1. Introduction

Sustainability transitions refer to profound, multi-faceted, and extended transformation processes within socio-technical systems, involving long-term structural changes across various dimensions. Manufacturing firms are increasingly embedding sustainability considerations throughout their supply chain operations, integrating them into conventional processes ranging from raw material sourcing to final product delivery [

1], which makes decision-making and operations more complex. Manufacturing firms are increasingly embedding sustainability considerations throughout their supply chain operations, integrating them into conventional processes ranging from raw material sourcing to final product delivery. These innovations support the alignment of intelligent systems with sustainability objectives, promoting the co-evolution of digital transformation and sustainable development [

2,

3].

Implementing DTs must evolve into capabilities that efficiently and effectively utilize resources [

4]. While much of the existing literature emphasizes the role of technological innovation in enhancing supply chain resilience and responsiveness, it often overlooks a more foundational element—dynamic capabilities [

5]. Within the framework of the dynamic resource-based view (RBV), two critical capabilities that underpin long-term competitive advantage are the ability to build strategic relationships and the capacity to process and utilize information effectively [

6]. This study defines and examines the following two supply chain sustainable dynamic capabilities (SC_SDCs): sustainable information capability (SIC), which denotes a firm’s capacity to effectively exchange meaningful sustainability-related data with its partners while minimizing the distortion of information both within and beyond organizational boundaries, and sustainable relationship capability (SRC), which concerns engaging in mutual adjustment activities and developing or utilizing inter-firm sustainable resources. This research centers on Chinese manufacturing enterprises, whose resource-intensive processes and complex supply chain interactions underscore the critical importance of examining how DT facilitates dynamic sustainable collaboration within the supply chain, making it a highly pertinent and valuable area of inquiry.

Numerous studies have examined the micro-level role of DTs, particularly in shaping internal decision-making and external stakeholder collaboration [

7]. However, limited research has explored how DTs influence the sustainable dynamic capabilities of different types of supply chain stakeholders. Specifically, few studies have systematically investigated the heterogeneous impacts of upstream resource-driven and downstream demand-driven mechanisms on firms sustainability performance. Shifts in inter-firm collaboration, coupled with the varied demands of enterprises at different supply chain positions adopting digital transformation to achieve sustainability goals, underscore the need to reinterpret inter-organizational relationships [

8]. Upstream supply chain firms leverage DTs to trace and manage raw materials, thereby increasing supply chain transparency and ensuring the traceability and sustainability of acquired resources [

9]. Closer to the production end, manufacturers must align long-term social and environmental objectives with product innovation and market demands [

10]. Hence, firms at various points in the supply chain exhibit distinct focal areas and pathways when realizing sustainability goals. This study aims to investigate: (1) how DTs influence sustainable collaboration capabilities in supply chains; (2) how these effects differ between suppliers and customers; and (3) what implications these findings have for managerial strategies.

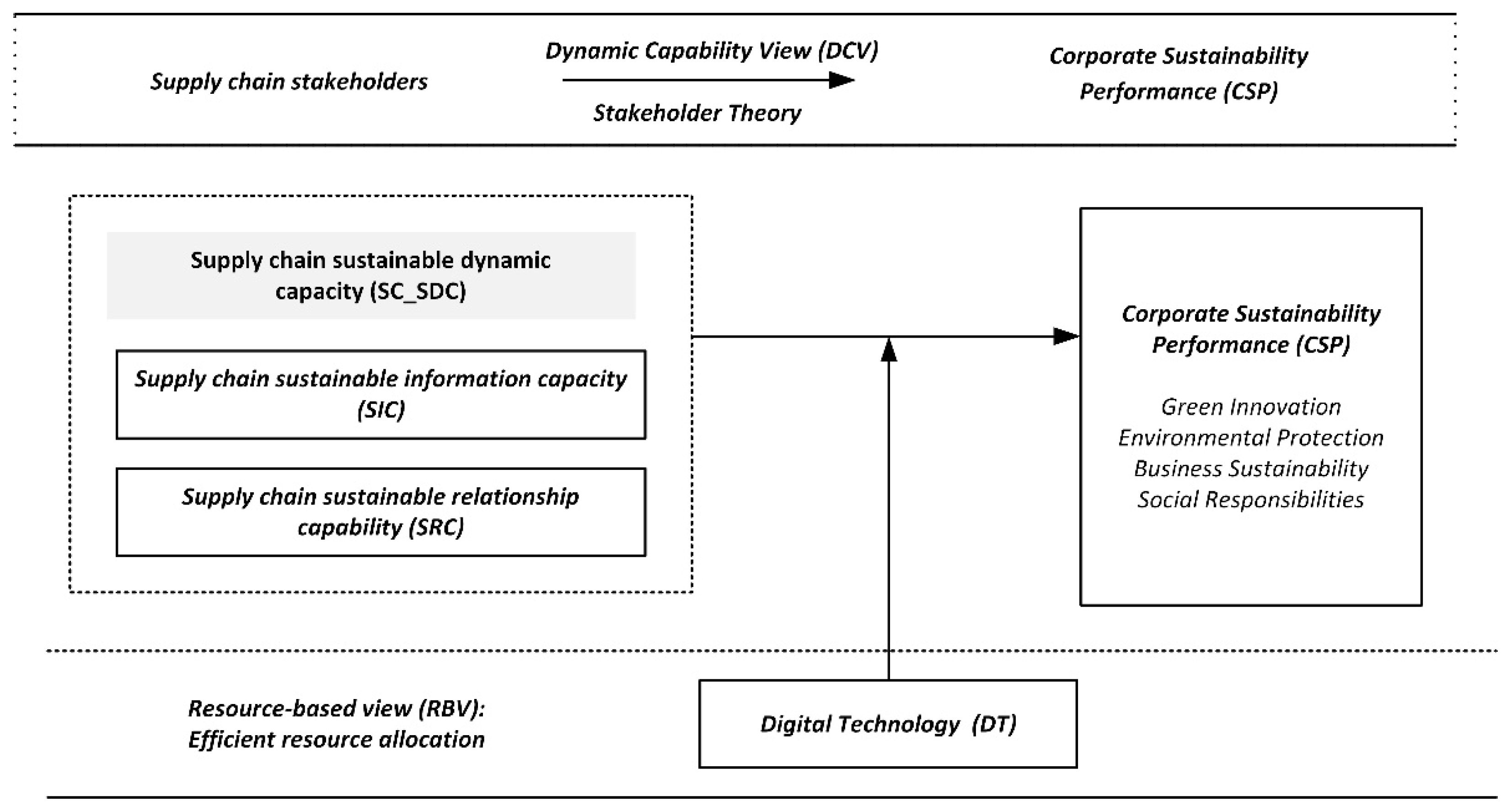

This study leverages data from publicly listed manufacturing firms spanning 2010 to 2023 to explore how DTs effectively enhance two key dynamic capabilities, thereby driving improvements in CSP. The sample begins in 2010, when CSR scores became consistently available and new accounting standards were widely adopted, ensuring reliable sustainability measurement. Grounded in the resource-based view (RBV), the study incorporates the dynamic capability view (DCV) to address the RBV’s limitations in explaining adaptation in dynamic environments. While the RBV emphasizes the acquisition of valuable, rare, inimitable, and non-substitutable resources to build competitive advantage, its static orientation limits its ability to capture the evolution of such advantages under change. The DCV advances this framework by highlighting firms abilities to sense changes, seize opportunities, and reconfigure resources—emphasizing the continuous renewal of capabilities as essential for sustained competitiveness. Within this framework, SIC is defined as a data-driven sensing capability, while SRC reflects the relationship-oriented capacity for resource integration and adaptation. Additionally, stakeholder theory introduces an external perspective, stressing that firms must respond to the environmental and social expectations of upstream and downstream partners to achieve joint value creation. Integrating these theoretical perspectives, this study identifies and differentiates how various stakeholders influence corporate sustainability performance through resource-push and value chain–pull mechanisms.

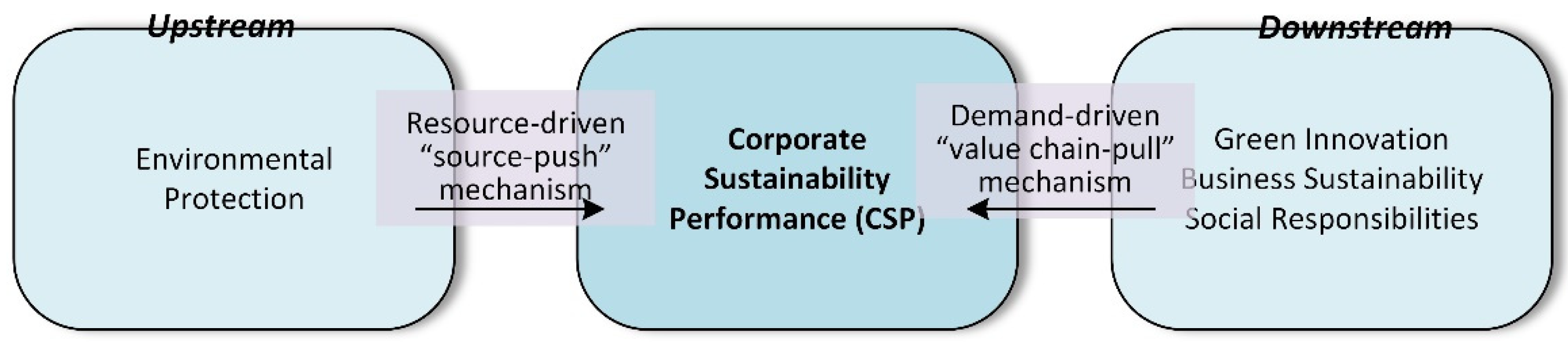

This paper makes several contributions. First, it establishes an innovative theoretical framework linking SC_SDC with CSP. From a dynamic resource perspective, the study uncovers how DT indirectly enhances CSP by strengthening SIC and SRC, offering new theoretical support for developing dynamic capability, optimizing external collaboration, and improving sustainability performance. Secondly, this study innovatively introduces framework defining SC_SDCs through information and relationship capacities, advancing existing research on enhancing CSPs via external collaboration. Notably, it details the specific pathways through which DT exerts a positive impact on CSP by reinforcing these two dynamic capabilities, providing a more refined theoretical foundation for empirical studies on SC_SDC. Third, the study further elucidates the distinct mechanisms by which suppliers and customers drive CSP. By proposing and validating two driving mechanisms—“source-driven” (resource input) and “value chain-driven” (demand output)—this work offers a fresh academic viewpoint on the division of roles and collaboration pathways within SC_SDC for sustainable development, thereby deepening the understanding of supply chain sustainability.

The structure of this paper is as follows:

Section 2 outlines the theoretical background, reviews related literature, and presents the hypotheses.

Section 3 details the research design, including data sources and methodology.

Section 4 present and interpret the empirical findings.

Section 5 discusses the study’s contributions, limitations, and directions for future research.

Section 6 is a conclusion.

3. Research Design

3.1. Variable Selection

This study draws on panel data from manufacturing firms listed on the Shanghai and Shenzhen Stock Exchanges from 2010 to 2023, covering 19 sectors such as general equipment, automotive, and electronic information manufacturing. The starting point of 2010 was chosen to align with the widespread adoption of new accounting standards and the availability of consistent CSR scores from Hexun, both of which are crucial for measuring corporate sustainability performance. After excluding firms designated as ST or *ST and those lacking sufficient data on digitalization and supply chain indicators, a final sample of 1233 firms was retained.

Data were collected from the China Stock Market & Accounting Research (CSMAR) and IFinD databases, with DT and supply chain variables sourced from CSMAR and control variables from IFinD. Given the longitudinal nature of the dataset, some missing values persisted despite prior filtering. To mitigate potential bias due to missing values in the panel dataset, we employed the MICE forest algorithm, which is based on a random forest-based chained equation method [

45]. This approach is particularly effective for large-scale panel datasets with mixed data types and non-linear relationships. We chose MICE forest over other imputation techniques due to its robustness and ability to preserve complex interactions between variables. The average missing rate across all variables is below 5%, and all imputed values were evaluated for consistency and plausibility.

(1) Digital technology

This study evaluates corporate digitalization through the following five key technological dimensions: big data, blockchain, artificial intelligence, digital applications, and cloud computing. The data obtained from the CSMAR database reflect the extent of digital transformation among listed firms. Building on existing research [

46], the study quantifies the adoption levels of these technologies by analyzing the frequency with which they are referenced in the publicly available reports of firms. These individual measures are then integrated to form a composite index representing the overall digital transformation of each firm.

To construct composite indicators for DT and CSP, we employed the entropy weighting method. This technique assigns objective weights based on the dispersion degree of each component indicator, thereby reducing subjectivity. Specifically, the entropy method follows the subsequent steps: (1) normalization of indicators; (2) calculation of entropy values to capture the information content of each indicator; (3) determination of divergence coefficients; and (4) generation of weighted composite scores. This method allows us to effectively synthesize multi-dimensional indicators into single indexes, improving interpretability and comparability.

(2) Sustainability development performance

Corporate sustainability performance data were sourced from corporate sustainability research reports in the CSMAR database, encompassing the following seven tertiary indicators: environmental emissions disclosure, environmental management costs, sustainability reporting guidelines, environmental sustainability disclosure, public relations and social service, system construction, and social donations. These indicators were categorized into three secondary indicators, environmental protection, commercial sustainability, and social responsibility, as detailed in

Table 1.

Based on existing research that uses green patents to measure industrial innovation [

47], the study further calculates green innovation performance using the super-efficiency SBM-based DEA method. Inputs included R&D expenses and R&D personnel, while outputs comprised green patent grants and operating revenue. Sustainability performance was determined by calculating indicator weights using the entropy method, resulting in the final composite index values.

(3) Supply chain sustainable dynamic capability

Supply chain data were obtained from each firm’s publicly disclosed top five suppliers and top five customers. We first compiled supplier and customer information for each firm and collected data on the DT adoption and sustainability performance of these supply chain partners. A firm whose supply chain partners exhibit high levels of digitalization is considered to possess high sustainable information management capabilities (SICs), as such partners are more efficient and accurate in acquiring, processing, and integrating sustainable information. Similarly, a firm whose supply chain partners demonstrate superior sustainability performance is deemed to have strong external sustainable relationship capabilities (SRCs), as effective sharing of green technologies and innovative ideas fosters deeper collaborative synergies with supply chain partners.

Additionally, six firm-level fundamentals were included as control variables to account for the potential influences of firm size, operational capacity, and other factors on the estimation results.

Table 1 provides a detailed description of all variables.

Source: digital technical, corporate sustainability performance from publicly available databases collated by CSMAR (China Stock Market & Accounting Research Database), URL:

https://data.csmar.com/ (accessed on 15 February 2024); Control variables from IFinD; Green patent data from Patent Star, URL:

https://www.patentstar.com.cn/ (accessed on 15 February 2024).

Table 2 presents the correlation matrix for all variables. As shown in Panel A, DT is positively correlated with CSP. To assess potential multicollinearity among the independent variables, diagnostic tests were conducted. The results confirm that multicollinearity is not a concern, as all variance inflation factor (VIF) values are below 10 and the tolerance levels exceed 0.1. Detailed results are provided in Panel B of

Table 2.

3.2. Measures

(1) Basic Regression Model

We used the following panel regression model to investigate the relationship between DT and CSP:

where X represents the four variables of DT, SC_SDC, SIC, and SRC, respectively. i is the firm and t is the year.

is the unobservable firm-specific effect and

is the error term. IC is a proxy variable for the innovation capability while

denotes firm fixed effects,

denotes industry fixed effects,

is the year fixed effect, and Z is the control variable.

(2) GMM Regression Model

Considering that the firm innovation capability may be characterized by continuity and dynamism, the lagged terms of the explanatory variables were included in the econometric model to avoid possible errors caused by omitted variables and to address the estimation bias caused by endogeneity issues [

48]. The model is as follows:

The regression model used both differential GMM and systematic GMM, where the lagged term of the explanatory

is set as the endogenous variable, the exogenous variable is X, and the rest of the control variables are predetermined.

representing the variables of DT and supply chain-related variables, respectively. The estimation results need to be tested after use, and usually the differences in the random error term are tested for the existence of first-order and second-order autocorrelation to ensure the consistent estimation of GMM [

49]. The estimation results are judged by the significance of AR (1) and AR (2). In addition, a Hansen test is required to determine whether the instrumental variables used are valid.

6. Conclusions

This study uses data from Chinese listed manufacturing firms from 2010 to 2023 to examine how DT reshapes supply chain collaboration actors and pathways, thereby influencing CSP through the development of sustainable dynamic capabilities. First, DT positively enhances CSP while strengthening firms’ dynamic collaboration capabilities with external stakeholders.

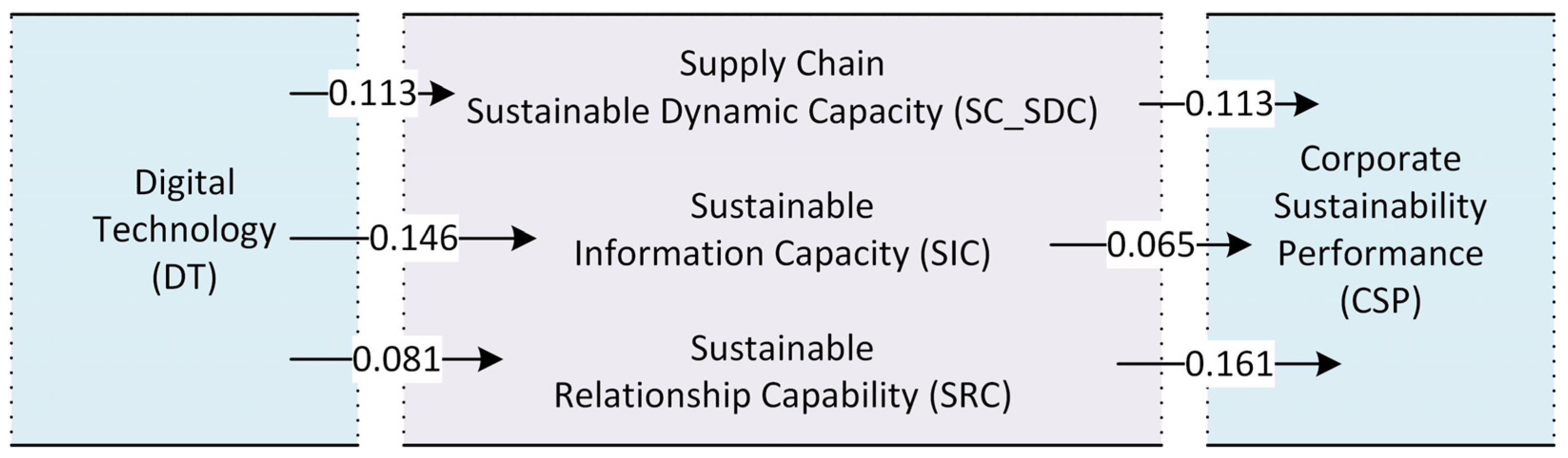

Based on the dynamic resource-based view, this study defines sustainable dynamic capabilities as either SRCs or SICs. The findings indicate that higher levels of DT amplify the impact of these two dynamic capabilities on CSP. Moreover, both capabilities exhibit mediating effects, as DT improves SIC, which subsequently enhances SRC, ultimately influencing CSP. This reveals a complete indirect pathway of DT’s impact on CSP. This reveals a full-chain mediation mechanism through which DT affects strategy, aligning closely with Teece’s (2007) three-stage logic of dynamic capabilities—sensing, seizing, and reconfiguring [

70]. Specifically, SIC reflects the firm’s sensing and information integration capacity in response to external forces (e.g., ESG policies, green demand), while SRC captures the ability to reconfigure stakeholder relationships and resource coordination, enabling sustainable performance improvements.

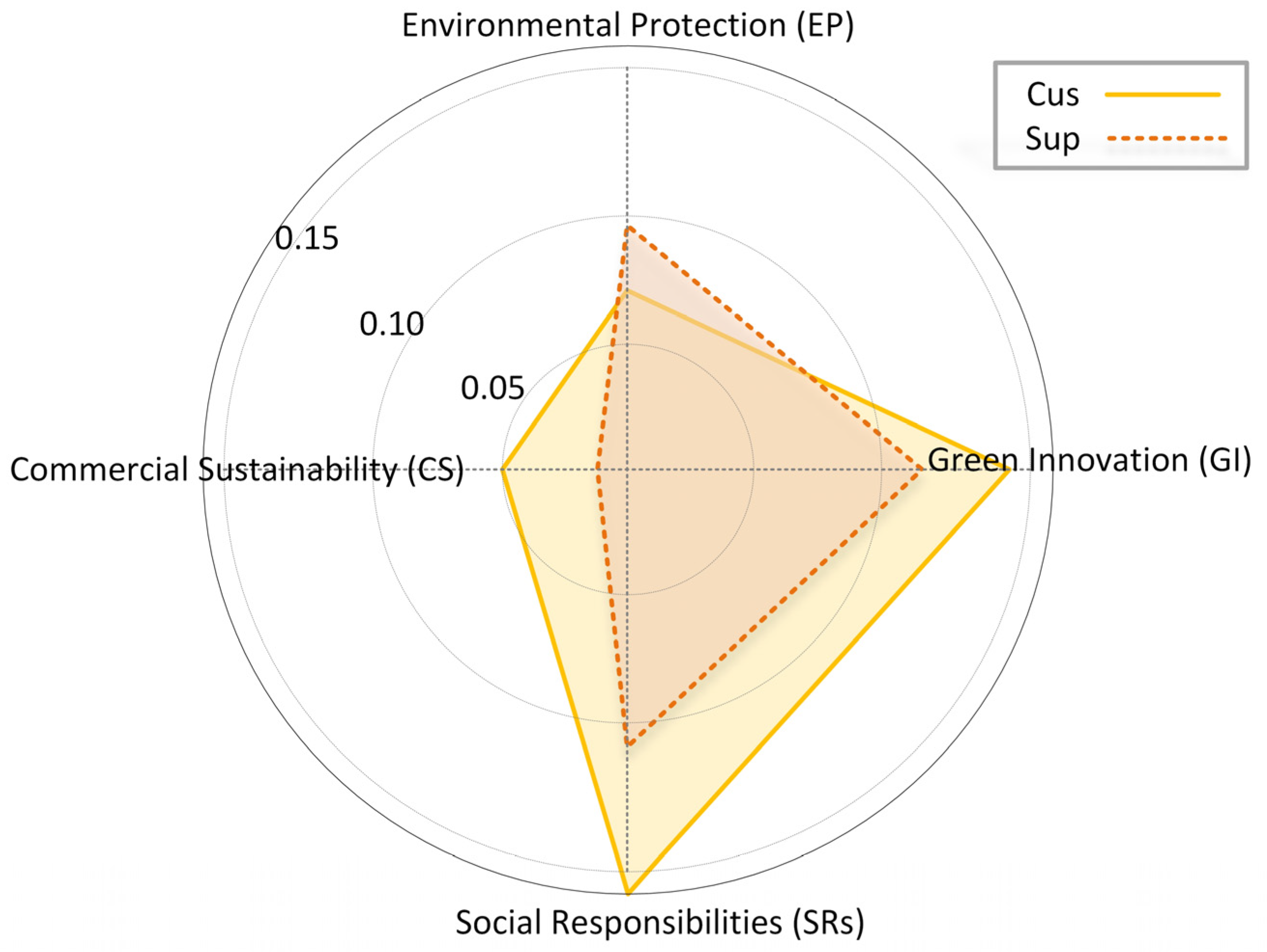

Building on this, the study explores the heterogeneity of actors implementing sustainable strategies. Across four dimensions—green innovation, environmental protection, commercial sustainability, and social responsibility—SC_SDCs exhibit distinct characteristics: resource-driven “source-push” mechanisms and demand-driven “value chain-pull” mechanisms. By examining both upstream inputs and downstream market demands, this study uncovers heterogeneous pathways through which firms develop sustainability-oriented dynamic capabilities across different supply chain stages. This not only extends RBV discussions on resource bundling but also contributes a dynamic perspective to how firms derive competitive advantage from value chain collaboration. It highlights that the transformation of resources into capabilities depends on the evolving dynamics of external networks. The differing focus and practices of firms at various supply chain positions intertwine and complement one another, creating a robust foundation for ensuring sustainability and efficiency across the entire supply chain.

Finally, consistent with stakeholder theory, this study underscores the importance of embedding sustainability strategies within trust-based collaboration with key stakeholders. By constructing a coordination pathway centered on SIC and SRC, the findings demonstrate that firms must recognize and respond to the interests of diverse actors to achieve multidimensional improvements in sustainability performance. This research addresses gaps in the literature by elucidating how different supply chain actors affect focal firms across various sustainability dimensions. It provides valuable insights for firms to tailor and implement targeted, efficient sustainability strategies based on their supply chain position and stakeholder dynamics.