Evaluation of Sustainability and Cost Effectiveness of Using LCO2 as Cutting Fluid in Industrial Hard-Turning Installations

Abstract

1. Introduction

2. Materials and Methods

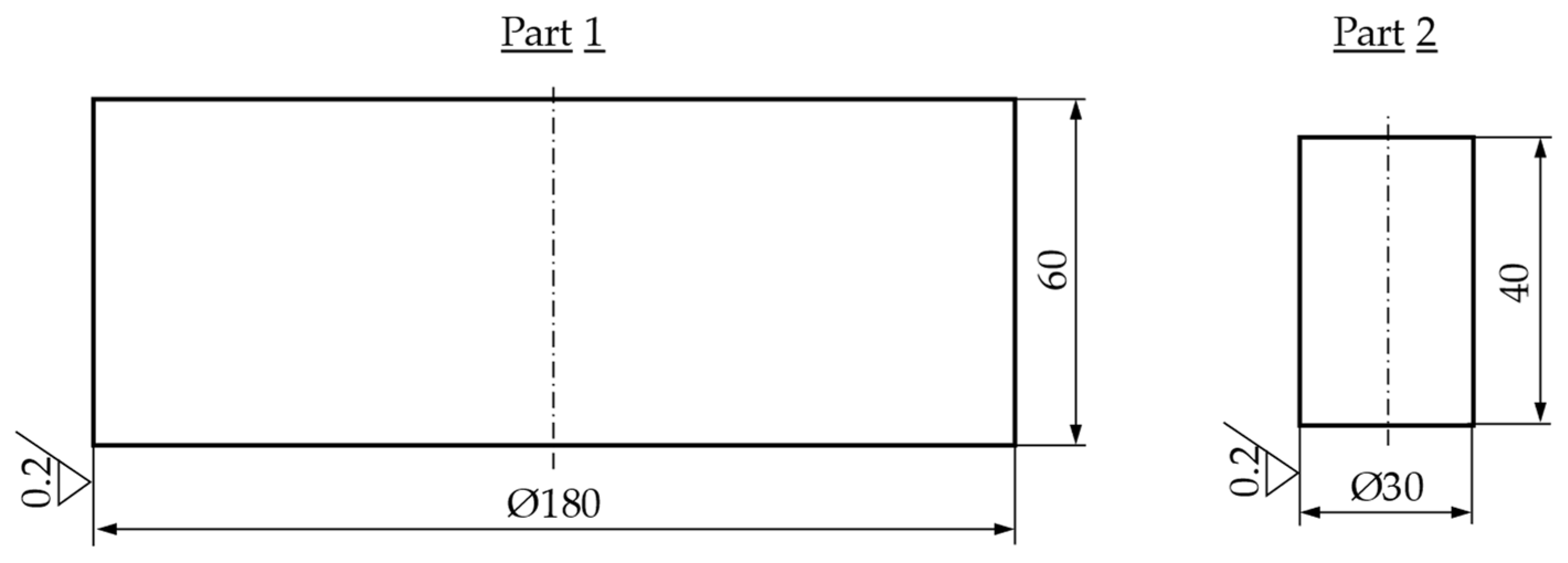

2.1. Test Cases for Roller Bearing Component Manufacturing

2.2. Materials and Experimental Process Performance Data

2.3. Life Cycle Assessment—LCA Calculation Method

2.3.1. Electrical Energy

2.3.2. Cutting Tools

2.3.3. Cutting Fluids

2.3.4. Cutting Process

2.4. Cost and Return on Investment—ROI Calculation Method

3. Results

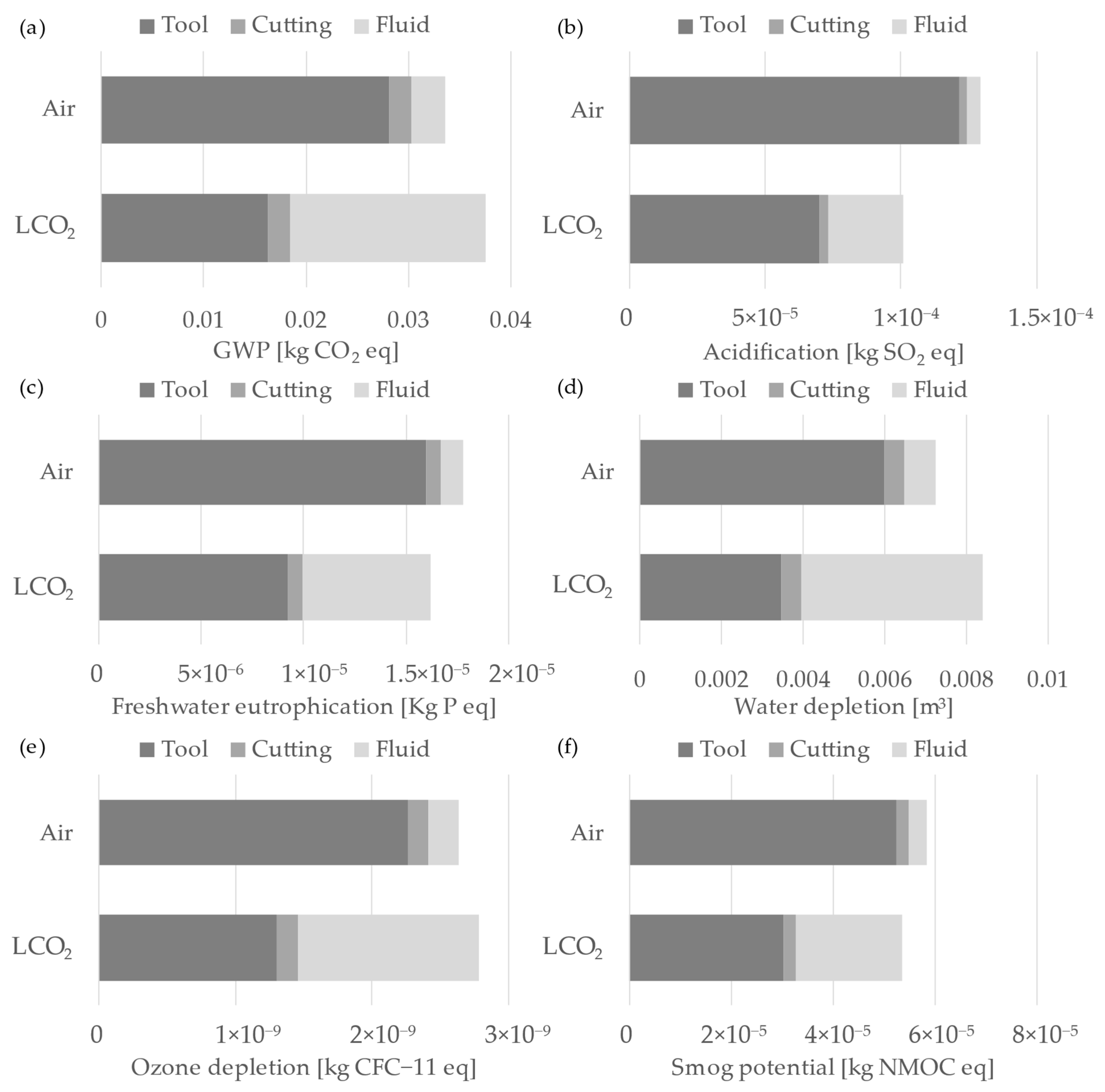

3.1. LCA Calculations

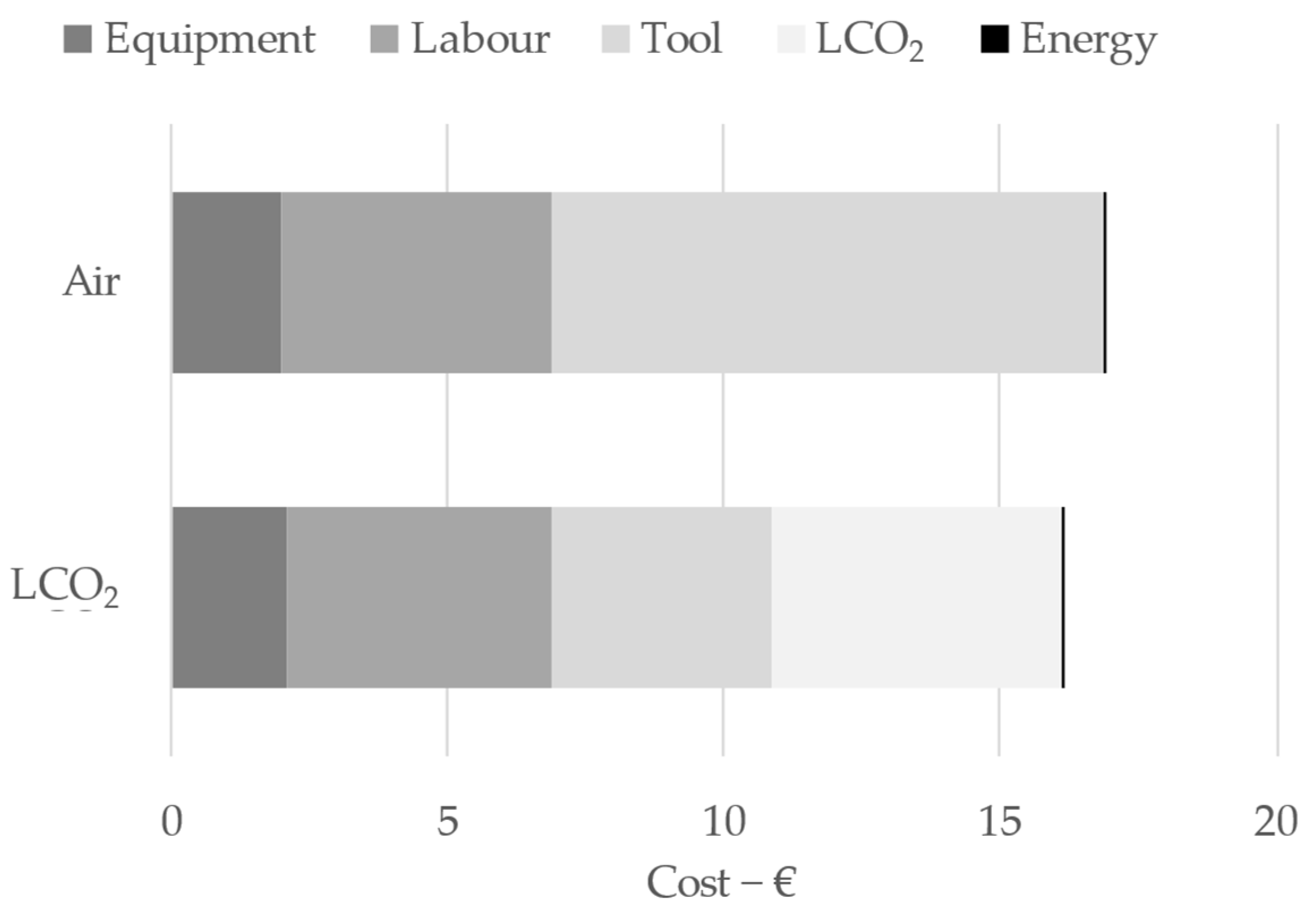

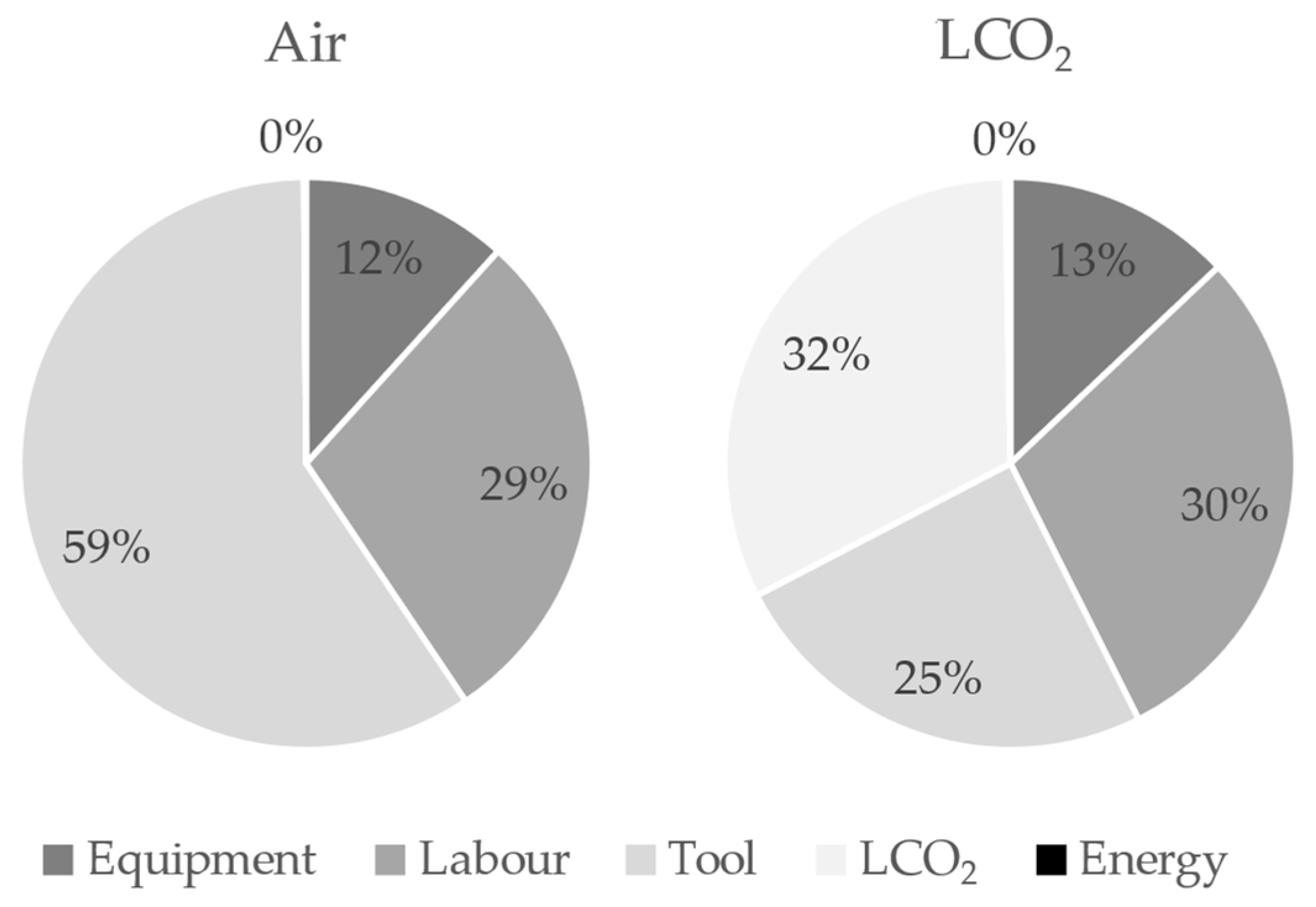

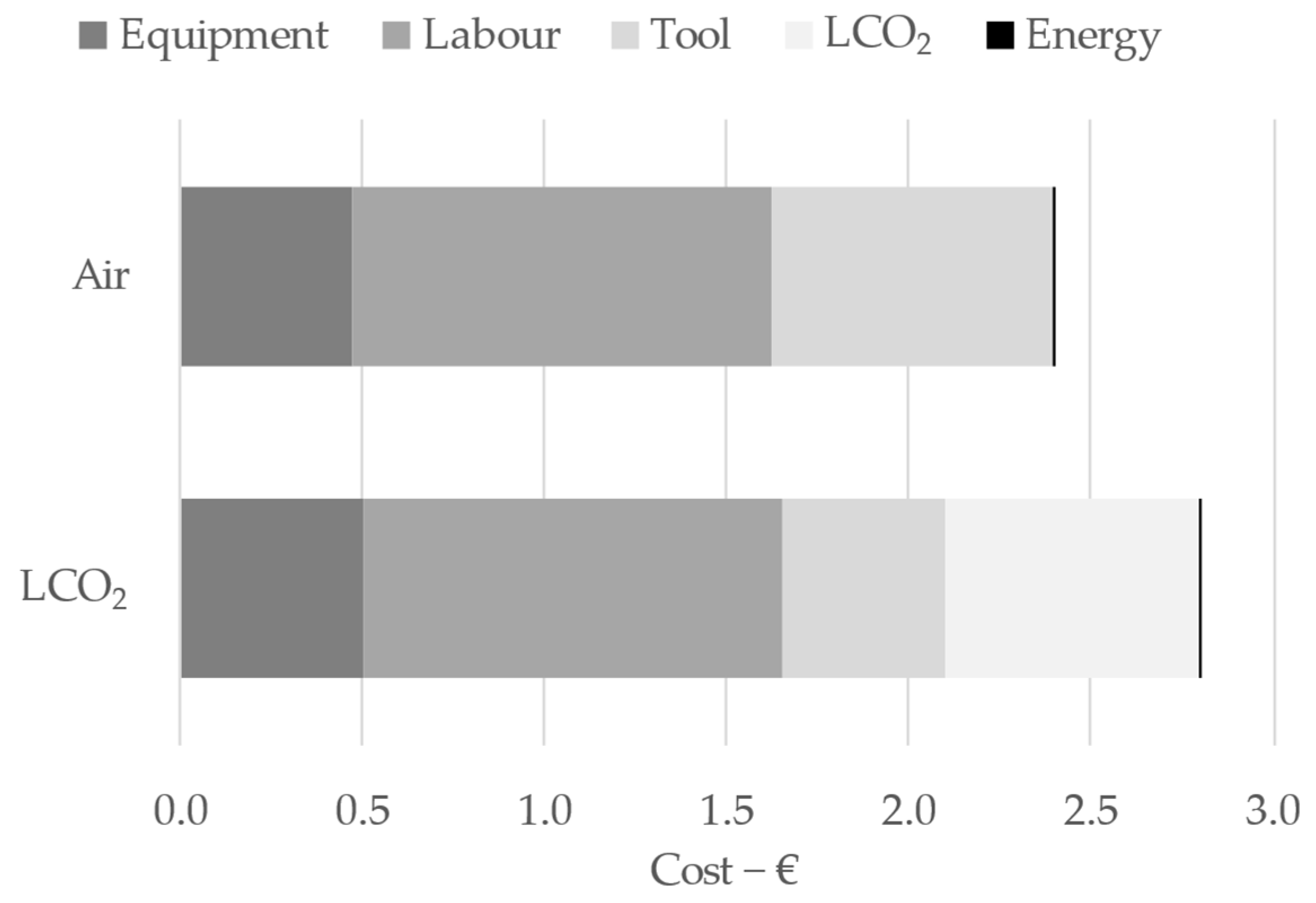

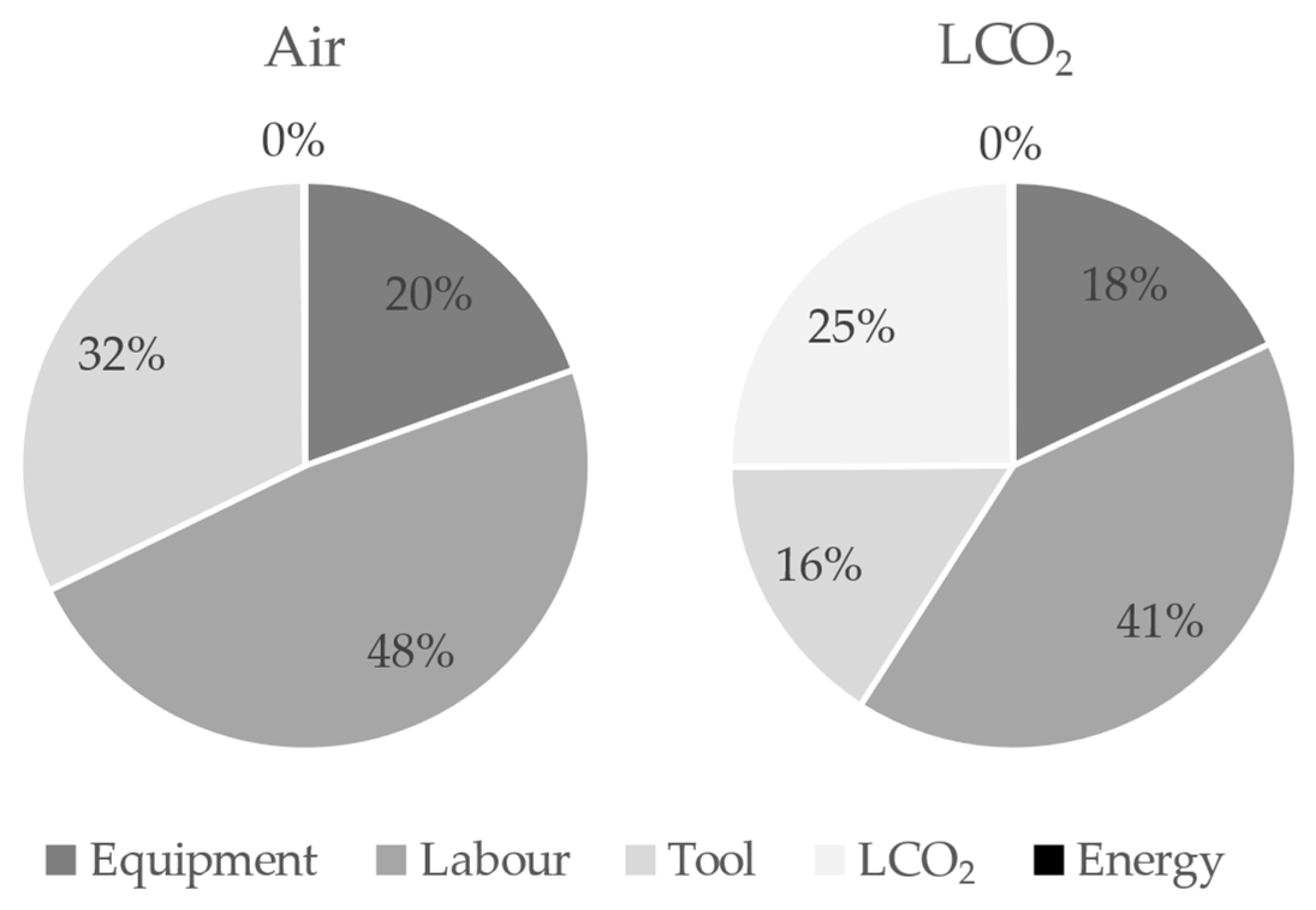

3.2. Cost and ROI Calculations

4. Discussion

5. Conclusions

- The environmental burden associated with both the tools and cryogenic fluids must be accounted for to properly evaluate the overall environmental impact of the cryogenic-assisted processes.

- The industrial viability of using cryogenic cutting fluids during hard-turning operations as a sustainable manufacturing practice relies on the cost and environmental impact reductions generated by improving the tool performance in comparison to conventional cutting fluids.

- Depending on the parts to be manufactured and the manufacturing scenario, the use of cryogenic LCO2 can outperform conventional cutting fluids, both in sustainability and cost-effectiveness. As a rule of thumb, test cases with longer machining times and higher tool consumption will be more likely to generate better results with cryogenic fluids.

- The use of LCA and ROI calculations can provide performance-based metrics for the quantitative evaluation of the industrial viability of cryogenic cooling as a sustainable and cost-effective solution.

- Quantitative metrics like the ones proposed here can enable the rigorous evaluation of manufacturing processes and products, supporting informed decisions and encouraging sustainable consumption and production practices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- König, W.; Berktold, A.; Koch, K.F. Turning versus Grinding—A Comparison of Surface Integrity Aspects and Attainable Accuracies. CIRP Ann. 1993, 42, 33–43. [Google Scholar] [CrossRef]

- Klocke, F.; Brinksmeier, E.; Weinert, K. Capability profile of hard cutting and grinding processes. CIRP Ann. 2005, 54, 22–45. [Google Scholar] [CrossRef]

- M’Saoubi, R.; Johansson, M.P.; Andersson, J.M. Wear mechanisms of PVD-coated PCBN cutting tools. Wear 2013, 302, 1219–1229. [Google Scholar] [CrossRef]

- Smith, S.; Melkote, S.N.; Lara-Curzio, E.; Watkins, T.R.; Allard, L.; Riester, L. Effect of Surface Integrity of Hard Turned AISI 52100 Steel on Fatigue Performance. Mater. Sci. Eng. A 2007, 459, 337–346. [Google Scholar] [CrossRef]

- M’Saoubi, R.; Outeiro, J.C.; Chandrasekaran, H.; Dillon, O.W.; Jawahir, I.S. A Review of Surface Integrity in Machining and Its Impact on Functional Performance and Life of Machined Products. Int. J. Sustain. Manuf. 2008, 1, 203–236. [Google Scholar] [CrossRef]

- Yildiz, Y.; Nalbant, M. A Review of Cryogenic Cooling in Machining Processes. Int. J. Mach. Tools Manuf. 2008, 48, 947–964. [Google Scholar] [CrossRef]

- Jawahir, I.S. Cryogenic manufacturing processes. CIRP Ann. 2016, 65, 713–736. [Google Scholar] [CrossRef]

- Jamil, M.; Iqbal, A.; He, N.; Cheok, Q. Thermophysical Properties and Heat Transfer Performance of Novel Dry-Ice-Based Sustainable Hybrid Lubri-Coolant. Sustainability 2022, 14, 2430. [Google Scholar] [CrossRef]

- Nabil, J.; Ruslan, M.S.M.; Ghani, J.A.; Haron, C.H.C. Sustainable High-Speed Milling of Magnesium Alloy AZ91D in Dry and Cryogenic Conditions. Sustainability 2023, 15, 3760. [Google Scholar] [CrossRef]

- Mallick, R.; Ramanuj, K.; Amlana, P.; Ashok, K.S. Current Status of Hard Turning in Manufacturing: Aspects of Cooling Strategy and Sustainability. Lubricants 2023, 11, 108. [Google Scholar] [CrossRef]

- Bicek, M.; Dumont, F.; Courbon, C.; Pušavec, F.; Rech, J.; Kopac, J. Cryogenic machining as an alternative turning process of normalized and hardened AISI 52100 bearing steel. J. Mater. Process. Technol. 2012, 212, 2609–2618. [Google Scholar] [CrossRef]

- Çetindağ, H.A.; Çiçek, A.; Uçak, N. The Effects of CryoMQL Conditions on Tool Wear and Surface Integrity in Hard Turning of AISI 52100 Bearing Steel. J. Manuf. Process. 2023, 56, 463–473. [Google Scholar] [CrossRef]

- Llanos, I.; Urresti, I.; Bilbatua, D.; Zelaieta, O. Cryogenic CO2 assisted hard turning of AISI 52100 with robust CO2 delivery. J. Manuf. Process. 2023, 98, 254–264. [Google Scholar] [CrossRef]

- Umbrello, D.; Pu, A.; Caruso, S.; Outeiro, J.C.; Jayal, A.D.; Dillon, O.W.; Jawahir, I.S. The Effects of Cryogenic Cooling on Surface Integrity in Hard Machining. Procedia Eng. 2011, 19, 371–376. [Google Scholar] [CrossRef]

- Umbrello, D.; Micari, F.; Jawahir, I.S. The effects of cryogenic cooling on surface integrity in hard machining: A comparison with dry machining. CIRP Ann. 2012, 61, 103–106. [Google Scholar] [CrossRef]

- Nie, G.C.; Zhang, X.M.; Zhang, D.; Ding, H. An Experimental Study of the White Layer Formation during Cryogenic Assisted Hard Machining of AISI 52100 Steel. Procedia CIRP 2018, 77, 223–226. [Google Scholar] [CrossRef]

- Bertolini, R.; Bedekar, V.; Ghiotti, A.; Savio, E.; Shivpuri, R.; Bruschi, S. Surface Integrity and Corrosion Performances of Hardened Bearing Steel after Hard Turning. Int. J. Adv. Manuf. Technol. 2020, 108, 1983–1995. [Google Scholar] [CrossRef]

- Zurecki, Z.; Ghosh, R.; Frey, J.H. Investigation of White Layers Formed in Conventional and Cryogenic Hard Turning of Steels. In Proceedings of the ASME 2003 International Mechanical Engineering Congress and Exposition, Washington, DC, USA, 15–21 November 2003; ASME: New York, NY, USA, 2003; pp. 211–220. [Google Scholar]

- Huang, A.H.; Kaynak, Y.; Umbrello, D.; Jawahir, I.S. Cryogenic Machining of Hard-To-Machine Material, AISI 52100: A Study of Chip Morphology and Comparison with Dry Machining. Adv. Mater. Res. 2012, 500, 140–145. [Google Scholar] [CrossRef]

- Kim, D.M.; Kim, H.I.; Park, H.W. Tool Wear, Economic Costs, and CO2 Emissions Analysis in Cryogenic Assisted Hard-Turning Process of AISI 52100 Steel. Sustain. Mater. Technol. 2021, 30, e00349. [Google Scholar] [CrossRef]

- Khan, A.M.; Zhao, W.; Li, L.; Alkahtani, M.; Hasnain, S.; Jamil, M.; He, N. Assessment of Cumulative Energy Demand, Production Cost, and CO2 Emission from Hybrid CryoMQL Assisted Machining. J. Clean. Prod. 2021, 292, 125952. [Google Scholar] [CrossRef]

- Narita, H.; Desmira, N.; Fujimoto, H. Environmental Burden Analysis for Machining Operation Using LCA Method. In Manufacturing Systems and Technologies for the New Frontier; Mitsuishi, M., Ueda, K., Kimura, F., Eds.; Springer: London, UK, 2008; pp. 65–68. [Google Scholar]

- Furberg, A.; Arvidsson, R.; Molander, S. Environmental Life Cycle Assessment of Cement-ed Carbide (WC-Co) Production. J. Clean. Prod. 2019, 209, 1126–1138. [Google Scholar] [CrossRef]

- Furberg, A.; Fransson, K.; Zackrisson, M.; Larsson, M.; Arvidsson, R. Environmental and Resource Aspects of Substituting Cemented Carbide with Polycrystalline Diamond: The Case of Machining Tools. J. Clean. Prod. 2020, 277, 123577. [Google Scholar] [CrossRef]

- United Nations Economic Commission for Europe. Carbon Neutrality in the UNECE Region: Integrated Life-Cycle Assessment of Electricity Sources; United Nations: Geneva, Switzerland, 2022. [Google Scholar]

- European Council Homepage. Available online: https://www.consilium.europa.eu/en/infographics/how-is-eu-electricity-produced-and-sold/ (accessed on 1 October 2024).

- Winter, M.; Ibbotson, S.; Kara, S.; Herrmann, C. Life Cycle Assessment of Cubic Boron Nitride Grinding Wheels. J. Clean. Prod. 2015, 107, 707–721. [Google Scholar] [CrossRef]

- Regufe, M.J.; Pereira, A.; Ferreira, A.F.P.; Ribeiro, A.M.; Rodrigues, A.E. Current Developments of Carbon Capture Storage and/or Utilization–Looking for Net-Zero Emissions Defined in the Paris Agreement. Energies 2021, 14, 2406. [Google Scholar] [CrossRef]

- Gross, D.; Hanenkamp, N. Energy Efficiency Assessment of Cryogenic Minimum Quantity Lubrication Cooling for Milling Operations. Procedia CIRP 2021, 98, 523–528. [Google Scholar] [CrossRef]

- Eurostat Statistics Explained, Electricity Price Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_price_statistics#Electricity_prices_for_non-household_consumers (accessed on 1 October 2024).

- Eurostat Statistics Explained, Hourly Labour Costs. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Hourly_labour_costs (accessed on 1 October 2024).

| Condition | Part 1 | Part 2 |

|---|---|---|

| Yearly production—Parts | 30,000 | 120,000 |

| Part purchase value—EUR | 20 | 3.5 |

| Cutting Fluid | Vc—m/min | fv—mm/v | ap—mm | Tool Life—m | Tool Life—min |

|---|---|---|---|---|---|

| LCO2 | 200 | 0.05 | 0.1 | 7000 | 35 |

| Blown Air | 200 | 0.05 | 0.1 | 4000 | 20 |

| Impact Indicator | 1 kWh | Tool Tip | 1 kg LCO2 | 1 L/min Air x min |

|---|---|---|---|---|

| Global warming potential [kg CO2 eq] | 2.48 × 10−1 | 7.30 × 10−1 | 8.94 × 10−2 | 4.59 × 10−5 |

| Acidification [kg SO2 eq] | 3.56 × 10−1 | 3.15 × 10−3 | 1.28 × 10−4 | 6.59 × 10−8 |

| Freshwater eutrophication [Kg Peq] | 8.07 × 10−5 | 4.15 × 10−3 | 2.91 × 10−5 | 1.49 × 10−8 |

| Water depletion [m3] | 5.77 × 10−2 | 1.55 × 10−1 | 2.08 × 10−2 | 1.07 × 10−5 |

| Ozone depletion [kg CFC-11 eq] | 1.72 × 10−8 | 5.87 × 10−8 | 6.19 × 10−9 | 3.18 × 10−12 |

| Photochemical oxidant formation [kg NMVOC eq] | 2.70 × 10−4 | 1.36 × 10−3 | 9.76 × 10−5 | 5.00 × 10−8 |

| Item | Cost (EUR) |

|---|---|

| Hard-turning machine | 500,000 |

| LCO2 equipment | 40,000 |

| Tool tip | 20 |

| LCO2 liter | 1.5 |

| Hourly labor | 35.6 |

| 1 kWh energy | 0.2008 |

| Years After Investment | Return on Investment—EUR, k | |

|---|---|---|

| LCO2 | Air | |

| 1 | −424.37 | −406.02 |

| 2 | −308.74 | −312.04 |

| 3 | −193.11 | −218.06 |

| 4 | −77.48 | −124.09 |

| 5 | 38.15 | −30.11 |

| 6 | 153.78 | 63.87 |

| 7 | 269.42 | 157.85 |

| 8 | 385.05 | 251.83 |

| Years After Investment | Return on Investment—EUR, k | |

|---|---|---|

| LCO2 | Air | |

| 1 | −456.07 | −367.44 |

| 2 | −372.14 | −234.88 |

| 3 | −288.21 | −102.32 |

| 4 | −204.28 | 30.24 |

| 5 | −120.35 | 162.80 |

| 6 | −36.42 | 295.36 |

| 7 | 47.51 | 427.92 |

| 8 | 131.43 | 560.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Llanos, I.; Urresti Espilla, I.; Bilbatua, D.; Zelaieta, O. Evaluation of Sustainability and Cost Effectiveness of Using LCO2 as Cutting Fluid in Industrial Hard-Turning Installations. Sustainability 2024, 16, 10078. https://doi.org/10.3390/su162210078

Llanos I, Urresti Espilla I, Bilbatua D, Zelaieta O. Evaluation of Sustainability and Cost Effectiveness of Using LCO2 as Cutting Fluid in Industrial Hard-Turning Installations. Sustainability. 2024; 16(22):10078. https://doi.org/10.3390/su162210078

Chicago/Turabian StyleLlanos, Iñigo, Iker Urresti Espilla, David Bilbatua, and Oier Zelaieta. 2024. "Evaluation of Sustainability and Cost Effectiveness of Using LCO2 as Cutting Fluid in Industrial Hard-Turning Installations" Sustainability 16, no. 22: 10078. https://doi.org/10.3390/su162210078

APA StyleLlanos, I., Urresti Espilla, I., Bilbatua, D., & Zelaieta, O. (2024). Evaluation of Sustainability and Cost Effectiveness of Using LCO2 as Cutting Fluid in Industrial Hard-Turning Installations. Sustainability, 16(22), 10078. https://doi.org/10.3390/su162210078