Evaluation of the Mechanical Performance of Warm Bio-Recycled Asphalt Mixtures

Abstract

1. Introduction

2. Materials and Methodology

2.1. Materials

2.1.1. Binders

2.1.2. Asphalt Mixtures

2.2. Methods

2.2.1. Binder Rheological Characterization

2.2.2. Asphalt Mixture Characterization

3. Results and Discussion

3.1. Binder Rheological Characterization

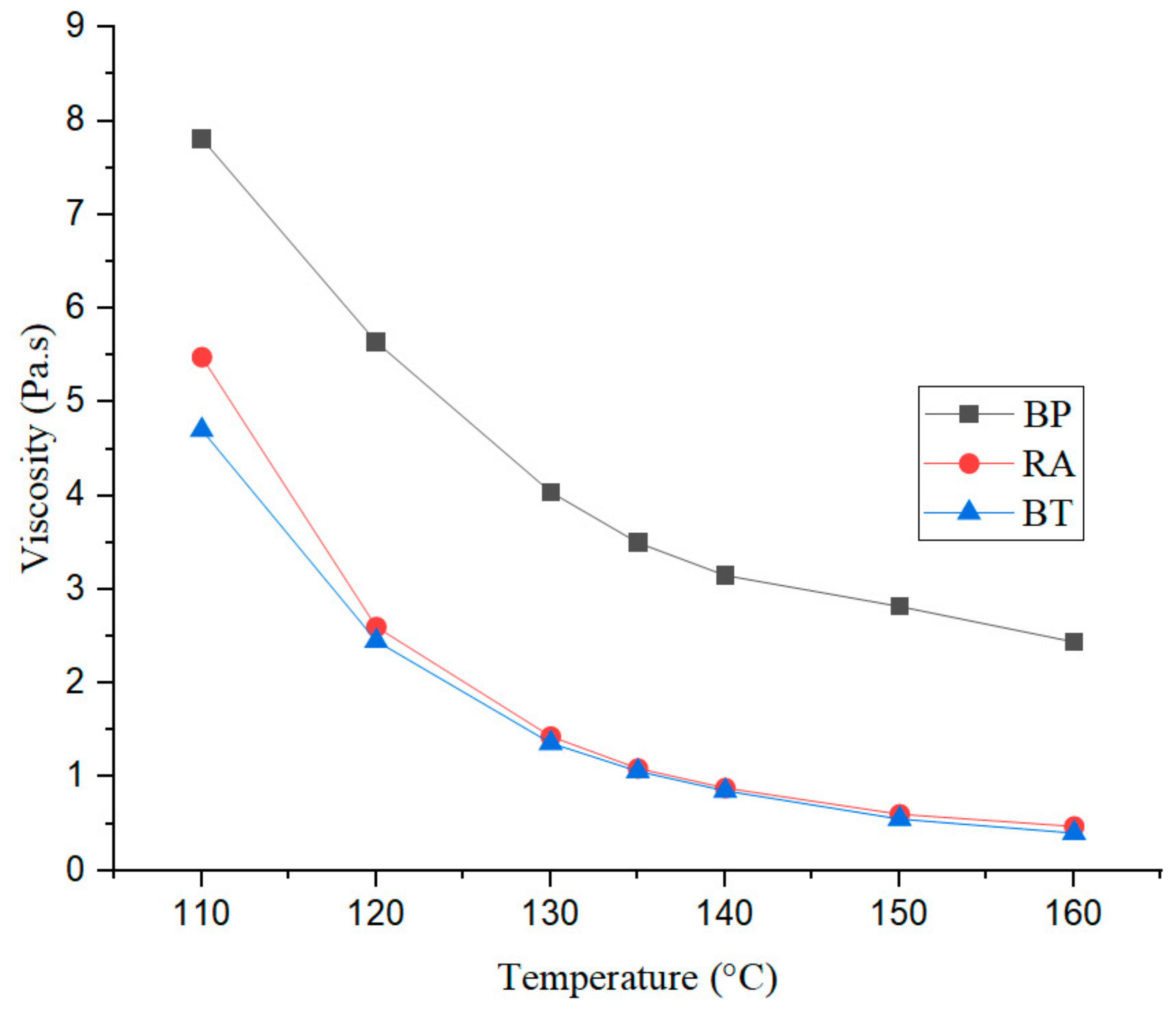

3.1.1. Brookfield Viscometer Test

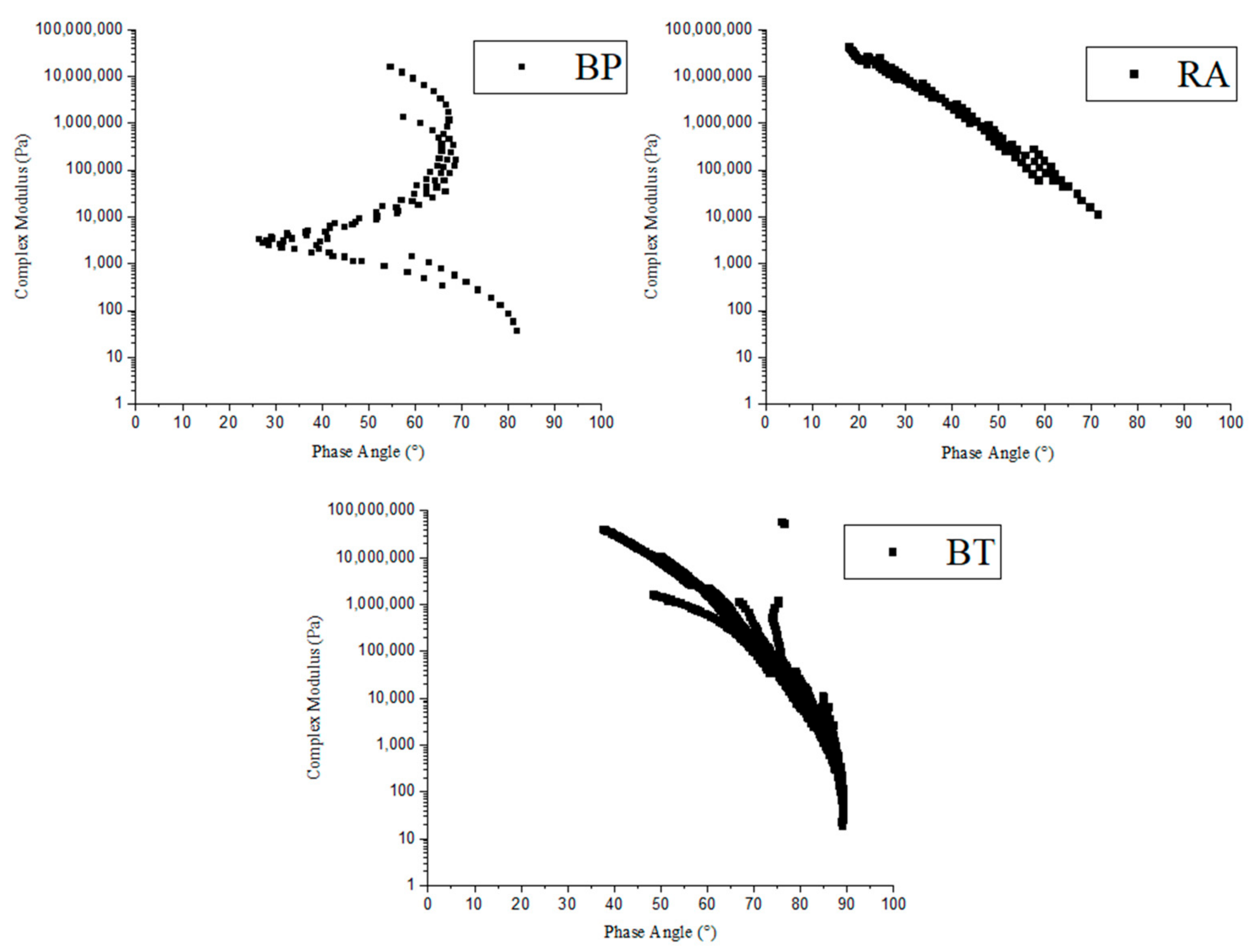

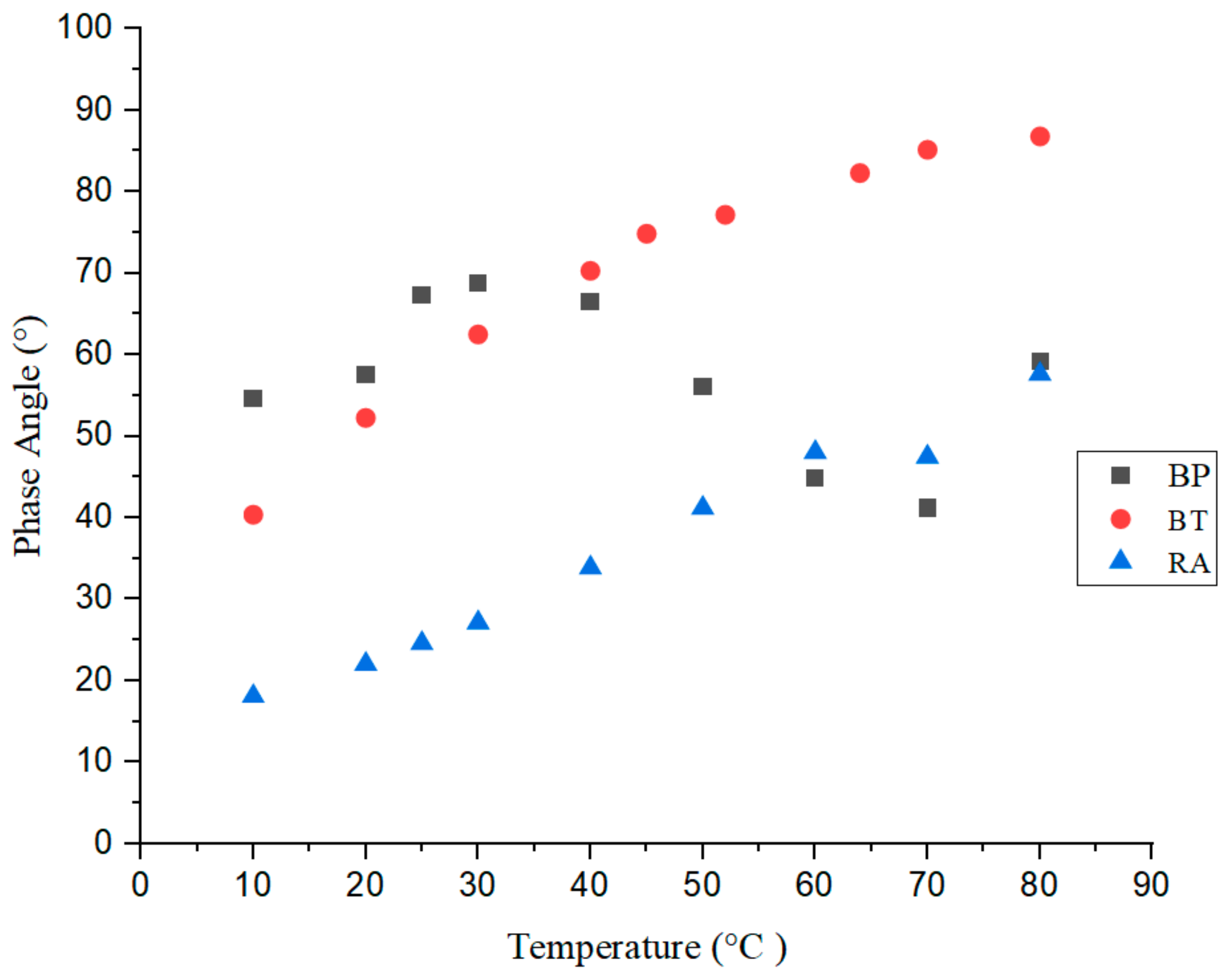

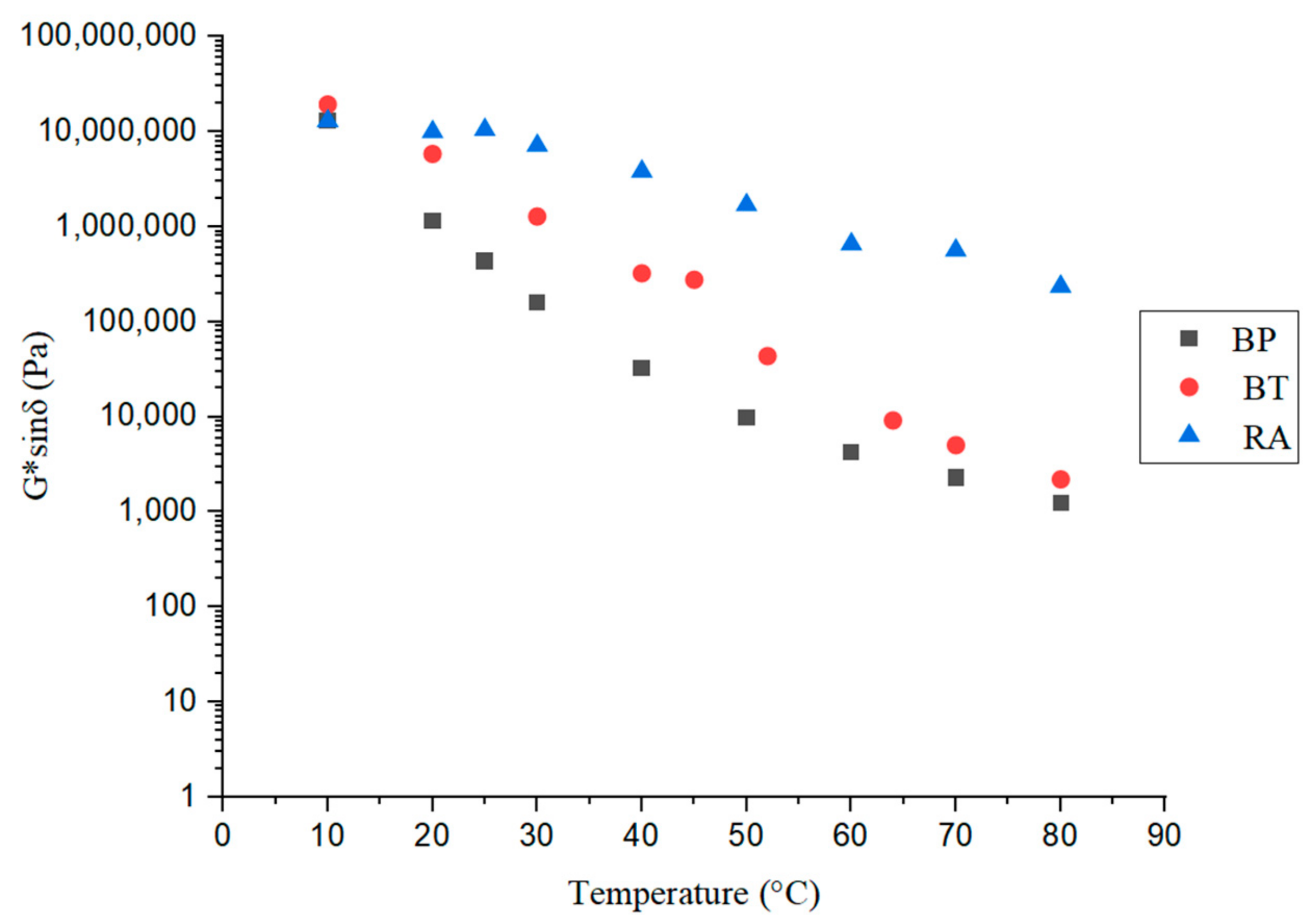

3.1.2. Frequency and Temperature Sweep Test

3.1.3. Multiple Stress Creep Recovery Test

3.2. Asphalt Mixture Characterization

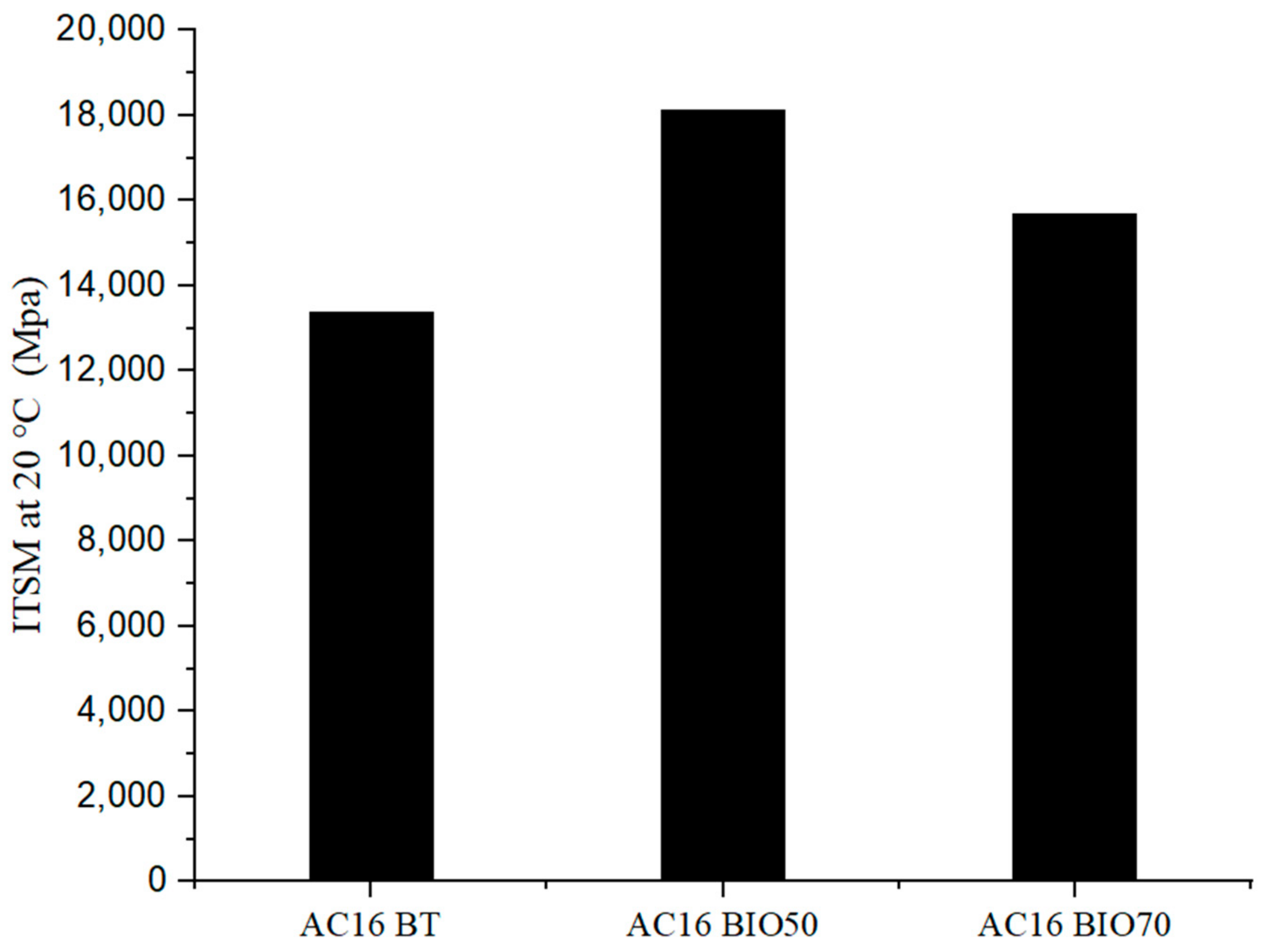

3.2.1. Bearing Capacity

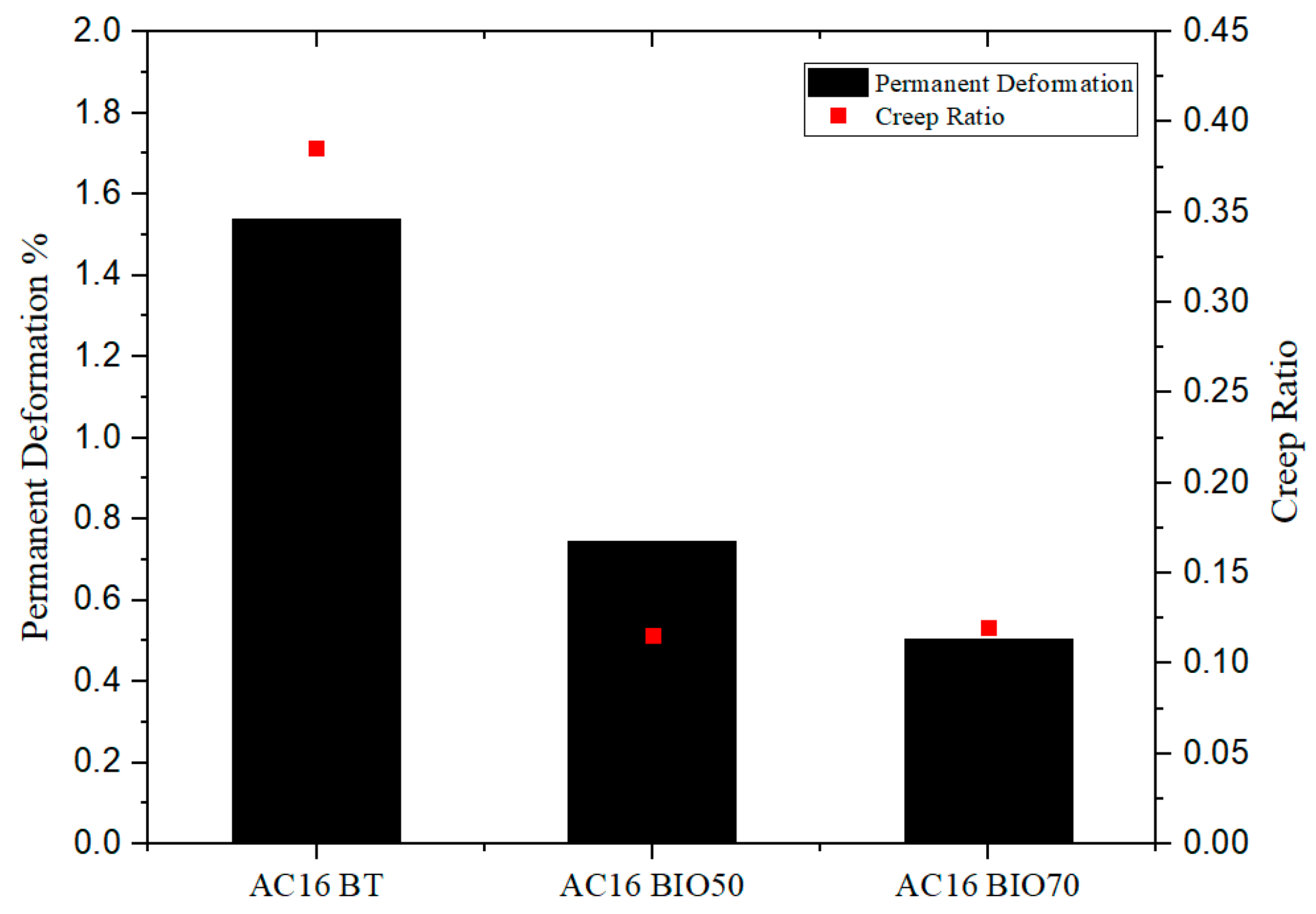

3.2.2. Permanent Deformations

3.2.3. Water Sensitivity

4. Conclusions

- At the binder level, the rheological characterization of the binders showed that the combination of the stiff RA binder and the soft biobinder might be suitable to achieve a compromise for the rutting and fatigue resistance of the warm bio-recycled asphalt mixtures.

- At the mixture level, the warm bio-recycled asphalt mixtures exhibited adequate mechanical properties, including enhanced bearing capacity and resistance to permanent deformations, shedding light on the possible issues regarding these distresses and the use of soft biobinders. The improvement in cohesion and water sensitivity reduced the concern about moisture damage in these types of asphalt mixtures.

- The soft consistency of the biobinder combined with the high stiffness of the RA provided favorable results and allowed the positive reduction in manufacturing temperatures. This temperature reduction implies energy consumption savings and decreased greenhouse gas emissions, which must be specifically measured in future research.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pasetto, M.; Baldo, N. Unified approach to fatigue study of high performance recycled asphalt concretes. Mater. Struct. 2017, 50, 113. [Google Scholar] [CrossRef]

- Lee, N.; Chou, C.-P.; Chen, K.-Y. Benefits in Energy Savings and CO2 Reduction by Using Reclaimed Asphalt Pavement. In Proceedings of the Transportation Research Board 91st Annual Meeting, Washington, DC, USA, 22–26 January 2012; p. 18. [Google Scholar]

- Foroutan Mirhosseini, A.; Kavussi, A.; Tahami, S.A.; Dessouky, S. Characterizing Temperature Performance of Bio-Modified Binders Containing RAP Binder. J. Mater. Civ. Eng. 2018, 30, 04018176. [Google Scholar] [CrossRef]

- Reyes-Ortiz, O.; Berardinelli, E.; Alvarez, A.E.; Carvajal-Muñoz, J.S.; Fuentes, L.G. Evaluation of Hot Mix Asphalt Mixtures with Replacement of Aggregates by Reclaimed Asphalt Pavement (RAP) Material. Procedia Soc. Behav. Sci. 2012, 53, 379–388. [Google Scholar] [CrossRef]

- Foroutan Mirhosseini, A.; Tahami, S.A.; Hoff, I.; Dessouky, S.; Ho, C.-H. Performance evaluation of asphalt mixtures containing high-RAP binder content and bio-oil rejuvenator. Constr. Build. Mater. 2019, 227, 116465. [Google Scholar] [CrossRef]

- Jahangiri, B.; Majidifard, H.; Meister, J.; Buttlar, W.G. Performance Evaluation of Asphalt Mixtures with Reclaimed Asphalt Pavement and Recycled Asphalt Shingles in Missouri. Transp. Res. Rec. J. Transp. Res. Board 2019, 2673, 392–403. [Google Scholar] [CrossRef]

- Ali, A.W.; Mehta, Y.A.; Nolan, A.; Purdy, C.; Bennert, T. Investigation of the impacts of aging and RAP percentages on effectiveness of asphalt binder rejuvenators. Constr. Build. Mater. 2016, 110, 211–217. [Google Scholar] [CrossRef]

- Movilla-Quesada, D.; Lagos-Varas, M.; Raposeiras, A.C.; Muñoz-Cáceres, O.; Andrés-Valeri, V.C.; Aguilar-Vidal, C. Analysis of Greenhouse Gas Emissions and the Environmental Impact of the Production of Asphalt Mixes Modified with Recycled Materials. Sustainability 2021, 13, 8081. [Google Scholar] [CrossRef]

- Oldham, D.; Rajib, A.; Phani, K.; Dandamudi, R.; Liu, Y.; Deng, S.; Fini, E.H. Transesterification of Waste Cooking Oil to Produce A Sustainable Rejuvenator for Aged Asphalt. Resour. Conserv. Recycl. 2021, 168, 105297. [Google Scholar] [CrossRef]

- Saha, R.; Melaku, R.S.; Karki, B.; Berg, A.; Gedafa, D.S. Effect of Bio-Oils on Binder and Mix Properties with High RAP Binder Content. J. Mater. Civ. Eng. 2020, 32, 04020007. [Google Scholar] [CrossRef]

- Do Nascimento Camargo, I.G.; Bernucci, L.L.B.; Vasconcelos, K.L. Aging Characterization of Biobinder Produced from Renewable Sources. In RILEM 252-CMB Symposium: Chemo-Mechanical Characterization of Bituminous Materials; Springer: Berlin/Heidelberg, Germany, 2019; pp. 9–14. [Google Scholar]

- Hill, B.; Oldham, D.; Behnia, B.; Fini, E.H.; Buttlar, W.G.; Reis, H. Evaluation of low temperature viscoelastic properties and fracture behavior of bio-asphalt mixtures. Int. J. Pavement Eng. 2018, 19, 362–369. [Google Scholar] [CrossRef]

- Fini, E.H.; Kalberer, E.W.; Shahbazi, A.; Basti, M.; You, Z.; Ozer, H.; Aurangzeb, Q. Chemical Characterization of Biobinder from Swine Manure: Sustainable Modifier for Asphalt Binder. J. Mater. Civ. Eng. 2011, 23, 1506–1513. [Google Scholar] [CrossRef]

- Espinosa, L.V.; Gadler, F.; Mota, R.V.; Guatimosim, F.V.; Camargo, I.; Vasconcelos, K.; Barros, R.M.d.V.; Bernucci, L.L.B. Multi-scale study of bio-binder mixtures as surface layer: Laboratory evaluation and field application and monitoring. Constr. Build. Mater. 2021, 287, 122982. [Google Scholar] [CrossRef]

- Abo-Shanab, Z.L.; Ragab, A.A.; Naguib, H.M. Improved dynamic mechanical properties of sustainable bio-modified asphalt using agriculture waste. Int. J. Pavement Eng. 2021, 22, 905–911. [Google Scholar] [CrossRef]

- Yu, D.; Jia, A.; Feng, C.; Liu, W.; Fu, T.; Qiu, R. Preparation and mechanical properties of asphalt mixtures reinforced by modified bamboo fibers. Constr. Build. Mater. 2021, 286, 122984. [Google Scholar] [CrossRef]

- Seferoğlu, A.G.; Seferoğlu, M.T.; Akpınar, M.V. Investigation of the Effect of Recycled Asphalt Pavement Material on Permeability and Bearing Capacity in the Base Layer. Adv. Civ. Eng. 2018, 2018, 2860213. [Google Scholar] [CrossRef]

- Ingrassia, L.P.; Lu, X.; Ferrotti, G.; Canestrari, F. Renewable materials in bituminous binders and mixtures: Speculative pretext or reliable opportunity? Resour. Conserv. Recycl. 2019, 144, 209–222. [Google Scholar] [CrossRef]

- Weir, A.; Jiménez del Barco Carrión, A.; Queffélec, C.; Bujoli, B.; Chailleux, E.; Uguna, C.N.; Snape, C.; Airey, G. Renewable binders from waste biomass for road construction: A review on thermochemical conversion technologies and current developments. Constr. Build. Mater. 2022, 330, 127076. [Google Scholar] [CrossRef]

- Manke, N.D.; Williams, R.C.; Sotoodeh-Nia, Z.; Cochran, E.W.; Porot, L.; Chailleux, E.; Pouget, S.; Olard, F.; Jiménez del Barco Carrión, A.; Planche, J.-P.; et al. Performance of a sustainable asphalt mix incorporating high RAP content and novel bio-derived binder. Road Mater. Pavement Des. 2021, 22, 812–834. [Google Scholar] [CrossRef]

- Blanc, J.; Hornych, P.; Sotoodeh-Nia, Z.; Williams, C.; Porot, L.; Pouget, S.; Boysen, R.; Planche, J.-P.; Lo Presti, D.; Jiménez del Barco Carrión, A.; et al. Full-scale validation of bio-recycled asphalt mixtures for road pavements. J. Clean. Prod. 2019, 227, 1068–1078. [Google Scholar] [CrossRef]

- EN 1426:2015; Bitumen and Bituminous Binders—Determination of Needle Penetration. European Committee for Standardization: Brussels, Belgium, 2015.

- EN 1427:2015; Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method. European Committee for Standardization: Brussels, Belgium, 2015.

- CEN/TC UNE-EN 12697-3:2013; Bituminous Mixtures Test Methods for Hot Mix Asphalt Part 3: Bitumen Recovery: Rotary Evaporator. European Committee for Standardization: Brussels, Belgium, 2013.

- EN13108 Part 1 2019; Bituminous Mixtures. Material specifications. Asphalt Concrete. European Committee for Standardization: Brussels, Belgium, 2019.

- Sol-Sánchez, M.; Jiménez del Barco Carrión, A.; Hidalgo-Arroyo, A.; Moreno-Navarro, F.; Saiz, L.; del Carmen Rubio-Gámez, M. Viability of producing sustainable asphalt mixtures with crumb rubber bitumen at reduced temperatures. Constr. Build. Mater. 2020, 265, 120154. [Google Scholar] [CrossRef]

- EN 12607-1:2015; Bitumen and bituminous binders—Determination of the Resistance to Hardening under Influence of Heat and air—Part 1: RTFOT Method. European Committee for Standardization: Brussels, Belgium, 2015.

- Moreno-Navarro, F.; Tauste, R.; Sol-Sánchez, M.; Rubio-Gámez, M.C. New approach for characterising the performance of asphalt binders through the multiple stress creep and recovery test. Road Mater. Pavement Des. 2019, 20, S500–S520. [Google Scholar] [CrossRef]

- Liu, H.; Zeiada, W.; Al-Khateeb, G.G.; Shanableh, A.; Samarai, M. Use of the multiple stress creep recovery (MSCR) test to characterize the rutting potential of asphalt binders: A literature review. Constr. Build. Mater. 2021, 269, 121320. [Google Scholar] [CrossRef]

- EN 13302:2018; Bitumen and bituminous binders—Determination of dynamic viscosity of bituminous binder using a rotating spindle apparatus. European Committee for Standardization: Brussels, Belgium, 2018.

- EN12697-26; Mezclas Bituminosas, Metodos de Ensayo. Parte 26: Rigidez. UNE Normalización Española: Madrid, Spain, 2019.

- UNE-EN 12697-12:2019; Mezclas Bituminosas. Métodos de Ensayo. Parte 12: Determinación de la Sensibilidad al Agua de Probetas de Mezcla Bituminosa. AENOR: Madrid, Spain, 2019.

- EN 12697-25; Bituminous mixtures—Test methods—Part 25: Cyclic compression test. European Committee for Standardization: Brussels, Belgium, 2016.

- Gao, J.; Wang, H.; You, Z.; Mohd Hasan, M.R. Research on properties of bio-asphalt binders based on time and frequency sweep test. Constr. Build. Mater. 2018, 160, 786–793. [Google Scholar] [CrossRef]

- Airey, G.D. Use of Black Diagrams to Identify Inconsistencies in Rheological Data. Road Mater. Pavement Des. 2002, 3, 403–424. [Google Scholar] [CrossRef]

- Sabouri, M.; Choi, Y.-T.; Wang, Y.; Hwang, S.; Baek, C.; Kim, R.Y. Effect of Rejuvenator on Performance Properties of WMA Mixtures with High RAP Content. In 8th RILEM International Symposium on Testing and Characterization of Sustainable and Innovative Bituminous Materials; Springer: Dordrecht, The Netherlands, 2016; pp. 473–484. [Google Scholar]

- Mogawer, W.; Bennert, T.; Daniel, J.S.; Bonaquist, R.; Austerman, A.; Booshehrian, A. Performance characteristics of plant produced high RAP mixtures. Road Mater. Pavement Des. 2012, 13, 183–208. [Google Scholar] [CrossRef]

- Gobierno de España PG-3. Artículo 542: Mezclas Bituminosas Tipo Hormigón Bituminoso; Ministerio de Fomento: Madrid, Spain, 2014; Volume 2018, pp. 39355–39357. [Google Scholar]

- Santagata, F.A.; Cardone, F.; Canestrari, F.; Bahia, H.U. Modified PATTI Test for the Characterization of Adhesion and Cohesion Properties of Asphalt Binders. In Proceedings of the Sixth International Conference on Maintenance and Rehabilitation of Pavements and Technological Control (MAIREPAV6), Turin, Italy, 8–10 July 2009; Volume 10. Available online: https://trid.trb.org/Results?q=&serial=%22%22 (accessed on 20 December 2023).

| Binder | Penetration at 25 °C (×0.1 mm) | Softening Point (°C) |

|---|---|---|

| BT | 50.3 | 46 |

| BP | 150.0 | 68 |

| RA binder | 8.8 | 125 |

| AC16BT | AC16BIO50 | AC16BIO70 | |

|---|---|---|---|

| Binder Type | BT | BP | BP |

| Optimum Binder Content (%) | 2.5 | 2.0 | 2.4 |

| RA Content (%) | 50 | 50 | 70 |

| Aggregate Temperature (°C) | 140 | 160 | 160 |

| RA Temperature (°C) | 140 | 140 | 140 |

| Binder Temperature (°C) | 160 | 140 | 140 |

| Manufacturing Temperature (°C) | 140 | 140 | 140 |

| Parameters | Standard Value |

|---|---|

| Test temperature | 20 °C |

| Rise time | 124 ± 4 ms |

| Horizontal deformation | 5 ± 2 µm (for diameter 100 mm) 7 ± 2 µm (for diameter 150 mm) |

| Poisson’s ratio for bituminous mixtures | 0.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsarayreh, D.; Jiménez del Barco Carrión, A. Evaluation of the Mechanical Performance of Warm Bio-Recycled Asphalt Mixtures. Sustainability 2024, 16, 1287. https://doi.org/10.3390/su16031287

Alsarayreh D, Jiménez del Barco Carrión A. Evaluation of the Mechanical Performance of Warm Bio-Recycled Asphalt Mixtures. Sustainability. 2024; 16(3):1287. https://doi.org/10.3390/su16031287

Chicago/Turabian StyleAlsarayreh, Daniah, and Ana Jiménez del Barco Carrión. 2024. "Evaluation of the Mechanical Performance of Warm Bio-Recycled Asphalt Mixtures" Sustainability 16, no. 3: 1287. https://doi.org/10.3390/su16031287

APA StyleAlsarayreh, D., & Jiménez del Barco Carrión, A. (2024). Evaluation of the Mechanical Performance of Warm Bio-Recycled Asphalt Mixtures. Sustainability, 16(3), 1287. https://doi.org/10.3390/su16031287