1. Introduction

Additive manufacturing (AM) is a pivotal technology in driving the transition towards a sustainable and circular economy, particularly through its application in repair and remanufacturing. Beyond simply extending product lifespans by restoring damaged components, AM fundamentally alters material flow by minimizing waste through precise, layer-by-layer deposition, a stark contrast to traditional subtractive methods. This resource efficiency is further amplified by the ability of AM to utilize recycled materials as feedstock, closing material loops and lessening the demand for virgin resources. The on-demand production of spare parts, enabled by AM, reduces the environmental burden of excess inventory and long-distance transportation, fostering localized, more agile supply chains. Moreover, the design flexibility of AM facilitates the creation of components optimized for durability and ease of repair, embedding circularity principles into the product’s very design. By enabling the production of lightweight components and contributing to reduced energy consumption during manufacturing and product use, AM actively works to lower the carbon footprint of industrial processes. To fully realize these benefits, ongoing advancements in sustainable material compatibility and life cycle assessment are crucial, ensuring that AM continues to be a driving force in creating a more environmentally responsible and resource-efficient manufacturing paradigm.

Figure 1 provides a visual representation of the multifaceted role AM plays in promoting sustainability within a circular economy framework. At its centre lies the concept of sustainability, encircled by five core benefits that AM offers. These include AM itself, emphasizing the technology’s precision and efficiency; “Lower energy use–Lower cost,” showcasing its potential for reducing both environmental impact and production expenses; and “Faster return to service,” highlighting its ability to streamline repair and remanufacturing processes. Additionally, “Repair rather than disposal” reflects AM’s contribution to waste minimization by enabling component restoration, while “Extended life of the product” underscores its role in prolonging product utility. Collectively, these elements illustrate how AM not only supports greener manufacturing practices but also fundamentally reshapes the lifecycle of products—from design and production to maintenance and reuse—thereby embedding sustainability at every stage. Collectively, the illustration in

Figure 1 serves as a concise yet powerful summary of AM’s strategic alignment with sustainable development goals and resource-efficient manufacturing paradigms.

The current market conditions are financially challenging and, as such, manufacturing industries are looking for methods of prolonging product life using cost effective repair methods as opposed to replacement of expensive parts and long lead time repairs. For oil-and-gas extraction, marine exploration, and other ocean technologies where the operating environment is corrosive and abrasive [

1], the use of duplex and super duplex stainless steels is common [

2]. These alloys (which are available in both cast and wrought forms) have a good combination of high strength, ductility, and corrosion resistance, which makes their application beneficial for processes such as pumps for sour process fluids and seawater services. The alloys are normally specified with a minimum pitting resistance equivalent number (PREN = %

Cr + 3.3%

Mo + 16%

N) [

3]. This formula provides a useful guide to the corrosion performance of different stainless steel grades. Standard duplex stainless steels have a PREN of circa 35 and super duplex stainless steels have a PREN > 40. To achieve consistent PREN values, the chemical composition and thermal processing (heat treatment) need to be accurately monitored and controlled within well-defined limits. The alloys are typically supplied in the solution annealed condition and the target microstructure is 50:50 austentite–ferrite [

4] and free from undesirable intermetallic phases. The same manufacturing practices and acceptance criteria need to be observed when conducting fusion welding repair processes.

Furthermore, the properties of duplex and super duplex stainless steel are tailored to withstand corrosive environments, in particular crevice corrosion and pitting damage, and maintain mechanical integrity sufficient for high-pressure pumping applications such as seawater injection and crude oil, and also low-pressure pumps such as seawater lift and fire pump duties. However, duplex and super duplex components such as pump shafts that incur minor damage in service or during manufacturing have to be rejected and replaced with expensive and long lead time counterparts.

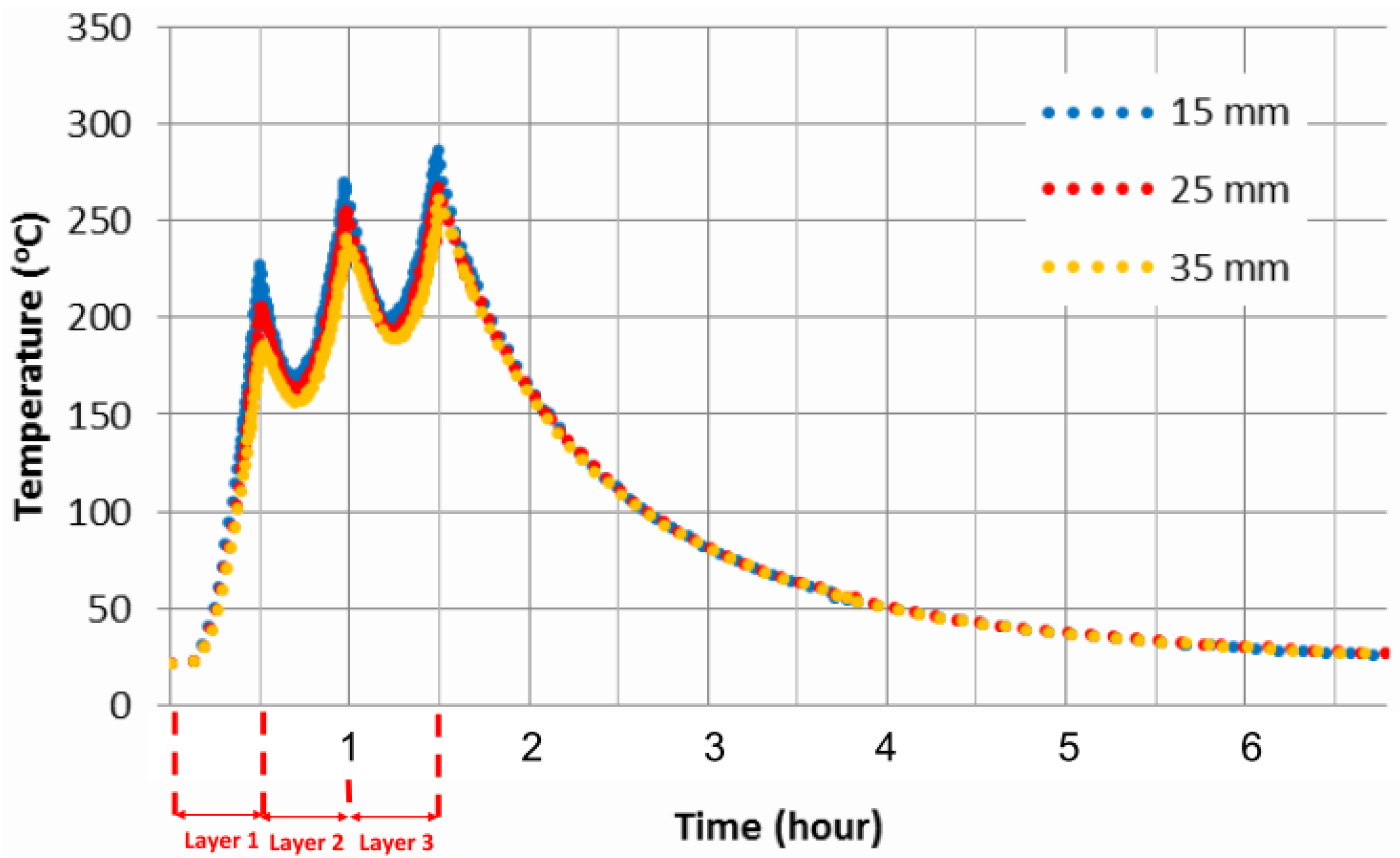

As the world is drilling deeper for reserves, super duplex components are required for more arduous operating environments and can experience damage due to fretting, erosion, and other types of wear. Conventional welding methods to repair super duplex can have a detrimental affect on the components that experience high temperatures for a long period of time—intermetallic phases can start occurring in the base material at very low temperatures (starting at 300 °C through to 1000 °C). The control of the welding process is essential for super duplex materials, including the avoidance of heat treatment during pre- and post-weld, and interpass temperature should be below 150 °C to avoid precipitations of intermetallic phases, as detailed by the API RP 582 [

5] standard. A list of the intermetallic phases and the temperatures associated with them according to [

6] are shown in

Table 1. These phases generally take time to develop and are not instantaneous. Lopez et al. (1999) [

7] showed a 27.2% drop in the ductility of duplex that was exposed to 10 h of heat treatment at 675 °C, causing the

σ-phase to develop.

Recent advances [

8,

9,

10] have been made to investigate the effects of additive manufacturing on duplex/super duplex materials. However, effort is required in the early design process to effectively remanufacture components in relation to the material selection process [

11]. The deployment of additive manufacture technology for the design, manufacture, and remanufacture of high-value super duplex components is relatively new to industries; additive manufacture promises to lower costs and reduce lead times while at the same time offering better functional, environmental, and remanufacturing performance [

12].

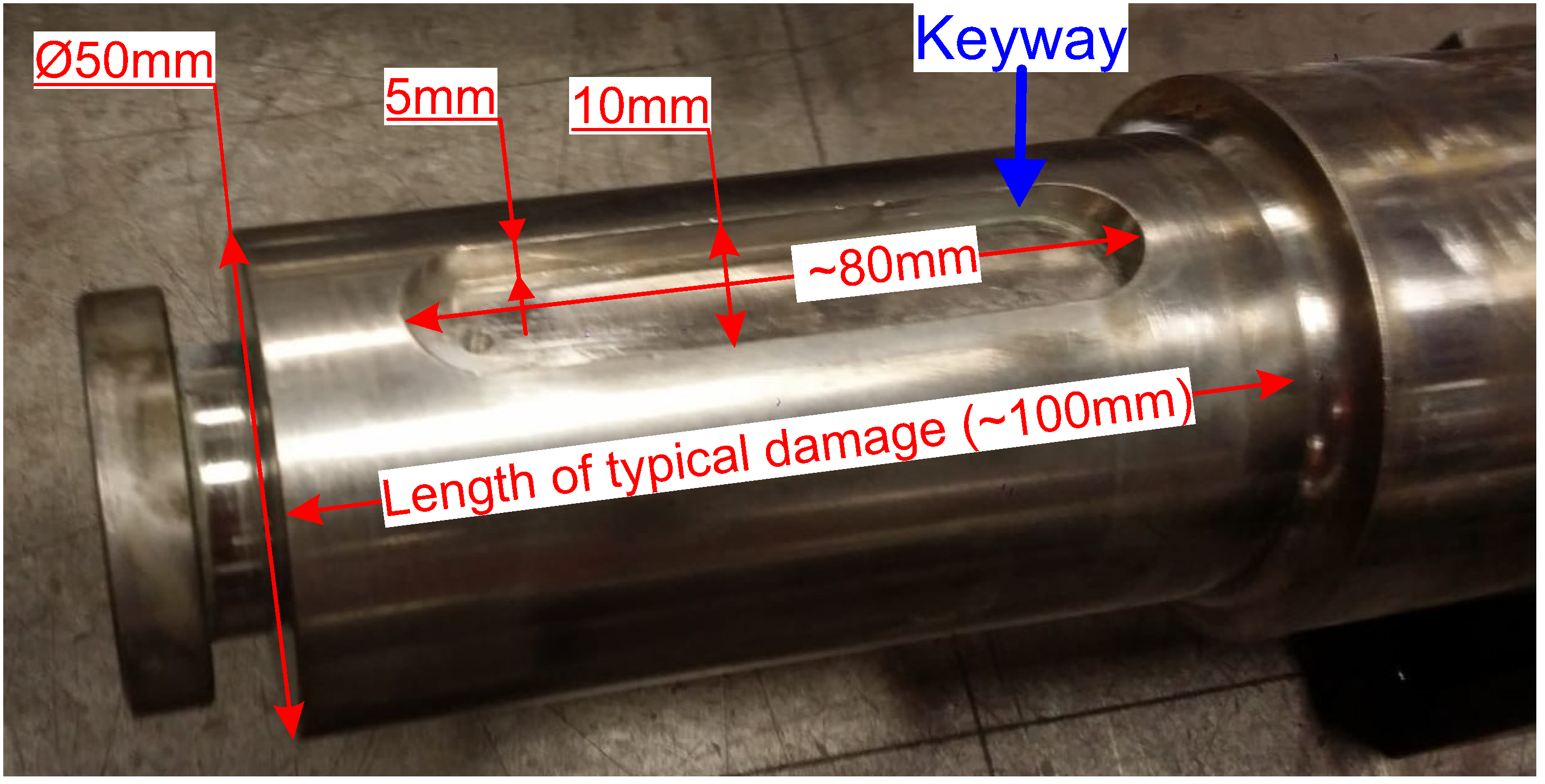

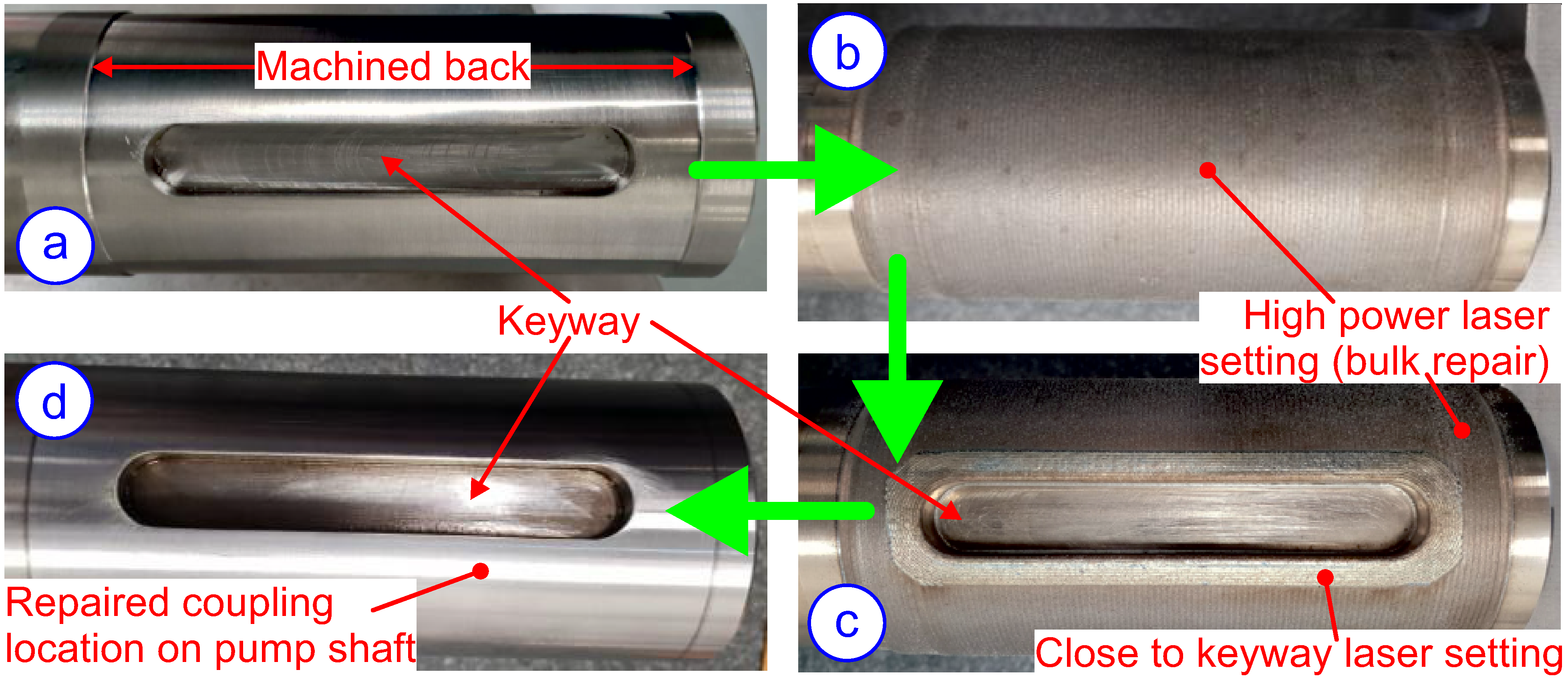

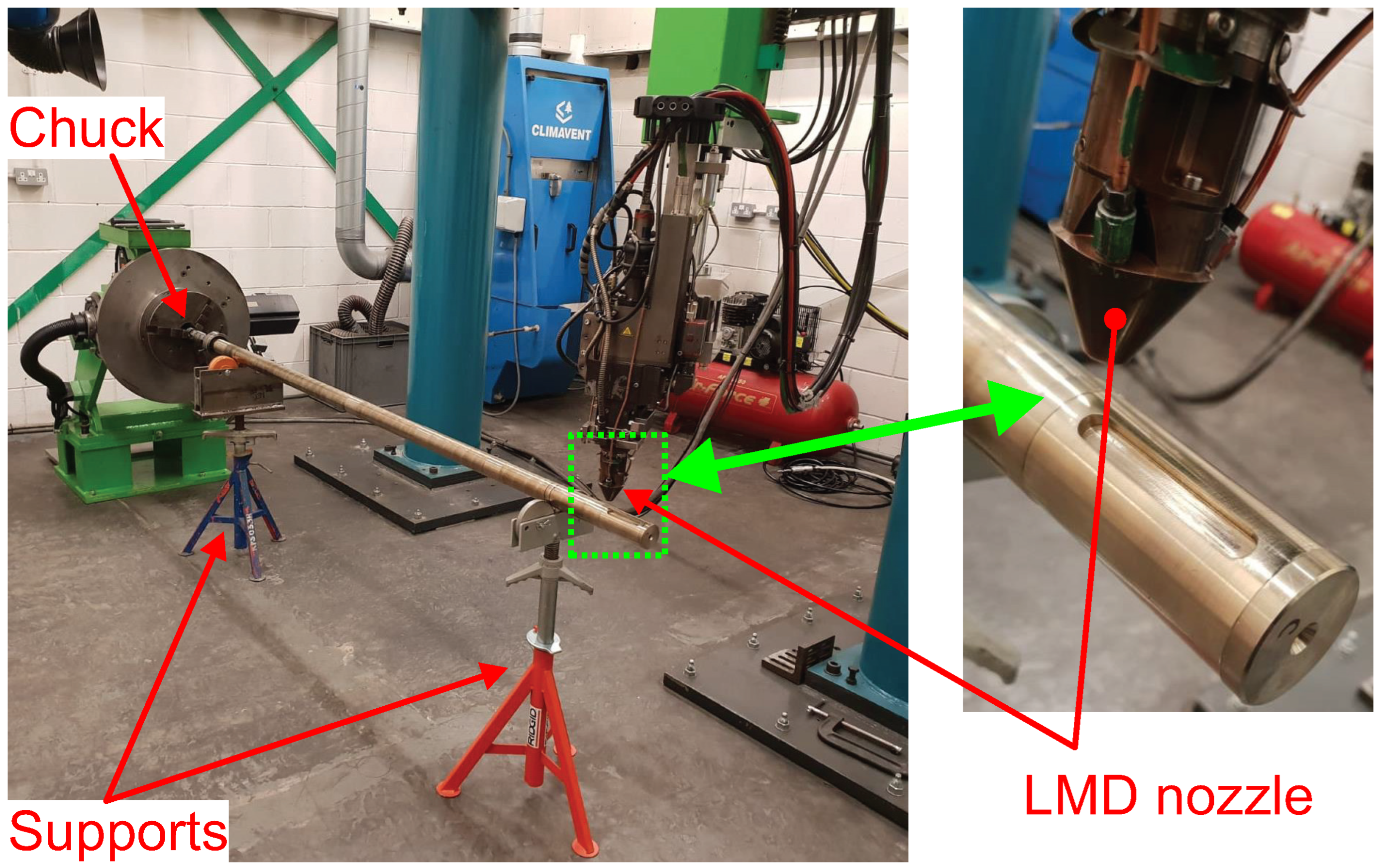

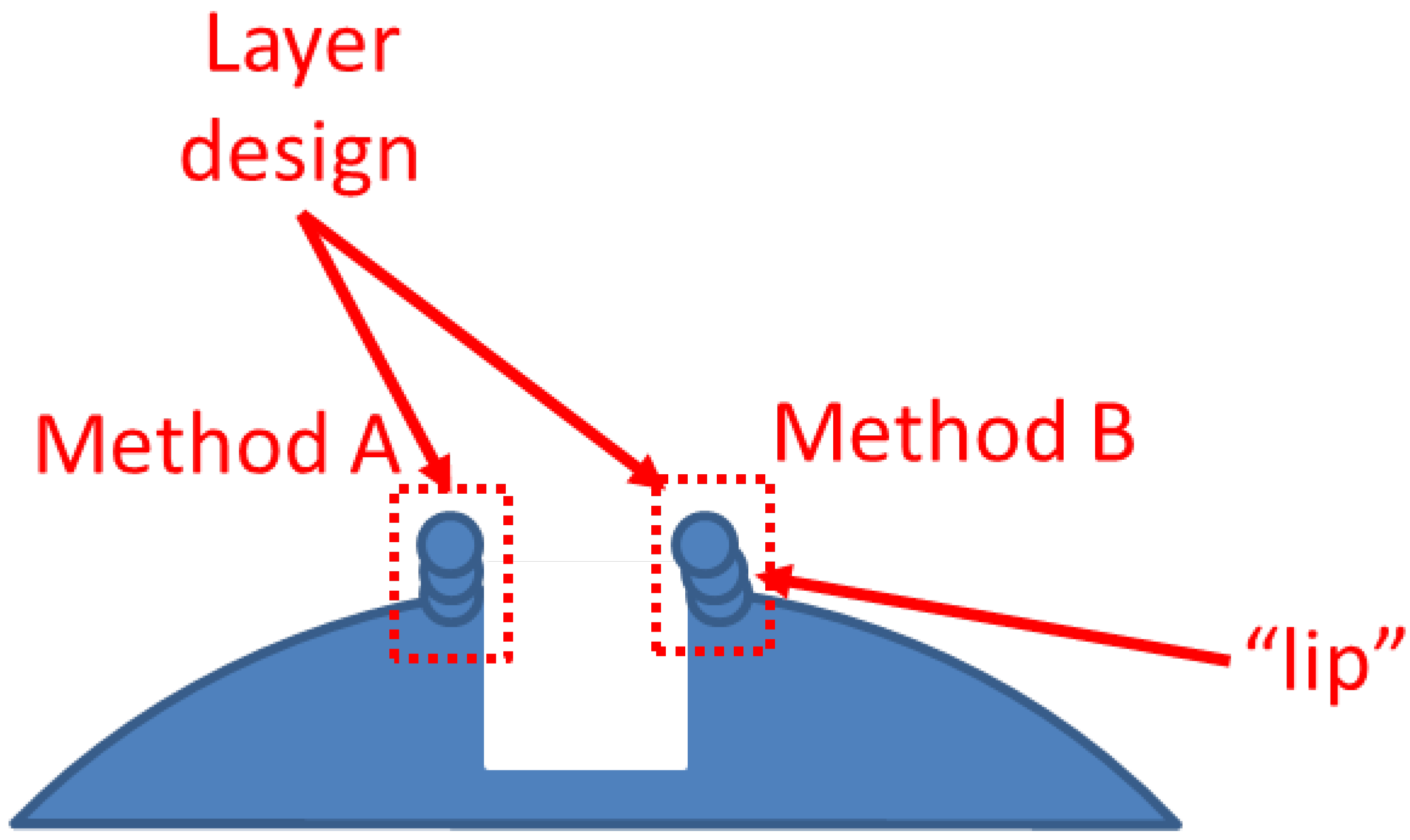

This paper details the development and validation, at technology readiness level (TRL) 6, of a new remanufacturing process based on additive manufacturing for the repair and salvaging of pump shafts, and in particular repairing one of the most challenging locations on the pump shaft, i.e., the coupling location. The design function of the shaft coupling location is to transmit torque loads between shafts, as in the case of (large vertically orientated) seawater lift and fire pumps, which commonly have a dozen or more shafts coupled together. Therefore, the coupling is a critical design feature, and repair of this area needs to be undertaken using fully evaluated and controlled processes.

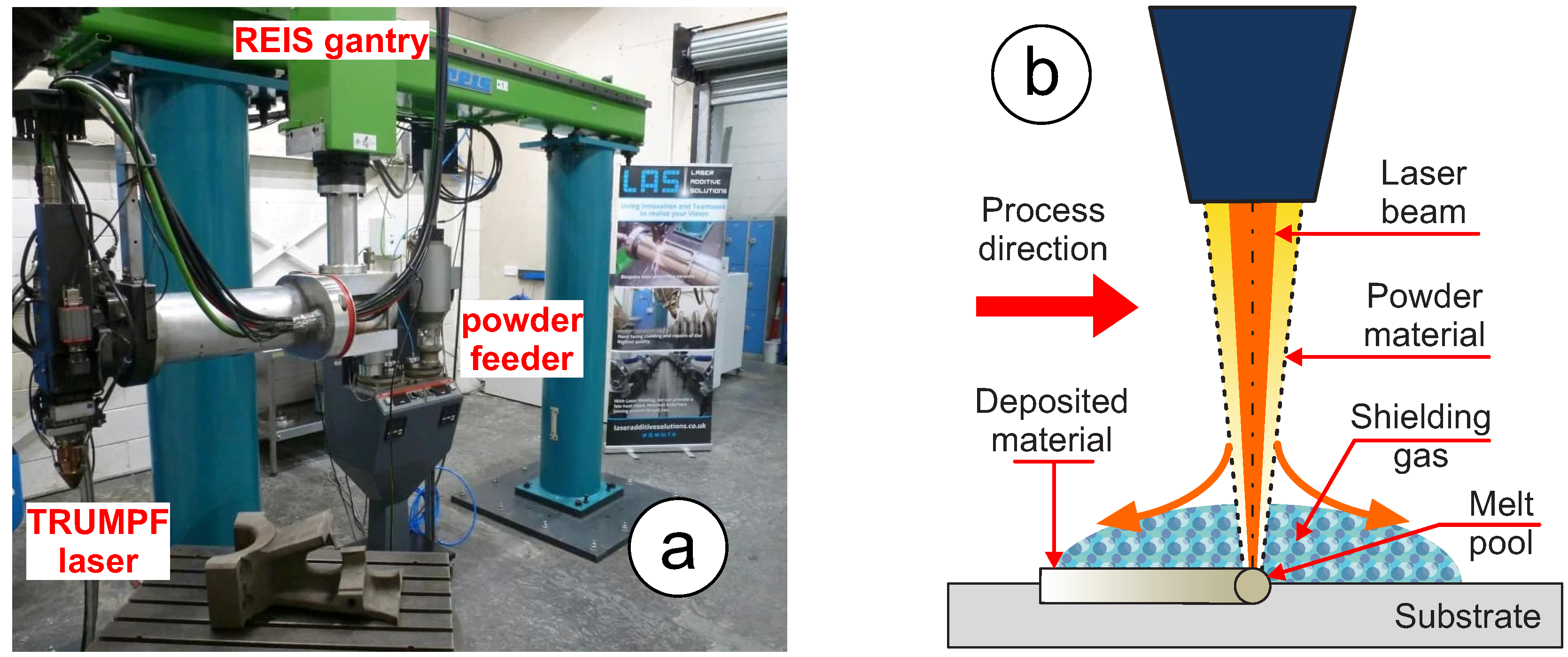

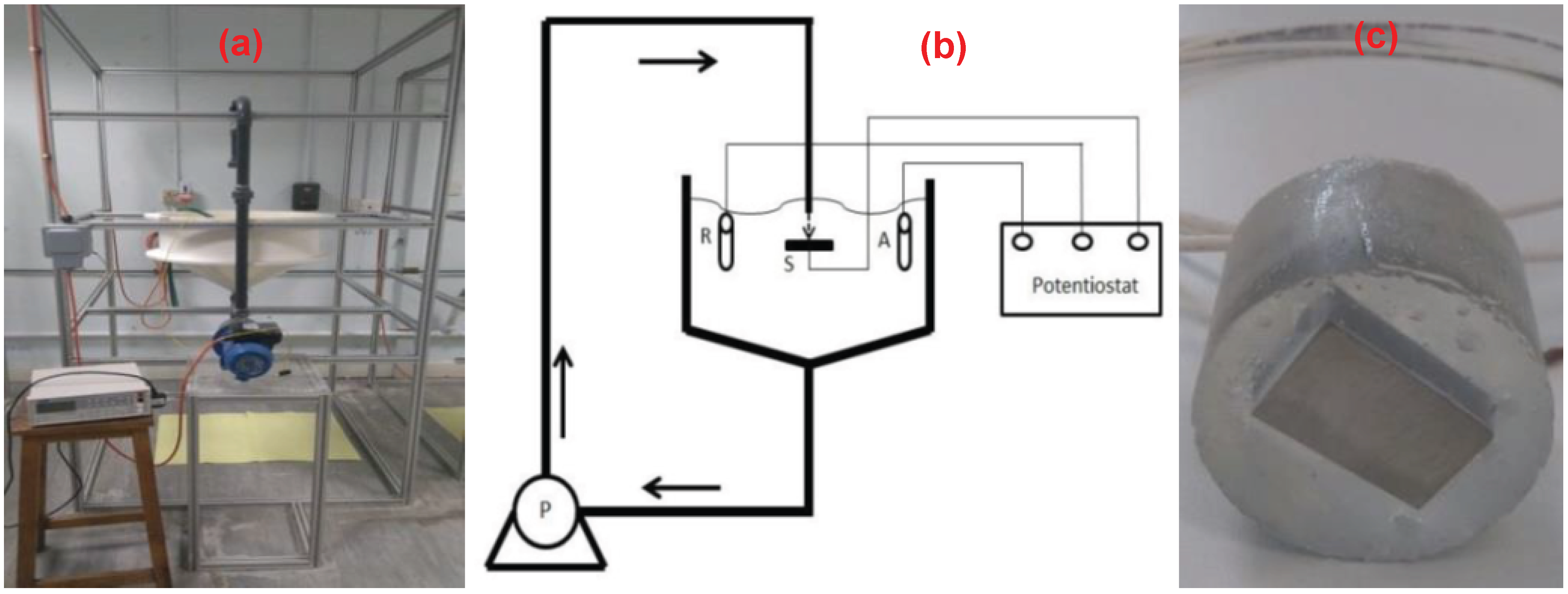

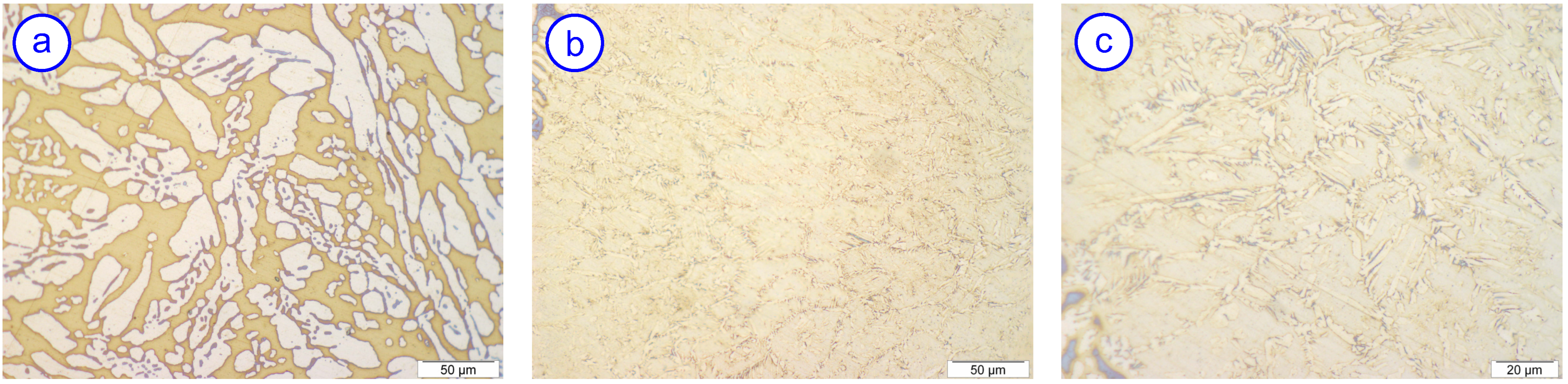

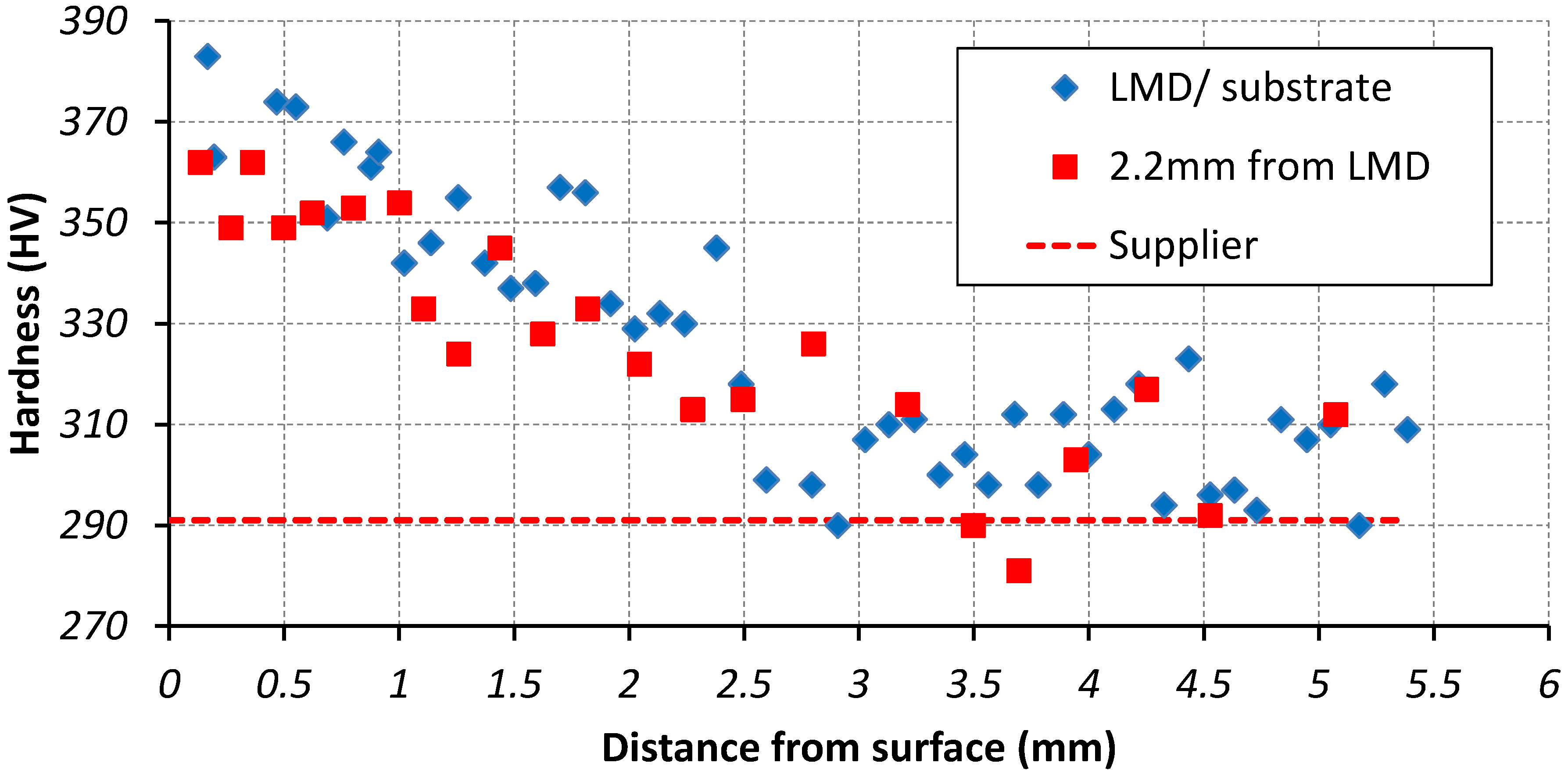

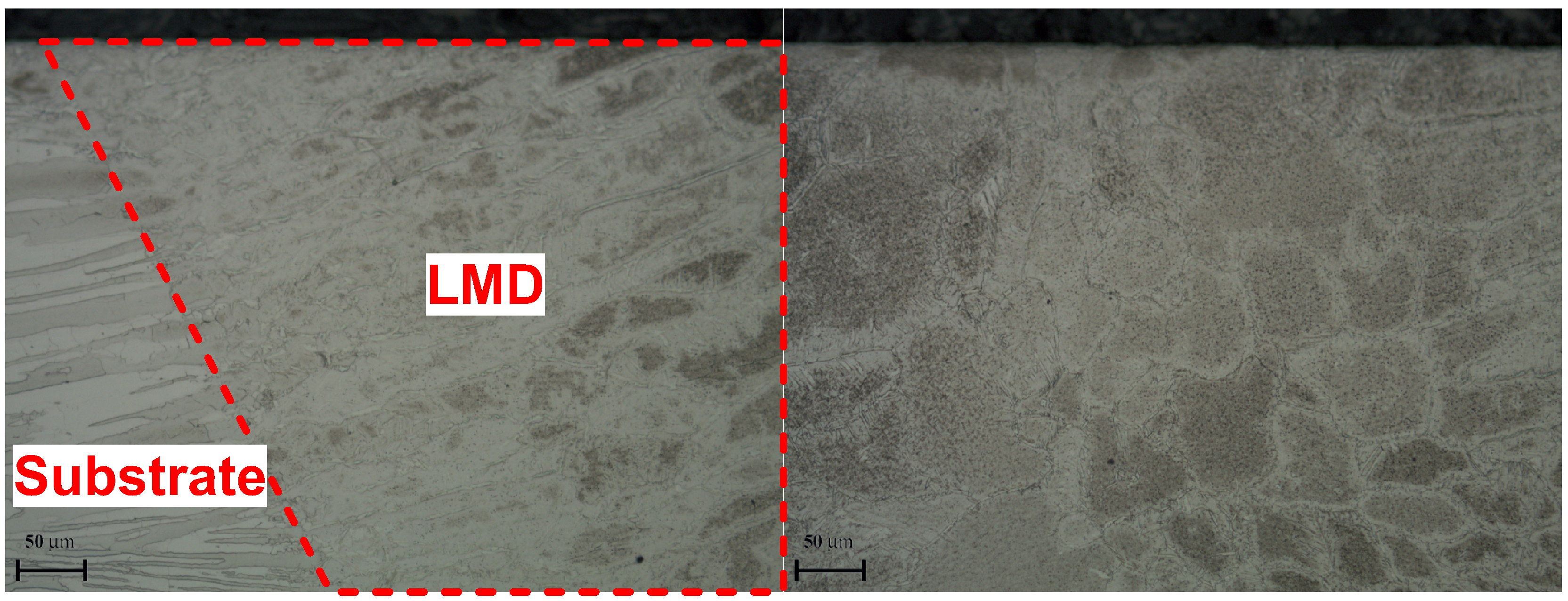

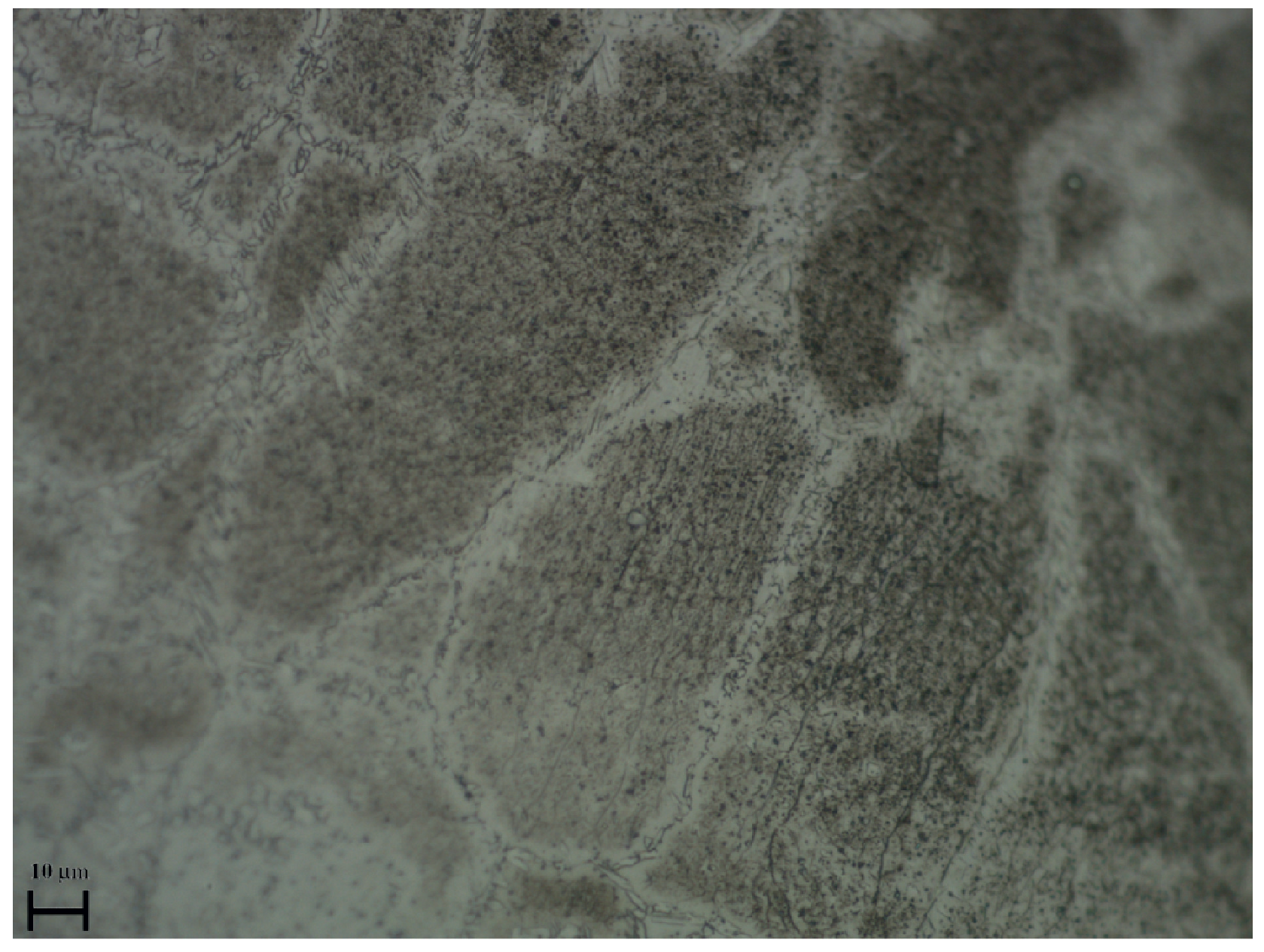

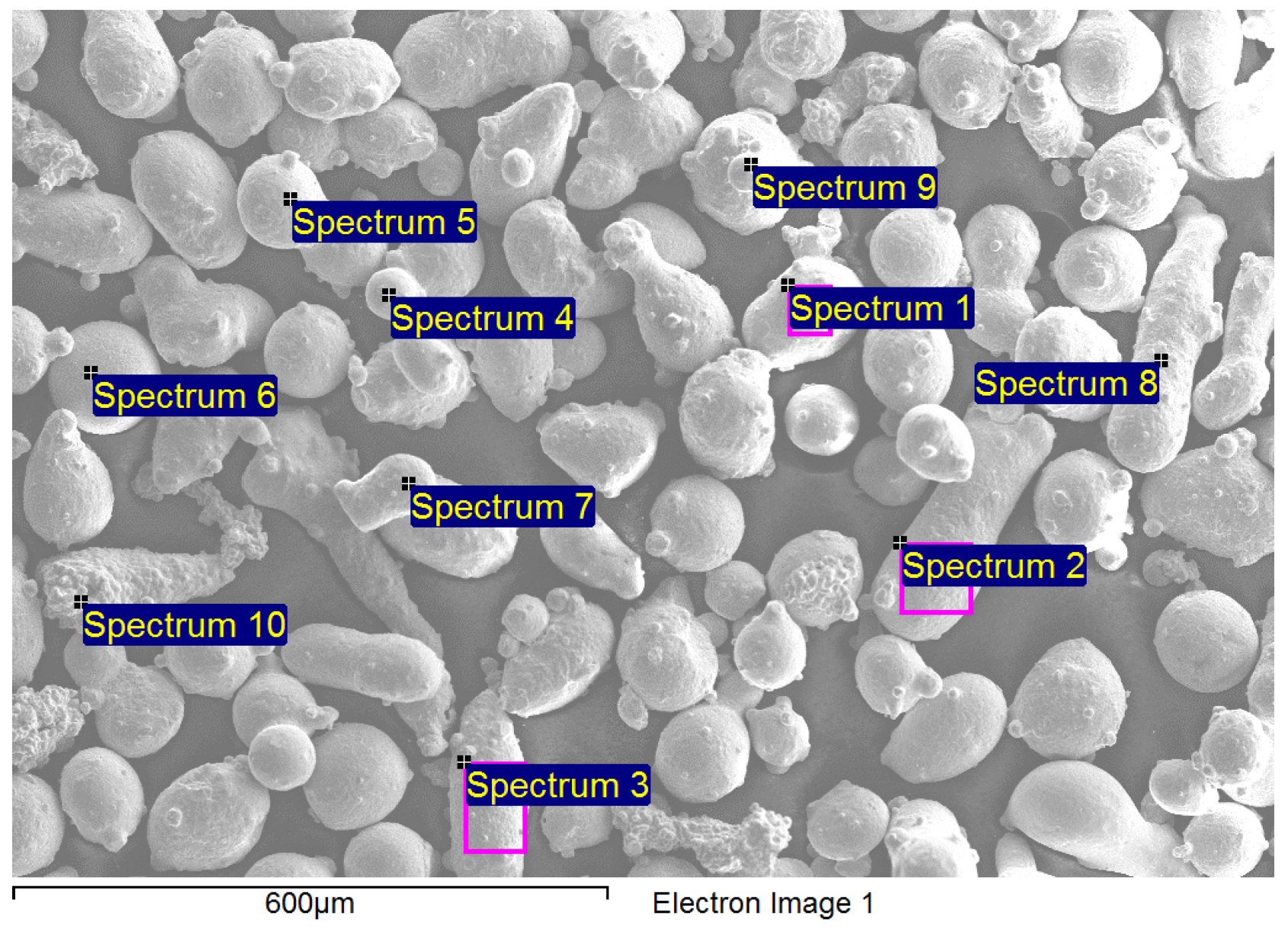

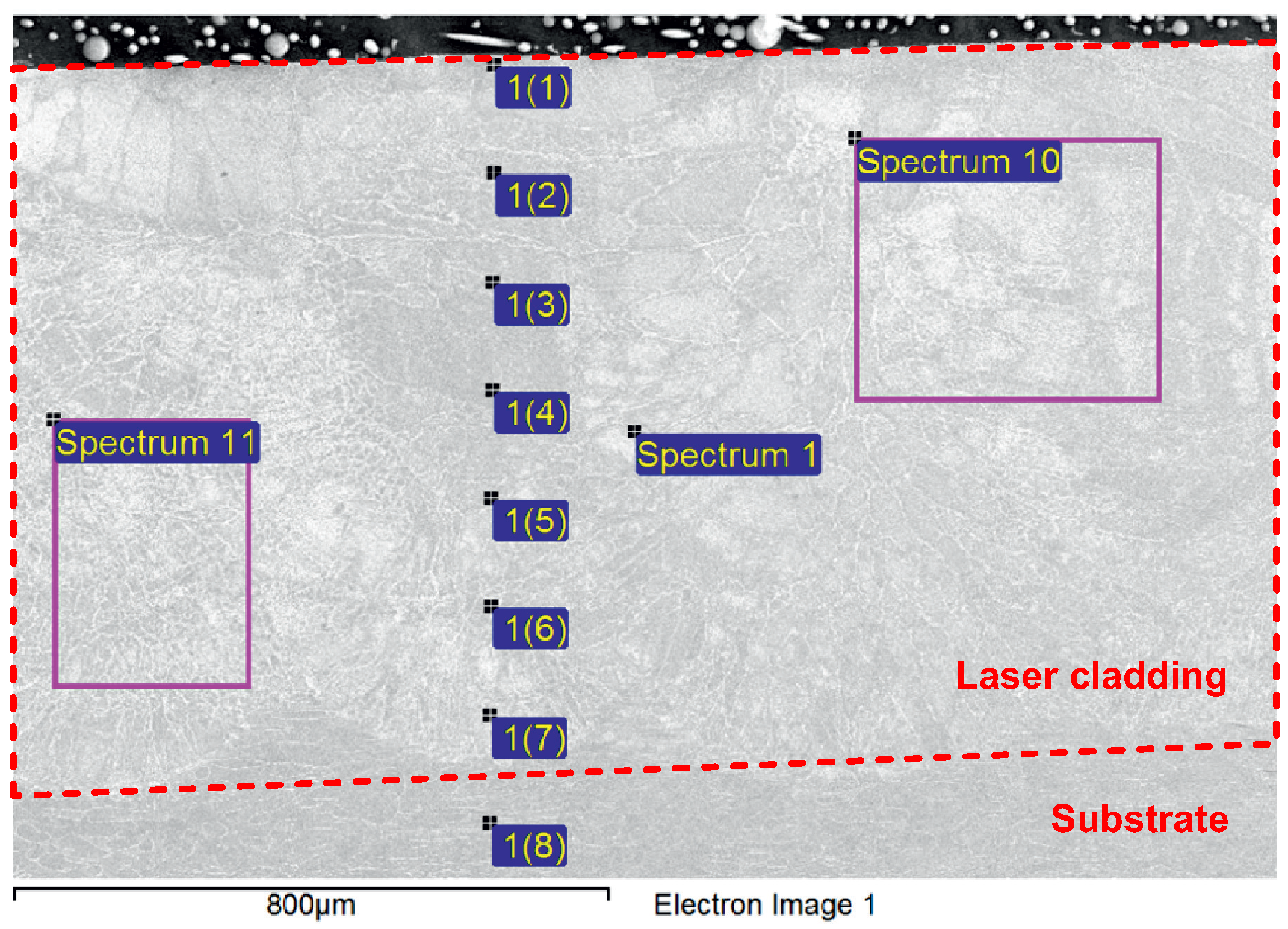

The additive manufacturing method, laser metal deposition (LMD), was used to repair the coupling location. The process parameters were defined to maintain mechanical and corrosion-resistant properties in accordance with industry standards. A semi-quantitative chemical composition of the additive layers, heat affected zone (HAZ), and substrate was obtained using energy dispersive X-ray spectroscopy, and the status of intermetallic phases was determined by etching procedures. Hardness and fatigue behaviours were also investigated. Based on the research in this paper, the expected resulting industrial impacts of the new remanufacturing process are significant, with a lead time reduction from 6–10 weeks to 1–2 weeks and repair cost only 25% of the replacement cost.

2. Previous Works

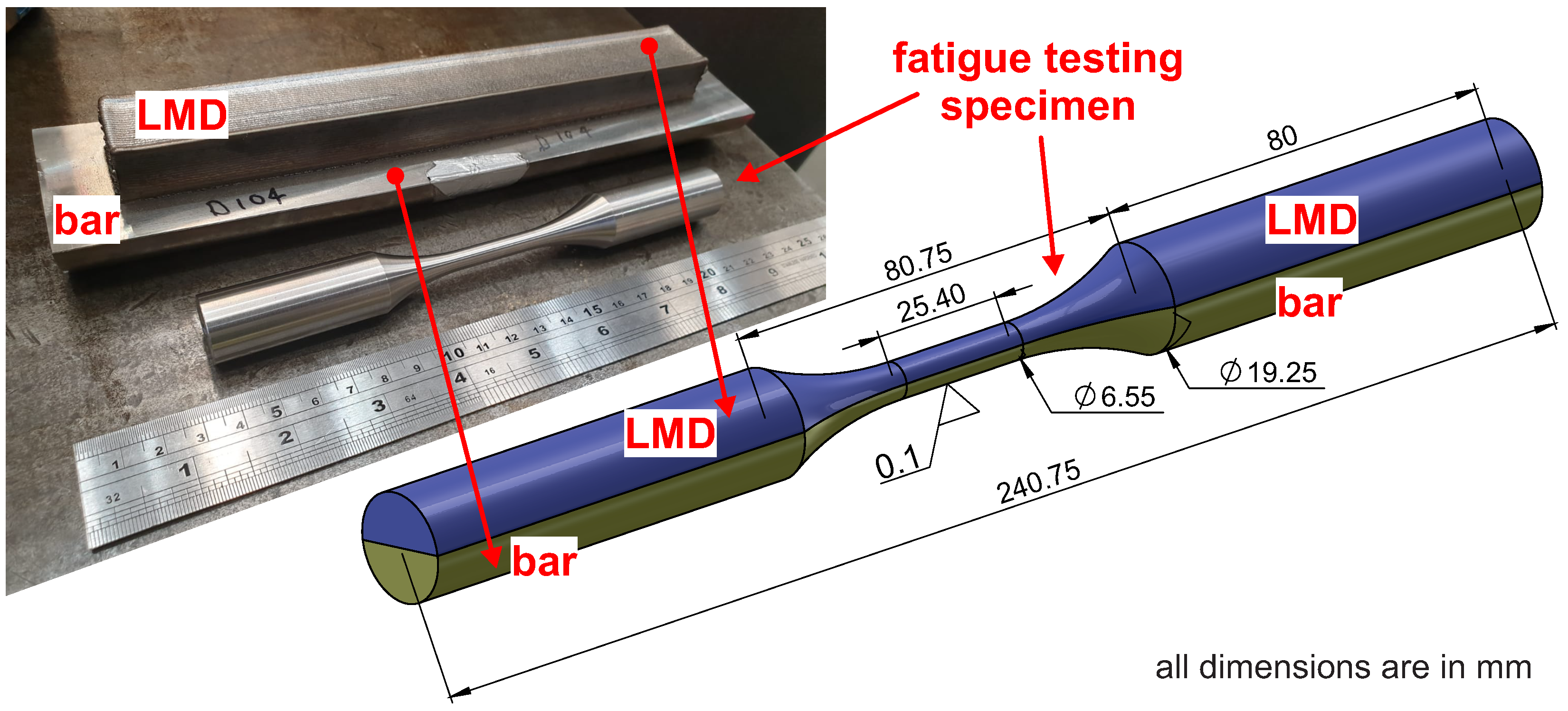

Full-scale fatigue testing was performed in [

13] on wrought AISI-SAE 4140H samples laser clad with martensitic stainless steel overlays with different preheat levels. It has been confirmed experimentally [

13] that both cladding process and preheating induce the compressive residual stress state, resulting in an improved fatigue life of the processed samples. However, the introduction of larger defects during the cladding process eliminates such improvements, resulting in minimal fatigue strength, similar to that shown by the base material, or even worse.

Fatigue testing was conducted in [

14] to investigate the potential of applying LMD as a repair method for Ti-6Al-4V aerospace components. Ti-6Al-4V powder was laser deposited on Ti-6Al-4V specimens [

14] with two different deposition strategies: a raster pattern with a continuous deposit (LMD-1) and a raster pattern deposit with an inter-track pause (LMD-2). The results showed that the fatigue lives of LMD-1 were higher when compared to LMD-2. This is because tensile residual stress in the deposit layer for LMD-1 was 150 MPa, which was 50% lower compared to that in LMD-2 (250 MPa). The high number of geometrical defects, in LMD-2 in addition to higher tensile residual stress, was the factor contributing to the shorter fatigue life when compared to LMD-1. Thus, heat treatment with lower temperature and longer duration is better for fatigue resistance.

Ref. [

15] focuses on developing basic fatigue resistance data for 17-4 PH stainless steel deposits made using the LMD process. The study [

15] demonstrated that heat treatment has an opposite effects on mechanical properties and fatigue resistance. The specimens that were direct aged (A) with interlayer temperature control and longer interlayer dwell times were observed to have a larger volume fraction of austenite (retained austenite and reverted austenite) in the microstructure compared with SA (solution treatment + ageing) and HSA (homogenization & solution treatment + ageing) samples. The differences in the microstructure resulted in varying the mechanical behaviour of the material, as evidenced by results from tensile and fatigue tests. Direct aged samples (A) have a much lower yield strength but much better fatigue resistance compared to SA and HSA samples, which are twice as strong in terms of yield. Thus, aggressive heat treatment types have no benefit for fatigue resistance.

By selecting the appropriate process parameters and welding strategy, it is possible to achieve tensile and fatigue strengths [

16] which are at least equal to the original material. Ref. [

16] investigates laser beam cladding, which is an established industrial precision process in the field of aero engine and gas turbine repair. The high-cycle fatigue testing was done on base and clad samples, with the duration of tests up to 10 million cycles. All specimens fractured outside the laser-generated zones in the base material. Thus, the fatigue strength of the laser-deposited structures apparently exceeds that of the base material. It was also found that the fatigue strength of the Ti6242 material used for the cladding experiments is slightly higher than that of the previously tested Ti6242 reference material. Thus, the fatigue resistance of repaired material can be no worse than of the base one, at least in the case of titanium alloys.

Laser cladding of AerMet100 powder on AerMet100 substrate was performed in [

17] to demonstrate the viability of repair. The selected material [

17], AerMet100, is a widely used ultra-high-strength steel in current and next generation aerospace components, such as landing gears. No micro-cracking and very little porosity were observed in the clad layer. A variable amplitude fatigue load was used for 1000 MPa maximum load and 0.1/0.7 load ratios. Both the as-clad and post-heat-treated (PHT) samples were compared to a baseline sample, with an artificial notch to simulate damaged condition. Results show that laser cladding significantly improves fatigue life, as compared to the baseline sample with a notch. However, the fatigue life of the as-clad sample is lower as compared to a baseline sample without a notch. A compressive residual stress of 300–500 MPa was observed in the clad region. The PHT condition, however, was not effective in improving the fatigue life—it was in fact the opposite, rather negative.

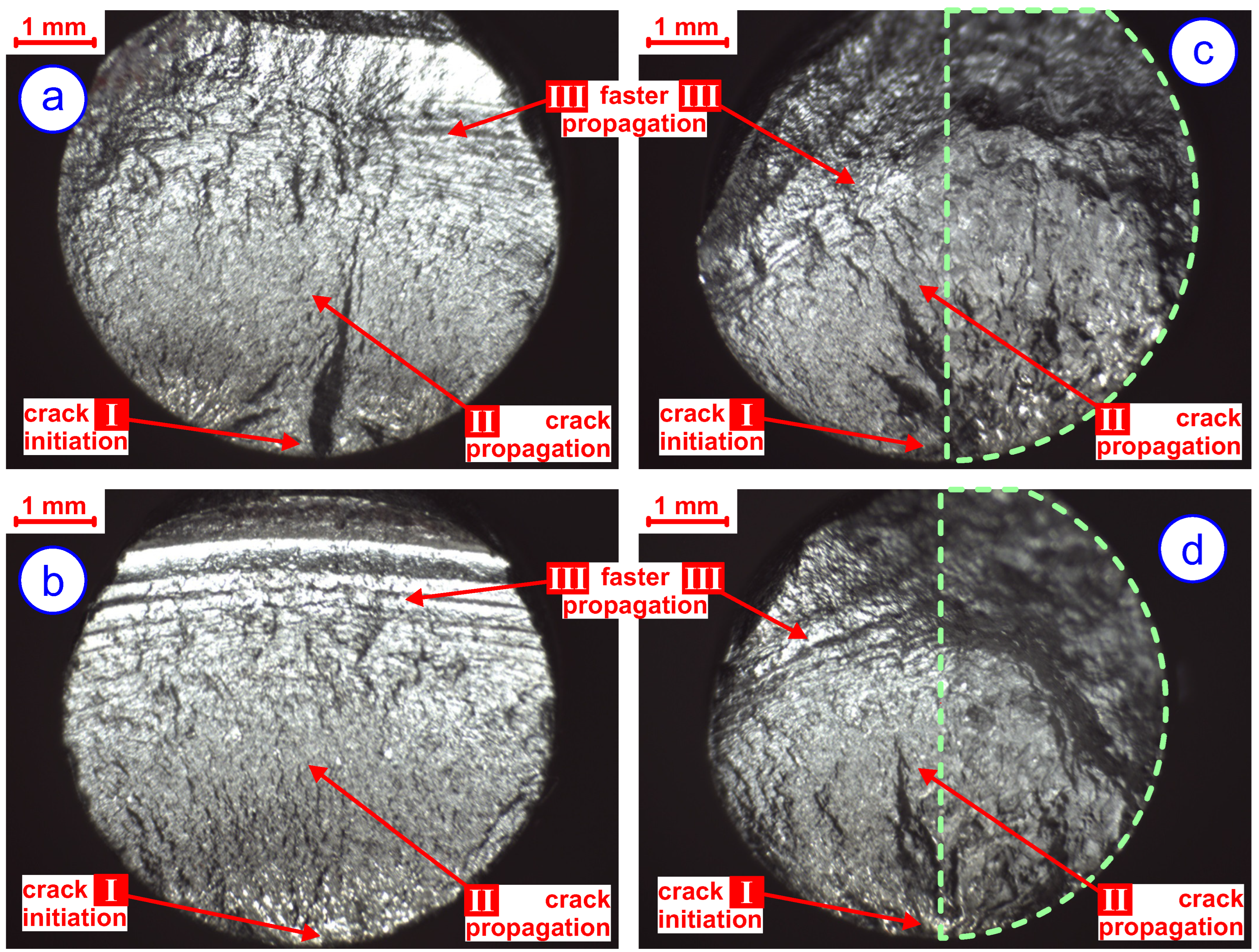

Based on observations in [

13,

14,

15,

16,

17], it can be concluded that this research work completely agrees with previous similar studies, especially in [

17] regarding the negative effect of PHT condition and the better fatigue resistance of baseline undamaged material. The samples with 50% LMD have a drop in fatigue resistance compared to the base material, because of the defects (porosity, etc.) induced by LMD. Forged/cast materials are most often better in fatigue resistance compared to their AM variants. As the samples are preheated before LMD, they thermally expand, and after LMD they shrink, thus generating additional compressive residual stresses in the deposited layer. The induced residual stress in the surface layer partly compensates for the negative influence of the defects from AM on the fatigue resistance. Therefore, the additionally applied thermal treatment actually has a negative effect on the structure and the material, because it eliminates the positive effect of compressive residual stress, and should be avoided. The suggestion would be to replace a heat treatment with a mechanical treatment, e.g., shot peening. This would increase the material density by closing the subsurface pores and increase the depth of the compressive residual stress penetration and peak value.

5. Conclusions

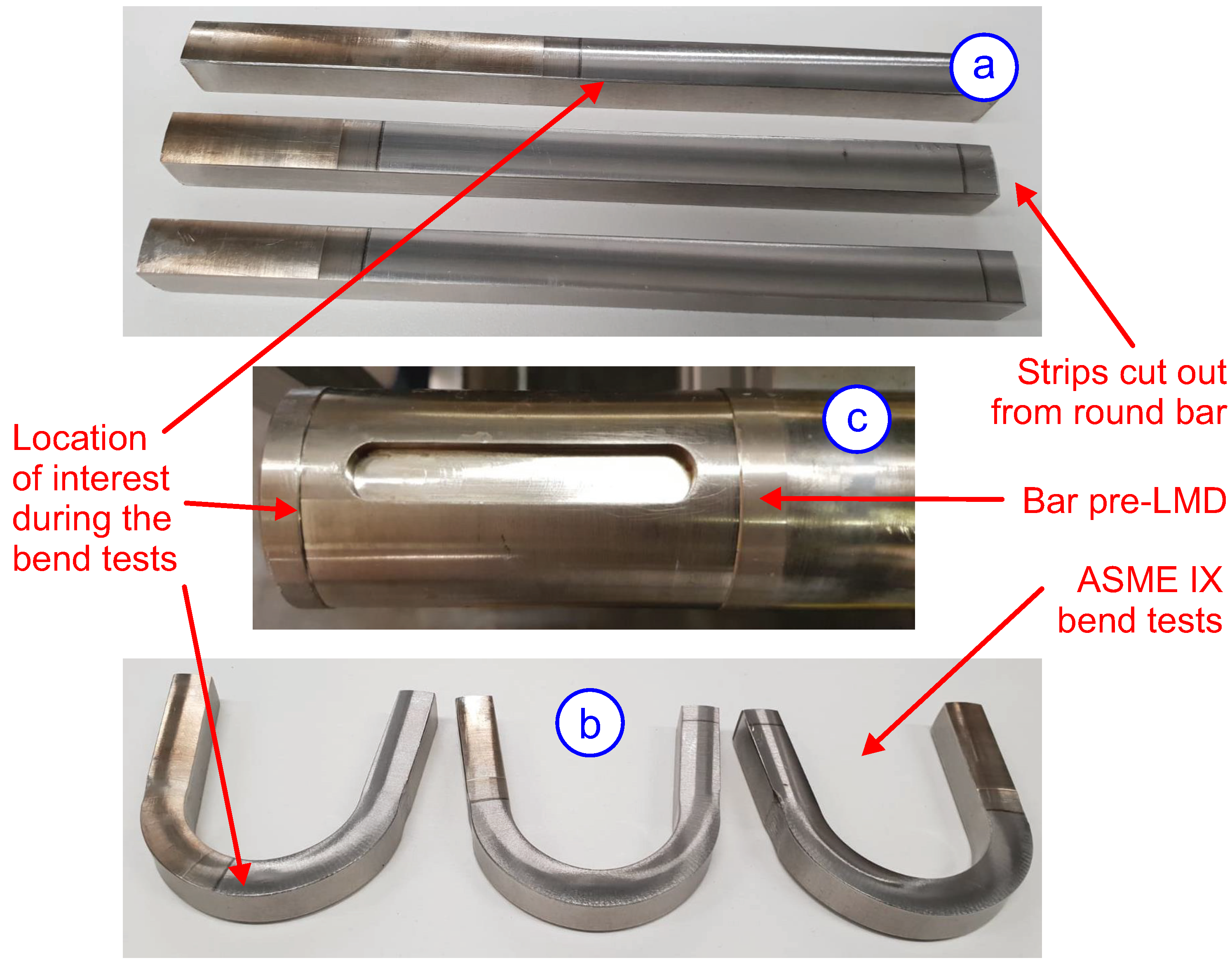

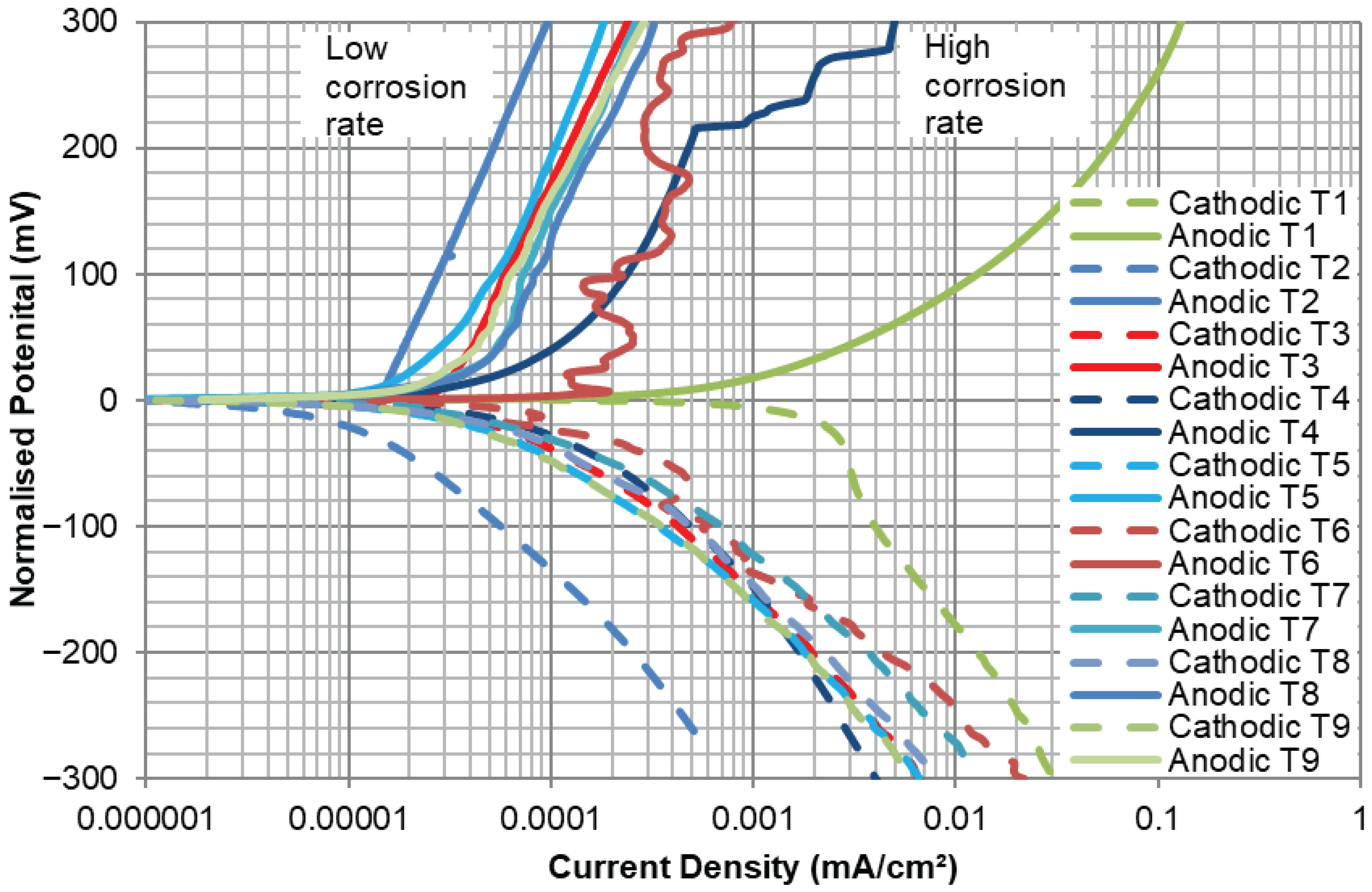

The paper discusses the development and validation of a laser metal deposition AM process for repairing damaged super duplex stainless steel components, addressing challenges in traditional repair methods and promoting sustainability in industrial applications. A new remanufacturing process, validated at TRL 6, is based on AM for the repair and salvaging of pump shafts for oil-and-gas applications. The repair of coupling location is addressed in this work as one of the most challenging locations on the pump shaft from a structural integrity point of view. This research directly contributes to the principles of a circular economy by extending the lifespan of critical components, reducing the need for raw material extraction and minimizing waste. By enabling the repair and reuse of damaged pump shafts, this process offers a sustainable alternative to traditional repair and replacement methods, leading to a reduced environmental footprint and promoting resource efficiency. The quality of the repair work and corresponding area was validated using the following types of testing:

Passed ASME IX mechanical bend test;

Passed ASTM G48 Method A corrosion test;

Passed dye penetrant investigation;

Successful potentiodynamic polarisation scans—all LMD test samples exhibited a significant reduction in corrosion rate (>91%) compared to wrought super duplex;

Additionally, the supplier’s nominal composition was met for the validation of the super duplex alloy chemical composition and ferrite content measurement using a Ferritescope. Furthermore, the overlay solidification structure is comprised mainly of ferrite with a grain boundary networks of austenite. Fine and well dispersed particles suspected to be silicate or other oxide/slag inclusions were observed throughout the overlay. However, these fine dispersed particles do not appear to have adversely affected weld quality (as demonstrated by the successful ASME IX bend-test coupons and successful ASTM G48 corrosion testing). The new remanufacturing process, by controlling the overall temperature of the pump shaft, met the operational requirements for straightness after LMD repair.

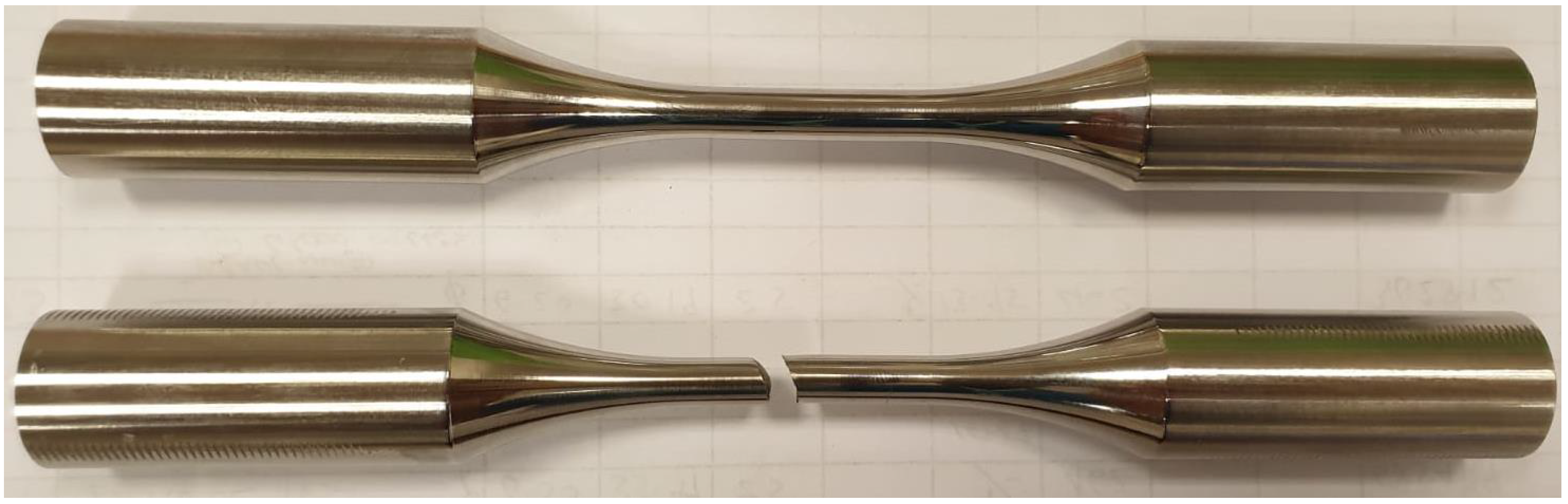

Most importantly, the fatigue life investigations and corresponding microstructural analysis were carried out in order to quantify the potential of repair work performance and value. The obtained fatigue life of specimens with LMD representing the repair work demonstrated the ability to restore potentially from 54% to 70% of the expected fatigue life of the original structural material, represented by specimens machined out of a shaft and stress relieved. The reduction in fatigue life needs to be considered when reviewing the repair potential for the industrial applications where the working stress level is high and service conditions are very demanding.

The economical aspects of the repair work should consider the energy consumed for repairing the pump shaft using AM, which is estimated at around 15% of a new pump shaft. Therefore, a total saving per year of around 6900 kWh could be achieved if all pump shafts were repaired using LMD, with the expectation of 78 pump shafts replaced per year. The expected resulting industrial impacts are significant using estimation based on the research outcomes in this project. The pump shaft repair lead time can be reduced from 6–10 weeks to 1–2 weeks, and the repair costs are estimated to be only 25% of a new shaft, which is solid evidence of the sustainable approach to manufacturing.

Finally, this work is an another proof of the growing role of AM in engineering, manufacturing, and sustainability. AM plays a crucial role in promoting sustainability and a circular economy by minimizing waste and enabling efficient resource use. It allows for on-demand production and design flexibility, which enhances durability and repairability. AM reduces waste through precise layer-by-layer deposition, contrasting with traditional subtractive methods. The technology supports the use of recycled materials, closing material loops and reducing the need for virgin resources. AM facilitates localized supply chains, reducing environmental impacts from excess inventory and transportation. Most importantly, using AM to repair empowers local businesses to be more self-sufficient, responsive to customer needs, and aligned with the growing demand for sustainable practices, ultimately fostering their growth and resilience within the community.