Abstract

The pursuit of sustainable energy production through the conversion of agricultural waste into different bioenergy resources is of paramount importance given its potential to mitigate environmental impact while meeting energy demands. In this review, a comprehensive overview of the technologies for the biochemical and thermochemical conversion of agricultural waste into bioenergy is provided. A summary of the process of its conversion into different bioenergy products such as biogas, bio-oil, and biofuel is provided, in addition to the potential advantages and challenges faced using different biomass conversion technologies. The review highlights the potential of agricultural waste valorization to address the current energy demand while at the same time contributing to environmental benefits and greenhouse gas emission reductions. Moreover, this review highlights some significant gaps for improvement. These include the challenges in the pretreatment of agricultural waste biomass in optimizing the conversion rates and lowering the required energy consumption throughout the process while enhancing both the quantity and quality of the output. Some recommendations are proposed to address the identified challenges. These include the need for further studies for a thorough assessment to evaluate the efficacity and sustainability of agricultural waste valorization technologies. Assessment methods such as life cycle assessment (LCA), life cycle analysis (LCA), net energy ratio (NER) calculations, life cycle costing (LCC), as well as techno-economic assessment (TEA), are recommended, together with collaboration among governments, farmers, and researchers, as well as the integration of cutting-edge technologies to enhance various aspects of agricultural waste, optimizing the conversion process, cost efficiency, time management, and labor requirements, consequently boosting the conversion efficiency and product quality.

1. Introduction

The agricultural sector is one of the leading generators of massive amounts of waste, which has raised public concern and has threatened the sustainability of agricultural regimes. A report provided by the Food and Agriculture Organization (FAO) indicated that agriculture produces over 140 billion metric tons of biomass every year, with over 2 tons per day in rural areas [1,2]. Of the huge quantities of annual global generation of agricultural residues, cereal crops are a major contributor at 66%, where sugarcane stems and leaves are the second largest contributors [3]. In Europe, about 23 Mt of dry biomass per year is produced as residual straw from cereals. In contrast, emerging economies like India and China generate significantly larger amounts, with around 368 Mt and 649 Mt of straw residue per year, respectively. It is noteworthy that major global crops such as wheat, maize, rice, soybean, barley, rapeseed, sugarcane, and sugar beet, particularly in regions with significant biomass potential (Europe, the United States of America, China, Canada, India, Argentina, and Brazil), collectively yield nearly 3.3 Gt of residue (fresh weight) annually [4,5]. In urban areas, 51% of the overall global municipal waste is food residues, with 88 million tons generated in Europe each year [6]. These residues are produced during food processing and preparation, as well as due to inadequate handling, storage, and factors like the passing of shelf life, leading to additional losses [7].

The management of agricultural waste poses considerable concerns, not only in agriculture but also in other domains, such as ecosystem preservation and sustainability. This waste can be categorized according to different sources, such as field waste, consisting of various parts of crops such as leaves, stems, stalks, husks, and roots; industrial waste, generated during the processing of crop or animal products, including byproducts from the food industry; livestock waste, consisting of materials like bedding/litter, animal carcasses, and wastewater from animal sanitation; as well as food waste, consisting of edible portions of food that are discarded at various stages of the food supply chain, among others [8]. The disposal of agricultural residues, byproducts, and organic waste presents significant environmental, health, and economic issues. Different studies have shown that underutilized and/or untreated agricultural waste is often disposed of by burning, dumping, or landfilling it [9]. These practices significantly contribute to greenhouse gas emissions (GHGs), the production of undesirable gaseous byproducts, soil and waterway pollution, endangering wildlife that ingests it or becomes entangled in it, and the outbreak of diseases, and these consequences pose a threat to both the environment and animal and human health through various pathways [10]. However, recent developments have highlighted the immense potential for its valorization as a sustainable solution. The concept of agricultural waste valorization involves the process of its reuse and recycling into valuable products or energy rather than its disposal as a useless byproduct. The goal is to reduce waste generation, minimize environmental impact, and create economic opportunities by turning agricultural waste into valuable resources. By valorizing agricultural waste, farmers and agricultural industries can contribute to sustainable practices, resource efficiency, and the circular economy [11]. Various approaches and technologies are now in place to recover valuable resources from this waste, including organic matter, energy, important bioactive compounds, and nutrients, reducing its negative effects on the whole ecosystem [8,10,12]. Agricultural waste contains a high amount of important bioactive compounds, including proteins, lignin, polyphenols, fibers, and carbohydrates, which can be used as raw materials for various products, such as soil nutrients, bio-pesticides, organic matter [13], energy [14], bio-based oil [15], plastics [16], and leather, paper, and board [17], as well as other agricultural, food, and pharmaceutical goods [18].

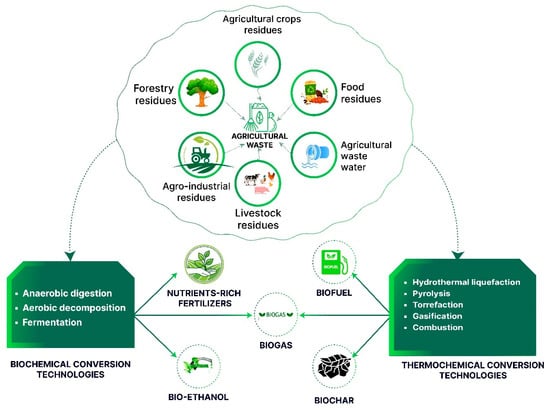

Despite the recognition that each agricultural waste valorization technology possesses unique attributes and utility, this review article emphasizes the overarching importance of the bio-refinery concept within an environmental context, focusing on mitigating the adverse effects of agricultural waste. This review aims to provide a comprehensive overview of environmentally friendly approaches to valorizing agricultural waste, considering bioenergy conversion and its applications in the agri–energy–environment sector. This highlights the interconnection between agriculture, energy, and environmental sustainability and the potential of the conversion of agricultural waste into bio-resources, contributing to a more sustainable future. (See Figure 1). Therefore, technologies for the biochemical and thermochemical conversion of agricultural waste into bioenergy are described. A summary of the process of conversion into different bioenergy products such as biogas, bio-oil, and biofuel is provided, in addition to the potential advantages of and challenges in different biomass conversion technologies. The review also highlights the potential of agricultural waste valorization to address the current energy demand while at the same time contributing to environmental benefits and greenhouse gas emission reductions and suggests some significant gaps for improvement for a more sustainable future of bioenergy derived from agricultural waste.

Figure 1.

Biochemical and thermochemical valorization of agricultural waste.

Some other reviews are conducted on different conversion strategies for agricultural biomass for energy production. Different conversion processes and byproducts and their various applications are described. However, in addition to a comprehensive overview of and comparative and critical approaches to thermochemical and biochemical conversion technologies and their resulting energy products, this review provides an insight into the less commonly addressed suggestions for the optimization of conversion technologies through the integration of cutting-edge technologies, as well as a sustainability assessment of these technologies.

By embracing innovative waste valorization strategies, we can unlock the untapped potential of agricultural waste, minimize impacts on the environment, optimize resource utilization, and foster a more sustainable and resilient agricultural sector.

2. Agricultural Waste and the Circular Economy

The world’s population growth has heightened our awareness of the limitations of the available resources, prompting a focus on their effective utilization [1]. Agricultural waste and the concept of the circular economy are interconnected, both being central to promoting sustainability within the agricultural sector. The circular economy represents an economic model aimed at minimizing waste and maximizing resource utilization through the promotion of recycling, reuse, and regeneration [2]. This system ensures that the waste from one process becomes a resource for others, eliminating the concept of waste itself [3].

Implementing a model based on the circular economy makes it possible to measure the degree of circularity in waste management and highlights the sustainable key of balancing the economic, environmental, and social aspects [4].

The historical perspective of applying circular economy principles to agricultural waste management dates back to an early awareness of resource limitations and the need for effective resource utilization. Over the years, the concept has evolved from a rudimentary understanding to a sophisticated approach aimed at promoting sustainability within the agricultural sector [5]. In the early stages, there was a prevalent focus on waste reduction and basic recycling efforts. As environmental consciousness grew globally, the agricultural industry witnessed a paradigm shift towards a more holistic circular economy model [19].

The evolution of circular economy practices in agricultural waste management can be traced across various stages of development. Initially, there was an emphasis on minimizing waste and promoting recycling and reuse within local communities [20]. As societies began to recognize the interconnectedness of environmental, economic, and social aspects, the circular economy gained prominence as an integral approach to addressing these challenges. The concept gradually expanded to encompass not only waste reduction but also regeneration and responsible resource utilization [7]. Throughout history, agricultural practices have been deeply rooted in the cyclical patterns of nature, reflecting an unintentional alignment with circular economy principles. The shift towards a more intentional adoption of these principles gained momentum as scientific understanding advanced and policymakers recognized the potential of sustainable agricultural practices [21]. Historical practices of communities utilizing crop residues for livestock feed or using organic waste as fertilizers provide glimpses into early circular economy practices within agriculture [12].

In recent decades, global initiatives and policies have played a pivotal role in shaping the application of circular economy principles to agricultural waste management. Various countries have implemented regulations, incentives, and awareness campaigns to encourage the adoption of sustainable practices. Case studies from regions around the world showcase the successful integration of circular economy principles into agricultural waste management systems, providing valuable insights and inspiration for further developments [22]. Emerging technologies have become key players in optimizing agricultural waste management within the circular economy framework. Innovations such as advanced composting techniques, anaerobic digestion, and bioenergy production from agricultural residues contribute to efficient resource utilization. These technologies not only reduce the environmental impact of waste but also create economic opportunities, aligning with the overarching goals of circularity [23]. Stakeholder engagement has proven essential in the successful implementation of circular economy practices in agricultural waste management. Collaboration between farmers, policymakers, industries, and local communities has facilitated the development of sustainable value chains and circular business models. The involvement of diverse stakeholders ensures that the circular economy approach is tailored to specific regional contexts, enhancing its effectiveness and fostering a sense of shared responsibility [24]

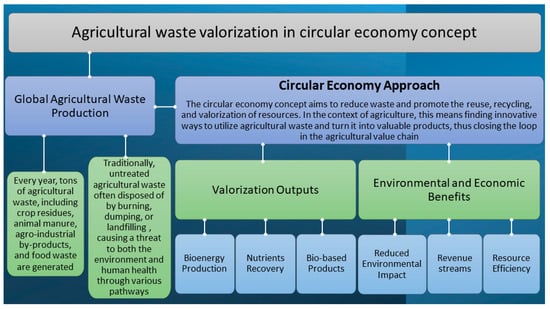

Looking ahead, the future of circular economy practices in agricultural waste management holds promising trends and prospects [25]. The integration of circular economy principles into agricultural waste management brings several benefits, as shown in Figure 2, including reduced environmental pollution, improved resource efficiency, economic opportunities through the creation of new industries or value chains, and enhanced sustainability in the agricultural sector [26]. As societies become increasingly aware of the interconnectedness of environmental, economic, and social well-being, the evolution of circular economy practices in agricultural waste management is poised to play a pivotal role in shaping the future of sustainable agriculture [21].

Figure 2.

Agricultural waste and circular economy.

3. Recycling and Resource Recovery

Agricultural waste often contains valuable materials that can be recycled or recovered using different technologies after separation, sorting, and mechanical processing. These technologies help extract useful components (like fibers, oils, nutrients, and proteins) for further utilization in various sectors, such as industrial production, insect and animal feed, biosorbents, soil amendment, plant growth, and others [27].

Recovery of energy: Different studies have demonstrated that agricultural waste in the form of residues from crop production can be processed through rapid pyrolysis and rapid cooling, converting them into bio-oil for industrial production, reducing the cost of oil for industrial and other uses [28,29]. Animal manure and straw can undergo anaerobic digestion, converting organic matter into biogas and methane. This biogas can be used as engine fuel, reducing engine fuel costs and the environmental problems associated with fossil fuel use. This also contributes to achieving fossil energy substitution. The biogas produces slurry as a secondary product, which is an environmentally friendly organic fertilizer [30,31].

Recycling and nutrient recovery: Refs. [32,33] have proven that woody biomass can be treated with hydrothermal carbonization technology to produce biochar, which can be used for soil improvement, increasing the area of usable soil In the United Kingdom, manufacturing or retail food waste and agricultural co-products can be converted into dry and wet insect and animal (pig) feed through anaerobic digestion and composting, reducing land use and providing feed to support a significant portion of protein production. This also contributes to carbon dioxide reduction and improves farmers’ profitability and meat quality [34]. Agricultural waste’s application to the soil, such as crop straw, bran, orange, mandarin, and banana peels, enhances the soil’s fertility, reduces carbon dioxide and nitrous oxide emissions, and promotes the management of peel-based agricultural waste [35]. This results in lower nitrous oxide emissions compared to the use of ammonium nitrate [36]. In Vietnam, various types of agricultural waste, including plant debris, food waste, plant waste, and animal waste, can be utilized for biochar production through physical steam-assisted reforming, improving plant productivity, agricultural profitability, and reducing airborne GHGs, fluid retention, and the soil’s acidity [37]. Furthermore, different countries use walnut shells and apricot kernels to produce biosorbents and liquid fertilizers through an aqueous ammonia soaking biomass processing technique, where biosorbents show a high exchange capacity and cost savings, and the byproduct liquid fertilizer enhances wheat’s and other crops’ growth intensity [38].

4. Agricultural Waste and Bioenergy Conversion

As the world’s population has risen and more nations have industrialized, energy demand has risen gradually in recent decades [39]. The primary source for supplying this rising energy demand seems to have been crude oil [40]. As a substitute for the prevalent usage of fossil fuels and oil to provide electricity, heat, and vehicle fuel, biofuels have recently gained popularity as an alternative [41].

A clean and sustainable energy supply consisting of biomass is known as bioenergy. It includes all flammable organic materials of biological origin as a consequence of photosynthesis [42]. Biomass is the most important and adaptable source of energy on the planet since it retains solar energy in chemical form [43]. Part of the solar energy that reaches the Earth’s atmosphere is absorbed by plants through the process of photosynthesis [44]. The maximum conversion efficiency of solar energy in plants has been reported to be between 5 and 6%, which can reach up to 0.5–1% more using the best methods [45,46]. On the other hand, the amount of energy that is annually generated by photosynthesis is several times higher than the world’s normal energy demand and about 200 times the world’s normal food energy consumption [47]. This biomass, about 90% of which is stored in trees, is equivalent to fossil fuel reserves that can be extracted and registered [48]. In general, the biomass resources that are suitable for energy production include a wide range of materials, which are mainly divided into five groups; (1) wood and forest waste, (2) agricultural, horticultural, and food waste, (3) livestock waste, (4) urban sewage, and (5) industrial organic waste [49,50,51].

Agricultural wastes are abundant in energy and include substantial quantities of organic materials such as cellulose and lignin [52]. Considering a number of challenges, including insufficient energy resources, recent fluctuations in oil prices, and global warming, as well as air pollution, that exacerbate the effect of greenhouse gases, investigation into the advancement of waste-into-energy techniques is a viable and long-term approach [53,54]. Agricultural residues are used in the production of the second generation of biofuel [55]. Due to the low cost of fossil fuels, biomass alteration methods for power generation were overlooked in the past [56]. However, these technologies have been given another look in light of the rising energy consumption and environmental issues connected to the use of fossil fuels to produce energy [57]. In static processes such as boilers, turbines, etc., as well as electricity-generating engines, the bio-oil created through pyrolysis can be utilized in place of diesel [58]. Moreover, it can be transformed into vehicle fuel by hydro-processing it with hydrogen and a catalyst [59]. Bio-oil may be utilized to obtain a variety of compounds, including resins and fertilizers [51]. The generated gas can also be utilized to generate electricity, heat, or a combination of these in a gas turbine, engine, or fuel cell [60]. Moreover, this gas can produce a large variety of compounds. It is possible to create liquid fuels due to the high calorific value provided by gasification when oxygen is used as the gasification agent [54]. The primary product of these carbonization and slow pyrolysis processes is charcoal [61]. According to Kadam and Panwar (2017), anaerobic digestion plants in the USA have the capacity to produce 13 million kilowatt hours annually [62]. Biogas is used extensively in nations like China and India [63,64], and important industrial biogas projects have begun in Scandinavian nations [65,66,67]. The methane in biogas can be extracted at the same levels as natural gas through the process of biogas upgrading, which may be injected into the residential supply pipeline system [66]. Additionally, biogas can be utilized as fuel for vehicles, and filling stations with 100% methane or methane combined with natural gas are readily available in many nations. Some nations have built automated scrubbing-based biogas purification facilities, and bottled biogas is frequently used to fuel automobiles [65,68].

5. Biochemical Conversion of Bio-Resources

The type and amount of organic matter in waste is a determining factor in choosing the conversion process, so with an increase in the amount of organic matter, the tendency to perform biological processes will increase [69]. The two main processes that occur in all biological processes are as follows: waste materials containing metabolizable energy + microorganisms → final product + more microorganisms [70]. Fermentation and anaerobic digestion are the two primary mechanisms that are utilized in this conversion. Table 1 highlights a brief overview of biochemical conversion technologies.

5.1. Anaerobic Digestion

Anaerobic digestion is a process where microbes decompose and convert organic waste into biogas, CH4, CO2, H2, and H2S, as well as nutrient-rich digestate, in the absence of oxygen [71].

Anaerobic digestion involves four stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis.

- Hydrolysis: Complex molecules in agricultural waste are broken down into simple monomers, a step that is driven by hydrolytic bacteria and enzymes, converting insoluble polymers into soluble derivatives [72].

- Acidogenesis: Acidogenic microorganisms convert hydrolytic products into volatile fatty acids (VFAs), such as acetic acid, propionic acid, butyric acid, ethanol, and lactate. Lower pH conditions favor VFA production [73].

- Acetogenesis: Acidogenesis products, particularly acetates and organic acids, are converted into hydrogen gas through dehydrogenation reactions. This hydrogen serves as a substrate for methanogenic microorganisms [74].

- Methanogenesis: Methane-producing bacteria (acetophilic, hydrogenophilic, etc.) convert intermediates into methane, carbon dioxide, and acetic acid [75].

Through the processes of anaerobic digestion, organic material is directly transformed into biogas, and methane and carbon dioxide makes up the majority of biogas’ composition, with trace amounts of many other gases, such as hydrogen sulfide. Within anaerobic environments, bacteria break down biomass into gas that has about a 20–40% energy output [76]. Today, anaerobic digestion technology is also used commercially, and it is widely used to process organic wastes with a high moisture content (80–90%) [59]. The generated biogas can be used as is in spark ignition gas engines, and it may be further improved by CO2 removal [77]. The productivity of converting biomass into power when applying biogas as a fuel for spark ignition gas engines is estimated to be between 10 and 16% [78].

Anaerobic digestion technology stands out as the preferable choice for promoting renewable energy over alternative technologies due to its independence from oxygen, lower nutrient demands, use of harmless methods for energy generation, and the opportunity for agricultural reuse of the residual biomass [79,80]. However, despite its advantages, it also presents drawbacks, such as challenges in biogas storage and the frequent occurrence of a substandard biogas quality, containing costly-to-remove hydrogen sulfide (H2S) [81].

5.2. Aerobic Decomposition

Composting is the aerobic decomposition of complex waste organic matter by microorganisms into simpler molecular chains, which further break down to form soil humus (compost + humic acid + fulvic acid + humins + CO2 + H2O + NO3− + SO42− + heat). In the degradation phase, simpler organic matter is broken down by aerobic microorganisms such as bacteria, fungi, algae, and protozoans over a period of a few months, depending on the materials’ composition and the environment. This thermophilic phase requires high temperatures and full aeration. It should be noted that during this phase, phytotoxins are released during decomposition. In the maturation phase, most of the microorganisms die due to a lack of food, and the temperature drops. During this mesophilic phase, some microorganisms such as actinomyces appear and break down the compost material from the decomposition phase into finer particles. Invertebrates like earthworms, ticks, and centipedes further contribute to the disintegration through chemical and biological transformations, a process called humification. These transformations are supported by the oxidative polymerization of the phenolic compounds acquired from the degradation of organic matter in the first phase [82]. Agricultural waste composting results in nutrient-rich compost and compost tea, organic fertilizers used in soil amendment, reducing the need for chemical fertilizers [14].

Although aerobic decomposition generates heat as a byproduct of microbial activity, it is typically not harnessed as a primary energy source. However, it is one of the most important approaches to agricultural waste valorization and soil enhancement, improving the soil structure, water retention, and nutrient content [83]. It offers numerous advantages, including the reduction of organic waste, the elimination of pathogens, and the conversion of waste into stable, nutrient-rich soil amendment. Nevertheless, the excessive emissions of greenhouse gases (GHGs) such as N2O, CH4, and CO2 during the composting processes diminishes its agricultural benefits and adds to environmental pollution [84]. In short, aerobic decomposition is a valuable method for reducing organic waste, but it necessitates strict adherence to standards throughout the process to ensure high-quality products and prevent any potential harm.

5.3. Fermentation

Fermentation is an anaerobic process involving using microorganisms to convert food and agricultural waste biomolecules into alcohol [85]. Food and agricultural waste contain abundant sugars in both soluble and insoluble forms. Soluble sugars can be readily used for fermentation to produce ethanol and other products. However, complex insoluble sugars (lignocellulosic structures: cellulose, hemicellulose, starch, and protein) require hydrolysis and then fermentation to reduce them and produce biofuels. Various pretreatment methods, such as alkali, acid, thermal, microwave, ultrasonic, or enzymatic hydrolysis, are used to break down the complex compounds in biomass or waste materials. Among others, enzymatic hydrolysis, or saccharification, is commonly employed to produce ethanol from food and agriculture waste, and saccharified biomass is fermented with microorganisms capable of cellulolytic activity and tolerance to hydrolysate inhibitors and high temperatures [86,87].

Nowadays, ethanol is produced from sugar plants and starch crops at a big scale and economically in a number of nations [88]. Using this method, after milling the biomass, enzymes change the starch into sugar, which yeasts then turn into ethanol [89]. Distillation is the next process that requires energy because it produces roughly 450 litters of ethanol for every ton of dry grain [90]. Powder from sugar cane can also be used as gasification or steam boiler fuel [91]. Because lignocellulose biomass (such as wood and grass) contains longer polysaccharide molecular chains, it requires acid or enzymatic breakdown before the resulting sugar is fermented to produce ethanol [90].

According to the study by [92], fermentation encounters the following challenges:

- Difficulties in breaking down lignocellulosic biomass into usable components, such as sugars and lignin.

- The requirement for energy-intensive pretreatment procedures to extract individual components from complex biomass.

- A considerable portion of the expense involved in processing lignocellulosic biomass for energy generation arises from the pretreatment phase, which can exceed 40% of the total cost.

To address these challenges, considerable efforts have been made over the past decade, including the utilization of specialized microorganisms or enzymes, optimization of the fermentation conditions, the co-cultivation of different microorganisms, and genetic modification of the microorganisms. However, despite these advancements, there still exist notable gaps between novel discoveries and their practical application [93,94,95].

Table 1.

Brief overview of biochemical conversion technologies (adapted from [96]).

Table 1.

Brief overview of biochemical conversion technologies (adapted from [96]).

| Technology | Biomass Type | Product | Advantages | Disadvantages | Source |

|---|---|---|---|---|---|

| Anaerobic digestion | Sewage sludge, livestock manure | Methane, CO2, digestate | Economic costs and the safe disposal of digestate | Complex products require additional processing to become refined products; storage and processing problems | [97,98,99] |

| Aerobic decomposition | Organic waste | Heat | Minimizes organic waste quantity and kills microorganisms | Causes secondary environmental pollution | [84,100] |

| Fermentation | Microalgae biomass | Alcohol | Lower cost, high ethanol yield, and short processing time | Cannot use commonly used yeasts, recombinant microorganism instability, and techno-economic limitations | [101,102] |

6. Thermochemical Conversion of Bio-Resources

Biomass is converted using thermochemical methods into fuels with increased heating values. The main thermochemical conversion processes include liquefaction, gasification, pyrolysis, and direct combustion [103]. The stored energy in biomass can either be easily transferred as heat by combustion or it can be turned into a solid, liquid, or gas through pyrolysis, liquefaction, or gasification for a variety of uses [104]. This makes it more commercially attractive regarding its enhanced effectiveness, selectivity in product generation, and higher conversion rate and the availability of diverse markets for its byproducts [105]. The biggest challenge facing thermochemical technologies lies in the need to work under high-temperature and high-pressure conditions, raising the operational cost and raising the need for advanced research to make it more cost-effective [96,106]. Ref. [96] summarized the advantages and disadvantages of thermochemical conversion technologies, as shown in Table 2.

6.1. Pyrolysis

Biomass pyrolysis is generally classified as a thermal conversion process. Pyrolysis can convert biomass into solid, liquid, and gas products in the absence of oxygen at atmospheric pressure and within the temperature range of 300 to 700 °C [107,108,109]. Pyrolysis consists of three distinct output phases with various chemical reactions of the raw components. The first stage, known as pre-decomposition, occurs between 120 and 200 °C, resulting in a modest weight loss. During this stage, certain intrinsic processes, such as the breaking of carbon bonds and the formation of carbonyl groups, occur, leading to the release of a small amount of H2O [110,111]. The second phase is the principal pyrolysis process, during which solids decompose and the primary biomass transmitted loses a significant amount of weight [112,113]. The continual release of carbon during the final stage is brought about by additional C-O and C-H bond breaks [114].

The chemical composition of the feedstock and the pyrolysis conditions have a major effect on the amount and effectiveness of the biomass pyrolysis products [115,116]. For instance, once the temperature is below 450 °C, the principal product is biochar, and when it is between 450 and 800 °C, the main product is bio-oil [109]. Gases arise at temperatures higher than 800 °C [117].

The process of pyrolysis can be classified into three subtypes: fast pyrolysis, slow pyrolysis, and flash pyrolysis.

6.1.1. Fast Pyrolysis

During fast pyrolysis, biomass is subjected to high temperatures (400–900 °C) for a very brief duration, typically less than 10 s [118]. Depending on the source material, fast pyrolysis procedures can produce around 60–75% in weight of liquid bio-oil, 15–25% in weight of solid coal, and 10–20% in weight of unsteady gases [119]. In comparison to slow pyrolysis, the reaction temperature is around 100 °C higher (500 vs. 400 °C).

Fast pyrolysis stands as a well-established technological process. Unfortunately, according to the study [120], the resulting bio-oil could potentially alter the properties derived from the inherent characteristics of the original feedstock, rendering it a less admirable alternative for fuel. Some studies on optimizing fast pyrolysis are underway, even though a considerable time period is likely to be necessitated before widespread commercial implementation is achieved [121].

6.1.2. Slow Pyrolysis

Slow pyrolysis, conducted at relatively lower reaction temperatures (300–700 °C) and extended residence times (over 30 min), is widely employed for high-yield biochar production, typically using traditional coal-fired furnaces [61]. Equal amounts of solid, liquid, and gas products can be yielded during slow pyrolysis. Catalytic effects are observed with an increasing temperature [122].

Combining all of the aforementioned points, slow pyrolysis can be used to achieve a higher amount of char at low temperatures and low heating rates [123]. If a liquid product is desired, it is important to combine a moderate temperature, a limited gas residence time, and a high heating rate.

It is worth mentioning that slow pyrolysis holds the advantage of producing notable environmentally friendly biochar with less CO2, but it also holds some disadvantages, including a high operational cost and limited scalability [96,124].

6.1.3. Flash Pyrolysis

This method, with a high efficiency of up to 70% and requiring only minimal initial investment, proves to be cost-effective on a small-scale basis [125]. To enhance the production of liquids for use as fuel, many flash pyrolysis methods have been recently introduced [126,127]. Processed crude oil can be utilized to provide power or heat. The flash pyrolysis process typically operates between 900 and 1000 °C [118]. When the cost of harvesting biomass waste is high, for example, for wood residues, the processing unit must be as close as possible to the biomass source. A gas with a moderate calorific value is produced, together with minor amounts of activated carbon being produced, both of which can be used as good-quality fuel [126]. However, the major challenge lies in the formation of pyrolytic water (from the thermal decomposition of organic matter at a high temperature), which is a disadvantage for bio-oil production [128,129].

6.2. Torrefaction

Torrefaction is a potential pretreatment method for reducing the humidity of and extracting low-weight organic volatiles from biomass, resulting in solid fuel. It operates at relatively low temperatures of 200–300 °C, with reaction periods of 15–60 min [130]. It produces a high calorific value and a greater grind ability, so it can be transported and stored outdoors without weather protection like coal [131]. Similar to pyrolysis, torrefaction also can result in the production of biochar, bio-oil, and biogas, with biochar serving as the primary end product [132]. Water is the most prevalent component of bio-oil, which also contains other ingredients, such as acids, phenols, and other compounds [133]. Throughout torrefaction, a minor quantity of biogas, primarily CO2, is formed, along with CH4 and other gases [134]. Torrefaction produces biogas that can be burned to provide heat for cracking, but it is not useful in engineering fields because of its poor heating value [135]. Torrefaction is implemented because some biomass has a high oxygen and moisture content, which limits the processes of gasification, combustion, pyrolysis, liquefaction, and iron formation [136]. As a result, this pretreatment approach can lower the oxygen and water content of the biomass while also increasing its uniformity, energy content, mill ability, and resilience to biodegradation [132].

Despite the considerable advantages offered by torrefaction, its full commercialization hinges upon resolving its economic and technical challenges. Furthermore, our scientific understanding of this process remains incomplete, necessitating further investigation into the effects of the reaction conditions [137].

6.3. Co-Combustion

Co-combustion involves burning multiple fuels together to generate power, also referred to as co-firing or co-utilization. When biomass is co-combusted, it serves as a substitute for fossil fuels, leading to a net reduction in CO2 emissions. Co-combustion of biomass and coal has lately gained relevance. This can be carried out directly by burning biomass and coal or indirectly by gasifying biomass first to provide clean fuel gas and then combusting it with coal in production boilers [138,139]. In comparison to the other thermo-chemical operations, it is an ideal method for achieving efficiency in biomass-into-energy systems for the production of power and very dramatically lowering GHG emissions [140].

Combined combustion is the biomass-based energy source that is most cost-effective because it only requires small modifications to the primary coal-fired power plants [141]. A co-combustion coal/biomass energy plant’s net power output can range from 36% to 44%, determined by its equipment, size, quality, and biomass content. Although co-combustion of 20% (on an energy basis) is already practical and co-combustion of more than 50% is technically possible, the typical biomass portion in use today is less than 5% and hardly ever rises above 10% regularly. Lower GHG emissions are indicated by a high biomass percentage. In general, 10% biomass co-combustion in coal power plants is predicted to lower CO2 emissions from 45 million to 450 million tons per year by 2035. High biomass shares, however, provide a number of technical challenges, such as the ongoing availability of biomass and potential slagging, fouling, and corrosion difficulties [142].

6.4. Hydrothermal Liquefaction (HTL)

Liquefaction is the thermochemical conversion of biomass into liquid fuel in a pressurized environment at a high temperature for less than 60 min, which breaks the polymer structure into components [143]. It is also known as hydrothermal conversion because water plays a significant role in this thermochemical conversion. The process is comparable to pyrolysis since water reacts and catalyzes at high temperatures [144]. In particular, direct liquefaction requires a lower reaction temperature (between 250 and 380 °C) but a higher pressure than pyrolysis (20–5 MPa for liquefaction versus 0.1–0.5 MPa for thermal decomposition) and also requires a longer residence time (5–30 min) [145,146]. Additionally, dewatering the feedstock is essential for pyrolysis but not for direct liquefaction. Furthermore, whereas catalysts are not crucial to pyrolysis, they are always required for liquefaction. Given that the liquefaction process requires more sophisticated and expensive engines and fuel supply systems than pyrolysis, it is more difficult to implement [147]. The key benefits of the liquefaction process over pyrolysis are a higher energy efficiency, a lower working temperature and greater efficiency, and lower oxygen needs (12–14%) [144,145]. Liquefaction is divided into three main stages, including polymer breakage, decomposition, and division. Biomass is often polymerized and reduced into small monomers which are extremely volatile. As a result, polymerization produces bio-oil and solid molecules [148].

Hydrothermal liquefaction offers several advantages over alternative thermochemical approaches. It eliminates the necessity for prior thermal drying, thereby offering cost-effective processing of wet materials. HTL employs pressurized water as both a reactant and a reaction medium, exhibiting versatility and environmental friendliness [149]. Additionally, bio-oil derived from HTL demonstrates superior quality and yield, characterized by reduced water and oxygen contents. However, the utilization of high pressure in this process may lead to the requirement for costly industrial-scale equipment [150].

6.5. Direct Combustion

The most popular method for converting biomass is direct combustion, which involves three phases: drying, volume reduction, and gas combustion. During combustion, over 70% of the total heat is produced by the burning of volatile gases [151]. This process, also known as biomass burning, is the simplest thermochemical conversion process when conducted in the presence of air [152]. The volatile components of lignocellulosic biomass, including carbon, hydrogen, oxygen, sulfur, and nitrogen, react with the oxygen in the air during combustion to produce heat [153]. The primary byproducts of the direct combustion of lignocellulosic biomass are heat and power or a combination of both [154]. Direct combustion is by far the most used technique for transforming biomass into useful thermal energy, and it accounts for about 90% of the total energy produced from biomass [142].

Combustion is a very dependable, well-known, and commercially available technique that is cost-effective. However, biomass often has a high oxygen concentration and moisture level, with its high humidity being a significant drawback. Despite the combustion being exothermic, the water evaporation process requires a significant amount of energy [152]. The particle size and characteristics of the raw materials, temperature, and combustion environment are the key determinants of biomass combustion [151]. Moreover, from an environmental standpoint, this operation is challenging due to significant emissions of CO, NOx, suspended particles, and other pollutants, as well as the transport of ash [154].

6.6. Biomass Gasification

Another form of thermochemical conversion method that can be considered effective and safe for the environment is gasification, which can be seen as a particular type of pyrolysis that uses higher temperatures to produce more gas [155]. Generally speaking, gasification is the process of converting biomass into flammable carbonaceous gases (like CO2, CO, C2H4, H2, and CH4) and other impurities (like nitrogen, sulfur, alkaline compounds, and soot) at specific heating rates while being exposed to partial oxygen (typically 35% of O2 for complete burning) or other proper oxidants, such as steam and CO2 [156]. Air gasification results in a product with a low to moderate heat value of 4–7 MJ Nm3, while gasification with oxygen or steam results in a product with a heat value of 14–10 MJ Nm3 [157]. When steam is used, more hydrogen is produced from the methane conversion reaction, resulting in a product with a higher calorific value [158]. However, steam gasification requires a higher temperature to evaporate the water, which makes it a more expensive alternative [159]. Therefore, using an air/steam mixture with a variable input ratio for better exploitation is one of the advantages of any other fluidizing gas [160]. The whole process is completed in the temperature range of 300–800 °C according to a series of chemical reactions, which is why it undergoes thermochemical conversion [161]. Gasification is a partial burning procedure but is similar to combustion when air or oxygen is employed. Overall, gasification aims to produce valuable gaseous products that may be kept for use in subsequent gasification processes or consumed directly, whereas combustion concentrates on the creation of heat [162].

Gasification is environmentally friendly since it uses solid byproducts in a variety of ways and emits fewer harmful gases into the atmosphere [162,163]. Reduced CO2 emissions, the requirement for small, lightweight equipment, accurate combustion control, and excellent thermal efficiency are among a few of the benefits of biomass gasification [68,158,162,164]. However, it possesses drawbacks that constrain its adaptability and effectiveness. To ensure the successful operation of an installation, a consistent and sufficient supply of biomass, as well as the appropriate type of biomass, must be assured [165].

Gasifiers

Gasification reactions occur within gasifiers, also referred to as gasification reactors. These reactions take place at high temperatures, typically ranging from 800 to 900 °C or even higher [166]. A traditional gasifier with air can be split into four process zones according to the types of reactions that take place in them, including the drying or dewatering zone, the pyrolysis zone, the combustion zone, and the reduction zone. The dewatering zone is where the water in the biomass is evaporated at a temperature of 150 °C [167]. The medium-energy biomass is transformed into volatile gases, liquid, and coal in the pyrolysis zone at temperatures between 150 and 700 °C [60]. The combustion zone is the region between 700 and 1500 °C where exothermic events take place and combustion reactions that require little or no oxygen or air oxidize the fuel elements [168]. The reduction (regeneration) zone, which is the last zone, produces H2 and CO at temperatures between 800 and 1100 °C [169].

Table 2.

Advantages and disadvantages of thermochemical conversion technologies [96].

Table 2.

Advantages and disadvantages of thermochemical conversion technologies [96].

| Technology | Product | Advantages | Disadvantages | Source |

|---|---|---|---|---|

| Pyrolysis | Bio-oil, biochar, and syngas | High efficiency, flexibility, and high-quality fuel | High operational and investment costs | [170,171,172] |

| Torrefaction | Solid fuel | Low energy, reduction in moisture, and increase in energy density | Process control, upscaling, and sustainability difficulties | [173,174] |

| Combustion | Thermal energy | The high calorific value of biomass and multiple fuel production | Only feasible for biomass with a moisture volume below 50% | [175,176] |

| Hydrothermal liquefaction | Bio-oil gases | Feedstock versatility, higher yield of and higher-quality bio-oil, capability to convert wet materials, and its beneficial environmental and economic potential | Energy consumption in high-pressure processes requires a longer residence time and is expensive | [177,178,179] |

| Gasification | Syngas | Flexible, better emission control, various uses of the produced syngas | Complex multi-stage process and the formation of tars and char | [180,181] |

7. Sustainability of Agricultural Waste Valorization Technologies

Agricultural waste management and valorization involves various technologies, methods, and approaches aimed at efficiently handling and utilizing the waste generated by agricultural activities. The suitability and applicability of these technologies, methods, and approaches may vary depending on various factors, such as the type of agricultural waste, local regulations, infrastructure availability, the specific agricultural practices in a given region, and many more [6]. The pursuit of sustainable energy production through the valorization of agricultural waste technologies is of paramount importance given its potential to mitigate environmental impact while meeting energy demands. For example, according to a study by Duque-Acevedo et al. (2020), different and improved techniques for agricultural waste valorization have been developed, leveraging industrial innovation and advanced technology. These advancements have played a role in ensuring efficient resource utilization, promoting sustainable production and consumption practices, and mitigating adverse environmental effects [8]. These technologies are rapidly evolving, driven by the urgency of addressing waste management challenges and reducing our reliance on conventional energy sources. However, despite this rapid progress, there remains a critical need for thorough assessments to evaluate the efficacity and sustainability of each technology, taking into account its environmental impact, energy efficiency, economic viability, and scalability.

Various assessment methods, such as life cycle assessment (LCA), life cycle analysis (LCA), net energy ratio (NER) calculations, and life cycle costing (LCC), as well as techno-economic assessment (TEA), should be considered, as they may serve as essential tools in this evaluation process, providing insights into the emissions, energy balance, and cost-effectiveness. Some researchers have already started to address this issue. For example, the impact of the hydrothermal liquefaction (HTL) conditions and the feedstock composition on the energy and elemental distribution of the process outputs was assessed by Watson et al. (2020), considering the economic and environmental concern of the HTL aqueous phase (HTL-AP). They also compared the current state of value-added product separation, along with some biochemical and thermochemical pathways. In addition, life cycle analysis (LCA) and techno-economic assessment (TEA) were also performed to appraise the environmental sustainability and economic implications of different valorization techniques. They also presented the challenges and future perspectives, highlighting the need for intensive research works addressing the environmental and economic strategies used to enhance the commercialization of these technologies [182]. Similarly, Daza Serna et al. (2016) conducted a techno-economic analysis to compare the feasibility of fermentation, anaerobic digestion, and combustion for the production of bioethanol, biogas, and electricity using plantain pseudo stems and rice husk in Colombia. Their study assured the feasibility of these processes but also noted that the moisture content of agricultural waste can be a challenge for waste valorization regarding the production cost [183].

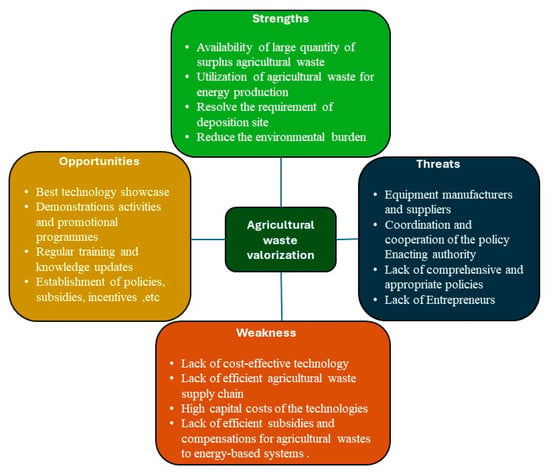

To analyze the suitability of agricultural waste valorization for energy production, Shah et al. (2021) conducted a SWOT (strengths, weaknesses, opportunities, and threats) analysis to identify the internal strengths and weaknesses of, as well as external opportunities for and threats to, agricultural waste valorization for energy production. They identified several strengths, such as the abundance of agricultural waste (in terms of its availability) and the simultaneous solution of the environmental and health problems associated with its improper disposal while contributing to energy production and reducing our dependency on fossil fuels [6]. They also identified some opportunities, as well as weaknesses and threats, as shown in Figure 3.

Figure 3.

SWOT analysis of agricultural waste valorization (adapted from [6]).

8. The Environmental Benefits of Bioenergy

According to the proposal of the Paris Agreement to hold the increase in the global average temperature below 2 °C and the pledge of world leaders to limit global warming to 1.5 °C by the end of this century, greenhouse gas emissions must peak before 2025 at the latest and decline by 43% by 2030 [184]. Different studies have proven that the broad adoption of biomass energy holds considerable promise for mitigating greenhouse gas emissions significantly [185]. For example, according to the study by Li Deming, China has accumulated approximately 280.0711 million tons of agricultural waste. The study revealed that if all of these resources were used to substitute fossil fuels, it could result in the avoidance of approximately 4,474,483 million tons of carbon dioxide emissions, a reduction of up to 12.024 million tons of methane emissions, and a decrease of up to 185,000 tons of nitrous oxide emissions [185]. This research emphasized that biomass energy, as a clean fuel, has the potential to substitute coal usage for power generation, heating, or cooking purposes among residents, thereby diminishing the CO2 emissions resulting from coal combustion while fulfilling equivalent energy requirements.

To enhance the development and utilization of agricultural biomass energy in rural parts of China, this study recommended the implementation of policies that promote the development and utilization of agricultural waste biomass energy. Additionally, it recommended the establishment of diverse facilities for the collection, transportation, and valorization of agricultural biomass resources. These efforts should consider various factors, such as variations in crop resources and energy systems and the current state of infrastructure across different regions.

Another example is the study by [186], which examined the potential contribution of bioenergy to reducing GHG emissions, taking the province of British Columbia in Canada as a case study. Their analysis led to the conclusion that by fully utilizing biomass resources, depending on the selected bioenergy options, an annual mitigation of 8.3–10.0 million tons of greenhouse gas emissions could be achieved, resulting in a reduction of greenhouse gas emissions by 13.0–15.7%.

Anaerobic digestion and gasification were analyzed for their suitability in district heating, while thermochemical conversion was explored for bioethanol production, and hydrothermal liquefaction was considered for biofuel generation. These processes aimed to replace natural gas heating, gasoline, and liquid transport fuels, respectively. The research employed life cycle assessment (LCA) to evaluate the potential reduction in greenhouse gas emissions associated with these options [186].

9. Challenges and Future Research Directions

Agricultural waste valorization into bioenergy resources presents promising eco-friendly and economically feasible benefits. However, the current progress in agricultural waste valorization technologies still holds significant gaps in need of improvement. One of these challenges lies in the pretreatment of agricultural waste biomass to optimize its conversion rates and lower the required energy consumption throughout the process while enhancing both the quantity and quality of the output [187]. Given the critical role of agricultural waste in biofuel production, innovative and enhanced pretreatment techniques are essential to facilitate more efficient degradation and conversion of crop residues and other agricultural waste into valuable products.

In line with Agriculture and Technology 4.0, the integration of cutting-edge technologies, such as machine learning and artificial intelligence, the Internet of Things (IoT), and robotics, is essential to enhance various aspects of the agricultural waste conversion process, optimizing the cost efficiency, time management, and labor requirements and consequently boosting the conversion efficiency and product quality. This will require collaboration and interdisciplinary research [188].

Another important recommendation is that it is imperative for governments at all levels to promote awareness among farm owners regarding the advantages of converting agricultural waste into valuable products. As a result, this will secure a steady and sustainable stream of agricultural waste, thus providing a reliable source of low-cost feedstock for biofuel production.

To fully realize the potential of agricultural waste valorization, continued research and development are needed to optimize the technologies, improve their efficiency, and explore new applications. Further studies are recommended for thorough assessments to evaluate the efficacity and sustainability of agricultural waste valorization technologies. Assessment methods such as life cycle assessment (LCA), life cycle analysis (LCA), net energy ratio (NER) calculations, and life cycle costing (LCC), as well as techno-economic assessment (TEA), are recommended [182]. Collaboration between academia, industry, and policymakers is crucial to create supportive frameworks and incentives for waste valorization initiatives.

10. Conclusions

The growth of the global population alongside expanded agricultural and food processing activities has driven a notable surge in agricultural waste production, leading to increased environmental concerns and greenhouse gas emissions. This review provided a comprehensive overview of sustainable and eco-friendly approaches to the efficient valorization of agricultural waste through bioenergy conversion. It illustrates the feasibility of converting agricultural residues into various bioenergy resources suitable for diverse uses to supply the currently increasing energy demand.

The valorization of agricultural waste holds significant potential for addressing the challenges of increasing energy production demand, waste management, and environmental sustainability, as energy production’s interaction with the environment is one of the most important steps needed to achieve sustainable development. With this ability and many other economic and social advantages, bioenergy can be considered a suitable option. The adoption of green innovations and technologies can help mitigate the harmful effects of waste on the environment and human health. Various methods, such as pyrolysis, torrefaction, gasification, anaerobic digestion, and fermentation, offer economically viable ways to transform agricultural waste into valuable resources. Pyrolysis and torrefaction processes can convert agricultural waste into bio-oil, biochar, and other byproducts, offering alternative energy sources and soil amendments. Gasification enables the production of synthesis gas or gaseous fuels from waste biomass, contributing to clean energy generation. Anaerobic digestion converts organic waste into biogas and digestate, providing renewable energy and organic fertilizer, while fermentation can transform waste biomolecules into ethanol and other biofuels.

By embracing these opportunities, we will not only address energy demand but also contribute to a more sustainable and circular agricultural system that minimizes waste and environmental impact.

Author Contributions

J.d.D.M.U., M.F., M.G., T.Z., P.O., R.B. and M.S.: conceptualization, writing—original draft; P.B.: conceptualization, funding acquisition, writing—review and editing; S.N.U.: visualization, writing—review and editing; Y.T.M.: conceptualization, writing—original draft; A.H., O.T., R.S. and P.Č.: writing—review and editing; Z.H.: conceptualization, writing—review and editing; L.S.: conceptualization, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This paper was created based on data obtained during the realization of the project TAČR Delta 2 TM03000063, which is financially supported by the Technology Agency of the Czech Republic.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Širá, E.; Kravčáková Vozárová, I.; Kotulič, R.; Dubravská, M. EU27 Countries’ Sustainable Agricultural Development toward the 2030 Agenda: The Circular Economy and Waste Management. Agronomy 2022, 12, 2270. [Google Scholar] [CrossRef]

- Nattassha, R.; Handayati, Y.; Simatupang, T.M.; Siallagan, M. Understanding Circular Economy Implementation in the Agri-Food Supply Chain: The Case of an Indonesian Organic Fertiliser Producer. Agric. Food Secur. 2020, 9, 10. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Plaza-Úbeda, J.A.; Camacho-Ferre, F. The Management of Agricultural Waste Biomass in the Framework of Circular Economy and Bioeconomy: An Opportunity for Greenhouse Agriculture in Southeast Spain. Agronomy 2020, 10, 489. [Google Scholar] [CrossRef]

- Jun, H.; Xiang, H. Development of Circular Economy Is A Fundamental Way to Achieve Agriculture Sustainable Development in China. Energy Procedia 2011, 5, 1530–1534. [Google Scholar] [CrossRef]

- Winans, K.; Kendall, A.; Deng, H. The History and Current Applications of the Circular Economy Concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Shah, S.; Venkatramanan, V.; Prasad, R. Bio-Valorization of Waste Trends and Perspectives: Trends and Perspectives; Springer: Berlin/Heidelberg, Germany, 2021; ISBN 978-981-15-9695-7. [Google Scholar]

- Kirchherr, J.; Yang, N.-H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resour. Conserv. Recycl. 2023, 194, 107001. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Cortés-García, F.J.; Camacho-Ferre, F. Agricultural Waste: Review of the Evolution, Approaches and Perspectives on Alternative Uses. Glob. Ecol. Conserv. 2020, 22, e00902. [Google Scholar] [CrossRef]

- Awogbemi, O.; Kallon, D.V.V. Pretreatment Techniques for Agricultural Waste. Case Stud. Chem. Environ. Eng. 2022, 6, 100229. [Google Scholar] [CrossRef]

- Koul, B.; Yakoob, M.; Shah, M.P. Agricultural Waste Management Strategies for Environmental Sustainability. Environ. Res. 2022, 206, 112285. [Google Scholar] [CrossRef] [PubMed]

- Haque, F.; Fan, C.; Lee, Y.-Y. From Waste to Value: Addressing the Relevance of Waste Recovery to Agricultural Sector in Line with Circular Economy. J. Clean. Prod. 2023, 415, 137873. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Lancellotti, I.; Andreola, F.; Barbieri, L.; Belmonte-Ureña, L.J.; Camacho-Ferre, F. Management of Agricultural Waste Biomass as Raw Material for the Construction Sector: An Analysis of Sustainable and Circular Alternatives. Environ. Sci. Eur. 2022, 34, 70. [Google Scholar] [CrossRef]

- Vaish, B.; Srivastava, V.; Kumar Singh, P.; Singh, P.; Pratap Singh, R. Energy and Nutrient Recovery from Agro-Wastes: Rethinking Their Potential Possibilities. Environ. Eng. Res. 2019, 25, 623–637. [Google Scholar] [CrossRef]

- Waqas, M.; Hashim, S.; Humphries, U.W.; Ahmad, S.; Noor, R.; Shoaib, M.; Naseem, A.; Hlaing, P.T.; Lin, H.A. Composting Processes for Agricultural Waste Management: A Comprehensive Review. Processes 2023, 11, 731. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, Z.; Tian, X.; Dai, L.; Jiang, L.; Zhang, S.; Wu, Q.; Wen, P.; Fu, G.; Liu, Y.; et al. Production of Bio-Oil from Agricultural Waste by Using a Continuous Fast Microwave Pyrolysis System. Bioresour. Technol. 2018, 269, 162–168. [Google Scholar] [CrossRef]

- Mostafa, N.A.; Farag, A.A.; Abo-dief, H.M.; Tayeb, A.M. Production of Biodegradable Plastic from Agricultural Wastes. Arab. J. Chem. 2018, 11, 546–553. [Google Scholar] [CrossRef]

- Fahmy, Y.; Fahmy, T.Y.A.; Mobarak, F.; El-Sakhawy, M.; Fadl, M.H. Agricultural Residues (Wastes) for Manufacture of Paper, Board, and Miscellaneous Products: Background Overview and Future Prospects. Int. J. ChemTech Res. 2017, 10, 424–448. [Google Scholar] [CrossRef]

- Chojnacka, K.; Gorazda, K.; Witek-Krowiak, A.; Moustakas, K. Recovery of Fertilizer Nutrients from Materials—Contradictions, Mistakes and Future Trends. Renew. Sustain. Energy Rev. 2019, 110, 485–498. [Google Scholar] [CrossRef]

- Esposito, B.; Sessa, M.R.; Sica, D.; Malandrino, O. Towards Circular Economy in the Agri-Food Sector. A Systematic Literature Review. Sustainability 2020, 12, 7401. [Google Scholar] [CrossRef]

- Adami, L.; Schiavon, M. From Circular Economy to Circular Ecology: A Review on the Solution of Environmental Problems through Circular Waste Management Approaches. Sustainability 2021, 13, 925. [Google Scholar] [CrossRef]

- Selvan, T.; Panmei, L.; Murasing, K.K.; Guleria, V.; Ramesh, K.R.; Bhardwaj, D.R.; Thakur, C.L.; Kumar, D.; Sharma, P.; Digvijaysinh Umedsinh, R.; et al. Circular Economy in Agriculture: Unleashing the Potential of Integrated Organic Farming for Food Security and Sustainable Development. Front. Sustain. Food Syst. 2023, 7, 1170380. [Google Scholar] [CrossRef]

- Kumar, S.; Darshna, A.; Ranjan, D. A Review of Literature on the Integration of Green Energy and Circular Economy. Heliyon 2023, 9, e21091. [Google Scholar] [CrossRef]

- Piscitelli, G.; Ferazzoli, A.; Petrillo, A.; Cioffi, R.; Parmentola, A.; Travaglioni, M. Circular economy models in the industry 4.0 era: A review of the last decade. Procedia Manuf. 2020, 42, 227–234. [Google Scholar] [CrossRef]

- Cherrington, R.; Manolchev, C.; Edwards, K.; Housni, I.; Alexander, A. Enabling Circular Economy Practices in Regional Contexts: Insights from the UK Southwest. Int. J. Entrep. Innov. 2024. [Google Scholar] [CrossRef]

- Weigend Rodríguez, R.; Pomponi, F.; Webster, K.; D’Amico, B. The Future of the Circular Economy and the Circular Economy of the Future. Built Environ. Proj. Asset Manag. 2020, 10, 529–546. [Google Scholar] [CrossRef]

- Yrjälä, K.; Ramakrishnan, M.; Salo, E. Agricultural Waste Streams as Resource in Circular Economy for Biochar Production towards Carbon Neutrality. Curr. Opin. Environ. Sci. Health 2022, 26, 100339. [Google Scholar] [CrossRef]

- Najahi, A.; Aguado, R.J.; Tarrés, Q.; Boufi, S.; Delgado-Aguilar, M. Harvesting Value from Agricultural Waste: Dimensionally Stable Fiberboards and Particleboards with Enhanced Mechanical Performance and Fire Retardancy through the Use of Lignocellulosic Nanofibers. Ind. Crops Prod. 2023, 204, 117336. [Google Scholar] [CrossRef]

- Guedes, R.E.; Luna, A.S.; Torres, A.R. Operating Parameters for Bio-Oil Production in Biomass Pyrolysis: A Review. J. Anal. Appl. Pyrolysis 2018, 129, 134–149. [Google Scholar] [CrossRef]

- Xiu, S.; Shahbazi, A. Bio-Oil Production and Upgrading Research: A Review. Renew. Sustain. Energy Rev. 2012, 16, 4406–4414. [Google Scholar] [CrossRef]

- Demirbas, A. Bio-Fuels from Agricutural Residues. Energy Sources Part Recovery Util. Environ. Eff. 2007, 30, 101–109. [Google Scholar] [CrossRef]

- Gao, M.; Wang, D.; Wang, H.; Wang, X.; Feng, Y. Biogas Potential, Utilization and Countermeasures in Agricultural Provinces: A Case Study of Biogas Development in Henan Province, China. Renew. Sustain. Energy Rev. 2019, 99, 191–200. [Google Scholar] [CrossRef]

- Ghorbani, M.; Neugschwandtner, R.W.; Konvalina, P.; Asadi, H.; Kopecký, M.; Amirahmadi, E. Comparative Effects of Biochar and Compost Applications on Water Holding Capacity and Crop Yield of Rice under Evaporation Stress: A Two-Years Field Study. Paddy Water Environ. 2023, 21, 47–58. [Google Scholar] [CrossRef]

- Liu, Z.; Quek, A.; Kent Hoekman, S.; Balasubramanian, R. Production of Solid Biochar Fuel from Waste Biomass by Hydrothermal Carbonization. Fuel 2013, 103, 943–949. [Google Scholar] [CrossRef]

- Salemdeeb, R.; Zu Ermgassen, E.K.H.J.; Kim, M.H.; Balmford, A.; Al-Tabbaa, A. Environmental and Health Impacts of Using Food Waste as Animal Feed: A Comparative Analysis of Food Waste Management Options. J. Clean. Prod. 2017, 140, 871–880. [Google Scholar] [CrossRef] [PubMed]

- Murindangabo, Y.T.; Kopecký, M.; Konvalina, P. Adoption of Conservation Agriculture in Rwanda: A Case Study of Gicumbi District Region. Agronomy 2021, 11, 1732. [Google Scholar] [CrossRef]

- Anastopoulos, I.; Omirou, M.; Stephanou, C.; Oulas, A.; Vasiliades, M.A.; Efstathiou, A.M.; Ioannides, I.M. Valorization of Agricultural Wastes Could Improve Soil Fertility and Mitigate Soil Direct N2O Emissions. J. Environ. Manag. 2019, 250, 109389. [Google Scholar] [CrossRef] [PubMed]

- Van Nguyen, T.T.; Phan, A.N.; Nguyen, T.-A.; Nguyen, T.K.; Nguyen, S.T.; Pugazhendhi, A.; Ky Phuong, H.H. Valorization of Agriculture Waste Biomass as Biochar: As First-Rate Biosorbent for Remediation of Contaminated Soil. Chemosphere 2022, 307, 135834. [Google Scholar] [CrossRef] [PubMed]

- Halysh, V.; Romero-García, J.M.; Vidal, A.M.; Kulik, T.; Palianytsia, B.; García, M.; Castro, E. Apricot Seed Shells and Walnut Shells as Unconventional Sugars and Lignin Sources. Molecules 2023, 28, 1455. [Google Scholar] [CrossRef] [PubMed]

- Miao, Y.; Razzaq, A.; Adebayo, T.S.; Awosusi, A.A. Do Renewable Energy Consumption and Financial Globalisation Contribute to Ecological Sustainability in Newly Industrialized Countries? Renew. Energy 2022, 187, 688–697. [Google Scholar] [CrossRef]

- Yu, Z.; Zia-ul-haq, H.M.; Irshad, A.U.R.; Tanveer, M.; Jameel, K.; Janjua, L.R. Nexuses between Crude Oil Imports, Renewable Energy, Transport Services, and Technological Innovation: A Fresh Insight from Germany. J. Pet. Explor. Prod. Technol. 2022, 12, 2887–2897. [Google Scholar] [CrossRef] [PubMed]

- Kumar, B.; Bhardwaj, N.; Agrawal, K.; Chaturvedi, V.; Verma, P. Current Perspective on Pretreatment Technologies Using Lignocellulosic Biomass: An Emerging Biorefinery Concept. Fuel Process. Technol. 2020, 199, 106244. [Google Scholar] [CrossRef]

- Ozturk, M.; Saba, N.; Altay, V.; Iqbal, R.; Hakeem, K.R.; Jawaid, M.; Ibrahim, F.H. Biomass and Bioenergy: An Overview of the Development Potential in Turkey and Malaysia. Renew. Sustain. Energy Rev. 2017, 79, 1285–1302. [Google Scholar] [CrossRef]

- Afolalu, S.A.; Yusuf, O.O.; Abioye, A.A.; Emetere, M.E.; Ongbali, S.O.; Samuel, O.D. Biofuel; A Sustainable Renewable Source of Energy-A Review. IOP Conf. Ser. Earth Environ. Sci. 2021, 665, 012040. [Google Scholar] [CrossRef]

- Tkemaladze, G.S.; Makhashvili, K.A. Climate Changes and Photosynthesis. Ann. Agrar. Sci. 2016, 14, 119–126. [Google Scholar] [CrossRef]

- Zheng, X.F.; Liu, C.X.; Yan, Y.Y.; Wang, Q. A Review of Thermoelectrics Research—Recent Developments and Potentials for Sustainable and Renewable Energy Applications. Renew. Sustain. Energy Rev. 2014, 32, 486–503. [Google Scholar] [CrossRef]

- de Vries, B.J.M.; van Vuuren, D.P.; Hoogwijk, M.M. Renewable Energy Sources: Their Global Potential for the First-Half of the 21st Century at a Global Level: An Integrated Approach. Energy Policy 2007, 35, 2590–2610. [Google Scholar] [CrossRef]

- Kalair, A.; Abas, N.; Saleem, M.S.; Kalair, A.R.; Khan, N. Role of Energy Storage Systems in Energy Transition from Fossil Fuels to Renewables. Energy Storage 2021, 3, e135. [Google Scholar] [CrossRef]

- McKinley, D.C.; Ryan, M.G.; Birdsey, R.A.; Giardina, C.P.; Harmon, M.E.; Heath, L.S.; Houghton, R.A.; Jackson, R.B.; Morrison, J.F.; Murray, B.C.; et al. A Synthesis of Current Knowledge on Forests and Carbon Storage in the United States. Ecol. Appl. 2011, 21, 1902–1924. [Google Scholar] [CrossRef] [PubMed]

- Abdul Malek, A.B.M.; Hasanuzzaman, M.; Rahim, N.A. Prospects, Progress, Challenges and Policies for Clean Power Generation from Biomass Resources. Clean Technol. Environ. Policy 2020, 22, 1229–1253. [Google Scholar] [CrossRef]

- Ben-Iwo, J.; Manovic, V.; Longhurst, P. Biomass Resources and Biofuels Potential for the Production of Transportation Fuels in Nigeria. Renew. Sustain. Energy Rev. 2016, 63, 172–192. [Google Scholar] [CrossRef]

- Henry, R.J. Evaluation of Plant Biomass Resources Available for Replacement of Fossil Oil. Plant Biotechnol. J. 2010, 8, 288–293. [Google Scholar] [CrossRef]

- Zhang, Z.; Gonzalez, A.M.; Davies, E.G.R.; Liu, Y. Agricultural Wastes. Water Environ. Res. 2012, 84, 1386–1406. [Google Scholar] [CrossRef]

- Ong, H.C.; Chen, W.-H.; Farooq, A.; Gan, Y.Y.; Lee, K.T.; Ashokkumar, V. Catalytic Thermochemical Conversion of Biomass for Biofuel Production: A Comprehensive Review. Renew. Sustain. Energy Rev. 2019, 113, 109266. [Google Scholar] [CrossRef]

- Siwal, S.S.; Sheoran, K.; Saini, A.K.; Vo, D.-V.N.; Wang, Q.; Thakur, V.K. Advanced Thermochemical Conversion Technologies Used for Energy Generation: Advancement and Prospects. Fuel 2022, 321, 124107. [Google Scholar] [CrossRef]

- Bhatia, L.; Bachheti, R.K.; Garlapati, V.K.; Chandel, A.K. Third-Generation Biorefineries: A Sustainable Platform for Food, Clean Energy, and Nutraceuticals Production. Biomass Convers. Biorefinery 2022, 12, 4215–4230. [Google Scholar] [CrossRef]

- Elgarahy, A.M.; Hammad, A.; El-Sherif, D.M.; Abouzid, M.; Gaballah, M.S.; Elwakeel, K.Z. Thermochemical Conversion Strategies of Biomass to Biofuels, Techno-Economic and Bibliometric Analysis: A Conceptual Review. J. Environ. Chem. Eng. 2021, 9, 106503. [Google Scholar] [CrossRef]

- Sivabalan, K.; Hassan, S.; Ya, H.; Pasupuleti, J. A Review on the Characteristic of Biomass and Classification of Bioenergy through Direct Combustion and Gasification as an Alternative Power Supply. J. Phys. Conf. Ser. 2021, 1831, 012033. [Google Scholar] [CrossRef]

- Van de Beld, B.; Holle, E.; Florijn, J. The Use of Pyrolysis Oil and Pyrolysis Oil Derived Fuels in Diesel Engines for CHP Applications. Appl. Energy 2013, 102, 190–197. [Google Scholar] [CrossRef]

- Castellani, B.; Rossi, F.; Filipponi, M.; Nicolini, A. Hydrate-Based Removal of Carbon Dioxide and Hydrogen Sulphide from Biogas Mixtures: Experimental Investigation and Energy Evaluations. Biomass Bioenergy 2014, 70, 330–338. [Google Scholar] [CrossRef]

- Prasad, L.; Subbarao, P.M.V.; Subrahmanyam, J.P. Pyrolysis and Gasification Characteristics of Pongamia Residue (de-Oiled Cake) Using Thermogravimetry and Downdraft Gasifier. Appl. Therm. Eng. 2014, 63, 379–386. [Google Scholar] [CrossRef]

- Yang, Y.; Heaven, S.; Venetsaneas, N.; Banks, C.J.; Bridgwater, A.V. Slow Pyrolysis of Organic Fraction of Municipal Solid Waste (OFMSW): Characterisation of Products and Screening of the Aqueous Liquid Product for Anaerobic Digestion. Appl. Energy 2018, 213, 158–168. [Google Scholar] [CrossRef]

- Kadam, R.; Panwar, N.L. Recent Advancement in Biogas Enrichment and Its Applications. Renew. Sustain. Energy Rev. 2017, 73, 892–903. [Google Scholar] [CrossRef]

- Mittal, S.; Ahlgren, E.O.; Shukla, P.R. Barriers to Biogas Dissemination in India: A Review. Energy Policy 2018, 112, 361–370. [Google Scholar] [CrossRef]

- Wang, X.; Lu, X.; Yang, G.; Feng, Y.; Ren, G.; Han, X. Development Process and Probable Future Transformations of Rural Biogas in China. Renew. Sustain. Energy Rev. 2016, 55, 703–712. [Google Scholar] [CrossRef]

- Winquist, E.; Van Galen, M.; Zielonka, S.; Rikkonen, P.; Oudendag, D.; Zhou, L.; Greijdanus, A. Expert Views on the Future Development of Biogas Business Branch in Germany, The Netherlands, and Finland until 2030. Sustainability 2021, 13, 1148. [Google Scholar] [CrossRef]

- Ottosson, M.; Magnusson, T.; Andersson, H. Shaping Sustainable Markets—A Conceptual Framework Illustrated by the Case of Biogas in Sweden. Environ. Innov. Soc. Transit. 2020, 36, 303–320. [Google Scholar] [CrossRef]

- Sarker, S. By-Products of Fish-Oil Refinery as Potential Substrates for Biogas Production in Norway: A Preliminary Study. Results Eng. 2020, 6, 100137. [Google Scholar] [CrossRef]

- dos Santos, R.G.; Alencar, A.C. Biomass-Derived Syngas Production via Gasification Process and Its Catalytic Conversion into Fuels by Fischer Tropsch Synthesis: A Review. Int. J. Hydrogen Energy 2020, 45, 18114–18132. [Google Scholar] [CrossRef]

- Soobhany, N. Insight into the Recovery of Nutrients from Organic Solid Waste through Biochemical Conversion Processes for Fertilizer Production: A Review. J. Clean. Prod. 2019, 241, 118413. [Google Scholar] [CrossRef]

- Kumar Awasthi, M.; Paul, A.; Kumar, V.; Sar, T.; Kumar, D.; Sarsaiya, S.; Liu, H.; Zhang, Z.; Binod, P.; Sindhu, R.; et al. Recent Trends and Developments on Integrated Biochemical Conversion Process for Valorization of Dairy Waste to Value Added Bioproducts: A Review. Bioresour. Technol. 2022, 344, 126193. [Google Scholar] [CrossRef] [PubMed]

- Pan, S.-Y.; Tsai, C.-Y.; Liu, C.-W.; Wang, S.-W.; Kim, H.; Fan, C. Anaerobic Co-Digestion of Agricultural Wastes toward Circular Bioeconomy. iScience 2021, 24, 102704. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, Y.; Zhang, H.; Hua, B.; Yuan, X.; Zhu, W.; Wang, X.; Cui, Z. Hydrolysis and Acidification of Agricultural Waste in a Non-Airtight System: Effect of Solid Content, Temperature, and Mixing Mode. Waste Manag. 2017, 59, 487–497. [Google Scholar] [CrossRef]

- Campuzano, R.; Trejo-Aguilar, G.M.; Cuetero-Martínez, Y.; Ramírez-Vives, F.; Monroy, O. Acidogenesis of Food Wastes at Variable Inlet and Operational Conditions. Environ. Technol. Innov. 2022, 25, 102162. [Google Scholar] [CrossRef]

- Litty, D.; Müller, V. Acetogenic Bacteria for Biotechnological Applications. In Enzymes for Solving Humankind’s Problems; Moura, J.J.G., Moura, I., Maia, L.B., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 109–130. ISBN 978-3-030-58314-9. [Google Scholar]

- Billington, R.S. A Review of the Kinetics of the Methanogenic Fermentation of Lignocellulosic Wastes. J. Agric. Eng. Res. 1988, 39, 71–84. [Google Scholar] [CrossRef]

- Kleerebezem, R.; Joosse, B.; Rozendal, R.; Van Loosdrecht, M.C.M. Anaerobic Digestion without Biogas? Rev. Environ. Sci. Biotechnol. 2015, 14, 787–801. [Google Scholar] [CrossRef]

- Tiwari, B.R.; Rouissi, T.; Brar, S.K.; Surampalli, R.Y. Critical Insights into Psychrophilic Anaerobic Digestion: Novel Strategies for Improving Biogas Production. Waste Manag. 2021, 131, 513–526. [Google Scholar] [CrossRef]

- Subramanian, K.A.; Mathad, V.C.; Vijay, V.K.; Subbarao, P.M.V. Comparative Evaluation of Emission and Fuel Economy of an Automotive Spark Ignition Vehicle Fuelled with Methane Enriched Biogas and CNG Using Chassis Dynamometer. Appl. Energy 2013, 105, 17–29. [Google Scholar] [CrossRef]

- Tiwary, A.; Williams, I.D.; Pant, D.C.; Kishore, V.V.N. Emerging Perspectives on Environmental Burden Minimisation Initiatives from Anaerobic Digestion Technologies for Community Scale Biomass Valorisation. Renew. Sustain. Energy Rev. 2015, 42, 883–901. [Google Scholar] [CrossRef]

- Choudhary, P.; Assemany, P.P.; Naaz, F.; Bhattacharya, A.; Castro, J.d.S.; Couto, E.d.A.d.C.; Calijuri, M.L.; Pant, K.K.; Malik, A. A Review of Biochemical and Thermochemical Energy Conversion Routes of Wastewater Grown Algal Biomass. Sci. Total Environ. 2020, 726, 137961. [Google Scholar] [CrossRef]

- Pham, T.H.; Rabaey, K.; Aelterman, P.; Clauwaert, P.; De Schamphelaire, L.; Boon, N.; Verstraete, W. Microbial Fuel Cells in Relation to Conventional Anaerobic Digestion Technology. Eng. Life Sci. 2006, 6, 285–292. [Google Scholar] [CrossRef]

- Shilev, S.; Naydenov, M.; Vancheva, V.; Aladjadjiyan, A. Composting of Food and Agricultural Wastes. In Utilization of By-Products and Treatment of Waste in the Food Industry; Oreopoulou, V., Russ, W., Eds.; Springer: New York, NY, USA, 2007; pp. 283–301. ISBN 978-0-387-33511-7. [Google Scholar]

- Tekin, K.; Karagöz, S.; Bektaş, S. A Review of Hydrothermal Biomass Processing. Renew. Sustain. Energy Rev. 2014, 40, 673–687. [Google Scholar] [CrossRef]

- Lu, W.; Alam, M.A.; Luo, W.; Asmatulu, E. Integrating Spirulina platensis Cultivation and Aerobic Composting Exhaust for Carbon Mitigation and Biomass Production. Bioresour. Technol. 2019, 271, 59–65. [Google Scholar] [CrossRef]