Influence of Iron Mining Waste Addition as a Sustainable Alternative on the Resilient and Physical Properties of Soils for Pavement Design

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- PRS: 100% phyllite residual soil

- LCS: 100% lateritic clay soil

- LCS80/IMW20: 80% lateritic clay soil and 20% iron mining waste

- PRS80/IMW20: 80% phyllite residual soil and 20% iron mining waste

- PRS60/IMW40: 60% lateritic clay soil and 40% iron mining waste

- PRS50/IMW50: 50% phyllite residual soil and 50% iron mining waste

2.2. Physical Characterization

2.3. Geotechnical Characterization

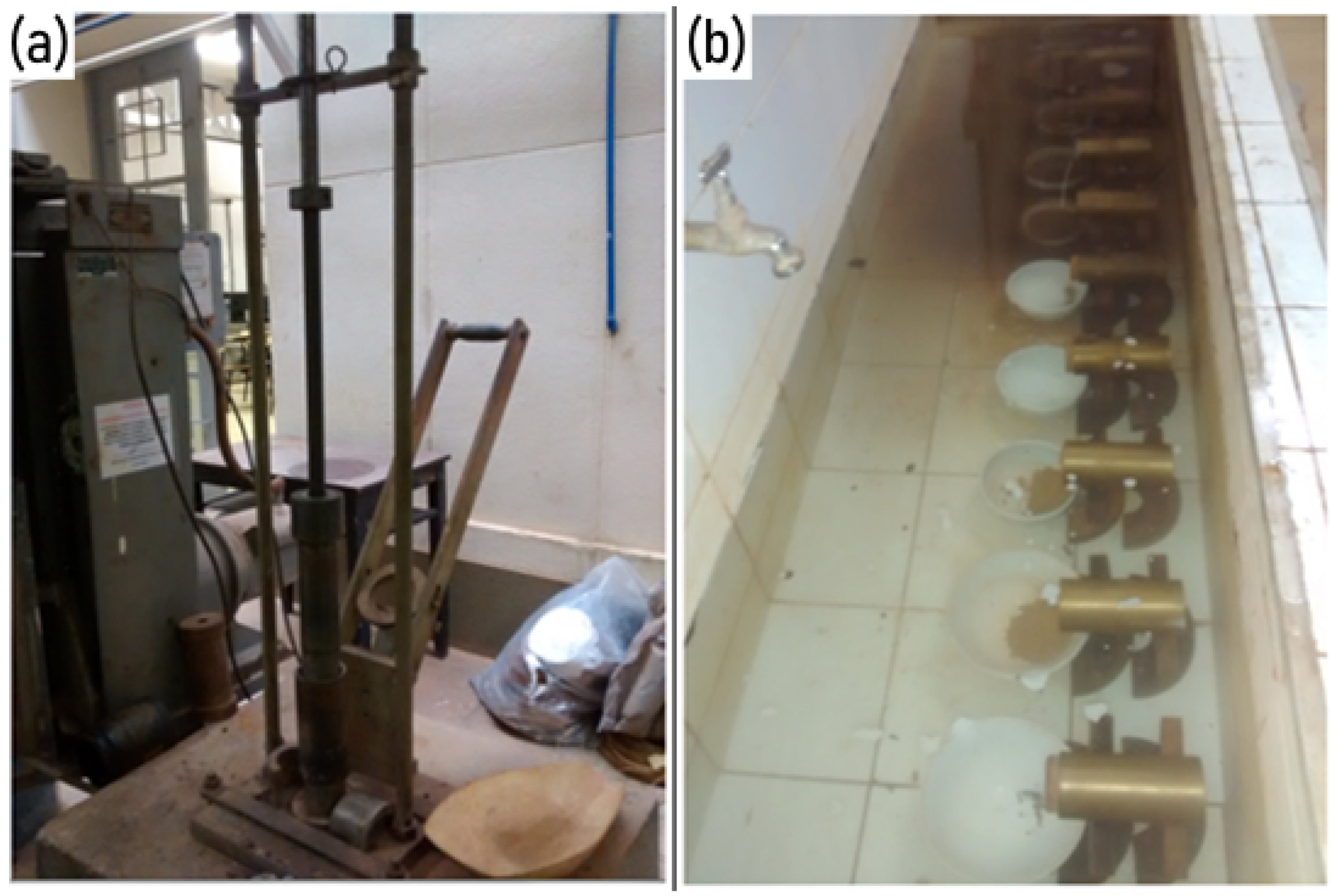

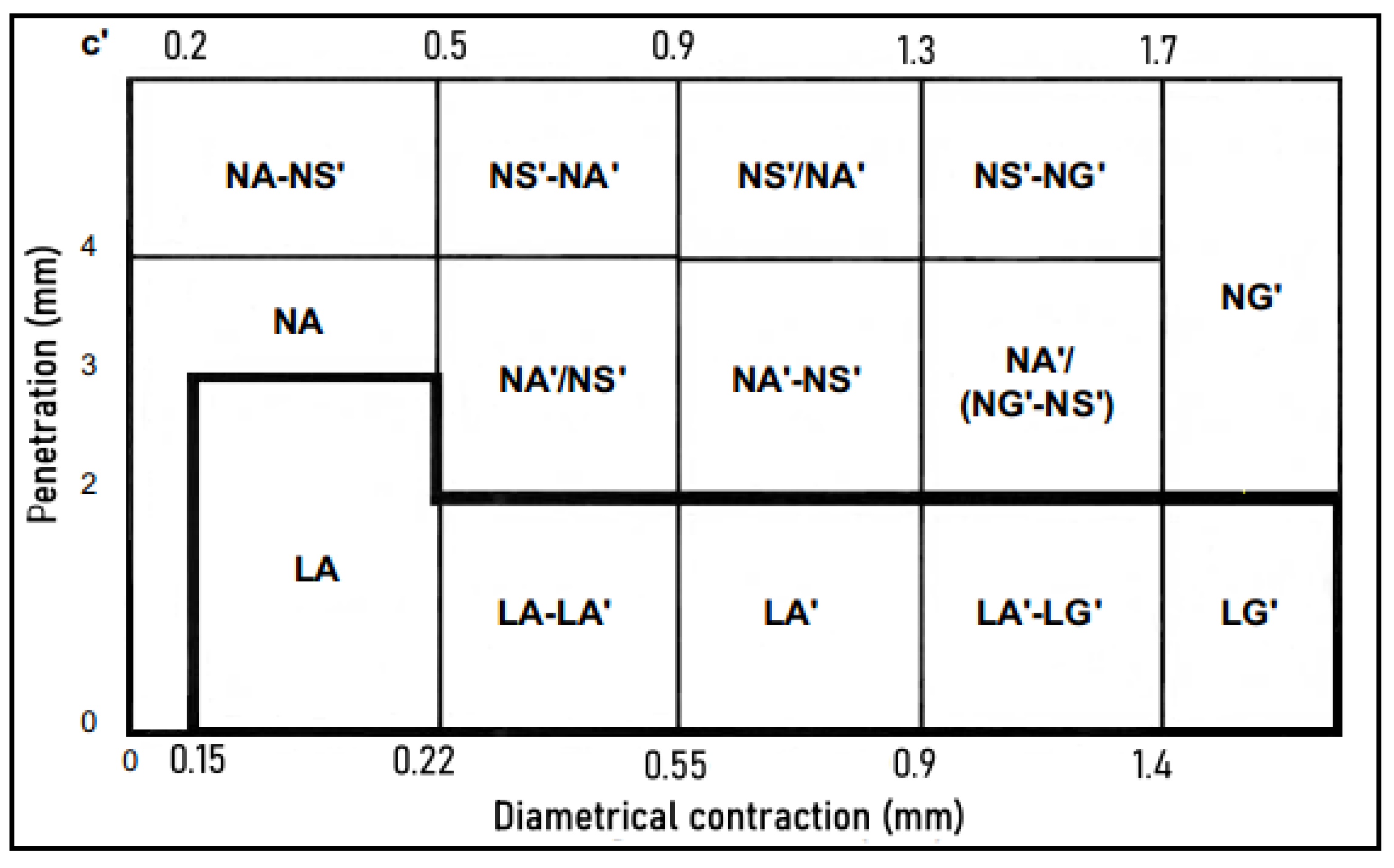

2.3.1. MCT Methodology

2.3.2. MCT Expedito

2.3.3. Scanning Electron Microscopy (SEM) and Energy-Dispersive X-Ray Spectroscopy (EDX)

2.3.4. X-Ray Diffraction (XRD)

2.3.5. Environmental Analysis

2.4. Mechanical Characterization

Resilience Modulus Test

- r is the ratio of h to . h is the maximum vertical displacement, and is the initial reference length of the cylindrical specimen.

3. Results and Discussion

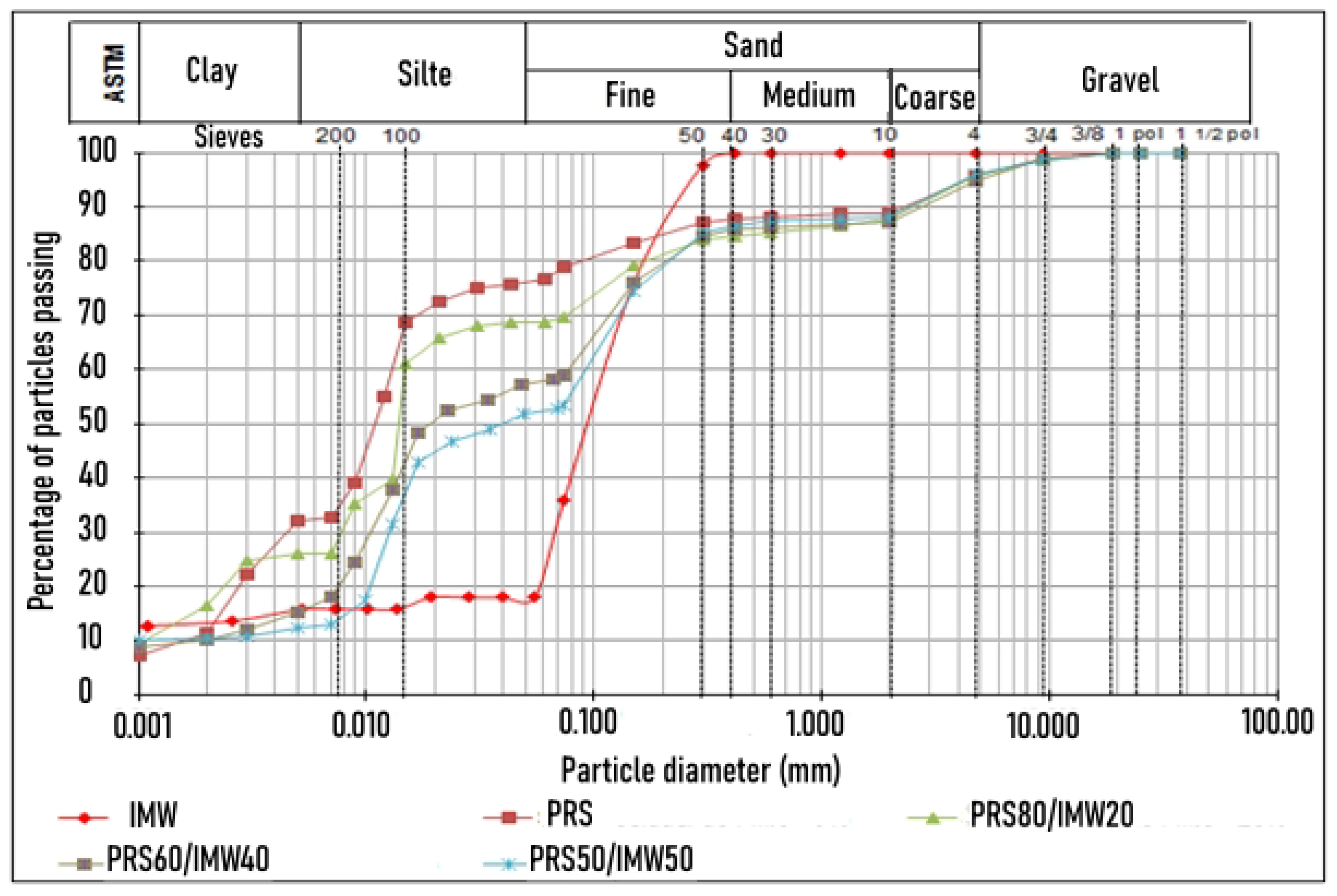

3.1. Physical Characterization

3.2. Geotechnical Characterization

3.3. Mineralogical, Chemical and Environmental Analysis of Materials

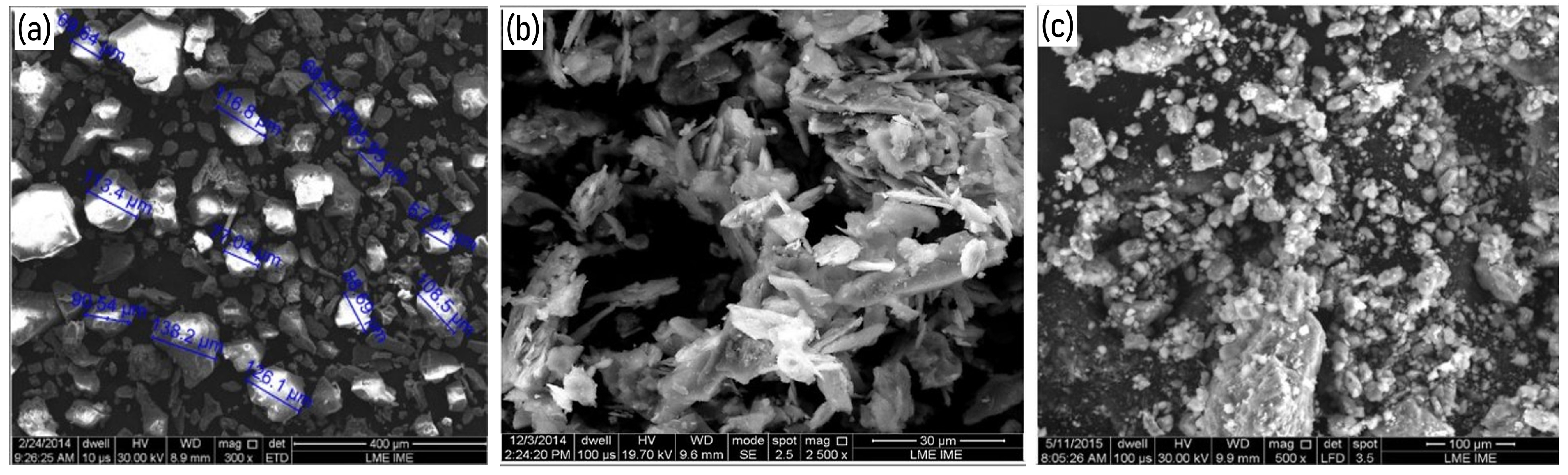

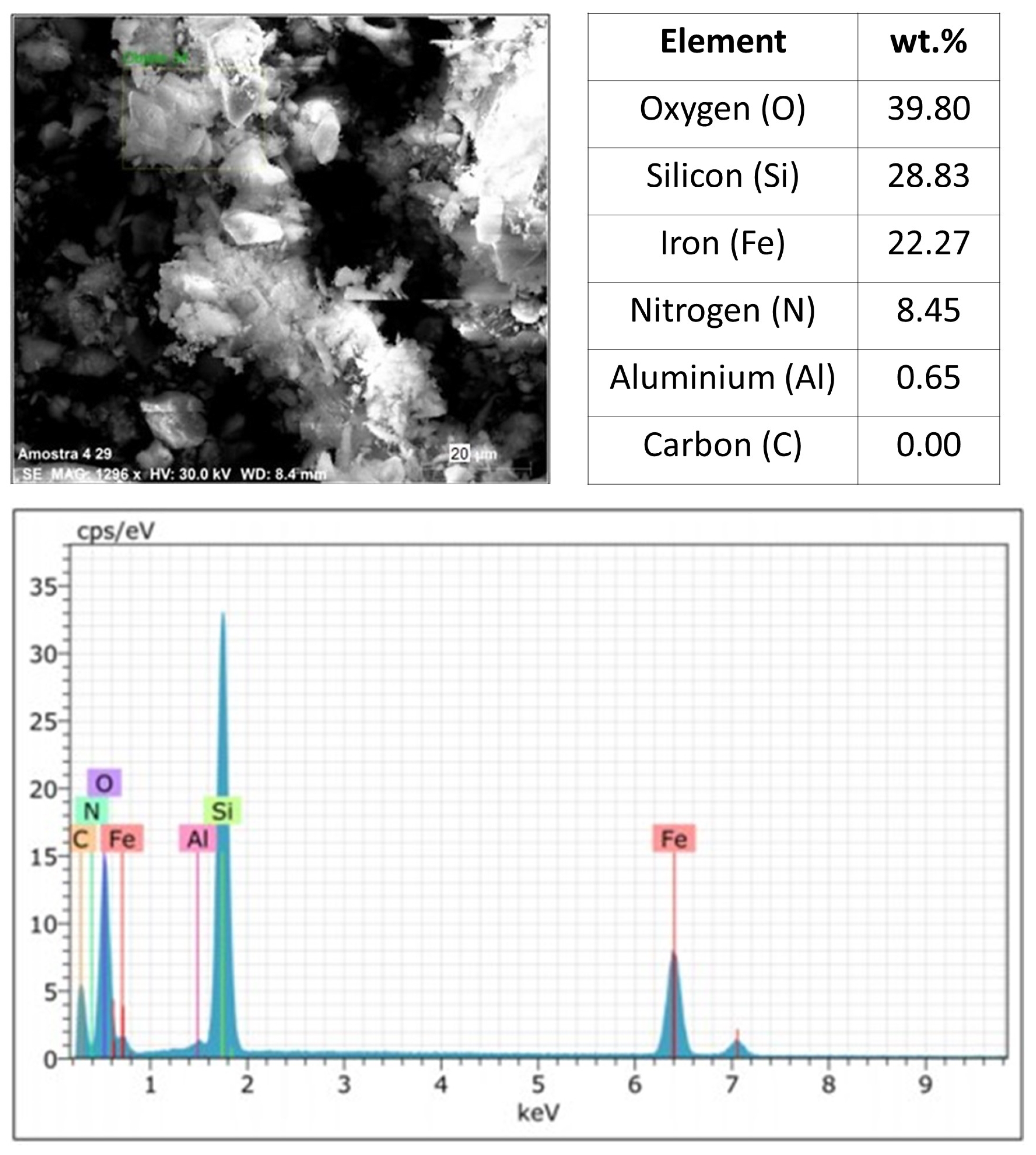

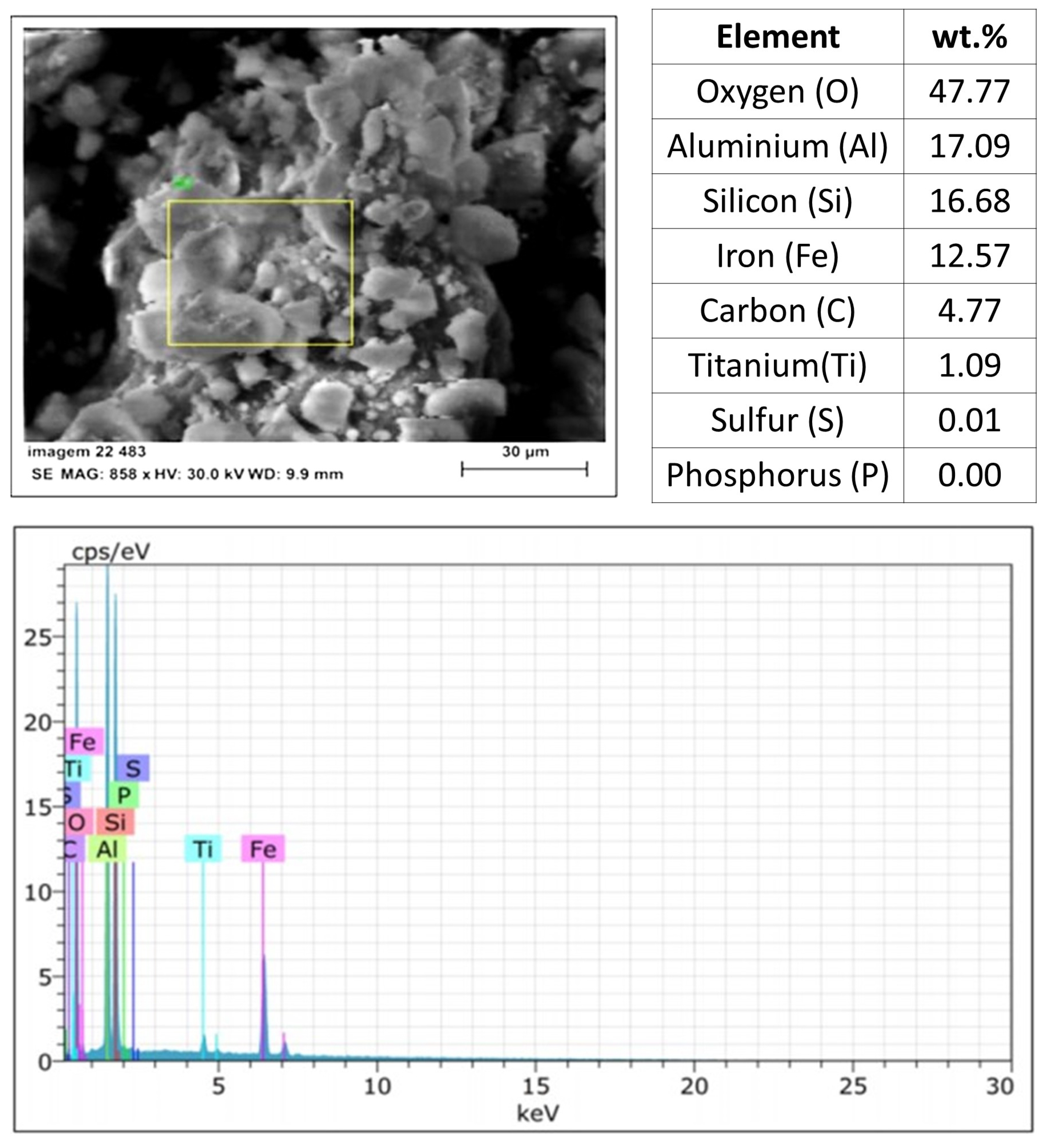

3.3.1. Scanning Electron Microscopy (SEM) and Energy-Dispersive X-Ray Spectroscopy (EDX)

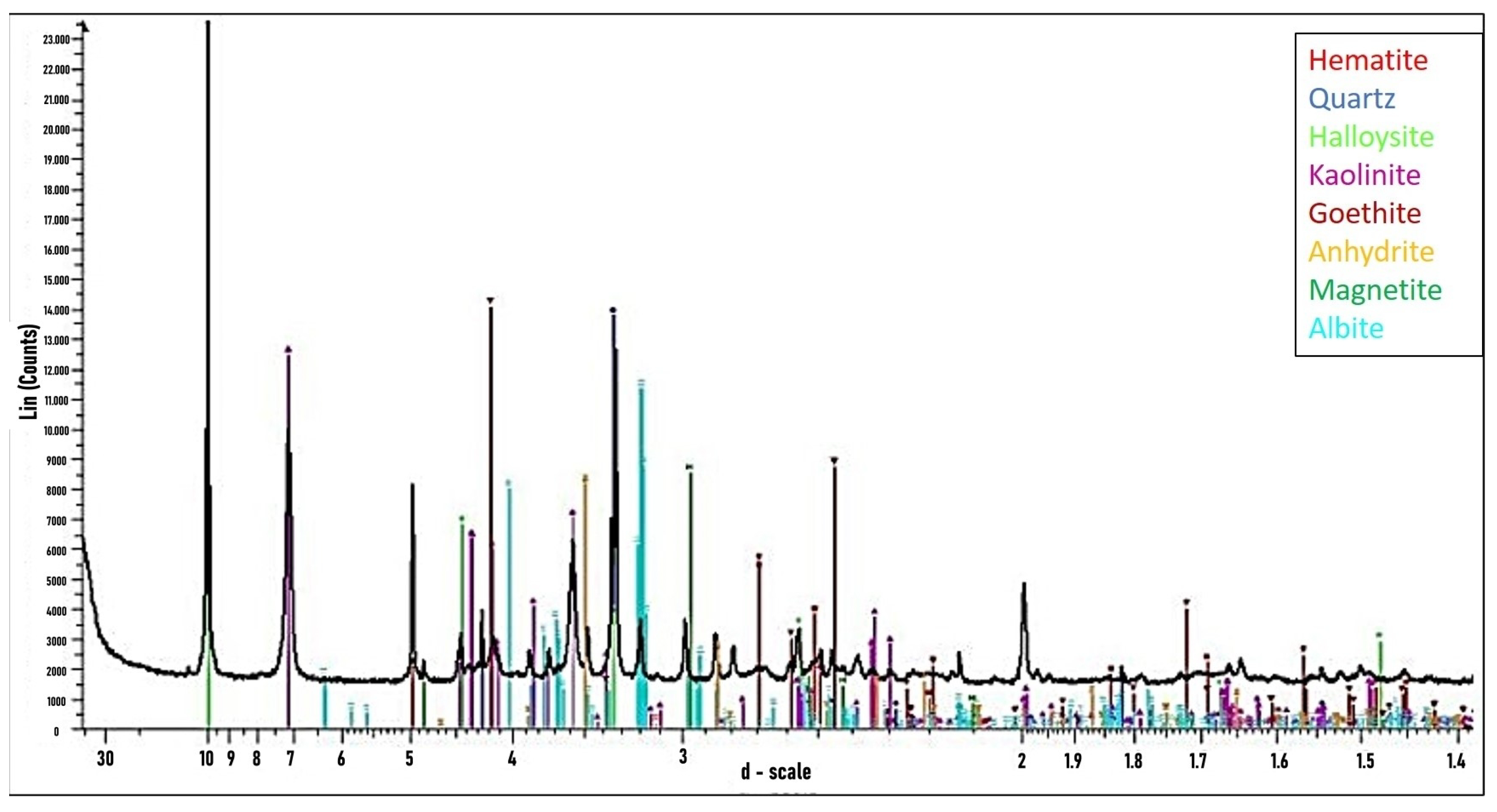

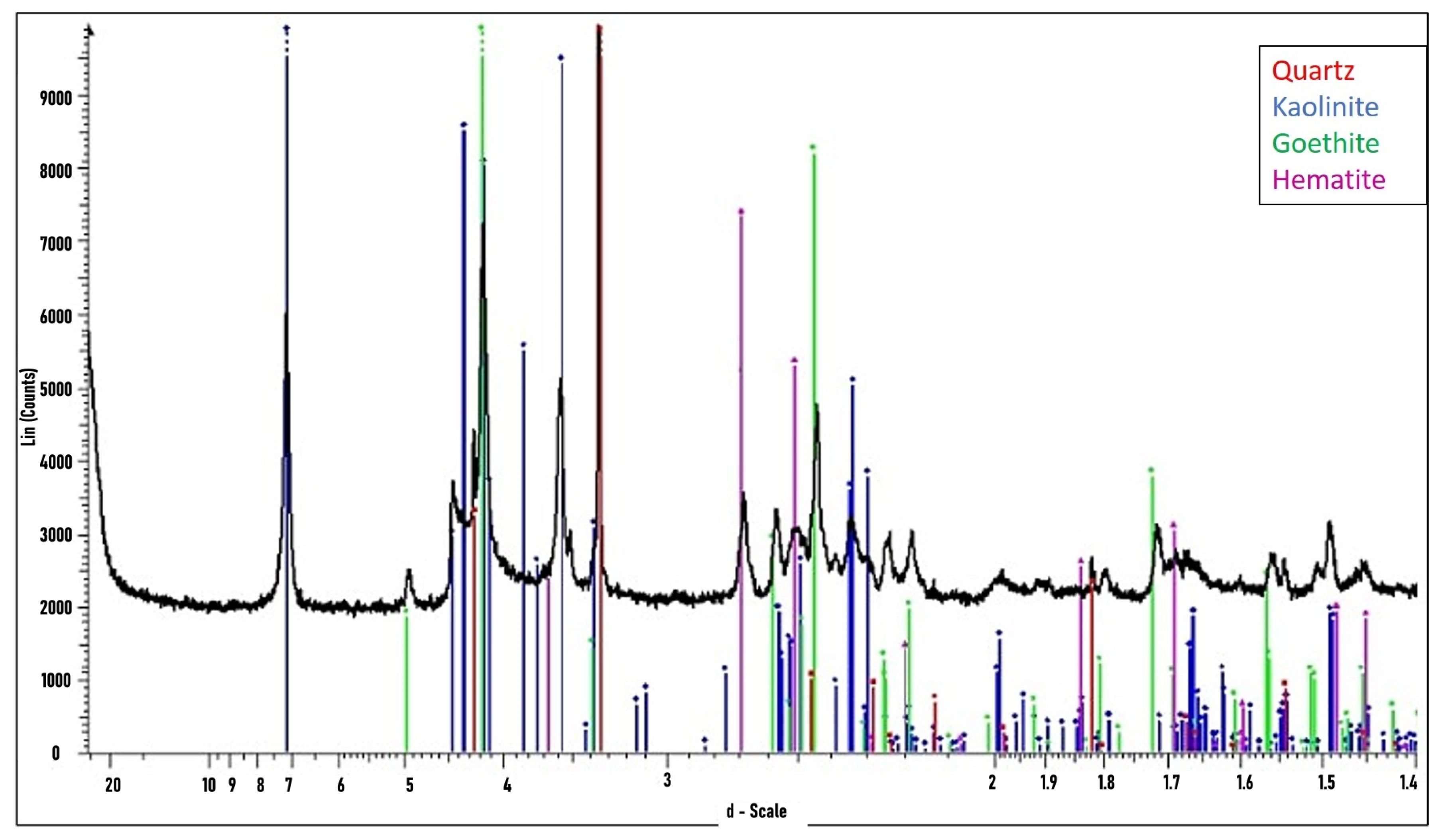

3.3.2. X-Ray Diffraction (XRD)

3.3.3. Environmental Analysis

3.4. Mechanical Characterization

4. Conclusions

- A significant reduction in plasticity indices was observed, particularly in mixtures with a higher content of waste, due to the low plasticity of this material, which is predominantly composed of quartz. This effect correlated with an increase in the specific weight of the mixtures, attributed to the higher specific mass of the waste compared to the pure soils.

- The compaction tests demonstrated that increasing the proportion of waste in the mixtures led to a decrease in optimum moisture content and an increase in maximum dry density, conditions that favor the use of the mixtures in situations where compaction and density are critical factors.

- The PRS alone is unsuitable for pavement applications due to its low resilient modulus (RM). However, adding 50% waste significantly improved its properties, increasing the RM values by approximately 29.6% under low stress, 130% under medium stress, and 100% under high stress, while also reducing expansibility. This improvement makes the phyllite–waste mixture a viable and sustainable option for reinforcing sub-base and subgrade layers in pavement structures.

- The RM results indicated that the addition of waste had a moderate impact on the LCS compared to the significant improvements observed in the PRS. Specifically, the LCS mixture with 20% waste showed a slight RM increase of approximately 8.8% under high-stress conditions, although there was a reduction of 27.4% and 1.9% under low and medium stress, respectively. The LCS mixture with 40% waste, however, displayed considerable reductions in RM across all stress levels, suggesting that higher waste content may adversely affect the stiffness of lateritic clay soils. These findings support the use of 20% waste in LCS for certain applications, particularly in base or sub-base layers, while highlighting the need for further optimization to balance stiffness and sustainability in pavement layers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AASHTO | American Association of State Highway and Transportation Official |

| ABCP | Brazilian Association of Portland Cement |

| ABNT | Brazilian Association of Technical Standards |

| CBR | California bearing ratio |

| COAM/CETEM | Laboratory of the Mineral Analysis Coordination at the Mineral Technology Center |

| EDX | Energy-dispersive X-ray |

| IME | Military Institute of Engineering |

| IMW | Iron mining waste |

| LCS | 100% Lateritic clay soil |

| LCS80/IMW20 | 80% Lateritic clay soil and 20% iron mining waste |

| MCT | Miniature, Compacted, Tropical |

| PRS | 100% phyllite residual soil |

| PRS50/IMW50 | 50% phyllite residual soil and 50% iron mining waste |

| PRS60/IMW40 | 60% phyllite residual soil and 40% iron mining waste |

| PRS80/IMW20 | 80% phyllite residual soil and 20% iron mining waste |

| R2 | Coefficient of determination |

| RAP | Reclaimed asphalt pavement |

| RM | Resilient modulus |

| SEM | Scanning electron microscopy |

| SUCS | Soil Use and Classification System |

| TRB | Transportation Research Board |

| XRD | X-ray diffraction |

References

- CNT—Confederação Nacional de Transporte. Boletim Unificado-Agosto 2024; CNT—Confederação Nacional de Transporte: Brasília, DF, Brazil, 2024; Available online: https://cnt.org.br/boletins (accessed on 27 October 2024).

- Guimarães, A.; Motta, L.D. A Study on Permanent Deformation of Lateritic Soils Including the Shakedown Concept, 1st ed.; CRC Press: Boca Raton, FL, USA, 2008; p. 8. [Google Scholar]

- Yaghoubi, E.; Yaghoubi, M.; Guerrieri, M.; Sudarsanan, N. Melhorando subleitos de argila expansiva usando vidro reciclado: Características de módulo resiliente e desempenho do pavimento. Construção E Mater. De Construção 2021, 302, 124384. [Google Scholar] [CrossRef]

- Maichin, P.; Jitsangiam, P.; Nongnuang, T.; Boonserm, K.; Nusit, K.; Pra-ai, S.; Binaree, T.; Aryupong, C. Stabilized High Clay Content Lateritic Soil Using Cement-FGD Gypsum Mixtures for Road Subbase Applications. Materials 2021, 14, 1858. [Google Scholar] [CrossRef] [PubMed]

- Hasan, M.M.; Islam, M.R.; Tarefder, R.A. Characterization of subgrade soil mixed with recycled asphalt pavement. J. Traffic Transp. Eng. (English Ed.) 2018, 5, 207–214. [Google Scholar] [CrossRef]

- de Almeida Silva, P.; Sergio de Souza Almeida, M.; Miller Machado Pereira, Í.; Rucas Andrade Achy, A.; Gustavo Silva Costa, W.; Dias Amancio de Lima, C.; Almeida Brito, J. Mechanistic-empirical evaluation of soil-RAP mixtures for use as unbound granular layers of asphalt pavements. Transp. Geotech. 2024, 47, 101290. [Google Scholar] [CrossRef]

- Boaventura, A.C.C.; Almeida, M.S.d.S.; Costa, W.G.S.; Pereira, I.M.M.; São Mateus, M.d.S.C.; Brito, J.A.; Fiuza-Jr, R.A. The influence of residual asphalt material in the mechanical behaviour of soil-RAP mixtures for use in paving. Int. J. Pavement Eng. 2024, 25, 2407901. [Google Scholar] [CrossRef]

- Coelho, L.; Guimarães, A.; de Azevedo, A.; Monteiro, S. Sustainable Reclaimed Asphalt Emulsified Granular Mixture for Pavement Base Stabilization: Prediction of Mechanical Behavior Based on Repeated Load Triaxial Tests. Sustainability 2024, 16, 5335. [Google Scholar] [CrossRef]

- Coelho, L.; Kox, R.; Guimarães, A.; Travincas, R.; Monteiro, S. Influence of Curing Time on the Mechanical Behavior of Cold Recycled Bituminous Mix in Flexible Pavement Base Layer. Appl. Sci. 2024, 14, 7612. [Google Scholar] [CrossRef]

- Rodrigues, K.H.d.P.; Silva, T.O.d.; Pitanga, H.N.; Almeida, M.S.d.S.; Pedroti, L.G.; Rodrigues, M.H.R.; Lopes, E.C. Effect of carbonation of soil-slag mixtures on the resilient behaviour and structural response of an asphalt pavement. Road Mater. Pavement Des. 2024, 25, 2101–2120. [Google Scholar] [CrossRef]

- Yao, Y.; Li, J.; Ni, J.; Liang, C.; Zhang, A. Effects of gravel content and shape on shear behaviour of soil-rock mixture: Experiment and DEM modelling. Comput. Geotech. 2022, 141, 104476. [Google Scholar] [CrossRef]

- Dantas Neto, S.A.; Pereira, C.G.F.; Abreu, A.A. Stabilization of sandy soil with high content of asphalt emulsion. REM-Int. Eng. J. 2020, 73, 163–169. [Google Scholar] [CrossRef]

- Purohit, S.; Panda, M.; Kumar Das, A. Performance of waste polyethylene modified bituminous paving mixes containing reclaimed asphalt pavement and recycled concrete aggregate. Constr. Build. Mater. 2022, 348, 128677. [Google Scholar] [CrossRef]

- Navarrete, C.; Guimarães, A.; Marques, M.; Castro, C.; Toulkeridis, T. Resistance to Fatigue in Asphalts Used in Military Airports of the Brazilian Amazon through the Use of Nickel-Holding Ash. Appl. Sci. 2022, 12, 9134. [Google Scholar] [CrossRef]

- Coelho, L.; Guimarães, A.; Alves Moreira, C.; dos Santos, G.; Monteiro, S.; da Silveira, P. Feasibility of Using Ferronickel Slag as a Sustainable Alternative Aggregate in Hot Mix Asphalt. Sustainability 2024, 16, 8642. [Google Scholar] [CrossRef]

- Guimarães, A.C.R.; Costa, K.A.; Reis, M.d.M.; Santana, C.S.A.; Castro, C.D. Study of controlled leaching process of steel slag in soxhlet extractor aiming employment in pavements. Transp. Geotech. 2021, 27, 100485. [Google Scholar] [CrossRef]

- Gomes, M.B.B.; Guimarães, A.C.R.; Nascimento, F.A.C.D.; Santos, J.T.A.D. Ballast with siderurgic aggregates: Variation analysis of the shape parameters of particles submitted to triaxial tests through 3D scanner. Rev. Eng. 2023, 46, e2023006122. [Google Scholar] [CrossRef]

- Guimarães, A.C.R.; Silva Filho, J.C.; Castro, C.D. Contribution to the use of alternative material in heavy haul railway sub-ballast layer. Transp. Geotech. 2021, 30, 100524. [Google Scholar] [CrossRef]

- Demchuk, Y.; Gunka, V.; Sidun, I.; Solodkyy, S. Comparison of Bitumen Modified by Phenol Formaldehyde Resins Synthesized from Different Raw Materials. In Proceedings of EcoComfort 2020; Blikharskyy, Z., Ed.; Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2021; Volume 100. [Google Scholar] [CrossRef]

- Xu, H.; Ji, W.; Jiang, W.; Cui, H.; Tan, Y. Preparation of inorganic binder-stabilised material with iron tailings: Strength formation and gradation optimisation. Road Mater. Pavement Des. 2023, 25, 618–636. [Google Scholar] [CrossRef]

- Divandari, H.; Heidari, M.; Zalnezhad, M.; Zalnezhad, A. The study of the feasibility and manufacture of slurry seal surface treatment with steel slag industry wastes: Use of basic oxygen furnace (BOF) slag filler as raw material replacement. Road Mater. Pavement Des. 2023, 25, 967–987. [Google Scholar] [CrossRef]

- Gunka, V.; Hidei, V.; Sidun, I.; Demchuk, Y.; Stadnik, V.; Shapoval, P.; Sobol, K.; Vytrykush, N.; Bratychak, M. Wastepaper Sludge Ash and Acid Tar as Activated Filler Aggregates for Stone Mastic Asphalt. Coatings 2023, 13, 1183. [Google Scholar] [CrossRef]

- Usanga, I.N.; Ikeagwuani, C.C.; Okafor, F.O.; Ambrose, E.E. Exploration of calcined clays and nanoclays as a potential construction material for sustainable development: A comprehensive and state-of-the-art review. Road Mater. Pavement Des. 2024, 1–34. [Google Scholar] [CrossRef]

- Friber, M.; Guimarães, A.; Martins, C.; Soares, J. Study of the Mining Waste in the Production of Calcined Aggregate for Use in Pavement. Minerals 2023, 13, 1543. [Google Scholar] [CrossRef]

- Apaza Apaza, F.R.; Rodrigues Guimarães, A.C.; Marcos Vivoni, A.; Schroder, R. Evaluation of the performance of iron ore waste as potential recycled aggregate for micro-surfacing type cold asphalt mixtures. Constr. Build. Mater. 2021, 266, 121020. [Google Scholar] [CrossRef]

- Silveira, V.; Guimarães, A.; Coelho, L.; dos Santos, W.; da Silveira, P.; Monteiro, S. Recycling Iron Ore Waste through Low-Cost Paving Techniques. Sustainability 2024, 16, 5570. [Google Scholar] [CrossRef]

- Guimarães, A.; Arêdes, M.; Castro, C.; Coelho, L.; Monteiro, S. Evaluation of the Mechanical Behavior of Asphaltic Mixtures Utilizing Waste of the Processing of Iron Ore. Mining 2024, 4, 889–903. [Google Scholar] [CrossRef]

- Institute for Applied Economic Research (IPEA). Research Report: Diagnosis of Urban Solid Waste; Research report; IPEA: Brasília, Brazil, 2012. [Google Scholar]

- ABNT–Associação Brasileira de Normas Técnicas. NBR 6457:2024. Amostras de sol -Preparação para Ensaios de Compactação e Ensaios de Caracterização; ABNT–Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2024. [Google Scholar]

- ABNT–Associação Brasileira de Normas Técnicas. NBR 6458:2017. Grãos de Pedregulho Retidos na Peneira de 4,8 mm -Determinação da Massa Específica, da Massa Específica Aparente e da Absorção de áGua; ABNT–Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2017. [Google Scholar]

- ABNT–Associação Brasileira de Normas Técnicas. NBR 6459:2016. Solo-Determinação do Limite de Liquidez; ABNT–Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2016. [Google Scholar]

- ABNT—Associação Brasileira de Normas Técnicas. In NBR 7180:2016. Solo-Determinação do Limite de Plasticidade; ABNT—Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2016; NBR 7180.

- ABNT—Associação Brasileira de Normas Técnicas. NBR 7181:2016. Solo-Análise granulométrica; ABNT—Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2016. [Google Scholar]

- ABNT—Associação Brasileira de Normas Técnicas. NBR 7182:2020. Solo-Ensaio de compactação; ABNT—Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2020. [Google Scholar]

- ABNT—Associação Brasileira de Normas Técnicas. NBR 9895:2017. Solo-Índice de Suporte Califórnia (ISC)- Método de Ensaio; ABNT—Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2017. [Google Scholar]

- AASHTO M145-91; Classification of Soils and Soil-Aggregate Mixtures for Highway Construction Purposes. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012.

- DNIT 259/2023; CLA: Soils—Classification of Fine Tropical Soils for Road Purposes Using Compacted Specimens in Miniature Equipment—Classification. National Department of Transport Infrastructure (DNIT): Brasilia, Brazil, 2023; Brazilian Standard.

- DNIT Standard 258/2023; ME: Soils—Compaction Using Miniature Equipment— Mini-MCV Tests and Mass Loss by Immersion—Test Method. National Department of Transport Infrastructure: Brasília, Brazil, 2023.

- DNER-ME 256; Solos Compactados com Equipamento Miniatura —Determinação da Perda de Massa por Imersão. Departamento Nacional de Estradas de Rodagem: Rio de Janeiro, Brazil, 1994.

- Nogami, J.; Villibor, D. Pavimentação de Baixo Custo com Solos LateríTicos; Ed. Villibor: São Paulo, SP, Brazil, 1995; p. 213. [Google Scholar]

- Nogami, J.; Villibor, D. Identificação expedita dos grupos da classificação MCT para solos tropicais. In Proceedings of the Anais do X Congresso Brasileiro de Mecânica dos Solos e Engenharia de Fundações, Foz do Iguaçu, PR, Brazil, October 1994; Volume 4, pp. 1293–1300. [Google Scholar]

- ABNT–Associação Brasileira de Normas Técnicas. Resíduos Sólidos-Classificação; ABNT–Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2004; NBR 10004. [Google Scholar]

- DNIT–Departamento Nacional de Infraestrutura de Transportes. In 134/2018-ME. Módulo de Resiliência-Método de Ensaio; DNIT–Departamento Nacional de Infraestrutura de Transportes: Rio de Janeiro, Brazil, 2018.

- Pascoal, P.T.; Sagrilo, A.V.; Baroni, M.; Specht, L.P.; da Silva Pereira, D. Lateritic soil deformability regarding the variation of compaction energy in the construction of pavement subgrade. Soils Rocks 2023, 46, e26755475. [Google Scholar] [CrossRef]

- Villibor, D.F.; Nogami, J.S.; Cincerre, J.R.; Serra, P.R.M.; Neto, A.Z. Pavimentos de Baixo Custo Para Vias Urbanas; Arte e Ciência: Campina Grande, Brazil, 2009; p. 196. [Google Scholar]

- Dana, J.D.; Hurlbut, C.S. Manual de Mineralogia; Livros Técnicos e Científicos, Editora S.A.: Rio de Janeiro, Brazail, 1974; Volume 2, p. 624. [Google Scholar]

- Santos, P.S. Ciência e Tecnologia das Argilas, 2nd, ed.; Editora Edgard Blucher Ltda: Sao Paulo, Brazil, 1992; Volume 3, p. 1089. [Google Scholar]

- Barbosa, V.H.; Marques, M.E.S.; Guimarães, A.C.R. Predicting Soil Swelling Potential Using Soil Classification Properties. Geotech. Geol. Eng. 2023, 41, 1–13. [Google Scholar] [CrossRef]

- Benatti, J.C.B.; Miguel, M.G. A proposal of structural models for colluvial and lateritic soil profile from southwestern Brazil on the basis of their collapsible behavior. Eng. Geol. 2013, 153, 1–11. [Google Scholar] [CrossRef]

- Guimarães, A.C.R.; Lima, C.D.A.d.; Aragão, F.T.S.; Motta, L.M.G.d.; Santos, J.T.A.d. Mechanical characterization of an alternative laterite gravel used as pavement material. Soils Rocks 2024, 47, 1–13. [Google Scholar] [CrossRef]

- Morin, W.; Toder, P. Laterite and Lateritic Soils, and Other Problem Soils of Africa; Lyon Associates: Kumisasi, Ghana, 1971; p. 290. [Google Scholar]

- ABNT–Associação Brasileira de Normas Técnicas. In NBR 10006:Solubilização de Resíduos -Procedimento.; ABNT–Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2004.

- Guimarães, A.; Motta, L. Mechanical Behavior of Basaltic Rocks from Serra Geral Formation Used as Road Material in Santa Catarina State, Brazil. Soils Rocks 2016, 39, 203–210. [Google Scholar] [CrossRef]

- Pascoal, P.; Sagrilo, A.; Baroni, M.; Specht, L.; Pereira, D. Evaluation of the Influence of Compaction Energy on the Resilient Behavior of Lateritic Soil in the Field and Laboratory. Soils Rocks 2021, 44, e2021071321. [Google Scholar] [CrossRef]

- Sagrilo, A.V.; Pascoal, P.T.; Baroni, M.; Back, A.H.; Pinheiro, R.J.B.; Specht, L.P.; Guimarães, A.C.R. Contribution to Resilient and Permanent Deformation Investigation of Unbound Granular Materials with Different Geological Origins from Rio Grande do Sul, Brazil. Soils Rocks 2023, 46, e2023009822. [Google Scholar] [CrossRef]

- de Lima, C.D.A.; de Oliveira Ubaldo, M.; Fritzen, M.A.; da Motta, L.M.G.; de Proença Franco, F.A.C. Análise de Módulo de Resiliência de Solos Finos Tropicais para Avaliação e Dimensionamento de Pavimentos. In Proceedings of the XX Congresso Brasileiro de Mecânica dos Solos e Engenharia Geotécnica, IX Simpósio Brasileiro de Mecânica das Rochas, IX Simpósio Brasileiro de Engenheiros Geotécnicos Jovens, VI Conferência Sul Americana de Engenheiros Geotécnicos Jovens, ABMS, Campinas, SP, Brasil, 15–18 September 2020. [Google Scholar] [CrossRef]

- Ramos, C.R.; Motta, L.M.G. Study of the Resilient Behavior of Various Soils and Crushed Materials from the Municipality of Rio de Janeiro. In Proceedings of the 35th Annual Pavement Meeting, Rio de Janeiro, Brazil, 11–12 November 2004; Volume 1. [Google Scholar]

- Veloso, J.F.; Guimarães, A.C.R.; Marques, M.E.S.; Souza, T.D.D. Analysis of Tropical Soils for Paving the Road BR-163/PA. Braz. J. Dev. 2020, 6, 53471–53493. [Google Scholar] [CrossRef]

| Conditioning Phase | |||

|---|---|---|---|

| Par | (KPa) | (KPa) | / |

| 1 | 70 | 70 | 2 |

| 2 | 70 | 210 | 4 |

| 3 | 105 | 315 | 4 |

| Loading Phase | |||

| Par | (KPa) | (KPa) | / |

| 1 | 20 | 2 | |

| 2 | 20 | 40 | 3 |

| 3 | 60 | 4 | |

| 4 | 35 | 2 | |

| 5 | 35 | 70 | 3 |

| 6 | 105 | 4 | |

| 7 | 50 | 3 | |

| 8 | 50 | 100 | 2 |

| 9 | 150 | 3 | |

| 10 | 70 | 2 | |

| 11 | 70 | 140 | 3 |

| 12 | 210 | 4 | |

| 13 | 105 | 2 | |

| 14 | 105 | 210 | 3 |

| 15 | 315 | 4 | |

| 16 | 140 | 2 | |

| 17 | 140 | 280 | 3 |

| 18 | 420 | 4 | |

| Samples | LL (%) | LP (%) | IP (%) | D (g/cm³) |

|---|---|---|---|---|

| IMW | NL | NP | NP | 2.959 |

| PRS | 40.4 | NP | NP | 2.556 |

| PRS80/IMW20 | NL | NP | NP | 2.625 |

| PRS60/IMW40 | NL | NP | NP | 2.703 |

| PRS50/IMW50 | NL | NP | NP | 2.741 |

| LCS | 43.2 | 29.2 | 14 | 2.653 |

| LCS80/IMW20 | 35.3 | 25.8 | 9.5 | 2.718 |

| LCS60/IMW40 | 26.5 | 17.2 | 9.3 | 2.761 |

| Material/Mixture | Optimal Moisture (%) | Density (g/cm3) | Expansion (%) |

|---|---|---|---|

| PRS | 20.5 | 1.693 | 6.1 |

| PRS80/IMW20 | 19.2 | 1.768 | 3.9 |

| PRS60/IMW40 | 14.7 | 1.875 | 2.4 |

| PRS50/IMW50 | 14.2 | 1.930 | 1.0 |

| LCS | 16.1 | 1.963 | 0.0 |

| LCS80/IMW20 | 13.4 | 2.010 | 0.0 |

| LCS60/IMW40 | 11.7 | 2.093 | 0.0 |

| Samples | SUCS | TRB | MCT | Expedited MCT |

|---|---|---|---|---|

| IMW | Silty Sand | Silty (A-4) | ||

| PRS | Clay | Clayey (A-7-6) | ||

| PRS80/IMW20 | Silt | Silty (A-4) | NA-NS’ | NA-NS’ |

| PRS60/IMW40 | Silt | Silty (A-4) | ||

| PRS50/IMW50 | Silt | Silty (A-4) | ||

| LCS0 | Silty Sand | Clayey (A-7-6) | ||

| LCS80/IMW20 | Silty Sand | Silty (A-4) | LA’-LG’ | LA’-LG’ |

| LCS60/IMW40 | Silty Sand | Silty (A-4) |

| Sample | Minerals | Approximate Chemistry |

|---|---|---|

| IMW | Goethite | FeO(OH) |

| Quartz | SiO2 | |

| Hematite | Fe2O3 | |

| PRS | Hematite | Fe2O3 |

| Quartz | SiO2 | |

| Halloysite | 10Å Al2(Si2O5)(OH)4 | |

| Kaolinite | Al2(Si2O5)(OH)4 | |

| Goethite | FeO(OH) | |

| Anhydrite | CaSO4 | |

| Magnetite | Fe3O4 | |

| Albite | Na(AlSi3O8) | |

| LCS | Quartz | SiO2 |

| Kaolinite | Al2(Si2O5)(OH)4 | |

| Goethite | FeO(OH) | |

| Hematite | Fe2O3 |

| Constituent | Unit | Results | Limits (mg/L) | ||

|---|---|---|---|---|---|

|

Quantification

Limits |

NBR 10004

(max) | ||||

| Silver | (Ag) | (mg/L) | N.D. | 0.025 | 5.0 |

| Arsenic | (As) | (mg/L) | N.D. | 0.025 | 1.0 |

| Barium | (Ba) | (mg/L) | N.D. | 0.010 | 70.0 |

| Cadmium | (Cd) | (mg/L) | N.D. | 0.003 | 0.5 |

| Chromium | (Cr) | (mg/L) | N.D. | 0.010 | 5.0 |

| Lead | (Pb) | (mg/L) | N.D. | 0.010 | 1.0 |

| Selenium | (Se) | (mg/L) | N.D. | 0.025 | 1.0 |

| Mercury | (Hg) | (mg/L) | N.D. | 0.0002 | 0.1 |

| Fluoride | (F-) | (mg/L) | N.D. | 0.02 | 150.0 |

| pH | - | - | 4.92 | - | |

| Constituent | Unit | Results | Limits (mg/L) | |

|---|---|---|---|---|

|

Quantification

Limits |

NBR 10004

(max) | |||

| Aldrin + Dieldrin | (mg/L) | N.D. | 0.00006 | 0.003 |

| Chlordane (isomers) | (mg/L) | N.D. | 0.00006 | 0.02 |

| DDT (isomers) | (mg/L) | N.D. | 0.00009 | 0.2 |

| 2,4-D | (mg/L) | N.D. | 0.0015 | 0.5 |

| Endrin | (mg/L) | N.D. | 0.0003 | 0.06 |

| Heptachlor and Heptachlor Epoxide | (mg/L) | N.D. | 0.00006 | 0.003 |

| Lindane (-BHC) | (mg/L) | N.D. | 0.0003 | 0.2 |

| Methoxychlor | (mg/L) | N.D. | 0.00003 | 2.0 |

| Pentachlorophenol | (mg/L) | N.D. | 0.0015 | 0.9 |

| Toxaphene | (mg/L) | N.D. | 0.000375 | 0.5 |

| 2,4,5-T | (mg/L) | N.D. | 0.0015 | 0.2 |

| 2,4,5-TP | (mg/L) | N.D. | 0.0015 | 1.0 |

| Benzene | (mg/L) | N.D. | 0.0030 | 0.5 |

| Benzo(a)pyrene | (mg/L) | N.D. | 0.0015 | 0.07 |

| Vinyl Chloride | (mg/L) | N.D. | 0.0030 | 0.5 |

| Chlorobenzene | (mg/L) | N.D. | 0.0030 | 100 |

| Chloroform | (mg/L) | N.D. | 0.0030 | 6.0 |

| o-Cresol | (mg/L) | N.D. | 0.0015 | 200.0 |

| m,p-Cresol | (mg/L) | N.D. | 0.0015 | 200.0 |

| 1,4-Dichlorobenzene | (mg/L) | N.D. | 0.0015 | 7.5 |

| 1,2-Dichloroethane | (mg/L) | N.D. | 0.0030 | 1.0 |

| 1,1-Dichloroethylene | (mg/L) | N.D. | 0.0030 | 3.0 |

| 2,4-Dinitrotoluene | (mg/L) | N.D. | 0.0015 | 0.13 |

| Hexachlorobenzene | (mg/L) | N.D. | 0.0015 | 0.1 |

| Hexachlorobutadiene | (mg/L) | N.D. | 0.0015 | 0.5 |

| Hexachloroethane | (mg/L) | N.D. | 0.0015 | 3.0 |

| Methyl Ethyl Ketone | (mg/L) | N.D. | 0.009 | 200.0 |

| Nitrobenzene | (mg/L) | N.D. | 0.0015 | 2.0 |

| Pyridine | (mg/L) | 1.13 | 0.0015 | 5.0 |

| Carbon Tetrachloride | (mg/L) | N.D. | 0.0030 | 0.2 |

| Tetrachloroethylene | (mg/L) | N.D. | 0.0030 | 4.0 |

| Trichloroethylene | (mg/L) | N.D. | 0.0030 | 7.0 |

| 2,4,5-Trichlorophenol | (mg/L) | N.D. | 0.0015 | 400.0 |

| 2,4,6-Trichlorophenol | (mg/L) | N.D. | 0.0015 | 20.0 |

| Constituent | Unit | Results | Limits (mg/L) | ||

|---|---|---|---|---|---|

|

Quantification

Limits |

NBR 10004

(max) | ||||

| Silver | (Ag) | (mg/L) | N.D. | 0.010 | 0.05 |

| Aluminum | (Al) | (mg/L) | N.D. | 0.010 | 0.2 |

| Arsenic | (As) | (mg/L) | N.D. | 0.008 | 0.01 |

| Barium | (Ba) | (mg/L) | N.D. | 0.010 | 0.7 |

| Cadmium | (Cd) | (mg/L) | N.D. | 0.003 | 0.005 |

| Chromium | (Cr) | (mg/L) | N.D. | 0.010 | 0.05 |

| Copper | (Cu) | (mg/L) | N.D. | 0.010 | 2.0 |

| Iron | (Fe) | (mg/L) | 0.027 | 0.010 | 0.3 |

| Manganese | (Mn) | (mg/L) | 0.008 | 0.005 | 0.1 |

| Lead | (Pb) | (mg/L) | N.D. | 0.007 | 0.01 |

| Selenium | (Se) | (mg/L) | N.D. | 0.008 | 0.01 |

| Zinc | (Zn) | (mg/L) | N.D. | 0.003 | 5.0 |

| Mercury | (Hg) | (mg/L) | N.D. | 0.0002 | 0.001 |

| Sodium | (Na) | (mg/L) | 1.85 | 0.060 | 200.0 |

| Sulfates | (SO42-) | (mg/L) | 1.85 | 0.5 | 250.0 |

| Nitrates | (N) | (mg/L) | 0.89 | 0.5 | 10.0 |

| Chlorides | (Cl-) | (mg/L) | 0.24 | 0.05 | 250.0 |

| Fluorides | (F-) | (mg/L) | N.D. | 0.02 | 1.5 |

| Cyanides | (CN-) | (mg/L) | N.D. | 0.05 | 0.07 |

| Phenols | - | (mg/L) | N.D. | 0.01 | 0.01 |

| pH | - | - | 6.28 | - | - |

| Constituent | Unit | Result | Limits (mg/L) | ||

|---|---|---|---|---|---|

|

Quantification

Limits |

NBR 10004

(max) | ||||

| Aldrin + Dieldrin | (mg/L) | N.D. | 0.00006 | 0.00003 | |

| Chlordane (isomers) | (mg/L) | N.D. | 0.00006 | 0.0002 | |

| DDT (isomers) | (mg/L) | N.D. | 0.00009 | 0.002 | |

| 2,4-D | (mg/L) | N.D. | 0.0009 | 0.03 | |

| Endrin | (mg/L) | N.D. | 0.00003 | 0.0006 | |

| Heptachlor + Heptachlor Epoxide | (mg/L) | N.D. | 0.00006 | 0.00003 | |

| Lindane (-BHC) | (mg/L) | N.D. | 0.00003 | 0.002 | |

| Methoxychlor | (mg/L) | N.D. | 0.00003 | 0.02 | |

| Toxaphene | (mg/L) | N.D. | 0.000375 | 0.005 | |

| 2,4,5-T | (mg/L) | N.D. | 0.0009 | 0.002 | |

| 2,4,5-TP | (mg/L) | N.D. | 0.0009 | 0.030 | |

| Hexachlorobenzene | (mg/L) | N.D. | 0.0009 | 0.001 | |

| Surfactants | (mg/L) | 0.132 | 0.1 | 5.0 | |

| Samples | Composite Model | |||

|---|---|---|---|---|

| R² | ||||

| PRS - CP1 | 23.78 | 0.188 | −0.768 | 0.973 |

| PRS - CP2 | 25.60 | 0.182 | −0.758 | 0.967 |

| PRS80/IMW20-CP1 | 56.13 | 0.243 | −0.682 | 0.925 |

| PRS80/IMW20-CP2 | 62.54 | 0.368 | −0.750 | 0.953 |

| PRS60/IMW40-CP1 | 62.70 | 0.190 | −0.568 | 0.761 |

| PRS60/IMW40-CP2 | 65.20 | 0.238 | −0.566 | 0.750 |

| PRS50/IMW50-CP1 | 96.87 | 0.246 | −0.574 | 0.724 |

| PRS50/IMW50-CP2 | 91.85 | 0.272 | −0.540 | 0.743 |

| LCS-CP1 | 240.18 | −0.041 | −0.409 | 0.923 |

| LCS-CP2 | 234.82 | 0.029 | −0.447 | 0.909 |

| LCS80/IMW20-CP1 | 388.32 | 0.094 | −0.316 | 0.923 |

| LCS80/IMW20-CP2 | 292.39 | 0.113 | −0.407 | 0.874 |

| LCS60/IMW40-CP1 | 307.41 | 0.254 | −0.409 | 0.768 |

| LCS60/IMW40-CP2 | 354.27 | 0.283 | −0.401 | 0.749 |

| Sample | MR (MPa) | ||

|---|---|---|---|

| ( = Lower) | ( = Medium) | ( = High) | |

| PRS | 230 | 50 | 46 * |

| PRS80/IMW20 | 290 | 82 | 61 |

| PRS60/IMW40 | 250 | 88 | 69 |

| PRS50/IMW50 | 298 | 115 | 92 |

| LCS | 1270 | 464 | 351 |

| LCS80/IMW20 | 922 | 455 | 382 |

| LCS60/IMW40 | 561 | 311 | 278 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galhardo, D.C.; Guimarães, A.C.R.; Martins, C.A.; Narciso, M.M.; Monteiro, S.N.; Coelho, L.M. Influence of Iron Mining Waste Addition as a Sustainable Alternative on the Resilient and Physical Properties of Soils for Pavement Design. Sustainability 2024, 16, 10211. https://doi.org/10.3390/su162310211

Galhardo DC, Guimarães ACR, Martins CA, Narciso MM, Monteiro SN, Coelho LM. Influence of Iron Mining Waste Addition as a Sustainable Alternative on the Resilient and Physical Properties of Soils for Pavement Design. Sustainability. 2024; 16(23):10211. https://doi.org/10.3390/su162310211

Chicago/Turabian StyleGalhardo, Daniel Corrêa, Antônio Carlos Rodrigues Guimarães, Camila Antunes Martins, Murilo Miguel Narciso, Sergio Neves Monteiro, and Lisley Madeira Coelho. 2024. "Influence of Iron Mining Waste Addition as a Sustainable Alternative on the Resilient and Physical Properties of Soils for Pavement Design" Sustainability 16, no. 23: 10211. https://doi.org/10.3390/su162310211

APA StyleGalhardo, D. C., Guimarães, A. C. R., Martins, C. A., Narciso, M. M., Monteiro, S. N., & Coelho, L. M. (2024). Influence of Iron Mining Waste Addition as a Sustainable Alternative on the Resilient and Physical Properties of Soils for Pavement Design. Sustainability, 16(23), 10211. https://doi.org/10.3390/su162310211