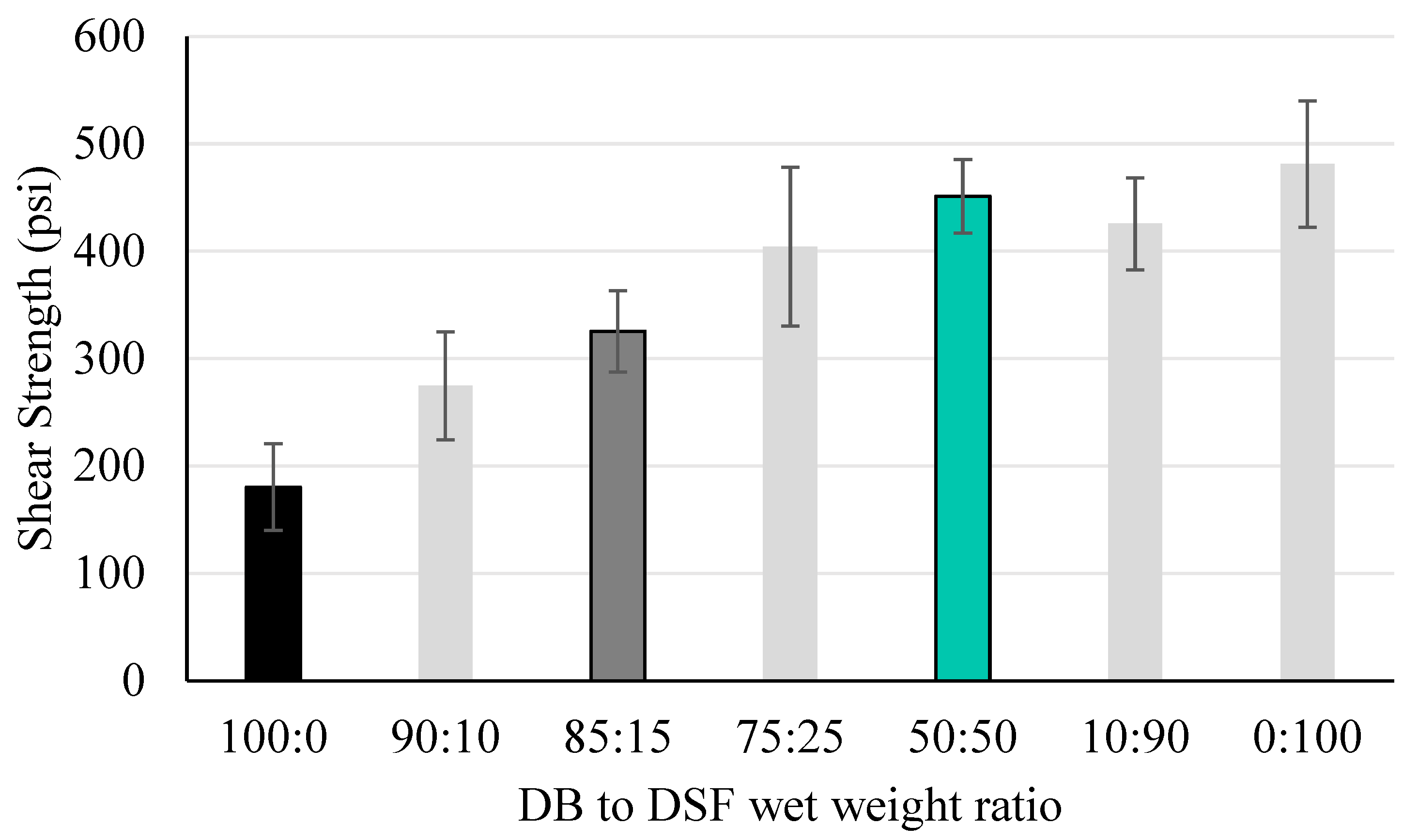

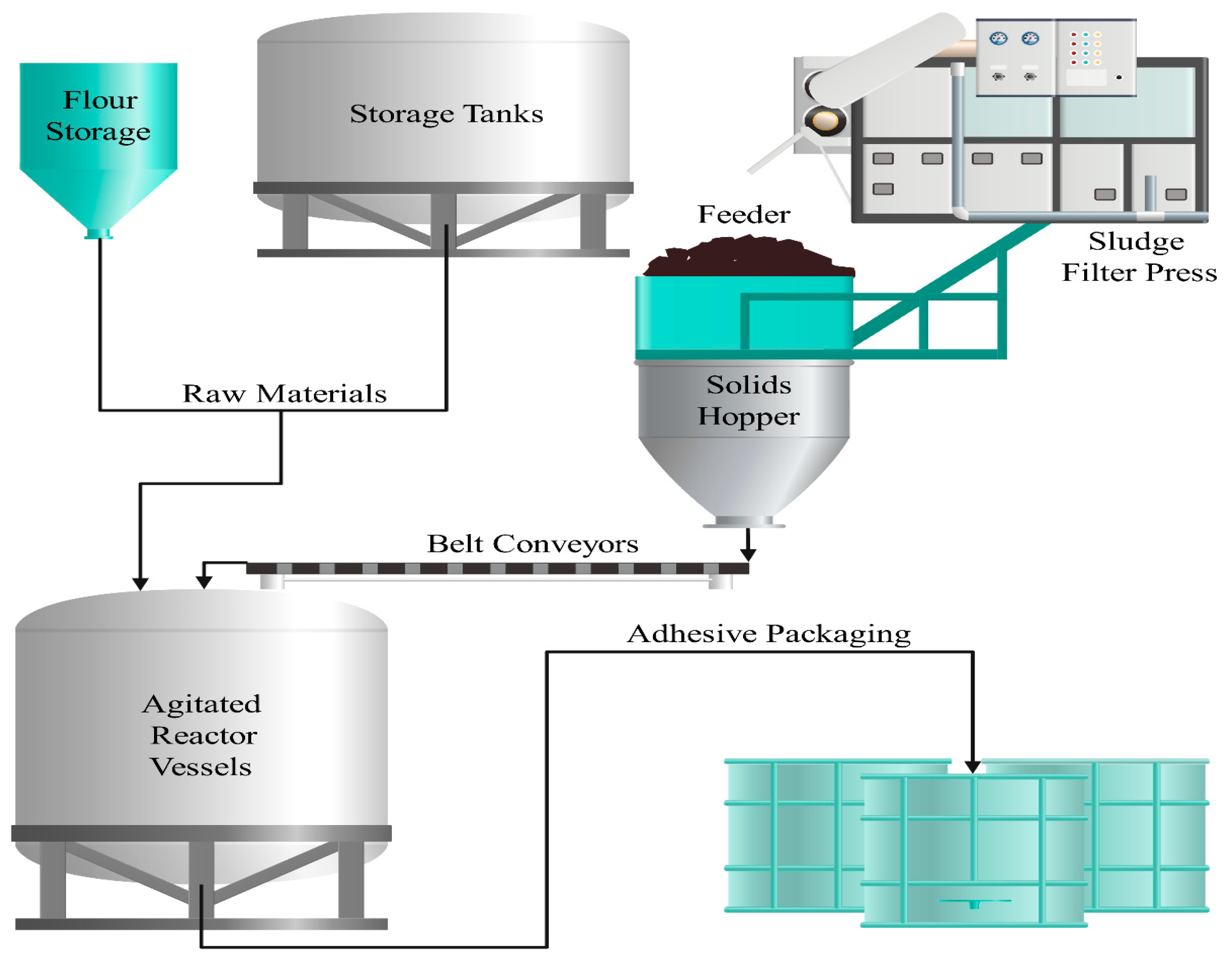

2.2. Process Design

3. Preparation of Economic Estimates

3.1. Economic and Discounted Cash Flow Calculations

3.2. Material and Energy Cost Estimation

3.3. Installed Equipment Cost Estimation

4. Results

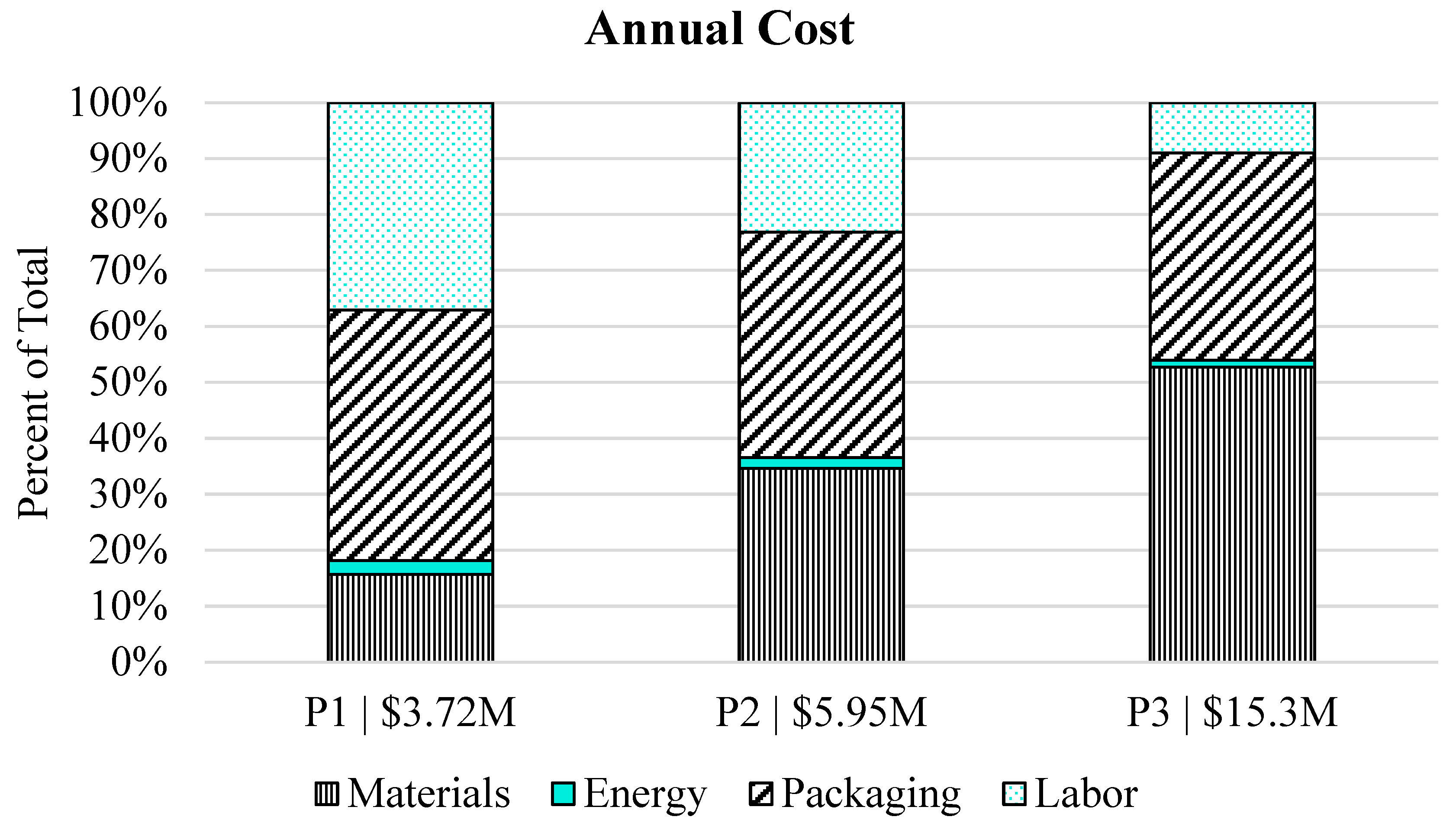

4.1. Annual Production Costs

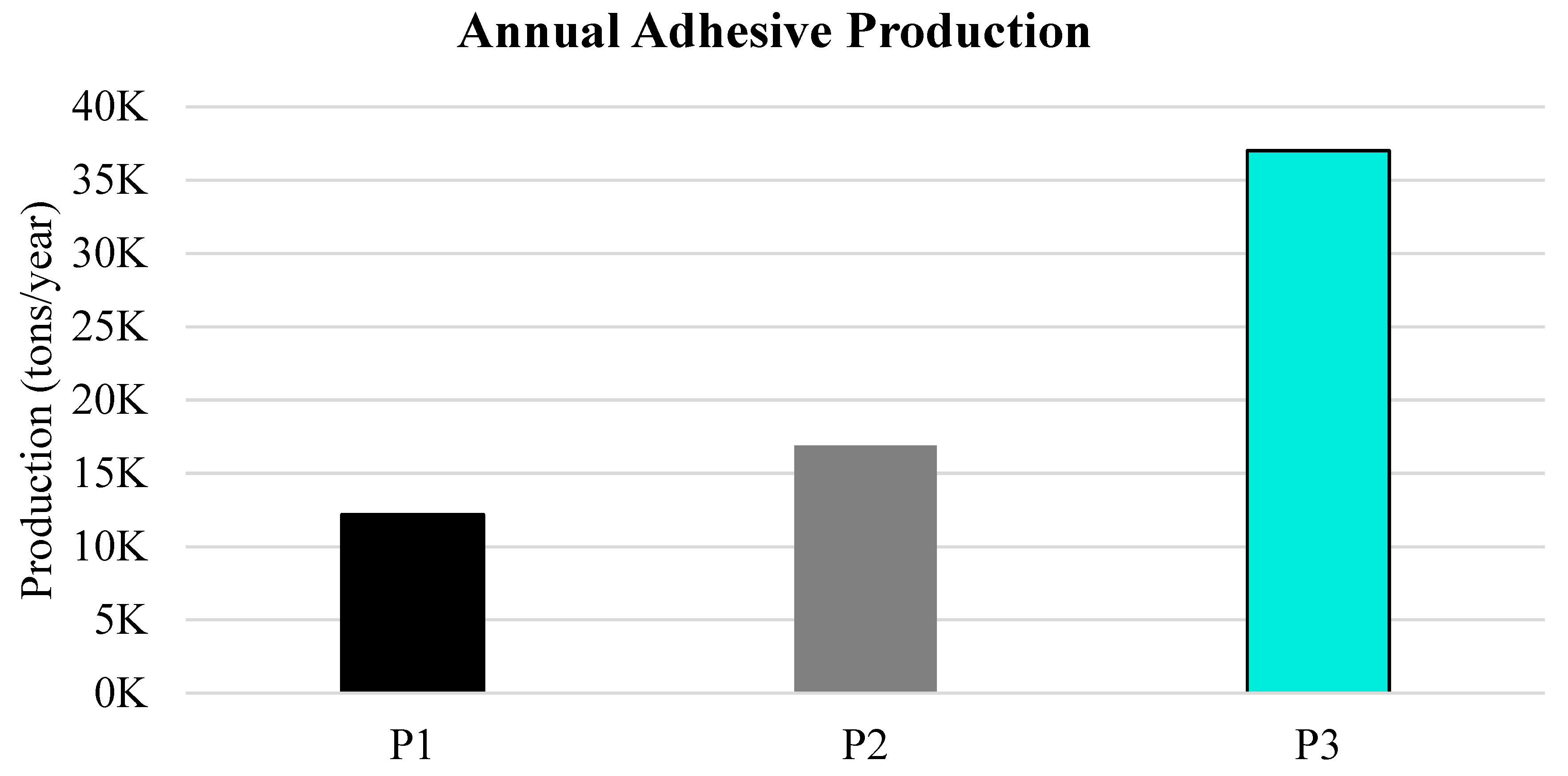

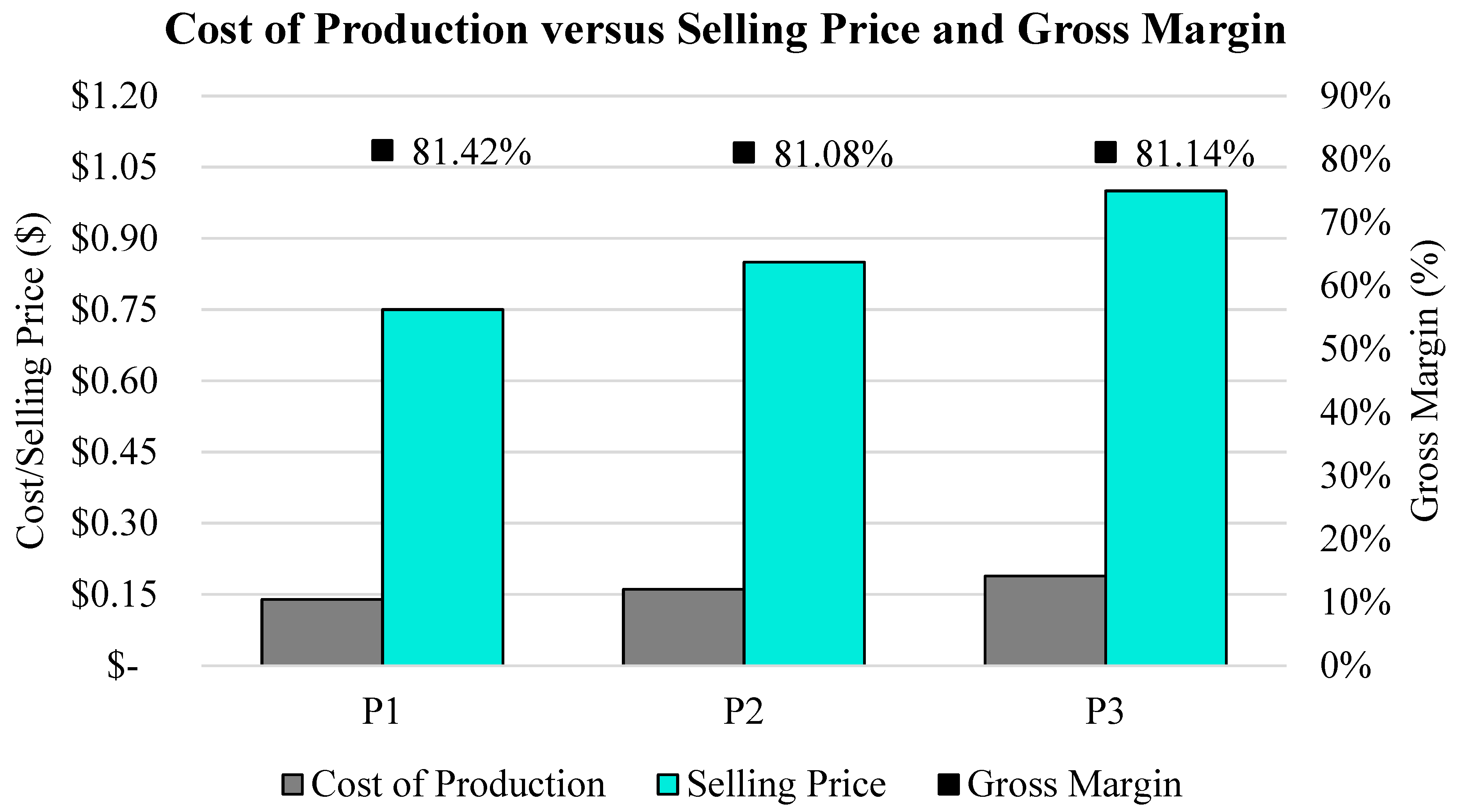

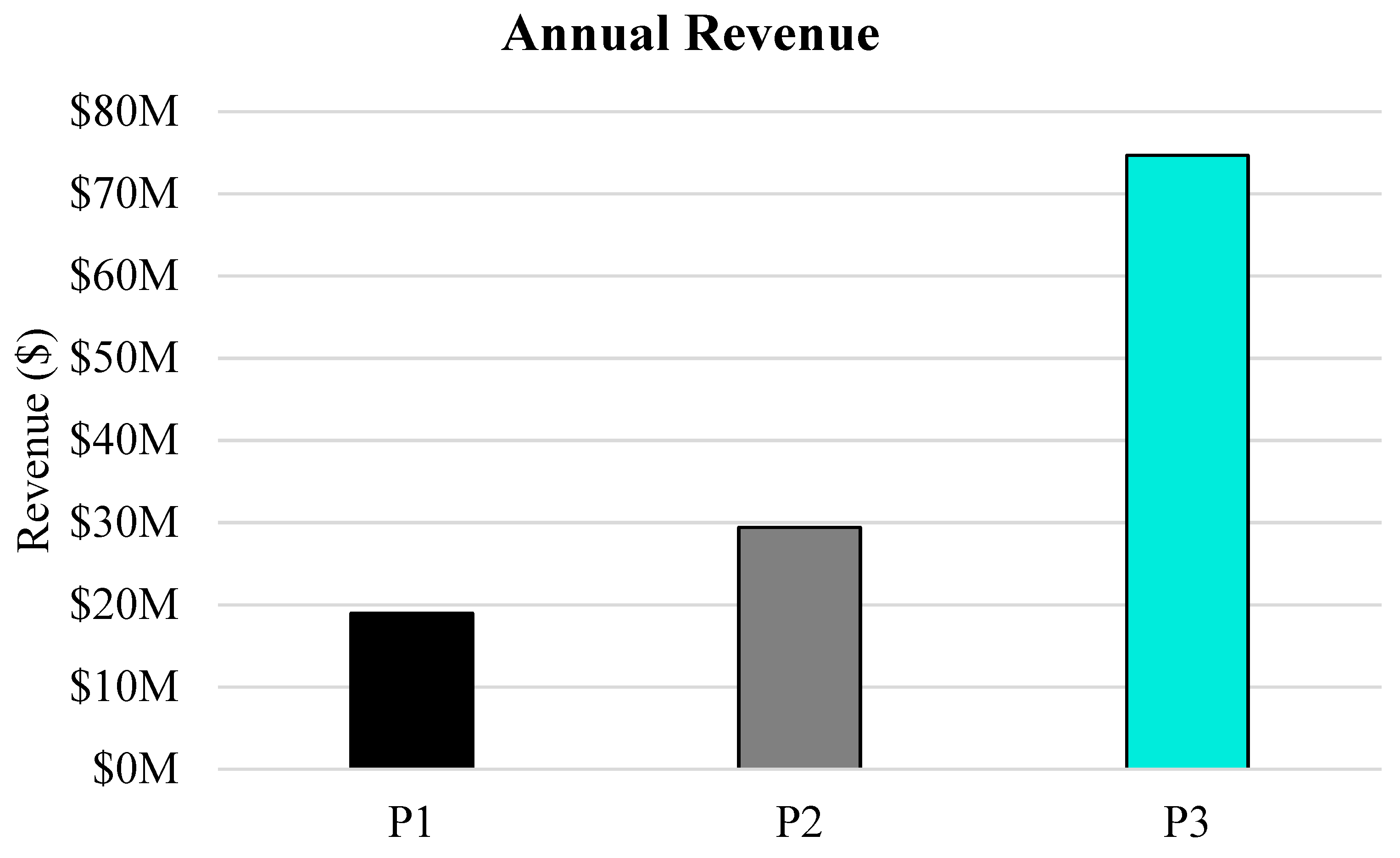

4.2. Revenue and Savings

5. Techno-Economic Analysis

5.1. Sensitivity Analysis

5.2. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brown, T.C.; Mahat, V.; Ramirez, J.A. Adaptation to Future Water Shortages in the United States Caused by Population Growth and Climate Change. Earth’s Future 2019, 7, 219–234. [Google Scholar] [CrossRef]

- Health Affairs. Water Insecurity and Population Health: Implications for Health Equity and Policy. Available online: https://www.healthaffairs.org/do/10.1377/hpb20230921.68748/ (accessed on 3 May 2024).

- Maddocks, A.; Young, R.S.; Reig, P. Ranking the World’s Most Water-Stressed Countries in 2040. 2015. Available online: https://www.wri.org/insights/ranking-worlds-most-water-stressed-countries-2040 (accessed on 2 March 2024).

- Kuzma, S.; Saccoccia, L.; Chertock, M.; World Resources Institute. 25 Countries, Housing One-quarter of the Population, Face Extremely High Water Stress, 16 August 2023. Available online: https://www.wri.org/insights/highest-water-stressed-countries (accessed on 2 March 2024).

- USEPA. Sources and Solutions: Wastewater. Available online: https://www.epa.gov/nutrientpollution/sources-and-solutions-wastewater (accessed on 5 May 2024).

- Bimaks. The Importance of Wastewater Treatment–Water Treatment Manufacturer. Available online: https://www.bimakskimya.com.tr/en/the-role-of-wastewater-treatment-in-environmental-sustainability/ (accessed on 4 May 2024).

- PT Water and Environment. Why Do We Need to Treat Wastewater? Available online: https://www.premiertechaqua.com/en-us/wastewater/why-do-we-need-treat-wastewater (accessed on 4 May 2024).

- Das, S.; Lee, S.H.; Kumar, P.; Kim, K.H.; Lee, S.S.; Bhattacharya, S.S. Solid Waste Management: Scope and the Challenge of Sustainability. J. Clean. Prod. 2019, 228, 658–678. [Google Scholar] [CrossRef]

- Wilson, D.C. Learning from the Past to Plan for the Future: An Historical Review of the Evolution of Waste and Resource Management 1970–2020 and Reflections on Priorities 2020–2030–The Perspective of an Involved Witness. Waste Manag. Res. 2023, 41, 1754–1813. [Google Scholar] [CrossRef] [PubMed]

- NEBRA. National Biosolid Survey. 2018. Available online: https://www.biosolidsdata.org/ (accessed on 21 October 2023).

- Jason Ren, Z.; Schnoor, J.L.; Pagilla, K.R. Toward a Net Zero Circular Water Economy. In Pathways to Water Sector Decarbonization, Carbon Capture and Utilization; IWA Publishing: London, UK, 2022; pp. 1–13. [Google Scholar] [CrossRef]

- USEPA. Basic Information About Biosolids. Available online: https://www.epa.gov/biosolids/basic-information-about-biosolids (accessed on 21 October 2023).

- Collivignarelli, M.C.; Canato, M.; Abbà, A.; Carnevale Miino, M. Biosolids: What Are the Different Types of Reuse? J. Clean. Prod. 2019, 238, 117844. [Google Scholar] [CrossRef]

- US Department of Health and Human Services. Workers Exposed to Class B Biosolids During and After Field Application. Appl. Occup. Environ. Hyg. 2001, 16, 105–107. [Google Scholar] [CrossRef] [PubMed]

- Transforming Sewage Sludge into Renewable Resources: How United Earth Energy’s Uni-Box Mobile Pyrolysis System Benefits Water-Processing Plants. Available online: https://unitedearth.energy/transforming-sewage-sludge-into-renewable-resources-how-united-earth-energys-uni-box-mobile-pyrolysis-system-benefits-water-processing-plants/ (accessed on 11 May 2025).

- PFAS in Biosolids: A Review of State Efforts & Opportunities for Action–The Environmental Council of the States (ECOS). Available online: https://www.ecos.org/documents/pfas-in-biosolids-a-review-of-state-efforts-opportunities-for-action/ (accessed on 7 July 2025).

- USEPA. Sewage Sludge Laws and Regulations. Available online: https://www.epa.gov/biosolids/sewage-sludge-laws-and-regulations (accessed on 25 October 2023).

- Radford, F.; Horton, A.; Hudson, M.; Shaw, P.; Williams, I. Agricultural Soils and Microplastics: Are Biosolids the Problem? Front. Soil. Sci. 2022, 2, 941837. [Google Scholar] [CrossRef]

- Kinney, C.A.; Vanden Heuvel, B. Translocation of Pharmaceuticals and Personal Care Products after Land Application of Biosolids. Curr. Opin. Env. Sci. Health 2020, 14, 23–30. [Google Scholar] [CrossRef]

- CDM Smith; NACWA; NEBRA; Water Environment Federation. Cost Analysis of the Impacts on Municipal Utilities and Biosolids Management to Address PFAS Contamination; CDM Smith: Boston, MA, USA, 2020. [Google Scholar]

- Kathi, S.; Singh, S.; Yadav, R.; Singh, A.N.; Mahmoud, A.E.D. Wastewater and Sludge Valorisation: A Novel Approach for Treatment and Resource Recovery to Achieve Circular Economy Concept. Front. Chem. Eng. 2023, 5, 1129783. [Google Scholar] [CrossRef]

- Yadav, A.; Rene, E.R.; Sharma, M.; Jatain, I.; Mandal, M.K.; Dubey, K.K. Valorization of Wastewater to Recover Value-Added Products: A Comprehensive Insight and Perspective on Different Technologies. Env. Res. 2022, 214, 113957. [Google Scholar] [CrossRef] [PubMed]

- Peeters, B.; Dewil, R.; Smets, I. Water Treatment Challenges of Drying Sticky Wastewater. Chem. Eng. Essent. CPI Prof. 2014, 120, 9–14. [Google Scholar]

- Zeringue, C.T.; Chirdon, W.M.; Sharp, W.; Gang, D.; Khattab, A.; Hernandez, R.; Revellame, E.; Holmes, W.E.; Zappi, M.E. Production of Green Adhesives from Sustainable Proteins Derived from Urban Based Sewage Sludges. Ph.D. Thesis, University of Louisiana at Lafayette, Lafayette, LA, USA, 2023. [Google Scholar]

- United Nations Department of Economic and Social Affairs. World Population Prospects: 2022 Summary of Results; United Nations: New York, NY, USA, 2022. [Google Scholar]

- Raydan, N.D.V.; Leroyer, L.; Charrier, B.; Robles, E. Recent Advances on the Development of Protein-Based Adhesives for Wood Composite Materials—A Review. Molecules 2021, 26, 7617. [Google Scholar] [CrossRef] [PubMed]

- Zeringue, C.T.; Chirdon, W.M.; Sharp, W.; Gang, D.; Khattab, A.; Hernandez, R.; Revellame, E.; Holmes, W.; Zappi, M.E. Production of Sustainable Green Adhesives from Proteinaceous Biomass with an Emphasis on Waste-Derived Protein Residuals: A Review. Ind. Eng. Chem. Res. 2023, 62, 12716–12731. [Google Scholar] [CrossRef]

- Conner, A.H. Wood: Adhesives. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2001; pp. 9583–9599. [Google Scholar] [CrossRef]

- Ülker, O. Wood Adhesives and Bonding Theory. In Adhesives–Applications and Properties; InTech: London, UK, 2016. [Google Scholar] [CrossRef]

- Frihart, C.R.; Lorenz, L. Protein Structures Dictate Their Adhesive Performance. Wood Mater. Sci. Eng. 2025, 1–10. [Google Scholar] [CrossRef]

- Jayachandran, B.; Parvin, T.N.; Alam, M.M.; Chanda, K.; MM, B. Insights on Chemical Crosslinking Strategies for Proteins. Molecules 2022, 27, 8124. [Google Scholar] [CrossRef] [PubMed]

- Dinte, E.; Sylvester, B. Adhesives: Applications and Recent Advances. In Applied Adhesive Bonding in Science and Technology; InTech: London, UK, 2018. [Google Scholar] [CrossRef]

- Frihart, C.R. Wood Adhesion and Adhesives. In Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2012; pp. 255–320. [Google Scholar] [CrossRef]

- Pizzi, A.; Mittal, K.L. (Eds.) Handbook of Adhesive Technology, Revised and Expanded, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar] [CrossRef]

- Chrobak, J.; Iłowska, J.; Chrobok, A. Formaldehyde-Free Resins for the Wood-Based Panel Industry: Alternatives to Formaldehyde and Novel Hardeners. Molecules 2022, 27, 4862. [Google Scholar] [CrossRef] [PubMed]

- Ghahri, S.; Yang, L.; Du, G.; Park, B.D. Transition from Formaldehyde-Based Wood Adhesives to Bio-Based Alternatives. BioResources 2025, 20, 2476–2479. [Google Scholar] [CrossRef]

- GVR. Wood Adhesives Market Size, Share & Trends Analysis Report by Product (Urea-Formaldehyde, Soy-Based), By Application (Flooring, Furniture), By Substrate, By Region, And Segment Forecasts, 2023–2030. Available online: https://www.grandviewresearch.com/industry-analysis/wood-adhesives-market (accessed on 4 May 2024).

- Hunt, C.G.; Dunky, M. Analysis of Future Prospects and Opportunities for Wood Adhesives: A Review. For. Prod. J. 2023, 72, 14–22. [Google Scholar] [CrossRef]

- Klein, B.; Davis, R. Algal Biomass Production via Open Pond Algae Farm Cultivation: 2022 State of Technology and Future Research; National Renewable Energy Laboratory: Golden, CO, USA, 2023. [Google Scholar]

- USDA. 2019-2020 USDA Food Price List; Washington State Department of Agriculture: Olympia, WA, USA, 2019. Available online: https://agr.wa.gov/getmedia/88869f61-e205-46bc-91ca-b626eaaffe67/2019-2020usdafoodpricelist (accessed on 28 November 2023).

- Commodity Prices—Price Charts, Data, and News—IndexMundi. Available online: https://www.indexmundi.com/commodities/#google_vignette (accessed on 9 May 2024).

- Tchobanoglous, G.; Burton, F.L. Wastewater Engineering: Treatment Disposal Reuse, 3rd ed.; Metcalf and Eddy, Inc.: New York, NY, USA, 1991; Volume 1. [Google Scholar]

- Benefield, L.A. Wastewater Quality/Strength/and Content. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=efa81072c6502d8fef916622cca63f04cc699a56 (accessed on 9 May 2024).

- Pellegrini, M.; Saccani, C.; Bianchini, A.; Bonfiglioli, L. Sewage Sludge Management in Europe: A Critical Analysis of Data Quality. Int. J. Env. Waste Manag. 2016, 18, 226. [Google Scholar] [CrossRef]

- United States Pharmacopeia. Good Storage and Shipping Practices; United States Pharmacopeia: Rockville, MD, USA, 2005. [Google Scholar]

- Ullah, H.I.; Dickson, R.; Mancini, E.; Malanca, A.A.; Pinelo, M.; Mansouri, S.S. An Integrated Sustainable Biorefinery Concept towards Achieving Zero-Waste Production. J. Clean. Prod. 2022, 336, 130317. [Google Scholar] [CrossRef]

- Prindle, J.C. Detailed Process Design Using ASPEN Plus; Department of Chemical Engineering, University of Louisiana at Lafayette: Lafayette, LA, USA, in press.

- Douglas, J. Conceptual Design of Processes; McGraw Hill: New York, NY, USA, 1988; pp. 1–589. [Google Scholar]

- Reniers, G.; Talarico, L.; Paltrinieri, N. Cost-Benefit Analysis of Safety Measures. In Dynamic Risk Analysis in the Chemical and Petroleum Industry: Evolution and Interaction with Parallel Disciplines in the Perspective of Industrial Application; Elsevier: Amsterdam, The Netherlands, 2016; pp. 195–205. [Google Scholar] [CrossRef]

- Saltelli, A.; Ratto, M.; Tarantola, S.; Campolongo, F. Sensitivity Analysis Practices: Strategies for Model-Based Inference. Reliab. Eng. Syst. Saf. 2006, 91, 1109–1125. [Google Scholar] [CrossRef]

- Yang, M.; Rosentrater, K.A. Life Cycle Assessment and Techno-Economic Analysis of Pressure Sensitive Bio-Adhesive Production. Energies 2019, 12, 4502. [Google Scholar] [CrossRef]

- Yang, M.; Rosentrater, K.A. Techno-Economic Analysis of the Production Process of Structural Bio-Adhesive Derived from Glycerol. J. Clean. Prod. 2019, 228, 388–398. [Google Scholar] [CrossRef]

- Mousavi-Avval, S.H.; Sahoo, K.; Nepal, P.; Runge, T.; Bergman, R. Environmental Impacts and Techno-Economic Assessments of Biobased Products: A Review. Renew. Sustain. Energy Rev. 2023, 180, 113302. [Google Scholar] [CrossRef]

- Chen, H.; Wu, Q.; Ren, X.; Zhu, X.; Fan, D. A Fully Bio-Based Adhesive with High Bonding Strength, Low Environmental Impact, and Competitive Economic Performance. Chem. Eng. J. 2024, 494, 153198. [Google Scholar] [CrossRef]

- USEPA. EPA State Revolving Funds and Grants Available to Water and Wastewater Utilities. Available online: https://www.epa.gov/fedfunds/epa-state-revolving-funds-and-grants-available-water-and-wastewater-utilities (accessed on 4 December 2023).

- Gu, Y.; Li, Y.; Li, X.; Luo, P.; Wang, H.; Wang, X.; Wu, J.; Li, F. Energy Self-Sufficient Wastewater Treatment Plants: Feasibilities and Challenges. Energy Procedia 2017, 105, 3741–3751. [Google Scholar] [CrossRef]

- Xin, C.; Addy, M.M.; Zhao, J.; Cheng, Y.; Ma, Y.; Liu, S.; Mu, D.; Liu, Y.; Chen, P.; Ruan, R. Waste-to-Biofuel Integrated System and Its Comprehensive Techno-Economic Assessment in Wastewater Treatment Plants. Bioresour. Technol. 2018, 250, 523–531. [Google Scholar] [CrossRef] [PubMed]

- Buller, L.S.; Sganzerla, W.G.; Berni, M.D.; Brignoli, S.C.; Forster-Carneiro, T. Design and Techno-Economic Analysis of a Hybrid System for Energy Supply in a Wastewater Treatment Plant: A Decentralized Energy Strategy. J. Environ. Manag. 2022, 305, 114389. [Google Scholar] [CrossRef] [PubMed]

- Makepa, D.C.; Chihobo, C.H. Barriers to Commercial Deployment of Biorefineries: A Multi-Faceted Review of Obstacles across the Innovation Chain. Heliyon 2024, 10, e32649. [Google Scholar] [CrossRef] [PubMed]

- Okolie, J.A.; Epelle, E.I.; Tabat, M.E.; Orivri, U.; Amenaghawon, A.N.; Okoye, P.U.; Gunes, B. Waste Biomass Valorization for the Production of Biofuels and Value-Added Products: A Comprehensive Review of Thermochemical, Biological and Integrated Processes. Process Saf. Environ. Prot. 2022, 159, 323–344. [Google Scholar] [CrossRef]

- Lei, H.; Zhou, X.; Pizzi, A.; Du, G.; Xi, X. Recent Developments in Bioadhesives and Binders. J. Renew. Mater. 2025, 13, 199–249. [Google Scholar] [CrossRef]

- Composite Panel Association. CPA Standards. Available online: https://www.compositepanel.org/resources/standards/ (accessed on 10 July 2025).

- Composite Panel Association. Eco-Certified Composites. Available online: https://www.compositepanel.org/sustainability/ecc/ (accessed on 10 July 2025).

- Al-Gheethi, A.A.; Efaq, A.N.; Bala, J.D.; Norli, I.; Abdel-Monem, M.O.; Ab Kadir, M.O. Removal of Pathogenic Bacteria from Sewage-Treated Effluent and Biosolids for Agricultural Purposes. Appl. Water Sci. 2018, 8, 74. [Google Scholar] [CrossRef]

- USEPA. Fact Sheet: Alkaline Stabilization of Biosolids. Available online: https://www.epa.gov/biosolids/fact-sheet-alkaline-stabilization-biosolids (accessed on 8 July 2025).

- Braine, M.F.; Kearnes, M.; Khan, S.J. Quality and Risk Management Frameworks for Biosolids: An Assessment of Current International Practice. Sci. Total Environ. 2024, 915, 169953. [Google Scholar] [CrossRef] [PubMed]

- Xue, J.; Verstraete, W.; Ni, B.J.; Giesy, J.P.; Kaur, G.; Jiang, D.; McBean, E.; Li, Z.; Shin, H.M.; Xiao, F.; et al. Rethink Biosolids: Risks and Opportunities in the Circular Economy. Chem. Eng. J. 2025, 510, 161749. [Google Scholar] [CrossRef]

| Protein Feedstocks | USD/t |

|---|---|

| Algae [39] | USD 681.00 |

| Corn Meal [40] | USD 404.57 |

| Defatted Soy Flour [40] | USD 692.38 |

| Fish Meal [41] | USD 1652.45 |

| Soy Flour [40] | USD 463.09 |

| Whey [40,41] | USD 788.00 |

| Value | Equation |

|---|---|

| Total Investment | = Fixed Capital + Working Capital + Start-up Costs = 2.36 (Installed Equipment Costs) |

| Total Production Cost | = Manufacturing Costs + General Expenses = 1.03 (Raw Materials + Utilities Costs) + 5.75E5 (NOL) + 0.187 (Installed Equipment Costs) + 0.026 (Revenue) |

| Number of Operators (NOL) | = (6.29 + 0.23Nnp)0.5 |

| Profit Before Tax | = Revenue − Total Production Costs = 0.974(Revenue) − 1.03 (Raw Materials + Utilities Costs) + 5.75E5 (NOL) + 0.187 (Installed Equipment Costs) |

| Depreciation | = 0.181 (Installed Equipment Costs) |

| Profit After Taxes | = (1 − 0.4) (Profit Before Taxes − Depreciation) = 0.584 (Revenue) − [(0.618) (Raw Materials + Utilities Costs) + 0.221 (Installed Equipment Costs) + USD 3.451E5 (NOL)] |

| Cash Flow | = Profit After Taxes + Depreciation = 0.584 (Revenue) − 0.618 (Raw Materials + Utilities Costs) − 0.04 (Installed Equipment Costs) − USD 3.451E5 (NOL) |

| P1 (USD) | P2 (USD) | P3 (USD) | ||

|---|---|---|---|---|

| 1. Total capital investment cost | 9,455,600 | 11,658,900 | 16,504,900 | |

| A. Equipment cost | 3,516,100 | 4,689,500 | 7,848,900 | |

| i. Jacketed agitated reactors | 2,014,400 | 2,565,200 | 5,160,000 | |

| ii. Jacketed storage tanks | 484,200 | 665,400 | 952,000 | |

| iii. Feeder/hopper | 262,400 | 262,400 | 262,400 | |

| iv. Belt conveyors | 17,500 | 17,500 | 17,500 | |

| v. Live bottom storage bins | 507,500 | 872,200 | 943,500 | |

| vi. Miscellaneous allowance | 230,100 | 306,800 | 513,500 | |

| B. Equipment setting | 26,000 | 40,300 | 66,300 | |

| C. Piping | 685,300 | 844,600 | 1,049,200 | |

| D. Civil | 153,500 | 260,100 | 331,100 | |

| E. Steel | 199,200 | 233,400 | 312,900 | |

| F. Instrumentation | 837,100 | 881,900 | 916,800 | |

| G. Electrical | 618,200 | 668,500 | 813,700 | |

| H. Insulation | 208,400 | 252,200 | 336,500 | |

| I. Paint | 13,500 | 30,800 | 39,200 | |

| J. Other | 1,793,800 | 2,037,800 | 2,389,700 | |

| K. General/admin overheads | 211,000 | 265,500 | 387,300 | |

| L. Contract fee | 334,000 | 394,400 | 512,600 | |

| M. Contingencies (10%) | 859,600 | 1,059,900 | 1,500,400 | |

| 2. Total annual production cost | 3,722,973 | 5,957,060 | 15,292,386 | |

| A. Direct operating costs | 2,056,173 | 3,557,060 | 9,625,586 | |

| i. Feedstock cost | 583,472 | 2,061,749 | 8,052,752 | |

| a. Dewatered biosolids | - | - | - | - |

| b. Defatted soy flour | 692.38/t | - | 1,146,499 | 6,496,826 |

| c. Sodium hydroxide | 570/t | 583,472 | 915,250 | 1,555,926 |

| d. Water | - | - | - | - |

| ii. Utilities | 92,301 | 114,911 | 192,434 | |

| Electricity | 0.0535/kWh | 92,301 | 114,911 | 192,434 |

| iii. Labor cost | 1,380,400 | 1,380,400 | 1,380,400 | |

| B. Indirect operating costs | 1,666,800 | 2,400,000 | 5,666,800 | |

| i. Packaging/Storage | 200/tote | 1,666,800 | 2,400,000 | 5,666,800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Foret, B.; Chirdon, W.M.; Hernandez, R.; Fortela, D.L.B.; Revellame, E.; Gang, D.; Ben Hmida, J.; Holmes, W.E.; Zappi, M.E. A Techno-Economic Analysis of Integrating an Urban Biorefinery Process Within a Wastewater Treatment Plant to Produce Sustainable Wood Adhesives. Sustainability 2025, 17, 6679. https://doi.org/10.3390/su17156679

Foret B, Chirdon WM, Hernandez R, Fortela DLB, Revellame E, Gang D, Ben Hmida J, Holmes WE, Zappi ME. A Techno-Economic Analysis of Integrating an Urban Biorefinery Process Within a Wastewater Treatment Plant to Produce Sustainable Wood Adhesives. Sustainability. 2025; 17(15):6679. https://doi.org/10.3390/su17156679

Chicago/Turabian StyleForet, Blake, William M. Chirdon, Rafael Hernandez, Dhan Lord B. Fortela, Emmanuel Revellame, Daniel Gang, Jalel Ben Hmida, William E. Holmes, and Mark E. Zappi. 2025. "A Techno-Economic Analysis of Integrating an Urban Biorefinery Process Within a Wastewater Treatment Plant to Produce Sustainable Wood Adhesives" Sustainability 17, no. 15: 6679. https://doi.org/10.3390/su17156679

APA StyleForet, B., Chirdon, W. M., Hernandez, R., Fortela, D. L. B., Revellame, E., Gang, D., Ben Hmida, J., Holmes, W. E., & Zappi, M. E. (2025). A Techno-Economic Analysis of Integrating an Urban Biorefinery Process Within a Wastewater Treatment Plant to Produce Sustainable Wood Adhesives. Sustainability, 17(15), 6679. https://doi.org/10.3390/su17156679