Effect of Slope on Stormwater Infiltration into Porous Asphalt Pavements

Abstract

1. Introduction

1.1. Background

1.2. Study Objectives

2. Materials and Methods

2.1. Experimental Environment

2.2. Asphalt Materials

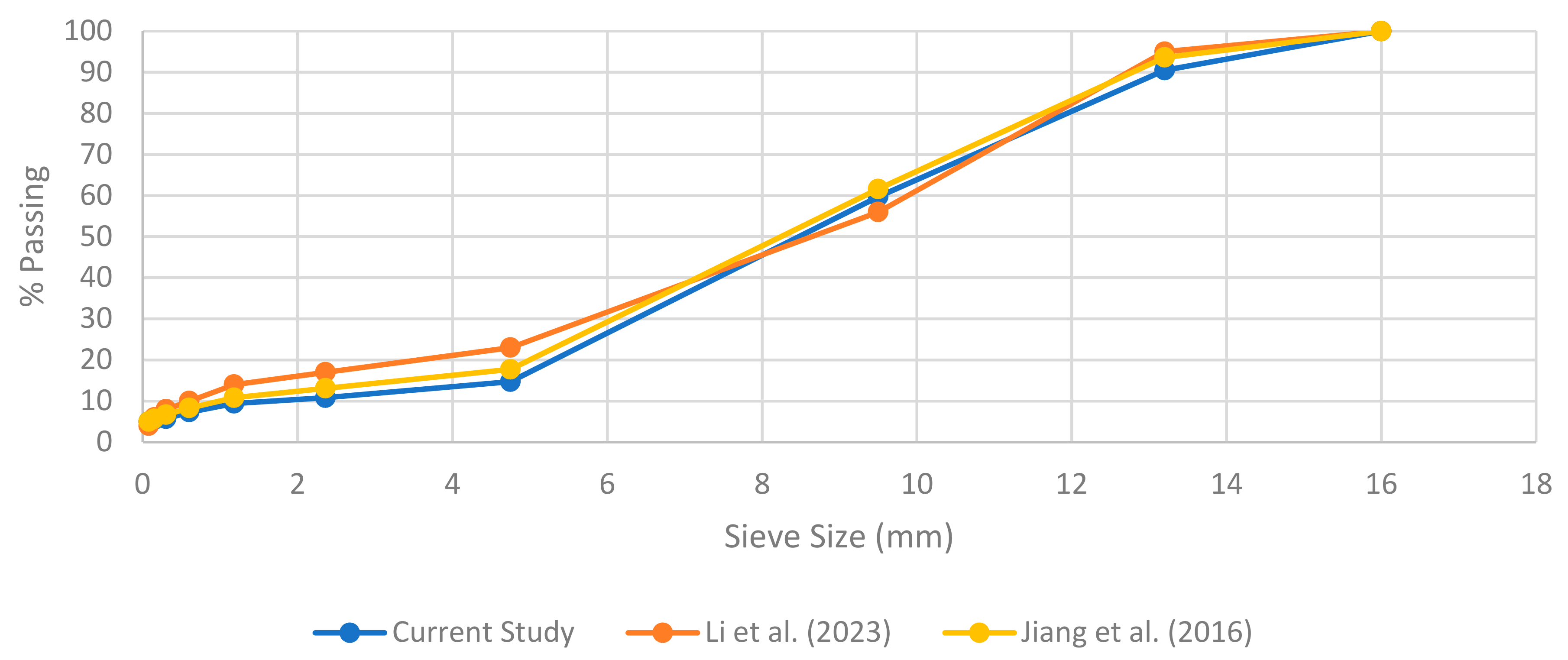

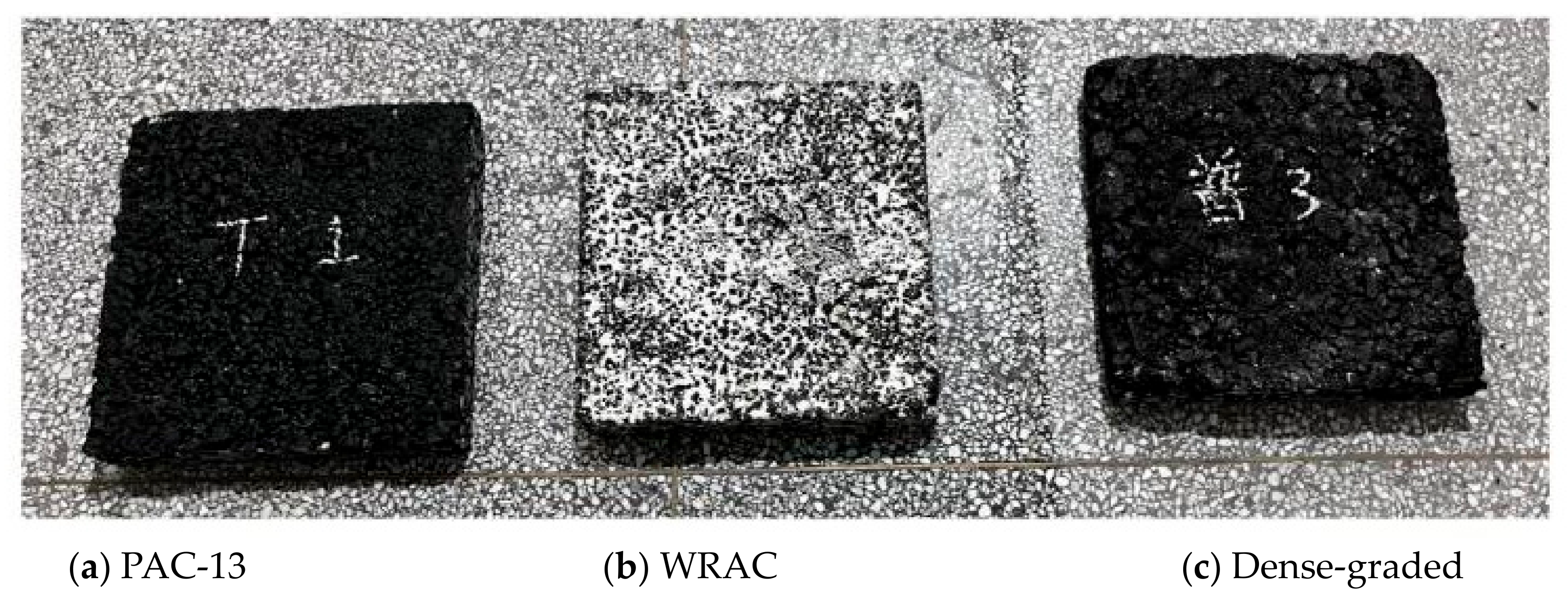

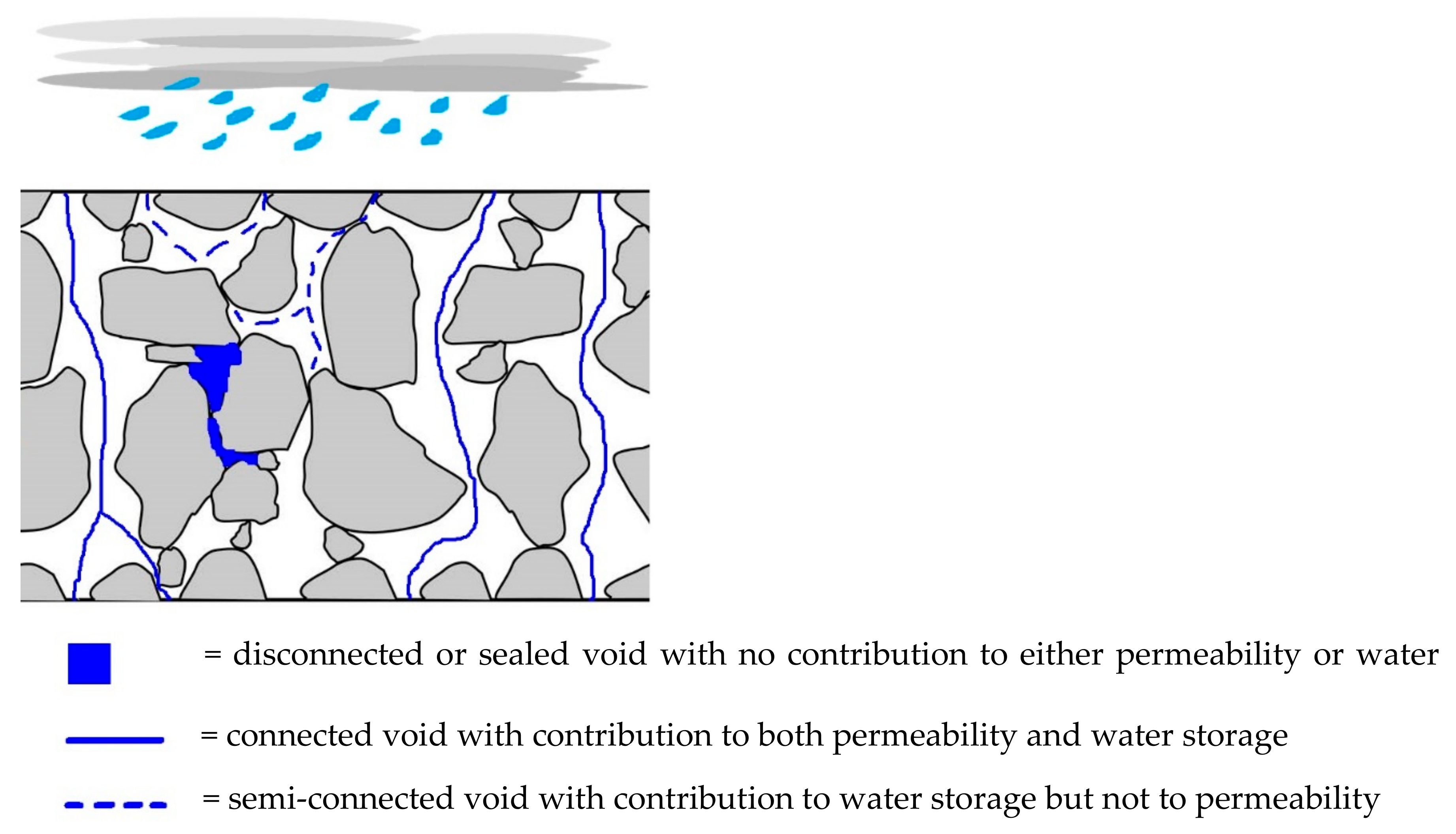

2.2.1. Porous Asphalt

2.2.2. Water-Retentive Asphalt Concrete

2.2.3. Dense-Graded Asphalt

2.3. Experimental Methods

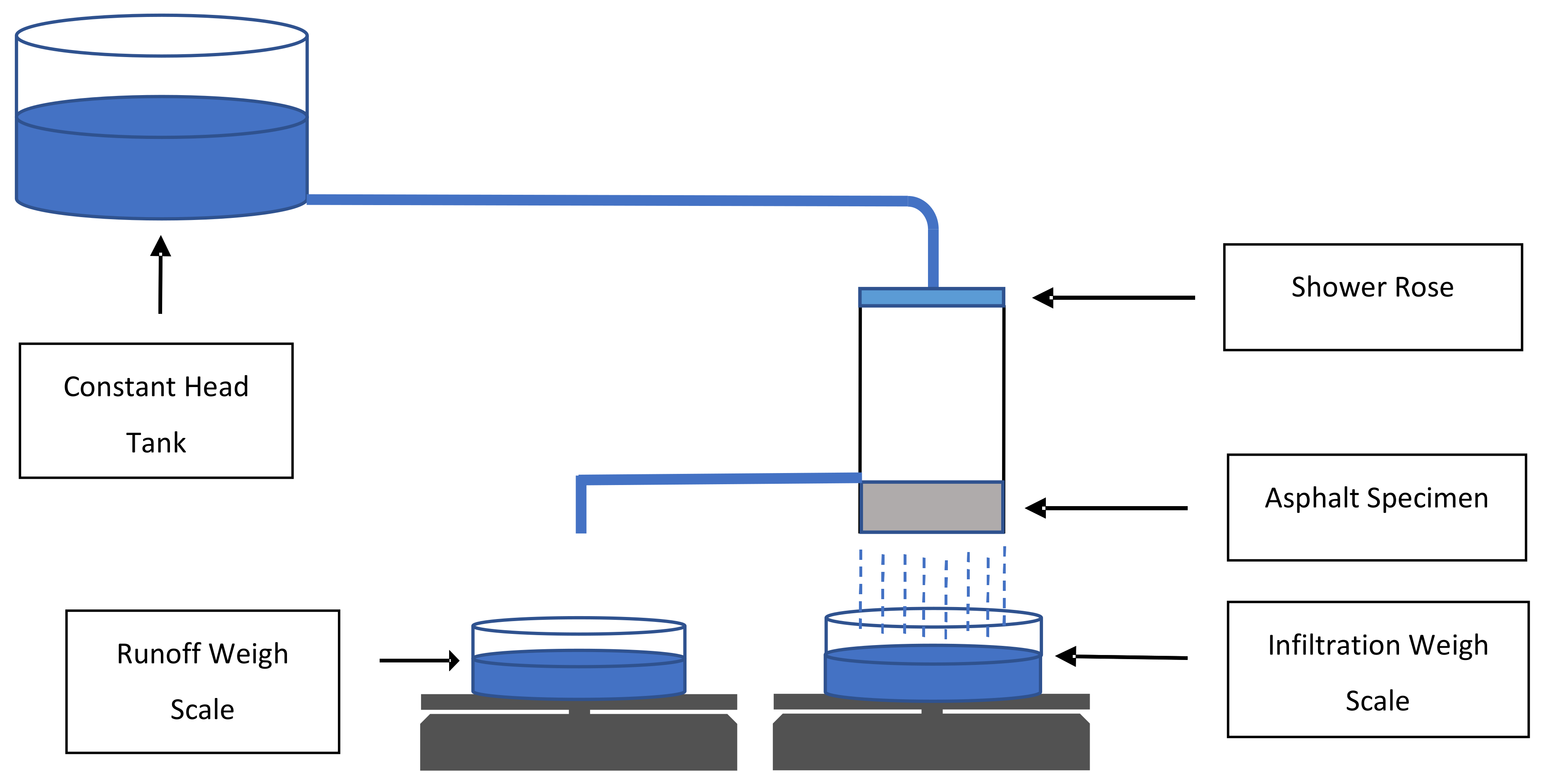

2.3.1. Rainfall Application Device

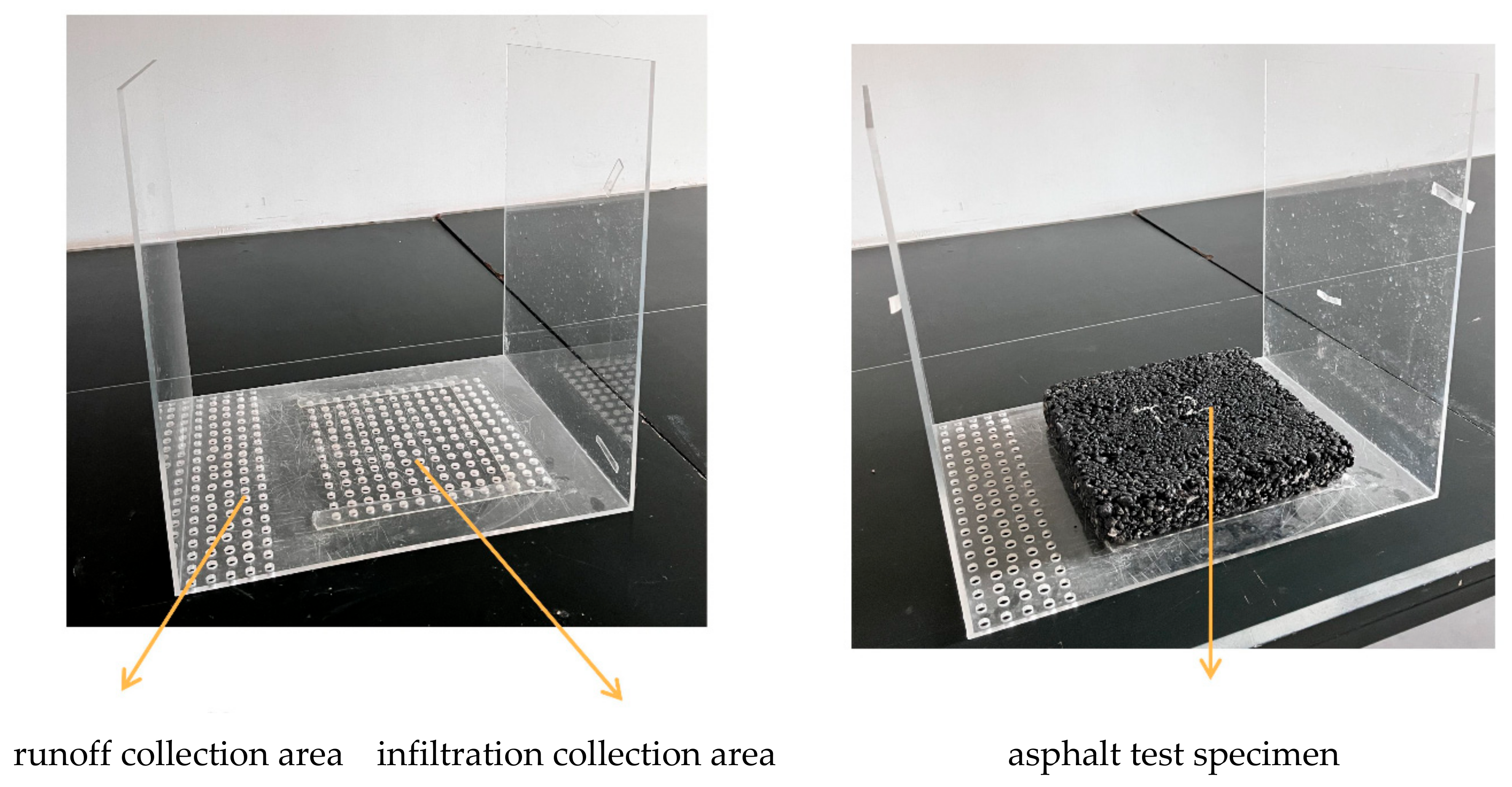

2.3.2. Infiltration Chamber

3. Results and Discussion

3.1. Runoff and Infiltration Response Times

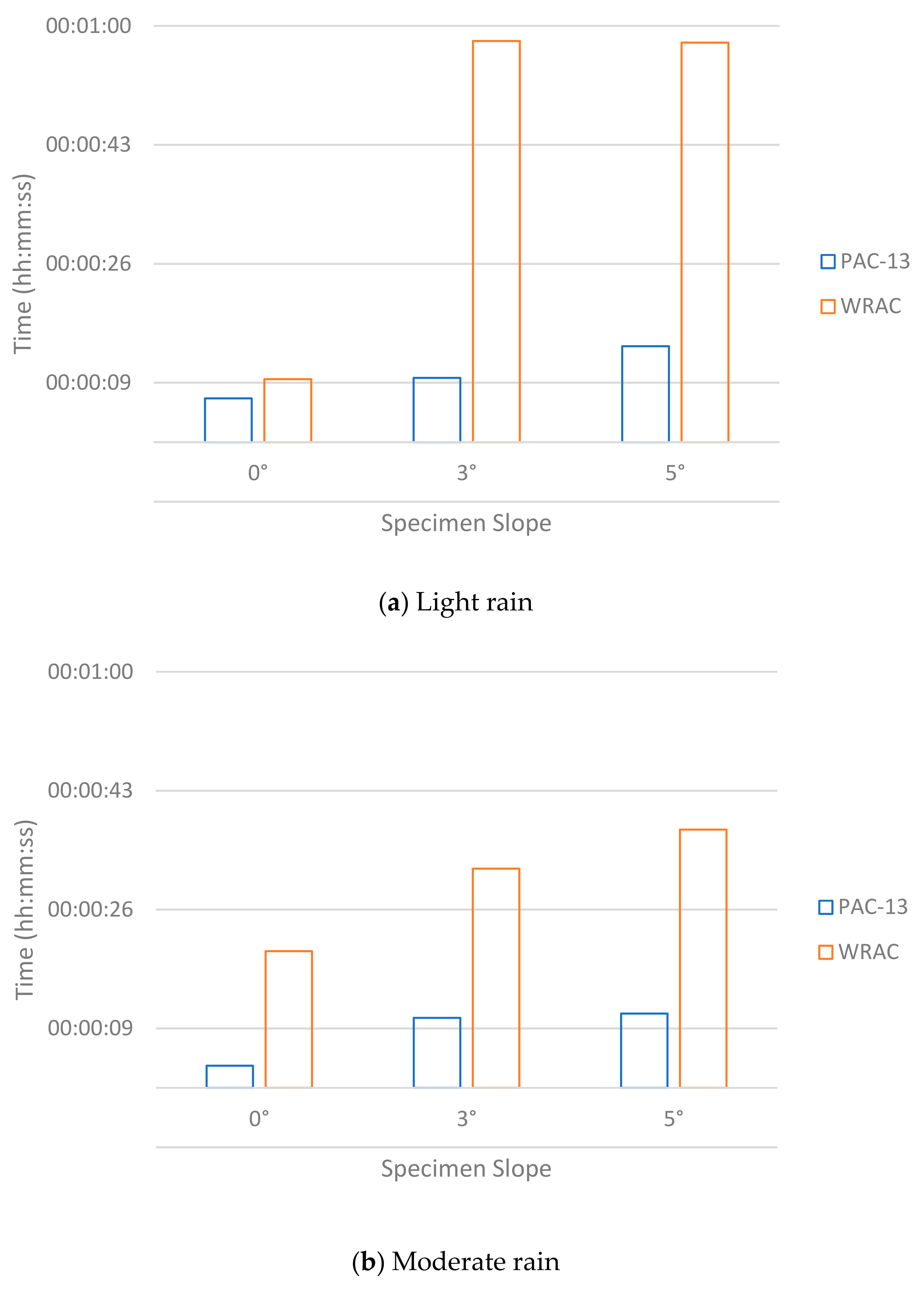

3.1.1. Runoff Times

3.1.2. Infiltration Times

3.2. Runoff and Infiltration Rates

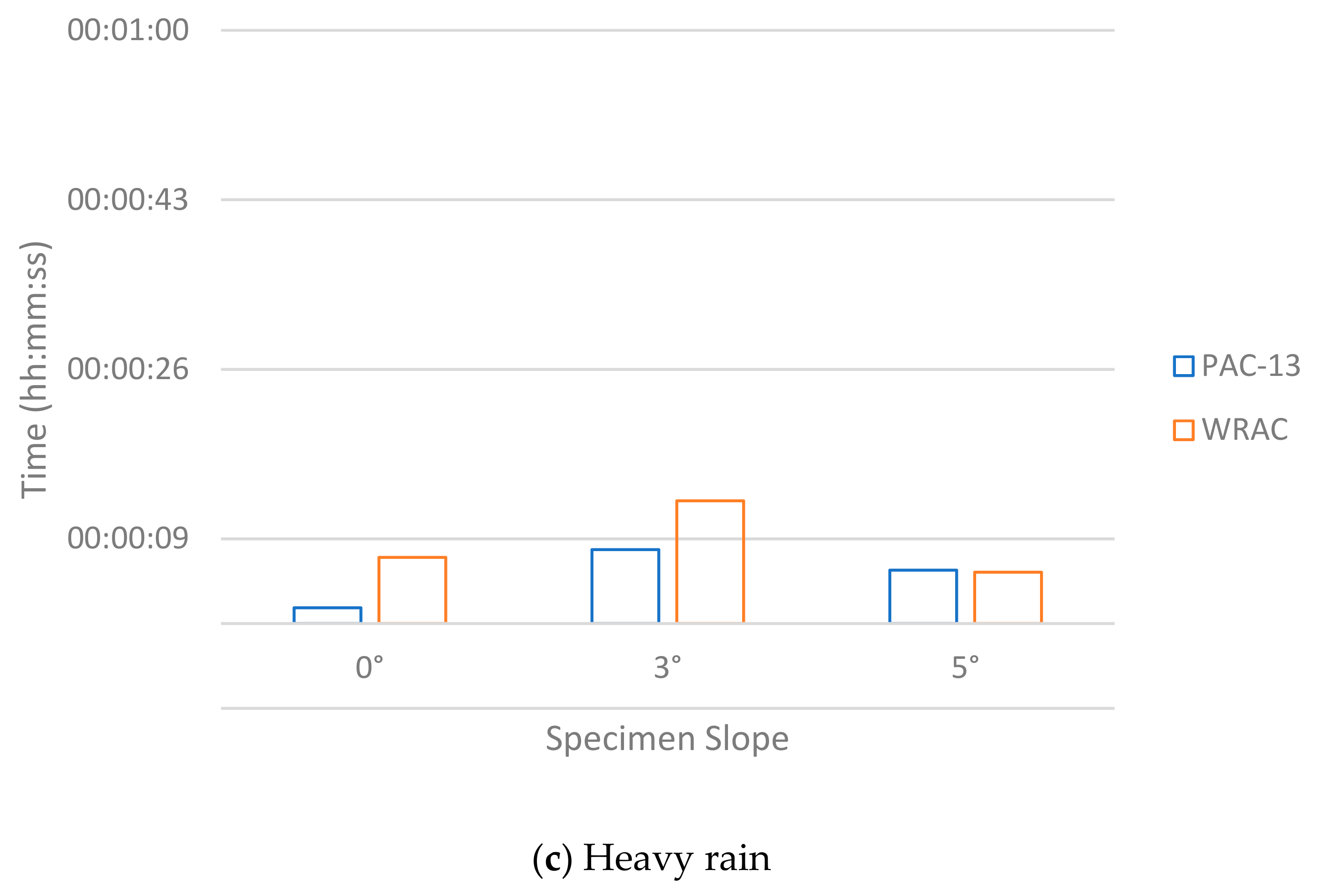

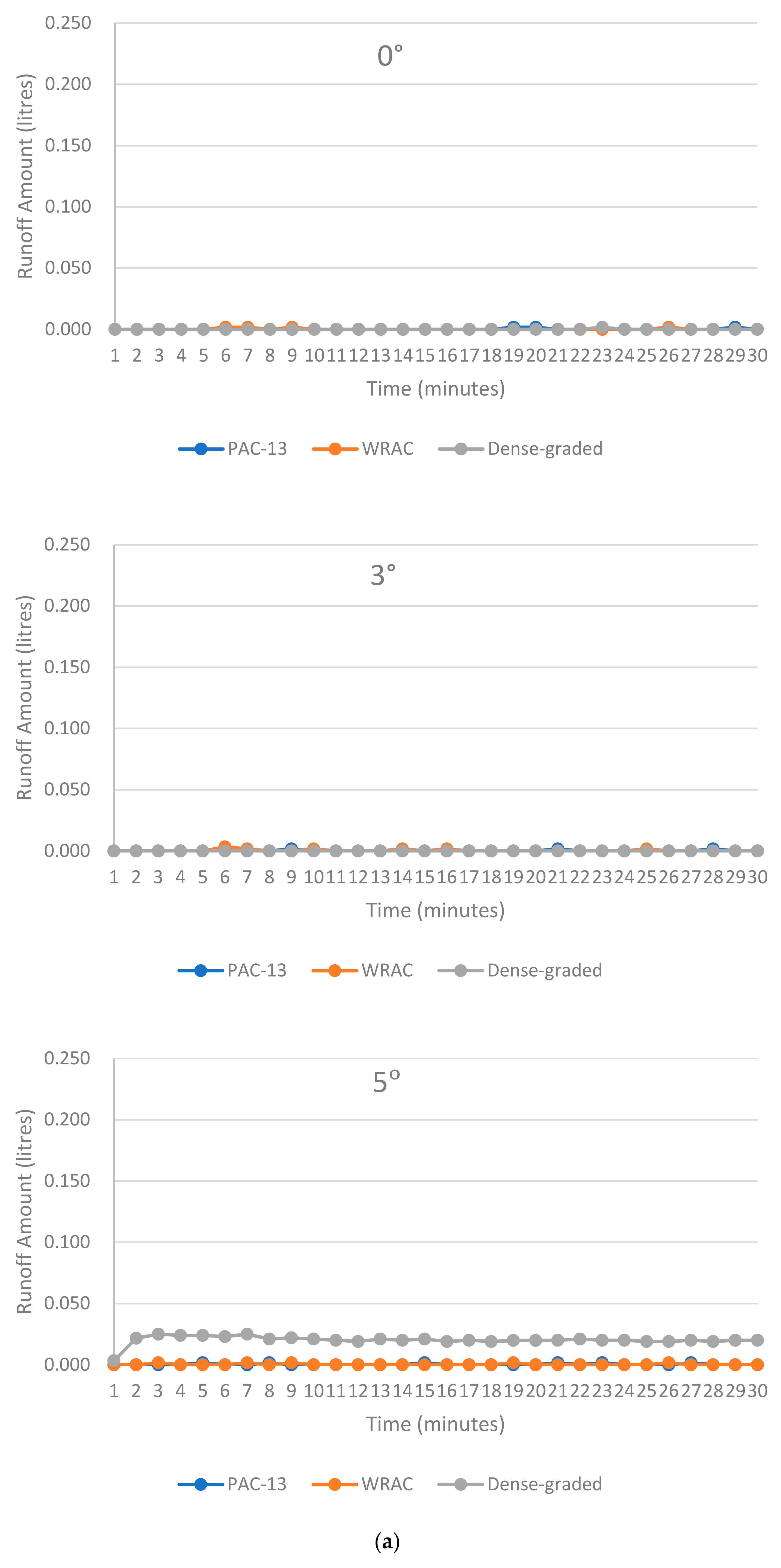

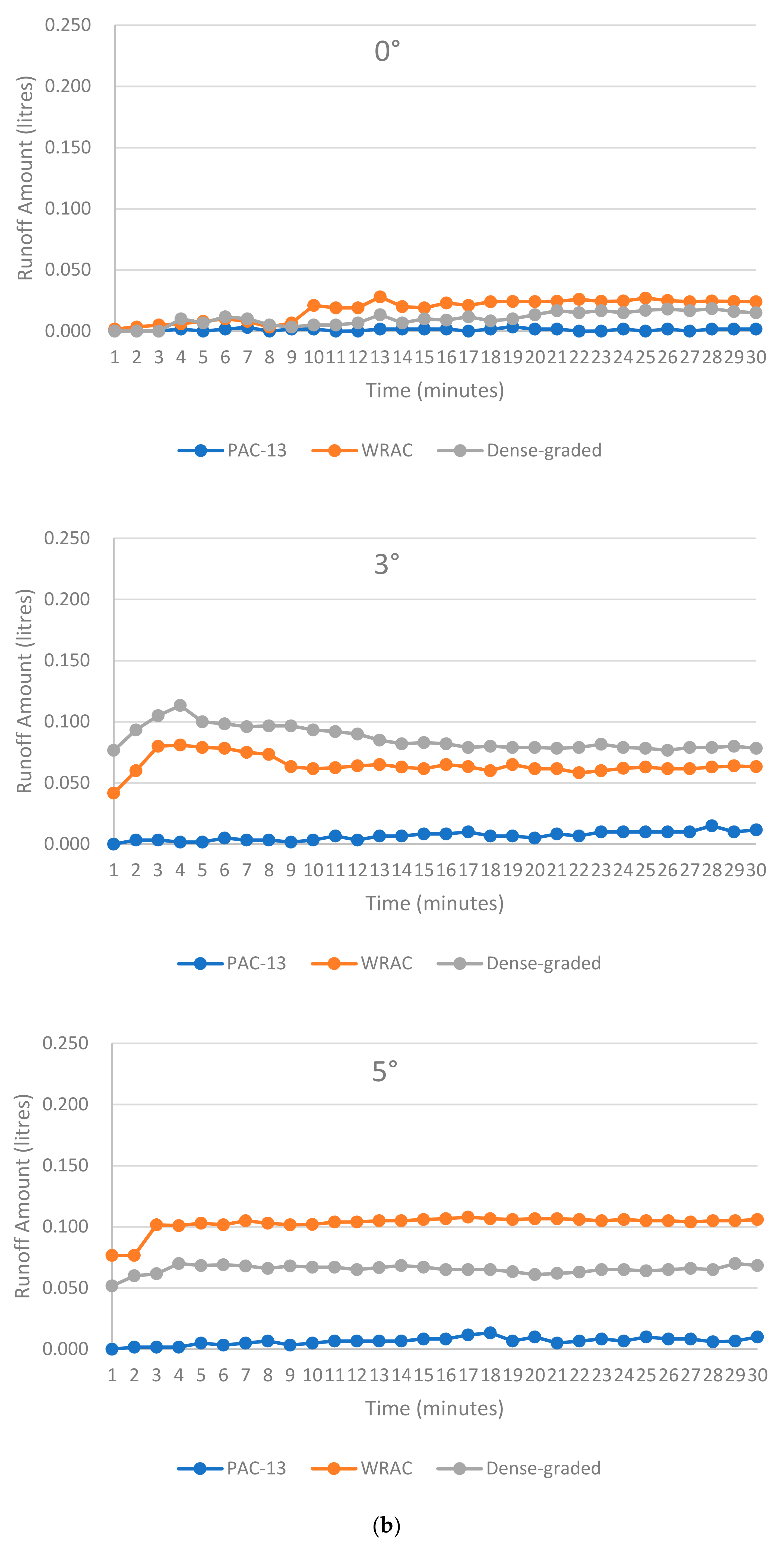

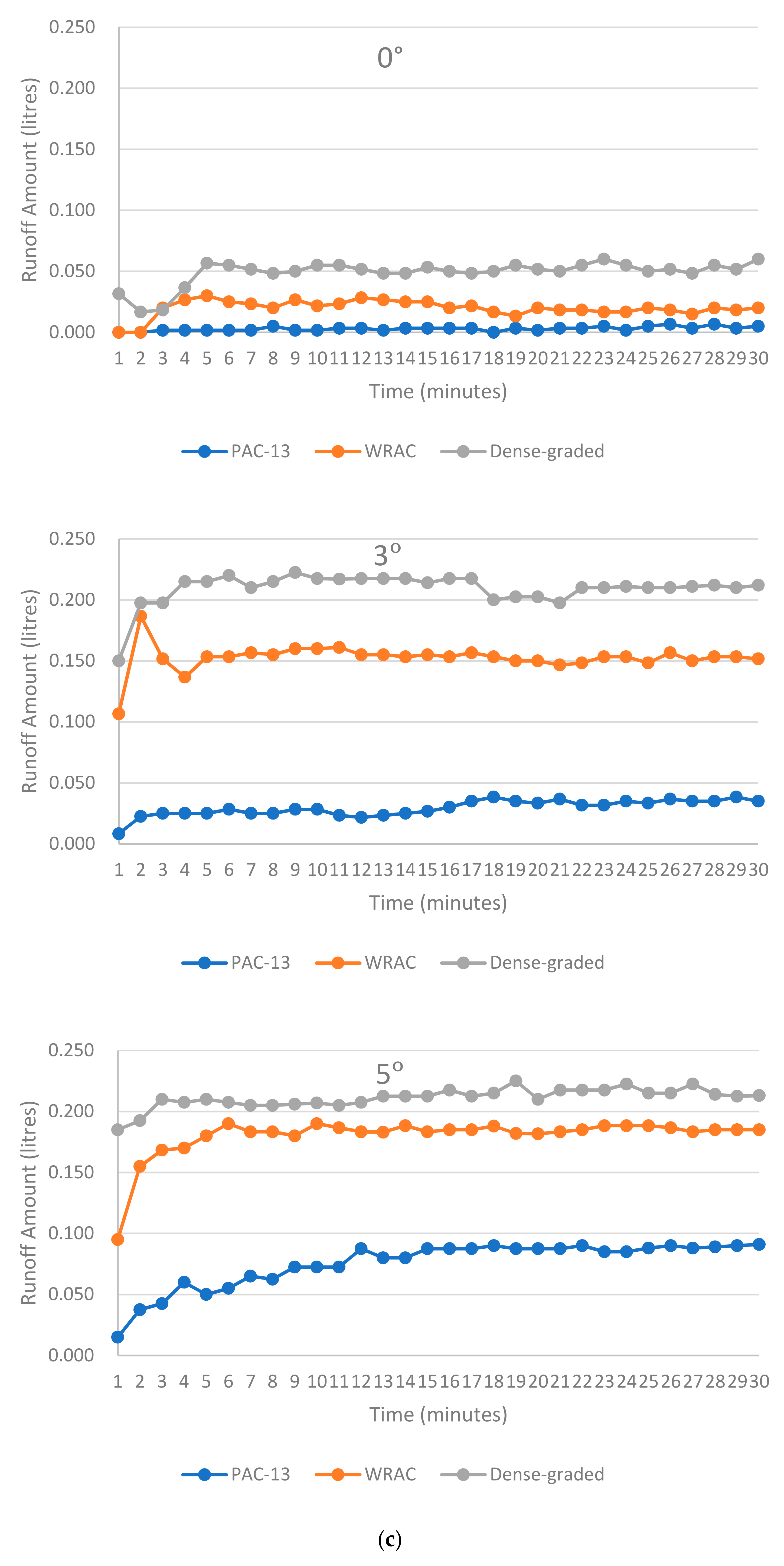

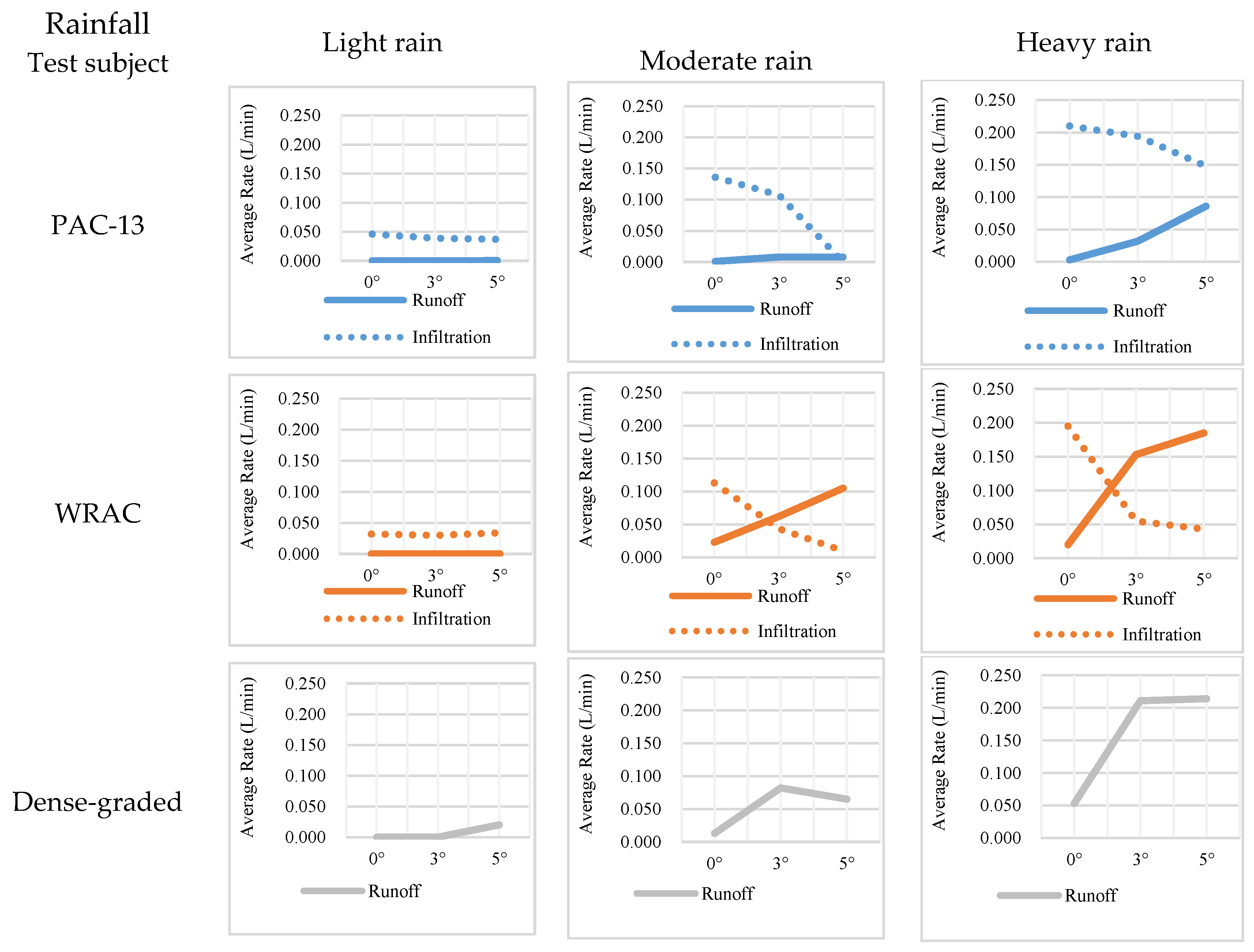

3.2.1. Runoff Rates

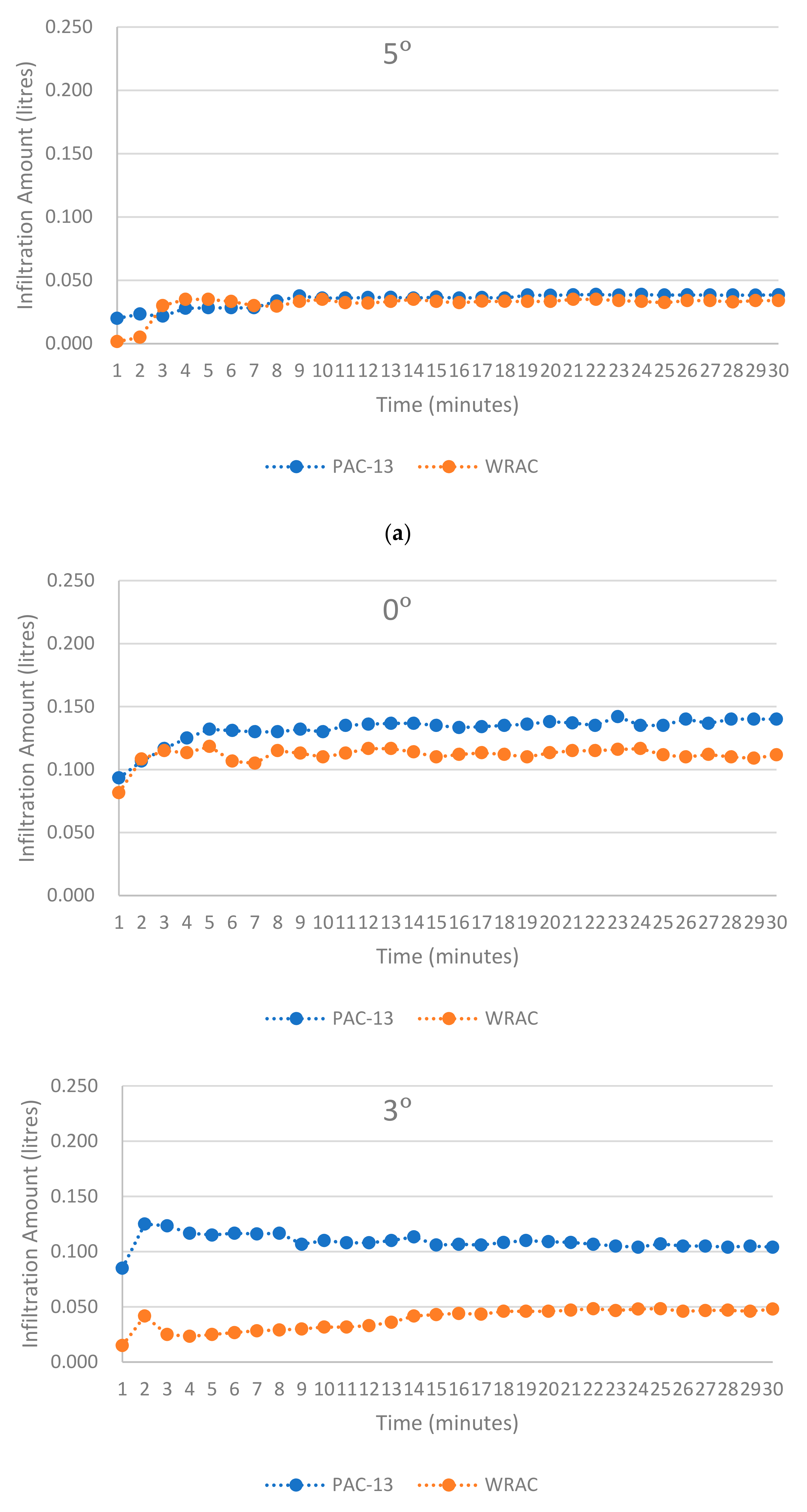

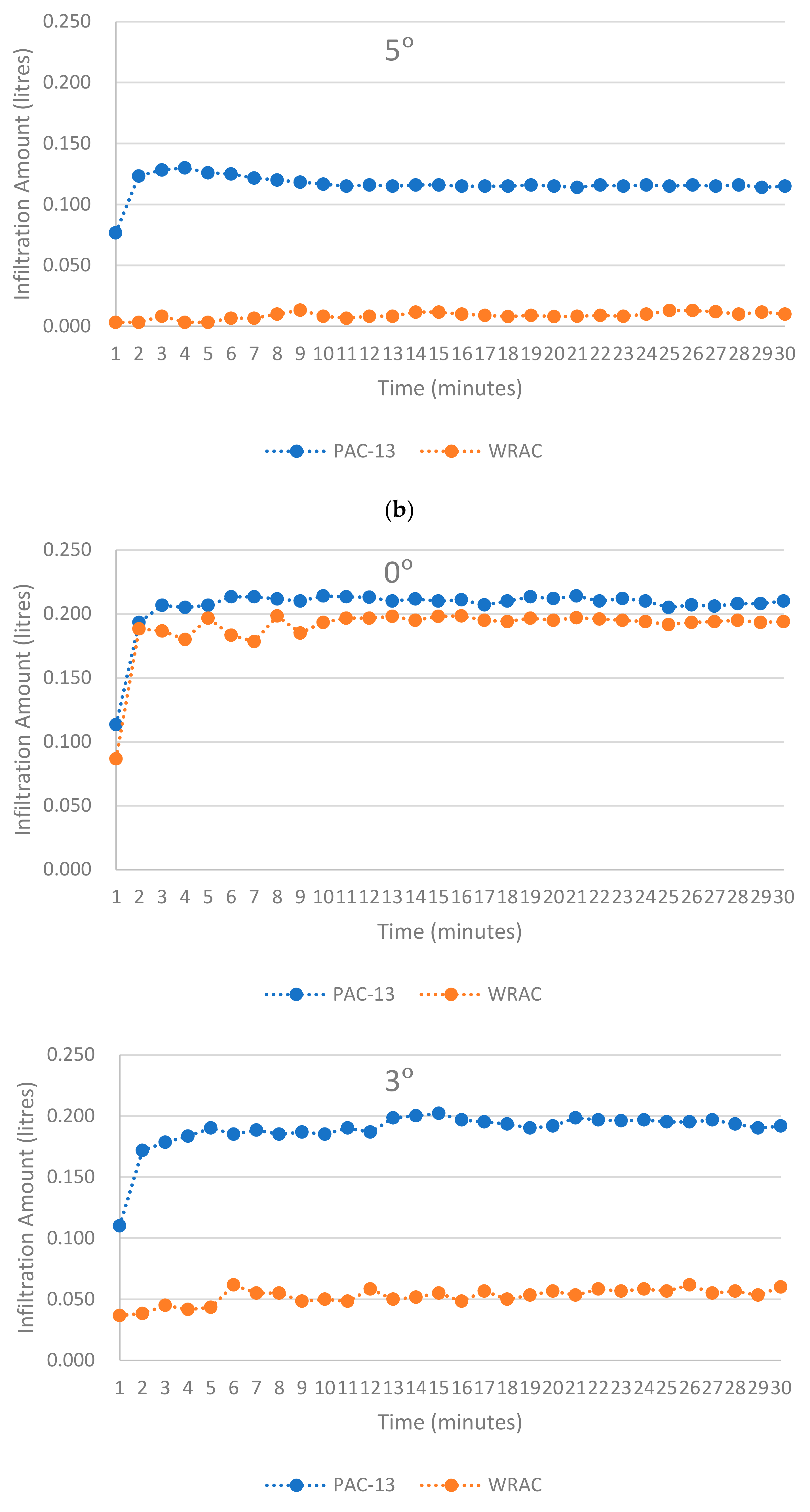

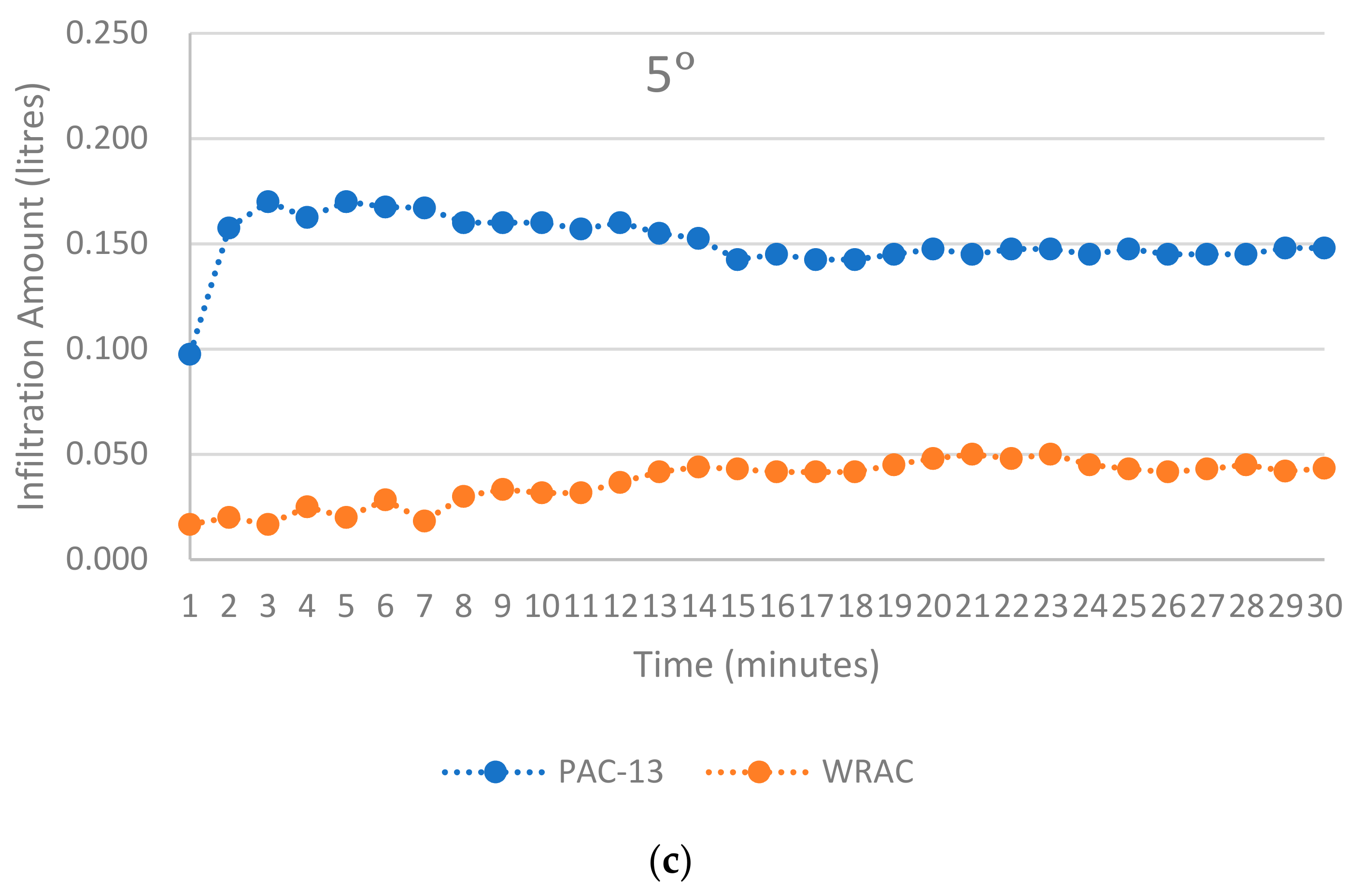

3.2.2. Infiltration Rates

3.3. Effect of Slope

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Güneralp, B.; Güneralp, İ.; Liu, Y. Changing global patterns of urban exposure to flood and drought hazards. Glob. Environ. Chang. 2015, 31, 217–225. [Google Scholar] [CrossRef]

- Garito, M.A.; Caforio, A.; Falegnami, A.; Tomassi, A.; Romano, E. Shape the EU future citizen. Environ. Educ. Eur. Green Deal. Energy Rep. 2023, 9, 340–354. [Google Scholar] [CrossRef]

- Yin, D.; Xu, C.; Jia, H.; Yang, Y.; Sun, C.; Wang, Q.; Liu, S. Sponge city practices in China: From pilot exploration to systemic demonstration. Water 2022, 14, 1531. [Google Scholar] [CrossRef]

- Ferguson, B. Porous Pavements, 1st ed.; CRC Press: Boca Raton, FL, USA, 2005; p. 600. [Google Scholar] [CrossRef]

- Roseen, R.M.; Ballestero, T.P.; Houle, J.J.; Briggs, J.F.; Houle, J.P. Water quality and hydrologic performance of a porous asphalt pavement as a stormwater treatment strategy in a cold climate. J. Environ. Eng. 2012, 138, 81–89. [Google Scholar] [CrossRef]

- Yang, Q.; Beecham, S.; Liu, J.; Pezzaniti, D. The influence of rainfall intensity and duration on sediment pathways and subsequent clogging in permeable pavements. J. Environ. Manag. 2019, 246, 730–736. [Google Scholar] [CrossRef] [PubMed]

- Drake, J.A.; Bradford, A.; Marsalek, J. Review of environmental performance of permeable pavement systems: State of the knowledge. Water Qual. Res. J. Can. 2013, 48, 203–222. [Google Scholar] [CrossRef]

- Lucke, T.; Beecham, S. An infiltration approach to reducing pavement damage by street trees. Sci. Total Environ. 2019, 671, 94–100. [Google Scholar] [CrossRef]

- Chen, J.S.; Yang, C.H. Porous asphalt concrete: A review of design, construction, performance and maintenance. Int. J. Pavement Res. Technol. 2020, 13, 601–612. [Google Scholar] [CrossRef]

- Yang, Q.; Gao, Z.; Beecham, S. A sustainable approach to cleaning porous and permeable pavements. Sustainability 2022, 14, 14583. [Google Scholar] [CrossRef]

- Interpave. Whole Life Cost Analysis for Various Pavement and Drainage Options; Report MP319; Interpave—The Precast Concrete Paving and Kerb Association, a Product Association of BPCF Ltd.: Glenfield, UK, 2006. [Google Scholar]

- Zhao, Y.; Wang, X.; Jiang, J.; Zhou, L. Characterization of interconnectivity, size distribution and uniformity of air voids in porous asphalt concrete using X-ray CT scanning images. Constr. Build. Mater. 2019, 213, 182–193. [Google Scholar] [CrossRef]

- Li, B.; Sun, M.; Zhu, X.; Cao, K.; Kong, Y. Investigation of permeability persistence of porous asphalt concrete under coupled conditions of clogging and cleaning. J. Transp. Eng. Part B Pavements 2023, 149, 05023001. [Google Scholar] [CrossRef]

- Martin, W.D.; Putman, B.J.; Neptune, A.I. Influence of aggregate gradation on clogging characteristics of porous asphalt mixtures. J. Mater. Civ. Eng. 2014, 26, 04014026. [Google Scholar] [CrossRef]

- Tan, S.A.; Fwa, T.F.; Chai, K.C. Drainage considerations for porous asphalt surface course design. Transp. Res. Rec. 2004, 1868, 142–149. [Google Scholar] [CrossRef]

- Jiang, W.; Sha, A.; Xiao, J.; Wanga, Z.; Apeagyei, A. Experimental study on materials composition design and mixture performance of water-retentive asphalt concrete. Constr. Build. Mater. 2016, 111, 128–138. [Google Scholar] [CrossRef]

- Yamagata, H.; Nasu, M.; Yoshizawa, M.; Miyamoto, A.; Minamiyama, M. Heat island mitigation using water retentive pavement sprinkled with reclaimed wastewater. Water Sci. Technol. 2008, 57, 763–771. [Google Scholar] [CrossRef] [PubMed]

- Nakayamaa, T.; Fujita, T. Cooling effect of water-holding pavements made of new materials on water and heat budgets in urban areas. Landsc. Urban Plan. 2010, 96, 57–67. [Google Scholar] [CrossRef]

- Elmagarhe, A.; Lu, Q.; Alharthai, M.; Alamri, M.; Elnihum, A. Performance of porous asphalt mixtures containing recycled concrete aggregate and fly ash. Materials 2022, 15, 6363. [Google Scholar] [CrossRef]

- Liu, H.; Luo, G.; Wang, L.; Gong, Y. Strength time-varying and freeze-thaw durability of sustainable pervious concrete pavement material containing waste fly ash. Sustainability 2019, 11, 176. [Google Scholar] [CrossRef]

- Aoki, Y.; Sri Ravindrarajah, R.; Khabbaz, H. Properties of pervious concrete containing fly ash. Road Mater. Pavement Des. 2012, 13, 1–11. [Google Scholar] [CrossRef]

- CJJ/T 190–2012; Technical Specification for Permeable Asphalt Pavement. Ministry of Housing and Urban-Rural Construction: Beijing, China, 2012. (In Chinese)

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Housing and Urban-Rural Construction: Beijing, China, 2011. (In Chinese)

- CJJ/T 206-2013; Technical Code for Lower-Heat-Absorbing Pavement of Urban Road. Ministry of Housing and Urban-Rural Construction: Beijing, China, 2013. (In Chinese)

- JTG D50-2006; Specifications for Design of Highway Asphalt Pavement. Ministry of Housing and Urban-Rural Construction: Beijing, China, 2006. (In Chinese)

- Sun, Y.; Song, W.; Wu, H.; Zhan, Y.; Wu, Z.; Yin, J. Investigation on performances and functions of asphalt mixtures modified with super absorbent polymer (SAP). Materials 2023, 16, 1082. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y.; Beecham, S. The relationship between porosity and strength for porous concrete. Constr. Build. Mater. 2011, 25, 4294–4298. [Google Scholar] [CrossRef]

- Praticò, F.G.; Moro, A. Permeability and volumetrics of porous asphalt concrete. Road Mater. Pavement Des. 2007, 8, 799–817. [Google Scholar] [CrossRef]

| High-Viscosity Asphalt | |

|---|---|

| Coarse aggregate | 10–15 mm and 5–10 mm diabase gravel |

| Fine aggregate | 0–3 mm sand |

| Mineral powder | limestone powder |

| Fibre | 0.3% lignin fibre by weight |

| Mineral ratio | Coarse aggregate (5–10 mm): Coarse aggregate (10–15 mm): Fine aggregate: Mineral powder = 46:43:7:4 |

| Optimum asphalt content | 5.39% |

| Gross weight | 5000 g |

| Asphalt dosage | 5.1%, 255 g |

| Aggregate weight (gross weight–bitumen–fibre mass) | 4730 g |

| Material Composition | Composition Ratio | Raw Material Properties |

|---|---|---|

| S95 grade slag micro-powder | 90% | Average particle size of slag powder < 75 μm and specific surface area > 400 kg/m2 |

| Fly ash powder | 10% | Average particle size of fly ash < 75 μm |

| Calcium hydroxide (% of S95 + fly ash powder) | 17% | pH of the liquid phase > 11 during mixing |

| Water (% of S95 + fly ash powder) | 70% | Normal tap water |

| Mesh Size (mm) | 26.5 | 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Passing Percentage (%) | 100.0 | 94.6 | 85.8 | 74.4 | 63.5 | 45.7 | 32.5 | 22.3 | 14.1 | 10.6 | 7.8 | 6.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Hu, J.; Beecham, S. Effect of Slope on Stormwater Infiltration into Porous Asphalt Pavements. Sustainability 2024, 16, 589. https://doi.org/10.3390/su16020589

Yang Q, Hu J, Beecham S. Effect of Slope on Stormwater Infiltration into Porous Asphalt Pavements. Sustainability. 2024; 16(2):589. https://doi.org/10.3390/su16020589

Chicago/Turabian StyleYang, Qiuxia, Jiaxuan Hu, and Simon Beecham. 2024. "Effect of Slope on Stormwater Infiltration into Porous Asphalt Pavements" Sustainability 16, no. 2: 589. https://doi.org/10.3390/su16020589

APA StyleYang, Q., Hu, J., & Beecham, S. (2024). Effect of Slope on Stormwater Infiltration into Porous Asphalt Pavements. Sustainability, 16(2), 589. https://doi.org/10.3390/su16020589