Dewatering and Transport in Sustainable Sediment Management: A Review

Abstract

1. Introduction

2. Dewatering of High-Water Sediments

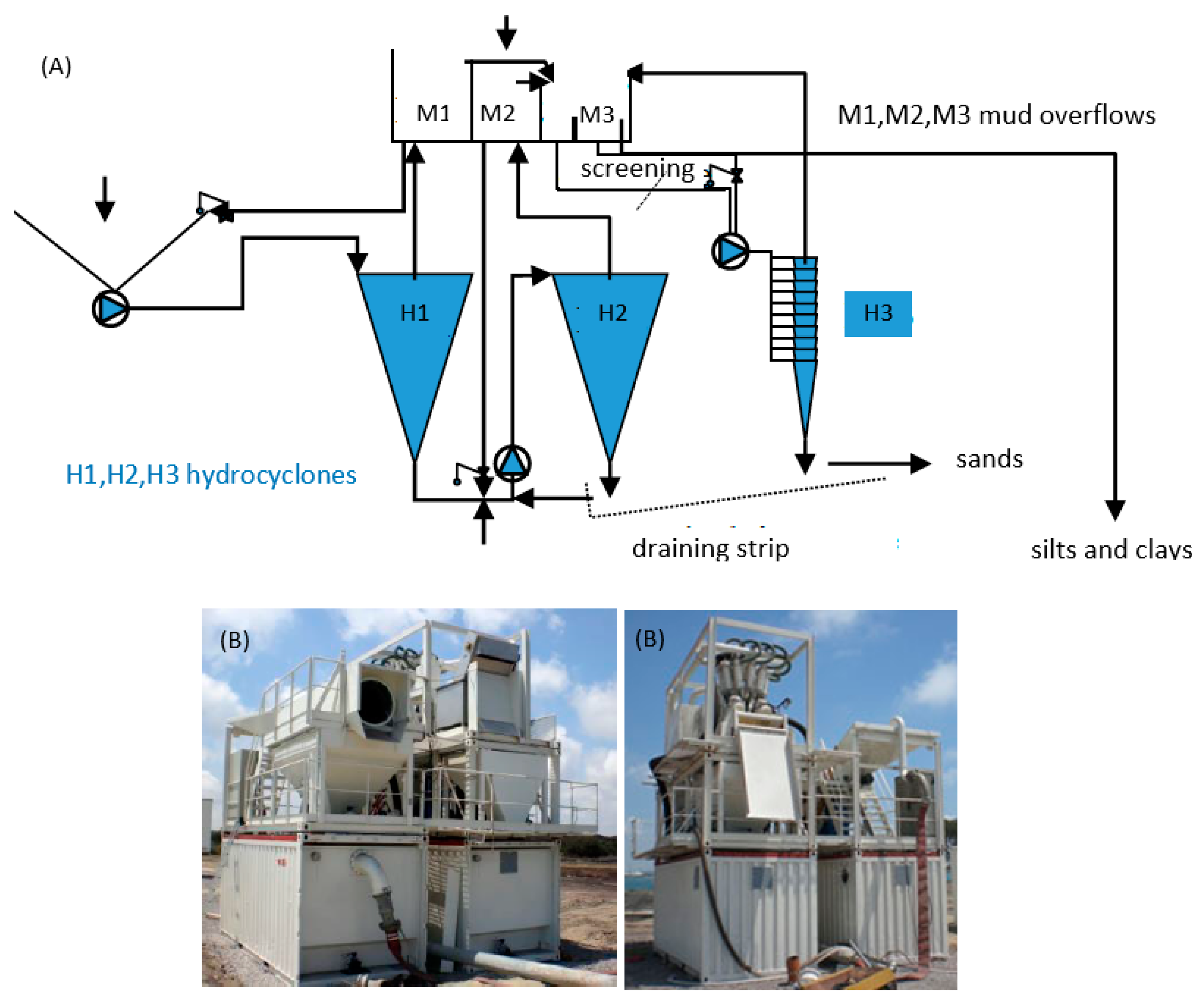

2.1. Available Dewatering Techniques

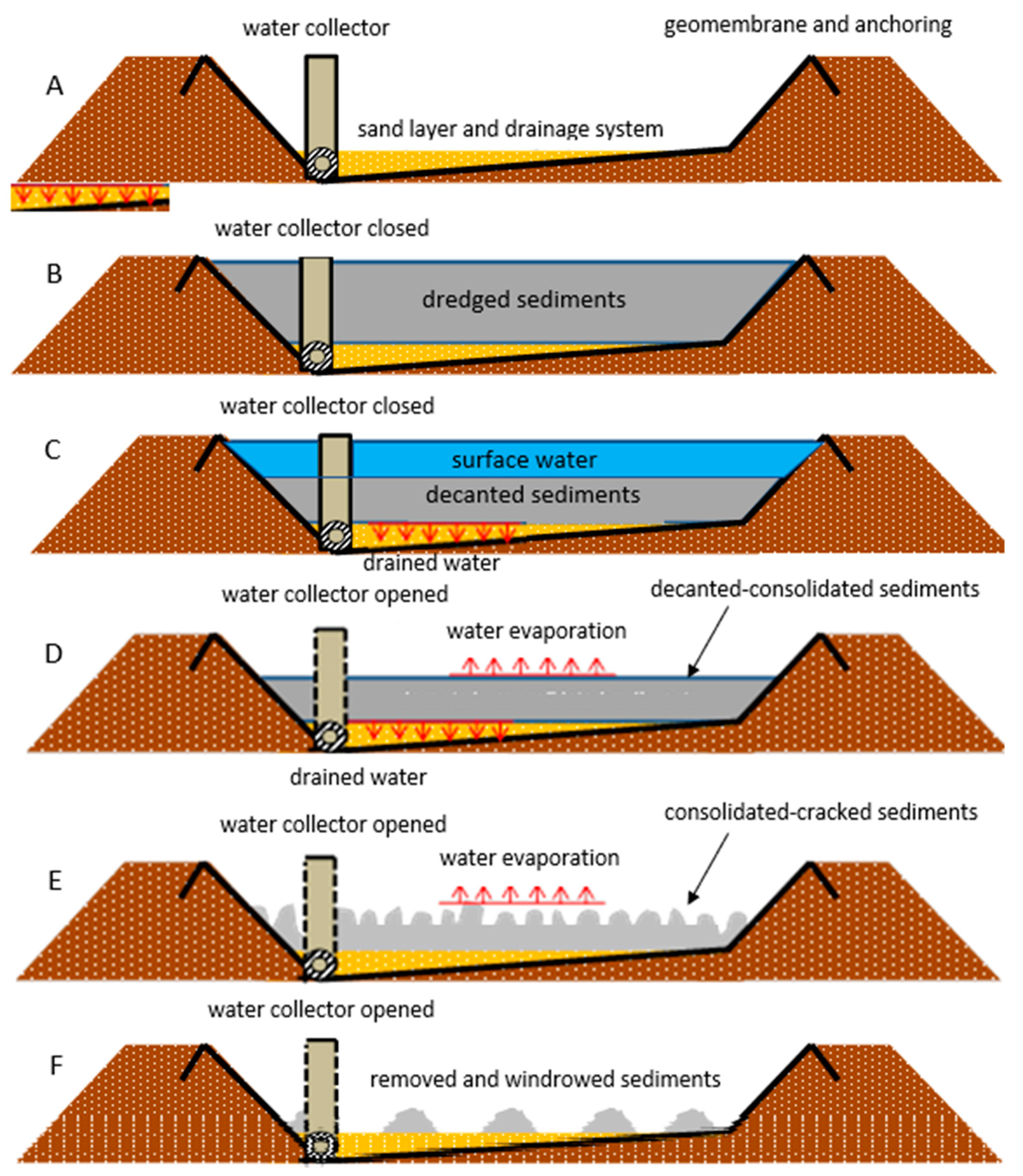

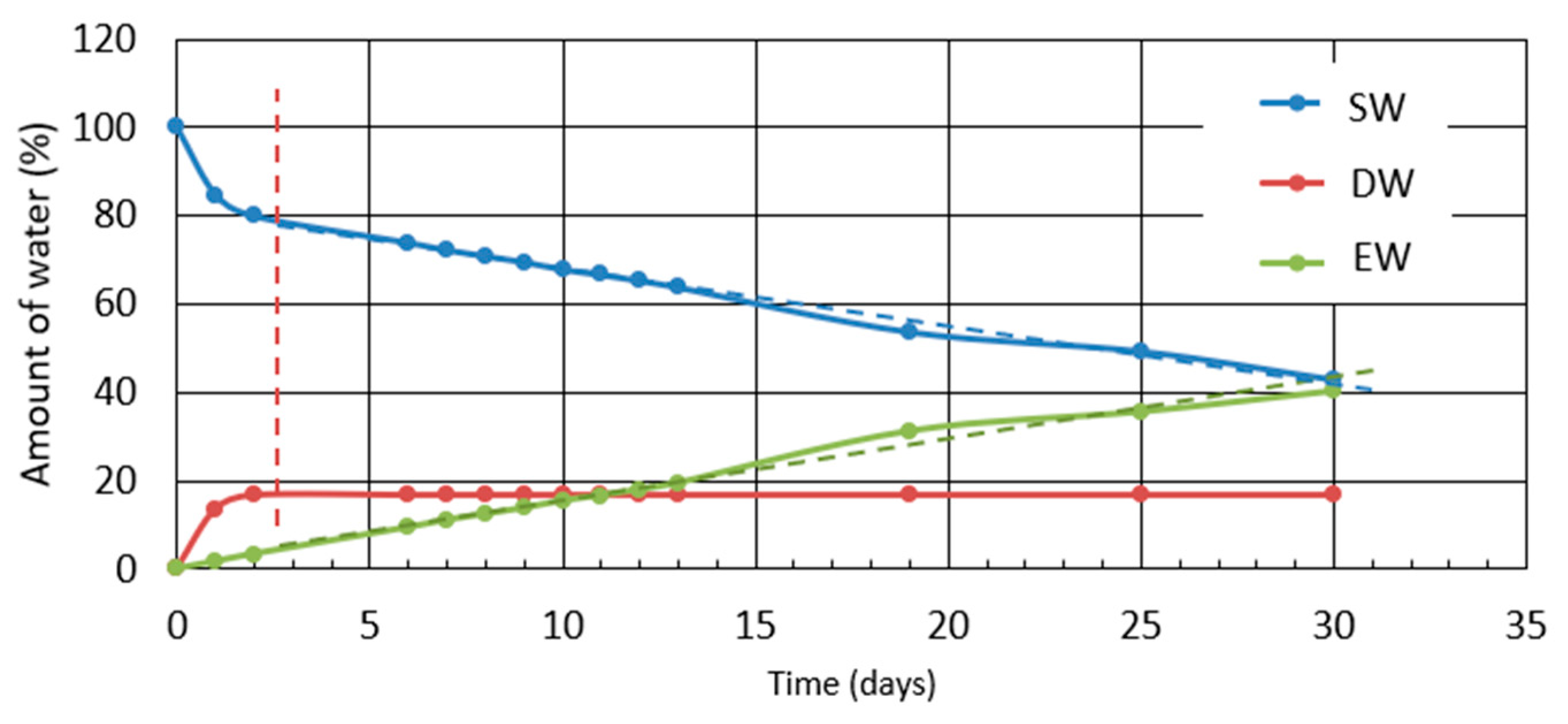

2.2. Laboratory Air-Drying Test

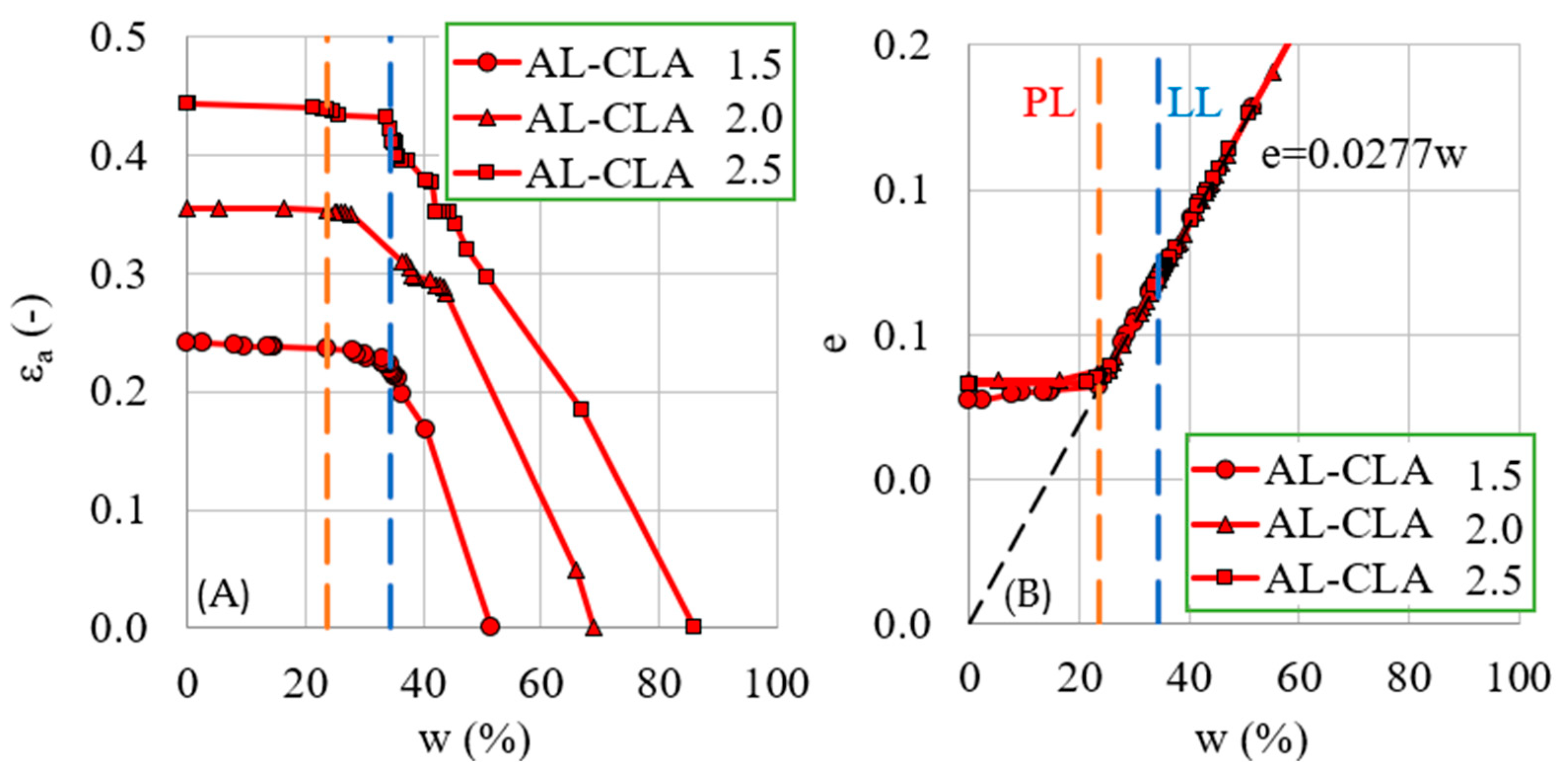

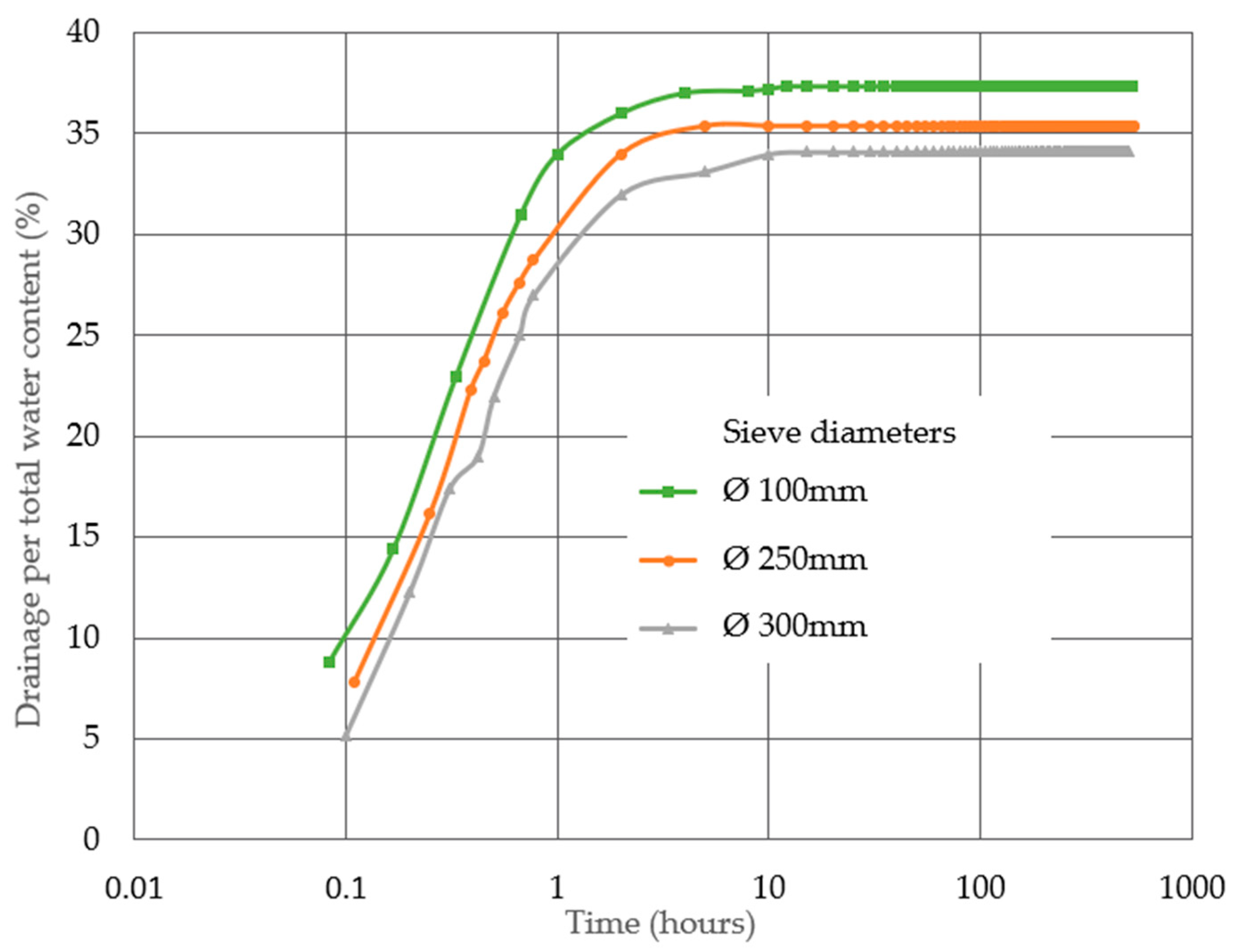

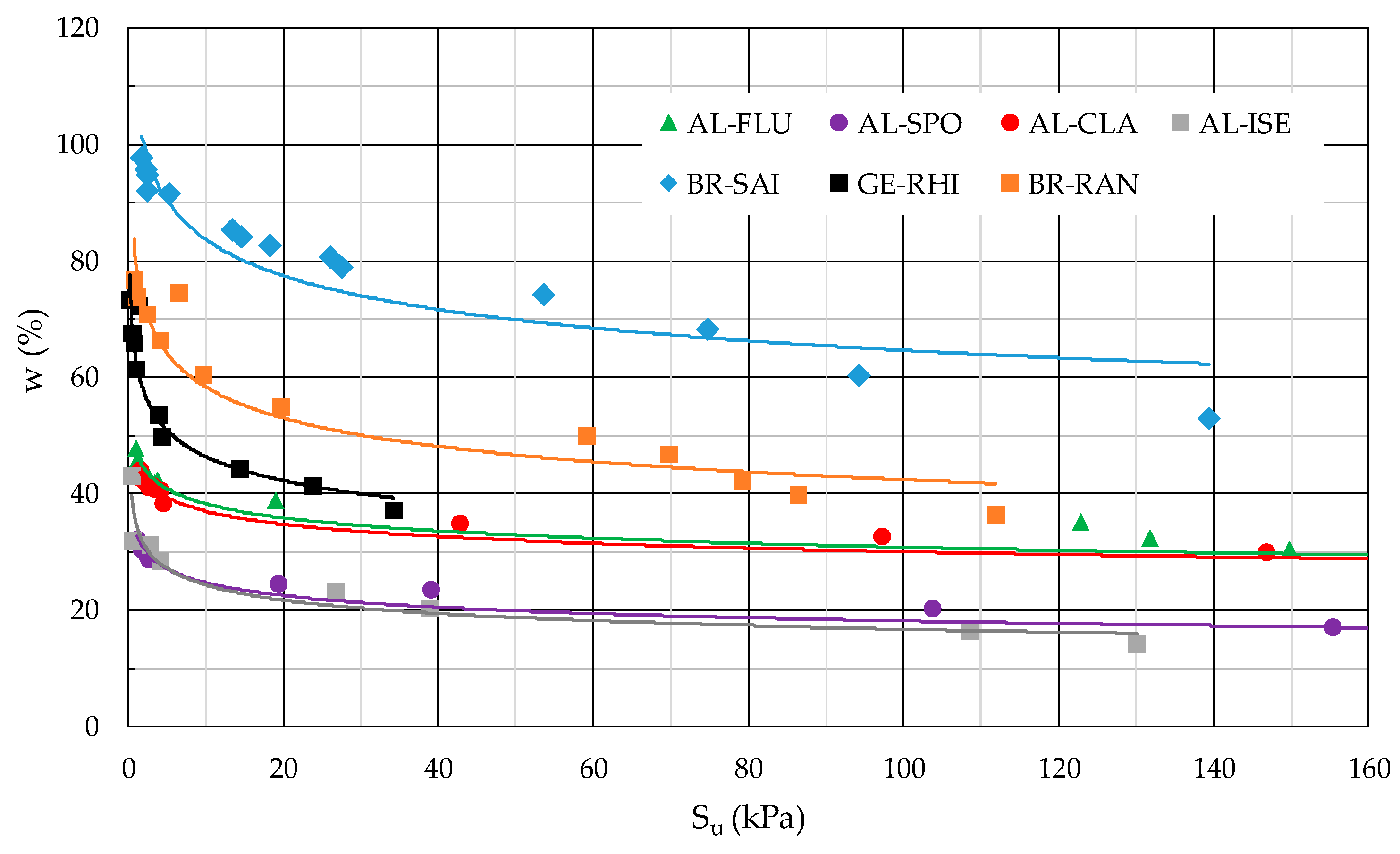

2.3. Laboratory Automated Dewatering Test

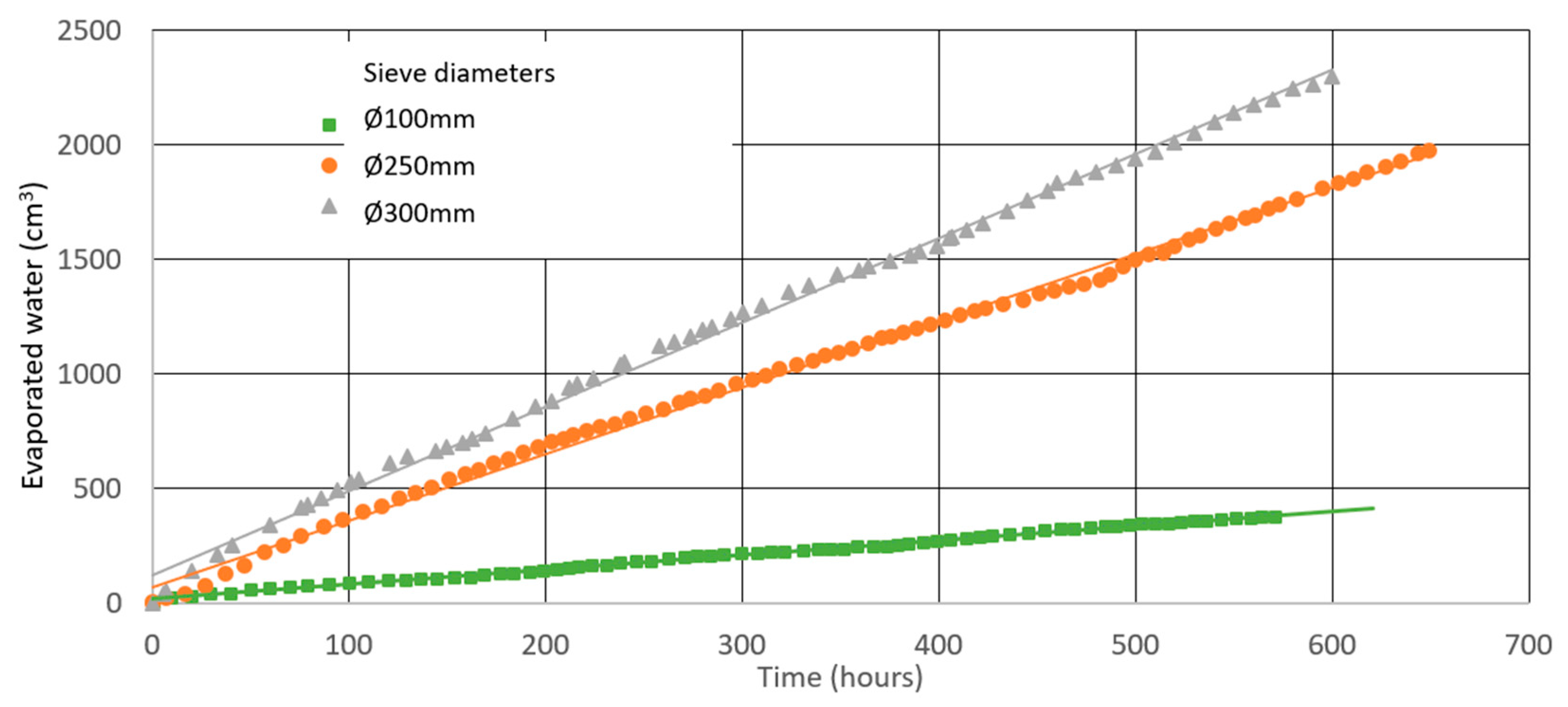

2.4. Comments on Water Evaporation Laws

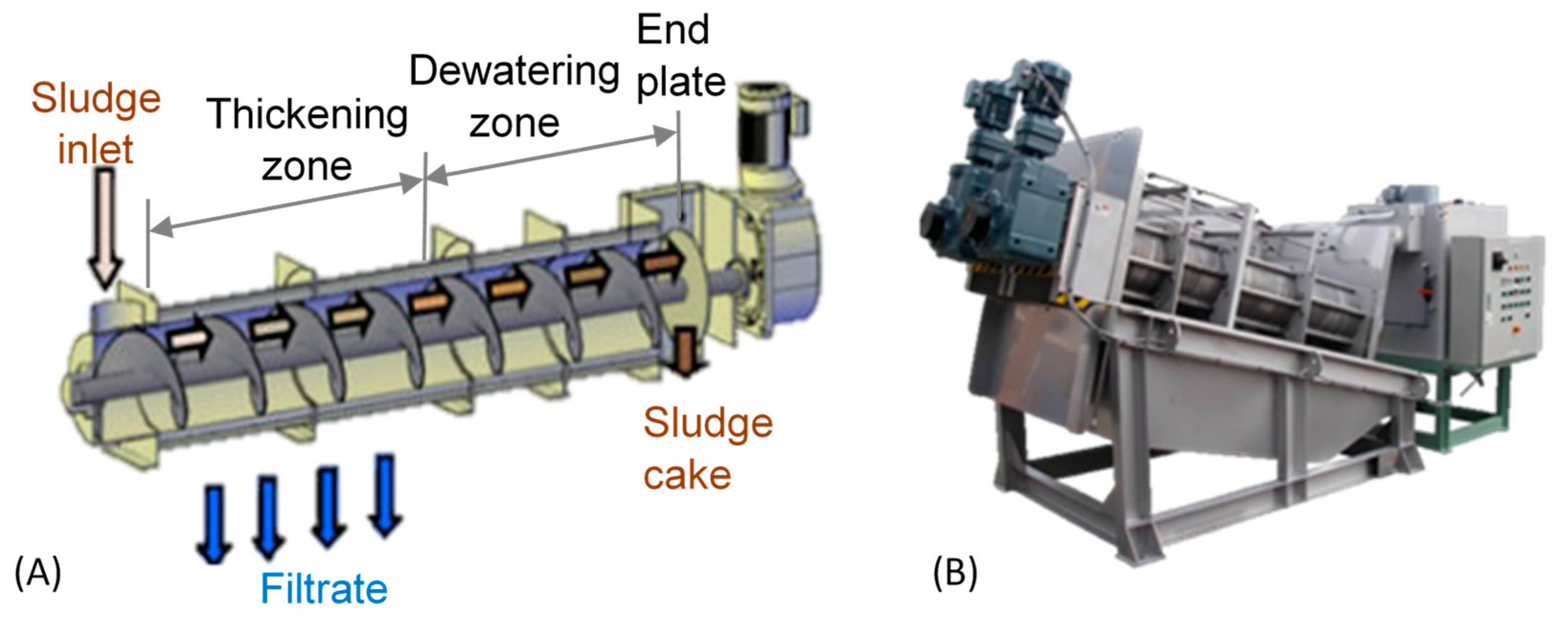

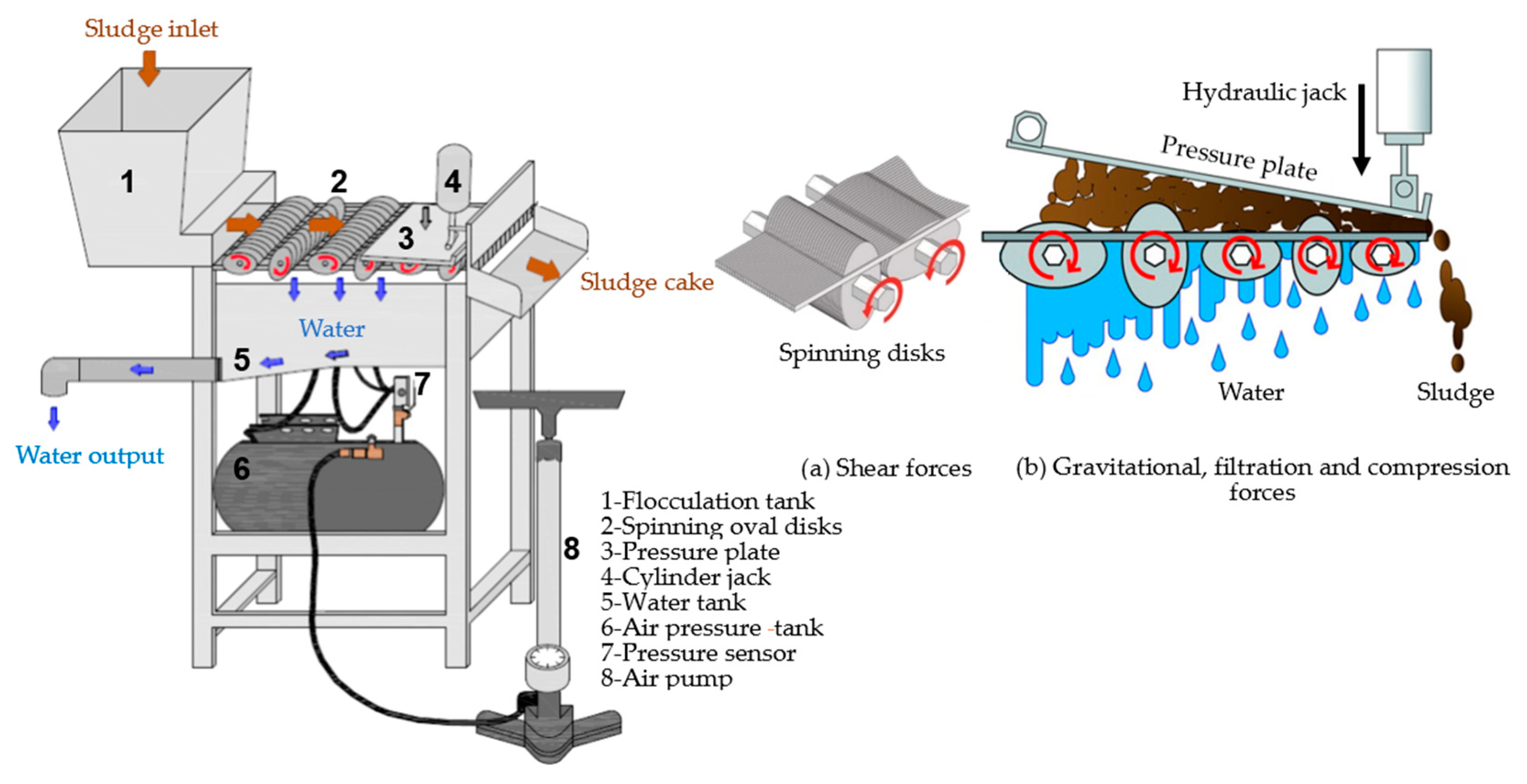

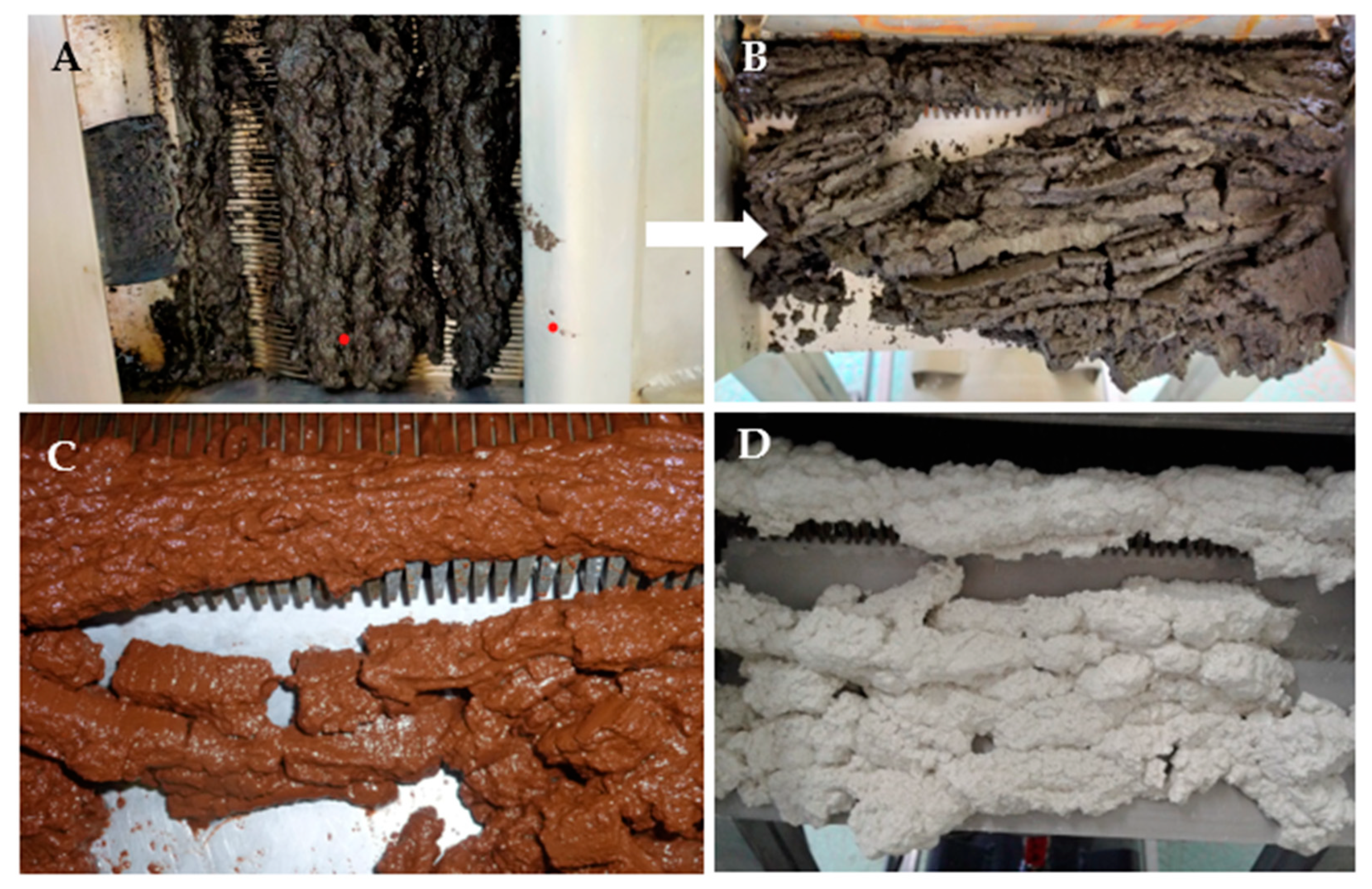

2.5. Mechanical Dewatering Laboratory Press Machine

3. Transportation of Sediments

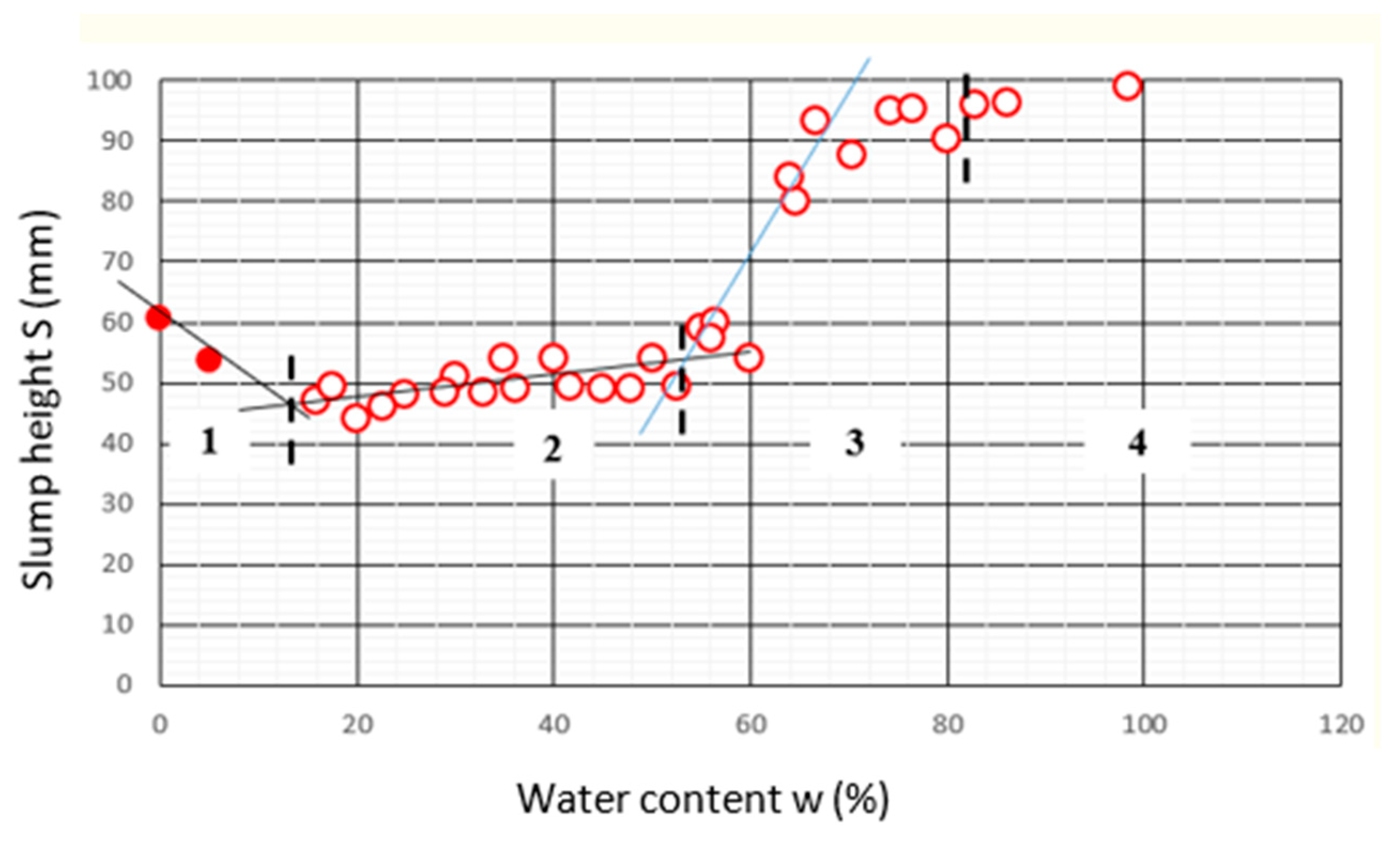

3.1. Shovelability of Sediments

- the state parameters of the sediment, see Section 2.2, and mainly the water content w;

- the consistency of the sediment defined by the Atterberg limits LL and PL;

- the mechanical properties of the sediment, such as undrained cohesion Su and adhesion.

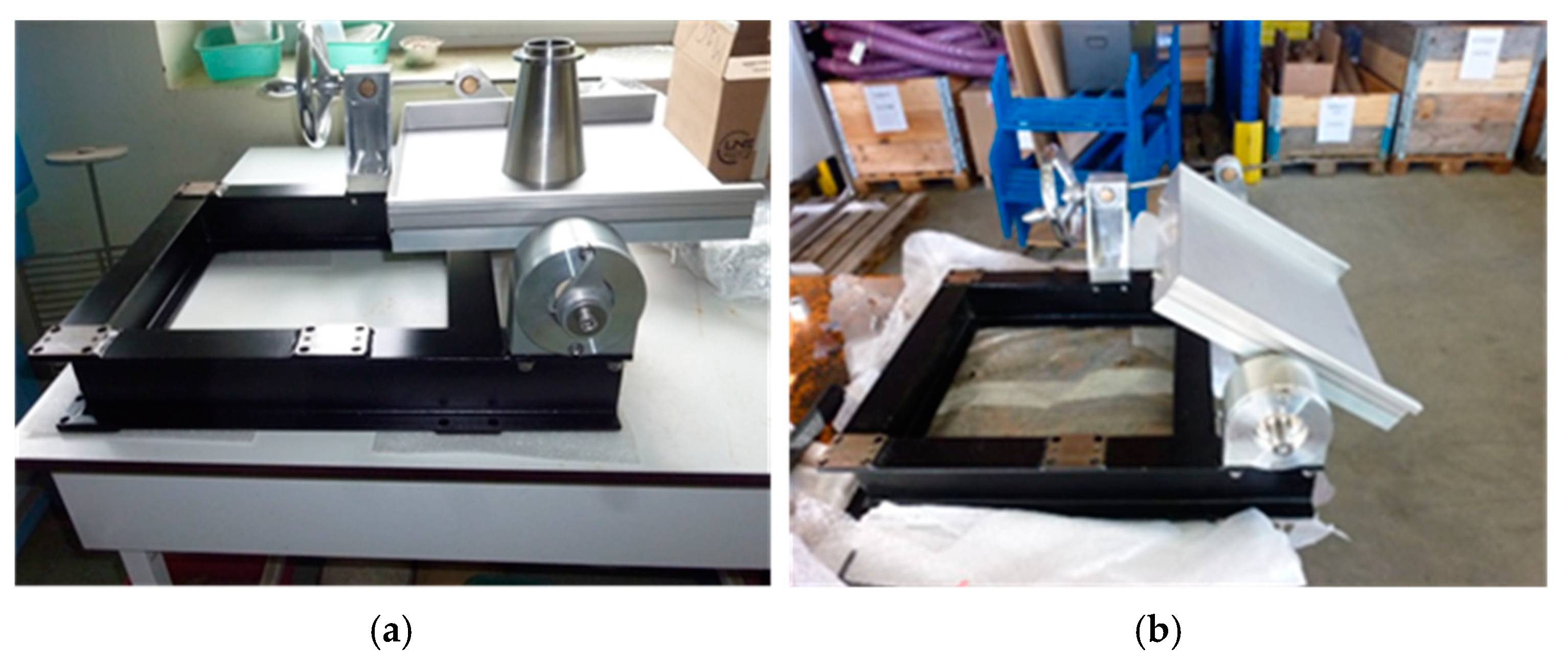

3.2. Shovelability Meter

- the slump S versus the water content w, where it was possible to represent the cone base footprint, i.e., average diameter, obtained after the slump versus water content;

- the undrained cohesion Su (from the vane shear or fall cone test) versus water content w;

- the limit angle of sliding versus water content.

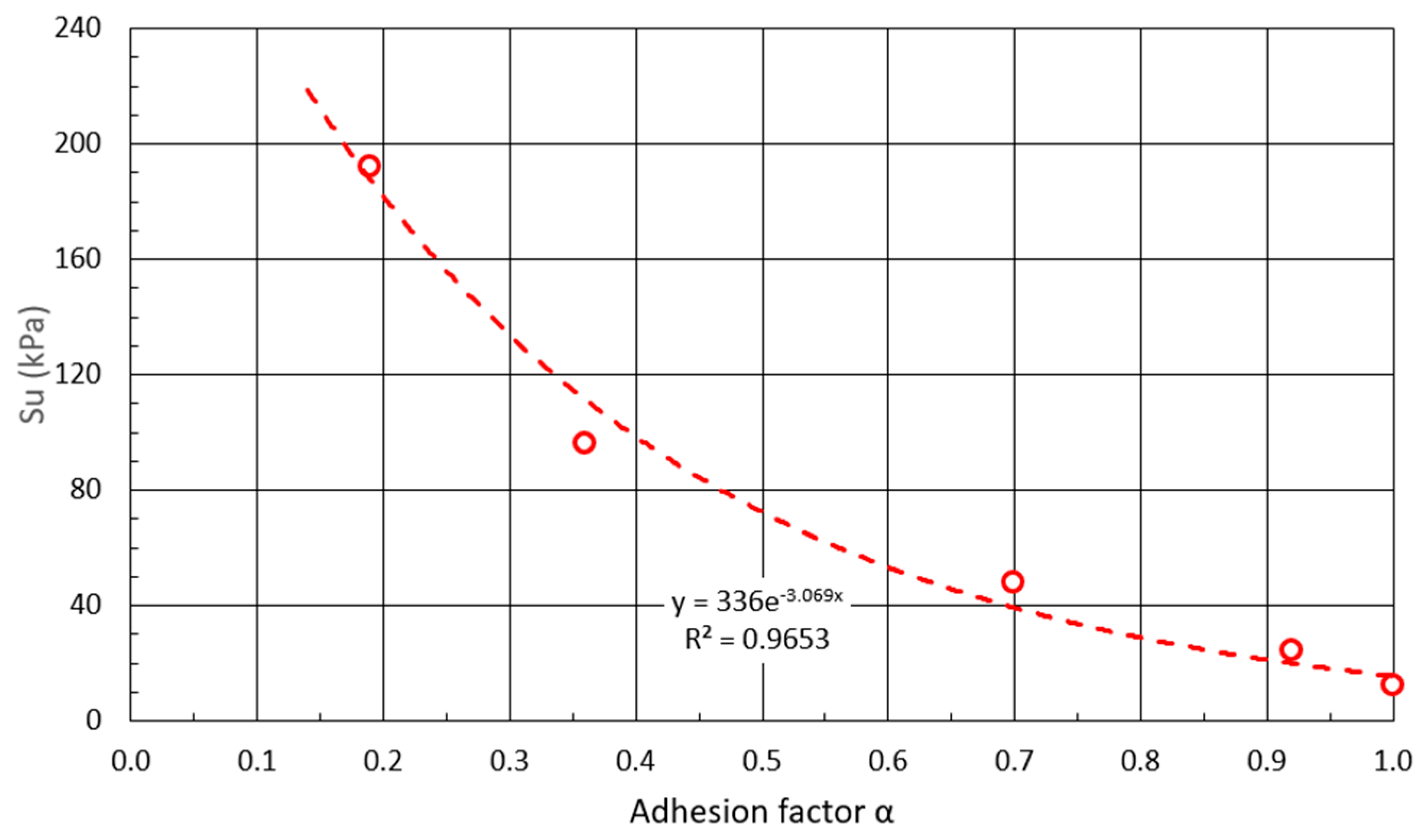

3.3. Adhesion of Sediments

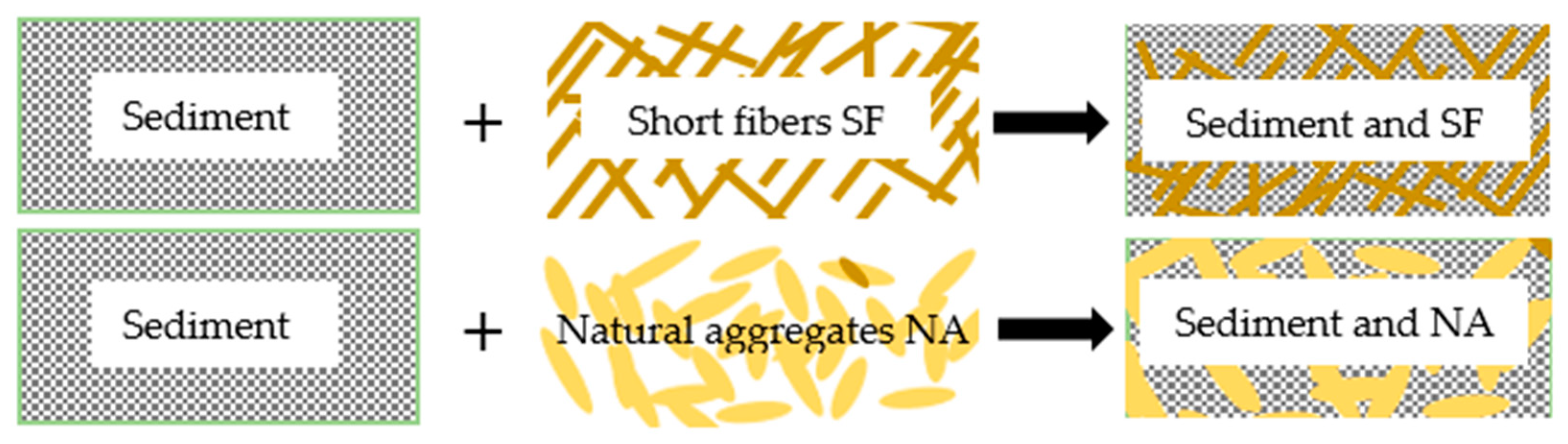

3.4. Loss of Adhesion and Upcycling

4. Conclusions

- Natural dewatering is the most sustainable, even ecological, method. The volume of sediment to be dewatered is significant, depending on the availability of land for ponds. This technique is time- and area-consuming. It requires little energy. It is best suited to harbor, estuary and coastal sediments.

- Mechanical dewatering is a more territorial method for river, canal and dam sediments. It is a sustainable method insofar as dewatering can be carried out close to the dredging site for small volumes of sediment. It is more energy-intensive and can be time-consuming for large volumes of sediment.

- The automated or non-automated dewatering tests (NADT and -ANDS) provide results for natural dewatering. They can contribute to the design of basins and also to the definition of sediment drying kinetics. In particular, they can be used to determine the time required to obtain water contents that are compatible with the removal of sediments by public works vehicles.

- The shovelability test defines the water content required for sediments to be shoveled, depending on the type of public works equipment used, but also provides valuable information on the phenomenon of adhesion. The more a sediment adheres to transport, by spreading or other methods, the more difficult it is to handle, spread or even unload.

- Testing on a mechanical dewatering laboratory press machine (DKS® model) helped in the design of a future full-scale mechanical press to be used and to define one or more flocculants to best dewater a given sediment. The laboratory press is a replica of presses already in use and manufactured for various applications. Its operating principle is exactly the same.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Michallet, I.; Charruau, P.; Monzón Alvarado, C. Les Sédiments du Bassin Versant de l’Usumacinta en 12 Questions, 1st ed.; GRAIE: Villeurbanne, France; ECOSUR: Villahermosa, Tabasco, Mexico, 2022; pp. 34–37. Available online: https://univ-lyon3.hal.science/hal-03739228 (accessed on 29 August 2024).

- Mastoi, A.K.; Bhanbhro, R.; Traore, A.F.; Oad, M.; Zardari, S.; Jhatial, A.A. Preliminary investigation of high-water content dredged sediment treated with chemical-physical combined method at low cement content. Environ Sci. Pollut. Res. 2022, 29, 32763–32772. [Google Scholar] [CrossRef] [PubMed]

- Mukasa, G.P. Stabilization-Solidification of Highwater Content Dredged Sediments—Strength, Compressibility and Durability Evaluations. Ph.D. Thesis, Lulea University of Technology, Lulea, Sweden, 2015. [Google Scholar]

- Pu, H.; Mastoi, A.K.; Chen, X.; Song, D.; Qiu, J.; Yang, P. An integrated method for the rapid dewatering and solidification/stabilization of dredged contaminated sediment with a highwater content. Front. Environ. Sci. Eng. 2021, 15, 67. [Google Scholar] [CrossRef]

- Zhang, Z.; Omine, K.; Flemmy, S.O.; Li, C. The liquid limit as a factor in assessing the improvement of stabilized cement-based highwater content clayey sediments. Materials 2022, 15, 7240. [Google Scholar] [CrossRef] [PubMed]

- Boullosa Allariz, B. Déshydratation Naturelle et Mécanisée de Sédiments—Étude des Processus Mis en Jeu et Applications. Ph.D. Thesis, Caen Normandie University, Caen, France, 2018. [Google Scholar]

- Hussan, A. Cοntrοlled Dewatering, Transpοrtability and Valοrizatiοn οf Sediments. Ph.D. Thesis, Caen Normandie University, Caen, France, 2022. [Google Scholar]

- Boullosa Allariz, B.; Levacher, D.; Thery, F. La Presse à Boues KDS®: Une Nouvelle Technique de Déshydratation Mécanisée en Continu des Sédiments. In Proceedings of the XVème Journées Nationales Génie Côtier-Génie Civil—JNGCGC, La Rochelle, France, 29–31 May 2018; pp. 607–615. [Google Scholar] [CrossRef]

- Bertrand, M. Optimisation de L’injection d’un Floculant Dans un Décanteur Dynamique. Master’s Thesis, University of Caen Normandy, Caen, France, 2010; 20p. [Google Scholar]

- Mancioppi, L.; Dhervilly, P.; Levacher, D. Breaking Technology for Dewatering and Valorization of Sediment in France. In Proceedings of the 20th World Dredging Congress and Exhibition 2013 (WODCON XX), The Art of Dredging, Brussels, Belgium, 3–7 June 2013; pp. 584–589. Available online: https://www.proceedings.com/content/021/021902webtoc.pdf (accessed on 29 August 2024).

- Levacher, D.; Hussan, A.; Haquin, S.; Friboulet, G. A combined slump-sliding test (SST) for dredged fine sediments. Geotech. Test. J. 2024; in progress. [Google Scholar]

- KENDENSHA, 2024, Kendensha Co., Ltd. Tokyo Office, 2F, 2-11-5 Nishikojiya, Ota, Tokyo, 144-0034, Japan. Available online: https://kendensha.com/product/kds-separator (accessed on 25 October 2024).

- Wakeman, R.J. Separation technologies for sludge dewatering. J. Hazard. Mater. 2007, 144, 614–619. [Google Scholar] [CrossRef] [PubMed]

- Chitte, P.G.; Tapsi, P.; Deshmukh, B.B. Design and Development of Dewatering Screw Press. In Recent Advances in Manufacturing Modelling and Optimization; Lecture Notes in Mechanical Engineering; Kumar, S., Ramkumar, J., Kyratsis, P., Eds.; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Wambui Mumbi, A.; Li, F.; Mwarania, F.; Uuganchimeg, B. An assessment of multi-plate screw press in dewatering process of sludge treatment (the best option?). Int. J. Adv. Res. 2017, 5, 740–747. [Google Scholar] [CrossRef] [PubMed]

- AMCON, 2024, Amcon, 1926, Nippa-cho, Kohoku-ku, Yokohama, Kanagawa 223-0057, Japan. Available online: https://www.amcon-jp.com/ (accessed on 25 October 2024).

- Mark Allen Group. Dewatering device for disposal issues. Filtr. Sep. 2019, 56, 28–30. [Google Scholar] [CrossRef]

- Suricates European Project 2017–2023, Ixsane, Company Partner, A Machine Test on a Site with River Sediment [Internet]. 2023. Available online: https://www.team2.fr/projets/projets-europeens/suricates (accessed on 8 July 2023).

- De Maeseneer, J.L. Constructed wetlands for sludge dewatering. Water Sci. Technol. 1997, 35, 279–285. [Google Scholar] [CrossRef]

- Molle, P.; Vincent, J.; Troesch, S.; Malamaire, G. Les Lits de Séchage de Boues Plantés de Roseaux Pour le Traitement des Boues et des Matières de Vidange. Guide de Dimensionnement et de Gestion, Guide LSPR. Office Français de la Biodiversité, 2013, 82p. Available online: https://oai-gem.ofb.fr/exl-php/document-affiche/ofb_recherche_oai/OUVRE_DOC/59608?fic=PUBLI/R7/92.pdf (accessed on 29 August 2024).

- Perroni, A.C. Gestion des Sédiments de Dragage: Inventaire des Méthodes de Prétraitement et Application aux Matériaux du Port Autonome du Havre en Vue de Leur Valorisation. Master’s Thesis, Université de Caen Normandie, Caen, France, 2006; 101p. [Google Scholar]

- Serratrice, J.-F. A Presentation of Shrinkage Curves for Clayey Soils. In Proceedings of the International Symposium SEC 2015, Marne-La-Vallée, France, 17–19 June 2015; pp. 179–186. [Google Scholar]

- Rohwer, C. Evaporation from different types of pans. Trans. Am. Soc. Civ. Eng. 1934, 99, 673–703. [Google Scholar] [CrossRef]

- Dalton, J. Experimental essays on the constitution of mixed gases; on the force of steam or vapour from water or other liquids in different temperatures, both in a Torricellian vacuum and in air; on evaporation; and on expansion of gases by heat. In Memoirs of the Literary and Philosophical Society of Manchester; Biodiversity Heritage Library: London, UK, 1798; Volume 5, pp. 536–602. Available online: https://www.biodiversitylibrary.org/partpdf/308525 (accessed on 29 August 2024).

- Penman, H.L. Natural evaporation from open water, bare soil and grass. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1948, 193, 120–145. [Google Scholar] [CrossRef]

- Wang, X. Méthodologies de Valorisation de Sédiments Mises en Œuvre Dans des Ouvrages Géotechniques en Chine. Ph.D. Thesis, Caen Normandie University, Caen, France, 2019. Available online: https://tel.archives-ouvertes.fr/tel-02520015v1 (accessed on 29 August 2024).

- Prabhakar, Y.S.; Satyeswararao, B. Earth Work Handling Problems due to Stickiness of Soils-Sticky Limit—Evaluation & Measurement Methods. In Proceedings of the TRACE-2012 Conference, National Conference Proceedings, San Diego, CA, USA, 30 August 2012; Amity School of Engineering & Technology, Amity University: Noida, UP, India, 2012; Volume 1, pp. 8–19. [Google Scholar]

- ISO 17892-6:2017; Reconnaissance et Essais Géotechniques—Essais de Laboratoire sur les Sols—Partie 6: Essai de Pénétration de Cône. AFNOR: Paris, France, 2017.

- Hansbo, S. A new approach to the determination of the shear strength of clay by the fall cone test. R. Swed. Geotech. Inst. Proc. 1957, 14, 5–47. [Google Scholar]

- Shimobe, S.; Spagnoli, G. Fall cone tests considering water content, cone penetration index, and plasticity angle of fine-grained soils. J. Rock Mech. Geotech. Eng. 2020, 12, 1347–1355. [Google Scholar] [CrossRef]

- Malusis, M.A.; Evans, J.C.; McLane, M.; Woodward, N.R. A miniature cone for measuring the slump of soil-bentonite cutoff wall backfill. Geotech. Test. J. 2008, 31, 373–380. [Google Scholar] [CrossRef]

- EN ISO 17892-12:2018; Geotechnical Investigation and Testing. Laboratory Testing of Soil. Determination of Liquid and plastic Limits. ISO: Geneva, Switzerland, 2018.

- Abbaspour-Gilandeh, Y.; Hasankhani-Ghavam, F.; Shahgoli, G.; Shrabian, V.R.; Abbaspour-Gilandeh, M. Investigation of the effect of soil moisture content, contact surface material and soil texture on soil friction and soil adhesion coefficients. Acta Technol. Agric. 2018, 2, 44–50. [Google Scholar] [CrossRef]

- Azadegan, B.; Massah, J. Effect of temperature on adhesion of clay soil to steel. Cercet. Agron. Mold. 2012, XLV, 21–27. [Google Scholar] [CrossRef]

- Bircha, R.A.; Ekwue, E.I.; Phillip, C.J. Soil-metal sliding resistance forces of some Trinidadian soils at high water contents. West Indian J. Eng. 2011, 38, 52–58. [Google Scholar]

- Chen, X.; Van Den Broecke, J.W.; Liu, G.; Hong, G.; Miedema, S.A. Experimental study on the adhesion factor of clay. Terra Aqua 2021, 163, 7–17. Available online: https://www.iadc-dredging.com/wp-content/uploads/2021/06/terra-et-aqua-163-complete-issue.pdf (accessed on 29 August 2024).

- NAVFAC. Foundation and Earth Structures; Design Manual-DM 7.02; U.S. Department of the Navy, Naval Facilities Engineering Command Publications Transmittal: Alexandria, VA, USA, 1986; 279p. [Google Scholar]

- Zimnik, A.R.; Van Baalen, L.R.; Verhoef, P.N.W.; Ngan-Tillard, D.J.M. The Adherence of Clay to Steel Surfaces. In Proceedings of the ISRM International Symposium, Melbourne, Australia, 19 November 2000; IS 2000 International Society for Rock Mechanics: Lisbon, Portugal, 2000. [Google Scholar]

| Basic Parameter | Filter Press | Belt Press | Screw Press | Centrifuge |

|---|---|---|---|---|

| Work system | Discontinuous | Discontinuous | Pseudo-continuous | Discontinuous |

| Surface area occupied (m2) | – | 6.0–6.5 | 10–10.50 | 4.0–4.50 |

| Rate of dryness (%) | ≈65 | 18–25 | 40 | ≈20 |

| Sludge flow (m3/h) | – | 0.5–80 | – | 3–20 |

| Energy use (kW/m3) | 0.25 | 0.5–2.75 | 0.20 | 1.95 |

| Noise (dB) | – | 71 | <70 | 82.4 |

| Flocculant consumption (kg/t DMS *) | 5–9 | 3–7 | 5–7 | 9–11 |

| Water consumption (m3/h) | – | 4.6 | 0.5 | 2.5 |

| Power consumption (kW/h) | – | 1.2 | 2.0 | 20.5 |

| kWh/DMS * | 30–40 | 40 | 10 | 150–200 |

| Basic Parameter | Nemeau® | Volute® * | KDS® ** | Doris® |

|---|---|---|---|---|

| Work system | Continuous | Continuous | Continuous | Continuous |

| Volume of sludge to be processed | 450 m3/h | 12–20 m3 | ≤75 m3/h | ≤80 m3/h |

| Rate of dryness (%) | 40–50 | ≈55 | 70–80 | ≤75 |

| Surface area occupied (m2) | 27.2–168 | 1.33–5.65 | Width = 0.3 m–1.2 m | 3 × 40 feet containers |

| Energy use | 0.25 kW/m3 | 0.2–1.95 kW | 0.4–1.5 | – |

| Operators for each machine | 2 | 2 | 2 | 2 |

| Water Content | Compact State | Low | Intermediate | High | Sludge State |

|---|---|---|---|---|---|

| w (%) | 0–30% | 30–80% | 80–120% | 120–200% | >200% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Levacher, D.; Boullosa Allariz, B.; Hussan, A. Dewatering and Transport in Sustainable Sediment Management: A Review. Sustainability 2024, 16, 9663. https://doi.org/10.3390/su16229663

Levacher D, Boullosa Allariz B, Hussan A. Dewatering and Transport in Sustainable Sediment Management: A Review. Sustainability. 2024; 16(22):9663. https://doi.org/10.3390/su16229663

Chicago/Turabian StyleLevacher, Daniel, Beatriz Boullosa Allariz, and Ali Hussan. 2024. "Dewatering and Transport in Sustainable Sediment Management: A Review" Sustainability 16, no. 22: 9663. https://doi.org/10.3390/su16229663

APA StyleLevacher, D., Boullosa Allariz, B., & Hussan, A. (2024). Dewatering and Transport in Sustainable Sediment Management: A Review. Sustainability, 16(22), 9663. https://doi.org/10.3390/su16229663