An Update on the Waste Management of the Amazonian Açaí Berry for the Civil Engineering Sector

Abstract

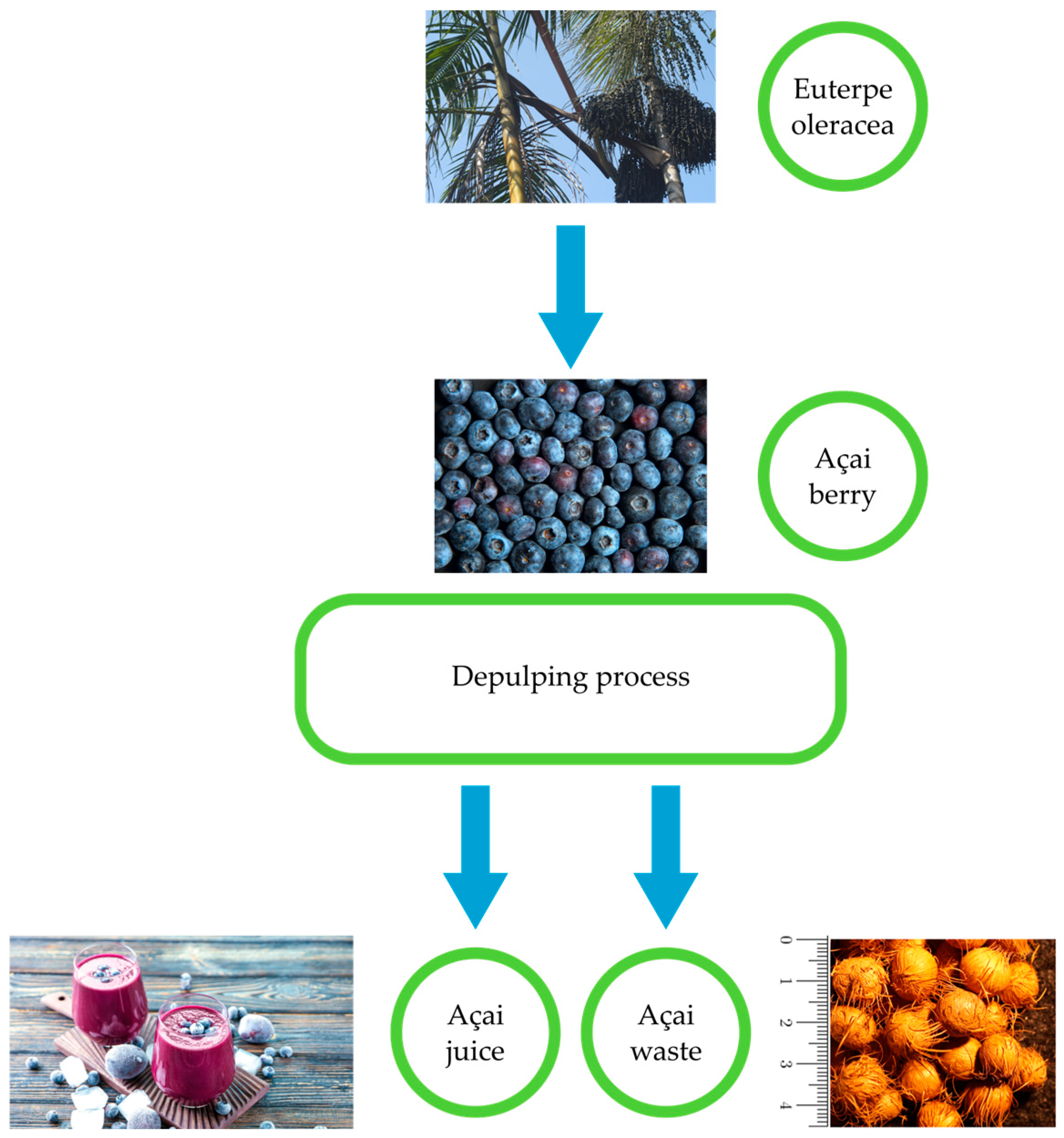

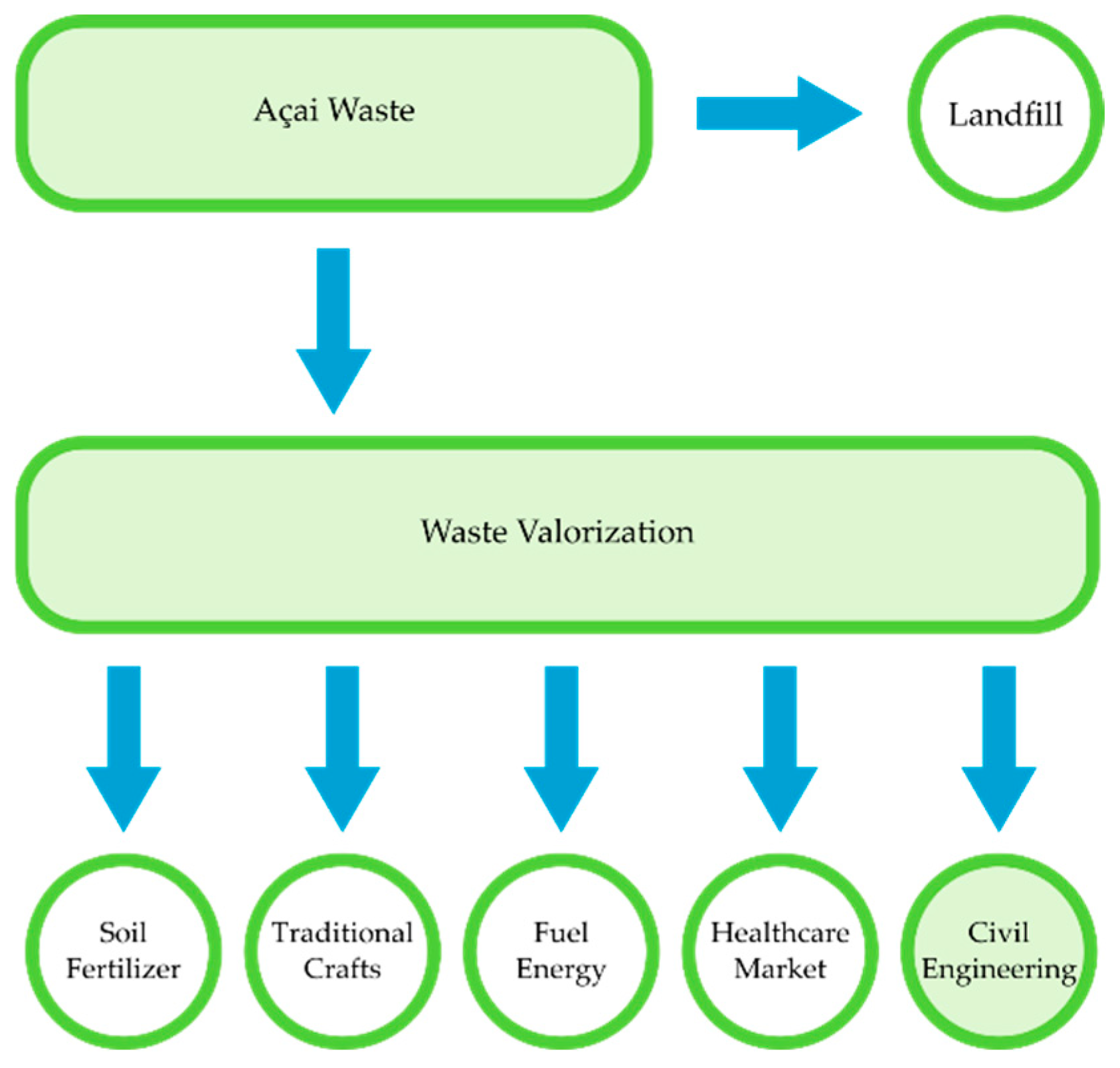

1. Introduction

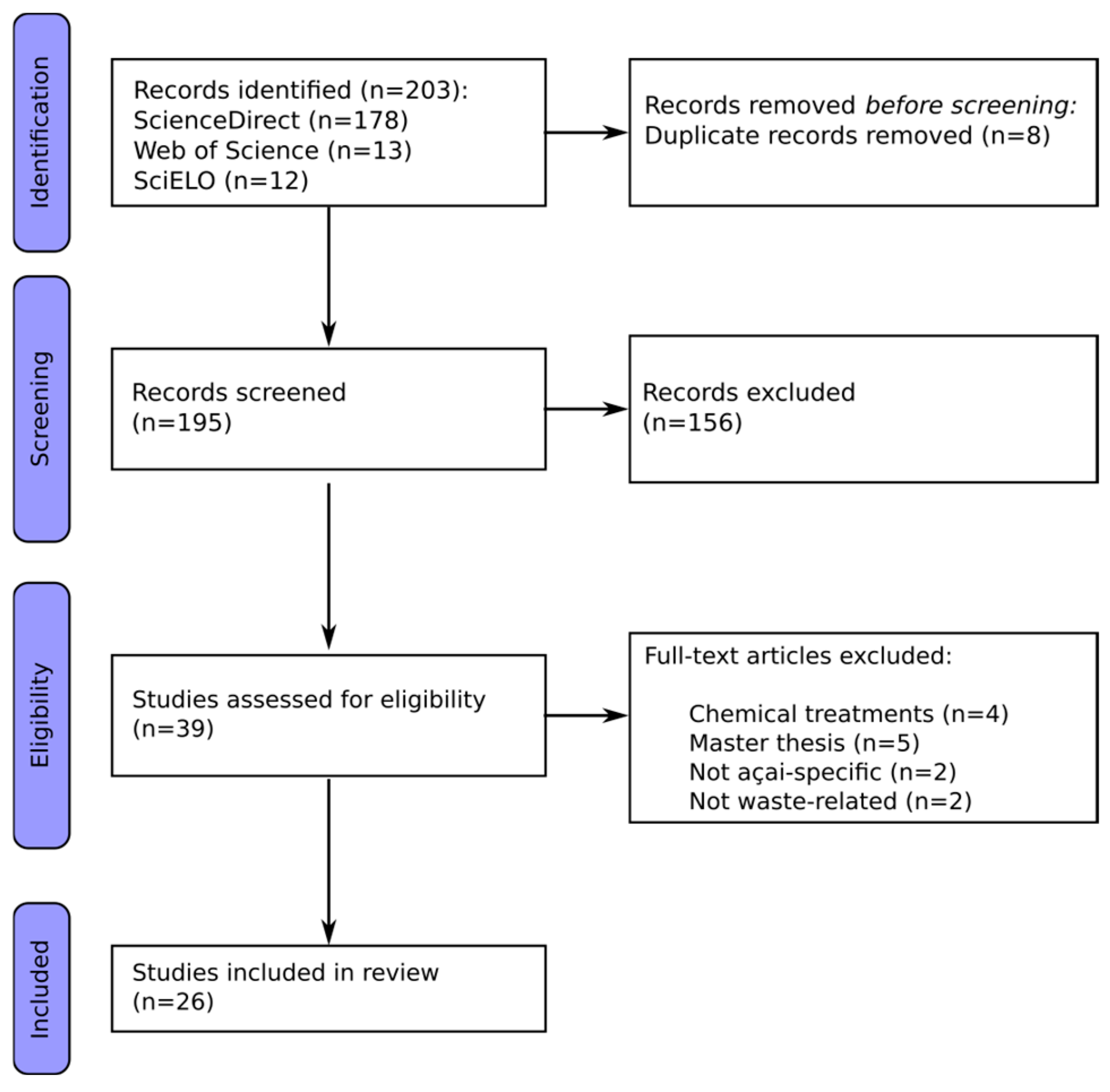

2. Materials and Methods

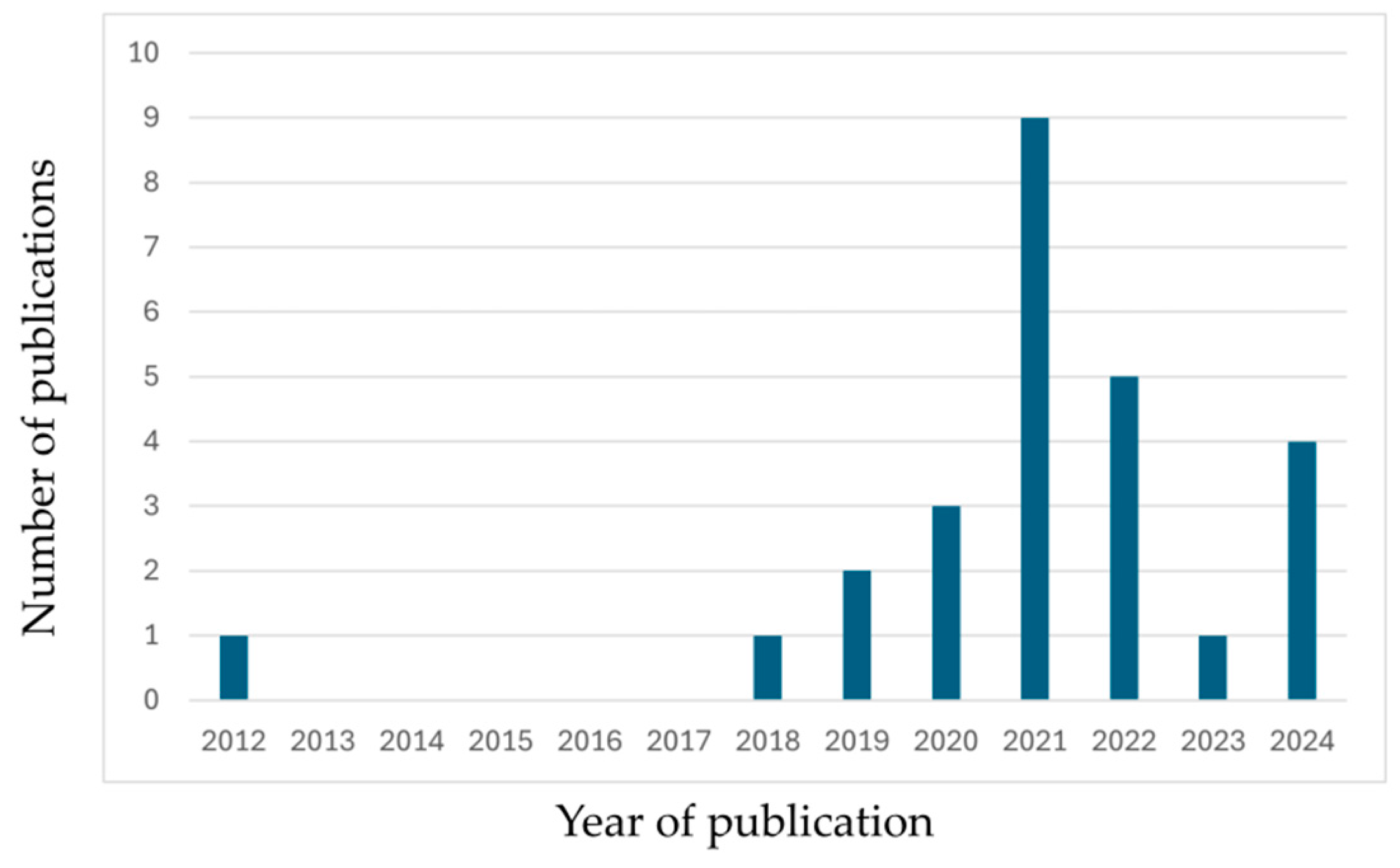

3. Results and Discussion

| Study | Year | Journal | Language | Type of Study | Targeted Civil Engineering Sector | Targeted Application | Technology Readiness Level |

|---|---|---|---|---|---|---|---|

| Characterization of açaí waste for potential use in civil engineering (as mentioned by authors) | |||||||

| [35] | 2021 | Applied Sciences | English | Experimental | Building | - | 2 |

| [36] | 2019 | Revista Materia | Portuguese | Experimental | Building | - | 1 |

| [37] | 2021 | Engenharia de Produtos Naturais | English | Experimental | Building | Particleboards | 3 |

| Preparation of cementitious composite | |||||||

| [6] | 2021 | Journal of Building Engineering | English | Experimental | Building | Façade coating | 2 |

| [38] | 2019 | Ambiente Construído | Portuguese | Experimental | Building | - | 4 |

| Composite sample testing | |||||||

| [39] | 2012 | Advances in Acoustics and Vibration | English | Experimental | Building | Sound-absorbing panels | 4 |

| [40] | 2021 | Mix Sustentável | English | Experimental | Building | Interior wall coating | 4 |

| [41] | 2021 | Revista de Engenharia e Tecnologia | Portuguese | Experimental | Building | - | 4 |

| [42] | 2018 | Industrial Crops and Products | English | Experimental | Building | Particleboards | 4 |

| [43] | 2021 | Brazilian Journal of Development | Portuguese | Experimental | Building | Non-structural lightweight concrete | 4 |

| [44] | 2020 | Research, Society and Development | Portuguese | Experimental | Building | Flooring, cladding | 4 |

| [45] | 2020 | Case Studies in Construction Materials | English | Experimental | Building | - | 4 |

| [46] | 2021 | AIMS Materials Science | English | Experimental | Building | Reparation of structural defects with low load demand | 4 |

| [47] | 2020 | Brazilian Journal of Development | Portuguese | Experimental | Building | - | 4 |

| [34] | 2021 | Desafios das Engenharias | English | Experimental | Public works | Pavement | 4 |

| [48] | 2021 | Agronomy Research | English | Experimental | Building | Cladding and slabbing in rural buildings | 4 |

| [49] | 2023 | Environmental Development | English | Experimental | Building | Cement | 4 |

| [50] | 2022 | Polymers and Polymer Composites | English | Experimental | Building | Particleboards | 4 |

| [51] | 2024 | Advances in Cement Research | English | Experimental | Building | Fiberboards | 4 |

| [52] | 2024 | Case Studies in Construction Materials | English | Experimental | Building | Soil–cement bricks | 4 |

| [53] | 2024 | Journal of Building Engineering | English | Experimental | Building | Coating mortars | 4 |

| [54] | 2022 | Sustainability | English | Experimental | Building | Self-leveling mortars | 4 |

| [55] | 2024 | Minerals, Metals and Materials Series | English | Experimental | Building | Coating mortars | 4 |

| Study | Year | Components of the Seed | Application | Outcomes |

|---|---|---|---|---|

| [35] | 2021 | Fibers | Portland cement pastes | Reinforcement of cementitious matrix with ground fibers treated with NaOH and HCl in proportions of 5 to 10% relative to cement mass increases fiber functionalization; the composite cement with 5% fibers compares to plain cement pastes. |

| [36] | 2019 | Stone and fibers | Characterization | The density and moisture of ground açaí stones and fibers make them good candidates for the elaboration of composite materials. |

| [39] | 2012 | Fibers | Panels | Panels made of açaí fiber in combination with other natural fibers feature promising acoustic properties, even greater than conventional acoustic materials over certain frequency ranges. |

| [40] | 2021 | Ground stone | Composite matrix material | The obtained material has high density and may replace synthetic materials in composites. |

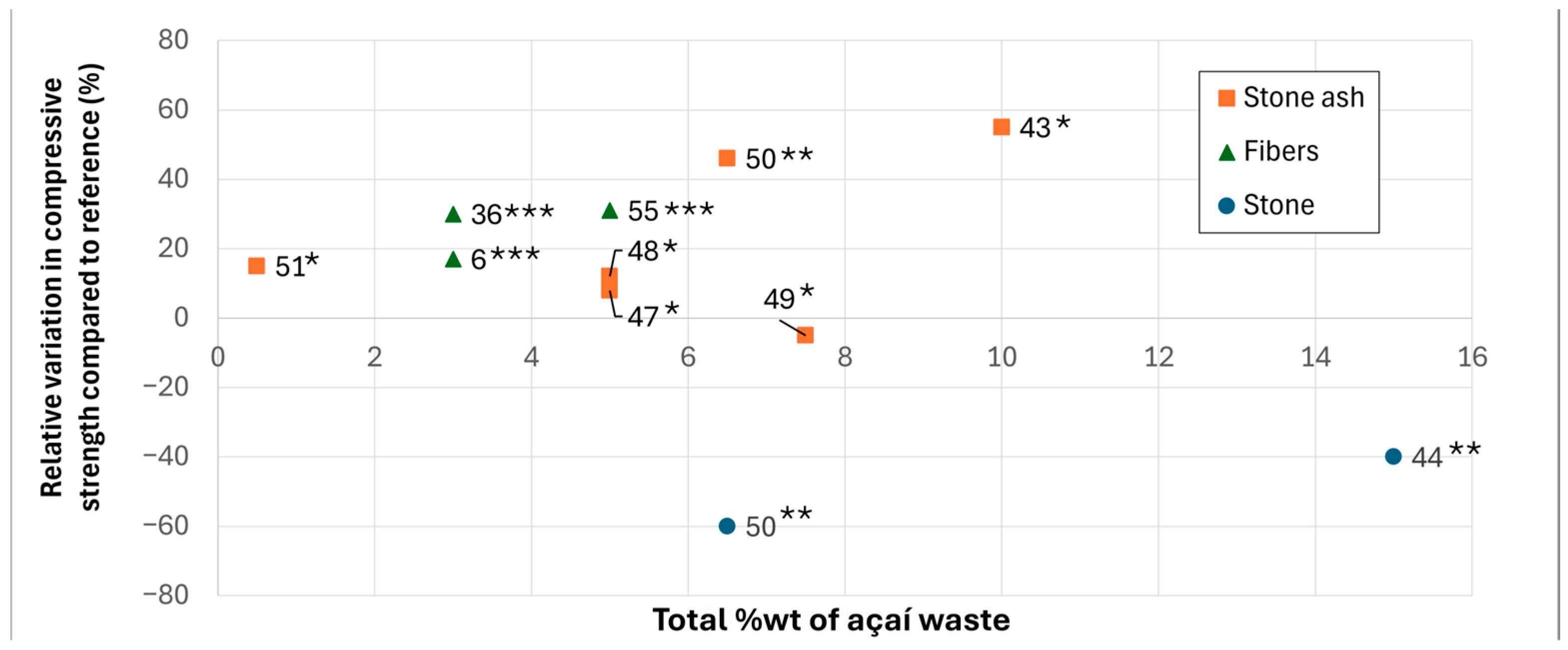

| [38] | 2019 | Stone ash | Concrete | Slight, but acceptable, decrease in axial compressive strength but an increase in water absorption of concrete with added açaí stone ash. |

| [41] | 2021 | Stone ash | Coating mortar | Water absorption, shrinking, and durability remain acceptable for 0, 5, and 10% of stone ash proportion, but flexural strength is affected negatively. |

| [6] | 2021 | Fibers | Cement-based mortars | Açaí fibers in additions of up to 3.0% relative to cement mass and properly treated with NaOH solution can be used as reinforcement mechanisms for mortar applications. |

| [42] | 2018 | Fibers | Characterization of açaí fibers treated with NaOH | Açaí fibers may be used as a raw material in the form of medium-density homogeneous particleboards. |

| [43] | 2021 | Stone | Non-structural lightweight concrete | Lightweight concrete with a 30/70% boiled açaí stone/pebble ratio displays lighter specific mass and higher compressive strength compared to untreated stone and stone coated with stone ash. |

| [44] | 2020 | Stone ash | Red ceramics | Açaí seed residues may be used up to 10% in mass proportion as a partial substitute in the red clay industry while retaining technological properties within the minimum standards. |

| [45] | 2020 | Fibers | Coating mortars | The durability of coating mortars containing NaOH-treated açaí fibers after wetting, drying, salt spray exposure, and thermal shock is enhanced, and the compressive strength of mortars containing 3.0% of açaí fibers is increased. |

| [37] | 2021 | Fibers | Medium-density particle boards | Açaí fibers treated with 0.5% NaOH solution are viable in the manufacturing of composites, and chemical composition is comparable with the usual values of the lignocellulosic vegetal fibers used in particleboards. |

| [46] | 2021 | Stone | Structural mortars | The compressive strength of mortars with 25% of sand mass replaced by açaí stones is decreased but remains above minimum values recommended, and the density is also decreased. However, its use should be limited to structural elements with low load demand. |

| [47] | 2020 | Stone ash | Concrete | A mass proportion of 5% of açaí stone ash results in higher carbonation resistance and enhanced workability. |

| [34] | 2021 | Fibers | Interlocked pavement concrete | Replacement proportions of 10, 1.5, and 1.0% of large and small aggregates by açaí fibers are not recommended for interlocking pavements in light and heavy vehicle traffic since they do not reach the recommended 35 MPa. However, they are suitable for sidewalks and pavements without heavy traffic. |

| [48] | 2021 | Fibers | Mortar applications in rural construction | Fibers added in the proportion of 2.5 and 5.0% relative to cement mass and treated with NaOH solution produce mortar suitable for rural construction in terms of compression strength. |

| [49] | 2023 | Stone ash | LC3 (Limestone Calcined Clay Cement) | The addition of 10% of açaí stone ash in a 45% Portland cement, 30% calcined clay, and 15% limestone mixture produces a composite that does not reach the minimum requirements in terms of compressive strength. |

| [54] | 2022 | Stone ash | Self-leveling mortar | Maintains mechanical performance (compression and bending) up to 10% Açai seed ash in the composite while reducing GHG emissions by 8%. |

| [53] | 2024 | Calcined seeds, crushed seeds | Mortar applications | The replacement of 10% of sand by mass in mortar with calcined, ground, or paraffin-treated cores resulted in the reduction of compressive and tensile strength in all cases and negatively affected the properties of coating mortar (application not feasible). |

| [52] | 2024 | Stone ash | LC3 (Limestone Calcined Clay Cement) | The replacement of 5, 10, 15, and 20% cement in LC3 (representing 10% of the cementitious composite) improved soil stabilization in the composite, with no statistically significant reduction in compressive strength up to 20% ash by cement clinker mass. |

| [50] | 2022 | Stone | Polymeric composite | The coarse particle size (between 1.19 and 2.38 mm) and 10% polyurethane resin give the best results for non-structural applications such as indoor partition and ceiling applications. |

| [51] | 2024 | Fibers | Cement-bonded fiberboards | Based on the compression strength, raw açaí fibers were ranked as most suitable to produce cement-bonded fiberboards, compared to thermal- and chemical-treated fibers. |

| [55] | 2024 | Fibers | Mortars | Adding 0.5, 1.0, and 3% fiber (tannic acid-treated or untreated) by mass in relation to cement reduced the consistency index and mass density of the mortars while increasing the air content. |

3.1. Açaí Fibers

3.2. Açaí Stones

3.3. Comparison with Similar Types of Agricultural Wastes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IBGE. Produção de Açaí (Cultivo). IBGE. 2021. Available online: https://www.ibge.gov.br/explica/producao-agropecuaria/acai-cultivo/br (accessed on 1 September 2024).

- Nobre, C. Brazil: Boost pro-forest economics. Nature 2014, 510, 210. [Google Scholar]

- Luo, R.; Tran, K.; Levine, R.A.; Nickols, S.M.; Monroe, D.M.; Sabaa-Srur, A.U.; Smith, R.E. Distinguishing Components in Brazilian Acai (Euterpe oleraceae Mart.) and in Products Obtained in the USA by Using NMR. Nat. Prod. J. 2012, 2, 86–94. [Google Scholar] [CrossRef]

- Schauss, A.G.; Wu, X.; Prior, R.L.; Ou, B.; Huang, D.; Owens, J.; Agarwal, A.; Jensen, G.S.; Hart, A.N.; Shanbrom, E. Antioxidant capacity and other bioactivities of the freeze-dried Amazonian palm berry, Euterpe oleraceae mart. (acai). J. Agric. Food Chem. 2006, 54, 8604–8610. [Google Scholar] [CrossRef]

- de Paula, J.E. Anatomia de Euterpe oleracea Mart. (Palmae da Amazônia). Acta Amaz. 1975, 5, 265–278. [Google Scholar] [CrossRef][Green Version]

- de Azevedo, A.R.G.; Marvila, M.T.; Tayeh, B.A.; Cecchin, D.; Pereira, A.C.; Monteiro, S.N. Technological performance of açaí natural fibre reinforced cement-based mortars. J. Build. Eng. 2021, 33, 101675. [Google Scholar] [CrossRef]

- Braga, D.G.; de Abreu, J.L.L.; da Silva, M.G.; de Souza, T.M.; Dias, M.C.; Tonoli, G.H.D.; de Oliveira Neto, C.F.; Claro, P.I.C.; Gomes, L.G.; Bufalino, L. Cellulose nanostructured films from pretreated açai mesocarp fibers: Physical, barrier, and tensile performance. Cerne 2021, 27, e-102783. [Google Scholar] [CrossRef]

- de Oliveira, D.N.P.S.; Claro, P.I.C.; de Freitas, R.R.; Martins, M.A.; Souza, T.M.; Breno, B.M.; Mendes, L.M.; Bufalino, L. Enhancement of the Amazonian Açaí Waste Fibers through Variations of Alkali Pretreatment Parameters. Chem. Biodivers. 2019, 16, e1900275. [Google Scholar] [CrossRef]

- Pessoa, J.D.C.; Arduin, M.; Martins, M.A.; de Carvalho, J.E.U. Characterization of açaí (E. oleracea) fruits and its processing residues. Braz. Arch. Biol. Technol. 2010, 53, 1451–1460. [Google Scholar] [CrossRef]

- Market Data Forecast. Acaí Berry Market Analysis by Applications. 2024. Available online: https://www.marketdataforecast.com/market-reports/acai-berry-market (accessed on 1 September 2024).

- Melo, P.S.; Selani, M.M.; Gonçalves, R.H.; de Oliveira Paulino, J.; Massarioli, A.P.; de Alencar, S.M. Açaí seeds: An unexplored agro-industrial residue as a potential source of lipids, fibers, and antioxidant phenolic compounds. Ind. Crops Prod. 2021, 161, 113204. [Google Scholar] [CrossRef]

- Monteiro, A.F.; Miguez, I.S.; Silva, J.P.R.B.; da Silva, A.S.A. High concentration and yield production of mannose from açaí (Euterpe oleracea Mart.) seeds via mannanase-catalyzed hydrolysis. Sci. Rep. 2019, 9, 10939. [Google Scholar] [CrossRef]

- Bufalino, L.; Guimarães, A.A.; Silva, B.M.D.S.E.; De Souza, R.L.F.; De Melo, I.C.N.A.; De Oliveira, D.N.P.S.; Trugilho, P.F. Local variability of yield and physical properties of açaí waste and improvement of its energetic attributes by separation of lignocellulosic fibers and seeds. J. Renew. Sustain. Energy 2018, 10, 053102. [Google Scholar] [CrossRef]

- da Silva, J.J.A.; Di Paolo, Í.F.; Quinto, W.A.d.S.; Braga, A.C.C.; Nunes, D.R.d.L.; Melo, A.C.S. Looking for Communicative Sinergy Between Generators and Consumers of Açaí Pulp Production Waste with Software Prototyping/ Procurando uma sinergia comunicativa entre geradores e consumidores de Açaí Resíduos de produção de celulose com Protótipo de softw. Braz. J. Dev. 2021, 7, 58194–58213. [Google Scholar] [CrossRef]

- Moreira, M.A.; de Sousa, A.L.F. Tratamento e análise de resíduos da produção de açaí: Um estudo sob a ótica da ecoeficiência. Rev. Ambient. CONTÁBIL-Univ. Fed. Rio Gd. Norte 2020, 12, 279–297. [Google Scholar] [CrossRef]

- Jorge, F.T.A.; da Silva, A.S.; Brigagão, G.V. Açaí waste valorization via mannose and polyphenols production: Techno-economic and environmental assessment. Biomass Convers. Biorefinery 2024, 14, 3739–3752. [Google Scholar] [CrossRef]

- Freitas, M.A.B.; Magalhães, J.L.L.; Carmona, C.P.; Arroyo-Rodríguez, V.; Vieira, I.C.G.; Tabarelli, M. Intensification of açaí palm management largely impoverishes tree assemblages in the Amazon estuarine forest. Biol. Conserv. 2021, 261, 109251. [Google Scholar] [CrossRef]

- Ulewicz, M. Recycled Materials in Civil Engineering Application. Materials 2023, 16, 7075. [Google Scholar] [CrossRef]

- Nunes, K.R.A.; Schebek, L. Sustainable supply chain initiatives in the Brazilian construction industry. Handb. Sustain. Manag. 2012, 713–732. [Google Scholar] [CrossRef]

- Law No. 12305-Brazilian National Policy on Solid Waste. 2010. Available online: http://www.braziliannr.com/brazilian-environmental-legislation/law-no-12305-brazilian-national-policy-solid-waste/ (accessed on 1 September 2024).

- Arrêté du 4 août 2021 relatif aux Exigences de Performance énergétique et Environnementale des Constructions de bâtiments en France Métropolitaine et Portant Approbation de la Méthode de calcul prévue à l’article R. 172-6 du code de la Construction et de. 2021. Available online: https://www.legifrance.gouv.fr/eli/arrete/2021/8/4/LOGL2107359A/jo/texte (accessed on 1 September 2024).

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Mo, K.H.; Thomas, B.S.; Yap, S.P.; Abutaha, F.; Tan, C.G. Viability of agricultural wastes as substitute of natural aggregate in concrete: A review on the durability-related properties. J. Clean. Prod. 2020, 275, 123062. [Google Scholar] [CrossRef]

- Raut, S.P.; Ralegaonkar, R.V.; Mandavgane, S.A. Development of sustainable construction material using industrial and agricultural solid waste: A review of waste-create bricks. Constr. Build. Mater. 2011, 25, 4037–4042. [Google Scholar] [CrossRef]

- Sadin, S.R.; Povinelli, F.P.; Rosen, R. The NASA technology push towards future space mission systems. Acta Astronaut. 1989, 20, 73–77. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Altman, D.; Antes, G.; Atkins, D.; Barbour, V.; Barrowman, N.; Berlin, J.A.; et al. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6. [Google Scholar] [CrossRef] [PubMed]

- de Lima, T.E.S.; de Azevedo, A.R.G.; Marvila, M.T.; Candido, V.S.; Fediuk, R.; Monteiro, S.N. Potential of Using Amazon Natural Fibers to Reinforce Cementitious Composites: A Review. Polymers 2022, 14, 647. [Google Scholar] [CrossRef] [PubMed]

- de Azevedo, A.R.G.; Amin, M.; Hadzima-Nyarko, M.; Saad Agwa, I.; Zeyad, A.M.; Tayeh, B.A.; Adesina, A. Possibilities for the application of agro-industrial wastes in cementitious materials: A brief review of the Brazilian perspective. Clean. Mater. 2022, 3, 100040. [Google Scholar] [CrossRef]

- Rocha, D.L.; Júnior, L.U.D.T.; Marvila, M.T.; Pereira, E.C.; Souza, D.; de Azevedo, A.R.G. A Review of the Use of Natural Fibers in Cement Composites: Concepts, Applications and Brazilian History. Polymers 2022, 14, 2043. [Google Scholar] [CrossRef]

- Chalapud, M.C.; Herdt, M.; Nicolao, E.S.; Ruseckaite, R.A.; Ciannamea, E.M.; Stefani, P.M. Biobased particleboards based on rice husk and soy proteins: Effect of the impregnation with tung oil on the physical and mechanical behavior. Constr. Build. Mater. 2020, 230, 116996. [Google Scholar] [CrossRef]

- Ciannamea, E.M.; Stefani, P.M.; Ruseckaite, R.A. Medium-density particleboards from modified rice husks and soybean protein concentrate-based adhesives. Bioresour. Technol. 2010, 101, 818–825. [Google Scholar] [CrossRef]

- Nicolao, E.S.; Leiva, P.; Chalapud, M.C.; Ruseckaite, R.A.; Ciannamea, E.M.; Stefani, P.M. Flexural and tensile properties of biobased rice husk-jute-soybean protein particleboards. J. Build. Eng. 2020, 30, 101261. [Google Scholar] [CrossRef]

- Olupot, P.W.; Menya, E.; Lubwama, F.; Ssekaluvu, L.; Nabuuma, B.; Wakatuntu, J. Effects of sawdust and adhesive type on the properties of rice husk particleboards. Results Eng. 2022, 16, 100775. [Google Scholar] [CrossRef]

- Ramos Rodrigues, F.C.; Avelino Rego, L.C.; Almeida da Silva, M.D.; Guimarães da Silva, S.R.; de Melo, S.G.; Sousa da Silva, H.R.A. Utilização da fibra do açaí na composição de pavimentos intertravados para passeio público na cidade de Santarém-Pa. Coleção Desafios Das Eng. Eng. Civ. 2 2021, 80–93. [Google Scholar]

- Azevedo, A.; De Matos, P.; Marvila, M.; Sakata, R.; Silvestro, L.; Gleize, P.; De Brito, J. Rheology, Hydration, and Microstructure of Portland Cement Pastes Produced with Ground Açaí Fibers. Appl. Sci. 2021, 11, 3036. [Google Scholar] [CrossRef]

- Barbosa, A.D.M.; Rebelo, V.S.M.; Martorano, L.G.; Giacon, V.M. Characterization of acai waste particles for civil construction use. Rev. Mater. 2019, 24, e12435. [Google Scholar] [CrossRef]

- Mesquita, A.M.; de Almeida Lins, A.L.F.; Barreto, N.M.G.; Santos, S.S.; Peres, C.E.B.; de Faria, L.J.G. Anatomical and physicochemical characterization of açaí fruit fiber as an alternative raw material in ecopanels production. In Engenharia de Produtos Naturais: Planejamento, Experimentação, Obtenção de Produtos e Purificação; Editora Científica Digital: São Paulo, Brazil, 2021; pp. 326–341. [Google Scholar]

- Cordeiro, L.d.N.P.; Paes, I.N.L.; Souza, P.S.L.; Azevedo, C.M. Characterisation of residual açaí stone ash for addition to concrete. Ambiente Construído 2019, 19, 45–55. [Google Scholar] [CrossRef]

- Bastos, L.P.; De Melo, G.D.S.V.; Soeiro, N.S. Panels manufactured from vegetable fibers: An alternative approach for controlling noises in indoor environments. Adv. Acoust. Vib. 2012, 2012, 698737. [Google Scholar] [CrossRef]

- Boaventura, B.P.; Cavalcanti, C.; Lira, G.; Souza, D.E. The usage of the açaí stone as reinforcement for the modeling of plant polyurethane matrix composite material. Mix. Sustent. 2021, 7, 19–28. [Google Scholar] [CrossRef]

- da Silva Araujo, J.C.; de Sousa Garcia, A.; Pereira Bonfirm, F.; Tigre de Souza, G. Influência da cinza do caroço de açaí nas propriedades de argamassas de chapisco. Rev. Eng. Tecnol. 2021, 13, 216–226. [Google Scholar]

- de Lima Mesquita, A.; Barrero, N.G.; Fiorelli, J.; Christoforo, A.L.; De Faria, L.J.G.; Lahr, F.A.R. Eco-particleboard manufactured from chemically treated fibrous vascular tissue of acai (Euterpe oleracea Mart.) Fruit: A new alternative for the particleboard industry with its potential application in civil construction and furniture. Ind. Crops Prod. 2018, 112, 644–651. [Google Scholar] [CrossRef]

- De Oliveira, M.A.B.; Costa, R.P.; Brandão, S.C.; Miranda, M.V.M.; da Costa Marques, C.A.; Caldas, A.A.; De Assunção, W.R.; da Chaves, P.S.; Racanelli, L.d.A. Concreto leve não estrutural com substituição parcial de seixo por caroço de Açaí / Lightweight non-structural concrete with partial replacement of pebble with Acaí seed. Braz. J. Dev. 2021, 7, 72543–72557. [Google Scholar] [CrossRef]

- da Silva Ferreira, T.; Mesquita, F.J.M.; Ishihara, J.H.; Souza, P.S.L. Análise das propriedades tecnológicas da cinza do caroço de açaí na cerâmica vermelha. Res. Soc. Dev. 2020, 9, e76996343. [Google Scholar] [CrossRef]

- Marvila, M.T.; Azevedo, A.R.G.; Cecchin, D.; Costa, J.M.; Xavier, G.C.; de Fátima do Carmo, D.; Monteiro, S.N. Durability of coating mortars containing açaí fibers. Case Stud. Constr. Mater. 2020, 13, e00406. [Google Scholar] [CrossRef]

- Monteiro, G.P.; de Azevedo, A.R.G.; Marvila, M.T. Effect of the addition of the natural and treated açaí stone in structural mortars. AIMS Mater. Sci. 2021, 8, 608–621. [Google Scholar] [CrossRef]

- da Costa Oliveira, T.M.; do Nascimento, K.F.S.; Junior, J.A.R.; da Silva, L.F.A.; Jacinto, M.d.A.S.; dos Santos, R.G.; Ribeiro, D.D.G.; da Rocha, S.N.V. Aproveitamento das cinzas de caroço de açaí na produção de concreto sustentável analisando sua durabilidade/Use of açaí stone ash in the production of sustainable concrete analyzing its durability. Braz. J. Dev. 2020, 6, 30749–30756. [Google Scholar] [CrossRef]

- Rocha, D.L.; Azevedo, A.R.G.; Marvila, M.T.; Cecchin, D.; Alexandre, J.; Carmo, D.F.; Ferraz, P.F.P.; Conti, L.; Rossi, G. Influence of different methods of treating natural açai fibre for mortar in rural construction. Agron. Res. 2021, 19, 910–921. [Google Scholar]

- Tino Balestra, C.E.; Garcez, L.R.; Couto da Silva, L.; Veit, M.T.; Jubanski, E.; Nakano, A.Y.; Pietrobelli, M.H.; Schneider, R.; Ramirez Gil, M.A. Contribution to low-carbon cement studies: Effects of silica fume, fly ash, sugarcane bagasse ash and acai stone ash incorporation in quaternary blended limestone-calcined clay cement concretes. Environ. Dev. 2023, 45, 100792. [Google Scholar] [CrossRef]

- de Melo Barbosa, A.; Machado dos Santos, G.; Medeiros de Melo, G.M.; Litaiff, H.A.; Martorano, L.G.; Giacon, V.M. Evaluation of the use of açaí seed residue as reinforcement in polymeric composite. Polym. Polym. Compos. 2022, 30, 09673911221108307. [Google Scholar] [CrossRef]

- de Oliveira, D.N.P.S.; de Souza, T.M.; dos Santos Ferreira, N.; Bezerra, J.B.; Polidori, G.; Bufalino, L. Amazon açaí fibre—Portland cement compatibility: A challenge to produce cement-bonded fibreboards? Adv. Cem. Res. 2024, 1–14. [Google Scholar] [CrossRef]

- Garcez, L.R.; dos Santos Lima, M.; Ribas, L.F.; Balestra, C.E.T.; Monteiro, N.B.R.; Melo Filho, J.d.A.; Gil, M.A.R. Characteristics of the açai seed (Euterpe precatoria Martius) after thermal processing and its potential in soil-cement brick. Case Stud. Constr. Mater. 2024, 20, e02816. [Google Scholar] [CrossRef]

- Monteiro, G.P.; Marvila, M.T.; Pedroti, L.G.; de Brito, J.; de Azevedo, A.R.G. Evaluation of coating mortars with addition of açaí seed (Euterpe oleracea Mart.) in different processing conditions. J. Build. Eng. 2024, 83, 108459. [Google Scholar] [CrossRef]

- Rocha, J.H.A.; de Siqueira, A.A.; de Oliveira, M.A.B.; da Silva Castro, L.; Caldas, L.R.; Monteiro, N.B.R.; Toledo Filho, R.D. Circular Bioeconomy in the Amazon Rainforest: Evaluation of Açaí Seed Ash as a Regional Solution for Partial Cement Replacement. Sustainability 2022, 14, 14436. [Google Scholar] [CrossRef]

- Natalli, J.F.; Pereira, I.S.A.; Júnior, E.R.G.; Malafaia, S.A.A.; Batista, I.D.; Barbosa, M.V.; Marvila, M.T.; Margem, F.M.; Lima, T.E.S.; Monteiro, S.N.; et al. Performance Evaluation of Açaí Fiber as Reinforcement in Coating Mortars. Miner. Met. Mater. Ser. 2024, 587–594. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Capelin, L.J.; Moraes, K.K.; Zampieri, J.P.; Vanderlei, R.D. Avaliação dos efeitos da fibra de coco e da microcelulose cristalina nas propriedades de argamassas cimentícias. Matéria 2020, 25, e-12551. [Google Scholar] [CrossRef]

- Azevedo, A.R.; Marvila, M.T.; Zanelato, E.B.; Alexandre, J.; Xavier, G.C.; Cecchin, D. Development of mortar for laying and coating with pineapple fibers. Rev. Bras. Eng. Agrícola Ambient. 2020, 24, 187–193. [Google Scholar] [CrossRef]

- The TRL Scale as a Research & Innovation Policy Tool, EARTO Recommendations. Available online: https://www.earto.eu/wp-content/uploads/The_TRL_Scale_as_a_R_I_Policy_Tool_-_EARTO_Recommendations_-_Final.pdf (accessed on 1 September 2024).

| Fiber | Study | Fiber Condition | Fiber Amount (% wt.) | Compressive Strength (MPa) |

|---|---|---|---|---|

| Açaí | [6] | Natural | 3 | 4.02 |

| Treated with NaOH | 3 | 4.23 | ||

| Coconut | [57] | Immersion in boiling water | 0.1 | 29.97 |

| Pineapple | [58] | Natural | 5 | 4.44 |

| Treated with NaOH | 7.5 | 5.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Polidori, G.; Murer, S.; Beaumont, F.; Lachi, M.; Bliard, C.; Nait-Rabah, O.; Bufalino, L.; Bogard, F. An Update on the Waste Management of the Amazonian Açaí Berry for the Civil Engineering Sector. Sustainability 2024, 16, 8451. https://doi.org/10.3390/su16198451

Polidori G, Murer S, Beaumont F, Lachi M, Bliard C, Nait-Rabah O, Bufalino L, Bogard F. An Update on the Waste Management of the Amazonian Açaí Berry for the Civil Engineering Sector. Sustainability. 2024; 16(19):8451. https://doi.org/10.3390/su16198451

Chicago/Turabian StylePolidori, Guillaume, Sébastien Murer, Fabien Beaumont, Mohammed Lachi, Christophe Bliard, Ouahcène Nait-Rabah, Lina Bufalino, and Fabien Bogard. 2024. "An Update on the Waste Management of the Amazonian Açaí Berry for the Civil Engineering Sector" Sustainability 16, no. 19: 8451. https://doi.org/10.3390/su16198451

APA StylePolidori, G., Murer, S., Beaumont, F., Lachi, M., Bliard, C., Nait-Rabah, O., Bufalino, L., & Bogard, F. (2024). An Update on the Waste Management of the Amazonian Açaí Berry for the Civil Engineering Sector. Sustainability, 16(19), 8451. https://doi.org/10.3390/su16198451