Hydrothermally Treated Biomass Fly Ash as an Additive for Portland Cement

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparations

2.3. Testing Methods

3. Results

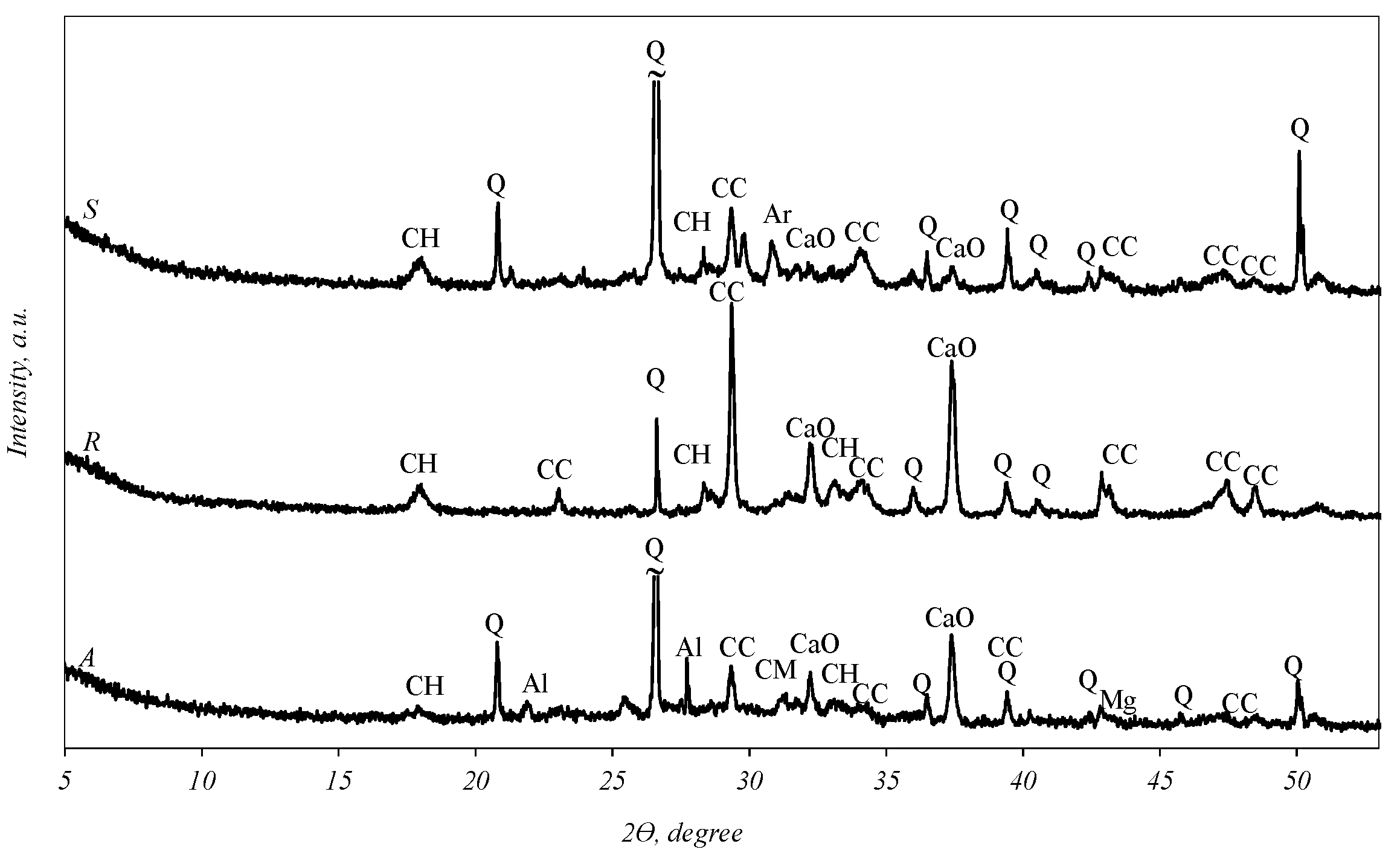

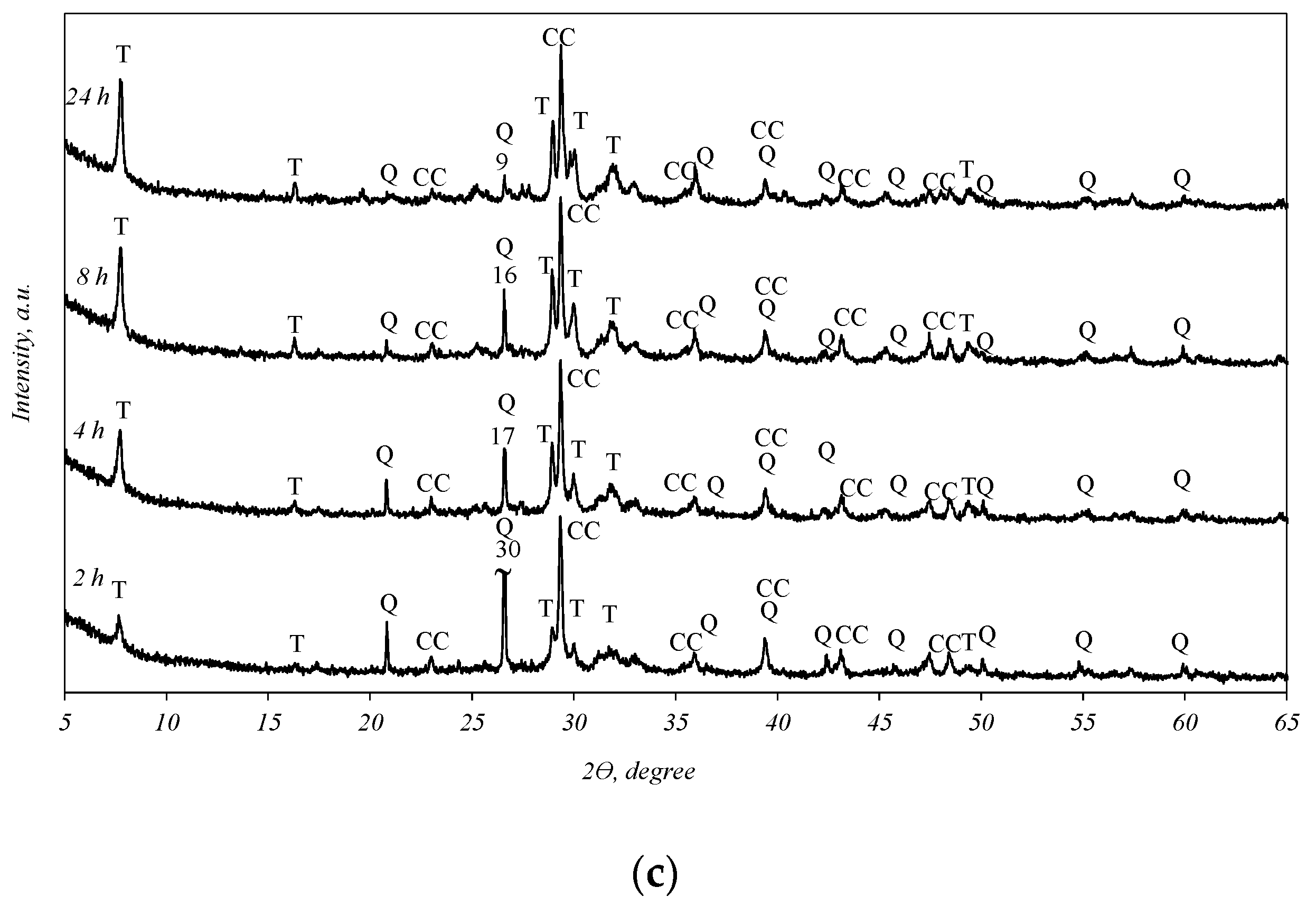

3.1. Hydrothermal Treatment of Biomass Fly Ash

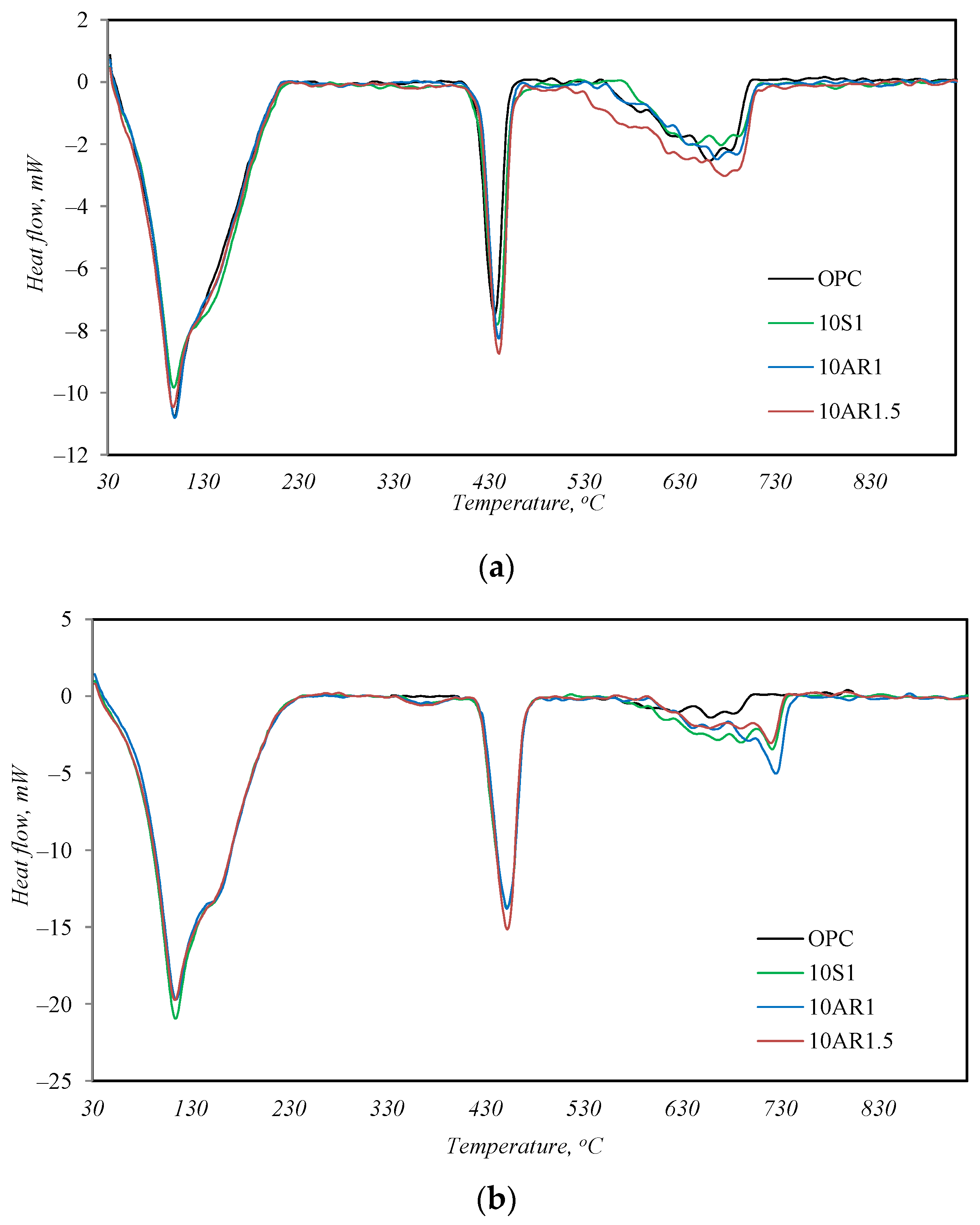

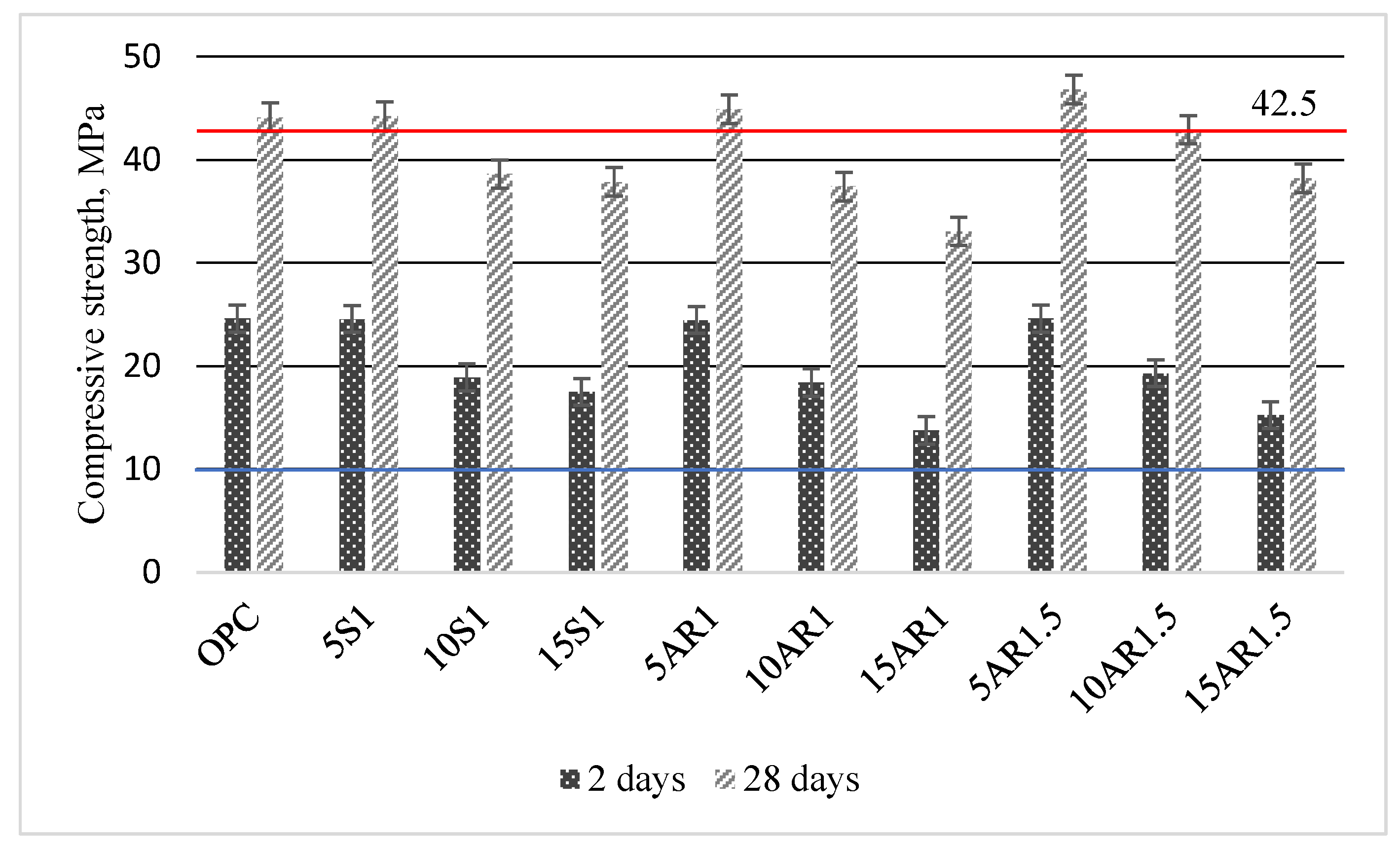

3.2. The Influence of Synthesized Additive on Portland Cement Hydration and Hardening

4. Conclusions

- The biomass fly ash collected in the e-filters was distinguished by the highest CaO/SiO2 ratio (7.39–8.57), and in the ash collected in a common gas treatment system or in cyclones, this ratio varied only in the range of 0.67–1.56.

- Calcium silicate hydrates had already formed after 2 h of hydrothermal treatment at 200 °C, when the initial CaO/SiO2 ratio of 1 and 1.5 was chosen. In the synthesis products, tobermorite and amorphous calcium silicate hydrates dominated. Together with these compounds, quartz, calcite, and hydrogarnets were identified.

- All synthesized additives accelerated the hydration of calcium silicates in the early period of hydration of Portland cement.

- 5% to 10% of the weight of cement can be replaced by hydrothermally treated biomass fly ash without reducing the compressive strength class of Portland cement samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sánchez, J.; Curt, M.D.; Robert, N.; Fernández, J. Chapter Two—Biomass Resources. In The Role of Bioenergy in the Bioeconomy; Lago, C., Caldés, N., Lechón, Y., Eds.; Academic Press: London, UK, 2019; pp. 25–111. [Google Scholar]

- Dogar, S.; Nayab, S.; Farooq, M.Q.; Said, A.; Kamran, R.; Duran, H.; Yameen, B. Utilization of Biomass Fly Ash for Improving Quality of Organic Dye-Contaminated Water. ACS Omega 2020, 5, 15850–15864. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, H.H.T.; Nguyen, H.T.; Ahmed, S.F.; Rajamohan, N.; Yusuf, M.; Sharma, A.; Arunkumar, P.; Deepanraj, B.; Tran, H.T.; Al, G.A.; et al. Emerging waste-to-wealth applications of fly ash for environmental remediation: A review. Environ. Res. 2023, 227, 115800. [Google Scholar] [CrossRef] [PubMed]

- Rajamma, R.; Ball, R.J.; Tarelho, L.A.C.; Allen, G.C.; Labrincha, J.A.; Ferreira, V.M. Characterisation and use of biomass fly ash in cement-based materials. J. Hazard. Mater. 2009, 172, 1049–1060. [Google Scholar] [CrossRef]

- Carevic, I.; Baricevic, A.; Štirmer, N.; Šantek, B.J. Correlation between physical and chemical properties of wood biomass ash and cement composites performances. Constr. Build. Mater. 2020, 256, 119450. [Google Scholar] [CrossRef]

- Ganesana, K.; Rajagopala, K.; Thangavelb, K. Evaluation of bagasse ash as supplementary cementitious material. Cem. Concr. Compos. 2007, 29, 515–524. [Google Scholar] [CrossRef]

- Jura, J. Influence of Type of Biomass Burned on the Properties of Cement Mortar Containing Fly Ash. Constr. Optim. Energy Potential. 2020, 9, 77–82. [Google Scholar] [CrossRef]

- Hamid, Z.; Rafiq, S. An experimental study on behavior of wood ash in concrete as partial replacement of cement. Mater. Today Proc. 2021, 46, 3426–3429. [Google Scholar] [CrossRef]

- Demis, S.; Rodrigues, C.S.; Santos, L.A.; Papadakis, V.G. An investigation of the effectiveness and durability characteristic of biomass ashes as pozzolanic materials. In Proceedings of the 13th International Conference on Durability of Building Materials and Components—XIII DBMC, Sao Paulo, Brazil, 2–5 September 2014. [Google Scholar]

- Kaminskas, R.; Cesnauskas, V. Influence of activated biomass fly ash on portland cement hydration. Ceram Silik 2014, 58, 260–268. [Google Scholar]

- Gabrijel, I.; Jelčić, M.R.; Štirmer, N. Influence of Wood Fly Ash on Concrete Properties through Filling Effect Mechanism. Materials 2021, 14, 7164. [Google Scholar] [CrossRef] [PubMed]

- Nicoleau, L. Accelerated growth of calcium silicate hydrates: Experiments and simulations. Cem. Concr. Res. 2011, 41, 1339–1348. [Google Scholar] [CrossRef]

- Houston, J.R.; Maxwell, R.S.; Carroll, S.A. Transformation of meta-stable calcium silicate hydrates to tobermorite: Reaction kinetics and molecular structure from XRD and NMR spectroscopy. Geochem. Trans. 2009, 10, 1. [Google Scholar] [CrossRef] [PubMed]

- Thomas, J.J.; Jennings, H.M.; Chen, J.J. Influence of nucleation seeding on the hydration mechanisms of tricalcium silicate and cement. J. Phys. Chem. C 2009, 113, 4327–4334. [Google Scholar] [CrossRef]

- Bost, P.; Regnier, M.; Horgnies, M. Comparison of the accelerating effect of various additions on the early hydration of Portland cement. Constr. Build. Mater. 2016, 113, 290–296. [Google Scholar] [CrossRef]

- Owens, K.; Russell, M.I.; Donnelly, G.; Kirk, A.; Basheer, P.A.M. Use of nanocrystal-seeding chemical admixture in improving Portland cement strength development: Application for precast concrete industry. Adv. Appl. Ceram. 2014, 113, 478–484. [Google Scholar] [CrossRef]

- John, E.; Matschei, T.; Stephan, D. Nucleation seeding with calcium silicate hydrate—A review. Cem. Concr. Res. 2018, 113, 74–85. [Google Scholar] [CrossRef]

- Artioli, G.; Valentini, L.; Dalconi, M.C.; Parisatto, M.; Voltolini, M.; Russo, V.; Ferrari, G. Imaging of nano-seeded nucleation in cement pastes by X-ray diffraction tomography. Int. J. Mater. Res. 2014, 7, 628–631. [Google Scholar] [CrossRef]

- Viallis, H.T.; Nonat, A.; Petit, J.C. Zeta-potential study of calcium silicate hydrates interacting with alkaline cations. J. Colloid. Interface Sci. 2001, 244, 58–65. [Google Scholar] [CrossRef]

- Lothenbach, B.; Nonat, A. Calcium silicate hydrates: Solid and liquid phase composition. Cem. Concr. Res. 2015, 78, 57–70. [Google Scholar] [CrossRef]

- EN 196-2:2013; Methods of Testing Cement—Part 2: Chemical Analysis of Cement. iTeh, Inc.: Newark, DE, USA, 2013.

- El, H.D.; Amer, A.A.; Sokkary, T.M.; El, S.H. Hydration and characteristics of metakaolin pozzolanic cement pastes. HBRC J. 2018, 14, 150–158. [Google Scholar]

- Tõnsuaadu, K.; Gross, K.A.; Plūduma, L.; Veiderma, M. A review on the thermal stability of calcium apatites. J. Therm. Anal. Calorim. 2012, 110, 647–659. [Google Scholar] [CrossRef]

- EN 196-3:2016; Methods of Testing Cement. Determination of Setting Times and Soundness. iTeh, Inc.: Newark, DE, USA, 2016.

- EN 196-1:2016; Methods of Testing Cement. Determination of Strength. iTeh, Inc.: Newark, DE, USA, 2016.

- Chen, M.; Lu, L.; Wang, S.; Zhao, P.; Zhang, W.; Zhang, S. Investigation on the formation of tobermorite in calcium silicate board and its influence factors under autoclaved curing. Constr. Build. Mat. 2017, 143, 280–288. [Google Scholar] [CrossRef]

- Pytel, Z. Synthesis of hydrogarnets in the system Al2O3·2SiO2-SiO2-CaO-H2O under hydrothermal conditions, Építôanyag. J. Silic. Based Compos. Mater. 2019, 71, 6. [Google Scholar]

- Gineika, A.; Siauciunas, R.; Baltakys, K. Synthesis of wollastonite from AlF3-rich silica gel and its hardening in the CO2 atmosphere. Sci. Rep. 2019, 9, 18063. [Google Scholar] [CrossRef] [PubMed]

- Kaminskas, R.; Monstvilaite, D.; Valanciene, V. Influence of low-pozzolanic activity calcined mica clay on hydration and hardening of Portland cement. Adv. Cem. Res. 2018, 30, 231–239. [Google Scholar] [CrossRef]

- EN 197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. iTeh, Inc.: Newark, DE, USA, 2011.

| Sample | S | R | A | Portland Cement (OPC) |

|---|---|---|---|---|

| CaO | 27.1 | 58.3 | 27.9 | 61.39 |

| SiO2 | 26.5 | 6.8 | 41.6 | 19.52 |

| K2O | 9.91 | 4.52 | 4.87 | 1.06 |

| SO3 | 7.55 | 1.9 | 3.22 | 2.5 |

| MgO | 2.77 | 4.59 | 3.59 | 3.93 |

| Al2O3 | 2.64 | 2.85 | 4.23 | 5.03 |

| P2O5 | 2.61 | 2.57 | 2.95 | - |

| Fe2O3 | 1.57 | 1.28 | 3.30 | 3.05 |

| Cl | 1.09 | 1.01 | 0.386 | - |

| Na2O | 0.475 | 0.788 | 0.597 | 0.12 |

| TiO2 | 0.359 | 1.64 | 0.353 | - |

| ZnO | 0.329 | 0.294 | 0.148 | - |

| MnO | 0.246 | 0.846 | 0.728 | - |

| BaO | 0.118 | 0.2 | 0.143 | - |

| SrO | 0.042 | 0.07 | 0.045 | - |

| WO3 | 0.04 | - | - | - |

| ZrO2 | 0.026 | 0.013 | 0.03 | - |

| CuO | 0.02 | 0.023 | 0.02 | - |

| Rb2O | 0.014 | 0.01 | 0.01 | - |

| PbO | 0.013 | 77 ppm | 80 ppm | - |

| Br | 53 ppm | 0.013 | - | - |

| CoO | 33 ppm | - | - | - |

| C/S ratio | 1.02 | 8.57 | 0.67 |

| Sample | Abbreviations | C/S Ratio |

|---|---|---|

| Fly ash collected from the common gas treatment system | S1 | 1.02 |

| Mix of fly ash collected from the common gas treatment system and e-filters | AR1 | 1.00 |

| Mix of fly ash collected from the common gas treatment system and e-filters | AR1.5 | 1.50 |

| Sample | Duration of Synthesis, h | |||

|---|---|---|---|---|

| 2 | 4 | 8 | 24 | |

| Mass Loss (%) | ||||

| S1 | 3.51 | 4.05 | 4.20 | 4.14 |

| AR1 | 3.97 | 4.53 | 4.60 | 4.66 |

| AR1.5 | 2.42 | 3.08 | 3.38 | 3.75 |

| Component | AR1 | AR1.5 | S1 |

|---|---|---|---|

| Concentration | wt.% | ||

| SO3 | 0.8 | 0.9225 | 0.4125 |

| K2O | 1.626923 | 1.852885 | 4.278205 |

| Na2O | 0.3875 | 0.377391 | 0.303261 |

| CaO | 0.000374 | 0.001426 | 0.003126 |

| Concentration | ppm | ||

| MgO | 0.55 | 0.55 | 3.516667 |

| P2O5 | 0.99629 | 0.618387 | 0.77871 |

| PbO | 0 | 0.118502 | 0.075411 |

| TiO2 | 0 | 0 | 0 |

| Al2O3 | 18.23722 | 90.57222 | 0.661111 |

| SrO | 0.171364 | 0.200909 | 0.165455 |

| CuO | 1.6125 | 0.475 | 0.43125 |

| ZnO | 0.311538 | 0.423692 | 0.174462 |

| BaO | 0.15635 | 0.34062 | 0.413212 |

| MnO | 0 | 0 | 0 |

| Fe2O3 | 0.485714 | 0.307143 | 0 |

| Total leached from ash, wt.% | 2.8170 | 3.1636 | 4.9977 |

| Component (wt.%) | Abbreviation | Normal Consistency W/C (%) | Setting Time (min) | ||||

|---|---|---|---|---|---|---|---|

| OPC | S1 | AR1 | AR1.5 | Initial | Final | ||

| 100 | - | - | - | OPC | 0.28 | 84 | 136 |

| 90 | 10 | - | - | 10S1 | 0.36 | 80 | 165 |

| 90 | - | 10 | - | 10AR1 | 0.34 | 85 | 170 |

| 90 | - | - | 10 | 10AR1.5 | 0.32 | 120 | 175 |

| Sample | Mass Loss (%) | ||

|---|---|---|---|

| Temperature Range (°C) | |||

| 50–220 | ~450 | 570–750 | |

| After 2 Days of Hydration | |||

| OPC | 7.04 | 2.01 | 2.40 |

| 10S1 | 7.40/7.05 * | 2.19 | 2.41 |

| 10AR1 | 7.74/7.35 * | 1.88 | 2.73 |

| 10AR1.5 | 7.28/7.04 * | 2.47 | 3.41 |

| After 28 days of hydration | |||

| OPC | 8.90 | 2.80 | 2.85 |

| 10S1 | 9.41/9.06 * | 2.55 | 3.63 |

| 10AR1 | 9.01/8.62 * | 2.76 | 3.82 |

| 10AR1.5 | 8.9/8.76 * | 2.87 | 3.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaminskas, R.; Eisinas, A.; Barauskas, I.; Gaivenis, M. Hydrothermally Treated Biomass Fly Ash as an Additive for Portland Cement. Sustainability 2024, 16, 2754. https://doi.org/10.3390/su16072754

Kaminskas R, Eisinas A, Barauskas I, Gaivenis M. Hydrothermally Treated Biomass Fly Ash as an Additive for Portland Cement. Sustainability. 2024; 16(7):2754. https://doi.org/10.3390/su16072754

Chicago/Turabian StyleKaminskas, Rimvydas, Anatolijus Eisinas, Irmantas Barauskas, and Motiejus Gaivenis. 2024. "Hydrothermally Treated Biomass Fly Ash as an Additive for Portland Cement" Sustainability 16, no. 7: 2754. https://doi.org/10.3390/su16072754

APA StyleKaminskas, R., Eisinas, A., Barauskas, I., & Gaivenis, M. (2024). Hydrothermally Treated Biomass Fly Ash as an Additive for Portland Cement. Sustainability, 16(7), 2754. https://doi.org/10.3390/su16072754