Information Barriers to Circularity for Electronic Products and the Potential of Digital Product Passports

Abstract

1. Introduction

Objectives

- RQ1: Which information barriers towards the circular economy prevail?

- RQ2: How can the DPP contribute to reducing identified information barriers?

2. Theoretical Background

2.1. The Circular Economy and Its Goals

2.2. Information Barriers and the Concept of “Information” in the Circular Economy

2.3. Theoretical Foundations of Information Barriers and Digital Product Passports

2.4. Scope of DPPs and Current Research

- Sector and product scope: The DPP is product-centric, including energy-related products (electronics), textiles, furniture, tyres, detergents, and other.

- Product life cycle and stakeholders (see Section 2.5): The stakeholder scope can be derived from the scope of information requirements—information on substances of concern is required, which includes the material producer as a potential stakeholder. According to ESPR Article 7 (Information requirements), the DPP will carry information, i.a., consumer and treatment facilities (recycler). In this manner, the stakeholder scope spans from material producers to treatment facilities.

- Circular economy (see Section 2.1): The DPP is a technology that should support and enable the circular economy by improving product circularity.

- Technical scope (see Section 2.6): Storage of digital information, identifiers and access rights, interoperability, standardised information, privacy rules and authorship, data authentication, reliability, and integrity.

2.5. Product Life Cycle Stages

2.6. Technical Scope

3. Method

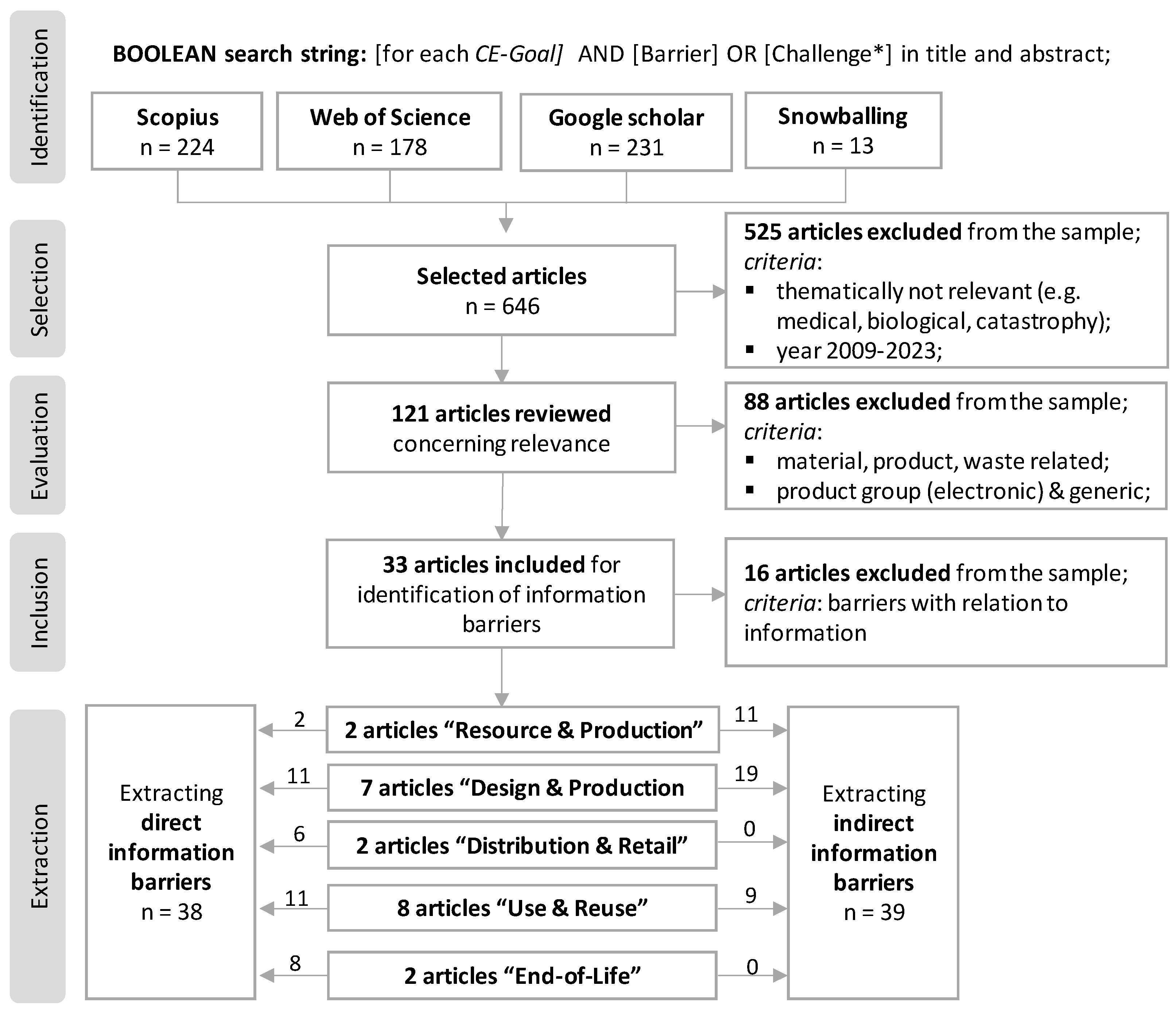

3.1. Literature Review of Barriers to the Circular Economy

3.2. Identification of Information Barriers

- (1)

- Initial Coding: During this phase, we conducted open coding of the 33 articles, noting references to any CE-related barriers within the study scope (relation to product, stakeholder, or lifecycle).

- (2)

- Categorisation: Within the analysis and categorisation, it was found that two groups of information barriers can be differentiated: direct and indirect information barriers. Direct barriers involve specific data gaps, such as missing material composition information or recycling instructions, which directly impact CE practices. Indirect barriers covered broader structural challenges, like consumer awareness and organisational readiness, which indirectly affect CE practices. For the discussion on potential coping strategies (see Section 5.1), it is useful to differentiate these two groups. The indication of direct (d) or indirect (i) can be found in the right column of each table in the Results section. Furthermore, the barriers—which are usually sentences—are coded with a short tag for comprehensive analysis and discussion.

- (3)

- Thematic Analysis: Each barrier was then mapped to one of the five lifecycle stages to examine stakeholder-specific information needs and the applicability of DPPs in addressing these needs.

4. Results: Direct and Indirect Information Barriers

4.1. Resource and Material Production

4.2. Design and Production

4.3. Distribution and Retail

4.4. Use and Reuse

4.5. End-of-Life

5. Discussion

5.1. Opportunities of Digital Product Passports to Overcome Information Barriers

5.2. Limitations and Challenges

6. Conclusions

6.1. Practical Implications

6.2. Outlook for Future Research

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ESPR | Ecodesign for Sustainable Product Regulation |

| BMUV | Bundesministerium für Umwelt, Naturschutz, nukleare Sicherheit und Verbraucherschutz |

| CE | Circular Economy |

| DPP | Digital Product passport |

| ICT | Information and communication technology |

| SRP | Socially responsible production |

| WEEE | Waste from Electrical and Electronic Equipment |

References

- UNEP. Global Resources Outlook 2019: Natural Resources for the Future We Want; United Nations Environment Programme: Nairobi, Kenya, 2019. [Google Scholar]

- Circle Economy. Circularity Gap Report 2022; Circle Economy: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Fiskel, J. Design for the Environment: A Guide to Sustainable Product Development; McGraw-Hill Education: New York, NY, USA, 2009. [Google Scholar]

- Karthikeyan, O.P.; Heimann, K.; Muthu, S.S. Recycling of Solid Waste for Biofuels and Bio-Chemicals; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- Potting, J.; Hekkert, M.; Worrell, E.H. Circular Economy: Measuring Innovation in the Product Chain; PBL Netherlands Assessment Agency: South Holland, The Netherlands, 2017. [Google Scholar]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence from the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Govindan, K.; Hasanagic, M. A systematic review on drivers, barriers, and practices towards circular economy: A supply chain perspective. Int. J. Prod. Res. 2018, 56, 278–311. [Google Scholar] [CrossRef]

- ESPR, REGULATION (EU) 2024/1781 Framework for the Setting of Ecodesign Requirements for Sustainable Products. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=OJ:L_202401781 (accessed on 1 June 2024).

- Jensen, S.; Kristensen, J.; Adamsen, S.; Christensen, A.; Waehrens, B. Digital product passports for a circular economy: Data needs for product life cycle decision-making. Sustain. Prod. Consum. 2023, 37, 242–255. [Google Scholar] [CrossRef]

- Van Capelleveen, G.; Amrit, C.; Yazan, D.M. The role of digital product passports in circular economy practices: A systematic review. J. Clean. Prod. 2023, 395, 136428. [Google Scholar]

- Berger, K.; Baumgartner, R.J.; Weinzerl, M.; Bachler, J.; Preston, K.; Schöggl, J.-P. Data requirements and availabilities for a digital battery passport—A value chain actor perspective. Clean. Prod. Lett. 2023, 4, 100032. [Google Scholar] [CrossRef]

- Wagner, E.; Eschenbach, K.; Baumgärtel, D.; Schlicht, H.; Malzacher, M.; Poppe, E.; Schneider-Ramelow, M. Environmental implications of the digital product passport—mass implementation of RFID for the textile and electronic sector. In Proceedings of the 5th International PLATE Conference, Helsinki, Finland, 31 May–2 June 2023. [Google Scholar]

- Schroeder, P.; Anggraeni, K.; Weber, U. The relevance of circular economy practices to the sustainable development goals. J. Ind. Ecol. 2019, 23, 77–95. [Google Scholar] [CrossRef]

- Rodríguez, J.; Rubio, L.; Celemín, M.; Alonso-Almeida, M. Analysis of the relations between circular economy and sustainable development goals. Int. J. Sustain. Dev. World Ecol. 2019, 26, 1–13. [Google Scholar]

- Mehta, S. Circular Economy and Sustainable Development Goals. MET Manag. Rev. 2023, 10, 24–29. [Google Scholar] [CrossRef]

- Blomsma, F.; Pieroni, M.; Kravchenko, M.; Pigosso, D.; Hildenbrand, J. Developing a circular strategies framework for manufacturing companies to support. J. Clean. Prod. 2019, 241, 118271. [Google Scholar] [CrossRef]

- OECD. Towards a More Resource-Efficient and Circular Economy the Role of the G20; OECD: Paris, France, 2021. [Google Scholar]

- Ellen MacArthur Foundation. Universal Circular Economy Policy Goals; Ellen MacArthur Foundation: Isle of Wight, UK, 2021. [Google Scholar]

- CEAP. Circular Economy Action Plan; The European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Müller, F.; Kohlmeyer, R.; Krüger, D.F.; Kosmol, J.; Krause, S.; Dorer, C.; Röhreich, M. 9 Principles for a Circular Economy; UBA: Yangon, Myanmar, 2020. [Google Scholar]

- Zero Waste Europe. A Zero Waste Hierarchy for Europe—Zero Waste Europe; Zero Waste Europe: Brussels, Belgium, 2019. [Google Scholar]

- Rolland, C.; Salinesi, C. Modeling goals and reasoning with them. In Engineering and Managing Software Requirements; Spinger: Berlin/Heidelberg, Germany, 2005; pp. 189–217. [Google Scholar]

- Koster, M.; Vos, B.; van der Valk, W. Drivers and barriers for adoption of a leading social management standard (SA8000) in developing economies. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 534–551. [Google Scholar] [CrossRef]

- Mont, O.; Leire, C. Socially responsible purchasing in supply chains: Drivers and barriers in Sweden. Soc. Responsib. J. 2009, 5, 388–407. [Google Scholar] [CrossRef]

- Risselin, O. Ecodesign: Analysis of Incentives and Barriers; Louvain School of Management, Université Catholique de Louvain: Ottignies-Louvain-la-Neuve, Belgium, 2016. [Google Scholar]

- Rahimifard, S.; Coates, G.; Staikos, T.; Edwards, C.; Abu-Bakar, M. Barriers, drivers and challenges for sustainable product recovery and recycling. Int. J. Sustain. Eng. 2009, 2, 80–90. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Ritala, P.; Mäkinen, S.J. Exploring institutional drivers and barriers of the circular economy: A cross-regional comparison of China, the US, and Europe. Resour. Conserv. Recycl. 2018, 135, 70–82. [Google Scholar] [CrossRef]

- Bey, N.; Hauschild, M.Z.; McAloone, T.C. Drivers and barriers for implementation of environmental strategies in manufacturing companies. CIRP Ann. 2013, 62, 43–46. [Google Scholar] [CrossRef]

- Chiappinelli, O.; Gerres, T.; Neuhoff, K.; Lettow, F.; de Coninck, H.; Felsmann, B.; Joltreau, E.; Khandekar, G.; Linares, P.; Richstein, J.; et al. A green COVID-19 recovery of the EU basic materials sector: Identifying potentials, barriers and policy solutions. Clim. Policy 2021, 21, 1328–1346. [Google Scholar] [CrossRef]

- Hagemann, H. Umweltrelevante Produktinformationen im E-Commerce—Chancen für Nachhaltigen Konsum; Umweltbundesamt: Dessau-Roßlau, Germany, 2015. [Google Scholar]

- Montalvo, C.; Peck, D.; Rietveld, E. Legal Obstacles to the Development of Repair Activities in the Field of Electrical and Electronic Equipment; Study No. IPOL_STU(2016)579000; European Parliament, Directorate-General for Internal Policies: Strasbourg, France, 2016. [Google Scholar]

- Svensson-Hoglund, S.; Richter, J.L.; Maitre-Ekern, E.; Russell, J.D.; Pihlajarinne, T.; Dalhammar, C. Barriers, enablers and market governance: A review of the policy landscape for repair of consumer electronics in the EU and the U.S. J. Clean. Prod. 2021, 288, 125488. [Google Scholar] [CrossRef]

- Tecchio, P.; Ardente, F.; Marwede, M.; Clemm, C.; Dimitrova, G.; Mathieux, F. Analysis of Material Efficiency Aspects of Personal Computers Product Group; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Cole, C.; Gnanapragasam, A.; Cooper, T.; Singh, J. Assessing barriers to reuse of electrical and electronic equipment, a UK perspective. Resour. Conserv. Recycl. X 2019, 1, 100004. [Google Scholar] [CrossRef]

- Pérez-Belis, V.; Braulio-Gonzalo, M.; Juan, P.; Bovea, M.D. Consumer attitude towards the repair and the second-hand purchase of small household electrical and electronic equipment. A Spanish case study. J. Clean. Prod. 2017, 158, 261–275. [Google Scholar] [CrossRef]

- Sandes, F.; Leandro, J. Exploring the motivations and barriers for second hand product consumption. In Proceedings of the 2019 Global Fashion Management Conference, Paris, France, 11–14 July 2019; pp. 292–296. [Google Scholar] [CrossRef]

- Van Yken, J.; Boxall, N.J.; Cheng, K.Y.; Nikoloski, A.N.; Moheimani, N.R.; Kaksonen, A.H.; Yken, V.; Boxall, J.; Cheng, N.J.; Nikoloski, K.Y.; et al. E-Waste Recycling and Resource Recovery: A Review on Technologies, Barriers and Enablers with a Focus on Oceania. Metals 2021, 11, 1313. [Google Scholar] [CrossRef]

- Reich, R.H.; Ayan, J.; Alaerts, L.; Van Acker, K. Defining the goals of Product Passports by circular product strategies. Procedia CIRP 2023, 116, 257–262. [Google Scholar] [CrossRef]

- Lawrenz, S.; Nippraschk, M.; Wallat, P.; Rausch, A.; Goldmann, D.; Lohrengel, A. Is it all about Information? The Role of the Information Gap between Stakeholders in the Context of the Circular Economy. In Proceedings of the CIRP Conference on Life Cycle Engineering, Jaipur, India, 10–12 March 2021; p. 364. [Google Scholar]

- EC. European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Charef, R.K. Barriers to Implementing the Circular Economy in the Construction Industry: A Critical Review. Sustainability 2021, 13, 12989. [Google Scholar] [CrossRef]

- Jaeger, B.; Upadhyay, A. Understanding barriers to circular economy: Cases from the manufacturing industry. J. Enterp. Inf. Manag. 2020, 33, 729–745. [Google Scholar] [CrossRef]

- Charef, R.; Emmitt, S. Uses of building information modelling for overcoming barriers to a circular economy. J. Clean. Prod. 2020, 285, 124854. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, A.; Garza-Reyes, J.; Sá, M. Managing operations for circular economy in the mining sector: An analysis of barriers intensity. Resour. Policy 2020, 69, 101752. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; Kafyeke, T.; Hirschnitz-Garbera, M.; Ioannou, A. The Circular Economy: Barriers and Opportunities for SMEs. In CEPS Working Documents; Centre for European Policy Studies: Bruxelles, Belgium, 2015; p. 412. [Google Scholar]

- Ada, N.; Silva, C.; Dias, A. Barriers to Circular Economy in the Food Supply Chain. Sustainability 2021, 13, 6812. [Google Scholar] [CrossRef]

- Demestichas, K.; Daskalakis, E. Information and Communication Technology Solutions for the Circular Economy. Sustainability 2020, 12, 7272. [Google Scholar] [CrossRef]

- Akerlof, G.A. The Market for “Lemons”: Quality Uncertainty and the Market Mechanism. Q. J. Econ. 1970, 84, 488–500. [Google Scholar] [CrossRef]

- Williamson, O.E. The economics of organization: The transaction cost approach. Am. J. Sociol. 1981, 87, 548–577. [Google Scholar] [CrossRef]

- Tilson, D.; Lyytinen, K.; Sørensen, C. Digital infrastructures: The missing IS research agenda. Inf. Syst. Res. 2010, 21, 748–759. [Google Scholar] [CrossRef]

- Luscuere, P. Materials passports: Optimising value recovery from materials. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2017, 170, 25–28. [Google Scholar] [CrossRef]

- Munaro, E.; Tavares, L.F. Exploring the role of digital product passports for circular economy in the electronics industry: Benefits and barriers. J. Clean. Prod. 2021, 291, 125880. [Google Scholar]

- Stratmann, L.; Hoeborn, G.; Pahl, C.; Schuh, G. Classification of product data for a Digital Product Passport in the manufacturing industry. In Proceedings of the Conference on Production Systems and Logistics: CPSL, Santiago de Querétaro, Mexico, 28 February 2023; pp. 448–458. [Google Scholar]

- Walden, J.; Steinbrecher, A.; Marinkovic, M. Digital Product Passports as Enabler of the Circular Economy. Chem. Ing. Tech. 2021, 93, 1717–1727. [Google Scholar] [CrossRef]

- Plociennik, C.; Pourjafarian, M.; Nazeri, A.; Windholz, W.; Knetsch, S.; Rickert, J.; Ciroth, A.; Lopes, A.; Hagedorn, T.; Vogelgesang, M.; et al. Towards a digital lifecycle passport for the circular economy. Procedia CIRP 2022, 105, 122–127. [Google Scholar] [CrossRef]

- Langley, D.; Rosco, E.; Angelopoulos, M.; Kamminga, O.; Hooijer, C. Orchestrating a smart circular economy: Guiding principles for digital product passports. J. Bus. Res. 2023, 169, 114259. [Google Scholar] [CrossRef]

- CIRPASS. D3.2 DPP System Architecture; European Commission: Brussels, Belgium, 2024; Available online: https://cirpassproject.eu/wp-content/uploads/2024/06/D3.2v1.9.pdf (accessed on 1 June 2024).

- Maignan, I.; Hillebrand, B.; McAlister, D. Managing socially-responsible buying: How to integrate non-economic criteria into the purchasing process. Eur. Manag. J. 2002, 20, 641–648. [Google Scholar] [CrossRef]

- Shahbazi, S.; Wiktorsson, M.; Kurdve, M.; Jönsson, C.; Bjelkemyr, M. Material efficiency in manufacturing: Swedish evidence on potential, barriers and strategies. J. Clean. Prod. 2016, 127, 438–450. [Google Scholar] [CrossRef]

- Vincenti, N.; Wagner, E.; Campadello, L.; Accili, A. Where the shoe pinches -tackling current market challenges for recycling plastics from WEEE. In Proceedings of the Conference: Going Green–CARE INNOVATION, Vienna, Austria, 2018; Available online: https://www.researchgate.net/publication/343826538_Where_the_shoe_pinches_-tackling_current_market_challenges_for_recycling_plastics_from_WEEE (accessed on 3 June 2025).

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- CIRPASS. Standardisation Gaps and Roadmap; CIRPASS: Brussels, Belgium, 2024. [Google Scholar]

- Global Battery Alliance. Battery Passport; Global Battery Alliance: Geneva, Switzerland, 2023; Available online: https://www.globalbattery.org/battery-passport (accessed on 1 June 2024).

- CIRPASS. D2.3 Stakeholder Consultation on Key-Data; European Commission: Brussels, Belgium, 2024. [Google Scholar]

| Product Life Cycle Stage | Circular Economy Goal | References with Barriers Per CE Goal |

|---|---|---|

| Resource/Material Production | Ensure ecological and social standards | [24,25] |

| Design and Production | Sustainable design | [7,26] |

| Longevity | [27] | |

| Recovery | [27] | |

| Material and resource efficiency | [28] | |

| Use recyclates | [13,29,30] | |

| Distribution and Retail | Ensure ecological standards | [25,31] |

| Ensure social standards | [25] | |

| Use and Reuse | Informed purchase | [31] |

| Repair | [32,33,34] | |

| Reuse | [34,35,36,37] | |

| Sufficiency | [31] | |

| End-of-life | Recycling | [34,38] |

| Life Cycle Stage | Goals | Tag | Barrier | Type |

|---|---|---|---|---|

| Resource/material production | Ensure ecological and social standards | Certification | Lack of resources for auditing all suppliers | i |

| Too many audits—cheating to simplify | i | |||

| Costs | Lack of money for audits | i | ||

| Costs (information asymmetry) | Discrepancy in expectations between producer and customer | i | ||

| Know-how | Lack of training and information | i | ||

| Top management lacks understanding | i | |||

| Low demand | Lack of customer demand for certification | i | ||

| Standardisation required | Low level of environmental and social standards | i | ||

| The market is not ready for strict purchasing criteria | i | |||

| Supplier identification | Lack of information about supplier | d | ||

| Problematic to obtain lists of suppliers and to check their performance | d | |||

| Traceability, certification | Impossible to ensure that all suppliers follow up the social policy | i | ||

| Validation | Problems to verify information presented by suppliers because of the risk of false figures and double booking | i |

| Life Cycle Stage | Goals | Tag | Barrier | Type |

|---|---|---|---|---|

| Design and Production | Longevity | Information asymmetry | Long-term in-service failure data | d |

| Sustainability benefits | Unclear advantage and sustainability benefits | i | ||

| Material and resource efficiency | Awareness | Lack of environmental education in general | i | |

| Limited environmental awareness of the directors | i | |||

| Low perceived role in activities of reuse and reduce | i | |||

| Certification | Lack of relevant/suitable tools for environmental initiatives | d | ||

| Communication | Lack of communication | d | ||

| Consumer perception | Customer perception that sustainability is a trade-off for price/performance | i | ||

| Customer prefer new products | i | |||

| Reuse of materials considered waste lacks normative support | i | |||

| Know-how | Lack of information and knowledge sharing | d | ||

| Lack of life cycle thinking and life cycle costing | i | |||

| Know-how, communication | Lack of ecodesign and communication with product development | d | ||

| Label, proper visualisation for end-consumer | Lack of accreditation or certification towards increasing reuse activities | i | ||

| Lack of awareness, understanding, knowledge, and experience with environmental issues | i | |||

| Low demand | Low public pressure, lack of demand from shareholders, investors, and community | i | ||

| Missing demand | Lack of market preference and customer demands | i | ||

| Missing indicator for consumers | Lack of indicators for normative support for CE outside recycling | d | ||

| Recovery | Information asymmetry | Unclear role in recovery process | i | |

| Sustainable design | Awareness | Identification and management of environmental impacts | i | |

| Missing responsibility from companies | i | |||

| Information asymmetry | Information asymmetry on sustainable design | d | ||

| Know-how | Bounded rationality (Customer prejudices) | i | ||

| Missing demand | Lacking consumer interest and awareness | i | ||

| Standardisation required | Limited standardisation | i | ||

| Sustainability benefits | Lack of data, e.g., on impacts | d | ||

| Use recyclates | Environmental impact | Finding environmental impact info | d | |

| Know-how | Too much specialist knowledge on how to use recyclates required | i | ||

| Material composition | Unknown mixture of different materials | d | ||

| Unknown material mixture | d |

| Life Cycle Stage | Goals | Barrier Category | Barrier | Type |

|---|---|---|---|---|

| Distribution and Retail | Ensure ecological and social standards | Availability of tools | Lack of practical tools and updated information | d |

| Ensure ecological standards | Certification | Lack of database access to certification and quality standards | d | |

| Supplier identification | Traceability of supply chain | d | ||

| Ensure social standards | Corporation | Lack of cooperation between different purchasing units | d | |

| Know-how | Information availability and time-consuming internal information collection | d | ||

| Know-how, lack of social and environmental impacts | Lack of knowledge and time for identifying specific social aspects and incorporating them into purchasing criteria and training kits tailored for the development of company needs | d |

| Life Cycle Stage | Goals | Barrier Category | Barrier | Type |

|---|---|---|---|---|

| Use and Reuse | Informed purchase | Certification | Few information obligations of online retailers | d |

| Heterogeneous label | d | |||

| Standardisation required | Non-comparable information and scales (low information quality) | d | ||

| Repair | Dismantling instructions | Need of information on dismantling of key components | d | |

| Know-how | Lack of necessary skills | i | ||

| Lack of information | Useful repair information missing | d | ||

| Missing demand | Lack of repair demand | i | ||

| Missing indicator for consumers | Consumer perception (lack of understanding of repairability at time of purchase) | i | ||

| Repair feedback to designer | Product design (cannot be disassembled) | i | ||

| Product design (low-quality, economically unfeasible) | i | |||

| Repair information | Lack of consumer awareness of repair options and warranty | d | ||

| Reuse | Counterfeit | Counterfeit of quality brands | i | |

| Data deletion | Uncertainty about secure data deletion | d | ||

| Data erasure certificate | Data confidentiality/clearance | i | ||

| Product condition | Contamination of hygiene products | i | ||

| Perceived low hygiene | i | |||

| Unknown product health | d | |||

| Unknown residual lifetime | d | |||

| Product history | Unknown product history | d | ||

| Sufficiency | Target application area | Unknown application area | d |

| Life Cycle Stage | Goals | Barrier Category | Barrier | Type |

|---|---|---|---|---|

| EoL | Recycling | Component map | Identifiability of batteries | d |

| Dismantling instructions | Need of information on dismantling of key components | d | ||

| Material composition | Declaration of flame-retardant content | d | ||

| Marking of plastic components | d | |||

| Need of information on critical raw materials | d | |||

| Need of information on the type of plastic using standardised symbols | d | |||

| Need of information on the use of flame retardants in plastics | d | |||

| Recycling statistics | More accurate information on feedstock generation and collection | d |

| Stage | Identified Direct Information Barrier | DPP Information for Overcoming Barriers | Potential Impact |

|---|---|---|---|

| Resource production | Lack of information about supplier | Supplier identification and verification data | Improved traceability and responsible sourcing |

| Problematic to obtain supplier lists and assess performance | Centralised and standardised supplier data | More efficient and transparent procurement processes | |

| Traceability of supply chain | End-to-end supply chain tracking and product genealogy | Enhanced sourcing transparency and accountability | |

| Design and Production | Long-term in-service failure data | Usage statistics and failure records | Enhanced product design for durability and reparability |

| Lack of relevant/suitable tools for environmental initiatives | Environmental performance data and evaluation tools | Informed decision-making and integration of ecodesign strategies | |

| Lack of communication | Structured DPP fields enabling stakeholder communication | Strengthened collaboration across the value chain | |

| Lack of information and knowledge sharing | Access to shared design, usage, and end-of-life data | Increased resource efficiency and innovation | |

| Lack of ecodesign and communication with product development | Feedback loops via DPP from recyclers and users | Design improvements based on real-world recovery and usage data | |

| Lack of indicators for CE beyond recycling | CE performance indicators (e.g., reuse rate, repairability score) | Better evaluation and promotion of broader circular strategies | |

| Information asymmetry on sustainable design | Design transparency and material sustainability data | Balanced stakeholder knowledge for sustainable innovation | |

| Lack of data on environmental impacts | Life Cycle Assessment (LCA) data and environmental footprint | Better environmental performance monitoring | |

| Finding environmental impact info | Embedded LCA summaries and sustainability metrics | Easier environmental assessment and comparison | |

| Distribution and Retail | Lack of access to certification and quality standards | Centralised repository of certifications and compliance info | Improved purchasing and reuse decisions |

| Lack of cooperation between purchasing units | DPP-enabled shared access to procurement-relevant information | Streamlined procurement and harmonised sustainability criteria | |

| Information availability and time-consuming internal collection | Central digital access to verified product and component data | Reduced information costs and improved decision speed | |

| Use and Reuse | Lack of practical tools and updated information | Updated repair manuals and handling instructions | Improved maintenance, repair, and end-of-life treatment |

| Few information obligations of online retailers | Legal integration of mandatory product info into DPP | Informed consumer choices and compliance assurance | |

| Heterogeneous labels | Standardised labels and harmonised rating systems | Better comparability of sustainability information | |

| Non-comparable info and low information quality | Uniform product declarations and metrics | Consistent evaluation across similar products | |

| Useful repair information missing | Maintenance and repair guidance, including tools and parts | Extended product life and support for independent repair | |

| Lack of consumer awareness of repair options and warranty | Clear DPP sections on warranty terms and repair opportunities | Higher repair uptake and reduced early disposal | |

| Uncertainty about secure data deletion | Certified data erasure protocols and tools | Increased reuse and resale of data-sensitive products | |

| Unknown product health | Usage history, diagnostics, and maintenance records | Enhanced confidence in second-hand markets | |

| Unknown residual lifetime | Estimated remaining life based on usage profiles | Informed decisions on reuse vs. recycling | |

| Unknown product history | Ownership and service history documentation | Increased trust in reused products | |

| Unknown application area | Defined intended use and application context | Better consumer understanding and avoidance of misapplication | |

| End-of-life | Unknown mixture of different materials | Detailed material breakdowns | Improved recyclability and material recovery |

| Unknown material mixture | Standardised material composition information | Reduced contamination and increased recycling quality | |

| Need for dismantling information | Step-by-step disassembly instructions for key components | Increased reparability and improved recycling practices | |

| Identifiability of batteries | Battery presence, type, and location information | Safe removal and specialised recycling handling | |

| Flame-retardant and hazardous substance declaration | Substance declaration and marking (e.g., plastics, FRs, CRMs) | Improved sorting and hazardous material handling | |

| Plastic marking and critical raw material information | Standardised plastic type markings and CRM indicators | Efficient material separation and prioritisation in recycling | |

| Feedstock collection and recycling statistics | Data on volumes collected, sorted, and recovered | Performance monitoring and system optimisation |

| Indirect Information Barrier | Features or Scope of the DPP | Potential Impact (From FAIR Principles) |

|---|---|---|

| Lack of information Unknown product sustainability | Identifiers and access rights | Improves the findability and accessibility |

| Storage of digital information | Enables the data availability and transparency | |

| Unsuitable information Complexity of information | Interoperability; standardised information (and technical infrastructure) | Improve interoperability, allow information exchange and comparison |

| Information asymmetry | Privacy rules and authorship | Enables the reusability |

| Uncertainty and risk of information | Data authentication, reliability, integrity | Improves the correctness |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wagner, E. Information Barriers to Circularity for Electronic Products and the Potential of Digital Product Passports. Sustainability 2025, 17, 5554. https://doi.org/10.3390/su17125554

Wagner E. Information Barriers to Circularity for Electronic Products and the Potential of Digital Product Passports. Sustainability. 2025; 17(12):5554. https://doi.org/10.3390/su17125554

Chicago/Turabian StyleWagner, Eduard. 2025. "Information Barriers to Circularity for Electronic Products and the Potential of Digital Product Passports" Sustainability 17, no. 12: 5554. https://doi.org/10.3390/su17125554

APA StyleWagner, E. (2025). Information Barriers to Circularity for Electronic Products and the Potential of Digital Product Passports. Sustainability, 17(12), 5554. https://doi.org/10.3390/su17125554