Obtaining Sustainable Electrical Energy from Pepper Waste

Abstract

1. Introduction

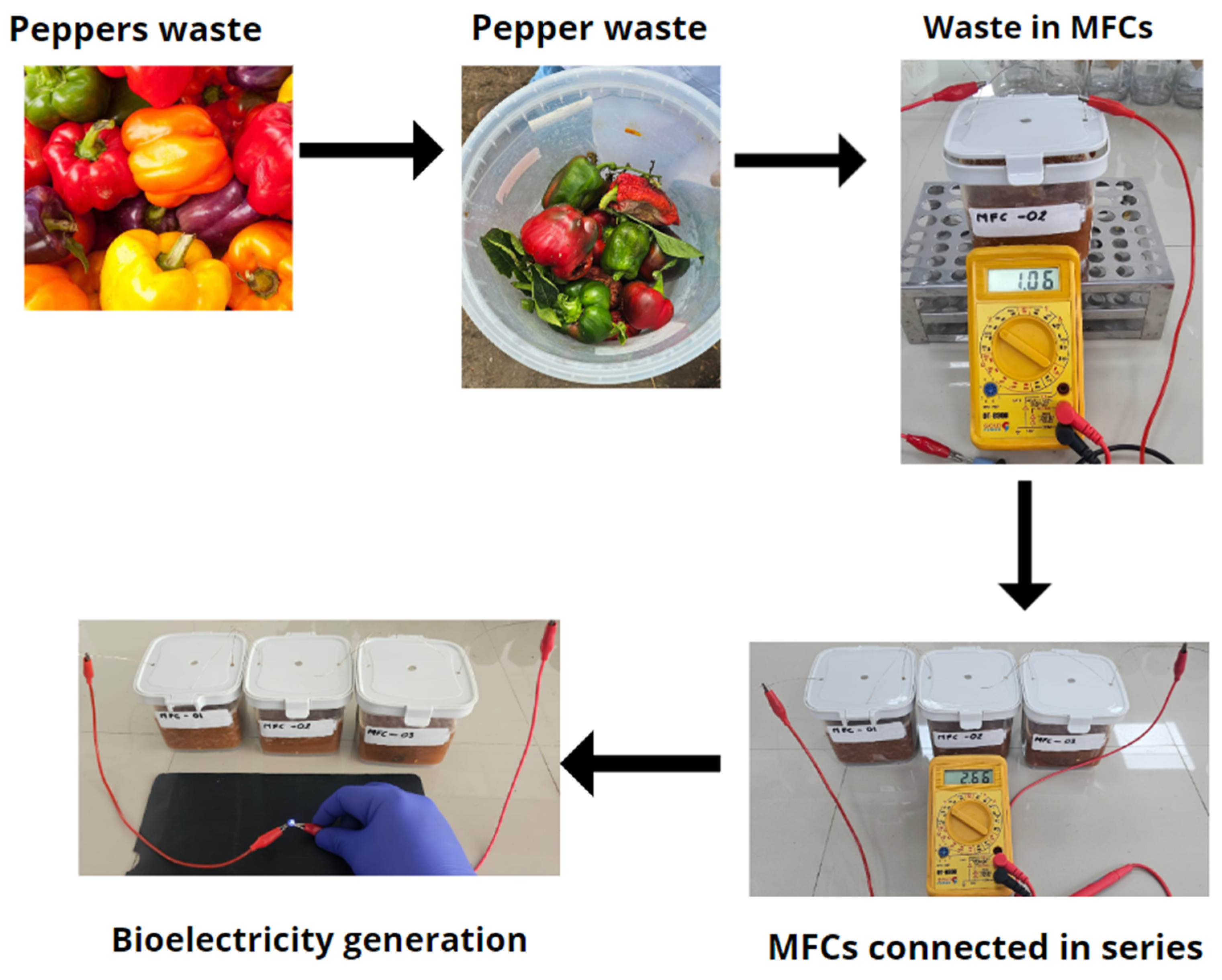

2. Materials and Methods

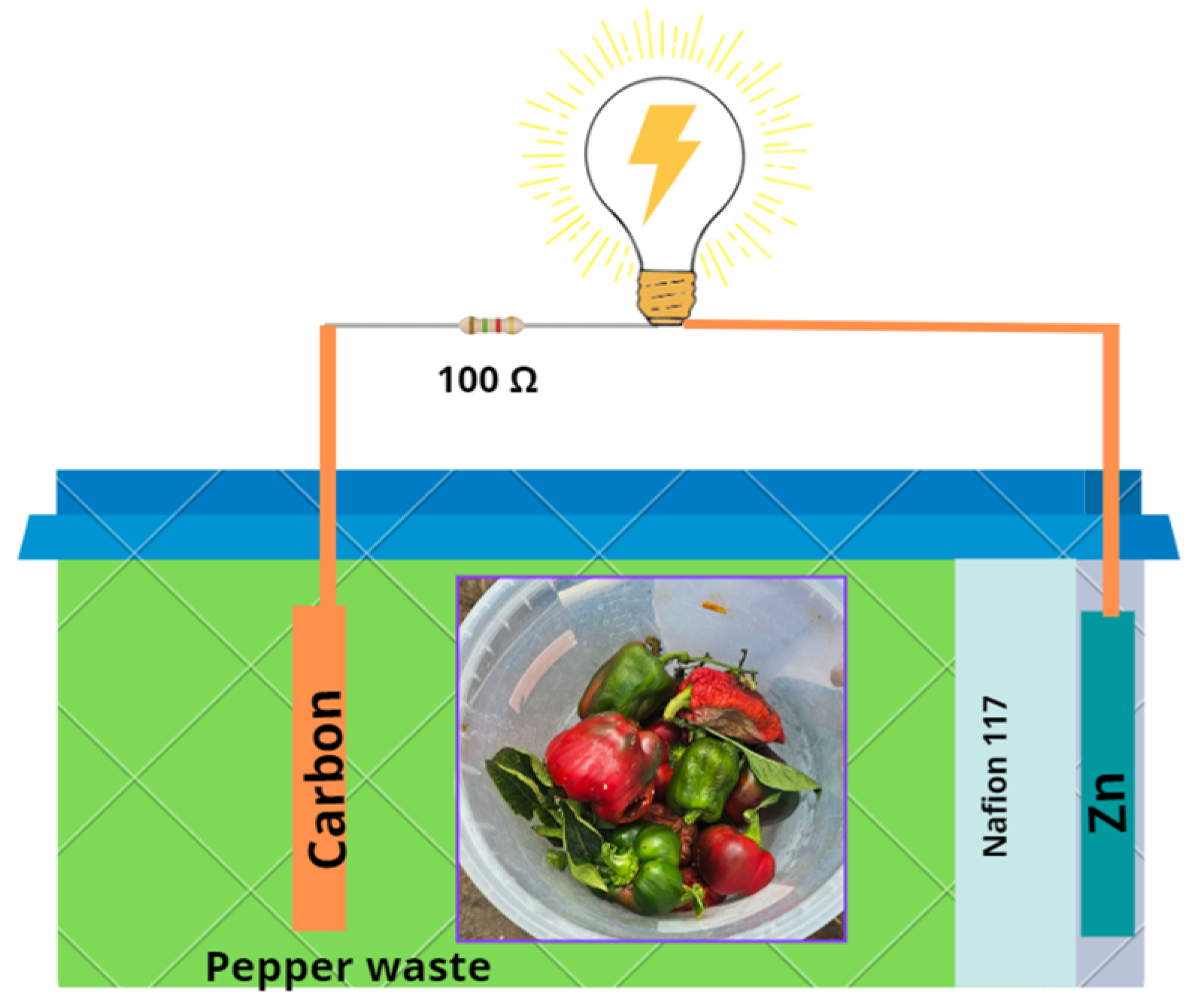

- Single-chamber microbial fuel cells:

- b.

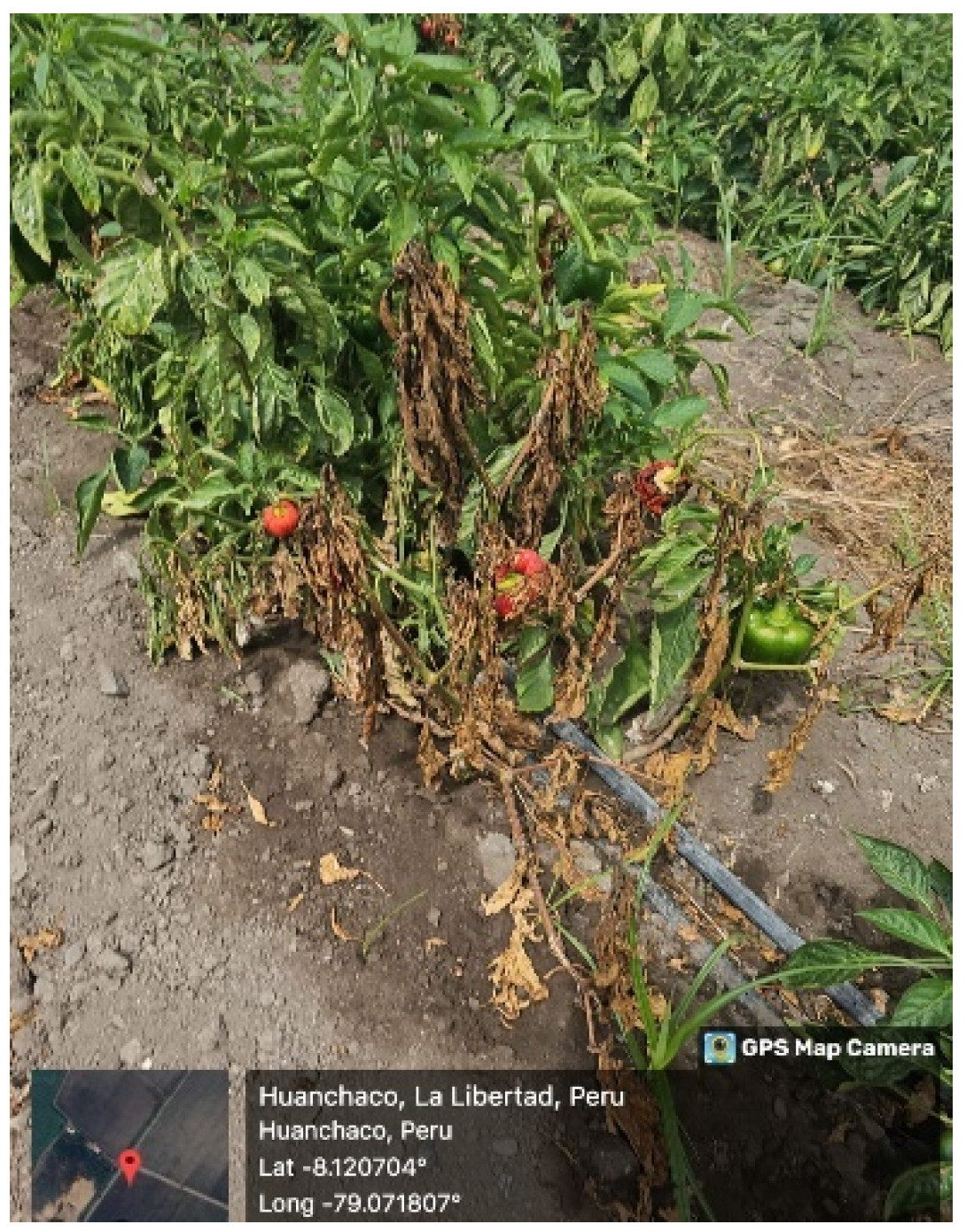

- Collection of samples used as substrates

- c.

- Analysis of electrochemical parameters

- d.

- Molecular characterization of energy-generating bacteria

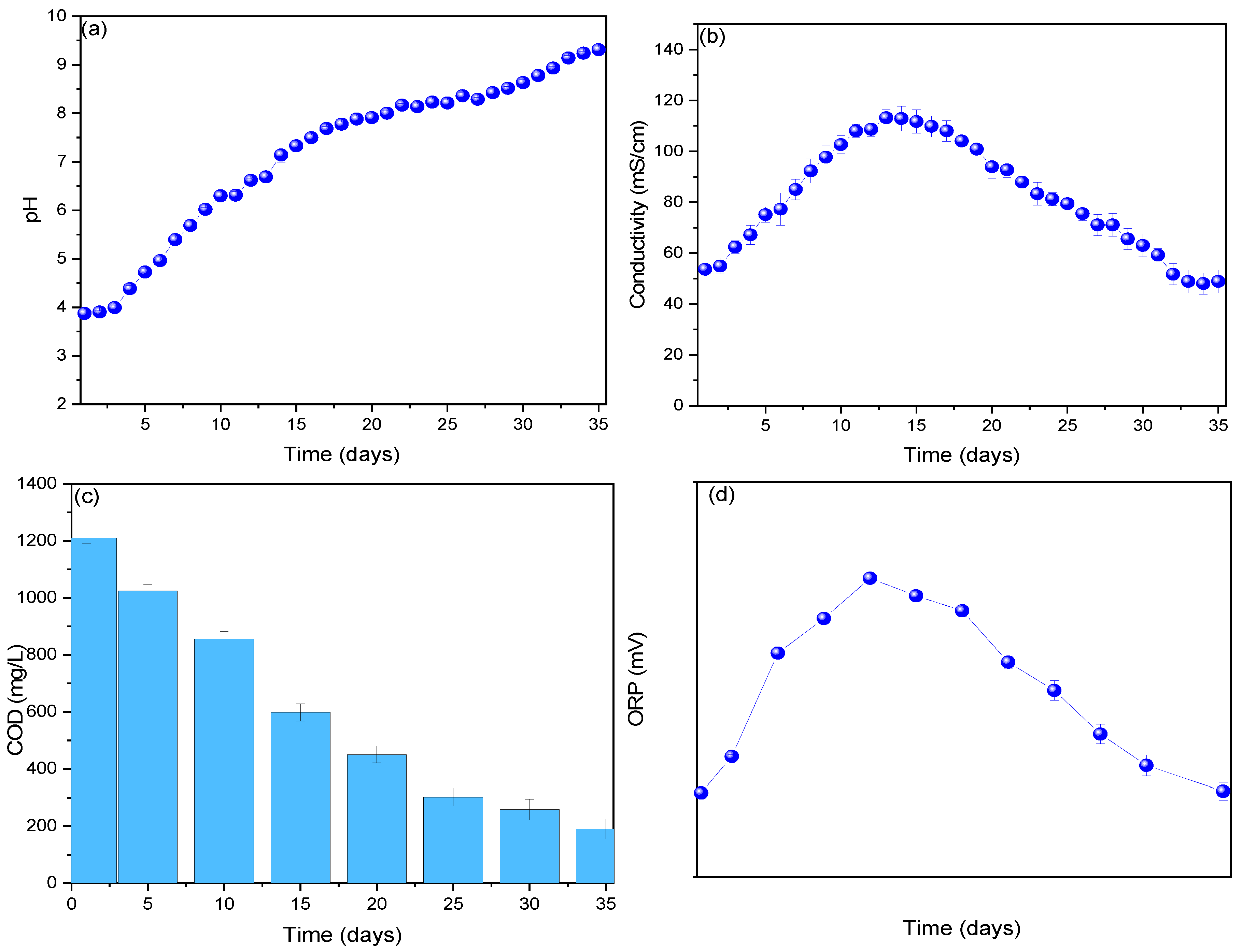

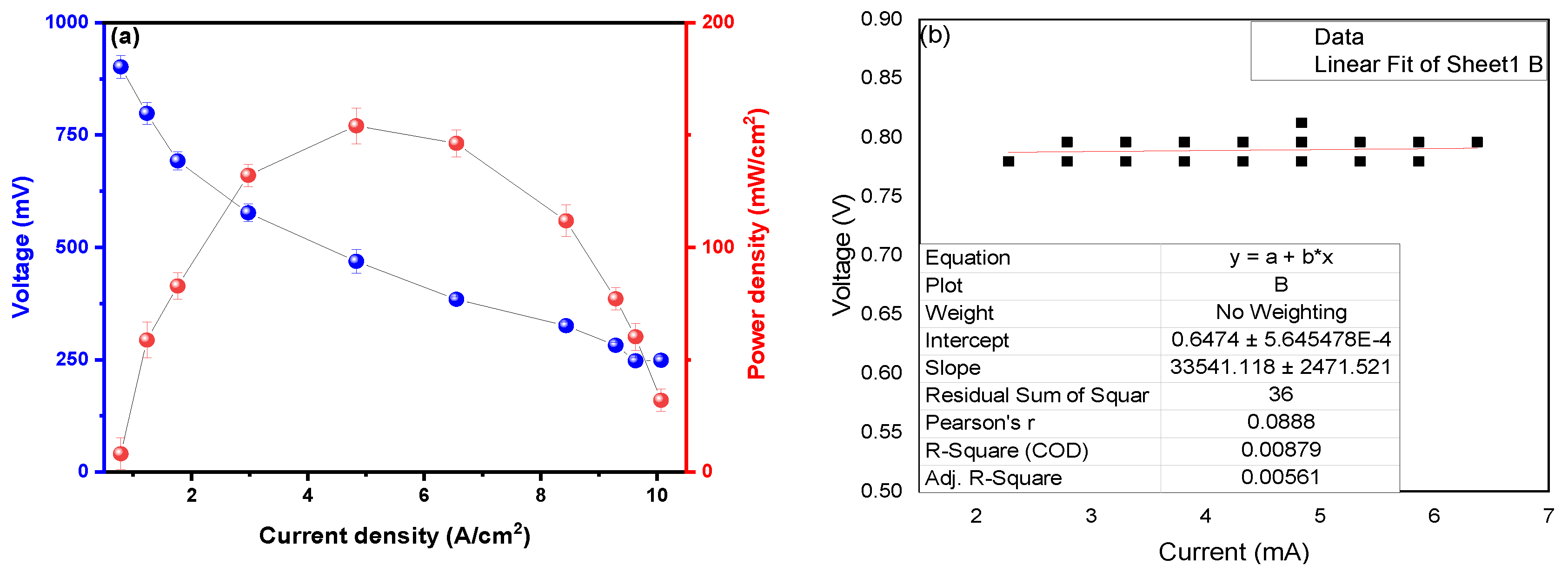

3. Results and Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Khedulkar, A.P.; Pandit, B.; Doong, R.A. Agricultural waste to real worth biochar as a sustainable material for supercapacitor. Sci. Total Environ. 2023, 869, 161441. [Google Scholar] [CrossRef] [PubMed]

- Waqas, M.; Hashim, S.; Humphries, U.W.; Ahmad, S.; Noor, R.; Shoaib, M.; Lin, H.A. Composting Processes for Agricultural Waste Management: A Comprehensive Review. Processes 2023, 11, 731. [Google Scholar] [CrossRef]

- Peng, X.; Jiang, Y.; Chen, Z.; Osman, A.I.; Farghali, M.; Rooney, D.W.; Yap, P.S. Recycling municipal, agricultural and industrial waste into energy, fertilizers, food and construction materials, and economic feasibility: A review. Environ. Chem. Lett. 2023, 21, 765–801. [Google Scholar] [CrossRef]

- Sarangi, P.K.; Singh, A.K.; Srivastava, R.K.; Gupta, V.K. Recent Progress and Future Perspectives for Zero Agriculture Waste Technologies: Pineapple Waste as a Case Study. Sustainability 2023, 15, 3575. [Google Scholar] [CrossRef]

- Gupta, S.; Sharma, S.; Aich, A.; Verma, A.K.; Bhuyar, P.; Nadda, A.K.; Kalia, S. Chicken feather waste hydrolysate as a potential biofertilizer for environmental sustainability in organic agriculture management. Waste Biomass Valoriz. 2023, 14, 2783–2799. [Google Scholar] [CrossRef]

- Perdana, T.; Kusnandar, K.; Perdana, H.H.; Hermiatin, F.R. Circular supply chain governance for sustainable fresh agricultural products: Minimizing food loss and utilizing agricultural waste. Sustain. Prod. Consum. 2023, 41, 391–403. [Google Scholar] [CrossRef]

- Pinto, R.; Henriques, S.T.; Brockway, P.E.; Heun, M.K.; Sousa, T. The rise and stall of world electricity efficiency: 1900–2017, results and insights for the renewables transition. Energy 2023, 269, 126775. [Google Scholar] [CrossRef]

- Boretti, A. Supply of abundant and low-cost total primary energy to a growing world needs nuclear energy and hydrogen energy storage. Int. J. Hydrogen Energy 2023, 48, 1649–1650. [Google Scholar] [CrossRef]

- Murshed, M.; Ozturk, I. Rethinking energy poverty reduction through improving electricity accessibility: A regional analysis on selected African nations. Energy 2023, 267, 126547. [Google Scholar] [CrossRef]

- Ritchie, H.; Rosado, P.; Roser, M. Electricity mix. Our World in Data, 2024. Available online: https://ourworldindata.org/electricity-mix (accessed on 1 January 2024).

- Jurakulov, S.Z. Nuclear energy. Educ. Res. Univ. Sci. 2023, 2, 514–518. [Google Scholar]

- Ida, T.K.; Mandal, B. Microbial fuel cell design, application and performance: A review. Mater. Today Proc. 2023, 76, 88–94. [Google Scholar]

- Bazina, N.; Ahmed, T.G.; Almdaaf, M.; Jibia, S.; Sarker, M. Power generation from wastewater using microbial fuel cells: A review. J. Biotechnol. 2023, 374, 17–30. [Google Scholar] [CrossRef] [PubMed]

- Sayed, E.T.; Rezk, H.; Abdelkareem, M.A.; Olabi, A.G. Artificial neural network based modelling and optimization of microalgae microbial fuel cell. Int. J. Hydrogen Energy 2024, 52, 1015–1025. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, J.; Zhang, Y.; Guo, Q.; Hu, T.; Xiao, H.; Jia, J. Progress on anodic modification materials and future development directions in microbial fuel cells. J. Power Sources 2023, 556, 232486. [Google Scholar] [CrossRef]

- Malik, S.; Kishore, S.; Dhasmana, A.; Kumari, P.; Mitra, T.; Chaudhary, V.; Rajput, V.D. A Perspective Review on Microbial Fuel Cells in Treatment and Product Recovery from Wastewater. Water 2023, 15, 316. [Google Scholar] [CrossRef]

- Sikder, S.; Rahman, M.M. Efficiency of microbial fuel cell in wastewater (municipal, textile and tannery) treatment and bioelectricity production. Case Stud. Chem. Environ. Eng. 2023, 8, 100421. [Google Scholar] [CrossRef]

- Sun, D.; Xie, B.; Li, J.; Huang, X.; Chen, J.; Zhang, F. A low-cost microbial fuel cell based sensor for in-situ monitoring of dissolved oxygen for over half a year. Biosens. Bioelectron. 2023, 220, 114888. [Google Scholar] [CrossRef] [PubMed]

- Verma, M.; Mishra, V. Bioelectricity generation by microbial degradation of banana peel waste biomass in a dual-chamber S. cerevisiae-based microbial fuel cell. Biomass Bioenergy 2023, 168, 106677. [Google Scholar] [CrossRef]

- Segundo, R.F.; De La Cruz-Noriega, M.; Cabanillas-Chirinos, L.; Otiniano, N.M.; Soto-Deza, N.; Rojas-Villacorta, W.; De La Cruz-Cerquin, M. The Potential Use of Pseudomonas stutzeri as a Biocatalyst for the Removal of Heavy Metals and the Generation of Bioelectricity. Fermentation 2024, 10, 113. [Google Scholar] [CrossRef]

- Aleid, G.M.; Alshammari, A.S.; Alomari, A.D.; Sa’ad Abdullahi, S.; Mohammad, R.E.A.; Abdulrahman, R.M.I. Degradation of Metal Ions with Electricity Generation by Using Fruit Waste as an Organic Substrate in the Microbial Fuel Cell. Int. J. Chem. Eng. 2023, 2023, 1334279. [Google Scholar] [CrossRef]

- Segundo, R.F.; Benites, S.M.; De La Cruz-Noriega, M.; Vives-Garnique, J.; Otiniano, N.M.; Rojas-Villacorta, W.; Díaz, F. Impact of Dragon Fruit Waste in Microbial Fuel Cells to Generate Friendly Electric Energy. Sustainability 2023, 15, 7316. [Google Scholar] [CrossRef]

- Sanatombi, K. Antioxidant potential and factors influencing the content of antioxidant compounds of pepper: A review with current knowledge. Compr. Rev. Food Sci. Food Saf. 2023, 22, 3011–3052. [Google Scholar] [CrossRef] [PubMed]

- Shim, J.H.; Eun, J.B.; Zaky, A.A.; Hussein, A.S.; Hacimüftüoğlu, A.; Abd El-Aty, A.M. A Comprehensive Review of Pesticide Residues in Peppers. Foods 2023, 12, 970. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Huang, H.; Li, X.; Yang, M.; Chi, S.; Pan, Y.; Lu, K. CaHMA1 promotes Cd accumulation in pepper fruit. J. Hazard. Mater. 2023, 460, 132480. [Google Scholar] [CrossRef] [PubMed]

- Mohi-Alden, K.; Omid, M.; Firouz, M.S.; Nasiri, A. A machine vision-intelligent modelling based technique for in-line bell pepper sorting. Inf. Process. Agric. 2023, 10, 491–503. [Google Scholar] [CrossRef]

- Dasgan, H.Y.; Yilmaz, M.; Dere, S.; Ikiz, B.; Gruda, N.S. Bio-Fertilizers Reduced the Need for Mineral Fertilizers in Soilless-Grown Capia Pepper. Horticulturae 2023, 9, 188. [Google Scholar] [CrossRef]

- Altaf, M.A.; Hao, Y.; Shu, H.; Mumtaz, M.A.; Cheng, S.; Alyemeni, M.N.; Wang, Z. Melatonin enhanced the heavy metal-stress tolerance of pepper by mitigating the oxidative damage and reducing the heavy metal accumulation. J. Hazard. Mater. 2023, 454, 131468. [Google Scholar] [CrossRef]

- Mamani Larico, A.J.; Zúñiga Medina, S.A. Application of WASP model for assessment of water quality for eutrophication control for a reservoir in the Peruvian Andes. Lakes Reserv.: Res. Manag. 2019, 24, 37–47. [Google Scholar] [CrossRef]

- Segundo, R.F.; De La Cruz-Noriega, M.; Milly Otiniano, N.; Benites, S.M.; Esparza, M.; Nazario-Naveda, R. Use of onion waste as fuel for the generation of bioelectricity. Molecules 2022, 27, 625. [Google Scholar] [CrossRef]

- Prasad, J.; Tripathi, R.K. Voltage control of sediment microbial fuel cell to power the AC load. J. Power Sources 2020, 450, 227721. [Google Scholar] [CrossRef]

- Koffi, N.D.J.; Okabe, S. High voltage generation from wastewater by microbial fuel cells equipped with a newly designed low voltage booster multiplier (LVBM). Sci. Rep. 2020, 10, 18985. [Google Scholar] [CrossRef] [PubMed]

- Barakat, N.A.; Gamal, S.; Ghouri, Z.K.; Fadali, O.A.; Abdelraheem, O.H.; Hashem, M.; Moustafa, H.M. Graphitized mango seed as an effective 3D anode in batch and continuous mode microbial fuel cells for sustainable wastewater treatment and power generation. RSC Adv. 2024, 14, 3163–3177. [Google Scholar] [CrossRef] [PubMed]

- Alshammari, A.S.; Aleid, G.M.; Ahmad, A.R.D.; Alomari, A.D.; Abdullahi, S.S.A.; Mohammad, R.E.A. Oil Palm Biomass Sap-Rotten Rice as a Source to Remove Metal Ions and Generate Electricity as By-Products through Microbial Fuel Cell Technology. J. Chem. 2024, 2024, 5570011. [Google Scholar] [CrossRef]

- Idris, M.O.; Noh, N.A.M.; Ibrahim, M.N.M.; Yaqoob, A.A. Sustainable microbial fuel cell functionalized with a bio-waste: A feasible route to formaldehyde bioremediation along with bioelectricity generation. Chem. Eng. J. 2023, 455, 140781. [Google Scholar] [CrossRef]

- Ghasemi, M.; Rezk, H. Performance improvement of microbial fuel cell using experimental investigation and fuzzy modelling. Energy 2024, 286, 129486. [Google Scholar] [CrossRef]

- Mkilima, T.; Zharkenov, Y.; Utepbergenova, L.; Smagulova, E.; Fazylov, K.; Zhumadilov, I.; Abdukalikova, G. Carwash wastewater treatment through the synergistic efficiency of microbial fuel cells and metal-organic frameworks with graphene oxide integration. Case Stud. Chem. Environ. Eng. 2024, 9, 100582. [Google Scholar] [CrossRef]

- Zafar, Z.; Naz, S.; Malik, N.H.; Ahmed, F.; Ali, N. Bioelectrogeneic performance of air-cathode microbial fuel cells with diesel contaminants. Fuel 2024, 355, 129407. [Google Scholar] [CrossRef]

- Rojas-Villacorta, W.; Rojas-Flores, S.; Benites, S.M.; Nazario-Naveda, R.; Romero, C.V.; Gallozzo-Cardenas, M.; Murga-Torres, E. Preliminary Study of Bioelectricity Generation Using Lettuce Waste as Substrate by Microbial Fuel Cells. Sustainability 2023, 15, 10339. [Google Scholar] [CrossRef]

- Abubackar, H.N.; Biryol, İ.; Ayol, A. Yeast industry wastewater treatment with microbial fuel cells: Effect of electrode materials and reactor configurations. Int. J. Hydrogen Energy 2023, 48, 12424–12432. [Google Scholar] [CrossRef]

- Latuihamallo, Y.; Mahulette, F.; Watuguly, T.W. Potential of vegetable waste as alternative production bioelectricity. BIOEDUPAT Pattimura J. Biol. Learn. 2023, 3, 90–94. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Lin, H. Effects of pH on simultaneous Cr (VI) and p-chlorophenol removal and electrochemical performance in Leersia hexandra constructed wetland-microbial fuel cell. Environ. Technol. 2024, 45, 483–494. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, A.; Calay, R.K.; Das, S. Effect of pH, COD, and HRT on the performance of microbial fuel cell using synthetic dairy wastewater. Water 2023, 15, 3472. [Google Scholar] [CrossRef]

- Navarro, E.S.C.; Boado, M.M.M. Air-Cathode Microbial Fuel Cell: Optimizing Graphene-Sponge Anode Thickness and Chamber pH using Taguchi Experimental Method. 2023; Preprint. [Google Scholar] [CrossRef]

- Verma, M.; Singh, V.; Mishra, V. Optimization of banana peel waste based microbial fuel cells by machine learning. Biomass Convers. Biorefin. 2023, 1–16. [Google Scholar] [CrossRef]

- Rojas-Flores, S.; De La Cruz-Noriega, M.; Cabanillas-Chirinos, L.; Benites, S.M.; Nazario-Naveda, R.; Delfín-Narciso, D.; Rojas-Villacorta, W. Use of Kiwi Waste as Fuel in MFC and Its Potential for Use as Renewable Energy. Fermentation 2023, 9, 446. [Google Scholar] [CrossRef]

- Sreelekshmy, B.R.; Basheer, R.; Sivaraman, S.; Vasudevan, V.; Elias, L.; Shibli, S.M.A. Sustainable electric power generation from live anaerobic digestion of sugar industry effluents using microbial fuel cells. J. Mater. Chem. A 2020, 8, 6041–6056. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Guerrero–Barajas, C.; Ibrahim, M.N.M.; Umar, K.; Yaakop, A.S. Local fruit wastes driven benthic microbial fuel cell: A sustainable approach to toxic metal removal and bioelectricity generation. Environ. Sci. Pollut. Res. 2022, 29, 32913–32928. [Google Scholar] [CrossRef]

- Kebaili, H.; Kameche, M.; Innocent, C.; Ziane, F.Z.; Sabeur, S.A.; Sahraoui, T.; Charef, M.A. Treatment of fruit waste leachate using microbial fuel cell: Preservation of agricultural environment. Acta Ecol. Sin. 2021, 41, 97–105. [Google Scholar] [CrossRef]

- Yuan, J.; Yuan, H.; Huang, S.; Liu, L.; Fu, F.; Zhang, Y.; Li, J. Comprehensive performance, bacterial community structure of single-chamber microbial fuel cell affected by COD/N ratio and physiological stratifications in cathode biofilm. Bioresour. Technol. 2021, 320, 124416. [Google Scholar] [CrossRef]

- Xin, S.; Shen, J.; Liu, G.; Chen, Q.; Xiao, Z.; Zhang, G.; Xin, Y. High electricity generation and COD removal from cattle wastewater in microbial fuel cells with 3D air cathode employed non-precious Cu2O/reduced graphene oxide as cathode catalyst. Energy 2020, 196, 117123. [Google Scholar] [CrossRef]

- Rincón-Catalán, N.I.; Cruz-Salomón, A.; Sebastian, P.J.; Pérez-Fabiel, S.; Hernández-Cruz, M.D.C.; Sánchez-Albores, R.M.; Nájera-Aguilar, H.A. Banana Waste-to-Energy Valorization by Microbial Fuel Cell Coupled with Anaerobic Digestion. Processes 2022, 10, 1552. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, P.; Dong, S.; Yu, Y.; Chen, H.; Xiao, J. Using watermelon rind and nitrite-containing wastewater for electricity production in a membraneless biocathode microbial fuel cell. J. Clean. Prod. 2021, 307, 127306. [Google Scholar] [CrossRef]

- León-Teran, N.; Garcia-Huertas, I.; Quezada-Alvarez, M.; Rodriguez-Yupanqui, M.; Rojas-Flores, S.; Nazario-Naveda, R.; Cabanillas-Chirinos, L. Effect of beef and chicken manure compost on the nutritional content of calcium and phosphorus in Alfalfa. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2023; Volume 3018. [Google Scholar]

- Shi, Y.; Yang, X.; Ning, X.; Yang, Q. Research progress of microbial fuel cell and constructed wetland coupling system. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 199, No. 5; p. 052014. [Google Scholar]

- Samudro, G.; Imai, T.; Hung, Y.T. Enhancement of Power Generation and Organic Removal in Double Anode Chamber Designed Dual-Chamber Microbial Fuel Cell (DAC-DCMFC). Water 2021, 13, 2941. [Google Scholar] [CrossRef]

- Agüero-Quiñones, R.; Ávila-Sánchez, Z.; Rojas-Flores, S.; Cabanillas-Chirinos, L.; De La Cruz-Noriega, M.; Nazario-Naveda, R.; Rojas-Villacorta, W. Activated Carbon Electrodes for Bioenergy Production in Microbial Fuel Cells Using Synthetic Wastewater as Substrate. Sustainability 2023, 15, 13767. [Google Scholar] [CrossRef]

- Tan, S.M.; Ong, S.A.; Ho, L.N.; Wong, Y.S.; Thung, W.E.; Teoh, T.P. The reaction of wastewater treatment and power generation of single chamber microbial fuel cell against substrate concentration and anode distributions. J. Environ. Health Sci. Eng. 2020, 18, 793–807. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, S.; Bhatnagar, P.; Dhingra, S.; Upadhyay, U.; Sreedhar, I. Wastewater treatment and energy production by microbial fuel cells. Biomass Convers. Biorefin. 2023, 13, 3569–3592. [Google Scholar] [CrossRef]

- Ahirwar, A.; Das, S.; Das, S.; Yang, Y.H.; Bhatia, S.K.; Vinayak, V.; Ghangrekar, M.M. Photosynthetic microbial fuel cell for bioenergy and valuable production: A review of circular bio-economy approach. Algal Res. 2023, 70, 102973. [Google Scholar] [CrossRef]

- Saran, C.; Purchase, D.; Saratale, G.D.; Saratale, R.G.; Ferreira, L.F.R.; Bilal, M.; Bharagava, R.N. Microbial fuel cell: A green eco-friendly agent for tannery wastewater treatment and simultaneous bioelectricity/power generation. Chemosphere 2023, 312, 137072. [Google Scholar] [CrossRef] [PubMed]

- Prasidha, W. Electricity Production from Food Waste Leachate (Fruit and Vegetable Waste) using Double Chamber Microbial Fuel Cell: Comparison between Non-aerated and Aerated Configuration. ROTASI 2020, 22, 162–168. [Google Scholar]

- Nguyen, D.T.; Taguchi, K. A floating microbial fuel cell: Generating electricity from Japanese rice washing wastewater. Energy Rep. 2020, 6, 758–762. [Google Scholar] [CrossRef]

- Flores, S.J.R.; Benites, S.M.; Rosa, A.L.R.A.L.; Zoilita, A.L.Z.A.L.; Luis, A.S.L. The Using Lime (Citrus × aurantiifolia), Orange (Citrus× sinensis), and Tangerine (Citrus reticulata) Waste as a Substrate for Generating Bioelectricity: Using lime (Citrus × aurantiifolia), orange (Citrus × sinensis), and tangerine (Citrus reticulata) waste as a substrate for generating bioelectricity. Environ. Res. Eng. Manag. 2020, 76, 24–34. [Google Scholar]

- Yaqoob, A.A.; Bakar, M.A.B.A.; Kim, H.C.; Ahmad, A.; Alshammari, M.B.; Yaakop, A.S. Oxidation of food waste as an organic substrate in a single chamber microbial fuel cell to remove the pollutant with energy generation. Sustain. Energy Technol. Assess. 2022, 52, 102282. [Google Scholar] [CrossRef]

- Arkatkar, A.; Mungray, A.K.; Sharma, P. Effect of microbial growth on internal resistances in MFC: A case study. In Innovations in Infrastructure: Proceedings of ICIIF 2018; Springer: Singapore, 2019; pp. 469–479. [Google Scholar]

- Jung, S.P.; Pandit, S. Important factors influencing microbial fuel cell performance. In Microbial Electrochemical Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 377–406. [Google Scholar]

- Miller, A.; Singh, L.; Wang, L.; Liu, H. Linking internal resistance with design and operation decisions in microbial electrolysis cells. Environ. Int. 2019, 126, 611–618. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Al-Zaqri, N.; Yaakop, A.S.; Umar, K. Potato waste as an effective source of electron generation and bioremediation of pollutant through benthic microbial fuel cell. Sustain. Energy Technol. Assess. 2022, 53, 102560. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, X.; Yin, D.; Cai, L.; Zhang, L. Suspended anode-type microbial fuel cells for enhanced electricity generation. RSC Adv. 2020, 10, 9868–9877. [Google Scholar] [CrossRef] [PubMed]

- La Cruz-Noriega, D.; Nazario-Naveda, R.; Benites, S.M.; Rojas-Flores, S.; Delfín-Narciso, D.; Rojas-Villacorta, W.; Diaz, F. Potential use of mango waste and microalgae Spirulina sp. for bioelectricity generation. Environ. Res. Eng. Manag. 2022, 78, 129–136. [Google Scholar] [CrossRef]

- NCBI Taxonomy Bacillus Marisflavi. Available online: https://microbewiki.kenyon.edu/index.php/Bacillus_Marisflavi (accessed on 1 March 2024).

- Chang, S.; Shin, M.J.; Kim, Y.; Jang, S.J.; Moon, S.I.; Jeong, S.; Shim, R.; Shen, F.; Kang, S.; Chung, P.S. Influence of red pepper (Capsicum annuum) addition on bioenergy production in microbial fuel cells. J. Sustain. Bioenergy Syst. 2019, 9, 179–188. [Google Scholar] [CrossRef]

- Rojas-Villacorta, W.; Rojas-Flores, S.; Benites, S.M.; Delfín-Narciso, D.; Cruz-Noriega, M.D.L.; Cabanillas-Chirinos, L.; Rodríguez-Serin, H.; Rebaza-Araujo, S. Potential Use of Pepper Waste and Microalgae Spirulina Sp. for Bioelectricity Generation. Energy Rep. 2023, 9, 253–261. [Google Scholar] [CrossRef]

- Yousef, N.M.H.; Danial, A.W.; Mawad, A.M.M. Fermentative Bioconversion of Non-Pretreated Wheat Bran to Hydrogen via Cellulolytic Rossellomorea Marisflavi and Role of Calcium Oxide Nanoparticles for Enhancement Gas Productivity. Waste Biomass Valoriz. 2024. [Google Scholar] [CrossRef]

- Anaya-Esparza, L.M.; la Mora, Z.V.; Vázquez-Paulino, O.; Ascencio, F.; Villarruel-López, A. Bell Peppers (Capsicum annum L.) Losses and Wastes: Source for Food and Pharmaceutical Applications. Molecules 2021, 26, 5341. [Google Scholar] [CrossRef]

| Code | Identified Species | Identity (%) | Accession Number |

|---|---|---|---|

| 1 | Rossellomorea marisflavi | 99.57% | JCM 11544 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Segundo, R.-F.; Magaly, D.L.C.-N.; Luis, C.-C.; Otiniano, N.M.; Soto-Deza, N.; Terrones-Rodriguez, N.; Mayra, D.L.C.-C. Obtaining Sustainable Electrical Energy from Pepper Waste. Sustainability 2024, 16, 3448. https://doi.org/10.3390/su16083448

Segundo R-F, Magaly DLC-N, Luis C-C, Otiniano NM, Soto-Deza N, Terrones-Rodriguez N, Mayra DLC-C. Obtaining Sustainable Electrical Energy from Pepper Waste. Sustainability. 2024; 16(8):3448. https://doi.org/10.3390/su16083448

Chicago/Turabian StyleSegundo, Rojas-Flores, De La Cruz-Noriega Magaly, Cabanillas-Chirinos Luis, Nélida Milly Otiniano, Nancy Soto-Deza, Nicole Terrones-Rodriguez, and De La Cruz-Cerquin Mayra. 2024. "Obtaining Sustainable Electrical Energy from Pepper Waste" Sustainability 16, no. 8: 3448. https://doi.org/10.3390/su16083448

APA StyleSegundo, R.-F., Magaly, D. L. C.-N., Luis, C.-C., Otiniano, N. M., Soto-Deza, N., Terrones-Rodriguez, N., & Mayra, D. L. C.-C. (2024). Obtaining Sustainable Electrical Energy from Pepper Waste. Sustainability, 16(8), 3448. https://doi.org/10.3390/su16083448