Drivers and Barriers for the Adoption of Circular Economy Principles towards Efficient Resource Utilisation

Abstract

1. Introduction

Literature Review

2. Materials and Methods

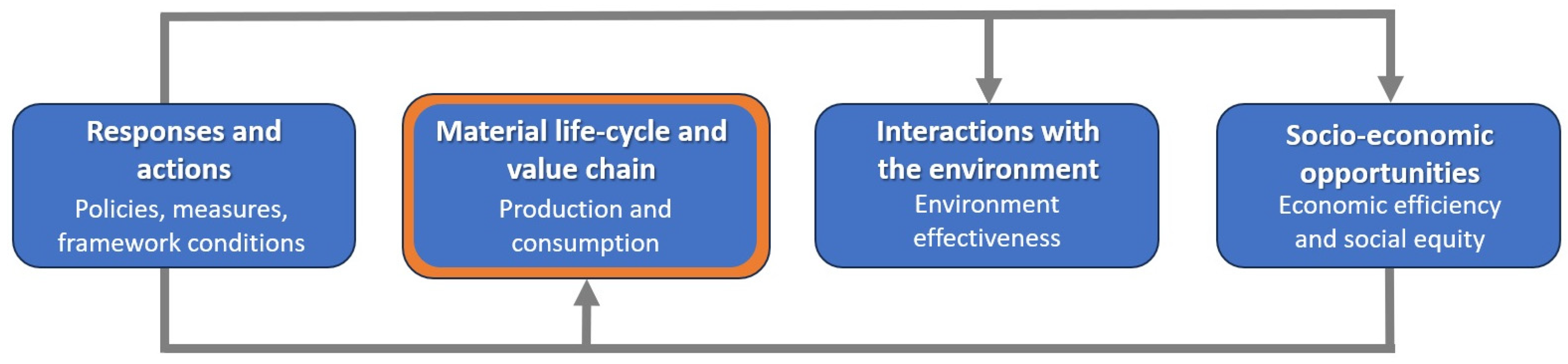

2.1. Structure of the Indicator Framework

- Overall recycling rates: recycling rates for (a) municipal waste (%) and (b) all waste excluding major mineral waste (%);

- Recycling rates for specific waste streams: recycling rates for (a) packaging, (b) plastic packaging waste (%), and (c) electrical and electronic equipment waste that is separately collected (%).

- Contribution of recycled materials to demand for raw materials: (a) circular material use rate (%) and (b) end-of-life recycling input rates (%);

- Trade in recyclable raw materials: (a) imports from outside the EU, (b) exports outside the EU, and intra-EU trade (all three in tonnes).

2.2. Measuring Circularity

- Operationalising circular strategies involves various actors and activities across the value chain (from suppliers and manufacturers to service providers and reverse logistics partners). In order to identify areas for improvement, it is necessary to measure and attribute the collective and individual impacts at both the product and company levels [36].

- Various factors directly influence circularity. These factors should be considered when measuring circular metrics. Some are servisation (i.e., provision of a service rather than ownership); digitalisation; and product design for modularity, repairability, disassembly, and reuse [36]. However, determining the appropriate boundaries for measurement can take time due to the involvement of multiple actors and factors in the value chain.

3. Results

4. Discussion

5. Conclusions

- The upgraded CMU rate formula on financial data produces the same results as the original one based on material data. This formula was the basis for the proposed CEIR equation covering all 9R strategies.

- The proposed model for monitoring the achieved degree of circularity based on the 9R framework gives a unique output, which can be used to compare the accomplished degree of circularity of systems of the same type. The practical verification of model applicability was shown by determining the degree of circularity achieved by passenger vehicles in the four observed EU countries.

- The proposed model equation is robust and open to various approaches. It covers products and services separately or combined, as shown in this paper.

- The model results are best discussed by comparing the results between different products or services, always using the same methodology for every R.

- It is necessary to expand the existing database of statistical data in order to better support 9R calculations based on the proposed model.

- Comparisons of calculation results should be the basis for incentives for further promotion of circular economy by individuals, society, businesses, investors, and the public sector.

- Better tracking of the obtained level of the circularity transition for products and services on the company, municipality, or state level could lead to a faster move away from a linear economic model.

- In general, a regulatory framework must be established to assist 9R strategies that aim to move away from traditional linear business models and to provide the necessary statistical data to measure this transition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission. Measuring Progress towards Circular Economy in the European Union—Key Indicators for a Revised Monitoring Framework Accompanying the Document, Communication on a Revised Monitoring Framework for the Circular Economy. 2023. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52023DC0306 (accessed on 15 June 2023).

- OECD European Commission. Cities in the World: A New Perspective on Urbanisation; Report OECD Urban Studies; OECD Publishing: Paris, France, 2020; Available online: https://read.oecd.org/10.1787/d0efcbda-en?format=pdf (accessed on 15 February 2023).

- OECD. The Circular Economy in Cities and Regions: Synthesis Report, towards a Circular Economy: Key Drivers, Report. 2020. Available online: https://read.oecd.org/10.1787/10ac6ae4-en?format=pdf (accessed on 17 January 2023).

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: Berkeley, CA, USA, 2002; pp. 157–187. [Google Scholar]

- Lacy, P.; Long, J.; Spindler, W. The Circular Economy Handbook—Realising the Circular Advantage; Palgrave Macmillan: London, UK, 2020; pp. 35–50. [Google Scholar]

- Lacy, P.; Rutqvist, J. The Roots of the Circular Economy. In Waste to Wealth; Palgrave Macmillan: London, UK, 2015; p. 21. [Google Scholar]

- Ellen MacArthur Foundation. Towards the Circular Economy Vol. 1: An Economic and Business Rationale for an Accelerated Transition. 2013. Available online: https://www.ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an (accessed on 18 January 2023).

- Ellen MacArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition. 2015. Available online: https://www.ellenmacarthurfoundation.org/towards-a-circular-economy-business-rationale-for-an-accelerated-transition (accessed on 18 January 2023).

- McCarthy, A.; Dellink, R.; Bibas, R. The Macroeconomics of the Circular Economy Transition: A Critical Review of Modelling Approaches; OECD Environment Working Papers, No. 130; OECD Publishing: Paris, France, 2018; Available online: https://www.oecd-ilibrary.org/environment/the-macroeconomics-of-the-circular-economy-transition_af983f9a-en (accessed on 18 January 2023).

- Blomsma, F.; Brennan, G. The emergence of circular economy: A new framing around prolonging resource productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Neves, S.A.; Marques, A.C. Drivers and barriers in the transition from a linear economy to a circular economy. J. Clean. Prod. 2022, 341, 130865. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualising the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Fassio, F.; Chirilli, C. The Circular Economy and the Food System: A Review of Principal Measuring Tools. Sustainability 2023, 15, 10179. [Google Scholar] [CrossRef]

- Stahel, W.R. The Utilisation Focused Service Economy: Resource Efficiency, the Greening of Industrial Ecosystems; National Academy Press: Washington, DC, USA, 1994; pp. 178–190. [Google Scholar]

- Kirchherr, J.; Yang, N.H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resour. Conserv. Recycl. 2023, 194, 107001. [Google Scholar] [CrossRef]

- The 3R Initiative. Available online: https://www.env.go.jp/recycle/3r/en/outline.html (accessed on 20 February 2023).

- UN Economic and Social Council. Joint United Nations Economic Commission for Europe/Organisation for Economic Cooperation and Development Guidelines for Measuring Circular Economy Part A: Conceptual Framework, Statistical Framework and Indicators; ECE/CES/2023/3. 2023. Available online: https://unece.org/statistics/documents/2023/04/informal-documents/joint-uneceoecd-guidelines-measuring-circular (accessed on 18 January 2023).

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; Policy Report; ©PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017. [Google Scholar]

- Van Buren, N.; Demmers, M.; Van der Heijden, R.; Witlox, F. Towards a Circular Economy: The Role of Dutch Logistics Industries and Governments. Sustainability 2016, 8, 647. [Google Scholar] [CrossRef]

- Hartley, K.; Baldassarre, B.; Kirchherr, J. Circular economy as crisis response: A primer. J. Clean. Prod. 2024, 434, 140140. [Google Scholar] [CrossRef]

- Hartley, K.; Schülzchen, S.; Bakker, C.A.; Kirchherr, J. A policy framework for the circular economy: Lessons from the EU. J. Clean. Prod. 2023, 412, 137176. [Google Scholar] [CrossRef]

- Johansson, N.; Forsgren, C. Is this the end of end-of-waste? Uncovering the space between waste and products. Resour. Conserv. Recycl. 2019, 155, 104656. [Google Scholar] [CrossRef]

- Figge, F.; Stevenson Thorpe, A.; Gutberlet, M. Definitions of the circular economy: Circularity matters. Ecol. Econ. 2023, 208, 107823. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the circular economy: Evidence from the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Bardhi, F.; Eckhardt, G.M. Access-Based Consumption: The Case of Car Sharing. J. Consum. Res. 2012, 39, 881–898. [Google Scholar] [CrossRef]

- Sopjani, L.; Arekrans, J.; Laurenti, R.; Ritzén, S. Unlocking the Linear Lock-In: Mapping Research on Barriers to Transition. Sustainability 2020, 12, 1034. [Google Scholar] [CrossRef]

- Arekrans, J.; Sopjani, L.; Laurenti, R.; Ritzén, S. Barriers to access-based consumption in the circular transition: A systematic review. Resour. Conserv. Recycl. 2022, 184, 106364. [Google Scholar] [CrossRef]

- Wit, M.; Hoogzaad, J.; Ramkumar, S.; Friedl, H.; Douma, A. The Circularity Gap Report: An Analysis of the Circular State of the Global Economy, Circle Economy. 2018. Available online: https://www.circularity-gap.world/2018 (accessed on 11 December 2023).

- Circle Economy. The Circularity Gap Report 2023; Circle Economy: Amsterdam, The Netherlands, 2023; pp. 1–64. Available online: https://www.circularity-gap.world/2023#current-state (accessed on 11 December 2023).

- Barrie, J.; Latifahaida, A.L.; Manuel, A.; Ieva, B.; Alexey, K.; Amelia, K.; Nanno, M.; Melissa, M.; Antoine, O.; Patrick, S. Trade for an Inclusive Circular Economy: A Framework for Collective Action; Recommendations from a Global Expert Working Group; Royal Institute of International Affairs: London, UK, 2022; Available online: https://chathamhouse.soutron.net/Portal/Public/en-GB/RecordView/Index/191157 (accessed on 11 December 2023).

- Deloitte. The Power of Blockchain in Revolutionising the Food Industry. Available online: https://www.deloitte.com/za/en/Industries/consumer-products/perspectives/the-power-of-blockchain-in-revolutionising-the-food-industry.html (accessed on 10 November 2023).

- ICLEI Europe. Circular Cities Declaration Report 2022, Report. 2022. Available online: https://circularcitiesdeclaration.eu/about/ccd-report (accessed on 5 March 2023).

- European Commission. A Monitoring Framework for the Circular Economy, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2018; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2018%3A29%3AFIN (accessed on 5 March 2023).

- Eurostat. Circular Economy. Available online: https://ec.europa.eu/eurostat/web/circular-economy (accessed on 9 March 2023).

- BCG. Circelligence by BCG. Available online: https://www.bcg.com/zh-cn/capabilities/climate-change-sustainability/circular-economy-circelligence (accessed on 5 March 2023).

- CEC. Measuring Circularity for Capital Equipment—Gaps, Challenges and Recommendations for an Evolving Metrics Landscape; Metrics Whitepaper—Report, Version 1.0. 2022. Available online: https://drive.google.com/file/d/1VvW7ckX8Dp-XigGEE5iXOcTaxTZy2wnh/view?usp=sharing (accessed on 5 March 2023).

- Rietveld, E.; Stegeman, H.; Tukker, A.; Keijzer, E.; Hauck, M.; Poliakov, E.; Bastein, T. Following-Up on Opportunities for a Circular Economy Better Data for Robust Policy Making; Report; TNO: Den Haag, The Netherlands, 2019; TNO-2019-R11712. [Google Scholar]

- Circular Metrics for Business—Introduction to the Circelligence Indicators Framework. Available online: https://assets.website-files.com/ (accessed on 10 December 2023).

- ISO/DIS 59020; Circular Economy—Measuring and Assessing Circularity. ISO: Geneva, Switzerland, 2022. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:59020:dis:ed-1:v1:en (accessed on 5 March 2023).

- Jerome, A.; Helander, H.; Ljunggren, M.; Janssen, M. Mapping and testing circular economy product-level indicators: A critical review. Resour. Conserv. Recycl. 2022, 178, 106080. [Google Scholar] [CrossRef]

- Eurostat. Circular Material Use Rate, Calculation Method, 2018 ed.; Publications Office of the European Union: Luxembourg, 2018; Available online: https://ec.europa.eu/eurostat/documents/3859598/9407565/KS-FT-18-009-EN-N.pdf/b8efd42b-b1b8-41ea-aaa0-45e127ad2e3f?t=1543310039000 (accessed on 15 March 2023). [CrossRef]

- Christis, M.; Vercalsteren, A.; Nuss, P.; Campanale, R.M.; Steger, S. Analysis of the Circular Material Use Rate and the Doubling Target, ETC CE Report 2023/6, European Environment Agency, European Topic Centre on Circular Economy and Resource Use. 2023. Available online: https://www.eionet.europa.eu/etcs/etc-ce/products/etc-ce-report-2023-6-analysis-of-the-circular-material-use-rate-and-the-doubling-target (accessed on 12 May 2023).

- Moraga, M.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Acker, K.V.; De Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef] [PubMed]

- Milos, L. Towards a Circular Economy Taxation Framework: Expectations and Challenges of Implementation. Circ. Econ. Sustain. 2021, 1, 477–498. [Google Scholar] [CrossRef]

- The World Bank. Squaring the Circle: Policies from Europe’s Circular Economy Transition © World Bank. 2022. Available online: https://www.worldbank.org/en/region/eca/publication/squaring-circle-europe-circular-economy-transition (accessed on 3 March 2023).

- Vogiantzi, C.; Tserpes, K. On the Definition, Assessment, and Enhancement of Circular Economy across Various Industrial Sectors: A Literature Review and Recent Findings. Sustainability 2023, 15, 16532. [Google Scholar] [CrossRef]

- Eurostat. Data Browser. Available online: https://ec.europa.eu/eurostat/databrowser/explore/all/all_themes (accessed on 9 January 2024).

- EuroDev. Mileage Reimbursement in Europe. Available online: https://www.eurodev.com/blog/mileage-reimbursement-in-europe (accessed on 12 January 2024).

- Statista. Available online: https://www.statista.com/ (accessed on 9 January 2024).

- Trading Economics. Available online: https://tradingeconomics.com/commodity/carbon (accessed on 15 January 2024).

- Petronijević, V.; Đorđević, A.; Stefanović, M.; Arsovski, S.; Krivokapić, Z.; Mišić, M. Energy Recovery through End-of-Life Vehicles Recycling in Developing Countries. Sustainability 2020, 12, 8764. [Google Scholar] [CrossRef]

- Schrott24. Available online: https://en.schrott24.de/scrap-prices/ (accessed on 15 January 2024).

- Central European Gas Hub AG. Market Data. Available online: https://www.cegh.at/en/exchange-market/market-data/ (accessed on 15 January 2024).

| Strategy | Description |

|---|---|

| R0 Refuse | Can be assessed by monitoring through the tax policy for redundant products. |

| R1 Rethink | It can be assessed by monitoring a specific number of items sold per capita and the volume of services provided. |

| R2 Reduce | It can be estimated by tracking individual consumption through all production sectors. |

| R3 Reuse | This is already monitored by volume in mass, but it could also be monitored in terms of new items sold per capita and GDP. Some reuse bypasses the waste management system and thus is not recorded by weight in a waste management system. This is especially true in low-income societies. Thus, it is indirectly seen in the reduced purchase of new items. |

| R4 Repair | It should be measured through the number of repair services and the financial flow of those services. Additionally, the sale of spare parts must be monitored in low-income countries, keeping in mind that people sometimes repair for themselves outside an official system that is included in state statistics. Repair is also indirectly visible through extended utilisation of products—the average age of products in use. |

| R5 Refurbish | This strategy is quite similar to R4 and can be monitored similarly. Refurbishment or its quality could be monitored through new specific consumption of refurbished items. Not all sectors can be monitored to differentiate between repair and refurbishment, but CE strategies consider both. If metrics include both, there is no need to differentiate between R4 and R5. |

| R6 Remanufacture | This should be monitored through separate statistics that would have to be reported to the state statistics office. Maybe the state should change the VAT to a reduced level for remanufactured products, making them more desired and easily monitored. However, remanufacture should mean that most of the product in the material sense (mass) should consist of old parts or products. |

| R7 Repurpose | This strategy can be monitored the same way as proposed for R6, except the amount of all parts or products included in a new product should be set at lower levels. |

| R8 Recycle | Material recycling is monitored, and statistical data are available. |

| R9 Recover | Energy recovery of nonrecyclable materials with high calorific value is covered by statistical data on refuse-derived fuels. |

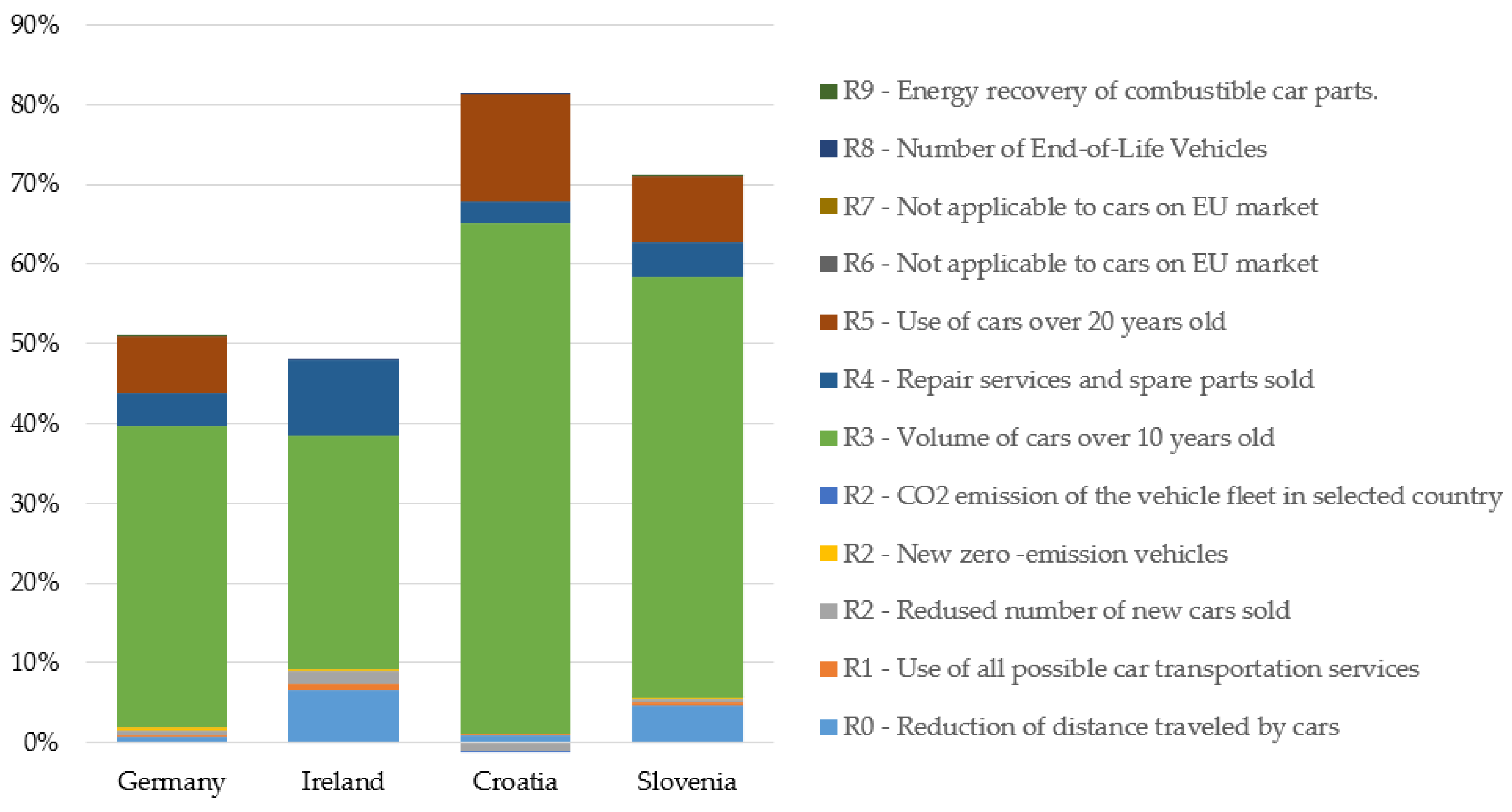

| R No. | Measure | Measure Description | Germany | Ireland | Croatia | Slovenia | Remark |

|---|---|---|---|---|---|---|---|

| R0 | Refuse | Reduction in distance travelled by cars | 12,893.91 | 4673.20 | 440.48 | 1405.89 | Based on the difference between the years 2015 and 2020 |

| R1 | Rethink | Use of all possible car transportation services | 5616.10 | 529.80 | 74.38 | 77.65 | Turnover of car-sharing, taxis, ride-hailing and car rentals |

| R2 | Reduce | Reduced number of new cars sold | 8874.40 | 1123.11 | −459.39 | 156.76 | Based on the difference between the years 2015 and 2020 |

| R2 | Reduce | New zero-emission passenger cars | 7293.55 | 124.27 | 13.42 | 43.30 | Value of new zero-emission passenger cars based on the average price of new cars in the selected country |

| R2 | Reduce | CO2 emission of the vehicle fleet in a selected country | 93.98 | 10.03 | −1.27 | 2.48 | Hypothetical value of the saved amount of money based on the difference between 2015 and 2020 fleet CO2 emissions and the EU carbon permit price |

| R3 | Reuse | Volume of cars over 10 years old | 684,582.94 | 20,485.93 | 28,098.93 | 15,554.31 | Value of cars over 10 years old calculated by the number of vehicles over 10 years old and multiplied by the average price of new cars in the selected country |

| R4 | Repair | Repair services and spare parts sold | 74,170.80 | 6532.30 | 1183.10 | 1269.80 | Turnover of car service companies and sale of spare car parts |

| R5 | Refurbish | Use of cars over 20 years old | 129,846.46 | - | 5933.05 | 2398.77 | Cars over 20 years old already need refurbishing to be safe and street-legal today. Value of cars over 20 years old calculated by the number of vehicles over 20 years old and multiplied by the average price of new cars in the selected country |

| R6 | Remanufacture | Not applicable to cars in the EU market | 0.00 | 0.00 | 0.00 | 0.00 | Remanufacturing cars is not possible due to strict EU legislation for cars to be used on public roads |

| R7 | Repurpose | Not applicable to cars in the EU market | 0.00 | 0.00 | 0.00 | 0.00 | The possibilities to repurpose cars or car parts are relatively small in the EU and cannot be assessed based on statistics available |

| R8 | Recycle | Number of end-of-life vehicles | 93.07 | 26.19 | 4.33 | 1.48 | Hypothetical value of scrap metal sold for recycling |

| R9 | Recovery | Energy recovery of combustible car parts | 4.74 | 0.00 | 0.00 | 0.06 | Hypothetical value of heat energy sold generated with combustible car parts in waste-to-energy plants |

| 9R Total | 923,469.96 | 33,504.84 | 35,287.02 | 20,910.50 | |||

| Denominator | 1,809,514.89 | 69,892.71 | 43,964.47 | 29,473.29 | |||

| CEIR [%] | 51.03 | 47.94 | 80.26 | 70.95 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alivojvodic, V.; Kokalj, F. Drivers and Barriers for the Adoption of Circular Economy Principles towards Efficient Resource Utilisation. Sustainability 2024, 16, 1317. https://doi.org/10.3390/su16031317

Alivojvodic V, Kokalj F. Drivers and Barriers for the Adoption of Circular Economy Principles towards Efficient Resource Utilisation. Sustainability. 2024; 16(3):1317. https://doi.org/10.3390/su16031317

Chicago/Turabian StyleAlivojvodic, Vesna, and Filip Kokalj. 2024. "Drivers and Barriers for the Adoption of Circular Economy Principles towards Efficient Resource Utilisation" Sustainability 16, no. 3: 1317. https://doi.org/10.3390/su16031317

APA StyleAlivojvodic, V., & Kokalj, F. (2024). Drivers and Barriers for the Adoption of Circular Economy Principles towards Efficient Resource Utilisation. Sustainability, 16(3), 1317. https://doi.org/10.3390/su16031317