Sustainable Supply Chain Practices in the Oil and Gas Industry: A Case Study

Abstract

1. Introduction

2. Literature Review

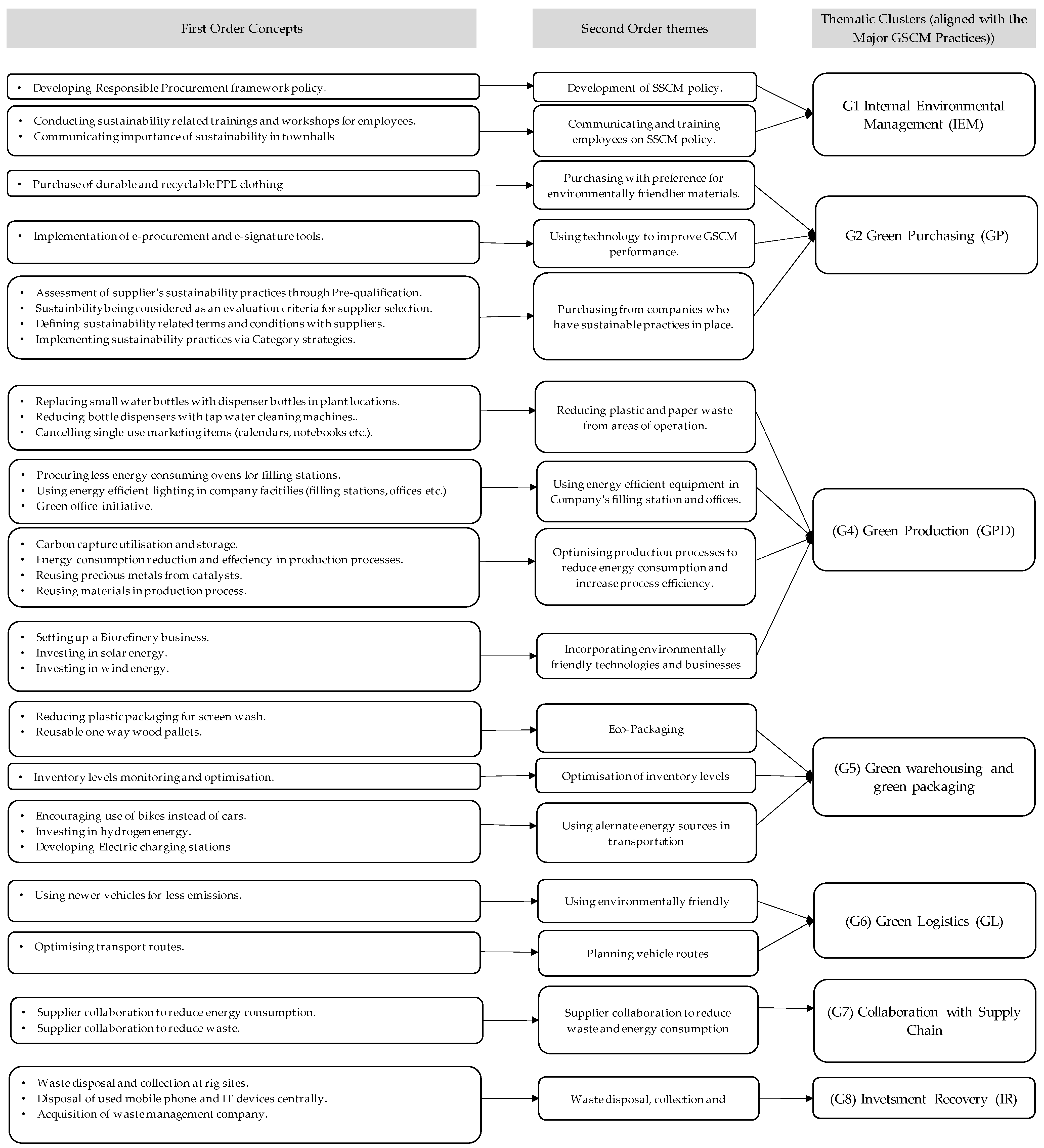

2.1. Literature Review Design

2.2. Green Supply Chain Management Practices

2.3. Sustainability Practices in the Oil and Gas Industry

3. Research Design

Primary Research Stage Design

4. Research Findings and Analysis

5. Discussion

6. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Florescu, M.S.; Ceptureanu, E.G.; Cruceru, A.F.; Ceptureanu, S.I. Sustainable Supply Chain Management Strategy Influence on Supply Chain Management Functions in the Oil and Gas Distribution Industry. Energies 2019, 12, 1632. [Google Scholar] [CrossRef]

- Alshammari, K.H.; Alshammari, A.F. Green Innovation and Its Effects on Innovation Climate and Environmental Sustainability: The Moderating Influence of Green Abilities and Strategies. Sustainability 2023, 15, 15898. [Google Scholar] [CrossRef]

- Raut, R.; Narkhede, B.E.; Gardas, B.B.; Luong, H.T. An ISM approach for the barrier analysis in implementing sustainable practices The Indian oil and gas sector. Benchmarking Int. J. 2018, 25, 1245–1271. [Google Scholar] [CrossRef]

- AlNuaimi, B.K.; Mazrouei, M.A.; Jabeen, F. Enablers of green business process management in the oil and gas sector. Int. J. Product. Perform. Manag. 2020, 68, 1671–1694. [Google Scholar] [CrossRef]

- Isallah, H. The Impact of the Petroleum Industry Act on Corporate Social Responsibility and Taxation in Nigeria’s Upstream Oil and Gas Sector: A Path towards Sustainable Development. Sustainability 2023, 15, 15538. [Google Scholar] [CrossRef]

- Mahmood, Y.; Afrin, T.; Huang, Y.; Yodo, N. Sustainable Development for Oil and Gas Infrastructure from Risk, Reliability, and Resilience Perspectives. Sustainability 2023, 15, 4953. [Google Scholar] [CrossRef]

- Czachorowski, K.V. Cleaning Up Our Act: Systems Engineering to Promote Business Model Innovation for the Offshore Exploration and Production Supply Chain Operations. Sustainability 2021, 13, 2113. [Google Scholar] [CrossRef]

- Elsayed, N.; Ammar, S. Sustainability governance and legitimisation processes: Gulf of Mexico oil spill. Sustain. Account. Manag. Policy J. 2020, 11, 253–278. [Google Scholar] [CrossRef]

- Jagoda, K.; Wojcik, P. Implementation of risk management and corporate sustainability in the Canadian oil and gas industry: An evolutionary perspective. Account. Res. J. 2019, 32, 381–398. [Google Scholar] [CrossRef]

- Busco, C.; Giovannoni, E.; Granà, F.; Izzo, M.F. Making sustainability meaningful: Aspirations, discourses and reporting practices. Account. Audit. Account. J. 2018, 31, 2218–2246. [Google Scholar] [CrossRef]

- Phatak, S.; Sople, V. Drivers and Barriers of Sustainable Supply Chain: A Literature Review on Indian Perspective. Int. J. Bus. Insights Transform. 2018, 12, 17–25. [Google Scholar]

- Lau, H.C.; Tsai, S.C. Toward Cleaner and More Sustainable Cement Production in Vietnam via Carbon Capture and Storage. Sustainability 2024, 16, 942. [Google Scholar] [CrossRef]

- Zihan, W.; Makhbul, Z.K.M.; Alam, S.S. Green Human Resource Management in Practice: Assessing the Impact of Readiness and Corporate Social Responsibility on Organizational Change. Sustainability 2024, 16, 1153. [Google Scholar] [CrossRef]

- Doni, F.; Corvino, A.; Martini, S.B. Corporate governance model, stakeholder engagement and social issues evidence from European oil and gas industry. Soc. Responsib. J. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Villegas, L.E.; Acuña-Duarte, A.A.; Salazar, C.A. Corporate Social Responsibility and the Willingness to Eco-Innovate among Chilean Firms. Sustainability 2023, 15, 9832. [Google Scholar] [CrossRef]

- Narimissa, O.; Kangarani-Farahani, A.; Molla-Alizadeh-Zavardehi, S. Drivers and barriers for implementation and improvement of Sustainable Supply Chain Management. Sustain. Dev. 2020, 28, 247–258. [Google Scholar] [CrossRef]

- Otsubo, Y.; Chapman, A.J. Assessing Corporate Vendor Selection in the Oil and Gas Industry: A Review of Green Strategies and Carbon Reduction Options. Sustainability 2023, 15, 16249. [Google Scholar] [CrossRef]

- Feng, M.; Yu, W.; Wang, X.; Wong, C.Y.; Xu, M.; Xiao, Z. Green supply chain management and financial performance: The mediating roles of operational and environmental performance. Bus. Strategy Environ. 2018, 27, 811–824. [Google Scholar] [CrossRef]

- Lopes, L.J.; Pires, S.R.I. Green supply chain management in the automotive industry: A study in Brazil. Bus. Strategy Environ. 2020, 29, 2755–2769. [Google Scholar] [CrossRef]

- Pinto, L. Green supply chain practices and company performance in Portuguese manufacturing sector. Bus. Strategy Environ. 2020, 29, 1832–1849. [Google Scholar] [CrossRef]

- Zhou, L.; Nunes, M.B. Doing qualitative research in Chinese contexts Lessons learned from conducting interviews in a Chinese healthcare environment. Libr. Hi Tech 2013, 31, 419–434. [Google Scholar] [CrossRef]

- Teixeira, A.A.; Moraes, T.E.D.C.; Stefanelli, N.O.; de Oliveira, J.H.C.; Teixeira, T.B.; de Souza Freitas, W.R. Green supply chain management in Latin America: Systematic literature review and future directions. Environ. Qual. Manag. 2020, 30, 47–73. [Google Scholar] [CrossRef]

- Jatav, S.; Nema, J. Green Supply Chain Management: Drivers, Practices and Performance. IUP J. Oper. Manag. 2021, 20, 45–71. [Google Scholar]

- Alghababsheh, M.; Gallear, D.; Rahman, M. Balancing the Scales of Justice: Do Perceptions of ‘Buyers Justice’ Drive Suppliers’ Social Performance? J. Bus. Ethics 2020, 163, 125–150. [Google Scholar] [CrossRef]

- Gruner, R.L.; Power, D. Analogical reasoning guidelines: A review and application to sustainable supply chains. Supply Chain. Manag. Int. J. 2021, 26, 153–173. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Islam, M.S.; Karia, N.; Fauzi, F.A. literature review on green supply chain management: Trends and future challenges. Resour. Conserv. Recycl. 2019, 141, 145–162. [Google Scholar] [CrossRef]

- Raman, R.; Sreenivasan, A.; Ma, S.; Patwardhan, A.; Nedungadi, P. Green Supply Chain Management Research Trends and Linkages to UN Sustainable Development Goals. Sustainability 2023, 15, 15848. [Google Scholar] [CrossRef]

- Abdullah, M.I.; Sarfraz, M.; Qun, W.; Javaid, N. Drivers Of Green Supply Chain Management. LogForum 2018, 14, 437–447. [Google Scholar] [CrossRef]

- Abebaw, H.; Virdi, S.S. Green Supply Chain Management Practices in Ethiopia’s Leather and Leather Product Industry. IUP J. Supply Chain. Manag. 2019, 16, 25–42. [Google Scholar]

- Khairani, N.S.; Kasim, E.S.; Rajamanoharan, I.D.; Misman, F.N. Critical Success Factors of Green Supply Chain Management: Case Evidence of a Malaysian Automotive Manufacturer. Asia-Pac. Manag. Account. J. 2017, 12, 105–127. [Google Scholar]

- Prasad, D.S.; Pradhan, R.P.; Gaurav, K.; Chatterjee, P.P.; Kaur, I.; Dash, S.; Nayak, S. Analysing the critical success factors for implementation of sustainable supply chain management: An Indian case study. Decision 2018, 45, 3–25. [Google Scholar] [CrossRef]

- Ali, S.S.; Kaur, R.; Ersöz, F.; Altaf, B.; Basu, A.; Weber, G.W. Measuring carbon performance for sustainable green supply chain practices: A developing country scenario. Cent. Eur. J. Oper. Res. 2020, 28, 1389–1416. [Google Scholar] [CrossRef]

- Zhu, Q.; Qu, Y.; Geng, Y.; Fujita, T. A Comparison of Regulatory Awareness and Green Supply Chain Management Practices Among Chinese and Japanese Manufacturers. Bus. Strategy Environ. 2017, 26, 18–30. [Google Scholar] [CrossRef]

- Aslam, H.; Waseem, M.; Khurram, M. Impact of Green Supply Chain Management Practices on Corporate Image: Mediating role of Green Communications. Pak. J. Commer. Soc. Sci. 2019, 13, 581–598. [Google Scholar]

- Jawaad, M.; Zafar, S. Improving sustainable development and firm performance in emerging economies by implementing green supply chain activities. Sustain. Dev. 2020, 28, 25–38. [Google Scholar] [CrossRef]

- Rentizelas, A.; de Sousa Jabbour, A.B.L.; Al Balushi, A.D.; Tuni, A. Social sustainability in the oil and gas industry: Institutional pressure and the management of sustainable supply chains. Ann. Oper. Res. 2020, 290, 279–300. [Google Scholar] [CrossRef]

- Munodawafa, R.T.; Johl, S.K. Measurement development for eco-innovation capabilities of Malaysian oil and gas firms. Int. J. Product. Perform. Manag. 2021, 71, 3443–3465. [Google Scholar] [CrossRef]

- Singh, A.S. Conducting case study research in non-profit organisations. Qual. Mark. Res. Int. J. 2014, 17, 77–84. [Google Scholar] [CrossRef]

- Verleye, K. Designing, writing-up and reviewing case study research: An equifinality perspective. J. Serv. Manag. 2019, 30, 549–576. [Google Scholar] [CrossRef]

- Silverman, D. Doing Qualitative Research: A Practical Handbook, 3rd ed.; Sage Publications: London, UK, 2010. [Google Scholar]

- Alam, M.K. A systematic qualitative case study: Questions, data collection, NVivo analysis and saturation. Qual. Res. Organ. Manag. Int. J. 2021, 16, 1–31. [Google Scholar] [CrossRef]

- Saunders, B.; Sim, J.; Kingstone, T.; Baker, S.; Waterfield, J.; Bartlam, B.; Burroughs, H.; Jinks, C. Saturation in qualitative research: Exploring its conceptualization and operationalization. Qual. Quant. 2018, 52, 1893–1907. [Google Scholar] [CrossRef] [PubMed]

- Yin, R. Validity and generalization in future case study evaluations. Evaluation 2013, 19, 321–333. [Google Scholar] [CrossRef]

- Kitsis, A.M.; Chen, I.J. Do motives matter? Examining the relationships between motives, SSCM practices and TBL performance. Supply Chain. Manag. Int. J. 2020, 25, 325–341. [Google Scholar] [CrossRef]

- Ndubisi, N.O.; Al-Shuridah, O.; Capel, C. Greening multinational enterprises in the oil, gas and petrochemicals Environmental sustainability and the moderation role of environmental sensitivity. Int. J. Manpow. 2020, 41, 967–985. [Google Scholar] [CrossRef]

- Seuring, S.A. Assessing the rigor of case study research in supply chain management. Supply Chain. Manag. Int. J. 2008, 13, 128–137. [Google Scholar] [CrossRef]

- Qu, S.Q.; Dumay, J. The qualitative research interview. Qual. Res. Account. Manag. 2011, 8, 238–264. [Google Scholar] [CrossRef]

- Rowley, J. Using Case Studies in Research. Manag. Res. News 2002, 25, 16–27. [Google Scholar] [CrossRef]

- Carruthers, J. A Rationale for the Use of Semi-structured Interviews. J. Educ. Adm. 1990, 28, 63–68. [Google Scholar] [CrossRef]

- Pathiranage, Y.L.; Jayatilake, L.V.K.; Abeysekera, R. Case Study Research Design for Exploration of Organizational Culture Towards Corporate Performance. Rev. Int. Comp. Manag. 2020, 20, 361–372. [Google Scholar]

- Braun, V.; Clarke, V. Using thematic analysis in psychology. Qual. Res. Psychol. 2006, 3, 77–101. [Google Scholar] [CrossRef]

- Corbin, J.M.; Strauss, A. Grounded theory research: Procedures, canons, and evaluative criteria. Qual. Sociol. 1990, 13, 3–21. [Google Scholar] [CrossRef]

- Williams, M.; Moser, T. The Art of Coding and Thematic Exploration in Qualitative Research. Int. Manag. Rev. 2019, 15, 45–55. [Google Scholar]

- Namagembe, S.; Ryan, S.; Sridharan, R. Green supply chain practice adoption and firm performance: Manufacturing SMEs in Uganda. Manag. Environ. Qual. Int. J. 2019, 30, 5–35. [Google Scholar] [CrossRef]

- Zaidi, S.A.H.; Mirza, F.M.; Hou, F.; Ashraf, R.U. Addressing the sustainable development through sustainable procurement: What factors resist the implementation of sustainable procurement in Pakistan? Socio-Econ. Plan. Sci. 2019, 68, 100671. [Google Scholar] [CrossRef]

- Kähkönen, A.-K.; Lintukangas, K.; Hallikas, J. Sustainable supply management practices: Making a difference in a firm’s sustainability performance. Supply Chain. Manag. Int. J. 2018, 23, 518–530. [Google Scholar] [CrossRef]

- Amemba, C.S. Green Supply Chain Best Practices in Hospitality Industry in Kenya. Glob. J. Commer. Manag. Perspect. 2013, 2, 7–18. [Google Scholar]

- Sebastianelli, R.; Tamimi, N. Antecedents of sustainable supply chain initiatives: Empirical evidence from the S&P 500. Bus. Soc. Rev. 2020, 125, 3–22. [Google Scholar]

- Verma, D.; Dixit, R.V.; Singh, K. Green Supply Chain Management: A Necessity for Sustainable Development. IUP J. Supply Chain. Manag. 2018, 15, 40–58. [Google Scholar]

- Panigrahi, S.S.; Bahinipati, B.; Jain, V. Sustainable supply chain management A review of literature and implications for future research. Manag. Environ. Qual. Int. J. 2019, 30, 1001–1049. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Al-Tahat, M.; Lepkova, N. Modelling Relationships Between Agility, Lean, Resilient, Green Practices in Cold Supply Chains Using ISM Approach. Technol. Econ. Dev. Econ. 2020, 26, 675–694. [Google Scholar] [CrossRef]

| GSCM Practices | Academic Sources |

|---|---|

| Internal GSCM practices | |

| G1. Internal Environmental Management (IEM) | [20,22,23,34,35] |

| G2. Green Design (GD) | [19,21,22,23,30,32,33,34,35] |

| G3. Green Purchasing (GP) | [11,19,20,21,22,23,30,32,34,35] |

| G4. Green Production (GPD) | [11,19,20,30] |

| External GSCM practices | |

| G5. Green Warehousing and Green Packaging | [11,20,21,30,35] |

| G6. Green Logistics (GL) | [11,19,20,32,33] |

| G7. Collaboration with Supply Chain | [19,20,22,23,33,34,35] |

| G8. Investment Recovery (IR) | [19,22,23,30,33,34,35] |

| Internal GSCM Practices | Sub-Practices | Practices Employed by the O&G Industry | Academic Sources |

|---|---|---|---|

| G1. Internal Environmental Management (IEM) | 1. Defining and communicating the organization’s environmental policy. | X | [2,5] |

| 2. Commitment and support of management to adopt environmentally practices. | X | [4,5,8] | |

| 3. Adopting environmental management systems (such as ISO 14001 certification). | X | [2,37] | |

| 4. Complying with legal regulations and adopting environmental audit programs. | |||

| 5. Cross-functional collaboration to improve the environment. | |||

| 6. Raising awareness through training and education of employees. | X | [2,9] | |

| G2. Green Design (GD) | 1. Designing products to reduce material or energy consumption. | X | [9] |

| 2. Designing products so that they can be reused, recovered, or recycled. | |||

| 3. Designing products to reduce usage of hazardous materials. | |||

| 4. Designing products for environmental improvements (packaging, etc.). | |||

| 5. Conducting life cycle analysis of products. | |||

| G3. Green Purchasing (GP) | 1. Purchasing with a preference for environmentally friendly raw materials, products, packaging, etc. | X | [5] |

| 2. Purchasing from suppliers who have environmental management systems in place (via pre-screening, prequalification, evaluation, etc.). | X | [1,5,6,36] | |

| 3. Conducting environmental audits of first- and second-tier suppliers. | |||

| 4. Collaboration, training, and encouragement of suppliers to adopt environmental management systems. | |||

| G4. Green Production (GPD) | 1. Optimizing production process to reduce consumption/efficient utilization of natural resources (water, energy, etc.). | X | [2] |

| 2. Production process to reduce waste and pollution (solid waste, liquid waste, air and noise pollution, etc.). | X | [4,5,9,37] | |

| 3. Optimizing and making the production process lean by reducing, reusing, recycling, and remanufacturing materials. | |||

| 4. Incorporating environmentally friendly technologies in the production/manufacturing process. | X | [4,5,9,12] | |

| External GSCM practices | |||

| G5. Green Warehousing and Green Packaging | 1. Reduction and optimization of inventory levels. | ||

| 2. Selling surplus inventory. | |||

| 3. Selling scrap and redundant inventory. | |||

| 4. Eco-packaging that can be recovered, returned, reused and recycled (environmentally friendly packaging). | Recommended but no evidence seen. | [1,3] | |

| G6. Green Logistics (GL) | 1. Reducing fuel consumption. | X | [2] |

| 2. Use of alternate energy sources in transportation. | X | [2,5] | |

| 3. Ordering and moving goods in complete batches. | |||

| 4. Using environmentally friendly vehicles and transportation. | X | [1,2,16] | |

| 5. Planning vehicle routes. | X | [5,16] | |

| 6. Reverse logistics: transportation of reverse supply chain (recovery, return, recycling, reuse of scarce resources and products). | X | [5,16] | |

| G7. Collaboration with Supply Chain (Suppliers, customers etc.) | 1. Joint definition and achievement of environmental objectives and goals. | X | [1,5] |

| 2. Joint development of eco-friendly solutions and technologies. | X | [1,16] | |

| 3. Joint environmental design. | |||

| 4. Developing recyclable products and packaging materials. | |||

| 5. Collaboration to use less energy. | |||

| 6. Collaboration to clean production process and employ product take backs or reverse logistics. | |||

| 7. Collaboration to reduce waste and pollution. | |||

| 8. Joint education and training programs with supply chain partners. | |||

| G8. Investment Recovery (IR) | 1. Selling excess inventory or raw materials. | ||

| 2. Selling excess capital machinery and equipment. | |||

| 3. Selling used, junk, or scrap materials. | |||

| 4. Collection and development of recycling systems of used, defective materials and end of life products. | X | [16] |

| GSCM Practices | Sub-Practices | Practices Employed by the O&G Industry | Evidence of GSCM Practices Found in Company “X” |

|---|---|---|---|

| G1. Internal Environmental Management (IEM) | 1. Defining and communicating organization’s environmental policy. | X | X |

| 2. Commitment and support of management to adopt environmentally practices. | X | X | |

| 3. Adopting environmental management systems (such as ISO 14001 certification). | X | Partial evidence | |

| 4. Complying with legal regulations and adopting environmental audit programs. | |||

| 5. Cross-functional collaboration to improve the environment. | |||

| 6. Raising awareness through training and education of employees. | X | X | |

| G2. Green Design (GD) | 1. Designing products to reduce material or energy consumption. | X | |

| 2. Designing products so that they can be reused, recovered or recycled. | |||

| 3. Designing products to reduce usage of hazardous materials. | |||

| 4. Designing products for environmental improvements (packaging etc.). | Partial evidence | ||

| 5. Conducting life cycle analysis of products. | |||

| G3. Green Purchasing (GP) | 1. Purchasing with a preference for environmentally friendly raw materials, products, packaging, etc. | X | Partial evidence |

| 2. Purchasing from suppliers who have environmental management systems in place (via pre-screening, prequalification, evaluation, etc.). | X | Partial evidence | |

| 3. Conducting environmental audits of first- and second-tier suppliers. | |||

| 4. Collaboration, training, and encouragement of suppliers to adopt environmental management systems. | |||

| G4. Green Production (GPD) | 1. Optimizing production process to reduce consumption/efficient utilization of natural resources (water, energy, etc.). | X | X |

| 2. Production process to reduce waste and pollution (solid waste, liquid waste, air and noise pollution, etc.). | X | Partial evidence | |

| 3. Optimizing and making production process lean through reduced, reuse, recycling, and remanufacturing of materials. | X | ||

| 4. Incorporating environmentally friendly technologies in the production/manufacturing process. | X | X | |

| G5. Green Warehousing and Green Packaging | 1. Reduction and optimization of inventory levels. | Partial evidence | |

| 2. Selling surplus inventory. | |||

| 3. Selling scrap and redundant inventory. | |||

| 4. Eco-packaging that can be recovered, returned, reused, and recycled (environmentally friendly packaging). | Recommended but no evidence seen. | X | |

| G6. Green Logistics (GL) | 1. Reducing fuel consumption. | X | X |

| 2. Use of alternate energy sources in transportation. | X | X | |

| 3. Ordering and moving goods in complete batches. | |||

| 4. Using environmentally friendly vehicles and transportation. | X | X | |

| 5. Planning vehicle routes. | X | X | |

| 6. Reverse logistics: transportation of reverse supply chain (recovery, return, recycling, and reuse of scarce resources and products). | X | Partial evidence | |

| G7. Collaboration with Supply Chain (suppliers, customers, etc.) | 1. Joint definition and achievement of environmental objectives and goals. | X | |

| 2. Joint development of eco-friendly solutions and technologies. | X | ||

| 3. Joint environmental design. | |||

| 4. Developing recyclable products and packaging materials. | Partial evidence | ||

| 5. Collaboration to use less energy. | X | ||

| 6. Collaboration to clean production process and employ product take backs or reverse logistics. | |||

| 7. Collaboration to reduce waste and pollution. | X | ||

| 8. Joint education and training programs with supply chain partners. | |||

| G8. Investment Recovery (IR) | 1. Selling excess inventory or raw materials. | ||

| 2. Selling excess capital machinery and equipment. | |||

| 3. Selling used, junk, or scrap materials. | |||

| 4. Collection and development of recycling systems of used, defective materials and end of life products. | X | Partial evidence |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasan, J.; Thomas, A.; Tomos, O. Sustainable Supply Chain Practices in the Oil and Gas Industry: A Case Study. Sustainability 2024, 16, 1720. https://doi.org/10.3390/su16051720

Hasan J, Thomas A, Tomos O. Sustainable Supply Chain Practices in the Oil and Gas Industry: A Case Study. Sustainability. 2024; 16(5):1720. https://doi.org/10.3390/su16051720

Chicago/Turabian StyleHasan, Jasim, Andrew Thomas, and Owain Tomos. 2024. "Sustainable Supply Chain Practices in the Oil and Gas Industry: A Case Study" Sustainability 16, no. 5: 1720. https://doi.org/10.3390/su16051720

APA StyleHasan, J., Thomas, A., & Tomos, O. (2024). Sustainable Supply Chain Practices in the Oil and Gas Industry: A Case Study. Sustainability, 16(5), 1720. https://doi.org/10.3390/su16051720