Sustainable Utilization of Phosphogypsum in Multi-Solid Waste Recycled Aggregates: Environmental Impact and Economic Viability

Abstract

1. Introduction

2. Experiment

2.1. Raw Materials

2.2. Experimental Methods

2.2.1. Mix Ratio Design

2.2.2. Specimen Preparation

2.3. Testing and Characterization

2.4. Compressive Strength and Softening Coefficient of Recycled Aggregate

3. Results and Discussion

3.1. Raw Material Properties and Morphology

3.2. Particle Grading Analysis of Raw Materials

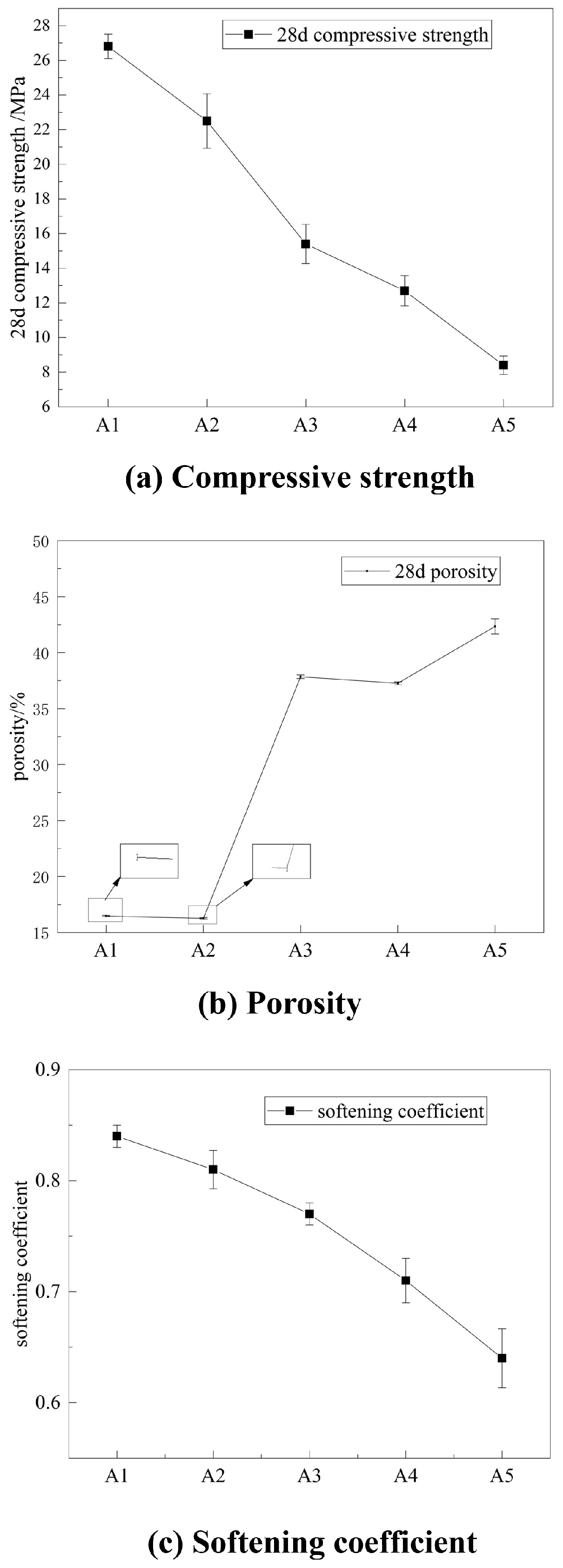

3.3. Effect of Mix Proportion

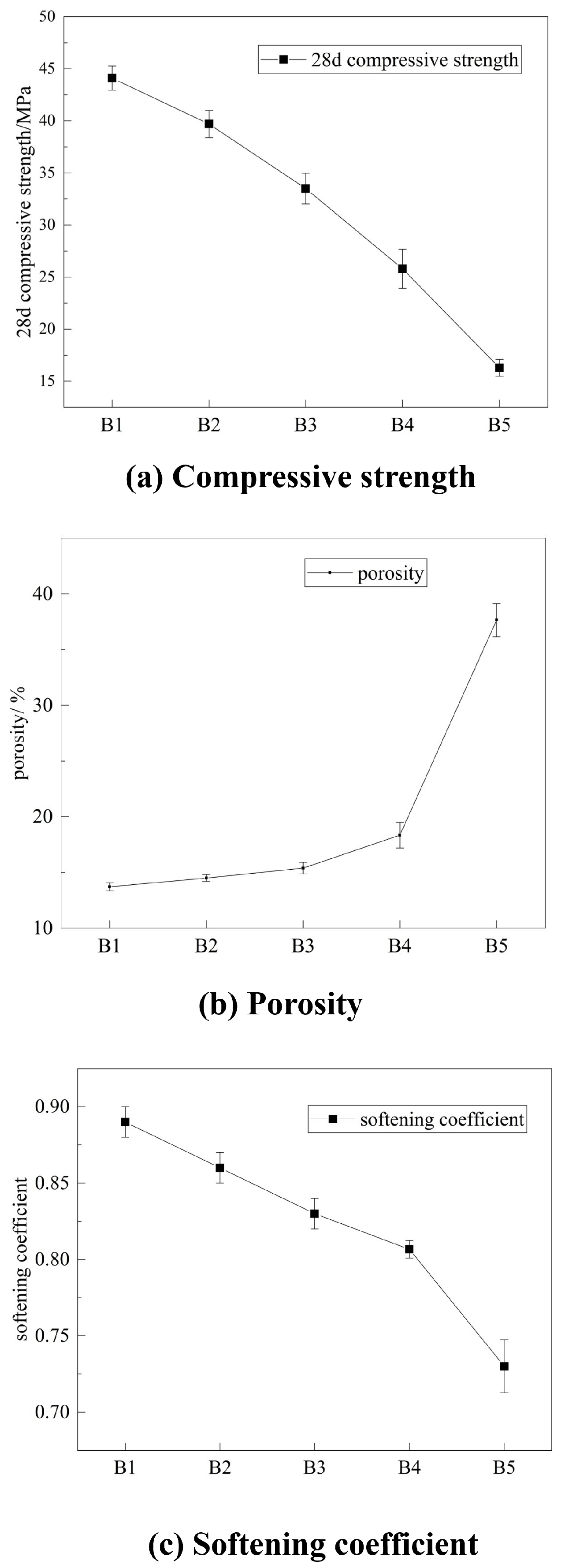

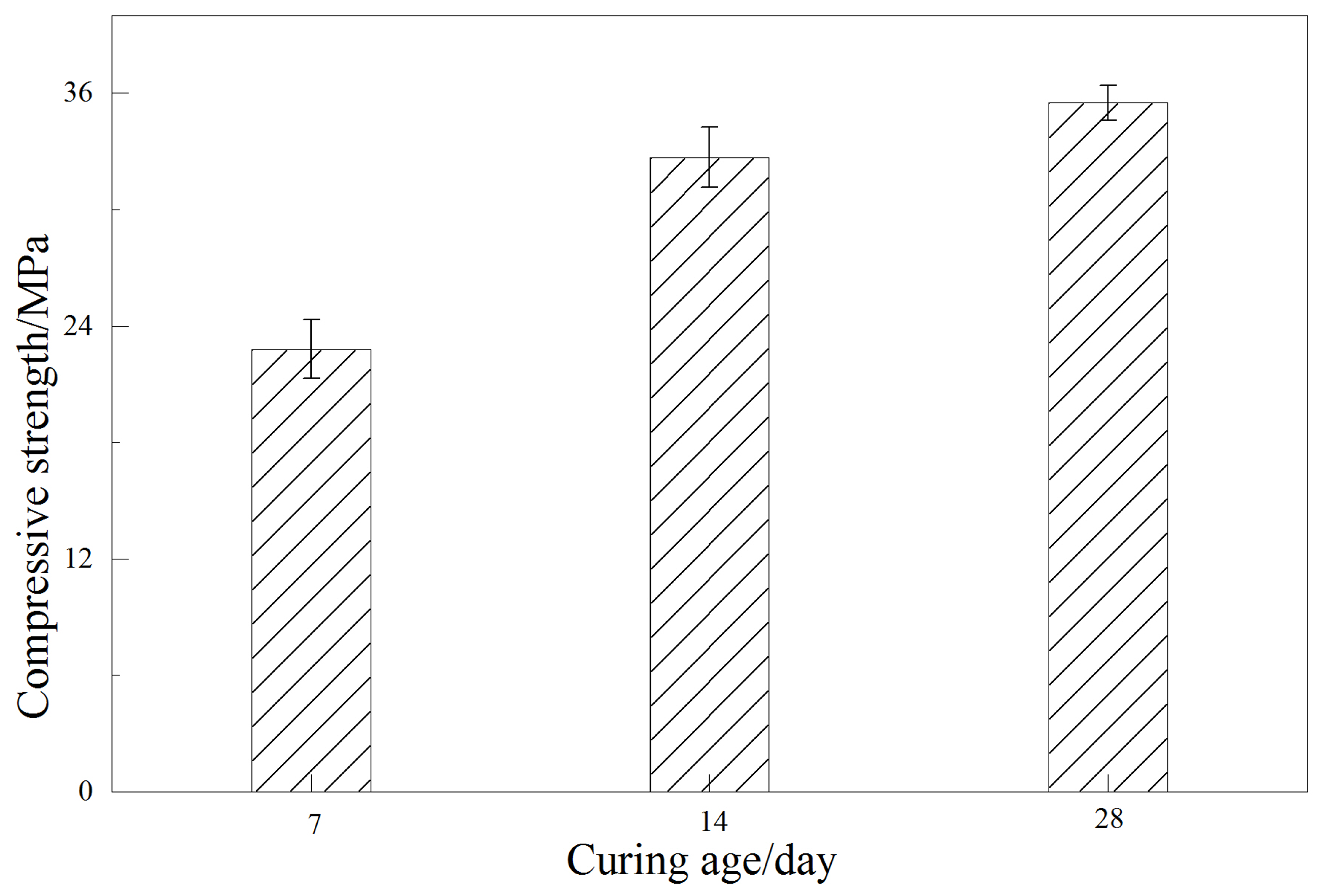

3.4. The Impact of Pressure Molding on the Compressive Strength and Water Resistance of Recycled Aggregate

3.5. Discussion on the Mechanism of Strength Formation of Recycled Aggregates

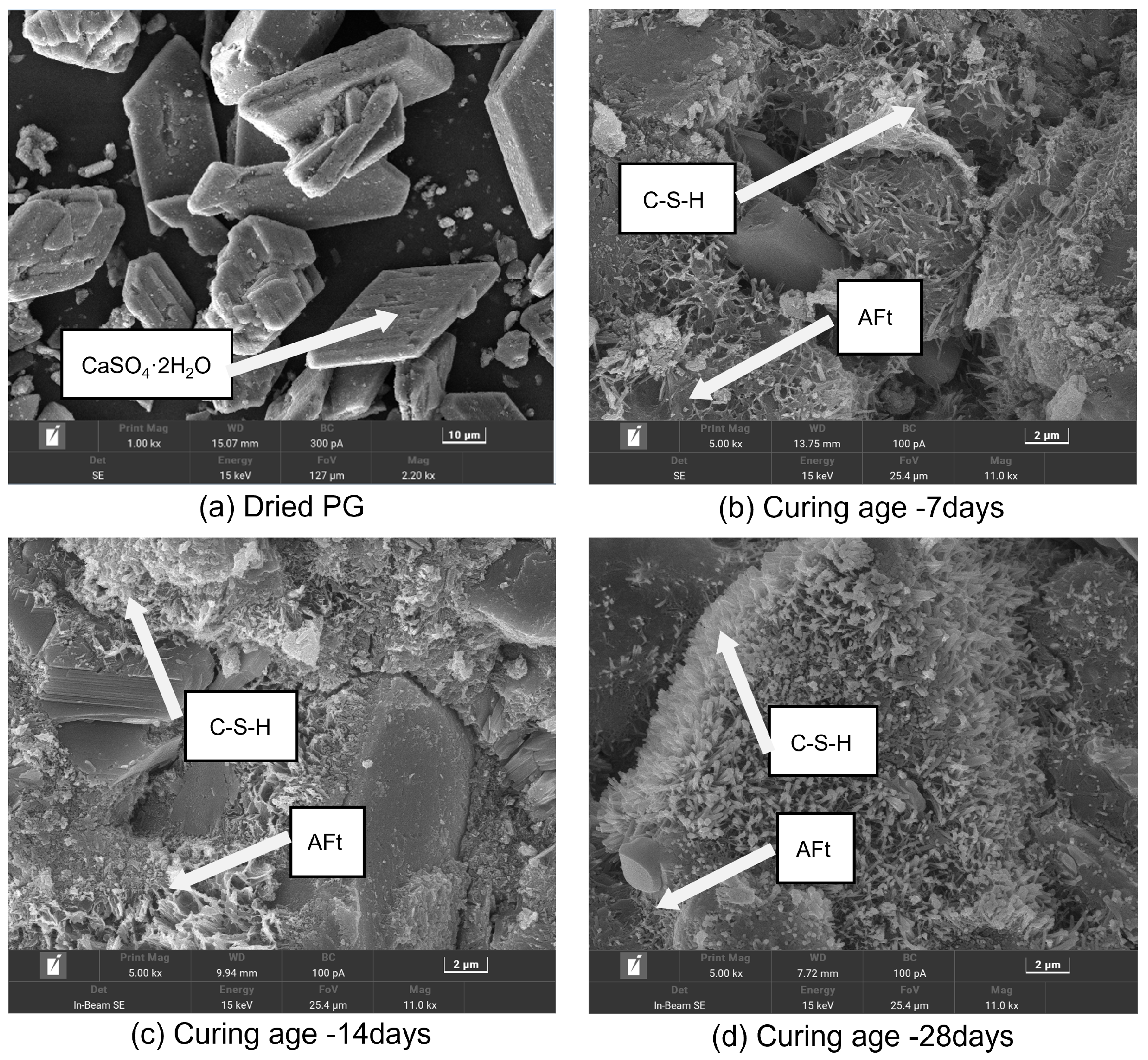

3.5.1. SEM Analysis

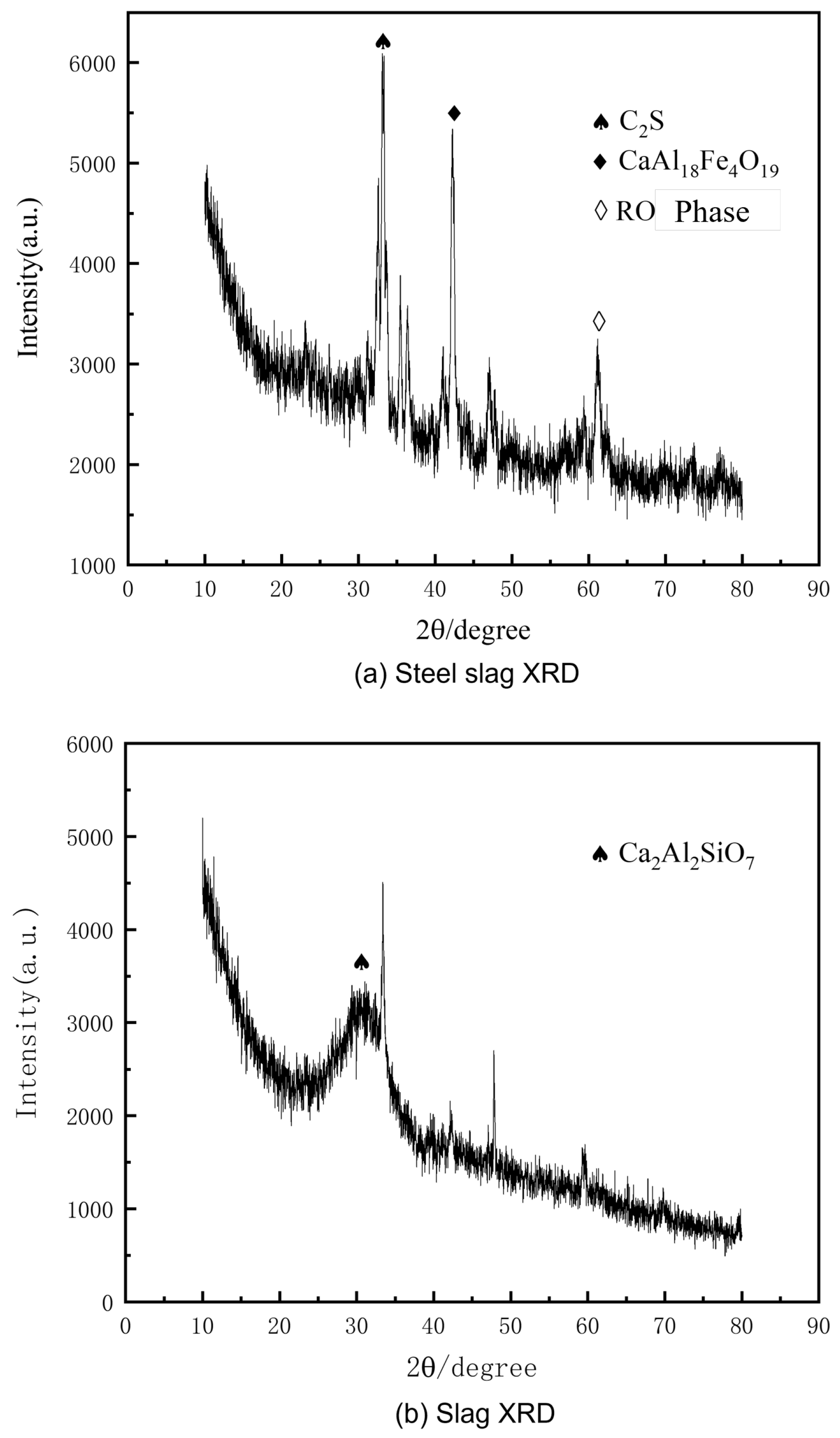

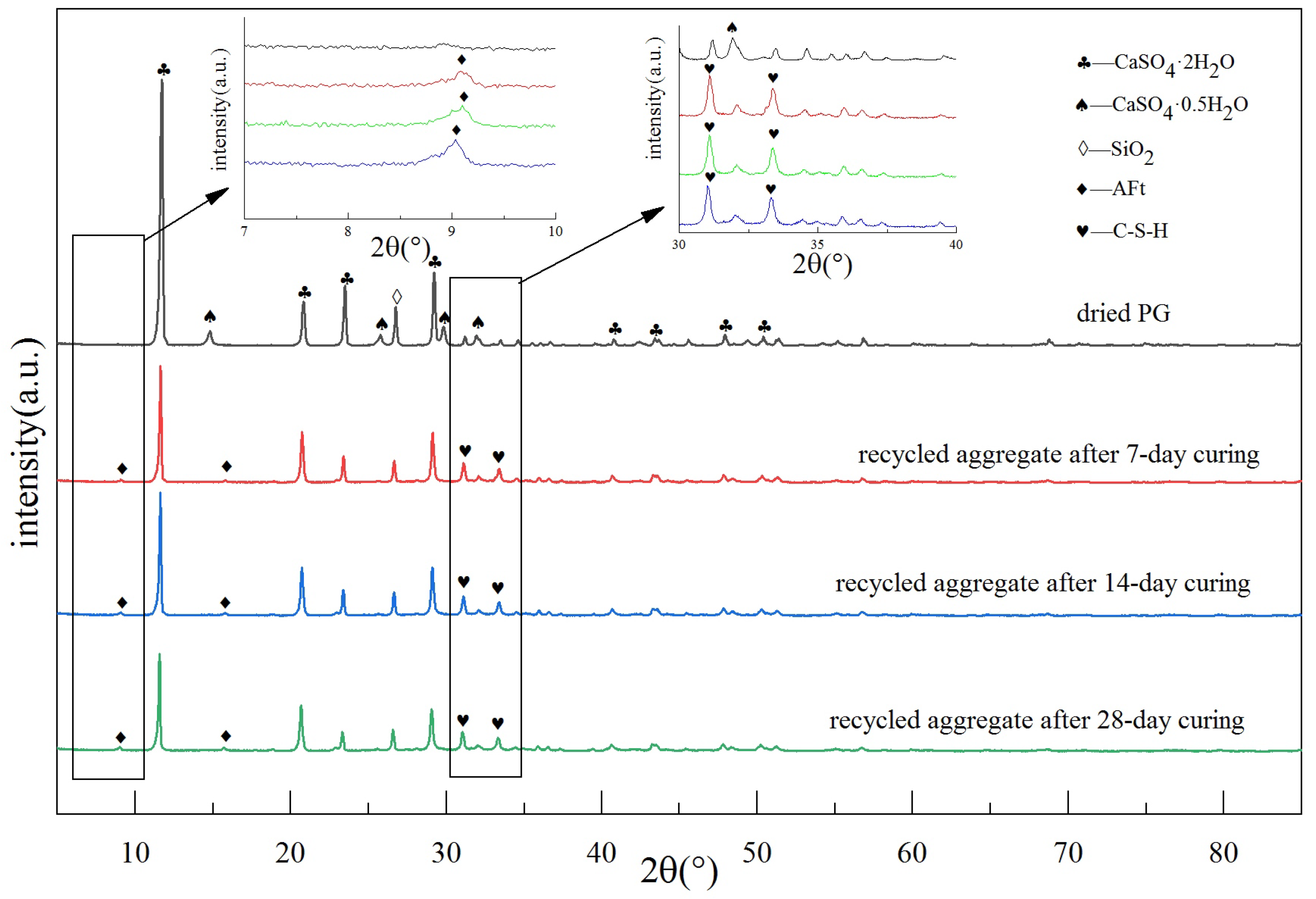

3.5.2. XRD Analysis

3.5.3. MIP Analysis

3.5.4. Mechanism of Strength Formation

3.6. Environmental Impact

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Haneklaus, N.; Bertau, M.; Fröhlich, P.; Pavón, S.; Barbossa, S.; Basallote, M.; Nieto, J.; Cánovas, C.; Bilal, E.; Chajduk, E.; et al. Closing the upcoming EU gypsum gap with phosphogypsum. Resour. Conserv. Recycl. 2022, 182, 106328. [Google Scholar] [CrossRef]

- Diwa, R.R.; Tabora, E.U.; Palattao, B.L.; Haneklaus, N.H.; Vargas, E.P.; Reyes, R.Y.; Ramirez, J.D. Evaluating radiation risks and resource opportunities associated with phosphogypsum in the Philippines. J. Radioanal. Nucl. Chem. 2022, 331, 967–974. [Google Scholar] [CrossRef]

- Bilal, E.; Bellefqih, H.; Bourgier, V.; Mazouz, H.; Dumitraş, D.G.; Bard, F.; Laborde, M.; Caspar, J.P.; Guilhot, B.; Iatan, L.; et al. Phosphogypsum circular economy considerations: A critical review from more than 65 storage sites worldwide. J. Clean. Prod. 2023, 414, 137561. [Google Scholar] [CrossRef]

- Cui, Y.; Bai, J.; Chang, I.S.; Wu, J. A systematic review of phosphogypsum recycling industry based on the survey data in China–applications, drivers, obstacles, and solutions. Environ. Impact Assess. Rev. 2024, 105, 107405. [Google Scholar] [CrossRef]

- Weiksnar, K.D.; Clavier, K.A.; Laux, S.J.; Townsend, T.G. Influence of trace chemical constituents in phosphogypsum for road base applications: A review. Resour. Conserv. Recycl. 2023, 199, 107237. [Google Scholar] [CrossRef]

- kumar Patel, J.; Patil, H.; Patil, Y.; Vesmawala, G. Production and performance of alkali-activated cold-bonded lightweight aggregate in concrete. J. Build. Eng. 2018, 20, 616–623. [Google Scholar] [CrossRef]

- Ilić, B.; Stojanovic, D.; Djukic, G. Green economy: Mobilization of international capital for financing projects of renewable energy sources. Green Financ. 2019, 1, 94–109. [Google Scholar] [CrossRef]

- Ren, P.; Ling, T.C.; Mo, K.H. Recent advances in artificial aggregate production. J. Clean. Prod. 2021, 291, 125215. [Google Scholar] [CrossRef]

- Tajra, F.; Abd Elrahman, M.; Stephan, D. The production and properties of cold-bonded aggregate and its applications in concrete: A review. Constr. Build. Mater. 2019, 225, 29–43. [Google Scholar] [CrossRef]

- Xu, S. International comparison of green credit and its enlightenment to China. Green Financ. 2020, 2, 75–99. [Google Scholar] [CrossRef]

- Xiao, Y.D.; Jin, H.X.; Wang, M.L.; Guo, Y.L. Collaborative utilization status of red mud and phosphogypsum: A review. J. Sustain. Metall. 2022, 8, 1422–1434. [Google Scholar] [CrossRef]

- Ben Chabchoubi, I.; Bouguerra, S.; Ksibi, M.; Hentati, O. Health risk assessment of heavy metals exposure via consumption of crops grown in phosphogypsum-contaminated soils. Environ. Geochem. Health 2021, 43, 1953–1981. [Google Scholar] [CrossRef] [PubMed]

- Silva, L.F.; Oliveira, M.L.; Crissien, T.J.; Santosh, M.; Bolivar, J.; Shao, L.; Dotto, G.L.; Gasparotto, J.; Schindler, M. A review on the environmental impact of phosphogypsum and potential health impacts through the release of nanoparticles. Chemosphere 2022, 286, 131513. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Ning, P.; Zheng, S.; Niu, X.; Zhang, W.; Du, Y. Reaction mechanism and kinetic analysis of the decomposition of phosphogypsum via a solid-state reaction. Ind. Eng. Chem. Res. 2010, 49, 3597–3602. [Google Scholar] [CrossRef]

- Feng, Y.; Yang, L.; Cao, J.; Wang, B.; Chen, L. Calcining Modification of Phosphogypsum to Prepare Self-Leveling Mortar. Bull. Chin. Ceram. Soc. 2020, 39, 2891–2897. [Google Scholar]

- Xu, F.; Li, H.; Sun, T.; Nie, Y.; Ding, C. Microstructure and mechanical properties of excess-sulfate phosphogypsum slag cementitious road base material. J. Build. Mater. 2022, 25, 228–234. [Google Scholar]

- Yang, J.; Ma, L.; Dong, S.; Liu, H.; Zhao, S.; Cui, X.; Zheng, D.; Yang, J. Theoretical and experimental demonstration of lignite chemical looping gasification of phosphogypsum oxygen carrier for syngas generation. Fuel 2017, 194, 448–459. [Google Scholar] [CrossRef]

- Zhang, Y.; Jingsong, Y.; Rongjiang, Y.; Xiangping, W.; Wenping, X. Short-term effects of biochar and gypsum on soil hydraulic properties and sodicity in a saline-alkali soil. Pedosphere 2020, 30, 694–702. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Q.; Cai, W.; Yi, M.; Xiang, L. Formation and application of hierarchical calcium silicate-calcium sulfate whiskers. Mater. Des. 2018, 146, 172–179. [Google Scholar] [CrossRef]

- Zhao, J.; Yan, P.; Wang, D. Research on mineral characteristics of converter steel slag and its comprehensive utilization of internal and external recycle. J. Clean. Prod. 2017, 156, 50–61. [Google Scholar] [CrossRef]

- Gao, D.; Wang, F.P.; Wang, Y.T.; Zeng, Y.N. Sustainable utilization of steel slag from traditional industry and agriculture to catalysis. Sustainability 2020, 12, 9295. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.C.; Shi, C.; Pan, S.Y. Characteristics of steel slags and their use in cement and concrete—A review. Resour. Conserv. Recycl. 2018, 136, 187–197. [Google Scholar] [CrossRef]

- Oluwasola, E.A.; Hainin, M.R.; Aziz, M.M.A. Characteristics and utilization of steel slag in road construction. J. Teknol. 2014, 70, 117–123. [Google Scholar] [CrossRef]

- Tripathy, S.K.; Dasu, J.; Murthy, Y.R.; Kapure, G.; Pal, A.R.; Filippov, L.O. Utilisation perspective on water quenched and air-cooled blast furnace slags. J. Clean. Prod. 2020, 262, 121354. [Google Scholar] [CrossRef]

- Anameric, B.; Kawatra, K.S. Manipulation of slag separation properties from pig iron nuggets with flux additions to dried greenball mixture. Miner. Process. Extr. Metall. Rev. 2018, 39, 73–88. [Google Scholar] [CrossRef]

- Bhatnagar, M.; Taneja, S.; Özen, E. A wave of green start-ups in India—The study of green finance as a support system for sustainable entrepreneurship. Green Financ. 2022, 4, 253–273. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, H.; He, X.; Yang, W.; Deng, X. Utilization of carbide slag-granulated blast furnace slag system by wet grinding as low carbon cementitious materials. Constr. Build. Mater. 2020, 249, 118763. [Google Scholar] [CrossRef]

- Wang, Q.; Li, M.; Shi, M. Hydration properties of cement-steel slag-ground granulated blast furnace slag complex binder. J. Chin. Ceram. Soc. 2014, 42, 629–634. [Google Scholar]

- Duan, S.; Liao, H.; Cheng, F.; Song, H.; Yang, H. Investigation into the synergistic effects in hydrated gelling systems containing fly ash, desulfurization gypsum and steel slag. Constr. Build. Mater. 2018, 187, 1113–1120. [Google Scholar] [CrossRef]

- Qi, F.; Sun, J.; Zhu, G.; Li, H.; Wu, Y.; Li, S.; Yang, C.; Zheng, J.; Zhang, Y. Recycling of blast furnace slag to prepare calcium silicate hydrate by mechanical-chemical co-activation and its application to calcium silicate fireproof board. Process Saf. Environ. Prot. 2022, 165, 1–12. [Google Scholar] [CrossRef]

- GB/T 14685-2011; Pebble and Crushed Stone for Construction. Standardization Administration of the People’s Republic of China: Beijing, China, 2011.

- Xiao-Meng, S.; Bao-Guo, L.; Yi, Q. Applicability of similar materials bonded by cement and plaster in solid-liquid coupling tests. Rock Soil Mech. 2015, 36, 2624–2630. [Google Scholar]

- Hougen, L. Introduction to Powder Technology; Tongji University Publishing: Shanghai, China, 1998; pp. 115–123. [Google Scholar]

- Zhang, Y.; Zhang, X. Grey correlation analysis between strength of slag cement and particle fractions of slag powder. Cem. Concr. Compos. 2007, 29, 498–504. [Google Scholar] [CrossRef]

- Li, S.; Gao, J.; Li, Q.; Zhao, X. Investigation of using recycled powder from the preparation of recycled aggregate as a supplementary cementitious material. Constr. Build. Mater. 2021, 267, 120976. [Google Scholar] [CrossRef]

- Deng, X.; Li, J.; Lu, Z.; Zhang, J.; Luo, K.; Niu, Y.; Hu, J.; He, K. Rheological and early hydration of cementitious material containing recycled concrete powders collected from recycled aggregates. Constr. Build. Mater. 2023, 393, 132108. [Google Scholar] [CrossRef]

- Nandhini, K.; Ponmalar, V. Effect of blending micro and nano silica on the mechanical and durability properties of self-compacting concrete. Silicon 2021, 13, 687–695. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, Z.; Ren, W.; Liu, G.; Zhang, C. 3D meso-scale fracture modelling and validation of concrete based on in-situ X-ray Computed Tomography images using damage plasticity model. Int. J. Solids Struct. 2015, 67, 340–352. [Google Scholar] [CrossRef]

- Li, Y.; Wu, B.H.; Ni, W.; Mu, X.L. Synergies in early hydration reaction of slag-steel slag-gypsum system. J. Northeast. Univ. (Nat. Sci. 2020, 41, 581. [Google Scholar]

- Zhang, L.; Zhou, J. Fractal characteristics of pore structure of hardened cement paste prepared by pressurized compact molding. Constr. Build. Mater. 2020, 259, 119856. [Google Scholar] [CrossRef]

- Živica, V.; Križma, M. Dependence of efficiency of pressure compaction on the cement type used. Constr. Build. Mater. 2011, 25, 3073–3077. [Google Scholar] [CrossRef]

- Qin, J.; Dai, F.; Ma, H.; Dai, X.; Li, Z.; Jia, X.; Qian, J. Development and characterization of magnesium phosphate cement based ultra-high performance concrete. Compos. Part B Eng. 2022, 234, 109694. [Google Scholar] [CrossRef]

- Wu, Z. Green high performance concrete and innovation. J. Build. Mater. 1998, 1, 1–7. [Google Scholar]

- Zhang, T.; Xia, B.; Lu, Y.; Zhang, X.; Chen, H.; Ying, R.; Jin, S. Assessment of the Effects of Heavy Metals in Soils after Removal by Nanoscale Zero-Valent Iron with Three Methods. Sustainability 2022, 14, 2273. [Google Scholar] [CrossRef]

- GB 8978-1996; Integrated Wastewater Discharge Standard. China Environmental Science Press: Beijing, China, 1996.

- Chen, Q.; Zhang, Q.; Qi, C.; Fourie, A.; Xiao, C. Recycling phosphogypsum and construction demolition waste for cemented paste backfill and its environmental impact. J. Clean. Prod. 2018, 186, 418–429. [Google Scholar] [CrossRef]

| Specimen No. | PG/% | CMWR/% | OPC/% | Water-Solids Ratio |

|---|---|---|---|---|

| A1/B1 | 50.00 | 45.00 | 5.00 | 0.21 |

| A2/B2 | 60.00 | 35.00 | 5.00 | 0.21 |

| A3/B3 | 70.00 | 25.00 | 5.00 | 0.21 |

| A4/B4 | 80.00 | 15.00 | 5.00 | 0.21 |

| A5/B5 | 90.00 | 5.00 | 5.00 | 0.21 |

| Materials | Median Particle Size/m | Volume Weighted Mean/m | Surface Weighted Mean/m | D10/m | D90/m |

|---|---|---|---|---|---|

| PG | 23.89 | 36.10 | 10.21 | 4.14 | 88.19 |

| GBS | 10.24 | 12.71 | 5.51 | 2.28 | 26.78 |

| HBSS | 14.52 | 20.28 | 6.35 | 2.42 | 47.51 |

| OPC | 15.46 | 21.63 | 6.87 | 2.65 | 50.32 |

| Mixed Materials | 22.84 | 37.83 | 9.75 | 3.90 | 88.21 |

| Curing Time/d | Average Pore Diameter | Porosity/% | Total Pore Area/m2·g−1 |

|---|---|---|---|

| 7 | 23.60 | 18.34 | 16.13 |

| 14 | 22.27 | 16.27 | 15.32 |

| 28 | 21.97 | 14.50 | 13.71 |

| Specimen No. | Total Chromium | Lead | Nickel | Total Phosphorus | Fluoride |

|---|---|---|---|---|---|

| Raw PG | 0.30 | 0.14 | 0.15 | 98.70 | 57.35 |

| B1 | 0.04 | 0.06 | 0.06 | 0.04 | 1.11 |

| B2 | 0.03 | 0.06 | 0.06 | 0.04 | 0.44 |

| B3 | 0.03 | 0.06 | 0.06 | 0.02 | 0.60 |

| B4 | 0.03 | 0.06 | 0.03 | 0.24 | 0.79 |

| B5 | 0.03 | 0.06 | 0.03 | 0.02 | 0.5 |

| GB 8978 | 1.50 | 1.00 | 1.00 | 0.50 | 10.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Ma, L.; Qiu, S.; Yin, X.; Dai, Q.; Du, W. Sustainable Utilization of Phosphogypsum in Multi-Solid Waste Recycled Aggregates: Environmental Impact and Economic Viability. Sustainability 2024, 16, 1161. https://doi.org/10.3390/su16031161

Li W, Ma L, Qiu S, Yin X, Dai Q, Du W. Sustainable Utilization of Phosphogypsum in Multi-Solid Waste Recycled Aggregates: Environmental Impact and Economic Viability. Sustainability. 2024; 16(3):1161. https://doi.org/10.3390/su16031161

Chicago/Turabian StyleLi, Wengang, Liping Ma, Shuyue Qiu, Xia Yin, Quxiu Dai, and Wang Du. 2024. "Sustainable Utilization of Phosphogypsum in Multi-Solid Waste Recycled Aggregates: Environmental Impact and Economic Viability" Sustainability 16, no. 3: 1161. https://doi.org/10.3390/su16031161

APA StyleLi, W., Ma, L., Qiu, S., Yin, X., Dai, Q., & Du, W. (2024). Sustainable Utilization of Phosphogypsum in Multi-Solid Waste Recycled Aggregates: Environmental Impact and Economic Viability. Sustainability, 16(3), 1161. https://doi.org/10.3390/su16031161