Evaluating Drivers and Barriers of Integrated Waste Management System Implementation in Indonesian Construction Industry: A DEMATEL-Based Analytical Network Process

Abstract

1. Introduction

- Affecting human health, such as respiratory diseases;

- Air pollution occurs in the form of dust and hazardous compounds;

- Water pollution appears in both ground and surface water;

- Esthetically unappealing surrounding environment;

- Reducing the quality and productivity of the soil.

2. Materials and Methods

- Knowledge: an individual who has a predetermined and proper knowledge and experience base.

- Experience: an individual who worked in a specific area for a certain period.

- Policy Influence: an individual recognized as an opinion-maker within national organizations.

- Hold, at minimum, bachelor’s degree;

- From the company: minimum position within a managerial level;

- Has worked in the construction industry for more than five years;

- Has a role that deals with waste management within the company.

- 1.

- Calculate the probability of change agreement (Pc)

- 2.

- Calculate the Modified Kappa score (k*)

DEMATEL-Based ANP

- 1.

- Obtain the matrix of direct influence from the expert panel that shows the impact of factor i on factor j represented by

- 2.

- The next stage is to form a direct relation matrix (Z). The matrix can be obtained using the following equation:

- 3.

- The third stage is to form a normalized direct relation matrix (D). Normalized direct relation matrix (D) can be calculated using

- 4.

- Calculate total relation matrix (T)

- 5.

- The fifth stage is to calculate the Network Relationship Map (NRM) obtained from the following parameters:

- 6.

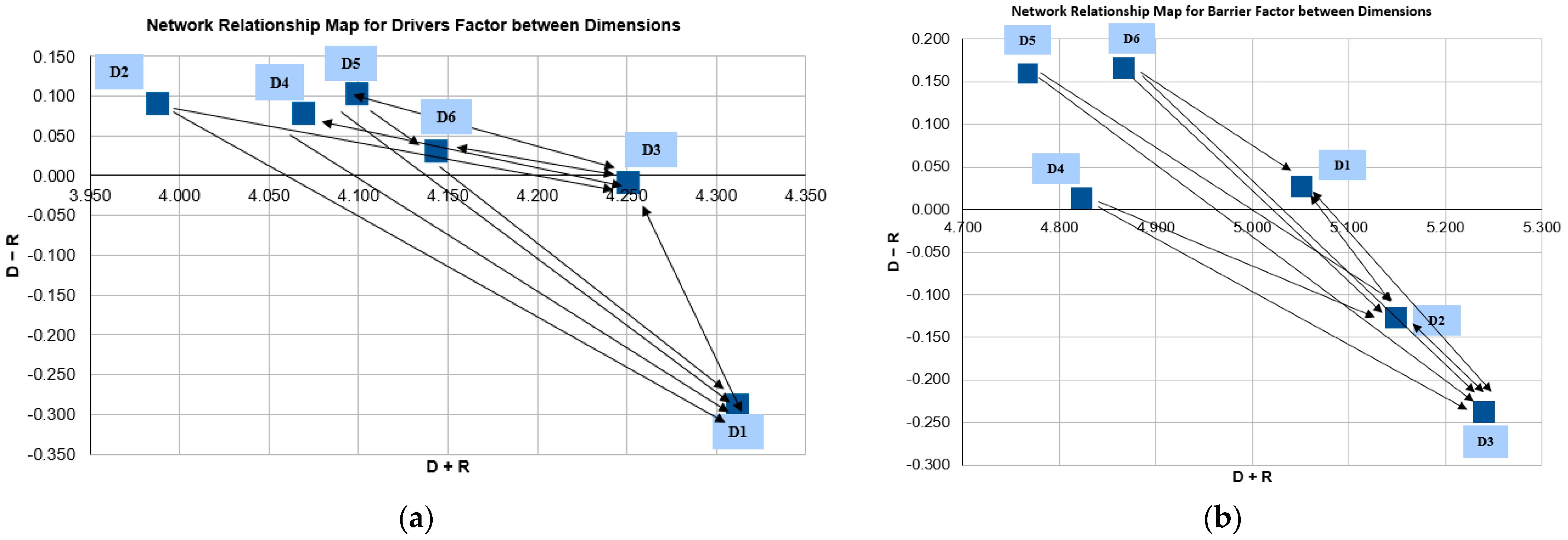

- The sum of the rows of the T matrix is represented by Di, which shows the effect of factor i on the other factors. Furthermore, the sum of the columns of the T matrix is represented by Ri, which shows the influence on factor j by other factors. Based on the values of Di + Ri and Di − Ri, a Network Relationship Map (NRM) can be formed. The individual influence of one factor on another is represented through arrows on the NRM. A threshold value needs to be selected to determine the individual influence between factors. This threshold value is calculated through the total relation matrix (T) average for each dimension and factor. When the value of the elements in the total relation matrix (T) exceeds the threshold value, an arrow will be drawn on the NRM. This indicates a direct relationship between factors. The sixth step is to form a normalized total relation matrix. The total relation matrix (T) includes TD for dimensions and TC for factors.

- 7.

- The next stage is to form an unweighted supermatrix (W). The matrix is obtained after normalizing total relation matrix (T). Next, the matrix is transposed to obtained unweighted supermatrix (W). The weighted supermatrix is obtained by multiplying unweighted supermatrix (W) with transpose.

- 8.

- The last step is to obtain the factor weights. The factor obtained by limiting the weighted supermatrix ( until the supermatrix is stable. The element values in the limit supermatrix are the weights of each factor.

3. Results

4. Discussion

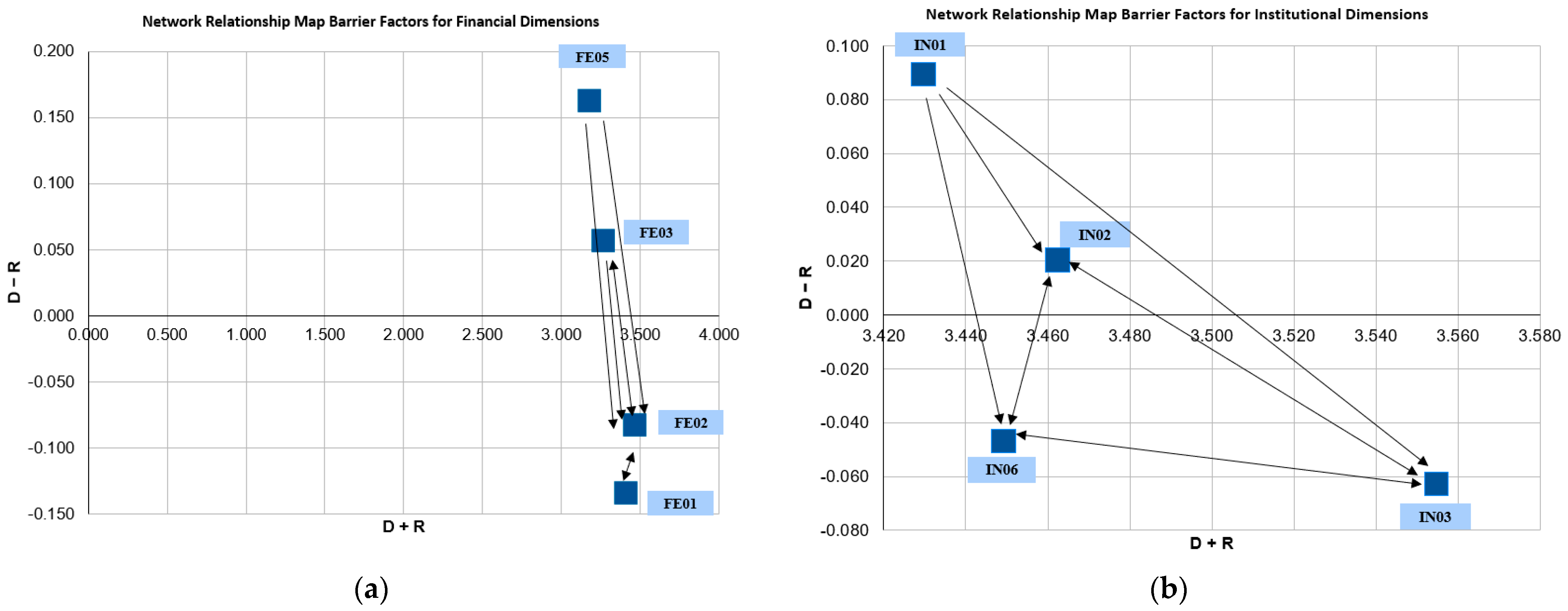

4.1. Financial or Economic Dimensions

4.2. Institutional Dimensions

4.3. Environmental Dimensions

4.4. Technical Dimensions

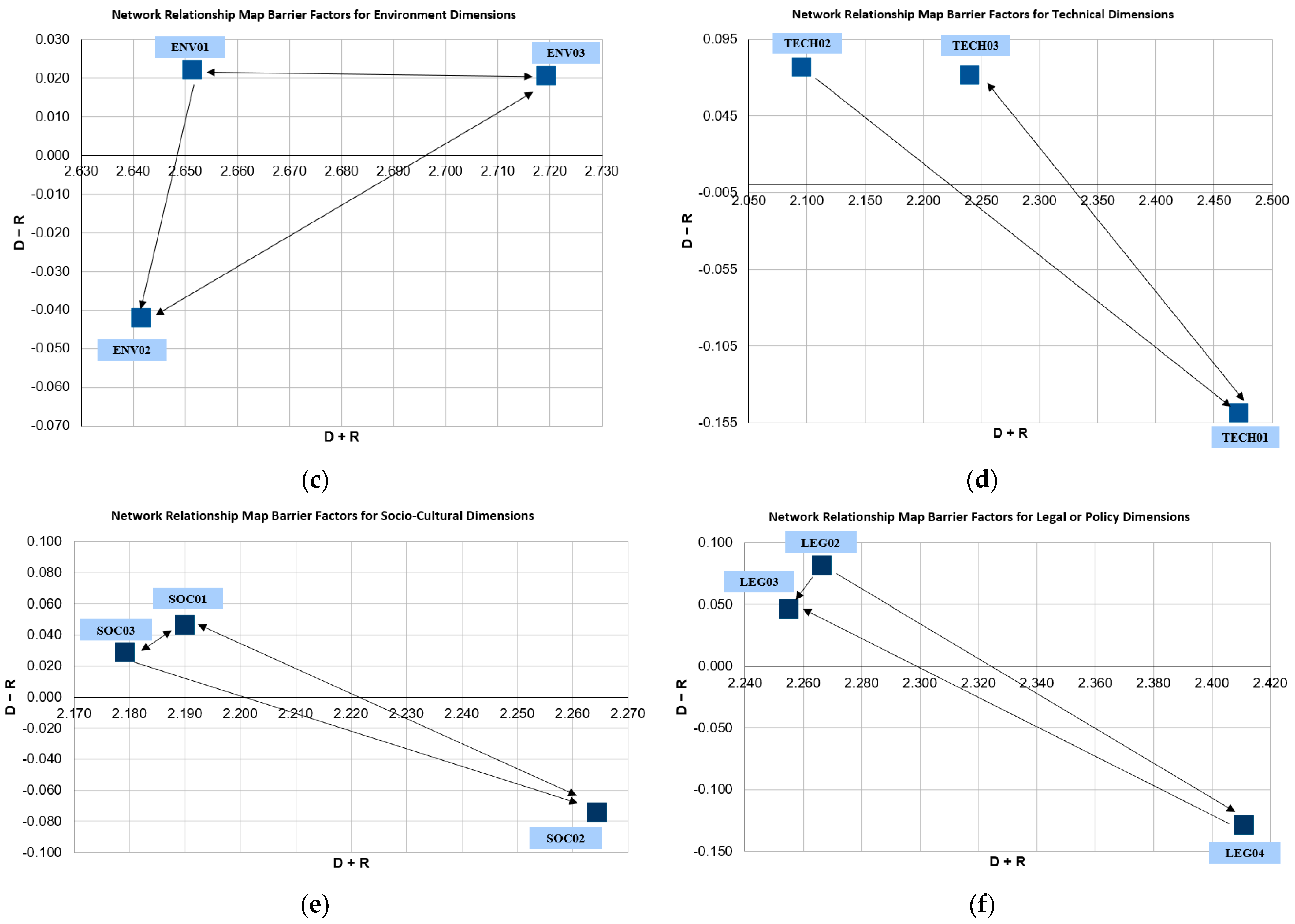

4.5. Socio-Cultural Dimensions

4.6. Legal or Policy Dimensions

4.7. Priority Level

4.8. Waste Management in Indonesian Construction Industries

5. Conclusions

- Awareness is the foremost driving factor for the construction industry’s implementation of waste management. This is supported by Hasan’s research in 2004 [45], where he stated that awareness and participation can lead to successful waste management.

- Knowledge can hinder the construction industry’s implementation of waste management. Insufficient knowledge regarding properly implementing construction waste management can impede its adoption.

- Research limitation: This research only relies on questionnaires. Therefore, interviews or focus group discussions (FGDs) could be conducted for future research to obtain more accurate and insightful responses. Additionally, further analysis of the specific results of this research can be undertaken by subsequent researchers.

- Future studies: Since there is much data involved, the authors recommend, for future studies, the use of machine learning techniques to identify patterns and analyze the data.

6. Practical Implications

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Indonesia Population. 2023. Available online: https://www.worldometers.info/world-population/indonesia-population/ (accessed on 6 January 2024).

- 7,2 Juta Ton Sampah di Indonesia Belum Terkelola Dengan Baik. 2023. Available online: https://www.kemenkopmk.go.id/72-juta-ton-sampah-di-indonesia-belum-terkelola-dengan-baik#:~:text=7%2C2JutaTonSampahdiIndonesiaBelumTerkelolaDenganBaik,-Gatot%3AButuhRevolusi&text=Daritotalproduksisampahnasional,tonbelumterkeloladenganbaik (accessed on 6 January 2024).

- Bappenas. Manfaat Ekonomi, Sosial, dan Lingkungan dari Ekonomi Sirkular di Indonesia. 2021. Available online: https://lcdi-indonesia.id/wp-content/uploads/2021/02/Ringkasan-Eksekutif-Manfaat-Ekonomi-Sosial-dan-Lingkungan-dari-Ekonomi-Sirkular-di-Indonesia.pdf (accessed on 10 January 2024).

- Kulatunga, U.; Amaratunga, D.; Haigh, R.; Rameezdeen, R. Attitudes and perceptions of construction workforce on construction waste in Sri Lanka. Manag. Environ. Qual. Int. J. 2006, 17, 57–72. [Google Scholar] [CrossRef]

- Tafesse, S.; Girma, Y.E.; Dessalegn, E. Analysis of the socio-economic and environmental impacts of construction waste and management practices. Heliyon 2022, 8, e09169. [Google Scholar] [CrossRef]

- Perkembangan Industri Konstruksi Indonesia. Available online: https://www.archive.bps.go.id/ (accessed on 10 January 2024).

- Widhiawati, I.A.R.; Astana, Y.; Indrayani, N.L.A. Kajian Pengelolaan Limbah Konstruksi Pada Proyek Pembangunan Gedung di Bali. Ilm. Tek. Sipil 2019, 23, 55–61. [Google Scholar]

- Yahya, K.; Halim Boussabaine, A. Eco-costing of construction waste. Manag. Environ. Qual. Int. J. 2006, 17, 6–19. [Google Scholar] [CrossRef]

- Kong, L.; Ma, B. Evaluation of environmental impact of construction waste disposal based on fuzzy set analysis. Environ. Technol. Innov. 2020, 19, 100877. [Google Scholar] [CrossRef]

- ISO 14001:2015; Environmental Management Systems. International Organization for Standardization: Geneva, Switzerland. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14001:ed-3:v1:en (accessed on 10 January 2024).

- Jumlah Perusahaan yang Menerapkan ISO 14001. Available online: https://www.bps.go.id/id/statistics-table/2/MTc0NCMy/jumlah-perusahaan-yang-menerapkan-sertifikasi-sni-iso-14001.html (accessed on 14 January 2024).

- Mhatre, P.; Gedam, V.V.; Unnikrishnan, S.; Raut, R.D. Circular economy adoption barriers in built environment- a case of emerging economy. J. Clean. Prod. 2023, 392, 136201. [Google Scholar] [CrossRef]

- Lee, C.; Chen, M.; Zainudin, N.; Fauzi, M.; Toh, T. Transformation of Industrial Revolution 4.0 in the Construction Industry: Understanding Drivers Barriers with Dematel Algorithm. Int. J. Ind. Manag. 2022, 16, 31–43. [Google Scholar] [CrossRef]

- Yadav, H.; Soni, U.; Kumar, G. Analysing Challenges to Smart Waste Management for a Sustainable Circular Economy in Developing countries: A fuzzy DEMATEL study. Smart Sustain. Built Environ. 2021, 12, 361–384. [Google Scholar] [CrossRef]

- Al-Otaibi, A.; Bowan, P.A.; Abdel Daiem, M.M.; Said, N.; Ebohon, J.O.; Alabdullatief, A.; Al-Enazi, E.; Watts, G. Identifying the Barriers to Sustainable Management of Construction and Demolition Waste in Developed and Developing Countries. Sustainability 2022, 14, 7532. [Google Scholar] [CrossRef]

- Ratnasabapathy, S.; Alashwal, A.; Perera, S. Exploring the barriers for implementing waste trading practices in the construction industry in Australia. Built Environ. Proj. Asset Manag. 2021, 11, 559–576. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W.Y. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Kadiri, K.O. Reducing waste to landfill: A need for cultural change in the UK construction industry. J. Build. Eng. 2016, 5, 185–193. [Google Scholar] [CrossRef]

- Zhao, X. Stakeholder-Associated Factors Influencing Construction and Demolition Waste Management: A Systematic Review. Buildings 2021, 11, 149. [Google Scholar] [CrossRef]

- Ullah, F.; Sepasgozar, S.M.E.; Jamaluddin Thaheem, M.; Cynthia Wang, C.; Imran, M. It’s all about perceptions: A DEMATEL approach to exploring user perceptions of real estate online platforms. Ain Shams Eng. J. 2021, 12, 4297–4317. [Google Scholar] [CrossRef]

- Chiu, W.Y.; Tzeng, G.H.; Li, H.L. A new hybrid MCDM model combining DANP with VIKOR to improve e-store business. Knowl. Based Syst. 2013, 37, 48–61. [Google Scholar] [CrossRef]

- Kamranfar, S.; Azimi, Y.; Gheibi, M.; Fathollahi-Fard, A.; Hajiaghaei-Keshteli, M. Analyzing Green Construction Development Barriers by a Hybrid Decision-Making Method Based on DEMATEL and the ANP. Buildings 2022, 12, 1641. [Google Scholar] [CrossRef]

- Wu, W. Choosing knowledge management strategies by using a combined ANP and DEMATEL approach. Expert Syst. Appl. 2008, 35, 828–835. [Google Scholar] [CrossRef]

- Abarca-Guerrero, L.; Maas, G.; van Twillert, H. Barriers and Motivations for Construction Waste Reduction Practices in Costa Rica. Resources 2017, 6, 69. [Google Scholar] [CrossRef]

- Park, J.; Tucker, R. Overcoming barriers to the reuse of construction waste material in Australia: A review of the literature. Int. J. Constr. Manag. 2017, 17, 228–237. [Google Scholar] [CrossRef]

- Baker, J.; Lovell, K.; Harris, N. How expert are the experts? An exploration of the concept of ‘expert’ within Delphi panel tech-niques. Nurs. Res. 2006, 14, 59–70. [Google Scholar] [CrossRef] [PubMed]

- Sugiharni, G.A.D. Pengujian Validitas Konten Media Pembelajaran Interaktif Berorientasi Model Creative Problem Solving. J. Penelit. Dan Pengemb. Pendidik. 2018, 2, 88. [Google Scholar] [CrossRef]

- Yusoff, M.S.B. ABC of Content Validation and Content Validity Index Calculation. Educ. Med. J. 2019, 11, 49–54. [Google Scholar] [CrossRef]

- Almanasreh, E.; Moles, R.; Chen, T.F. Evaluation of methods used for estimating content validity. Res. Soc. Adm. Pharm. 2019, 15, 214–221. [Google Scholar] [CrossRef]

- Garvin, B.J.; Kennedy, C.W.; Cissna, K.N. Reliability in category coding systems. Nurs. Res. 1988, 37, 52–55. [Google Scholar] [CrossRef] [PubMed]

- Topf, M. Three estimates of interrater reliability for nominal data. Nurs. Res. 1986, 35, 253–255. [Google Scholar] [CrossRef] [PubMed]

- Crocker, L. Content Validity. In International Encyclopedia of the Social Behavioral Sciences, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; Volume 1, pp. 774–777. [Google Scholar] [CrossRef]

- Cicchetti, D.V.; Sparrow, S.A. Developing criteria for establishing interrater reliability of specific items: Applications to assessment of adaptive behavior. Am. J. Ment. Defic. 1981, 86, 127–137. [Google Scholar]

- Chen, F.H.; Hsu, T.S.; Tzeng, G.H. A balanced scorecard approach to establish a performance evaluation and relationship model for hot spring hotels based on a hybrid MCDM model combining DEMATEL and ANP. Int. J. Hosp. Manag. 2011, 30, 908–932. [Google Scholar] [CrossRef]

- Khan, S.; Maqbool, A.; Haleem, A.; Khan, M.I. Analyzing critical success factors for a successful transition towards circular economy through DANP approach. Manag. Environ. Qual. Int. J. 2020, 31, 505–529. [Google Scholar] [CrossRef]

- Nawaz, A.; Chen, J.; Su, X.; Zahid Hassan, H.M. Material Based Penalty-Cost Quantification Model for Construction Projects Influencing Waste Management. Front. Environ. Sci. 2022, 10, 807359. [Google Scholar] [CrossRef]

- Udawatta, N.; Zuo, J.; Chiveralls, K.; Yuan, H.; Zillante, G.; Elmualim, A. Major factors impeding the implementation of waste management in Australian construction projects. J. Green Build. 2018, 13, 101–121. [Google Scholar] [CrossRef]

- Foltean, F.S.; Trif, S.M.; Tuleu, D.L. Customer relationship management capabilities and social media technology use: Consequences on firm performance. J. Bus. Res. 2019, 104, 563–575. [Google Scholar] [CrossRef]

- Nykvist, B.; Borgström, S.; Boyd, E. Assessing the adaptive capacity of multi-level water governance: Ecosystem services under climate change in Mälardalen region, Sweden. Reg. Environ. Chang. 2017, 17, 2359–2371. [Google Scholar] [CrossRef]

- Yusuf, R.; Fajri, I. Differences in behavior, engagement and environmental knowledge on waste management for science and social students through the campus program. Heliyon 2022, 8, e08912. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, Y.; Shen, L. Application of low waste technologies for design and construction: A case study in Hong Kong. Renew. Sustain. Energy Rev. 2012, 16, 2973–2979. [Google Scholar] [CrossRef]

- Pollington, C. Legal and procurement practices for sustainable development. Build. Res. Inf. 1999, 27, 409–411. [Google Scholar] [CrossRef]

- Kompas. Tahun 2010, Pengelola Gedung Tinggi di Jakarta Wajib Terapkan “Green Building.” 2009. Available online: https://biz.kompas.com/read/2009/09/10/18490643/~Megapolitan~News (accessed on 4 March 2024).

- Pidugu, A.; Khandelwal, U.; Rathi, R. C and D Waste Treatment and Policies in Australia, China, and India: A Comparative Study. NICMAR-J. Constr. Manag. 2023, 37, 227–233. [Google Scholar]

- Hasan, S.E. Public Awareness Is Key to Successful Waste Management. J. Environ. Sci. Health—Part A Toxic/Hazard. Subst. Environ. Eng. 2004, 39, 483–492. [Google Scholar] [CrossRef]

- Ramos, M.; Martinho, G.; Pina, J. Strategies to promote construction and demolition waste management in the context of local dynamics. Waste Manag. 2023, 162, 102–112. [Google Scholar] [CrossRef]

- Wilson, D. Development drivers for waste management. Waste Manag. Res. 2007, 25, 198–207. [Google Scholar] [CrossRef]

- Yilmaz, M. Sustainability in Construction Sector. Procedia—Soc. Behav. Sci. 2015, 195, 2253–2262. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F. A review on barriers, drivers, and stakeholders towards the circular economy: The construction sector perspective. Clean. Responsible Consum. 2023, 8, 100107. [Google Scholar] [CrossRef]

- Zhang, A.; Venkatesh, V.; Liu, Y.; Wan, M.; Qu, T.; Huisingh, D. Barriers to smart waste management for a circular economy in China. J. Clean. Prod. 2019, 240, 118198. [Google Scholar] [CrossRef]

| Expert | Background | Experience | Contribution |

|---|---|---|---|

| Expert 1 | Academia | >20 years | Validating Factors and Pairwise Comparison Questionnaire |

| Expert 2 | Quality and Human Safety Environment Manager | >20 years | Validating Factors and Pairwise Comparison Questionnaire |

| Expert 3 | Operational Director | >20 years | Validating Factors and Pairwise Comparison Questionnaire |

| Expert 4 | Project Engineering Manager | 5–10 years | Validating Factors and Pairwise Comparison Questionnaire |

| Expert 5 | Commitment-maker | 15–20 years | Validating Factors and Pairwise Comparison Questionnaire |

| Expert 6 | Head of Commercial Environment | 5–10 years | Pairwise Comparison Questionnaire |

| Expert 7 | Site Engineer Manager | 5–10 years | Pairwise Comparison Questionnaire |

| Kappa Score | Interpretation |

|---|---|

| <0.40 | Poor |

| 0.40–0.59 | Fair |

| 0.60–0.74 | Good |

| 0.75–1.00 | Excellent |

| Dimension | Code | Factors | Descriptions | Kappa Score | Interpretation |

|---|---|---|---|---|---|

| Financial or Economics (D1) | FE06 | High Disposal Cost | The cost of disposal is high when disposing of construction waste directly to the final disposal site | 0.76 | Excellent |

| FE07 | Cost Reduction Awareness | There is an awareness of the need to reduce costs by minimizing material loss and conserving raw materials | 1.00 | Excellent | |

| FE08 | Compensation | Decreasing legal expenses related to environmental issues (fines, compensation) | 1.00 | Excellent | |

| FE09 | Additional Profit | Gaining extra profit by reselling construction waste that can be reused | 0.13 | Poor | |

| Institutional (D2) | IN07 | Culture | A culture of construction waste management exists within the company | 0.76 | Excellent |

| IN08 | Promotion | Proper waste management can enhance the company’s reputation | 1.00 | Excellent | |

| IN09 | Increase Market Share | Increasing market share and consumer appeal for the produced goods | 1.00 | Excellent | |

| IN10 | Competitors | Following what actions competitors have performed to remain competitive | 0.42 | Fair | |

| Environmental (D3) | ENV04 | Awareness | Awareness of the importance of protecting the environment and avoiding environmental pollution by the company | 1.00 | Excellent |

| Technical (D4) | TECH04 | Experience | The company already has experience in construction waste management | 1.00 | Excellent |

| TECH05 | Procedure Development | Development of procedures and specifications for recyclable materials | 0.76 | Excellent | |

| TECH06 | Space | Adequate space is available for construction waste management | 0.42 | Fair | |

| TECH07 | Low-Waste Technology (LWT) | Methods and systems designed to minimize waste production during various processes focusing on efficiency, recycling, and reducing environmental impact | 0.42 | Fair | |

| TECH08 | Investment | Purchasing equipment or machinery to minimize construction waste as an investment | 0.05 | Poor | |

| TECH09 | Expertise | Improving the skills of operators in managing construction waste | 0.05 | Poor | |

| TECH10 | Relationship Between Suppliers | Improving relationships with suppliers to obtain assistance and information regarding waste management | 1.00 | Excellent | |

| Socio-cultural (D5) | SOC04 | Protection Area | Proximity to or within the vicinity of local environmental protection areas (water, soil, and air) | 0.76 | Excellent |

| SOC05 | Client Request | Increasing client demand for the construction of sustainable buildings | 0.42 | Fair | |

| Legal or Policy (D6) | LEG05 | Authorization | Government authorization to manage waste independently | 0.76 | Excellent |

| LEG06 | Strict Regulation | Stringent government regulations regarding construction waste management | 1.00 | Excellent | |

| LEG07 | Special Regulations | Specific regulations for the use of recyclable and reusable materials | 0.76 | Excellent |

| Dimension | Code | Factors | Descriptions | Kappa Score | Interpretation |

|---|---|---|---|---|---|

| Financial or Economics (D1) | FE01 | Higher Project Cost | Reluctance to engage in construction waste management that could result in higher project costs due to intense competition | 1.00 | Excellent |

| FE02 | Legal Stringency | Insufficient legal rigor in economic waste management for contractors | 0.76 | Excellent | |

| FE03 | Perception | The perception that waste reduction activities are not cost-effective, efficient, and aligned with core construction activities | 0.76 | Excellent | |

| FE04 | Separating Recycled Materials | Reluctance to separate recyclable or reusable materials from those with low economic value or difficult reusability | 0.13 | Poor | |

| FE05 | Profit Prioritization | The primary priority is profit for the company rather than environmental concerns | 0.42 | Fair | |

| Institutional (D2) | IN01 | Coordination | Lack of coordination regarding the implementation of construction waste management across different company divisions | 0.76 | Excellent |

| IN02 | Standard Operating Procedure | Absence of standardized operating procedures for waste management | 0.42 | Fair | |

| IN03 | Support and Commitment | Lack of support and commitment from company management regarding waste issues | 0.76 | Excellent | |

| IN04 | Performance Standards | The absence of performance standards for managing waste from both the government and companies | 0.13 | Poor | |

| IN05 | Lack of Skilled Operator | The lack of expertise and experience among operators in the process of managing construction waste | 0.13 | Poor | |

| IN06 | Plan Development | Limited time for developing waste reduction or management plans | 0.76 | Excellent | |

| Environmental (D3) | ENV01 | Education | Inadequate education on sustainable building practices at the university level | 0.76 | Excellent |

| ENV02 | Training | Insufficient training for construction workers on waste-handling issues | 1.00 | Excellent | |

| ENV03 | Environmental Awareness | Lack of environmental awareness among the political decision-makers and clients | 1.00 | Excellent | |

| Technical (D4) | TECH01 | Knowledge | Lack of knowledge on how to implement eco-technology | 1.00 | Excellent |

| TECH02 | Space Limitations | Ineffective construction waste management due to space limitations | 1.00 | Excellent | |

| TECH03 | Operator Skills | Poor skills in construction waste management practices by on-site operators | 0.76 | Excellent | |

| Socio-cultural (D5) | SOC01 | Demand | Low demand or orders from clients to purchase sustainable buildings | 0.76 | Excellent |

| SOC02 | Conventional Procedure | Difficulty in transitioning conventional practices and procedures toward waste management in the workforce | 1.00 | Excellent | |

| SOC03 | Reassurance | Belief that efforts to reduce waste will never be sufficient to eliminate waste problems | 0.76 | Excellent | |

| Legal or Policy (D6) | LEG01 | Regulation Support | The lack of regulatory support from the government | 0.13 | Poor |

| LEG02 | Operation | Existing regulations on waste management are challenging to implement in the real world | 0.76 | Excellent | |

| LEG03 | Policy Enforcement | Lack of policy enforcement in waste management regulations in the construction industry | 1.00 | Excellent | |

| LEG04 | Information | Insufficient information available regarding environmental norm requirements | 1.00 | Excellent |

| Risk Dimension | Weight | Factors Code | Driving Factors | Local Weight | Local Rank | Global Weight | Global Rank |

|---|---|---|---|---|---|---|---|

| Financial or Economics (D1) | 0.185 | FE06 | High Disposal Cost | 0.312 | 3 | 0.058 | 6 |

| FE07 | Cost Reduction Awareness | 0.344 | 1 | 0.064 | 4 | ||

| FE08 | Compensation | 0.344 | 2 | 0.064 | 5 | ||

| Institutional (D2) | 0.157 | IN07 | Culture | 0.274 | 1 | 0.043 | 10 |

| IN08 | Promotion | 0.257 | 2 | 0.040 | 11 | ||

| IN09 | Increase Market Share | 0.242 | 3 | 0.038 | 12 | ||

| IN10 | Competitors | 0.228 | 4 | 0.036 | 13 | ||

| Environmental (D3) | 0.171 | ENV04 | Awareness | 1.000 | 1 | 0.171 | 1 |

| Technical (D4) | 0.161 | TECH04 | Experience | 0.210 | 2 | 0.034 | 15 |

| TECH05 | Procedure Development | 0.218 | 1 | 0.035 | 14 | ||

| TECH06 | Space | 0.187 | 4 | 0.030 | 17 | ||

| TECH07 | Low Waste Technology (LWT) | 0.179 | 5 | 0.029 | 18 | ||

| TECH10 | Relationship Between Suppliers | 0.205 | 3 | 0.033 | 16 | ||

| Socio-cultural (D5) | 0.161 | SOC04 | Protection Area | 0.528 | 1 | 0.085 | 2 |

| SOC05 | Client Request | 0.472 | 2 | 0.076 | 3 | ||

| Legal or Policy (D6) | 0.165 | LEG05 | Authorization | 0.305 | 3 | 0.050 | 9 |

| LEG06 | Strict Regulation | 0.348 | 1 | 0.058 | 7 | ||

| LEG07 | Special Regulations | 0.347 | 2 | 0.057 | 8 |

| Risk Dimension | Weight | Factors Code | Barrier Factors | Local Weight | Local Rank | Global Weight | Global Rank |

|---|---|---|---|---|---|---|---|

| Financial or Economics (D1) | 0.168 | FE01 | Higher Project Cost | 0.264 | 2 | 0.045 | 15 |

| FE02 | Legal Stringency | 0.268 | 1 | 0.045 | 14 | ||

| FE03 | Perception | 0.240 | 3 | 0.040 | 19 | ||

| FE05 | Profit Prioritization | 0.228 | 4 | 0.38 | 20 | ||

| Institutional (D2) | 0.177 | IN01 | Coordination | 0.239 | 4 | 0.042 | 18 |

| IN02 | Standard Operating Procedure | 0.249 | 3 | 0.044 | 17 | ||

| IN03 | Support and Commitment | 0.261 | 1 | 0.046 | 13 | ||

| IN06 | Plan Development | 0.251 | 2 | 0.044 | 16 | ||

| Environmental (D3) | 0.183 | ENV01 | Education | 0.327 | 3 | 0.060 | 4 |

| ENV02 | Training | 0.335 | 2 | 0.061 | 3 | ||

| ENV03 | Environmental Awareness | 0.338 | 1 | 0.062 | 2 | ||

| Technical (D4) | 0.161 | TECH01 | Knowledge | 0.386 | 1 | 0.062 | 1 |

| TECH02 | Space Limitations | 0.295 | 3 | 0.048 | 12 | ||

| TECH03 | Operator Skills | 0.319 | 2 | 0.051 | 7 | ||

| Socio-cultural (D5) | 0.154 | SOC01 | Demand | 0.323 | 3 | 0.050 | 11 |

| SOC02 | Conventional Procedure | 0.352 | 1 | 0.054 | 6 | ||

| SOC03 | Reassurance | 0.325 | 2 | 0.050 | 9 | ||

| Legal or Policy (D6) | 0.159 | LEG02 | Operation | 0.314 | 3 | 0.050 | 10 |

| LEG03 | Policy Enforcement | 0.367 | 1 | 0.058 | 5 | ||

| LEG04 | Information | 0.319 | 2 | 0.051 | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Izzati, S.N.; Ardi, R.; Kim, S.; Putri, S.A. Evaluating Drivers and Barriers of Integrated Waste Management System Implementation in Indonesian Construction Industry: A DEMATEL-Based Analytical Network Process. Sustainability 2024, 16, 2264. https://doi.org/10.3390/su16062264

Izzati SN, Ardi R, Kim S, Putri SA. Evaluating Drivers and Barriers of Integrated Waste Management System Implementation in Indonesian Construction Industry: A DEMATEL-Based Analytical Network Process. Sustainability. 2024; 16(6):2264. https://doi.org/10.3390/su16062264

Chicago/Turabian StyleIzzati, Savina Nur, Romadhani Ardi, Sunkuk Kim, and Shafira Arindra Putri. 2024. "Evaluating Drivers and Barriers of Integrated Waste Management System Implementation in Indonesian Construction Industry: A DEMATEL-Based Analytical Network Process" Sustainability 16, no. 6: 2264. https://doi.org/10.3390/su16062264

APA StyleIzzati, S. N., Ardi, R., Kim, S., & Putri, S. A. (2024). Evaluating Drivers and Barriers of Integrated Waste Management System Implementation in Indonesian Construction Industry: A DEMATEL-Based Analytical Network Process. Sustainability, 16(6), 2264. https://doi.org/10.3390/su16062264