Abstract

High-quality development enhances economic quality and resource allocation efficiency through various effective and sustainable means, with particularly notable results in the manufacturing sector. Quality policies, through establishing standards, norms, and incentive measures, aim to foster technological innovation, efficient resource utilization, and quality improvement in manufacturing, thereby supporting its high-quality development. This study explores the impact of quality policies on high-quality development in manufacturing and their configurational pathways, providing theoretical foundations and practical guidance for optimizing policy combinations and promoting sustainable development. This analysis is based on quality policies released from 2013 to 2022 and sample data from 30 Chinese provinces. The findings reveal that quality policies significantly promote high-quality development in manufacturing, particularly through incentive, capacity building, and system changing instruments, while command instruments may exert certain pressures on high-quality development. Configuration analysis further indicates that a single instrument is insufficient to support high-quality development in manufacturing fully; the synergistic effect of multiple policy instruments is essential, and regions should optimize policy combinations according to their characteristics. This study provides valuable insights for sustainable development, offering a deeper understanding of the complex causal relationship between quality policies and high-quality development in manufacturing.

1. Introduction

Sustainable development is a core aspect of high-quality development that emphasizes coordinating economic growth, environmental protection, and social equity. Achieving high-quality development not only requires progress in economic efficiency but also ensures the sustainable use of resources and the protection of the ecological environment. As China moves into a new stage of high-quality development, quality policies are playing an increasingly important role in promoting sustainable development. Quality policies enhance the standards of products and services, promote the effective allocation of resources, and drive green technologies and innovations, helping to address issues such as environmental pollution and resource waste. Therefore, it is crucial to assess the impact of quality policies on high-quality development.

From the perspective of high-quality development, its manifestations can be observed at the micro level in products, the miso level in industries, and the macro level in the national economy and productivity. High-quality development can be observed at three levels: micro (in products), meso (in industries), and macro (in the national economy and productivity).

Since the concept of high-quality development was proposed, it has been explored from multiple perspectives in academia. Bei [1] examines the connotation of high-quality development and its related theoretical issues from an economic theory perspective. He argues that high-quality development is centered on the new development concepts of innovation, coordination, greenness, openness, and sharing. Unlike the traditional economic development model that focuses on GDP growth, high-quality development emphasizes the quality and efficiency of economic growth rather than merely pursuing the quantity of economic growth. It calls for a shift from traditional quantity-oriented economic growth policies to policies that prioritize quality and efficiency. Chen [2] explores the close relationship between high-quality development and ecological urban construction, asserting that high-quality development requires not only economic growth but also environmental sustainability and the enhancement of social welfare. Xue [3] emphasizes the importance of corporate social responsibility for high-quality development, particularly in the current context of pursuing sustainable development and environmental protection. He suggests that promoting high-quality development can be achieved more effectively through green innovation and environmental investment, providing significant theoretical support and practical guidance for policy formulation. Jahanger [4] finds that the impact of foreign direct investment (FDI) on China’s high-quality development varies significantly. High-tech and high-value FDI can contribute to technological innovation and the optimization of economic structure, promoting green and sustainable development. He recommends that the government adopt differentiated strategies in FDI policies to maximize the positive effects of FDI on high-quality development.

The ultimate goal of high-quality development is to meet people’s growing needs for a better life, requiring development to be of high quality, effective, and sustainable. The introduction of the 2023 Outline for Building a Quality Strong Nation is a significant measure to promote high-quality development, with its guiding principle being the enhancement of the quality of products, projects, and services. The proposal to build a quality, strong nation aims to promote sustained economic growth, keep pace with the times, follow economic laws, and shift from quantitative to qualitative growth. However, on the supply side, China still faces challenges in meeting the basic quality needs of its people in areas such as food, medicine, engineering, environment, and services. Additionally, systemic issues such as imperfect factor markets, resource allocation, and quality assurance systems persist. Therefore, high-quality development requires both the effective supply of micro-level products, projects, and services and is an intrinsic requirement for economic high-quality development.

Quality development and improvement are inseparable from the guidance of quality policies. Quality policies are regarded as a series of laws, regulations, and administrative rules used to convey Party and State guidelines, enhance the value of products, projects, and matters in multiple dimensions, meet corresponding expectations, and promote the construction and development of relevant matters. Over the years, the proposals of documents like the Outline for Quality Revitalization and the Outline for Quality Development have governed the overall quality development landscape. These series of quality policies issued subsequently have continuously improved quality levels in the fields of products, projects, and services, with these core documents as the center. Quality policy levers have played a crucial guiding and promoting role in the process of quality development in China. For example, manufacturing pass rates have stayed above 93% for five years, China ranks second in international patent applications, and public service satisfaction has reached 79 points. However, it is still important to recognize that challenges remain on the supply side in meeting the basic quality needs of the people, such as in food, medicine, engineering, environment, and services. Systemic issues such as imperfect factor markets, resource allocation, and quality assurance systems also persist.

The sustainable development of the manufacturing sector is the most direct manifestation of high-quality development. Currently, scholars have conducted extensive explorations on the sustainable development of manufacturing. For example, Zhang [5] found that while foreign-funded enterprises have brought advanced technology and management experience, their impact on the skill enhancement of low-skilled workers is limited, failing to significantly reduce the wage gap associated with skills. The average wage level in economically developed coastal regions is significantly higher than that in inland areas, further exacerbating wage inequality between regions. The government should take measures to guide foreign direct investment (FDI) to flow more into inland and economically underdeveloped regions to reduce regional wage disparities and promote sustainable development in manufacturing. Han [6] discovered that the regional differences in the high-quality development of China’s manufacturing industry reflect the issue of unbalanced economic development. Reasonable policy guidance and resource allocation are needed to enhance the level of high-quality development in manufacturing across different regions, achieving regional coordination and sustainable development goals.

Another group of scholars has explored the issue from a policy perspective. He [7] revealed the significant role of free trade zone policies in promoting regional innovation capabilities, arguing that policy implementation positively impacts economic transformation and high-quality development. Xie [8] examined the varying effects of different policy instruments in China’s implementation of the Sustainable Development Goals (SDGs), noting that command type policies are effective in enforcement but may face issues of inadequate implementation by local governments. Incentive type policies excel in promoting investment and technological innovation, but have limited impact on long-term sustainability. Capacity building policies help enhance the overall effectiveness of policy execution. Many research findings indicate that policies play an important role in promoting sustainable development and high-quality development in China. As quality improvement is a crucial foundation for high-quality development, a question arises: do quality policies promote sustainable development and high-quality development in China?

Simultaneously, previous regression-based methods have typically explored the effects of single factors, thereby failing to consider the inherently multifaceted and complex nature of high-quality development. The impact of policies is complex, often involving combinations of different policy instruments to achieve policy goals, resulting in multiple pathways under different policy tool combinations. These combinations can either complement and reinforce each other or produce opposing effects due to negative interactions. The academic community frequently employs configurational methods to elucidate the causality behind these complex issues, providing a valuable insight for this study [9].

Although sustainable development has become an important research topic globally, the current academic literature primarily focuses on the factors influencing sustainable development, such as economic growth, social equity, and environmental protection. However, the systematic exploration of the role of policies in sustainable development remains relatively scarce. Most existing studies concentrate on specific policies, such as sustainable development policies or trade policies, failing to comprehensively consider quality policies as a key factor. Quality policies play a crucial role in the relationship between high-quality development and sustainable development; however, they have received little in-depth discussion in the existing literature. Quality policies not only pertain to products and services but also influence enterprises’ innovation capabilities, competitiveness, and market adaptability. Therefore, incorporating quality policies into the framework of sustainable development research will help provide a comprehensive understanding of how policies affect the synergistic development of the economy, society, and environment.

To fill this research gap, this paper aims to explore the role of quality policies in the sustainable development and high-quality development of China’s manufacturing industry, providing a more systematic and comprehensive perspective. This paper systematically analyzes the role of five quality policy tools in China’s manufacturing industry, explores the impact of different tool combinations on high-quality development, and provides theoretical support for optimizing policy configuration and future policy formulation. It reveals significant differences in the demand for policy tools between the eastern, central, western, and northeastern regions, and emphasizes the importance of differentiated policy implementation based on regional characteristics for precise governance. Analyzing changes in the configuration of policy instruments from a dynamic perspective deepens the theory of policy instruments and combines quality policies with sustainability and high-quality growth, which makes up for the shortcomings of the existing literature and provides new paths for future research.

2. Institutional Background and Theoretical Foundation

2.1. Institutional Background

With the substantial progress made by China’s economy over the past decade, positioning itself as the world’s second-largest economy and acting as a “ballast stone” for global economic growth, the 19th National Congress of the Communist Party of China declared that “China’s economy has transitioned from a phase of rapid growth to a stage of high-quality development”. The 20th Congress emphasized that “high-quality development is the primary task in the comprehensive construction of a socialist modern country” and proposed the building of a quality strong nation, culminating in the issuance of the Outline for Building a Quality Strong Nation, an essential measure to implement the spirit of the 20th Congress. However, despite its rapid economic development, China still faces a series of quality issues. The Outline for Building a Quality Strong Nation points out that “currently, the improvement of quality levels in China still lags behind economic and social development, and the foundation for quality development is not yet solid”.

Quality drives economic prosperity; strong quality leads to robust industries. The promulgation and implementation of quality policies are critical institutional measures to address quality issues. At the beginning of China’s reform and opening-up, the transition from a planned economy to a market economy led to rapid social and economic development, significantly improving people’s living standards and material needs. However, due to a shortage of various goods and a relative lack of quality awareness, severe quality issues emerged. To address these issues, policy documents such as the “Draft Decision on Accelerating Industrial Development” (1978), the “Notice on Excluding Substandard Products from Production and Output Calculations” (1980), and the “Interim Measures for Comprehensive Quality Management in Industrial Enterprises” (1980) were issued. The State ensured product quality by centrally controlling resources and production, but the quality management mechanisms of this period were relatively singular and lacked the impetus of market competition.

As the reform and opening-up deepened, especially after China acceded to the World Trade Organization (WTO), there was a significant contrast between the quality of imported and exported products, subjecting China to intense quality competition. Gradually, China recognized that quality is a key factor in enhancing comprehensive national strength. In 1998, the State Bureau of Quality and Technical Supervision was incorporated into a direct subordinate agency of the State Council, marking the beginning of a relatively stable period for China’s quality management. To bridge the gap with international standards, the “Outline for Quality Revitalization (1996–2010)” was issued in 1996, outlining a long-term plan for China’s quality development and expanding the scope of its quality policies. The government began to emphasize the improvement of product quality through standardization and certification systems, promoting quality development in various fields such as products, projects, services, and education.

Since the 18th National Congress, General Secretary Xi Jinping has repeatedly emphasized that quality is the foundation for development. In his letter to the 39th ISO General Assembly, he stressed the importance of quality across multiple fields. Documents such as the “Outline for Quality Development (2011–2020)”, the “Plan for Standardization and Quality Improvement of Equipment Manufacturing Industry”, and the “Plan for Standardization and Quality Improvement of Consumer Goods (2016–2020)” have driven quality improvements in products, projects, services, and other areas.

Quality is the cornerstone of economic development and daily life. The issuance of the Outline for Building a Quality Strong Nation was a crucial measure to enhance the quality of China’s economy, promote high-quality development, and transform the economy from large to strong. Policies like the Implementation Opinions on Excellent Quality Engineering in Manufacturing, the Implementation Opinions on Water Conservancy Quality, and the 2023 Work Guidelines for High-Quality Intellectual Property Development have followed. These policies aim to improve the quality of products, projects, and services, placing the focus of economic construction and development on quality, thereby laying the foundation for building a quality strong nation and achieving high-quality development.

Reviewing the development and evolution of quality policies over the years, the focus on quality policies has extended beyond merely satisfying the level of excellence in matters, products, and services. It has expanded the scope of “excellence” to include efficiency, ecology, innovation, and the economy, promoting multidimensional development. This provides a practical basis for the research presented in this paper.

The proposal of the Quality Development Outline (2011–2020) has promoted the sound and coordinated development of China’s quality work system. The regulations have gradually improved, including the Product Quality Law, Standardization Law, and other laws and administrative rules, forming a responsibility system for quality work. In terms of product quality in the manufacturing industry, we have focused on improving industrial quality, with special attention paid to establishing quality management systems for small and micro enterprises. The quality of manufacturing products has achieved a pass rate of over 93% for five consecutive years, with aerospace and rail transit reaching internationally advanced levels, and the manufacturing quality competitiveness index reaching 84.78. Therefore, this article will analyze the quality policy of the manufacturing industry as its research object.

2.2. Government Regulation Theory

Government regulation theory encompasses various ways and methods through which governments intervene in market behavior, primarily through the promulgation and implementation of legally effective administrative measures such as permits, incentives, and constraints. These measures manage and regulate economic entities to achieve specific social, economic, and environmental goals [10]. In a perfectly competitive market, economic entities are influenced by the “invisible hand”, achieving Pareto efficiency in resource allocation [11]. However, in the real world, no market operates under perfect competition, and the “invisible hand” fails to effectively allocate resources, leading to market failures. Thus, government regulation becomes an effective means to address market deficiencies [12]. Government regulatory actions impact market economic activities by identifying opportunities and shaping the necessary institutional environment based on these opportunities, laying the operational foundation for economic activities to achieve optimal resource allocation efficiency.

Furthermore, in the conditions of imperfect competition, the theory of information asymmetry posits that in an environment where both parties possess unequal information about a transaction, the Party with the information advantage may exploit their position to the detriment of the other Party, thereby reducing resource allocation efficiency [13]. Market failures arising from this phenomenon are not limited to product quality issues but also manifest in labor markets and environmental protection. To maintain market fairness and avoid market failures, government regulation reduces uncertainty, mitigates negative externalities, and stabilizes market expectations to some extent.

The development of government regulation theory has been widely applied to explain practical issues such as agricultural safety production [14], carbon emission reduction [15], and corporate environmental responsibility [16]. Government regulation exists outside enterprises, providing external supervision and governance.

Government regulation theory, based on market failure theory, holds that markets sometimes cannot efficiently allocate resources, requiring government intervention to protect public interests and maintain order. Typical forms of market failure include information asymmetry and asymmetrical information between firms and consumers, or between firms and the government, which can lead to inferior products or services entering the market, thereby reducing overall market efficiency. Externalities occur when firm activities produce negative effects, like pollution or safety hazards, that the market cannot address, requiring government intervention. Public goods and some products and services possess the characteristics of public goods, such as public services and infrastructure, which the market mechanism is unable to provide efficiently. Based on market failure theory, the primary goal of government regulation is to ensure market fairness, efficiency, and the maximization of public interest through policies and regulations. As part of government regulation, quality policies mainly aim to improve the quality of products and services through measures such as standard setting, quality monitoring, and technical support, thereby promoting high-quality development.

The theory of government regulation originates from the market failure theory, which posits that market mechanisms may fail to allocate resources effectively under certain circumstances, necessitating government intervention to maintain market order and safeguard public interests. Typical market failures include the following:

Information asymmetry: information asymmetry between enterprises and consumers, or between enterprises and the government, can lead to the entry of substandard products or services into the market, thereby reducing overall market efficiency;

Externalities: the production and operational activities of enterprises may generate negative externalities, such as environmental pollution or safety hazards, which cannot be effectively addressed through market mechanisms and require government intervention.

Based on the market failure theory, the primary goal of government regulation is to ensure fairness, efficiency, and the maximization of social public welfare through the formulation of policies and regulations. As a part of government regulation, quality policies primarily aim to improve the quality of products and services through measures such as standard-setting, quality monitoring, and technical support, thereby promoting high-quality development.

Manufacturing drives economic development, but globalization and technological changes push many enterprises to prioritize low costs and efficiency over quality improvement. Intense competition in manufacturing leads some enterprises to chase short-term profits by reducing product quality or ignoring innovation, causing information asymmetry and a rise in low-quality products. Due to cost considerations, manufacturing enterprises may neglect technological innovation. In this context, the government, through quality policies, provides research and development (R&D) funding and technical standard support, encouraging enterprises to innovate and enhance product competitiveness. Additionally, to ensure fair competition and consistent product quality in the market, the government needs to establish unified quality standards and monitoring mechanisms to prevent the circulation of substandard products. Quality policies that set industry standards and encourage innovation can tackle market failures, improve product quality, and boost the global competitiveness of manufacturing.

2.3. Signaling Theory

Signaling theory, first proposed by Spence [17], primarily examines how market participants transmit and receive signals to reduce uncertainty in the presence of information asymmetry, Lerner applied this theory to the policy domain, expanding its reach beyond economics to fields such as management, finance, and marketing, making it a vital tool for understanding and explaining information asymmetry phenomena [17].

In the context of policy signaling, the focus is on how governments communicate signals through policies, statements, and actions to influence the behavior and decisions of the public, markets, and other countries. Research on policy signaling mechanisms has gradually extended to multiple fields. In economic policy, governments convey signals about economic prospects and policy intentions through fiscal and monetary policies. For instance, when a government announces tax cuts, the market may interpret this as a signal of economic stimulus, thereby boosting confidence and increasing investment and consumption [18]. Similarly, governments may use ESG (environmental, social, and governance) policies to signal their environmental commitments, thereby encouraging enterprises to engage in green innovation [19].

In public health policy, researchers focus on how governments signal information to the public through actions such as health guidelines and vaccination programs. For example, the implementation of a sugar-sweetened beverage (SSB) tax can signal the health risks associated with such beverages to the public, thereby reducing SSB sales. This policy intervention is seen as an effective public health measure aimed at changing consumer behavior and improving public health [20].

In recent years, quality policies have evolved beyond addressing initial quality issues to encompass a multidimensional approach to quality development, including regulation of quality, innovation, and environmental protection, as seen in the implementation of policies such as the Implementation Opinions on the Excellence in Manufacturing Quality Engineering and the Guidance on Promoting High-Quality Development of the Light Industry. However, existing research suggests that while the stringent requirements of such policies may have a negative impact on economic entities in the initial stages, they can eventually compel these entities to enhance their capabilities, thus leading to positive outcomes over time [16]. At the same time, regional differences may exist due to varying levels of economic development and infrastructure conditions across regions. Therefore, this study hypothesizes that quality policies, through constraints and incentives, focus economic development on quality, serving as a foundation for building a quality-driven nation. These policies may have a positive impact on the high-quality development of the manufacturing sector, but they may also have negative effects, with regional disparities being evident.

3. Materials and Methods

3.1. Data Sources and Variable Setting of Quality Policy

3.1.1. Data Sources and Selection of Policy Instruments for Quality Policy

From the perspective of quality connotation, “quality” can be regarded as a measure of the excellence of things, work, and products [21]. It encompasses multiple dimensions, with its foundation being value enhancement that meets a series of expected behaviors [22]. Quality policy can be defined as a series of documents, including notices, opinions, plans, regulations, and others, used to convey the guidelines of the Party and the State, enhancing the value of products, work, and things in multiple dimensions, and meeting corresponding expectations to promote the construction and development of related matters.

This study uses McDonnell’s policy instrument theory, based on domestic and international research on policy tools [23]. First, McDonnell’s theory is well-suited to China’s policy structure and has been widely used in Chinese policy analysis, offering valuable insights for this research. Second, China’s quality policies—covering mandatory standards, talent development, incentives, system creation, and promotion—align with McDonnell’s categories of command-and-control, incentive-based, and capacity building instruments, making this selection logical and effective.

3.1.2. Dimensions and Standards for Quantitative Evaluation of Policy Effectiveness

Policy effectiveness refers to the validity of policy content and its additional impact. There is a relatively unified consensus in academia on its quantification, represented by a three-dimensional policy text quantitative evaluation model comprising policy intensity, policy measures, and policy objectives [24].

Policy intensity describes the administrative level and legal effectiveness of the issuing institution. The higher the legal status and administrative level of the issuing department, the greater the policy intensity. Policy objectives describe the measurability of the goals to be achieved by the policy; the more quantifiable the policy objectives, the higher the score, as quantitative targets are easier to achieve [25]. Policy measures are the methods and means adopted in the policy text to achieve policy objectives. Based on the characteristics of quality policy text content organized in this study, policy measures are categorized into command-and-control, incentive-based, symbolic and exhortative, capacity building, and systemic change.

Drawing on the evaluation model constructed by Peng [24] and others, quality policies are quantified across three dimensions: policy intensity, policy measures, and policy objectives. The specifics are shown in Table 1 and Table 2.

Table 1.

Scoring standards for policy intensity and policy objectives.

Table 2.

Scoring standards for policy measures of policy instruments.

3.1.3. Policy Effectiveness Evaluation Model

After establishing the quantitative standards for quality policies, a scoring group comprising 2 experts in the field and 10 graduate students was invited to score the policies according to the established standards. Any discrepancies were resolved through joint discussion to finalize the scores for each policy document. Based on these scores, the overall effectiveness of quality policies for each year was calculated using Equation (1), and the average effectiveness value for a single year’s quality policies was calculated using Equation (2).

where ZLPi refers to the overall effectiveness value of quality policies in year i, and AZLPi refers to the average effectiveness value of quality policies in year i. i represents the year when the policy begins to be implemented, j refers to the j-th policy executed in year i, N denotes the number of policies initiated in year i, pj is the policy strength score for the j-th policy, and (mj + gj) represents the policy measures and goals scores for the j-th policy.

Quality policies are numbered according to their publication order. Each measure within the policy is encoded based on its chapters and clauses, with the encoding format being “1—A\B\C\D\E”. The first number indicates the policy number, while the letters A, B, C, D, and E represent the command type, incentive type, symbolic and exhortative-type, capacity building type, and system changing type instruments, respectively. p denotes the policy strength score, mmm indicates the policy measures score, and g represents the policy goals score. s is the policy tool text effectiveness score.

3.2. Construction of High-Quality Development Indicators for Manufacturing Industry

The concept of high-quality development in the manufacturing sector is relatively rich, and scholars mainly conduct research on evaluation indicators of high-quality development in manufacturing from two perspectives. The first perspective uses total factor productivity (TFP) to reflect the level of high-quality development in manufacturing, such as the contribution rate of TFP to economic growth [26], and the calculation of TFP for listed manufacturing companies using the OP method [27]. The second perspective involves constructing indicators based on the concept and connotation of high-quality development, such as a five-dimensional indicator system based on quality, green development, talent, innovation, and structure [28].

Referring to the connotation of high-quality development in manufacturing, as well as the research findings of many scholars [29], and considering data availability, this paper defines the connotation of high-quality development in manufacturing as follows: it should focus on economic efficiency, place innovation at its core, support green development, emphasize industrial coordination as a key element, and consider openness as a supplementary aspect. Based on this, five dimensions of measurement indicators are constructed, as shown in Table 3.

Table 3.

Indicator Attribute and Weights of high-quality development of manufacturing industry indicators.

3.3. Data Sources, Indicator Measurement, and Variable Definitions

3.3.1. Data Sources

- Data Sources for Quality Policies

Based on the objective requirements of authority and universality for the research subjects, this study focused exclusively on policies issued at the national level to ensure consistency in policy research. The primary source for retrieval was the Peking University Law Database for laws and regulations, supplemented by the China Policy Network and the website of the Central People’s Government of the People’s Republic of China. Text searches were conducted using core keywords such as “quality”, “high quality”, and “improvement”. Considering that the indicators for high-quality development in manufacturing were only updated until 2022, policy texts from 2013 to 2022 were searched. After three rounds of manual review and screening to eliminate low-relevance and duplicate texts, a total of 716 valid quality policy texts were obtained as research samples. Among them, 129 policies related to manufacturing quality were manually selected as the research samples.

- Data Sources for Indicators of High-Quality Development in Manufacturing

Considering the availability of data samples, this study covered the period from 2013 to 2022 and selected panel data from various provinces in China for empirical research. Due to significant missing indicators from Hong Kong, Macao, Taiwan, and Tibet, only data from the remaining 30 provinces were included. The sample data were sourced from the “China Statistical Yearbook”, “China High-Tech Industry Statistical Yearbook”, “China Science and Technology Statistical Yearbook”, “China Energy Statistical Yearbook”, “China Industrial Statistical Yearbook”, as well as data from the National Bureau of Statistics. For individual missing data points, the geometric growth rate method and interpolation method were used to fill in the gaps.

3.3.2. Measurement of High-Quality Manufacturing Industry Development Indicators

Considering the potential strong correlations among the dimensions of high-quality development indicators, which may lead to multicollinearity issues in the model, this study adopted the entropy weight method to assign weights to the indicators. This method was not influenced by subjective judgment and had a certain degree of scientific and objectivity. The specific results were as follows:

3.3.3. Variable Definition and Selection

- Dependent Variable

Based on existing research findings and considering the relevant content of quality policies and data availability, the evaluation system for high-quality development in manufacturing was constructed with five primary indicators: innovation-driven, economic efficiency, industrial coordination, green development, and degree of openness. This was further subdivided into a total of 20 secondary indicators. The entropy method was used to calculate the level of high-quality development in manufacturing across provinces.

- Independent Variable

Documents such as policies and regulations in China served as important references for guiding development directions and pathways. Existing research indicated that the quantification and assignment of policy effectiveness proposed by Peng Jisheng [24] had feasibility and reference value, while also avoiding the subjectivity issues associated with expert scoring. Therefore, the effectiveness of quality policies corresponding to manufacturing is used as the independent variable.

- Control Variables

Based on existing theories and empirical research findings, select the Degree of Government Intervention, Urbanization Rate, Economic Development Level, Return on Assets, Leverage Ratio, and Growth Potential as control variables for empirical analysis.

4. Results and Discussion

4.1. Manufacturing Industry High-Quality Development Model Specification

4.1.1. Model Specification

This study examined the direct impact of manufacturing quality policies on the sector’s high-quality development, considering potential regional differences. We accounted for the typical lag in policy effectiveness after implementation. Referencing existing research findings, we considered the impact of policies lagging by one period. Additionally, since the effectiveness of a policy is not solely influenced by the current policy issuance but also by the cumulative effects of past policies, this paper used the high-quality development indicators from the previous period to represent the cumulative effects of past policy issuances. The regression model was constructed as follows:

In model (3), the subscript i represents the province, and t represents the year. HDMi,t denotes the level of high-quality development of manufacturing industry, while HDMi,t−1 indicates the value of policy effects in the previous period. MLZ, JLZ, NLZ, XZZ, XTZ represent the effectiveness of the command type, the incentive type, the capability building type, the symbolic and hortatory type, the capacity building, and the system changing policy instruments, respectively. Control includes the degree of government intervention, the urbanization rate, the economic development level, the asset return rate, and others denote year fixed effects, nt represents province fixed effects, and εi,t is the random disturbance term.

4.1.2. Empirical Results

- Descriptive Statistics

Table 4 analyzes the descriptive statistics for each variable in the model. It reveals significant disparities in the levels of high-quality development in manufacturing across provinces, with a maximum value of 0.674, a minimum value of 0.0619, and an average of 0.155. There were also considerable differences in policy effectiveness: for command type policies, the maximum value was 2590, the minimum value was 288, and the average was 1275. For incentive type policies, the maximum value was 450, the minimum value was 36, and the average was 233.6. For capacity building policies, the maximum value was 764, the minimum value was 120, and the average was 285.2. For symbolic and hortatory policies, the maximum value was 284, the minimum value was 24, and the average was 139.1. For system changing policies, the maximum value was 314, the minimum value was 24, and the average was 125. These statistics illustrate the varied landscape of manufacturing quality development and the differing impacts of various policy tools across provinces.

Table 4.

Descriptive statistics of manufacturing industry high-quality development variables.

- Collinearity Test

To prevent inflated standard errors caused by multicollinearity, which can lead to insignificant regression results, the variance inflation factor (VIF) values for each variable were calculated. According to the results in Table 5, the individual VIF values for each variable, as well as the overall VIF value, were all below 10. Some studies suggest that a variance inflation factor (VIF) value exceeding 10 indicates a significant multicollinearity issue, while others adopted a more conservative threshold of 5. According to James [9], a VIF value greater than 5 does not necessarily indicate a serious problem, particularly when all variables are core independent variables rather than control variables. Furthermore, even if the VIF surpasses 5, it may not adversely affect the overall validity of regression analysis, especially in larger samples. This study utilized data from 30 provinces in China from 2013 to 2022 and included 129 policy texts, resulting in a relatively large sample size. Therefore, the presence of certain variables with a VIF greater than 5 did not undermine the findings of this research, allowing us to proceed to the next step of the analysis.

Table 5.

Results of the collinearity test for variables.

- Baseline Model Results

Before conducting the regression model analysis, a Hausman test was performed. The results indicated a p-value of less than 0.01, thus the fixed effects model was selected. Table 6 presents the baseline results of the impact of quality policies on high-quality development in the manufacturing sector. In the regression model, the control variables included the government intervention level, the urbanization rate, the economic development level, the return on assets, and the revenue growth rate. The regression model has been subjected to a robust check.

Table 6.

Baseline Regression Results.

Based on the regression results presented in Table 6, it is evident that the policy tools embedded within the manufacturing quality policies exhibited varying degrees of significance, with the notable exception of the symbolic and hortatory policy tool, which lacked statistical significance. This lack of significance may have stemmed from the inherent nature of symbolic and hortatory policies, which do not provide direct economic incentives. Consequently, their ability to influence the behaviors of manufacturing entities was limited. These tools often depend on the reputational leverage of government or industry associations; however, such influence may not be robust enough to effectively guide and constrain enterprise behavior in the manufacturing sector.

Among the findings, the negative coefficient associated with the command type policy tool indicated a detrimental relationship between this tool and high-quality development in manufacturing. This adverse impact may be attributed to excessively stringent quality standards that impose heightened operational costs on enterprises. For instance, the requirements for technological upgrades, equipment renewal, and employee training can create significant financial burdens. These cost pressures may compel companies to curtail investments in other critical areas, such as research and development innovation. Consequently, this reduction in investment can hinder overall high-quality development, suggesting a need for a more balanced approach to policy implementation.

In contrast, incentive type and capacity -building policy tools provide crucial support through mechanisms such as funding, tax benefits, demonstration projects, and infrastructure improvements. Such support is instrumental during technological upgrades and innovation processes within the manufacturing sector. By alleviating financial constraints, these tools enable manufacturing entities to effectively meet higher quality standards. This not only facilitates the optimization and upgrading of industrial structures but also enhances resource utilization efficiency and minimizes waste and environmental pollution. These outcomes align seamlessly with the principles of sustainable development, contributing to green development initiatives while concurrently reducing operational costs for enterprises.

Additionally, system changing policy tools play a vital role in enhancing government regulatory capabilities. They help to establish market order, combat counterfeit and substandard products, and maintain a fair competitive environment. Such regulatory measures foster a virtuous cycle of competition that can drive improvements in high-quality development levels within manufacturing. For instance, the effective enforcement of quality standards can lead to increased consumer trust and market demand for higher-quality products, thereby incentivizing enterprises to prioritize quality.

However, it is worth noting that the coefficient for the level of government intervention was negative and significant at the 5% level. This finding suggests that increasing government intervention in manufacturing entities may inadvertently suppress high-quality development in this sector. Such suppression may stem from excessive regulation, which limits the innovation capacity and flexibility of enterprises.

Strict government oversight of manufacturing companies can lead to additional costs in complying with regulations and standards, including investments in human resources, time, and financial resources. These costs may inhibit enterprises’ investments in technological innovation and market adaptation. For instance, companies may prioritize funding for compliance over research and development (R&D) innovation in order to meet regulatory requirements. Frequent regulatory demands may lead to instability in strategic planning for enterprises. This uncertainty can weaken companies’ willingness to take risks, thereby limiting their innovation capabilities and flexibility. When faced with an uncertain policy environment, businesses often choose conservative operational strategies, reducing their exploration of new products or markets.

To address this issue, policymakers should consider adopting a more nuanced approach to intervention, striking a balance between regulatory oversight and empowering manufacturing entities to innovate and adapt to changing market conditions. For example, providing clear and stable quality standards and regulatory policies can help enterprises better understand and comply with regulations, thereby reducing the burden of policy uncertainty. Establishing regular communication mechanisms between businesses and government can allow companies to directly provide feedback on challenges and suggestions encountered during policy implementation. This two-way interaction can assist the government in adjusting policies in a timely manner to better support enterprise development. Additionally, the government should flexibly adjust relevant policies according to market changes and industry developments to avoid imposing excessive intervention on enterprises.

4.2. Robustness Checks

To ensure the robustness and reliability of the research findings, this study conducted robustness tests from three perspectives. First, we reduced the number of control variables, retaining only three: government intervention level, urbanization rate, and economic development level. Second, we enhanced the original model by adding the leverage ratio as a control variable. Lastly, we adjusted the sample size, modifying the panel data period from 2013 to 2022 to 2014 to 2021, to observe whether the results were affected.

Through these three methods of robustness testing, the results of the robustness tests were consistent with the baseline regression results, confirming the robustness and reliability of the research conclusions. Due to space constraints and the repetitive nature of the results, we decided not to present the specific tables of the robustness tests. It is worth noting that the results of the robustness tests were consistent with the main analysis results, further supporting the conclusions of this paper.

4.3. Regional Heterogeneity Analysis

The previous sections empirically demonstrated the significance of command type, incentive type, capacity building, and system reform policy tools within quality policies on the high-quality development of the manufacturing industry. This provided fundamental proof that quality policies impact high-quality manufacturing development.

Given the differences in geography, resources, human capital, and levels of economic development across the 30 provinces in China, it is essential to consider whether quality policies may exhibit regional heterogeneity in their effects on manufacturing development. Therefore, based on the regional development policies formulated by the State Council, the 30 provinces were categorized into four major regions: eastern, central, western, and northeastern China. This regional heterogeneity approach allowed for a detailed analysis of the impact of quality policies on high-quality manufacturing development within different sample segments.

The regression results presented in Table 7 reveal the regional differences in the impact of manufacturing quality policies on high-quality development across different areas of China.

Table 7.

Heterogeneity analysis: regional heterogeneity.

The eastern region is the most economically developed area in China, including provinces and cities like Beijing, Shanghai, Guangdong, and Jiangsu. This region ranks among the top nationwide in terms of total GDP and per capita income, with intense market competition and strong economic vitality. This region primarily focuses on manufacturing and service industries, particularly with rapid growth in high-tech industries and modern services. Most enterprises are large or medium-sized, with strong technological innovation capabilities.

From the perspective of policy impact, policy tools—command type, incentive type, capacity building, and system reform—significantly influence the high-quality development of the manufacturing sector. However, the symbolic and hortatory tools show no impact. This may be attributed to the intense market competition in the eastern region, where manufacturing entities focus more on practical market feedback and short-term economic benefits. In contrast, symbolic and hortatory policies often rely on moral and social responsibility to guide behavior, which may be insufficient to alter actual corporate practices.

The central region includes provinces such as Henan, Hubei, and Hunan. Although its economic development level is relatively lower than that of the eastern region, it has shown strong growth momentum in recent years. The economic structure in the central region is gradually transitioning towards higher-quality development. Traditionally, the region has been dominated by manufacturing and agriculture, but with government policy support, it is steadily developing high-tech industries and modern services. The enterprises in this region are generally smaller in scale, with innovation capabilities that need further enhancement.

From the perspective of policy impact, all the policy tools except for the command type significantly affect high-quality manufacturing development. This discrepancy might arise from shortcomings in the execution and supervision of policies by administrative agencies in this region, leading to inadequate implementation and less noticeable effects. Furthermore, the strict nature of command type tools may lack feasibility and flexibility in practical application, conflicting with the market adaptability and operational habits of manufacturing entities.

The western region includes provinces such as Sichuan, Yunnan, and Shaanxi. The overall economic development level is relatively low, but in recent years, the region has seen accelerated growth due to national policy support, attracting increased investment. The economy in the western region is primarily based on resource-oriented industries and agriculture. In recent years, there has been a strong push towards industrialization and urbanization. Most enterprises in this region are small local businesses, facing challenges related to limited technological capacity and management skills.

From the perspective of policy impact, all the manufacturing quality policy tools significantly contribute to high-quality development, indicating a more uniformly positive impact across the board.

Interestingly, in the northeastern region, only capacity building and system reform policy tools show significant effects on high-quality development. This suggests that local administrative agencies play a crucial role in this region.

The northeastern region, which includes Liaoning, Jilin, and Heilongjiang provinces, has historically been known as a heavy industry base. However, due to its single-industry structure and changing market conditions, economic growth has been sluggish, leading to pressure for transformation. This region’s industries are primarily concentrated in heavy industry and traditional manufacturing. In recent years, local governments have implemented revitalization policies, aiming to guide industries toward high value-added sectors. Although the region’s innovation capacity is relatively weak, it is gradually improving through the introduction of external resources and policy support.

From the perspective of policy impact, the northeastern manufacturing sector has a historical foundation in traditional heavy industry, but due to various historical reasons, it lags in modern manufacturing technology and innovation capacity. With the gradual advancement of the revitalization strategy in northeast China, local administrative bodies are guiding resources towards industries with high added value and technological content. They are also improving the policy environment and reducing operational burdens on enterprises through measures like infrastructure development, management training, talent recruitment and training, and institutional optimization. These efforts help to invigorate corporate vitality and stimulate innovation momentum.

Therefore, in the economically developed eastern region, where market competition is intense and enterprises have strong technological innovation capabilities, policies should focus on tools that can directly incentivize market behavior. Building on existing incentive-based policies, the government can further encourage continuous innovation and technological upgrading through tax reductions, R&D subsidies, and innovation awards. At the same time, capacity building tools should also play a key role. By strengthening collaborations between industry, academia, and research institutions, the government can promote capacity building activities like technical training, R&D lab construction, and the introduction of innovative talent, helping companies improve their R&D and innovation capabilities. Regarding the ineffectiveness of symbolic and hortatory policy tools, the government can enhance corporate social responsibility (CSR) among high-tech companies by promoting industry alliances and associations, establishing corporate honors and CSR awards, thereby indirectly guiding companies to fulfill social responsibilities and enhancing their long-term competitiveness and sustainable development capabilities.

The central region is currently in an economic transition phase, primarily focused on traditional manufacturing and agriculture. Therefore, policy implementation should be more flexible, reducing reliance on command type tools. Although command type tools help regulate market order, they lack adaptability. The government can optimize policy implementation procedures, strengthen administrative oversight, and improve the operability of policies. Incentive-based and capacity building tools should continue to expand their scope. By providing technical subsidies, technology transfers, and financial support, the government can enhance the innovation capabilities of small- and medium-sized enterprises (SMEs). For the central region, system reform tools play a crucial role. The government should optimize administrative processes, reduce the administrative burden associated with business registration and approvals, and establish and improve industrial parks and clusters. Additionally, fostering partnerships with large enterprises will enable SMEs to integrate into a broader industrial ecosystem, gaining more resources and opportunities.

The western region, which is resource-rich but has a relatively low level of economic development, requires a comprehensive application of various policy tools, with a particular emphasis on system reform and capacity building. The government should continue to promote infrastructure development, the establishment of technology innovation centers, and the improvement of the education system to enhance the region’s human resources and technological capabilities. System reform tools should focus on optimizing the investment environment and simplifying administrative procedures, creating a favorable business environment for enterprises. Incentive policies can be more targeted; for instance, specific subsidies could be offered for projects in certain industries to boost corporate participation. Regarding capacity building, the government can leverage regional resource advantages to develop specialized industrial chains, and promote industries like new energy and energy-saving environmental protection in line with the region’s resource endowment. System reform should emphasize improving financial services and building technology innovation platforms, helping businesses access more development opportunities.

The northeastern region, dominated by traditional heavy industry, faces challenges in modern manufacturing technology and innovation capabilities. The government’s primary task here is to continue advancing revitalization policies, particularly in capacity building and system reform. The government can strengthen collaboration with universities and research institutions to train local technical talent, while also improving corporate personnel quality through management training and internal innovation training. In terms of system reform, the focus should be on phasing out outdated production capacity and upgrading industries, specifically guiding companies toward high value-added and technology-intensive sectors. Capacity building efforts can involve introducing external technology partners, hosting international technology exchange forums, and providing support for international talent development to enhance companies’ technological levels. Additionally, in system reform, State-owned enterprise reform can be deepened to optimize property structures and improve operational efficiency. Policymakers should further create a stable and innovation-friendly policy environment by reducing taxes, offering tax exemptions, and providing financial support to ease the burden on enterprises.

4.4. Dynamic QCA

4.4.1. Research Methodology

The factors influencing high-quality development are complex and interactive, presenting a multi-factorial and systemic issue. Understanding which quality policies can enhance high-quality development involves multiple concurrent causalities under different institutional logics, representing a complex causal relationship problem. Configurational analysis, which focuses on “multiple causes leading to a single effect”, is useful for explaining the causality of coexisting factors in this study. To better analyze necessary conditions, the Necessity Criteria Analysis (NCA) method [30] was used before QCA to thoroughly examine the conditions under which antecedent variables become necessary for producing results [31,32]. Following this, dynamic QCA methods were employed. Firstly, the QCA method combines both quantitative and qualitative analyses and applies to large, medium, and small samples. Secondly, QCA focuses on the complexity of logical relationships within sets rather than mere correlations, breaking away from the traditional assumption of uniform causal effects. This means that the same antecedent conditions may lead to different outcomes depending on their combinations. QCA allows for the identification of equivalence among different configurations and the substitutability of antecedent conditions, thereby revealing the mechanisms behind phenomena of “diverse paths leading to the same end”. Additionally, QCA has demonstrated high effectiveness in addressing endogeneity issues [33]. Traditional QCA methods often use cross-sectional data, making it challenging to explore longitudinal configurational effects. Thus, this study employed dynamic QCA, which was measured from inter-group, intra-group, and aggregate dimensions.

4.4.2. Variable Calibration

Considering the inherent lag in policy implementation, lagged conditions were used for the variable calibration. Based on existing theories and prior research findings [34], a direct method was employed to calibrate the variable data. The 95th percentile, 50th percentile, and 5th percentile were set as calibration anchors, representing full membership, crossover point, and full non-membership, respectively. The calibration results for manufacturing are presented in Table 8.

Table 8.

Variable calibration.

The 95th, 50th, and 5th percentiles are commonly used calibration anchors that represent the upper limit, median, and lower limit of data, respectively. This method effectively reflects the distribution of data. The 95th and 5th percentiles can capture the extreme situations of data distribution, helping to identify the key factors that influence results. Extreme values often represent cases of success and failure, and analyzing these cases can provide deeper insights into the outcomes under different conditions. The 50th percentile, or median, reflects the central tendency of the data; selecting the median ensures that the baseline for analysis is representative of the overall performance of the dataset. By combining high and low percentiles, we could consider both extreme and typical situations, making the analysis more comprehensive and capable of identifying pathways and mechanisms under different conditions. Different percentile anchors may have impacted the calibration results, especially when data distribution was uneven. Choosing these percentile anchors enhanced the robustness of the analysis, as they encompassed various aspects of the data. This allowed the research findings to be applicable not only to the overall dataset but also to the analyses in specific situations, thereby strengthening the generalizability of the conclusions. Additionally, it effectively mitigated biases associated with the over-reliance on mean values.

Based on the research approach of Zhang [35], the analysis of Table 8 indicates that the average values for command type tools, incentive type tools, capacity building tools, symbolic and hortatory tools, and system changing tools are all higher than the 50% calibration anchor point. This suggests that the distribution of each indicator among the sample provinces and cities was quite skewed, indicating significant differences between the provinces and cities.

4.4.3. NCA

According to the results presented in Table 9, neither the CR nor the CE estimation methods indicated that any of the condition variables met the criteria of an effect size greater than 0.1 and a significant p-value [36]. This demonstrates that no single condition variable is a necessary condition for high-quality development in the manufacturing industry sector.

Table 9.

NCA of high-quality development in manufacturing industry.

The bottleneck level analysis results presented in Table 10 indicate that achieving a 100% high-quality development level in manufacturing requires a significant contribution from various policy tools within manufacturing quality policies. Specifically, the analysis reveals the following proportions of each policy tool needed:

Table 10.

Bottleneck-level NCA of high-quality development in manufacturing industry under the cr method (%).

56.2% of command type tools: this suggests that a substantial reliance on strict regulatory measures is essential for driving high-quality development in the manufacturing sector;

75% of incentive type tools: the high requirement for incentive type tools highlights the importance of providing financial support, tax breaks, and other benefits to encourage manufacturers to meet high-quality standards;

6% of capacity building tools: this relatively low percentage indicates that while capacity building measures are important, they play a lesser role compared to the other policy tools in achieving high-quality development;

2.5% of symbolic and hortatory tools: the minimal need for symbolic and hortatory tools suggests that these measures alone are insufficient to drive significant change in manufacturing practices, particularly when competing with the more concrete benefits offered by other tools;

23.8% of system-reform tools: this percentage underscores the necessity of systemic changes to create an enabling environment that supports high-quality development.

Overall, these findings demonstrate that high levels of quality development in the manufacturing sector are constrained by multiple factors, emphasizing the need for a comprehensive approach that combines various policy tools to effectively address the challenges and promote sustainable growth.

4.4.4. Analysis of Individual Necessary Conditions for High-Quality Development in Manufacturing Industry

An analysis of the individual necessary conditions for high-quality development in the manufacturing industry was conducted. The conditions were judged based on a consistency greater than 0.9 and an adjusted consistency distance of less than 0.2. If the adjusted consistency distance exceeded 0.2, further investigation using panel data was required [37]. As shown in Table 11, the summary consistency for the five condition variables—command, incentive, capacity building, symbolic and exhortative, and system reform instruments—were all less than 0.9, indicating that no single necessary condition was initially identified. However, since some condition variables have adjusted consistency distances greater than 0.2, further examination is warranted.

Table 11.

Analysis of necessary conditions for high-quality development in manufacturing industry.

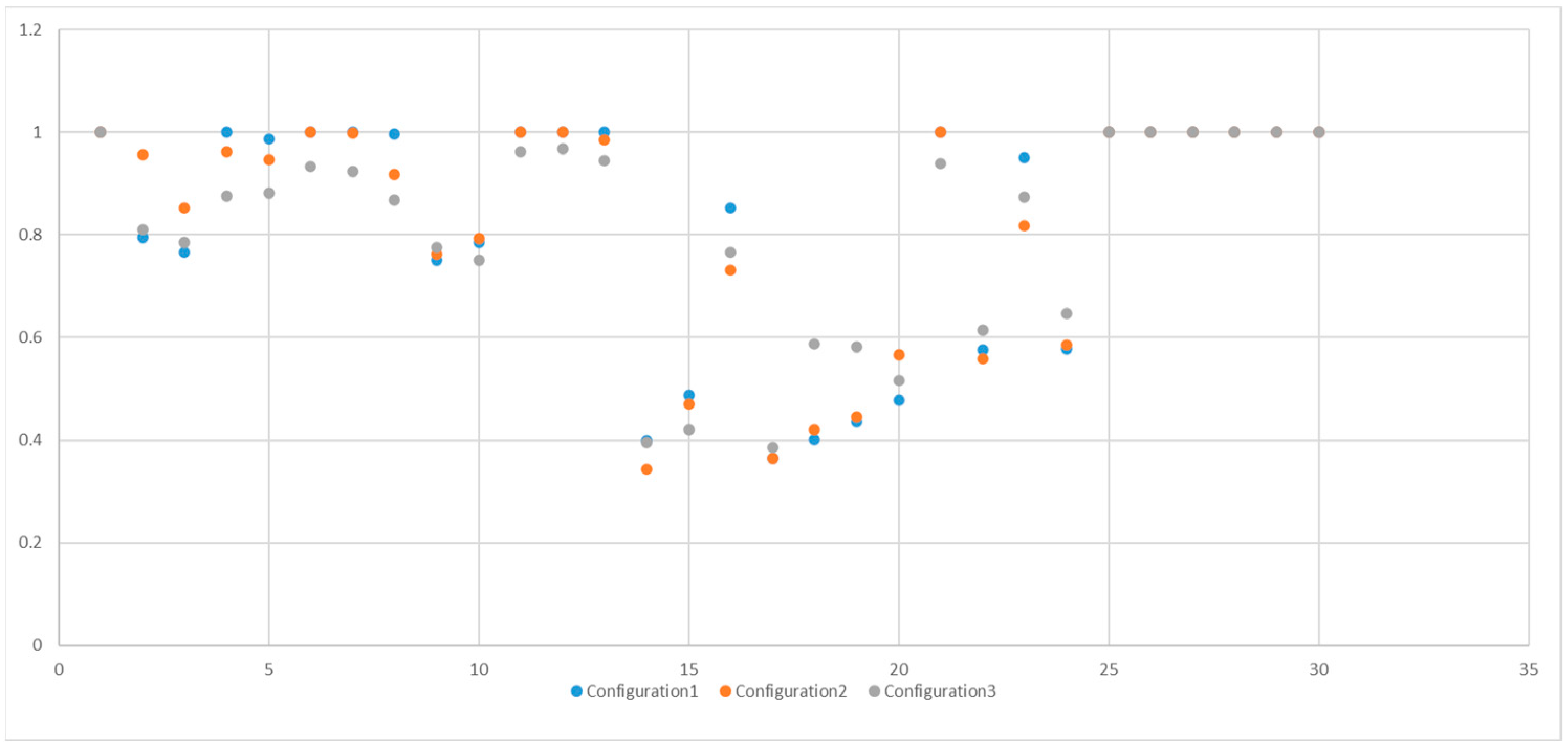

Through the analysis of the consistency and coverage among the corresponding variable groups, the results shown in Table 12 indicate that only the strong incentive tools-high-quality development in manufacturing condition had individual years with consistency greater than 0.9 and coverage greater than 0.5. However, the scatter plot analysis revealed that these instances cluster on the right side of the y-axis, failing the necessary condition test. The other cases exhibited either a consistency less than 0.9 or a consistency greater than 0.9 but coverage less than 0.5, thus not constituting a necessary relationship [37]. Furthermore, an analysis of individual necessary conditions for high-quality development in manufacturing revealed that no single condition variable drove this development, which is consistent with the NCA results.

Table 12.

Variable combinations with consistency adjustment distances greater than 0.2 for high-quality development of manufacturing industry.

4.4.5. Sufficiency Analysis of Configurational Conditions

This study employs R language to conduct dynamic panel data configurational analysis, with the core method being qualitative comparative analysis (QCA), to explore how different combinations of condition variables impact the outcome variable. Based on previous research findings, the consistency threshold was set at 0.75, the PRI consistency was set at 0.7, and the frequency threshold was set at 5 during the construction of the truth table. Given China’s vast territory and significant disparities in resource endowments, it is challenging to determine the directional impact of condition variables on the outcome. Therefore, no directional pre-setting was performed; all the variables were categorized as either “presence or absence”.

- Summary Analysis

From the analysis in Table 13, the overall consistency of the configuration for high-quality development in manufacturing was 0.764. The adjustment distances between each configuration group were all less than 0.2, indicating that the overall consistency had a good explanatory power. These three configuration results can represent sufficient conditions for high-quality development in manufacturing.

Table 13.

Results of the configuration analysis of high-quality manufacturing industry development.

- Configuration 1: Capability Building Dominant

In Configuration 1, the capability building tools in manufacturing quality policies were the core conditions, playing a central role in high-quality development. When capability building tools were present, while command type and symbolic and exhortatory tools were absent, the impacts of incentive and system changing tools were negligible. This indicates that capability building tools can independently explain the sufficient conditions driving high-quality development in manufacturing. This also suggests that when command type tools impose strict standards and requirements, which can constrain manufacturing entities, capability building tools can alleviate this constraint through training and technical support. Typical representatives of this path include Guangdong, Jiangsu, Zhejiang, and Hubei. Firstly, in economically developed areas like Guangdong and Jiangsu, these regions possess strong economic power and financial resources, enabling them to provide substantial funding support for capability building policy tools. Additionally, these developed areas usually attract a large number of high-tech enterprises and large manufacturing firms that have a strong demand for capability building tools. Secondly, in areas focused on industrial upgrading, such as Zhejiang, significant progress has been made in the digital economy and intelligent manufacturing, with local governments actively promoting industrial upgrades and high enterprise participation in capability building tools. Finally, regions with relatively rich educational resources, such as Hubei, possess numerous higher education institutions and vocational training centers, providing ample talent and training resources for the manufacturing sector. Manufacturing enterprises rely on universities and research institutions for technical support and innovation services, with close cooperation among government, enterprises, universities, and research institutions to promote the implementation of capability building tools. Economically developed areas, regions undergoing industrial transformation and upgrading, and those with rich educational resources provide solid economic, talent, and technological foundations to support the effective implementation of capability building policy tools, thus facilitating high-quality development in manufacturing.

When designing capability building tools, local governments should make full use of local economic and educational resources to establish specialized innovation funds that support enterprises’ R&D investment and talent cultivation. At the same time, they can learn from the successful experiences of Guangdong and Jiangsu, strengthening cooperation with universities and research institutions by setting up joint industry–academia-research laboratories to promote the industrialization of academic research results. Moreover, during the implementation of policies, emphasis should be placed on the precision and flexibility of policies, adjusting the level of support according to the actual needs of enterprises to ensure the effectiveness of policy tools.

- Configuration 2: Capability Building and System Change Synergy

This path centers on the synergy between capability building and system changing tools, with incentive tools playing a supplementary role in jointly promoting high-quality development in manufacturing. In this path, capability building and system changing tools are in a relatively balanced state, with multidimensional collaboration and interactivity. Capability building tools provide talent and technical support, while system changing tools offer an efficient operational platform, creating a positive feedback loop. As challenges faced by manufacturing become increasingly complex, the collaboration of capability building and system changing tools can comprehensively enhance enterprises’ ability to adapt to market changes and technological advancements. Incentive tools serve as a supplementary factor, further motivating and enabling enterprises to effectively implement capability building and system changing tools, thereby achieving high-quality development in manufacturing. Typical representatives of this configuration are Shandong and Sichuan. Both regions have many universities and research institutions that provide talent and technical support for manufacturing enterprises. Moreover, Shandong has a complete range of manufacturing industries, while cities like Chengdu and Mianyang in Sichuan have solid manufacturing foundations, with gradually increasing enterprise innovation capabilities. Both regions also have relatively sound economic foundations, with governments promoting industrial transformation and upgrading, alongside relevant incentive policies.

Local governments should formulate policies that encourage internal innovation and external collaboration among enterprises, further enhancing their human resources and technical capabilities through capability building tools. Additionally, regional innovation platforms can be established to provide resources and technical services for enterprises. In the application of system changing tools, a “pilot first, then scale up” strategy can be adopted, starting with management reform and process optimization in a select group of companies, then gradually expanding to a wider range of enterprises to generate scale effects and demonstration benefits.

- Configuration 3: Command Type Dominant with Incentives and Symbolic and Exhortatory Support

The path of Configuration 3 is dominated by command-oriented policy tools, supplemented by incentive-based and symbolic/hortatory policy tools, working together to promote high-quality development in the manufacturing industry. Command-oriented policy tools set strict quality, safety, and environmental standards to ensure that enterprises meet government requirements in terms of basic compliance. These tools are supported by robust policy enforcement and monitoring mechanisms to ensure effective implementation, compelling enterprises to adhere to fundamental regulations. While the strict requirements of command-oriented tools may increase compliance costs for enterprises, incentive-based tools partially offset these costs through subsidies and tax incentives. Additionally, incentive-based tools provide economic rewards, encouraging enterprises to actively comply with and even exceed the standards set by command-oriented policies. In order to maintain their brand reputation and market competitiveness, enterprises respond to symbolic and hortatory policy tools by enhancing their quality management practices. Through public oversight and media campaigns, these tools motivate enterprises to elevate their quality standards. For instance, the government mandates the adoption of high-standard production technologies while offering research and development subsidies and recognition for exemplary enterprises. This configuration is typically represented by regions like Beijing and Shanghai. Beijing is home to industries with high technological content and stringent standards, such as pharmaceuticals, information technology, and advanced manufacturing. Command-oriented tools ensure that products meet strict quality standards, while enterprises, to maintain their brand reputation and market competitiveness, respond to symbolic and hortatory policy tools by improving their quality management practices. In Shanghai, there are stringent regulations of the manufacturing sector, particularly in environmental protection and safety. Local manufacturing enterprises have a strong sense of brand awareness and are willing to leverage symbolic and hortatory policy tools to enhance their brand image and market competitiveness. Furthermore, the relatively advanced economies in these regions enable incentive-based tools to partially offset the costs associated with command-oriented policy tools through subsidies and rewards, thereby reducing the financial burden on enterprises and increasing their motivation to proactively enhance quality and innovation.

In regions that adopt command type tools, local governments should accompany strict standards with corresponding incentives, such as special rewards and tax reductions for enterprises that meet these standards, to lower compliance costs. Additionally, media promotion and industry associations can be leveraged to publicize exemplary practices and successful experiences, encouraging more enterprises to participate in high-quality development. In the application of symbolic and hortatory tools, specific corporate social responsibility awards and honors should be established. These can be promoted through industry forums and exhibitions to enhance enterprises’ sense of social responsibility and market competitiveness.

From the analysis of these three paths, it is clear that different regions and manufacturing sectors at various development stages need to choose and apply different combinations of policy tools based on local conditions. Policymakers should flexibly adjust the application strategies of policy tools according to regional realities to achieve the goal of high-quality development in manufacturing.

- Between-Group Analysis

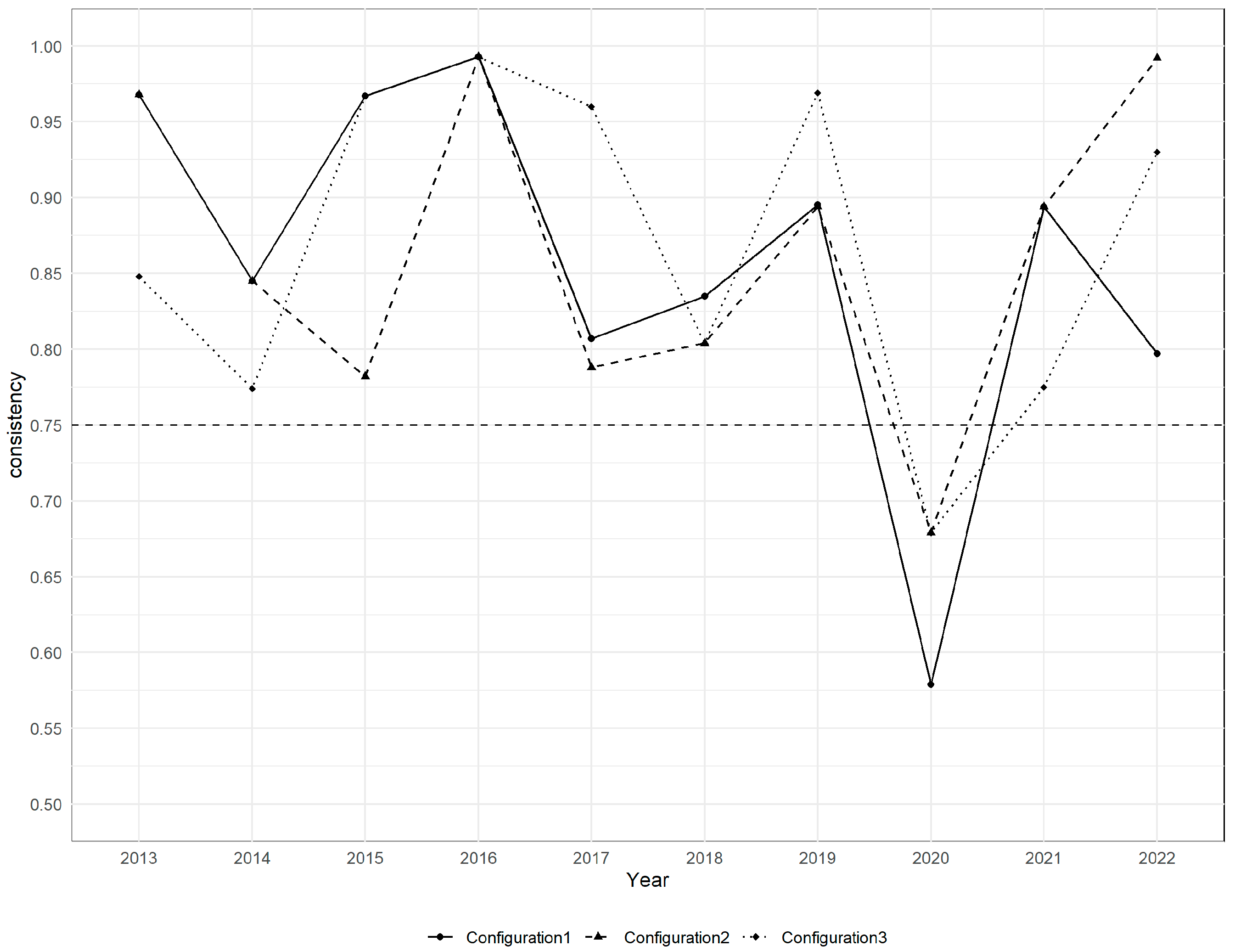

From Figure 1, it can be seen that the adjustment distances of inter-group consistency for the three configurations did not exceed 0.2, indicating that there are no significant cross-time effects and that the configurations are relatively stable. However, further analysis reveals that while the consistency levels of the three configurations fluctuated above 0.75 between 2013 and 2019, they all exhibited a sharp decline in 2020, dropping below 0.75. This decline may be attributed to the outbreak of a public health crisis in 2020, which significantly impacted the manufacturing sector as an essential component of economic development. Due to a series of restrictive measures, the level of high-quality development in manufacturing declined markedly.

Figure 1.

Between-group consistency of manufacturing industry high-quality development configurations.