Abstract

This study investigates efficient dehydration and solidification techniques for waste mud generated from loess pile foundations during highway construction in Lanzhou, Northwest China. The waste mud, characterized by high viscosity (85% moisture content) and alkalinity (pH 11.2), poses environmental risks if untreated. Dehydration experiments identified an optimal composite flocculant mixture of 3.5 g polyaluminum chloride (PAC) and 22 mL anionic polyacrylamide (APAM) per 500 mL waste mud, accelerating sedimentation and reducing the supernatant pH to 8.65, compliant with discharge standards. Solidification tests employed a composite curing agent (CG-T1+cement), demonstrating enhanced mechanical properties. The California Bearing Ratio (CBR) of the solidified sediment reached 286%, and the unconfined compressive strength (UCS, 7-day) exceeded 2.0 MPa, meeting roadbed specifications. The combined use of PAC-APAM for dehydration and CG-T1–cement for solidification offers an eco-friendly and economically viable solution for reusing treated waste mud in construction applications, addressing regional challenges in mud disposal and resource recovery.

1. Introduction

During drilling operations for highways, railways, bridges, and tunnels, substantial quantities of mud are employed to safeguard drilling equipment, stabilize borehole walls, and facilitate drilling debris removal. This process consequently generates significant volumes of waste mud. Characterized as a complex mixture, waste mud exhibits high viscosity, an elevated moisture content, strong fluidity, and low structural strength and contains considerable amounts of crushed sand, gravel, and diverse chemical additives. Improper disposal methods such as direct discharge or burial may result in severe environmental consequences, including water and soil contamination.

The conventional treatment approach for waste mud involves a two-phase separation process: initially separating mud and water through sedimentation, followed by the removal of the supernatant liquid. Subsequently, solidifying agents are introduced to the sediment for the recycling and production of various engineering materials. However, due to its stable colloidal system characteristics, waste mud presents significant challenges for natural solid–liquid separation [1,2,3]. The predominant solid–liquid separation techniques currently employed are chemical flocculation and mechanical dewatering. Chemical flocculants, being water-soluble polymers, operate through multiple mechanisms including bridging, entrapment, adsorption, and electrical neutralization. These agents destabilize the mud–water system, promoting the rapid aggregation and sedimentation of mud particles, thereby achieving efficient mud–water separation. Compared with traditional mechanical dewatering methods, chemical flocculation demonstrates superior performance in terms of separation effectiveness, treatment efficiency, and environmental compatibility.

Current research on the dehydration and solidification of waste mud is extensive. For instance, Cao et al. [4] and Xu et al. [5] found that finer waste mud particles are more likely to form mud skins on filter media, reducing permeability and causing blockages. Berilgen et al. [6] used anionic and cationic coagulants to pretreat waste mud, achieving faster dehydration through flocculation followed by filtration. Sun et al. [7] conducted dehydration experiments using inorganic low-molecular-weight flocculants, while Gonzalez-Perez et al. [8], Pulgar et al. [9], Li et al. [10], and Ma et al. [11] used inorganic polymer flocculants. Yang et al. [12], Abdollahi et al. [13], and Chen et al. [14] employed organic flocculants and Aguilar et al. [15] and Zhang et al. [16] used composite flocculants for dehydration tests. She et al. [17], Jiang et al. [18], and Gökçe et al. [19] conducted solidification research using cement, fly ash, gypsum, lime, and other materials. In order to reuse the solidified waste mud, many scholars such as Zhang et al. [20], Ding et al. [21], Jiang et al. [22], and Wang et al. [23] have studied its mechanical properties.

Existing research has provided valuable references and guidance for mud treatment methodologies. However, substantial variations in geological conditions across different regions result in significant differences in the properties of waste mud generated during construction activities, consequently leading to diverse optimal flocculation conditions. The resource utilization of waste mud requires a complete set of processes, including the dewatering of waste mud and the treatment of dewatered sediment, and at present, there are many studies on the dewatering mode of waste mud and there are few studies on the recycling of sediment. Notably, there is a paucity of research focusing on the treatment of waste mud derived from loess pile foundations in Northwest China. In light of this research gap, the present study concentrates on a highway project in Lanzhou City, aiming to investigate and develop efficient treatment strategies for waste mud originating from loess pile foundations.

2. Materials and Methods

2.1. Materials

2.1.1. Waste Mud

The waste mud used in the experiment was collected from the construction site of the Fujiayao to Kushui Expressway section in Lanzhou City, as shown in Figure 1 and Figure 2.

Figure 1.

Waste mud pit.

Figure 2.

Waste mud samples.

- Chemical Composition Test

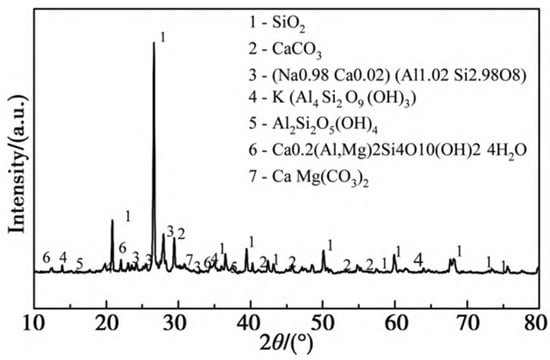

The moisture content of the waste mud was determined to be 85% (calculated as the percentage of water mass to mud mass) using the drying method. After allowing the waste mud to settle, the pH value of the supernatant was measured at 11.2 using a portable pH meter, indicating strong alkalinity. A small sample of waste mud was naturally dried in the sun for eight hours, ground with a grinder, and screened through a 0.075 mm mesh for X-ray diffraction (XRD) testing. The instrument used was an X-ray diffractometer MiniFlex600, which was provided by Beijing Jiadelida Technology Co., Ltd. (Beijing, China) The results are presented in Figure 3.

Figure 3.

XRD pattern of waste mud.

The data were analyzed using MDI Jade software (Version 6.5), and the semi-quantitative method was used to calculate the composition content. The results are listed in Table 1. The main chemical components of the waste mud are SiO2, Al2O3, MgO, CaO, and Fe2O3, accounting for up to 90% of the total content, with SiO2 having the highest content at 67.2%.

Table 1.

The main chemical composition (wt%) of waste mud.

- 2.

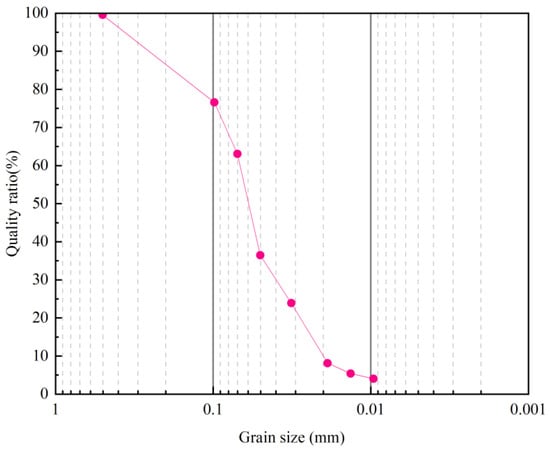

- Characteristics of Mud Particle Size

The particle size of mud plays a pivotal role in determining its natural settling rate and the efficacy of dewatering following the introduction of coagulants. The particle size distribution of the mud in Figure 4 was determined by the densitometer method in accordance with the “Standard for Geotechnical Engineering Test Methods” (GB/T50123-2019) [24]. The effectiveness of various coagulants is contingent upon the spectrum of mud particle sizes. Notably, coagulants do not facilitate the flocculation of larger sand particles; instead, they predominantly act upon the finer clay and silt particles. The distribution of particle sizes within the mud, as quantified, is depicted in Figure 4. The waste mud comprises 25.05% sand, which denotes the fraction of non-cohesive soil particles exceeding 74 μm in relation to the total mass of the mud. In contrast, the fraction of silt and clay particles amenable to flocculation constitutes 74.95%. As a result, this waste mud presents an appropriate medium for the execution of mud–water separation experiments utilizing flocculants.

Figure 4.

Particle size distribution curve of waste mud particles.

2.1.2. Flocculant

The chemical composition of engineering mud is predominantly inorganic, characterized by low concentrations of heavy metals, total phosphorus, and total nitrogen. Consequently, with the primary objective of optimizing the flocculation settling rate, commonly utilized inorganic flocculants, such as PAC, and organic polymer flocculants, such as APAM, were selected for flocculation settling experiments. These experiments aimed to investigate the dewatering performance of waste mud following the addition of flocculants.

- PAC

The PAC used in this experiment, as shown in Figure 5, is a yellow-brown particulate substance characterized by high water solubility and a propensity for hydrolysis. This hydrolysis process is accompanied by complex physicochemical phenomena, including electrochemical reactions, adsorption, coagulation, and precipitation. The flocculation mechanism of PAC primarily operates through adsorption and colloidal destabilization. As the hydrolysis products of aluminum salts possess positive charges, they effectively neutralize the negatively charged colloidal particles present in waste mud. This neutralization disrupts the stability of the colloidal suspension system, enabling clay particles to undergo free collision and subsequent aggregation through bridging mechanisms. Consequently, these aggregated particles form larger flocs that settle under gravitational forces via net capture and sweeping actions.

Figure 5.

PAC.

- 2.

- APAM

APAM, as depicted in Figure 6, is a water-soluble organic polymer flocculant. APAM flocculants typically exhibit a linear molecular structure, enabling them to adsorb various substances and form strong bonds with colloidal particles. From a microscopic viewpoint, these flocculants can adsorb individual particles and bridge the surfaces of two colloidal particles separated by relatively large gaps, facilitating flocculation through polymer adsorption and bridging mechanisms. Consequently, APAM primarily induces particle flocculation and sedimentation via adsorption bridging and net trapping mechanisms.

Figure 6.

APAM.

The flocculation performance of APAM is determined by five key parameters: charge type (cationic, anionic, and non-ionic), charge density (quantified by the number of positive and negative charges), molecular weight, molecular structure, and monomer type. Preliminary experimental investigations revealed that among the three types of APAM—anionic, cationic, and non-ionic—the cationic and non-ionic variants demonstrated inferior coagulation and dewatering efficacy for waste mud, whereas the anionic APAM exhibited optimal performance. Furthermore, the coagulation and dewatering efficiency of the mud was found to be positively correlated with the molecular weight of the anionic APAM. Based on these findings, this experiment employs anionic APAM with a molecular weight of 16 million for subsequent investigations.

2.1.3. Solidification Materials

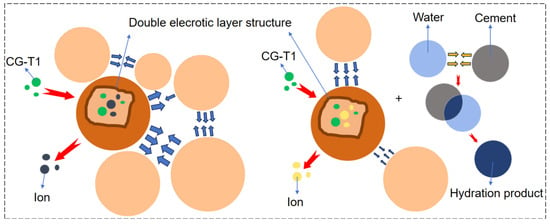

CG-T1 is a proprietary ionic blend composed of inorganic polymers (alumino-silicate colloids) and organic polymers (polycarboxylate derivatives). Its active components include inorganic ions (Al3+, Ca2+, and SiO32−) that function as ion exchange agents, as well as organic polycarboxylate ether (PCE) derivatives, which are used for particle dispersion and hydration control. The reinforcement mechanism of CG-T1 primarily involves disrupting the double-layer structure on particle surfaces, thereby thinning the water film bound to the particles. It facilitates ion exchange reactions that reduce the spacing between soil particles, promote particle aggregation, and enhance soil strength. This curing agent, a brown solution depicted in Figure 7, is composed of a blend of inorganic and organic polymers. It exhibits stable physical and chemical properties at room temperature and is fully soluble in water with a density of 1.303 g/cm3; in addition, its aqueous solution is non-toxic, harmless, non-corrosive, and environmentally benign, with minimal metal content. It is suitable for long-term storage and transportation under normal conditions.

Figure 7.

Solidification test material.

Based on the analysis of the curing effect of a single curing agent, this study employs a composite curing agent comprising CG-T1 and cement, as detailed in Table 2.

Table 2.

Different curing solutions with varying curing agent compositions.

2.2. Methods

2.2.1. Dehydration Test Procedure

Through comprehensive investigation, significant variations were observed in the initial moisture content of mud samples collected from different locations and at varying time intervals within the same site. To examine the natural settling characteristics of the mud, a 500 mL sample with a moisture content of 85% was homogenized by stirring at a speed of 200 r/min for 3 min using a quadruple digital agitator. Following a 5 min mixing period of the waste mud, a distinct mud–water interface became apparent. This phenomenon occurs because, upon completion of mixing, fine particles within the mud undergo irregular motion due to inertial forces. As settling time progresses, the velocity of these irregularly moving particles gradually diminishes due to interparticle collisions and the viscous resistance exerted by water. Consequently, the particles begin to aggregate and settle under gravitational influence.

Based on the natural settling tests of waste mud, it was determined that the natural settling process requires an extended duration, approximately 72 h. To enhance dehydration efficiency and mitigate the adverse environmental and engineering impacts of waste mud, the incorporation of coagulants was implemented. This study presents a detailed analysis of flocculation experiment results obtained through three distinct approaches: single addition of PAC, single addition of APAM, and combined addition of PAC and APAM.

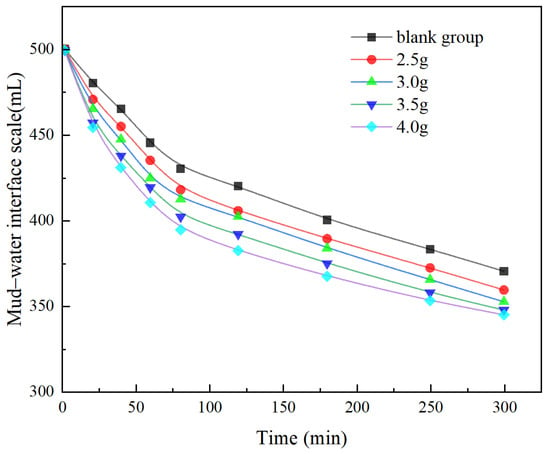

- PAC Single Addition Flocculation Test

Owing to the high water solubility of PAC, the solid particulate form of PAC was directly introduced in the experimental procedure. The experiment employed four distinct dosage levels of PAC [25]: 2.5 g, 3 g, 3.5 g, and 4 g. Concurrently, a control group without flocculant addition was established to serve as a blank reference for comparative analysis. The sedimentation volumes observed after a 120 min flocculation period with these varying PAC dosages are depicted in Figure 8.

Figure 8.

Mud flocculation settlement under different PAC dosages (120 min).

- 2.

- APAM Single Addition Flocculation Test

In this experiment, an APAM (anionic APAM) flocculant with a concentration of 0.02% was utilized, and the APAM solution was prepared 2 h prior to the commencement of the experiment. Given the variability in mud properties across different regions, the optimal dosage of flocculant for waste mud, as determined by existing studies, exhibits significant variation. To ascertain the optimal flocculant dosage for the waste mud at the Fujiayao to Kushui Highway construction site, four distinct dosages of APAM were established, each differing by 2 mL. The dosages administered were 20 mL, 22 mL, 24 mL, and 26 mL [26]. The sedimentation volumes observed after a 120 min flocculation period with these varying APAM dosages are depicted in Figure 9.

Figure 9.

Mud flocculation settlement under different APAM dosages (120 min).

- 3.

- Flocculation Test with Mixed Addition of PAC and APAM

Through flocculation tests involving PAC and APAM, it was observed that APAM exhibits a rapid flocculation settling rate and forms large flocs. However, varying dosages of APAM do not influence the pH of the supernatant derived from waste mud. This outcome fails to comply with the pH threshold of 6–9 mandated for tailwater discharge or reuse, as outlined in the “Integrated wastewater discharge standard” (GB 8978-1996) and the “Water quality of urban miscellaneous water for urban wastewater reuse “ (GB/T18 920-2020). Conversely, PAC, while having a comparatively modest impact on the settling rate of waste mud, significantly lowers the pH of the waste mud supernatant. Consequently, leveraging the distinct properties of PAC and APAM, a composite flocculation test for waste mud was undertaken.

Building upon the optimal PAC dosage of 3.5 g, the dosage of APAM was fine-tuned. First, 3.5 g of PAC was added, followed by the addition of APAM. Similarly, based on the optimal APAM dosage of 24 mL, the PAC dosage was adjusted accordingly. Specifically, 24 mL of APAM was added first, and then PAC was added. This process culminated in the identification of 8 composite flocculant dosages for flocculation experimentation.

2.2.2. Solidification Test Procedure

The optimal moisture content and maximum dry density of the solidified sediment were determined through compaction tests. The reference standard for the experiment is the “Test Methods of Soils for Highway Engineering” (JTG 3430-2020) [27].

The CBR serves as a pivotal metric in assessing the suitability of subgrade fill materials. The equipment used in the experiment is a Multi-functional Pavement Material Strength Tester, and the reference specification is outlined in “Test Methods of Soils for Highway Engineering” (JTG 3430-2020) [27].

The 7-day UCS is a critical parameter for evaluating the effectiveness of reaction curing agents in sediment solidification. The equipment used in the test is a universal pressure testing machine, and the referenced standard is “Test methods of soils for highway engineering” (JTG_3430-2020) [27]. In this experiment, cylindrical specimens measuring 50 mm in height and 50 mm in diameter, with a volume of 98.17 cm3, were prepared to assess the solidification performance. For each experimental group, three parallel specimens were prepared. After being subjected to curing in a standard curing room for 7, 14, and 28 days, respectively, the specimens underwent unconfined compressive strength testing. The experimental procedure is depicted in Figure 10. The calculation method for unconfined strength is as follows:

where Qc is the UCS of the specimen (MPa), P is the maximum pressure at which the specimen fails (N), A is the cross-sectional area of the specimen (mm2), and D is the diameter of the specimen (mm).

Figure 10.

Unconfined compression test of solidified sediment. (a) The dosage of the CG-T1 curing agent is 0.015%. (b) The dosage of the CG-T1 curing agent is 0.020%. (c) The dosage of the CG-T1 curing agent is 0.025%.

3. Results

3.1. Dehydration Test

- PAC Single-Addition Flocculation Test

The volume of the supernatant serves as a crucial indicator of the coagulation and sedimentation rate of the mud. Simultaneously, a reduction in the scale of the mud–water interface corresponds to an accelerated coagulation and sedimentation rate, consequently resulting in an increased volume of the supernatant. Figure 11 illustrates the variation curve of the mud–water interface scale over time under different PAC dosages. As depicted, the scale of the mud–water interface diminishes after 120 min with increasing flocculant dosage, although the reduction is not markedly significant. At the 300 min mark, the scale of the mud–water interface remains essentially consistent when 3.5 g and 4.0 g of PAC are added, indicating that further addition of PAC does not alter the final sedimentation volume of the mud.

Figure 11.

Mud flocculation settlement curve with different PAC content.

The slope of the curve serves as an indicator of the settling rate of the waste mud. As observed, the slopes of the flocculation settling curves remain essentially consistent across different dosage levels. The addition of PAC does not result in a significant enhancement of the waste mud’s settling rate. This phenomenon can be attributed to the primary mechanism of PAC, which functions through electrical neutralization to reduce the viscosity of the waste mud. However, PAC alone is insufficient to facilitate the formation of large flocs from mud particles. Consequently, the settling rate of the mud does not exhibit substantial improvement.

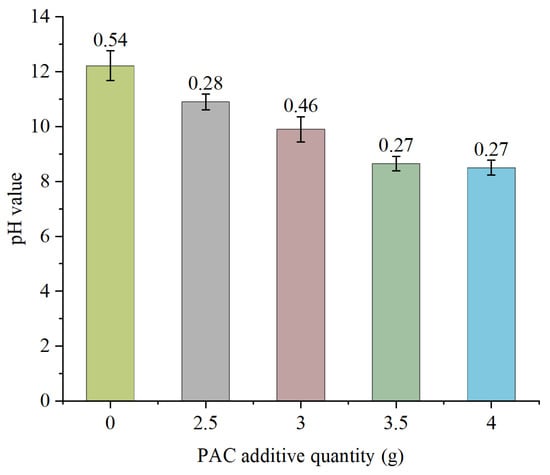

At the 120 min mark following the commencement of the experiment, the pH level of the mud supernatant was assessed. The pH measurements of the supernatant, corresponding to varying quantities of PAC, are graphically represented in Figure 12. The data illustrated in Figure 12 indicate a marked decline in the pH of the supernatant as the quantity of the flocculant is augmented. Specifically, when the flocculant dosage reaches 3.5 g, the supernatant’s pH diminishes to 8.65. This represents a reduction of 3.57 pH units, or a 29.2% decrease, relative to the supernatant devoid of flocculant. Upon further increment of the flocculant dosage, the pH of the supernatant exhibits only marginal variations. Notably, at a PAC addition of 3.5 g, the supernatant’s pH complies with the stipulated limits of the “Integrated wastewater discharge standard” (GB 8978-1996) [28] and the “Water quality of urban miscellaneous water for urban wastewater reuse” (GB/T18920-2020) [29], which mandate effluent discharge or reuse pH values to be within the range of 6 to 9.

Figure 12.

pH value of mud supernatant under different PAC content.

The significant reduction in the pH of the supernatant by PAC can be attributed to its primary constituent, Al2O3. Upon dissolution of PAC in water, Al2O3 undergoes partial hydrolysis, releasing free Al3+ ions into the mud. These Al3+ ions subsequently react with CO32− ions present in the mud, and the resultant CO2 from this reaction is responsible for the decrease in the mud’s pH.

- 2.

- APAM Single-Addition Flocculation Test

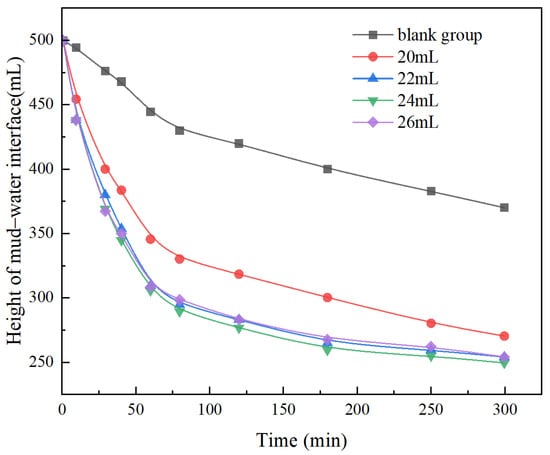

As illustrated in Figure 13, the addition of APAM markedly expedites the sedimentation rate of waste mud. The moisture interface levels of the mud after 2 h, corresponding to APAM additions of 20 mL, 22 mL, 24 mL, and 26 mL, were recorded at 319 mL, 283 mL, 279 mL, and 282 mL, respectively. In comparison to the control group, these figures represent reductions in interface height at the 120 min mark by 101 mL, 137 mL, 141 mL, and 138 mL. The sedimentation rate of waste mud exhibits considerable variation with different APAM dosages, and it does not consistently escalate with increasing amounts of APAM. The sedimentation rate peaks when the APAM dosage reaches 24 mL. Beyond this point, further increments in APAM do not augment the sedimentation rate; rather, they lead to a decline. This phenomenon is attributed to the excessive adsorption of APAM molecules onto the surface of mud particles at higher dosages, which forms a spatial barrier and consequently impairs the flocculation process.

Figure 13.

Mud flocculation and sedimentation curves at different APAM dosages.

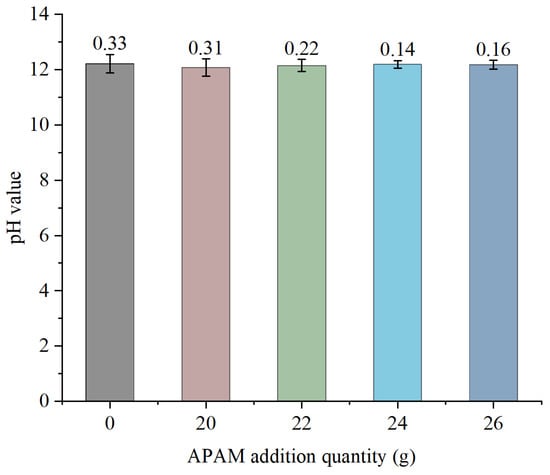

Figure 14 illustrates the pH levels of the supernatant in response to varying quantities of APAM. The data reveal that the incorporation of APAM has a negligible impact on the pH of the supernatant. This is attributable to APAM’s nature as a polymeric flocculant with a neutral aqueous solution, whose flocculation mechanism is predominantly governed by adsorption and bridging rather than chemical interactions with the waste mud.

Figure 14.

pH of the supernatants at different APAM dosages.

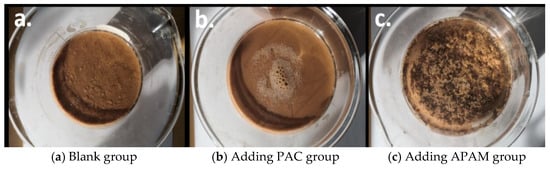

Subsequent to the flocculation and sedimentation processes of the untreated mud, mud treated with 3.5 g of PAC, and mud treated with 24 mL of APAM, the supernatant was decanted, and the surface morphology of the flocs was examined, as depicted in Figure 15. The observations indicate that the addition of 24 mL of APAM results in the most voluminous flocs, which exhibit a flocculent appearance, signifying that APAM effectively facilitates adsorption and bridging. Conversely, the floc volume is smallest following the addition of 3.5 g of PAC, even smaller than that of mud particles without any coagulant. This is primarily because waste mud without flocculant addition naturally undergoes flocculation, forming smaller floc particles. In contrast, PAC induces an electric neutralization reaction within the mud, which reduces the viscosity of the mud solution but does not significantly promote particle adsorption and bonding to form larger particles.

Figure 15.

Flocculation of waste mud.

- 3.

- Flocculation Test with Mixed Addition of PAC and APAM

As delineated in Table 3, with a fixed PAC dosage of 3.5 g, the pH level of the supernatant remains relatively stable as the APAM dosage escalates, while the sedimentation volume post-120 min exhibits an incremental trend. Notably, at an APAM dosage of 24 mL, the supernatant’s pH markedly declines with the augmentation of PAC dosage, and the sedimentation volume after 120 min surpasses that achieved with the sole addition of 24 mL APAM. The pH of the mud supernatant is predominantly governed by the PAC within the composite flocculant, and the flocculation efficacy of the composite flocculant surpasses that of the individual flocculant.

Table 3.

Results of flocculation tests using PAC + APAM composite flocculant.

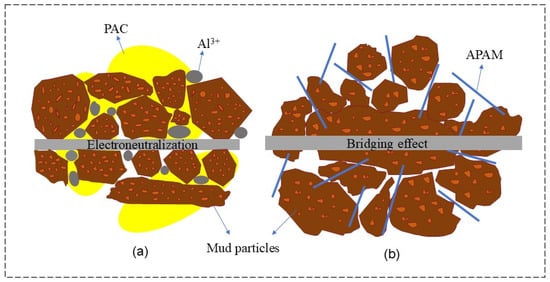

Under the condition that the supernatant pH of the waste mud adheres to the standard requisites, the optimal dosage of PAC+APAM is ascertained based on the minimal sedimentation volume at 120 min. In accordance with the flocculation test outcomes presented in Table 3, the introduction of 3.5 g PAC and 22 mL APAM to 500 mL of waste mud with an 85% moisture content yields the most effective flocculation. The synergy of PAC and APAM capitalizes on the strengths of both coagulants, markedly expediting the flocculation sedimentation rate and efficaciously diminishing the pH of the mud supernatant. PAC disrupts the colloidal suspension system of the mud via electrical neutralization, thereby reducing the viscosity of the waste mud and destabilizing it, which facilitates the coagulation and sedimentation of APAM, consequently enhancing the mud’s sedimentation rate.

3.2. Solidification Test

Upon the addition of coagulants, the waste mud can be segregated into supernatant and sediment via filtration. The supernatant is amenable to recycling or discharge into the sewage treatment system, whereas the sediment undergoes solidification treatment and is repurposed as roadbed filling material. This study employs the CG-T1 curing agent alongside Portland cement for solidification tests, aiming to investigate the impact of the curing agent dosage on the mechanical properties of the sediment and to determine the optimal quantity of curing agent required.

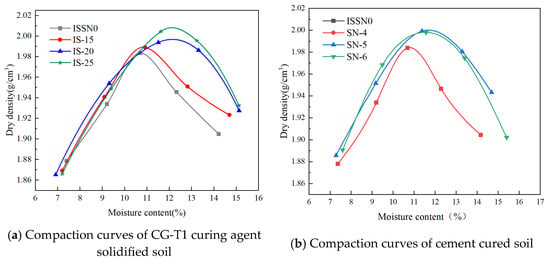

- Compaction Test

Table 4 shows the compaction test data of composite curing agent solidified sediment. The optimal moisture content of sediment solidified with different dosages of composite curing agent varies slightly, and the optimal moisture content is determined to be 11.6%.

Table 4.

CG-T1 cement solidified sediment compaction data.

As illustrated in Figure 16, the CG-T1 solidifying agent significantly influences the compaction characteristics of the sediment. The undisturbed sediment exhibits an optimal moisture content of 10.8%. However, upon the addition of the 0.02% CG-T1 solidifying agent, the optimal moisture content increases to 12.2%, representing a 1.4% rise. This indicates that the CG-T1 solidifying agent enhances the water retention capacity of the sediment, thereby altering its compaction properties.

Figure 16.

Results of compaction test.

- 2.

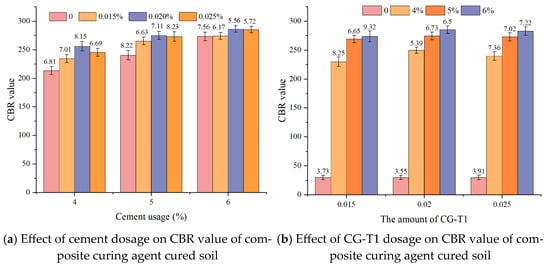

- CBR Test

This study undertakes CBR testing on sediment solidified with varying concentrations of stabilizer, with a particular focus on the impact of CG-T1 stabilizer and cement content on the CBR values of the treated sediment. The outcomes of these tests are meticulously detailed in Table 5.

Table 5.

CBR value of solidified soil.

Figure 17 illustrates the influence of cement content and CG-T1 content on the CBR of sediment solidified with a composite curing agent. A comparative analysis of the CBR values for sediment treated with varying amounts of solidifying agents reveals that the dosage of CG-T1 exerts a relatively minor impact on the CBR of the composite-solidified sediment. In contrast, the cement dosage significantly affects the CBR, with the value escalating rapidly as the cement content increases. Specifically, the CBR value soars to 275% when the cement dosage reaches 6%. The pinnacle CBR value achieved with the composite curing agent is 286%, markedly surpassing that of sediment solidified with cement alone. These CBR values of the solidified sediment are in full compliance with the stipulations for the subgrade layer of highway asphalt pavements as outlined in the “Design specification for highway asphalt pavement”(JTG D50-2017) [30].

Figure 17.

CBR value of composite curing agent solidified sediment.

- 3.

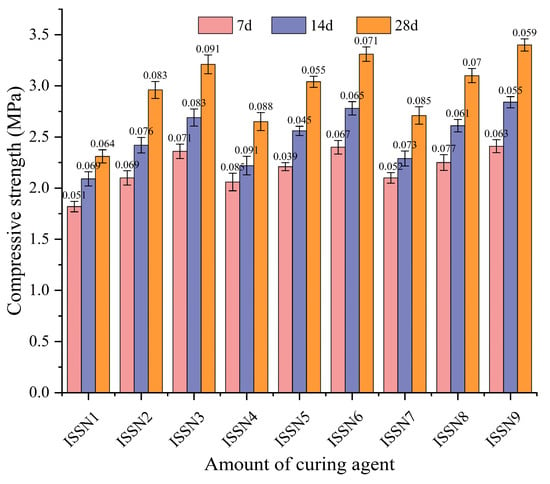

- UCS Test

Figure 18 and Table 6 present the UCS of the sediment solidified with a composite curing agent at various curing ages. As stipulated by the “Technical standard for application of soil curing agent” (CJJ/T 286-2018) [31], the UCS of cured soil in the subgrade layer with a pavement structure must not fall below 2.0 MPa after 7 days. The data reveal that among all the dosage formulations of the composite curing agent, ISSN4 and ISSN7 exhibit the lowest cement content while still satisfying the strength criteria. Notably, ISSN4 demonstrates a more economical use of the CG-T1 curing agent compared to ISSN7, achieving comparable strength with a reduced dosage, thereby offering a more cost-effective solution.

Figure 18.

UCS of solidified sediment.

Table 6.

UCS of solidified sediment.

4. Discussion

The efficient dehydration and solidification of waste mud from loess pile foundations, as demonstrated in this study, addresses critical challenges in construction waste management, particularly in environmentally sensitive regions like Northwest China. The experimental results highlight the synergistic effects of composite flocculants and curing agents, offering a dual solution to enhance dewatering efficiency and mechanical performance while ensuring environmental compliance. Below, the findings are contextualized within existing research, and their implications for sustainable engineering practices are discussed.

4.1. Flocculation Mechanisms and Optimization

The composite flocculation mechanism is shown in Figure 19. The composite flocculant (3.5 g PAC + 22 mL APAM per 500 mL mud) emerged as the optimal formulation for accelerating sedimentation and reducing the supernatant pH. PAC, an inorganic coagulant, primarily functions through charge neutralization, destabilizing the colloidal suspension by neutralizing negatively charged clay particles. This aligns with prior studies where aluminum-based coagulants effectively reduced colloidal stability in high-alkalinity mud systems. The observed pH reduction (from 11.2 to 8.65) can be attributed to PAC’s hydrolysis, releasing Al3+ ions that react with in the mud, releasing CO2 and lowering alkalinity. This mechanism ensures compliance with discharge standards (pH 6–9), mitigating risks of soil and water contamination.

Figure 19.

The flocculation mechanism of composite flocculants.

In contrast, APAM, an anionic polymer, enhanced sedimentation via adsorption and bridging effects. At a 24 mL dosage, APAM formed large flocs, maximizing settling velocity. However, exceeding this dosage led to reduced efficiency due to excessive polymer adsorption, creating steric hindrance between particles—a phenomenon well documented in organic flocculant studies. The combined use of PAC and APAM capitalized on their complementary roles: PAC destabilized the colloidal system, while APAM aggregated fine particles into settleable flocs.

4.2. Solidification Performance and Mechanical Enhancement

The solidification mechanism of the composite curing agent is shown in Figure 20. The composite curing agent (CG-T1+cement) significantly improved the mechanical properties of the sediment. CG-T1, an ionic agent, disrupted the double-layer structure of clay particles, reducing interparticle spacing and promoting aggregation. The cement further enhanced the strength by forming cementitious bonds, a process amplified by CG-T1’s ability to optimize moisture distribution. The CBR of the solidified sediment reached 286%, far exceeding the 275% value achieved with cement alone. This outperformance underscores the synergistic role of CG-T1 in reducing cement demand while achieving superior strength—a critical factor for cost-effective roadbed applications.

Figure 20.

Solidification mechanism of composite curing agent.

The UCS tests further validated the composite agent’s efficacy. The 7-day UCS values (2.10–2.42 MPa) met the CJJ/T 286-2018 standard (>2.0 MPa), ensuring suitability for subgrade layers. Notably, the optimal ratio (0.02% CG-T1 + 4% cement) achieved comparable strength to higher cement dosages (e.g., 6% cement), reducing material costs by 33%. Similar results were reported by Chen et al. [32], who studied the feasibility of using waste mud for roadbed filling.

4.3. Environmental and Economic Implications

This study emphasizes balancing environmental safety with economic feasibility. The PAC-APAM flocculant not only accelerated dewatering but also adjusted the pH to permissible levels, addressing a key regulatory hurdle in waste mud disposal. Traditional methods, such as mechanical dewatering or single-flocculant systems, often fail to meet pH standards or require additional neutralization steps, increasing operational complexity. By contrast, the composite flocculant streamlined the process, reducing treatment time and chemical consumption. As shown in Table 7, a comparison is provided between PAC/APAM flocculation and mechanical dewatering.

Table 7.

PAC/APAM flocculation vs. mechanical dewatering.

For solidification, the CG-T1–cement combination minimized cement usage while enhancing mechanical performance. Cement production is energy-intensive and contributes significantly to CO2 emissions; reducing its proportion in stabilization aligns with global sustainability goals. The comparison between CG-T1 combined with cement and pure cement curing is shown in Table 8. Furthermore, reusing treated mud as a roadbed filler reduces the reliance on virgin materials, promoting circular economy principles in construction—a strategy advocated by Zhang et al. [33], Wang et al. [34], Fang et al. [35], and Sun et al. [36] in similar geotechnical applications.

Table 8.

CG-T1+cement vs. pure cement solidification.

This study investigated the flocculation and dewatering performance of waste slurry using a commonly used inorganic flocculant (PAC) and organic flocculant (APAM). However, the experiment used limited types of flocculants. Since there are numerous flocculants available in the market, further research can be conducted on the effects of novel flocculants and the combined use of multiple flocculants on the dewatering performance of waste mud.

5. Conclusions

This study systematically investigated efficient dehydration and solidification techniques for waste mud derived from loess pile foundations during highway construction in Lanzhou, Northwest China. The experimental results demonstrated that the composite flocculant (3.5 g PAC + 22 mL APAM per 500 mL waste mud) significantly improved the dehydration efficiency of waste mud with an initial moisture content of 85%. The PAC component effectively reduced the pH of the supernatant from 11.2 to 8.65, ensuring compliance with discharge standards, while APAM accelerated sedimentation by forming large flocs through adsorption and bridging mechanisms. The synergistic effect of PAC and APAM addressed both the sedimentation rate and environmental compliance, offering a practical solution for on-site mud–water separation.

For solidification, the composite curing agent (CG-T1 + cement) exhibited superior performance in enhancing the mechanical properties of the sediment. The CG-T1 ionic agent disrupted the double-layer structure of particles, promoting aggregation, while cement provided binding strength. The CBR of the solidified sediment reached 286%, far exceeding the requirements for highway subgrade materials. UCS tests revealed that the 7-day UCS values (2.10–2.42 MPa) met the criteria specified in CJJ/T 286-2018. The optimal composite curing agent ratio (0.02% CG-T1 + 4% cement) balanced cost and performance, achieving a maximum dry density of 1.99 g/cm3 and optimal moisture content of 11.6%. These results confirm that the solidified sediment is suitable for reuse as a roadbed filler, aligning with sustainability goals.

Environmental and economic considerations were integral to this study. The composite flocculant minimized pH-related risks, and the dual-action curing agent reduced reliance on high cement dosages, lowering material costs. The treatment process not only mitigated environmental hazards (e.g., water and soil contamination) but also transformed waste mud into a reusable resource, addressing regional challenges in Northwest China.

In conclusion, the integration of PAC-APAM for dehydration and CG-T1–cement for solidification provides a technically viable, environmentally compliant, and economically feasible strategy for managing loess-derived waste mud. This approach supports the circular economy in construction by converting waste into subgrade materials, with implications for similar geotechnical applications in arid and semi-arid regions. Future research should focus on the long-term durability of solidified materials under varying environmental conditions and scalability of the proposed method to diverse geological settings.

Author Contributions

Validation, J.W.; Investigation, J.W.; Data curation, J.W., Z.H. and F.P.; Writing—original draft, J.W. and Z.H.; Writing—review & editing, J.W., Y.W., G.C. and J.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to express their gratitude to the Xin Jiang Key Lab of Building Structure and Earthquake Resistance, Xinjiang University, and the Tianchi Talent Plan of the Xinjiang Uygur Autonomous Region.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rengshausen, R.; Tauriainen, R.; Raedle, A. TBM and spoil treatment selection process -case history Crossrail C310 Thames Tunnel. GeoMech. Tun. 2014, 7, 45–54. [Google Scholar] [CrossRef]

- Guo, Z.W.; Lai, J.Q.; Zhang, K.N. Geosciences in Central South University: A state-of-theart review. J. Cent. S. Univ. 2020, 27, 975–996. [Google Scholar] [CrossRef]

- Mondal, K.; Ghosh, S.; Haque, S. A review on contamination, bioaccumulation and toxiceffect of cadmium, mercury and lead on freshwater fishes. Int. J. Zool. Stud. 2018, 3, 153–159. [Google Scholar]

- Cao, Y.; Xu, J.; Bian, X. Effect of Clogging on Large Strain Consolidation with Prefabricated Vertical Drains by Vacuum Pressure. KSCE J. Civ. Eng. 2019, 23, 4190–4200. [Google Scholar] [CrossRef]

- Xu, B.H.; He, N.; Jiang, Y.B. Experimental study on the clogging effect of dredged fill surrounding the PVD under vacuum preloading. Geotext. Geomembr. 2020, 48, 614–624. [Google Scholar] [CrossRef]

- Berilgen, S.A.; Bulut, B.T. Laboratory investigations for dewatering of golden horn dredged sludge with geotextile tubes. Mar Georesour Geotechnol. 2016, 34, 638–647. [Google Scholar] [CrossRef]

- Sun, Y.; Zheng, H.; Tan, M. Synthesis and characterization of composite flocculant PAFS–CPAM for the treatment of textile dye wastewater. J. Appl. Polym. Sci. 2014, 131, 40062. [Google Scholar] [CrossRef]

- Gonzalez-Perez, A.; Hägg, K.; Duteil, F. Optimizing NOM removal: Impact of calcium chloride. Sustainability 2021, 13, 6338. [Google Scholar] [CrossRef]

- Pulgar, F.; Ayala, L.; Jeldres, M. Lime/sodium carbonate treated seawater to improve flocculation and sedimentation of clay-based tailings. Polymers 2021, 13, 4108. [Google Scholar] [CrossRef]

- Li, S.; Kang, Y. Effect of PO43− on the polymerization of polyferric phosphatic sulfate and its flocculation characteristics for different simulated dye wastewater. Sep. Purif. Technol. 2021, 276, 119373. [Google Scholar] [CrossRef]

- Ma, J.Y.; Jiang, L.Y.; Fu, X. Flocculation property of composite flocculants PAC/CPAM for polluted landscape water pretreatment. Desalin Water Treat. 2018, 136, 212–225. [Google Scholar] [CrossRef]

- Yang, Z.; Li, H.; Yan, H. Evaluation of a novel chitosan-based flocculant withhigh flocculation performance, low toxicity and good floc properties. J. Hazard. Mater. 2014, 276, 480–488. [Google Scholar] [CrossRef]

- Abdollahi, Z.; Founchi, M.; Dadbin, S. Synthesis, characterization and comparison of PAM, cationic PDMC and P(AM-co-DMC) based on solution polymerization. J. Ind. Eng. Chem. 2011, 17, 580–586. [Google Scholar] [CrossRef]

- Chen, N.; Liu, W.; Huang, J. Preparation of octopus-like lignin-grafted cationic APAM flocculant and its application for water flocculation. Int. J. Biol. Macromol. 2020, 146, 9–17. [Google Scholar] [CrossRef]

- Aguilar, M.I.; Sáez, J.; Lloréns, M. Improvement of coagulation–flocculation process using anionic APAM as coagulant aid. Chemosphere 2005, 58, 47–56. [Google Scholar] [CrossRef]

- Zhang, F.J.; Kong, C.; Sun, X.Y. Study on preparation and properties of novel ternary flocculant for rapid separation of underground continuous wall waste mud. Pigm Resin Technol. 2020, 49, 421–429. [Google Scholar]

- She, W.; Du, Y.; Zhao, G.T. Effect of coarse fly ash on the performance of foamed and its application in high-speed railway roadbeds. Constr. Build. Mater. 2018, 170, 153–166. [Google Scholar] [CrossRef]

- Jiang, J.; Lu, Z.Y.; Niu, Y.H. Investigation of the properties of high-porosity cement foams based on ternary Portland cement-metakaolin-silica fume blends. Constr. Build. Mater. 2016, 107, 181–190. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Hatungimana, D.; Ramyar, K. Effect of fly ash and silica fume on hardened properties of foamed concrete. Constr. Build. Mater. 2019, 194, 1–11. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, S.; Yao, Z. Environmental aspects and pavement properties of red mud waste as the replacement of mineral filler in asphalt mixture. Constr. Build. Mater. 2018, 180, 605–613. [Google Scholar] [CrossRef]

- Ding, Z.; Liu, T.; Zhang, Y. The Curing and Strength Properties of Highly Moist Waste Mud from Slurry Shield Tunnel Construction. Appl. Sci. 2022, 12, 3762. [Google Scholar] [CrossRef]

- Jiang, L.N.; Zhen, L.; Wang, J. Research on Dewatering Characteristics of Waste Slurry from Pipe Jacking Construction. Materials 2022, 15, 2242. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Xiong, H.; Huang, J. Macro–Micro Properties of Remodeled Waste Slurry Under Freeze–Thaw Cycles. Materials 2025, 18, 178. [Google Scholar] [CrossRef]

- GB/T50123-2019; Standard for Geotechnical Engineering Test Methods. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China.

- Yang, X.N.; Yang, H.; Chen, Y. Experiment on the optimum conditions of coagulated deposition treatment for rainwater in the northwest Loess Plateau. J. Arid Land Resour. Environ. 2016, 30, 101–106. [Google Scholar]

- Yang, J.L.; Li, S.Y.; Di, H.G.; Liu, D.R.; Wang, X.Z.; Jian, Y. Experimental investigations on the physico-mechanical and microstructural properties of loess reinforced with anionic APAM. J. Constr. Build. Mater. 2023, 409, 134124. [Google Scholar] [CrossRef]

- JTG_3430-2020; Test Methods of Soils for Highway Engineering. Ministry of Communications of the People’s Republic of China: Beijing, China.

- GB 8978-1996; Integrated Wastewater Discharge Standard. Ministry of Environmental Protection of the People’s Republic of China: Beijing, China.

- GB/T 18920-2020; Water Quality of Urban Miscellaneous Water for Urban Wastewater Reuse. Ministry of Ecology and Environment of the People’s Republic of China: Beijing, China.

- JTG D50-2017; Design Specification for Highway Asphalt Pavement. Ministry of Transport of the People’s Republic of China: Beijing, China.

- CJJ/T 286-2018; Technical Standard for Application of Soil Curing Agent. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China.

- Chen, Y.H.; Zhang, W.L.; Zhao, L.Y.; Peng, Z.H. Field in-situ stabilization of bored pile mud: Engineering properties and application for pavement. Constr. Build. Mater. 2018, 165, 541–547. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Liu, J.; Jing, H.Z. Hydrothermal solidification of underground construction wastes into building materials: Waste slurry recycling, industrial application and evaluation. J. Cleaner Prod. 2023, 426, 139091.1–139091.13. [Google Scholar] [CrossRef]

- Wang, D.F.; Min, F.; Zhang, W.J. Recycling waste sand from slurry shield tunneling: A sustainable filter aid for waste slurry dehydration. J. Cleaner Prod. 2023, 383, 135387.1–135387.11. [Google Scholar] [CrossRef]

- Fang, Y.; Yao, Y.; Wang, J. Effective dewatering and resourceful utilization of high-viscosity waste slurry through magnetic flocculation. Constr. Build. Mater. 2024, 425, 136014. [Google Scholar] [CrossRef]

- Sun, X.; Chen, Z.; Guo, K. Geopolymeric flocculation-solidification of tail slurry of shield tunnelling spoil after sand separation. Constr. Build. Mater. 2023, 374, 130954. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).