Abstract

This study investigates the efficiency of cold storage warehouses and contributes to sustainable supply chain management by integrating eco-friendly practices into storage operations. In facilities for milk and its derivatives, unregulated order handling significantly increases energy consumption due to frequent door openings in the cooler. To address this challenge, we developed a novel mathematical model aimed at optimizing order sequences and minimizing energy costs, addressing a previously unexplored gap in the literature. A genetic algorithm (GA) was employed to solve this model, with careful consideration of carbon emissions generated during the algorithm’s execution. We utilized the Yates notation, an experimental design technique, to systematically optimize the GA’s parameters, ensuring robust and statistically valid results. This methodology enabled a thorough analysis of the factors influencing energy consumption. The findings enhance energy efficiency in cold storage warehouses, leading to reduced carbon dioxide emissions and fostering sustainable practices within supply chain management. Ultimately, this study successfully integrates green practices into cold storage operations, supporting broader sustainability objectives.

1. Introduction

The climate system has evolved to the present day, showing extraordinary rises and falls in temperature. Natural disasters, such as droughts, floods, typhoons, hurricanes, and earthquakes, which have occurred one after the other in recent years and have triggered each other, are probably caused by global warming. Man’s influence on the increase in global warming is so great that it cannot be ignored. With the industrial revolution came an increase in fossil fuel consumption; people started preferring private vehicles to public transport, which increased greenhouse effects by cutting down forests to urbanise certain areas and thus made humans the cause of global warming. If this situation is not taken care of, the effects of global warming on our planet will continue to increase and there might not be any habitable places left [1]. There has been a constant increase in population since the industrial revolution began in the first quarter of the eighteenth century, and people have emitted large amounts of carbon dioxide, methane, and nitrite gases to maintain their quality of life. These exacerbate the greenhouse effect and lead to a gradual rise in the earth’s surface temperature. This increase in the surface temperature of the earth will in turn damage the marine ecosystem and cause sea levels to rise [2]. One of the solutions to reduce the impact of the greenhouse effect on the environment is to reduce the carbon footprint [3].

The carbon footprint, the total amount of greenhouse gases released by the impact of a person’s lifestyle, whether directly or indirectly, is represented in terms of carbon dioxide. A person’s carbon footprint is derived from their daily use of transport and household electrical appliances, as well as the damage they cause to nature in their life. With the help of the carbon footprint, it is possible to reduce energy waste. In this way, we can make our environment more environmentally friendly by reducing global warming [4].

Warehouses, which cover all activities from the raw material stage through the production line to the distribution and consumption centres, play an important role in today’s supply chain. They are structures that ensure a shorter picking time so that customer requests and orders can be fulfilled more precisely, and products are stored for a specific period. Warehouses, which are used by various industries such as trading companies, import and export companies, wholesalers, and transport companies, are an important part of business processes for the logistics industry [5]. Cold storage, one of the various specialised warehouses that embody the roles of manufacturer, consumer, packer, and freezer, improves operational processes by extending the life of rapidly perishable goods and reducing quality losses [6]. Cold storage preserves perishable goods, such as fresh vegetables or fruit, milk and dairy products, and animal products, and extends their life so that people can benefit from them for a longer period [7]. In addition to their beneficial properties, cold storage facilities also incur high costs, such as high electricity consumption, to keep the storage at the desired temperature. This shows that the energy used in cold storage can significantly increase costs.

The limited number of studies on cold storage highlights the need for further research in the areas of energy efficiency and sustainability. This study proposes a model that aims to reduce energy consumption in cold storage by optimizing order sorting, thereby achieving both energy savings and reducing the carbon footprint. The implementation of this model not only enhances energy efficiency but provides significant contributions to sustainable supply chain management. By reducing energy consumption in the operational processes of warehouses, this model allows for more efficient use of resources while helping to minimize environmental impacts. This, in turn, supports businesses in developing eco-friendly strategies and achieving their sustainability goals.

In this project, it is anticipated that optimizing the order sequencing processes in cold storage warehouses will significantly reduce energy consumption and operational costs. According to the hypothesis, shortening the processing time of orders and maintaining the warehouse temperature at an appropriate level will make warehouse operations more efficient and environmentally friendly. Optimizing energy-intensive processes, particularly cooling systems, will lead to lower energy consumption, thereby reducing the carbon footprint of businesses. Additionally, by lowering costs, the sustainability of logistics processes will be enhanced. This hypothesis aims to improve both operational efficiency and environmental sustainability.

Green order refers to environmentally friendly practices in order processing and delivery, while green supply chain encompasses sustainable practices throughout the entire supply chain, from production to distribution. The concept of a green supply chain has been discussed in the literature and the concepts of corporate environmental protection or green management over the last 30 years. In [8], six different factors for the adoption of the green concept by logistics service providers were investigated using 162 sample surveys of logistics companies in Taiwan. To investigate the impact of the green concept in companies, [9] tested 13 invalid hypotheses using a questionnaire with employees of a company. The results of the survey showed that the departments of the company that were least affected by the company’s environmental performance were supply chain management, human resources, and information technology. By contrast, the departments most affected were sales, production, and logistics. Ref. [10] used a multi-criteria decision-making method to increase efficiency in supply chain design, planning, and control through green logistics studies. The study identified the environmental areas that should be integrated into operational research. The authors of [11] optimised inventory levels to reduce carbon emissions through inventory planning and technology investment under carbon emission regulations: carbon tax, cap-and-trade, and carbon limit. Ref. [12] studied a company that supplies frozen tropical vegetables and a company that manufactures recyclable bags in India to understand whether their green idea met environmental targets. In addition to this research, an employee of the company in the United Kingdom was interviewed to clarify whether carbon reduction was feasible or not?

Warehouses, one of the building blocks of the supply chain, are structures that serve the green concept when considering the most commonly used equipment and building materials. However, cold storage, another form of warehousing, plays a significant role in the carbon footprint of companies in terms of the energy consumed to keep the warehouse at the desired temperature. Ref. [7] proposed a model to measure the efficiency of cold storage using data envelopment analysis. The proposed model was tested on a different example. They found that the inefficiency of cold storage was due to the inadequacy of the system. Ref. [13] investigated temperature performance to keep it as cold storage. They suggested that a phase change material was needed to ensure products were kept stable at required temperatures. They therefore developed and tested their analytical model. The results showed that the ratio of insulation maximised the melting time.

Despite the lack of studies on cold storage in the literature, there are studies on warehouse efficiency that can serve the green concept in warehouses. To increase the internal efficiency of a warehouse, the authors of [14] implemented a perishables application in an enterprise resource planning (ERP) system. They emphasised that, to increase the internal efficiency of existing warehouses, their logistics processes could be redesigned, and the ERP system improved. First, the physical and logical structures of the warehouse were defined; the work was then applied to an existing warehouse. Ref. [15] studied the changes in energy consumption over time by investigating the reduction of energy consumption in warehouses. The authors of [16] developed an algorithm that determined the number of storage levels and the size of the warehouse to reduce the cost of material handling and storage space by determining the importance of warehouse layout on warehouse efficiency. Ref. [17] addressed the problem of designing rectangular warehouses in fully or partially automated factories and distribution centres. They developed a model using the formulas obtained from solving the nonlinear optimisation problem with linear constraints from the Lagrangian transform, and designed shelves with lower energy consumption by using the proposed model. Ref. [18] used the 3D Navier–Stokes equation to investigate the exchange of heat, moisture, and air caused by the use of sliding doors to ensure the efficiency of cold storage. As a result of this study, it was found that product cooling and energy exchange were affected by the propellers and doors of the warehouse. Ref. [19] explored eight storage location assignment strategies to enhance order picking efficiency in cold warehouses, demonstrating that effective strategies can significantly reduce order picking and wait times, thereby minimizing food loss due to temperature abuse. Ref. [20] analysed the flexibility potential of a cold storage facility using different refrigeration compressors, proposing a new method for defining and quantifying the flexibility of energy systems; the findings indicated potential reductions in energy costs by 50%, CO2 emissions by 25–30%, and maximum electric load by 50%.

The GA, one of the predominant and oldest metaheuristic algorithms, has been used to shorten the solution time of the NP-hard structure of the optimisation problem. The authors of [21] introduced a method to improve genetic algorithms (GAs) for optimizing multimodal functions, where multiple optimal solutions exist. They proposed a “fitness sharing” mechanism that encourages the population of solutions to distribute across various peaks in the solution space rather than converging prematurely to a single optimum. By reducing the fitness of individuals that are too similar to others, the algorithm promoted diversity, allowing GAs to maintain multiple high-quality solutions simultaneously. This approach is particularly valuable for problems where exploring various local optima is essential, and it has made a significant contribution to the field of evolutionary computation.

Ref. [22] explained how genetic algorithms inspired by biological evolution can be used to solve search and optimization problems. GAs simulate biological processes, such as selection, crossover, and mutation, to explore large and complex solution spaces effectively. The author argued that these methods are more flexible and powerful compared to classical optimization techniques, emphasizing their applications in fields such as engineering, artificial intelligence, and machine learning. His work has become a foundational reference in the literature on genetic algorithms. Numerous studies involving the use of GA can be found in the literature.

There are a few studies using GA in cold storage. The authors of [23] developed a model that built a green supply chain by minimising annual warehouse and refrigeration costs and proposing energy costs for the picking process. They optimised AS-RS (Automated Storage Retrieval System) decision variables in the refrigerated warehouse, such as aisles, columns, strips, and surface volume design. They studied the cooling loads considering transmission, infiltration, internal, and external properties. As a result, Crane satellite systems were modelled to reserve space for cold storage. Given the rapid development of food freezing technology, the authors of [24] used an analytical GA to determine the cold chain distribution route and the most suitable route according to the lowest total cost. The authors of [25] created an optimisation model to reduce operating costs and fully utilise the standard energy microgrid system with cold storage, heat storage, batteries, and gas turbines. In building this model, they used the taboo algorithm, GA, particle swarm optimisation, and the linear weighted sum method. They investigated a garlic market in Henan and found that the proposed optimisation model reduced operating costs.

A study was conducted by the authors of [26] using GA and green storage to solve a multi-trip Green Capacitated Arc Routing problem for greenhouse production and emissions by finding the shortest route and reducing the total cost, including driving and routing costs. A hybrid GA was developed. By testing the hybrid GA with the annealing simulation algorithm to generate the first solution, the GA had the best solution. Numerical data was used to test that the algorithm worked with high efficiency. Ref. [27] proposed an approach to determine a strategy for controlling thermal energy in a cold air system within a region. This approach optimised a model based on an artificial neural network combined with a GA. Air intake and weather forecasts were tested for one hour. Ref. [28] addressed different scenarios to optimize energy consumption. They calculated the cooling load for each season. The authors of [29] built a soft path model to reorganize the layout of a green warehouse. The established soft path solution improved the efficiency of warehouse operation, warehouse space utilization, and energy.

Even though many important scientific breakthroughs have been made possible by advancements in high-performance computing, the environmental impact of these developments is often overlooked. In the literature, a methodological framework has been introduced to reliably and consistently estimate the carbon footprint of any computational method used [30]. Criteria have been established to better understand greenhouse gas emissions. These studies aim to determine the amount of greenhouse gases released during the operation of the algorithms used.

Sustainability is becoming increasingly important in today’s business world, particularly in the food sector, where there is a high demand for reducing environmental impacts. In this context, cold storage facilities play a critical role in enhancing energy efficiency and reducing carbon emissions. This study aims to contribute to sustainable supply chain management by promoting the integration of eco-friendly practices in cold storage operations. The developed mathematical model and the employed genetic algorithm (GA) systematically analyse environmental impacts while minimizing energy costs. Ultimately, this research supports the alignment of cold storage processes with environmental sustainability goals, fostering more sustainable business practices from both economic and ecological perspectives.

A search in the literature found many studies on green purchasing, green production, and green packaging, which are other areas of the green supply chain. However, it should be noted that there are not many studies on green storage. Since there are insufficient studies on green warehouses in the literature, we proposed a new green order sorting model to carry out proper order sorting in cold storage. The efficiency of the warehouse was increased, and the result was that the warehouse was used in the most energy efficient way. By reducing the consumption of fossil fuels and shortening the product picking time of the vehicles in the warehouse, the warehouse became more environmentally friendly and complied with the green concept. This study, conducted in the cold storage sector and focusing on the above areas, is different from most other studies on the concept of green warehousing in the literature.

2. Materials and Methods

This study employs a comprehensive approach to address the problem of optimizing cold storage operations using genetic algorithms (GAs). The comprehensive approach involves combining multiple aspects of optimization, including energy efficiency, order sorting, and environmental sustainability, to improve the overall performance of cold storage systems. First, we introduce genetic algorithms, an optimization technique inspired by natural selection processes, which are used to find optimal solutions for complex problems through iterative improvements. Next, we describe the problem context, which focuses on enhancing the efficiency of cold storage warehouses by addressing challenges related to order sorting, energy consumption, and logistics. The comprehensive approach also incorporates a green order sorting mathematical model, which is designed not only to optimize warehouse operations but to minimize environmental impact by reducing energy consumption. Finally, the implementation of a GA for this problem is detailed, including how the algorithm is applied to solve the proposed model. This section outlines the specific GA parameters, operators, and steps used to develop effective solutions and optimize cold storage systems holistically by addressing multiple operational and environmental factors.

2.1. Genetic Algorithms

Artificial intelligence aims to find a solution to a problem by taking its cue from nature and living beings. GA artificial intelligence, a subset of artificial intelligence, is based on the theory of evolution. John Holland was the first to work on the GA, inspired by Darwin’s theory of evolution. Moreover, at the end of their research, Holland and his collaborators published a book entitled, Adaptation in Natural and Artificial Systems [31]. Ref. [31] outlined the genetic process and proved that complex structures can be written in a binary sequence. Rather than elaborating a mechanical system, the ability of the system at hand to create new and successful individuals through specific genetic operators was established. After the publication of the research results, the method was further developed. A student from Holland demonstrated the applicability of the GA in writing his doctoral thesis. He used a combinatorial GA in monitoring gas pipelines. In conjunction with the presentation of 83 application areas in his book, Ref. [22] stated that the GA can be used in any field.

The GA used in solving optimisation problems is a random search algorithm. The GA attempts to find the best fit (i.e., the highest quality individual in a population) through processes such as natural selection, interbreeding, and mutation. If the best individual is not available, the optimal solution is close to the present solution. The methods of natural selection, crossing, and mutation used in the studies are listed in Table 1.

Table 1.

Natural selection, crossover, and mutation methods used in the studies examined in the literature research.

Consider Table 1, which lists the methods of natural selection, crossover, and mutation used in the studies examined in the literature review. Natural selection generally uses the tournament and roulette wheel methods, crossover uses the one-point and two-point crossover methods, and mutation uses the permutation method.

2.2. Problem Description

This study was conducted to improve energy efficiency in a cold storage warehouse with milk and other dairy products. The warehouse has 12 chambers and 44 types of milk and dairy products. The products stored in this cold environment are kept in separate chambers named according to their characteristics; temperature is one of them. The lack of a specific order in the arrangement of the products in the chamber means that the gates of the chambers are constantly opened and closed, resulting in heat exchange. Therefore, the coolers consume additional energy to bring the chambers to the required temperature, resulting in inefficiency and higher costs.

The most important factor to consider when reducing cold storage costs is insulation. Insulation provides energy savings by keeping the temperature stable and the humidity inside the chamber at the desired level. Milk and other dairy products stored in these cold chambers must be stored separately due to their individual characteristics such as temperature, capacity, and variety. Each of these separate chambers has a gate, and they are huge. When the gates are opened during picking, heat from the outside enters the chambers, causing the internal temperature to change due to heat exchange. In one day, several consecutive orders arrive at the cold storage. When a customer places an order, the requests are entered through the gates. The products to which the order relates are taken and leave the warehouse again through the gates. Each order contains more than one product, such as plain yoghurt, cream yoghurt, milk, and butter. For each order, the gates of the chamber are opened, which causes a heat exchange and changes the internal temperature. By opening and closing the gates and the associated heat exchange, the storage refrigerators consume energy to restore the desired temperature. When a new order is received, the process and heat exchange is repeated. In certain cases, the gates may open before the desired internal temperature is reached. In these cases, the coolers constantly try to bring the internal temperature to the expected value, i.e., the coolers consume more energy.

Suppose, for example, that two orders arrive at the factory. The first order consists of milk, cream, and plain yoghurt; the second of plain yoghurt, milk, and creamy yoghurt. The picker first enters the warehouse through the gate and then goes into the milk room to take the milk. While the gate is opened, the above-mentioned heat exchange with the outside air takes place, i.e., the inside temperature of 4 °C rises to 6 °C when the gate is opened. When the picker moves into the cream chamber, the milk chamber consumes energy to bring its internal temperature back to the desired 4 °C. When he leaves the cream chamber, the gates open again, and another heat exchange takes place. As the picker collects other products, the cream chamber consumes energy to return to the desired temperature. After the picker has successfully collected the products for the first order, he leaves the warehouse and returns to start working on the second order. The picker makes his way to the yoghurt warehouse to collect the products for the second order. The internal temperature of the yoghurt chamber may not yet have reached the ideal value, and the heat exchange takes place again. The yoghurt chamber consumes energy to reach its optimal temperature again while the picker makes his way to the milk chamber. Once in the dairy chamber, the gates open and the same processes are carried out again.

Picking successive orders of the same products within the same cold storage throughout the day ensures efficient use of the coolers in the warehouse, thus saving energy. The aim of this study is to reduce costs through energy savings and to make cold stores more environmentally friendly. We developed a new mathematical model for sorting orders in an environmentally friendly way to solve the problem.

2.3. Green Order Sorting Mathematical Model

- Parameters

- Ukj = Transport time from k. product to j. product

- Tkin = Arrival time to k product in n. queue on i. order

- Lkin = Check-out time to from k product on i. order on n. queue

- Okip = value to be added to the objective function if the warehouse did not reach the appropriate temperature, k. product i. in order while in the p. sequence

- Kkip = value to be added to the objective function if the warehouse reached the appropriate temperature, k. product i. in order while in the p. sequence

- Sk = Processing time

- Theta = The time for the warehouse to reach the required temperature (mins)

- Alpha = Fixed number to be added to the objective function even though the warehouse has reached the required temperature

- G =

- Indices

- k, f, g = Products

- i, e, m = Orders

- n, p, z = Ordering sequence

- k0 = Dock

- Variables

- =

- =

- =

- Objective Function

- Constraint

The new mathematical model developed in this study is a non-linear and binary optimization model specifically designed to improve energy efficiency in cold storage operations. The primary goal of this model is to minimize the ordering time between different orders that contain the same products, which in turn leads to significant energy savings. The L variable represents the processing time of a specific product in a particular order, and reducing this time helps lower energy consumption in cold storage facilities. The H variable is a binary variable, indicating whether an order is processed or not, taking values of zero or one. This ensures that orders are processed in the most optimal sequence, thereby optimizing energy-intensive processes. The objective function ultimately saves energy and improves operational efficiency by optimizing the order sequencing process. By minimizing the time interval between the fulfilment of similar orders, the model ensures that energy-intensive processes, such as cooling and product retrieval, are optimized for maximum efficiency. The first constraint ensures that each order belongs to a single item in the sequence. The second condition refers to the fact that each item in the sequence belongs to a single order. The third condition guarantees that the time to leave the dock for each order is zero. The fourth condition ensures that an order belonging to a particular position does not belong to any other position. The time to exit for each order that does not belong to the position of the product in the order is zero. The fifth constraint ensures that, in cases where the time difference between orders is less than the theta value and overcrowding of cold storage is required, the difference is added to the objective function. The sixth constraint ensures that a fixed alpha value is added to the objective function when the time difference between orders is greater than the theta value. In this way, the internal temperature remains constant even if the warehouse has already reached the desired temperature. When switching from one product to another, the seventh constraint indicates the arrival time of the second product. The eighth condition states that the arrival time is zero if there is no movement from one product to another and an order has been assigned to a position in the sequence. The ninth condition states that the arrival time is zero if the order is not assigned to a position. The tenth condition states that the exit time is calculated when a product is part of an order and has been assigned to a specific position in the sequence. The eleventh condition states that when the picking process is completed, the arrival time of the picked order at the dock and the exit time of the following order at the dock must be the same. The twelfth condition states that the variables must be equal to zero.

2.4. Implementation of Genetic Algorithm for the Problem

In the cold stores where milk and dairy products are kept, they are stored separately according to the temperature required. Each time an order arrives at the warehouse, the storage gates are opened. The optimal temperature at which the products should be kept changes due to the heat outside the chamber. The cooling system is put into operation to bring the internal temperature back to the desired level, thereby increasing costs.

We aimed to reduce operating costs by saving electricity consumption in the warehouse. The problem of optimal green order sorting was solved by minimising the time between orders arriving at the cold storage to keep the internal temperature of the storage at the desired level. A GA was used to solve this problem. The pseudocode of the version GA adapted for this study is shown in Algorithm A1 in Appendix A.

Many chromosomes and gene-related information are required to create the initial population. In this study, the number of chromosomes and genes was set as n and the ordinal number. Each gene represents the order, and the chromosomes formed by joining genes indicate the selection sequence of the order. According to the mathematical model developed for this study, there could only be one order (one gene) in a commission set (chromosome); therefore, only one occurrence of a particular gene within a chromosome could be guaranteed. The initial population used in this cold storage study was generated by random numbers. After obtaining the gene and chromosome information, the initial population was randomly generated subject to constraints.

The value of the fitness function was derived from the objective function of the mathematical model used in this study. The objective function found the optimal structure for the orders by minimising the time between the arrival of the orders at the warehouse. The value of the fitness function in the developed GA determined the sum of the time difference between the orders (genes) belonging to the order set (chromosome). The optimal solution was the chromosome with the lowest fitness function value in the newly formed population. The optimal solution specified the order of picking. The parameters, variables, and indices used in the fitness function of the GA are listed in Table A1 in Appendix A.

After calculating the value of the fitness function for each order set (chromosome), the individuals from that set are subjected to a natural selection process in which those of poor quality are eliminated from the population while the remaining individuals survive. In this study on cold storage, the roulette wheel method was used as a method of natural selection. Individuals were placed on a roulette wheel based on their fitness function in the roulette wheel method. The fitness function determined the areas that the individuals occupied on the roulette wheel. The areas occupied by individuals with high fitness functions were huge compared to those with low fitness functions. Each function is made for each individual in the roulette wheel. The roulette was spun, and the individual assigned the area upon which the ball landed was included in the matching pool as a quality individual.

After applying the natural selection operator, the surviving individuals proceeded to the crossover stage, generating a new population. In this cold storage study, the one-point crossover method was utilized. This method involves selecting pairs of individuals to undergo crossover based on randomly generated numbers. Similarly, the specific crossover points where genetic material will be exchanged are determined by random numbers. Once the crossover point is identified, the genes that follow this point in both parent individuals are exchanged between them. Importantly, the order of the genes remains unchanged during the exchange, preserving the overall structure of the genetic sequences. This method facilitates the blending of genetic traits from two parent individuals, resulting in new offspring that may carry improved characteristics, which can be advantageous for the optimization process being studied.

In the mathematical model, condition (1) ensured that each order belonged to a single sequence, while condition (2) ensured that a sequence belonged to a single order. However, new individuals formed after a crossover had two of the same genes; the same order could belong to two sequences in an order picking set. This situation was in contradiction with condition (1) and condition (2) of the mathematical model. To eliminate this problem, a co-operator was used to regulate the structure of the new individuals formed after implementation of the crossover operator. A new method for this could not be found in the literature. A function called the chromosome editing function (CEF) was created, and the co-operator was called a cluster to adapt the technique. The structure of these chromosomes is designed using the co-operator to meet the requirements of the mathematical model. The pseudocode of the developed clustering method is given as Algorithm 1.

| Algorithm 1. Pseudocode for Crossover |

|

Once the individuals created after the crossover operation formed a new population, they were subjected to the mutation operator. In this cold storage study, the swap mutation method was used as the mutation method.

Taking into account the probability that a population would not undergo mutation, the individuals participating in this operation were determined using random numbers. Then, the individuals who were to undergo the mutation operation were assigned two genes, which were later mutated with each other using random numbers. This proved that each individual had only one gene. A new population was formed by the mutation operation of the previously existing population.

For the GA, the initial population was determined, the fitness value of the chromosomes was calculated and then the number of iterations was determined. Within a given cycle, the operations of natural selection, crossover, and mutation were performed up to the specified number of iterations, resulting in new populations. The result of the iteration is the chromosome solution with the best fitness value, i.e., the smallest fitness value. The solution chromosome provides us with the most suitable picking sequence to keep the stock stable at optimal temperature.

2.5. Experimental Design and Results

In this study, an experimental design was developed to achieve higher quality results and to evaluate the impact of key parameters such as the number of chromosomes, crossover ratio, mutation ratio, and the number of iterations in the genetic algorithm (GA). The Yates notation was used during this phase to systematically investigate the influence of these factors on the solution. By analysing the effects of these variables, this study aimed to better understand how different parameter settings influence the performance of the GA and to optimize the results based on these findings.

Table 2 shows the maximum and minimum values that can be assigned to parameters such as the number of iterations, chromosome number, mutation ratio, and crossover ratio. A (−) indicates the lowest possible value, while a (+) indicates the highest possible value that can be assigned to the parameters.

Table 2.

Upper and lower bound of parameters.

According to the Yates notation, the value 2k represents the number of experiments required to optimize the parameters, where k is the number of parameters being studied. In this study, four parameters were considered: iteration number, chromosome number, mutation ratio, and crossover ratio, making the k value 4. As a result, 24, or 16 experiments, were carried out to explore the effects of these parameters on the results. These 16 experiments were conducted using the highest and lowest values for each parameter, as outlined in Table 2. By systematically varying the parameters, the influence of each parameter on the outcome was assessed. Detailed results on the impact of the parameters are provided in Appendix A, offering insights into how each factor contributes to the optimization process.

According to Table 3, the genetic algorithm (GA) achieved better results in less time when the iteration number (−), chromosome number (+), mutation ratio (−), and crossover ratio (−) were used. The specific control parameters applied in the GA are detailed in Table 3.

Table 3.

Parameters used in the Genetic Algorithm.

The Yates notation was applied to optimize the parameters in the experimental design and results sections of the genetic algorithm (GA), and the obtained results were utilized for statistical analysis.

3. Results

This section offers a detailed analysis of the findings from the research, providing a thorough presentation of the key results and their implications. This study involved 17 distinct series of experiments, each varying by the order of operations and the products involved. Initially, these experiments were manually solved using a sorting method aligned with the green concept, focusing on energy efficiency. Following this, the genetic algorithm (GA) was implemented, involving crossover and mutation processes as part of the natural selection mechanism. Application of the GA allowed for a random determination of an optimal order sequence. This optimized sequence effectively minimized the time intervals between orders in the cold storage system, reducing the frequency of gate openings to product chambers. As a result, significant energy savings were achieved by minimizing the unnecessary opening of storage gates, which would otherwise lead to energy loss. The outcomes from the 17 different trial series demonstrated a clear reduction in energy consumption, highlighting the effectiveness of the GA approach. These energy-related results are presented in Table 4, providing a quantitative overview of the energy savings achieved through the optimization process in cold storage operations. The findings emphasize the potential for the GA to enhance operational efficiency and sustainability in cold storage systems.

Table 4.

Results in terms of energy consumption.

The algorithm was executed on a system equipped with 7 CPUs, specifically utilizing an Intel Core i7-9700F processor. The carbon footprint generated by running this algorithm was calculated using the CFA parameter, as detailed in Table 4. To assess the environmental impact, these calculations were conducted using the green-algorithms.org v2.2 tool [30]. This tool provides a method for estimating the carbon emissions associated with computational processes, offering a clear and detailed measure of the environmental footprint resulting from the execution of the algorithm on this particular hardware configuration.

This study proposed a new order sorting system to adapt a cold storage without order pickers to the green concept. This study aimed to ensure that similar orders arrive one after the other, thus preventing the coolers from working harder to ensure that the cold storage reaches the optimal temperature. The proposed new model of green order sorting created the best possible picking for the cold storage, saving energy and thus costs by preventing the coolers from working harder.

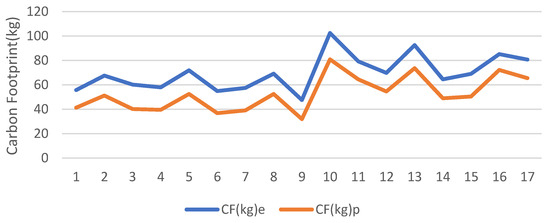

Seventeen different sets of tests with other products and multiple products were investigated; the test results are shown in Table 4. The difference between the existing and the proposed order sorting in terms of the daily operation time of the chillers can be seen in Table 4. With the proposed model, the opening time of the refrigeration doors was reduced in each series of tests, i.e., the additional energy that the refrigeration units had to expend to reach the correct temperature was reduced. it has been observed that the parameter concerning the cooler operating time per day has been decreased by an average of 2.42 h. A notable reduction in the energy consumed per day parameter, averaging more than 40 kWh, has been realized. The carbon footprint has been reduced by an average of 0.035 tons. As shown in Figure 1, the comparison between the carbon footprint in the existing system (CF(kg)e) and the proposed system (CF(kg)p) highlights the improvements achieved.

Figure 1.

Carbon footprint comparison.

The carbon footprint is the value, expressed in carbon dioxide, of the greenhouse gas emitted directly or indirectly into the atmosphere by a person, institution, or community. For this reason, a greener environment can be created by reducing the carbon footprint value. While carbon footprint can be reduced in many ways, in this study the impact of energy on carbon footprint was investigated and the cold storage was made greener. According to Ref. [52], the carbon footprint of companies depends on the vertical integration of the company, the capital intensity of the company, and the centrality of production.

The impact of the problem on the carbon footprint is shown in Table 4. Table 4 shows that thanks to the proposed new green sorting model, the energy consumption of the refrigerators in a day has decreased and, accordingly, the carbon footprint has also decreased. Thus, the amount of carbon dioxide released into the environment was reduced and the green concept was adapted to cold storage. Whether the proposed model made a significant difference or not was determined with a T-test and is shown in Table 5.

Table 5.

The results of the T-test.

- T—Hypothesis Testing:

- H0—There is no significant difference between the means of the results

- H1—There is a significant difference between the means of the results

According to the results, the lowest value in the 95% confidence interval was 3.56, while the highest value was 5.43, and the p-value was 0.001. Since the p-value was less than 0.05 (p < 0.05), the H0 hypothesis was rejected and the H1 hypothesis was accepted. According to the results of the T-test, there is therefore a significant difference between the average results.

4. Conclusions

In recent years, growing awareness of environmental issues and the depletion of natural resources has driven consumers, institutions, and governments to seek sustainable solutions. They aim for a cleaner environment, emphasizing recycling and reducing damage to nature. This has led to the rise of the green concept, with green supply chain management playing a key role in maintaining ecological balance. It focuses on minimizing toxic gas emissions from fossil fuels during production and transport, reducing environmental harm, protecting human health, and combating global warming. Additionally, it helps businesses reduce waste, lower costs, and use resources more efficiently.

The results of this study strongly support the previously defined hypothesis, as the optimizations have led to significant reductions in both energy consumption and operational costs. Specifically, improving the order sequencing processes in cold storage warehouses has optimized processing times, enabling more efficient management of energy-intensive operations. This demonstrates that the objective function has successfully worked, reducing energy consumption significantly by processing orders faster. The cooling systems, operating with the warehouse temperature maintained at an optimal level, consumed less energy, which in turn led to both reduced costs and a lower carbon footprint.

Moreover, the results show that the increase in operational efficiency has not only saved energy but improved labour and equipment utilization. The acceleration of order sequencing in the warehouse has contributed to reduced labour costs and increased operational capacity. As a result, orders are completed in shorter times and with less energy, making the logistics processes more environmentally friendly and sustainable.

These findings confirm the two key assumptions of the hypothesis: first, optimizing order sequencing processes reduces energy consumption and operational costs; second, maintaining warehouse temperature at the appropriate level contributes significantly to environmental sustainability and reduces carbon emissions. Therefore, this study enhances both operational efficiencies, boosting the competitive advantage of businesses, and promotes the development of eco-friendly logistics processes.

The developed mathematical model, which is unique and not found in the literature, effectively shortened the duration of refrigeration door openings during the order sorting process, ensuring the preservation of an optimal temperature. As a result, the energy costs required for cooling the chambers decreased. Specifically, the cooler operating time per day was reduced by an average of 2.42 h. Moreover, a significant decrease in the parameter of energy consumed per day was observed, with an average reduction exceeding 40 kWh. Additionally, the implementation of the proposed model led to a notable reduction in the carbon footprint, averaging 0.035 tons.

For business leaders and industry representatives, this project offers a strategic opportunity not only to achieve cost savings but to facilitate the attainment of environmental sustainability goals. By optimizing order sequencing processes, energy efficiency is enhanced, allowing cooling systems to consume less energy, which significantly reduces the carbon footprint. This approach enables companies to achieve economic gains while simultaneously meeting their sustainability objectives. By doing so, industry pioneers improve their financial performance while adopting a responsible business model that is conscious of both the environment and society. Future research should further explore the integration of green practices in logistics to enhance sustainability in the supply chain.

Author Contributions

Conceptualization, F.Y.; methodology, F.Y.; software, F.Y.; writing—original draft, F.Y.; writing—review and editing, H.R.Y.; supervision, H.R.Y.; project administration, H.R.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

The effects of parameters on results.

Table A1.

The effects of parameters on results.

| Sıra | A | B | C | D | Avg. Time | Objective Function Value |

|---|---|---|---|---|---|---|

| 1 | + | + | + | + | 3.49 | 64 |

| 2 | + | + | + | − | 4.03 | 64 |

| 3 | + | + | − | − | 4.04 | 64 |

| 4 | + | + | − | + | 4.01 | 64 |

| 5 | + | − | − | + | 2.18 | 76 |

| 6 | + | − | − | − | 2.25 | 81 |

| 7 | + | − | + | + | 2.16 | 81 |

| 8 | + | − | + | − | 2.20 | 95 |

| 9 | − | − | + | − | 1.11 | 76 |

| 10 | − | − | + | + | 11 | 76 |

| 11 | − | − | − | + | 1.11 | 76 |

| 12 | − | − | − | − | 1.13 | 98 |

| 13 | − | + | − | − | 1.57 | 64 |

| 14 | − | + | + | − | 2.01 | 64 |

| 15 | − | + | + | + | 1.58 | 64 |

| 16 | − | + | − | + | 1.59 | 64 |

| Algorithm A1. Pseudocode of the genetic algorithm |

| Genetic Algorithm Parameters

|

References

- Cossutta, M.; Foo, D.C.; Tan, R.R. Carbon emission pinch analysis (CEPA) for planning the decarbonization of the UK power sector. Sustain. Prod. Consum. 2021, 25, 259–270. [Google Scholar] [CrossRef]

- Chatterjee, S. Toward a Sustainable Green’ Planet Earth’: On the Impact of Global Warming on Biodiversity and the Ecosystem. SSRN Electron. J. 2013, 3, 1–31. [Google Scholar] [CrossRef][Green Version]

- Mallidis, I.; Vlachos, D. A Framework for Green Supply Chain Management. In Proceedings of the 1st Olympus ICSC, Katerini, Greece, 1–2 October 2010; pp. 1–16. [Google Scholar]

- Wackernagel, M.; William, R. Reducing Human Impact on the Earth. In Our Ecological Footprint; Global Footprint Network: Oakland, CA, USA, 1962; pp. 1–35. [Google Scholar]

- Richards, G. Warehouse Management: A Complete Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse; Kogan Page Publishers: New York, NY, USA, 2017. [Google Scholar]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Green Supply Chain Management Implications for ‘Closing the Loop’. Transp. Res. Part E Logist. Transp. Rev. 2008, 44, 1–18. [Google Scholar] [CrossRef]

- Andrejić, M. Energy Efficiency of Refrigerated Warehouses. IMK-14-Istraživanje I Razvoj 2011, 17, 47–52. [Google Scholar]

- Lin, C.Y.; Ho, Y.H. An Empirical Study on Logistics Service Providers’ Intention to Adopt Green Innovations. J. Technol. Manag. Innov. 2008, 3, 17–26. [Google Scholar]

- Perks, S.; Smith, E.E. A Perceptual Study of the Impact of Green Practice Implementation on the Business Functions. South. Afr. Bus. Rev. 2010, 14, 1–29. [Google Scholar]

- Dekker, R.; Bloemhof, J.; Mallidis, I. Operations Research for Green Logistics—An Overview of Aspects, Issues, Contributions and Challenges. Eur. J. Oper. Res. 2012, 219, 671–679. [Google Scholar] [CrossRef]

- Hasan, M.R.; Roy, T.C.; Daryanto, Y.; Wee, H.M. Optimizing inventory level and technology investment under a carbon tax, cap-and-trade and strict carbon limit regulations. Sustain. Prod. Consum. 2021, 25, 604–621. [Google Scholar] [CrossRef]

- Ramanathan, U.; Bentley, Y.; Pang, G. The Role of Collaboration in the UK Green Supply Chains: An Exploratory Study of the Perspectives of Suppliers, Logistics and Retailers. J. Clean. Prod. 2014, 70, 231–241. [Google Scholar] [CrossRef]

- Kozak, Y.; Farid, M.; Ziskind, G. Experimental and Comprehensive Theoretical Study of Cold Storage Packages Containing PCM. Appl. Therm. Eng. 2017, 115, 899–912. [Google Scholar] [CrossRef]

- Rizzi, A.; Zamboni, R. Efficiency Improvement in Manual Warehouses through ERP Systems Implementation and Redesign of the Logistics Processes. Logist. Inf. Manag. 1999, 12, 367–377. [Google Scholar] [CrossRef]

- Fan, X.; Weber, W.D.; Barroso, L.A. Power Provisioning for a Warehouse-Sized Computer. Int. Symp. Comput. Archit. 2007, 35, 13–23. [Google Scholar] [CrossRef]

- Rakesh, V.; Adil, G.K. Layout Optimization of a Three Dimensional Order Picking Warehouse. IFAC-PapersOnLine 2015, 28, 1155–1160. [Google Scholar] [CrossRef]

- Derpich, I.S.; Sepúlveda, J.M. A Model for Storage Facility Design with Energy Costs. In Proceedings of the 2016 6th International Conference on Computers Communications and Control (ICCCC), Oradea, Romania, 10–14 May 2016; pp. 147–150. [Google Scholar] [CrossRef]

- Ayarmal, A.; Melhus, O.; Chaudhuri, A. The Effects of Fan and Opening of a Sliding Door on a Cold Storage Room: A Numerical Study. In Proceedings of the 59th Conference on Simulation and Modelling (SIMS 59), Oslo, Norway, 26–28 September 2018; Volume 153, pp. 201–209. [Google Scholar] [CrossRef]

- Benaglia, M.F.; Chen, M.H.; Lu, S.H.; Tsai, K.M.; Hung, S.H. Improving the picking efficiency of a cold warehouse to avoid temperature abuse. Int. J. Logist. Manag. 2024, 35, 1434–1464. [Google Scholar] [CrossRef]

- Khorsandnejad, E.; Malzahn, R.; Oldenburg, A.K.; Mittreiter, A.; Doetsch, C. Analysis of Flexibility Potential of a Cold Warehouse with Different Refrigeration Compressors. Energies 2023, 17, 85. [Google Scholar] [CrossRef]

- Goldberg, D.E.; Richardson, J. Genetic algorithms with sharing for multimodal function optimization. In Proceedings of the Genetic Algorithms and Their Applications: Proceedings of the Second International Conference on Genetic Algorithms, Cambridge, MA, USA, 1 October 1987; Volume 4149, pp. 414–425. [Google Scholar]

- Goldberg, D.E. Genetic Algorithms in Search. In Optimization, and Machine Learning; Addison-Wesley: Boston, MA, USA, 1989. [Google Scholar]

- Meneghetti, A.; Monti, L. Greening the Food Supply Chain: An Optimisation Model for Sustainable Design of Refrigerated Automated Warehouses. Int. J. Prod. Res. 2015, 53, 6567–6587. [Google Scholar] [CrossRef]

- Lu, J.; Zhao, Y. Selection of Cold Chain Logistics Distribution Center Location Based on Improved Genetic Algorithm. MATEC Web Conf. 2018, 227, 02018. [Google Scholar] [CrossRef][Green Version]

- Xu, B.; Luo, S.; Tian, Y.; Chen, X.; Xiong, B.; Zhou, B. Optimization of Joint Energy Micro-Grid with Cold Storage. IOP Conf. Ser. Earth Environ. Sci. 2018, 121, 042001. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Hosseinabadi, A.A.R.; Soltani, M.; Sangaiah, A.K.; Wang, J. A Hybrid Genetic Algorithm for Multi-Trip Green Capacitated Arc Routing Problem in the Scope of Urban Services. Sustainability 2018, 10, 1366. [Google Scholar] [CrossRef]

- Parikhani, T.; Gholizadeh, T.; Ghaebi, H.; Sadat, S.M.S.; Sarabi, M. Exergoeconomic Optimization of a Novel Multigeneration System Driven by Geothermal Heat Source and Liquefied Natural Gas Cold Energy Recovery. J. Clean. Prod. 2019, 209, 550–571. [Google Scholar] [CrossRef]

- Almutairi, K.; Esfahani, E.M.; Mostafaeipour, A.; Issakhov, A.; Kaewpraek, C.; Techato, K. A Novel Policy to Optimize Energy Consumption for Dairy Product Warehouses: A Case Study. Sustainability 2021, 13, 2445. [Google Scholar] [CrossRef]

- Ren, Q.; Ku, Y.; Wang, Y.; Wu, P. Research on design and optimization of green warehouse system based on case analysis. J. Clean. Prod. 2023, 388, 135998. [Google Scholar] [CrossRef]

- Lannelongue, L.; Grealey, J.; Inouye, M. Green algorithms: Quantifying the carbon footprint of computation. Adv. Sci. 2021, 8, 2100707. [Google Scholar] [CrossRef] [PubMed]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Application to Biology; The MIT Press: Cambridge, MA, USA, 1975. [Google Scholar] [CrossRef]

- Katić, D. Genetic Algorithm Tuning of Connectionist Controller for Compliant Robotic Tasks. IFAC Proc. Vol. 1999, 32, 641–646. [Google Scholar] [CrossRef]

- Poulos, P.N.; Rigatos, G.G.; Tzafestas, S.G.; Koukos, A.K. A Pareto-Optimal Genetic Algorithm for Warehouse Multi-Objective Optimization. Eng. Appl. Artif. Intell. 2001, 14, 737–749. [Google Scholar] [CrossRef]

- Lee, K.; Kim, B.S.; Joo, J.M. Genetic Algorithms for Door-Assigning and Sequencing of Trucks at Distribution Centers for the Improvement of Operational Performance. Expert Syst. Appl. 2012, 39, 12975–12983. [Google Scholar] [CrossRef]

- Sana, S.S.; Mateus, H.O.; Arrieta, G.B.; Chedid, J.A. Application of Genetic Algorithm to Job Scheduling under Ergonomic Constraints in Manufacturing Industry. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 2063–2090. [Google Scholar] [CrossRef]

- Manzoni, L.; Vanneschi, L.; Mauri, G. A Distance between Populations for One-Point Crossover in Genetic Algorithms. Theor. Comput. Sci. 2012, 429, 213–221. [Google Scholar] [CrossRef]

- Moon, C.; Kim, J.; Choi, G.; Seo, Y. An Efficient Genetic Algorithm for the Traveling Salesman Problem with Precedence Constraints. Eur. J. Oper. Res. 2010, 140, 606–617. [Google Scholar] [CrossRef]

- Baker, B.M.; Ayechew, M.A. A Genetic Algorithm for the Vehicle Routing Problem. Comput. Oper. Res. 2003, 30, 787–800. [Google Scholar] [CrossRef]

- Ho, S.Y.; Chen, J.H.; Huang, M.H. Inheritable genetic algorithm for biobjective 0/1 combinatorial optimization problems and its applications. IEEE Trans. Syst. Man Cybern. Part B (Cybern.) 2004, 34, 609–620. [Google Scholar] [CrossRef] [PubMed]

- Hsu, C.M.; Chen, K.Y.; Chen, M.C. Batching Orders in Warehouses by Minimizing Travel Distance with Genetic Algorithms. Comput. Ind. 2005, 56, 169–178. [Google Scholar] [CrossRef]

- Jeon, G.; Leep, H.R.; Shim, J.Y. A Vehicle Routing Problem Solved by Using a Hybrid Genetic Algorithm. Comput. Ind. Eng. 2007, 53, 680–692. [Google Scholar] [CrossRef]

- Tsai, C.Y.; Liou, J.J.H.; Huang, T.M. Using a Multiple-GA Method to Solve the Batch Picking Problem: Considering Travel Distance and Order Due Time. Int. J. Prod. Res. 2008, 46, 6533–6555. [Google Scholar] [CrossRef]

- Chen, S.M.; Chien, C.Y. Solving The Traveling Salesman Problem Based on The Genetic Simulated Annealing Ant Colony System with Particle Swarm Optimization Techniques. Expert Syst. Appl. 2011, 38, 14439–14450. [Google Scholar] [CrossRef]

- Azadnia, A.H.; Taheri, S.; Ghadimi, P.; Saman, M.Z.M.; Wong, K.Y. Order Batching in Warehouses by Minimizing Total Tardiness: A Hybrid Approach of Weighted Association Rule Mining and Genetic Algorithms. Sci. World J. 2013, 2013, 246578. [Google Scholar] [CrossRef]

- Beire, A.R.; Pita, H.; Cota, N. Optimizing Propagation Models on Railway Communications Using Genetic Algorithms. Procedia Technol. 2014, 17, 50–57. [Google Scholar] [CrossRef][Green Version]

- Lai, G.; Yuan, D.; Yang, S. A New Hybrid Combinatorial Genetic Algorithm for Multidimensional Knapsack Problems. J. Supercomput. 2014, 70, 930–945. [Google Scholar] [CrossRef]

- Victer Paul, P.; Ramalingam, A.; Baskaran, R.; Dhavachelvan, P.; Vivekanandan, K.; Subramanian, R. A New Population Seeding Technique for Permutation-Coded Genetic Algorithm: Service Transfer Approach. J. Comput. Sci. 2014, 5, 277–297. [Google Scholar] [CrossRef]

- Ene, S.; Küçükoğlu, İ.; Aksoy, A.; Öztürk, N. A Genetic Algorithm for Minimizing Energy Consumption in Warehouses. Energy 2016, 114, 973–980. [Google Scholar] [CrossRef]

- Hallawi, H.; Mehnen, J.; He, H. Multi-Capacity Combinatorial Ordering GA in Application to Cloud Resources Allocation and Efficient Virtual Machines Consolidation. Future Gener. Comput. Syst. 2017, 69, 1–10. [Google Scholar] [CrossRef]

- Yang, Z.; Xiao, M.Q.; Ge, Y.W.; Feng, D.L.; Zhang, L.; Song, H.F.; Tang, X.L. A Double-Loop Hybrid Algorithm for the Traveling Salesman Problem with Arbitrary Neighbourhoods. Eur. J. Oper. Res. 2018, 265, 65–80. [Google Scholar] [CrossRef]

- Yerukala, S.S.; Sahu, D.; Huang, H.C.; Lin, Y.; Ho, S.Y. Identification and Characterization of the LncRNA Signature Associated with Overall Survival in Patients with Neuroblastoma. Sci. Rep. 2019, 9, 5125. [Google Scholar] [CrossRef]

- Goldhammer, B.; Busse, C.; Busch, T. Estimating Corporate Carbon Footprints with Externally Available Data. J. Ind. Ecol. 2017, 21, 1165–1179. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).