Ultimate Pit Limit Optimization Method with Integrated Consideration of Ecological Cost, Slope Safety and Benefits: A Case Study of Heishan Open Pit Coal Mine

Abstract

1. Introduction

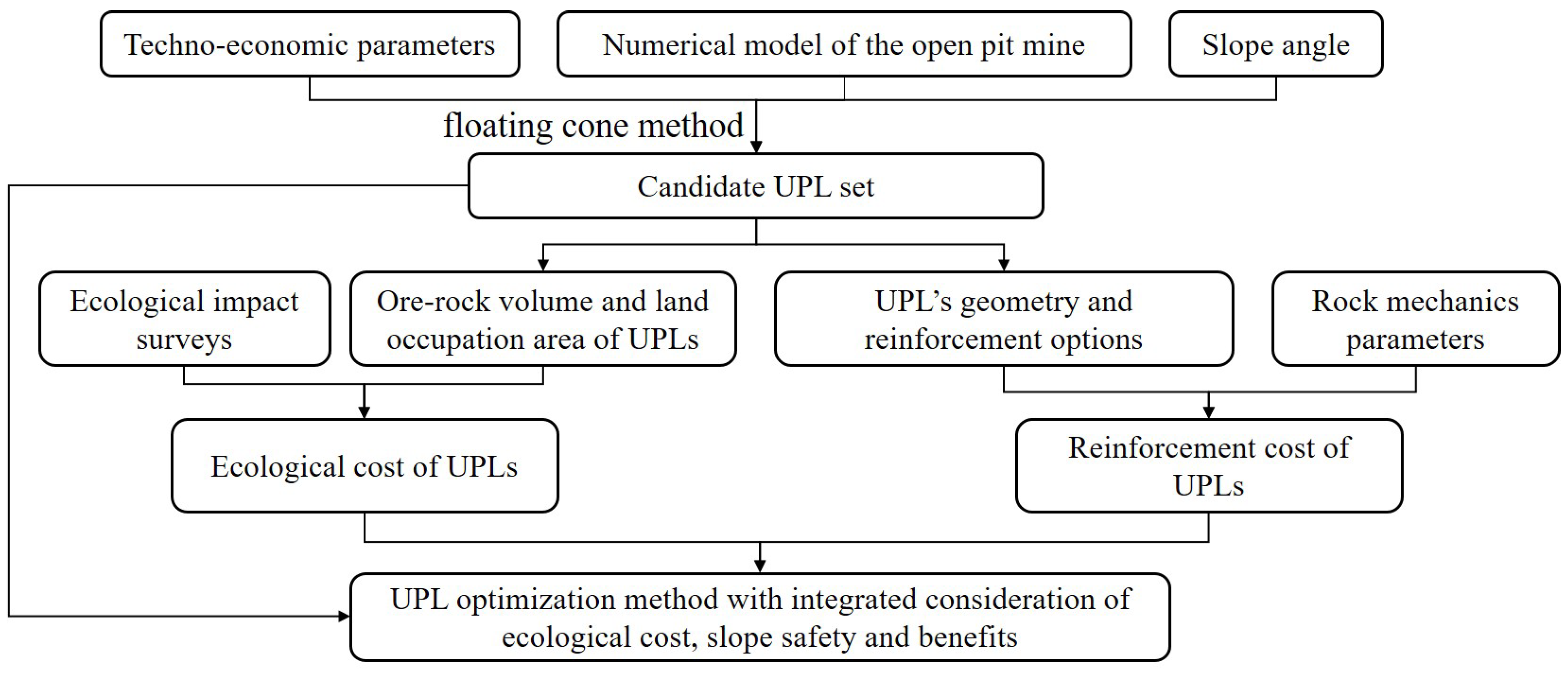

2. Methods

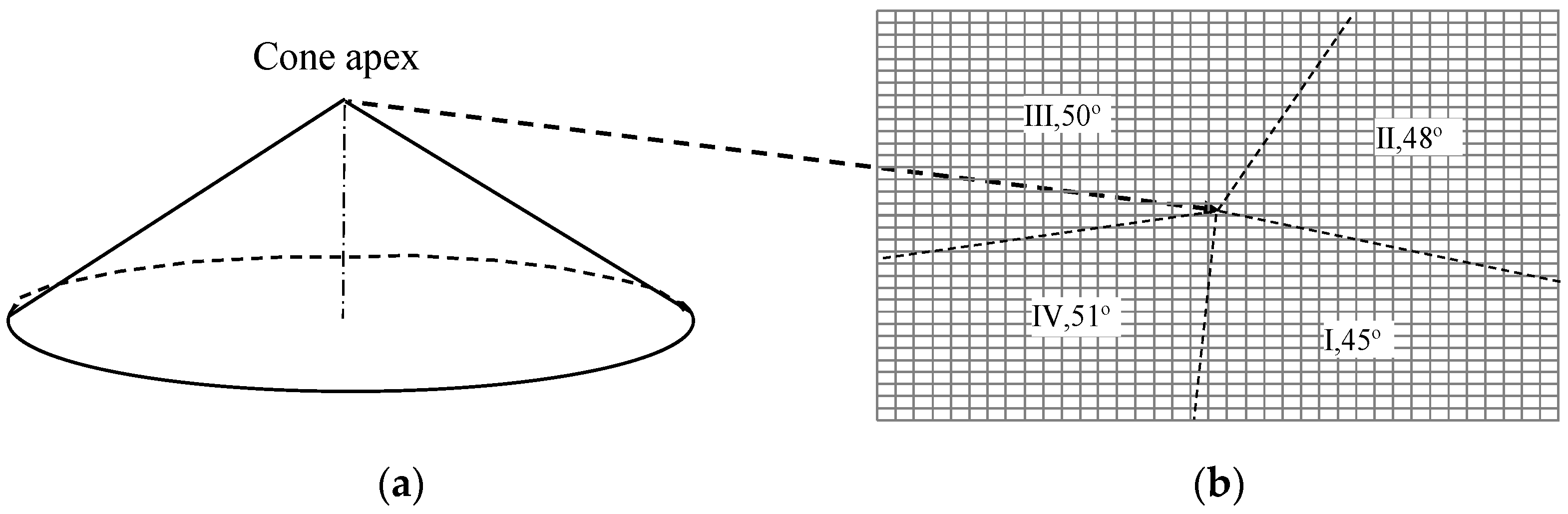

2.1. UPL Optimization Using Floating Cone Method

2.2. Ecological Cost Model of Open-Pit Coal Mine in Arid or Semi-Arid Weak Ecological Land

2.2.1. Evaluation Method of Occupied and Damaged Area Caused by Mining

2.2.2. Direct Economic Loss

2.2.3. Exogenous Ecological Value Loss

2.2.4. Treatment Cost of Environmental Pollution

2.2.5. Ecological Cost of Energy Consumption

2.2.6. Reclamation Cost

2.3. Safety Cost Calculation Model of Open Pit Mine Slope

2.3.1. Reliability Analysis of Open-Pit Coal Mine Slope

2.3.2. Reinforcement Cost of Open-Pit Coal Mine Slope

2.4. UPL Optimization Model with Integrated Consideration of Ecological Cost, Slope Safety, and Benefits

3. Case Study

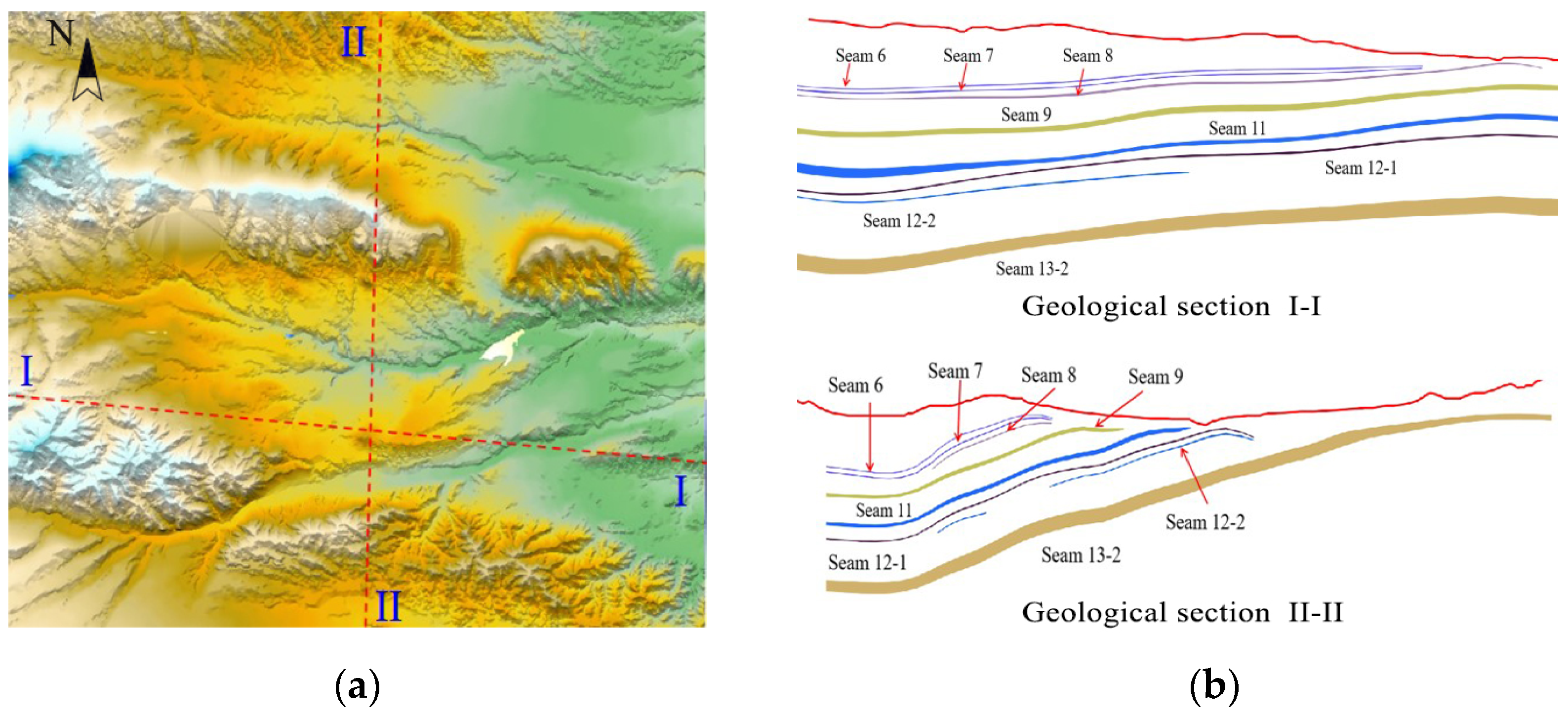

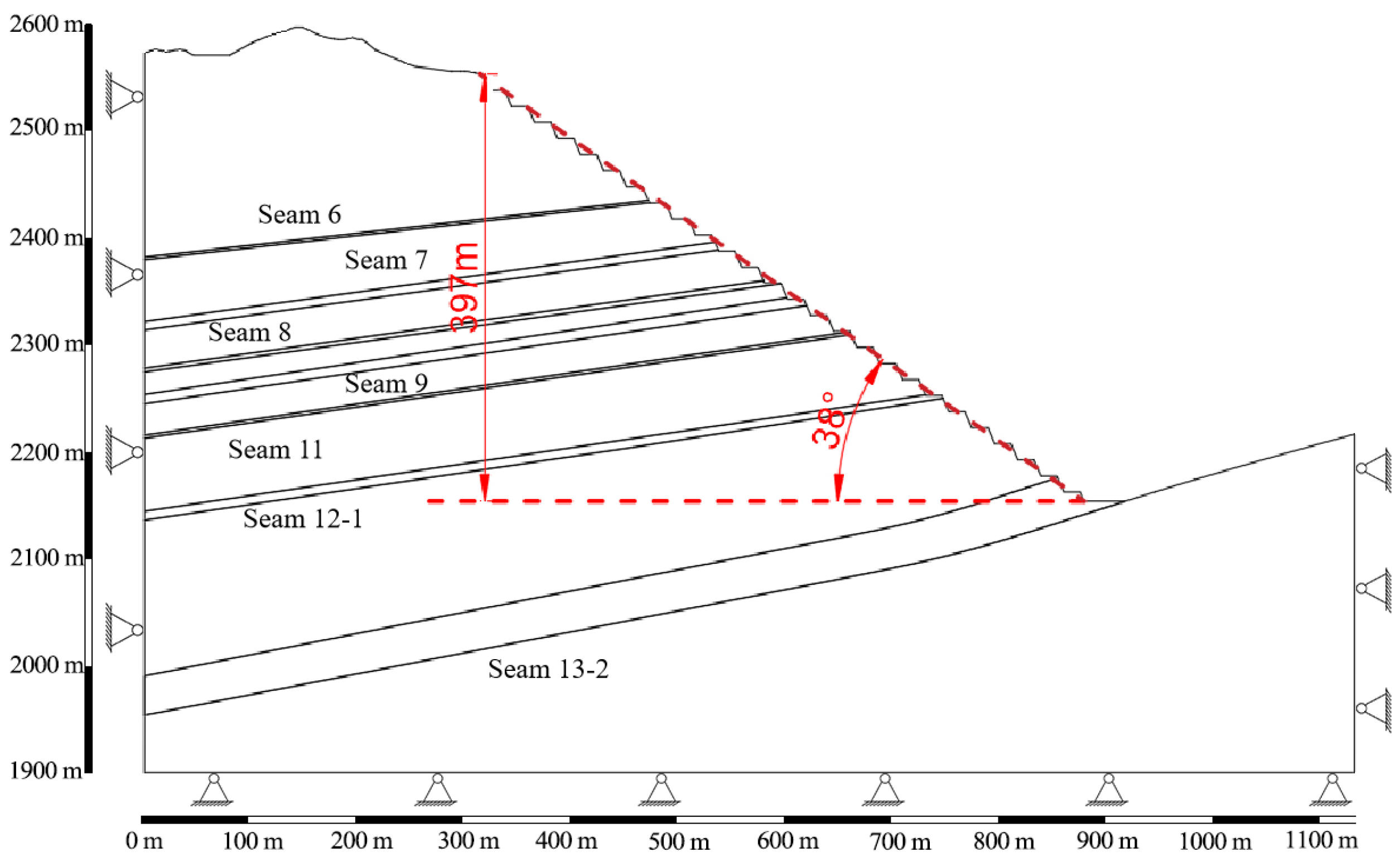

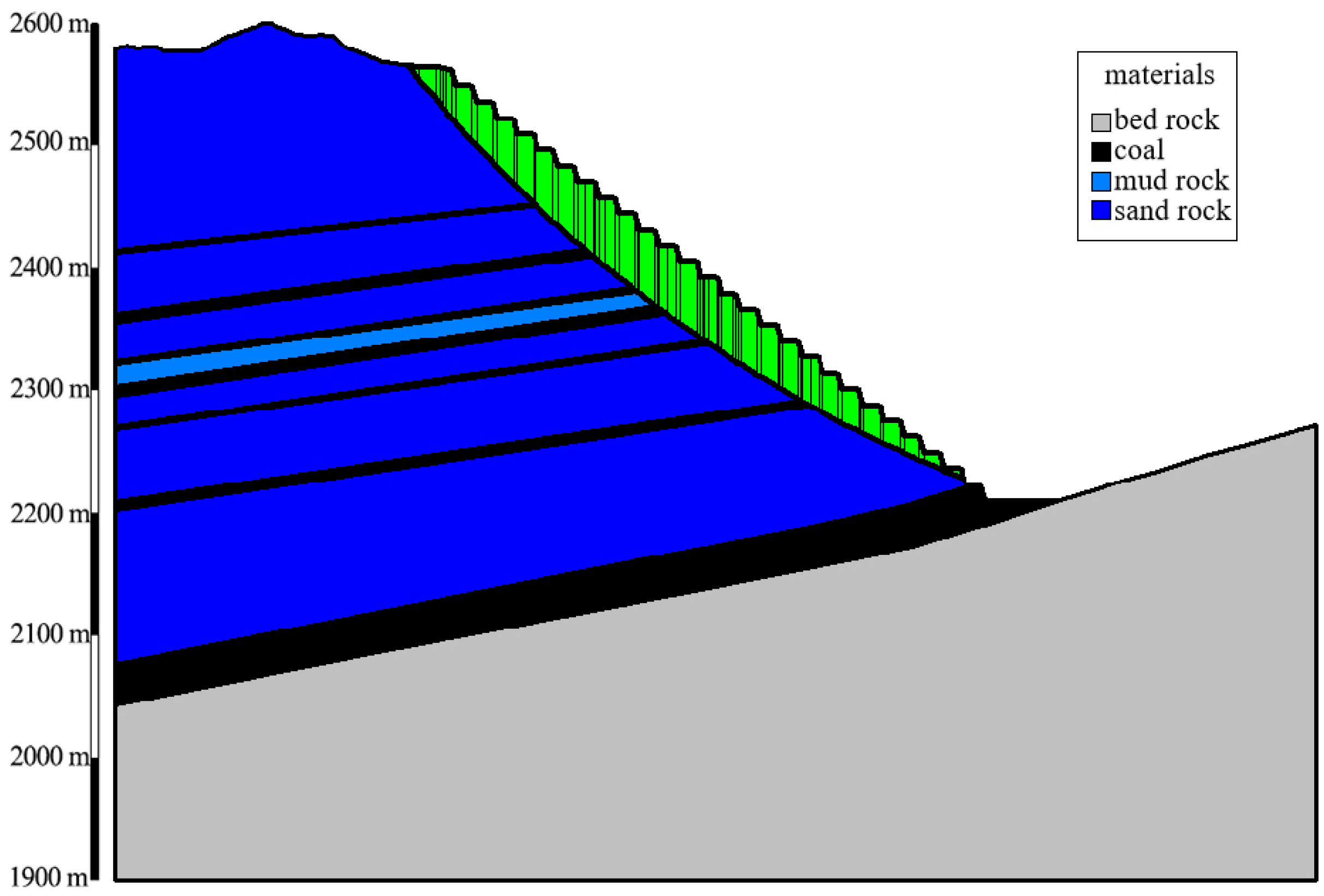

3.1. Engineering Situations

3.2. Natural Environmental Conditions

3.3. UPL Optimization Results for Heishan Open Pit Coal Mine

3.4. Ecological Cost of Heishan Open-Pit Coal Mine

3.5. Safety Cost of Heishan Open-Pit Coal Mine

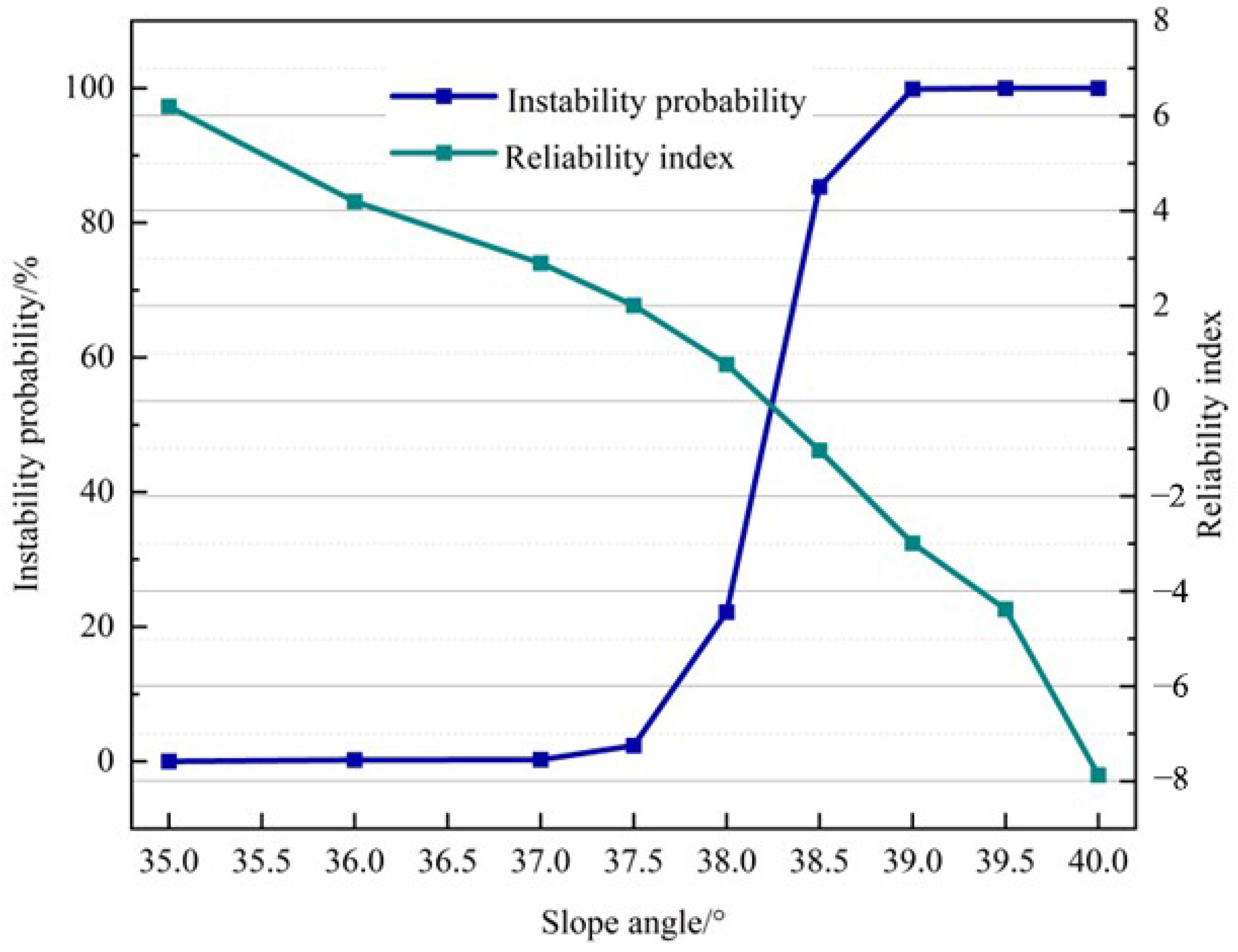

3.5.1. Stability Analysis of Open-Pit Coal Mine Slope

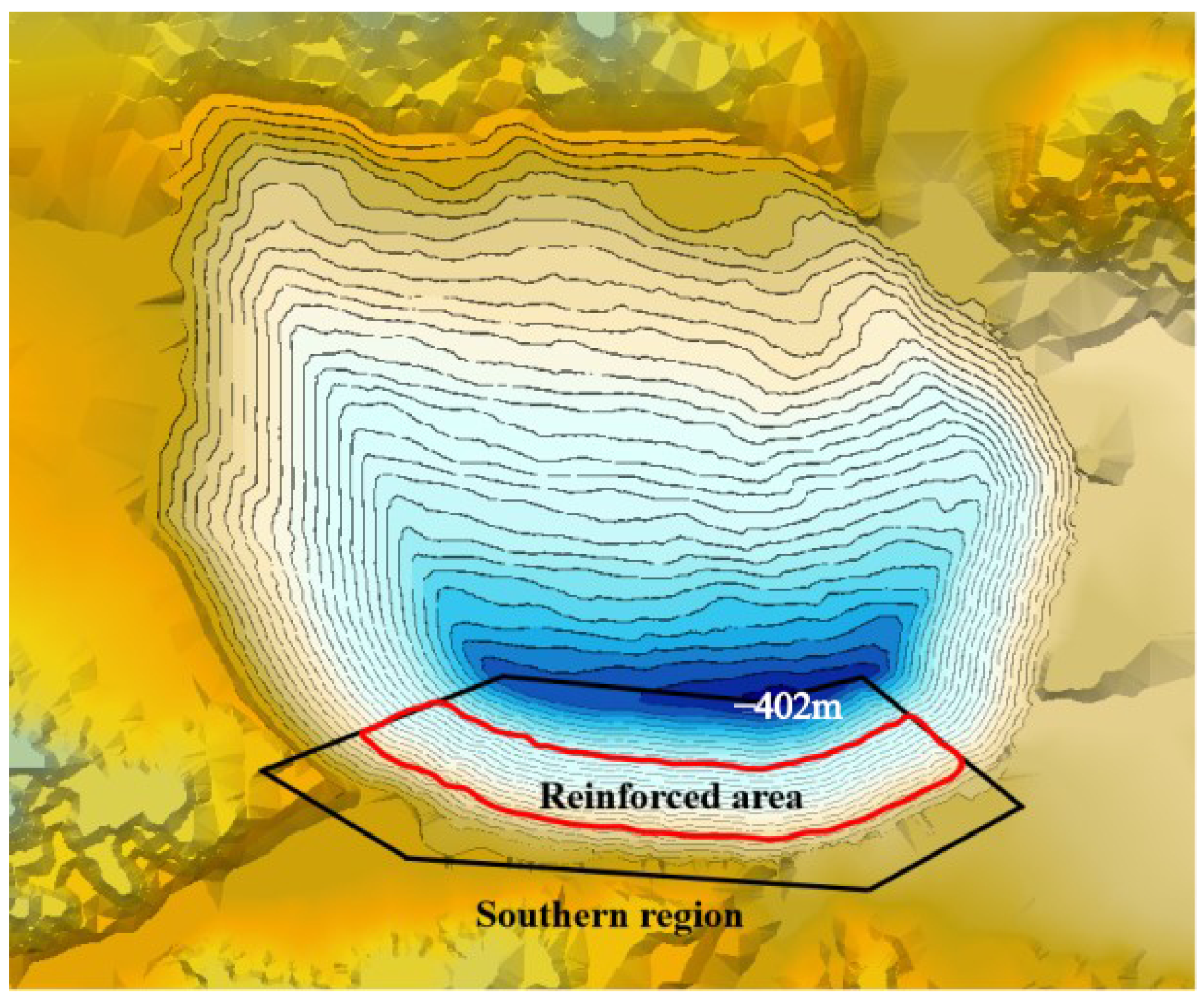

3.5.2. Reinforcement Plan Selection and Safety Cost Calculation of Heishan Open-Pit Coal Mine

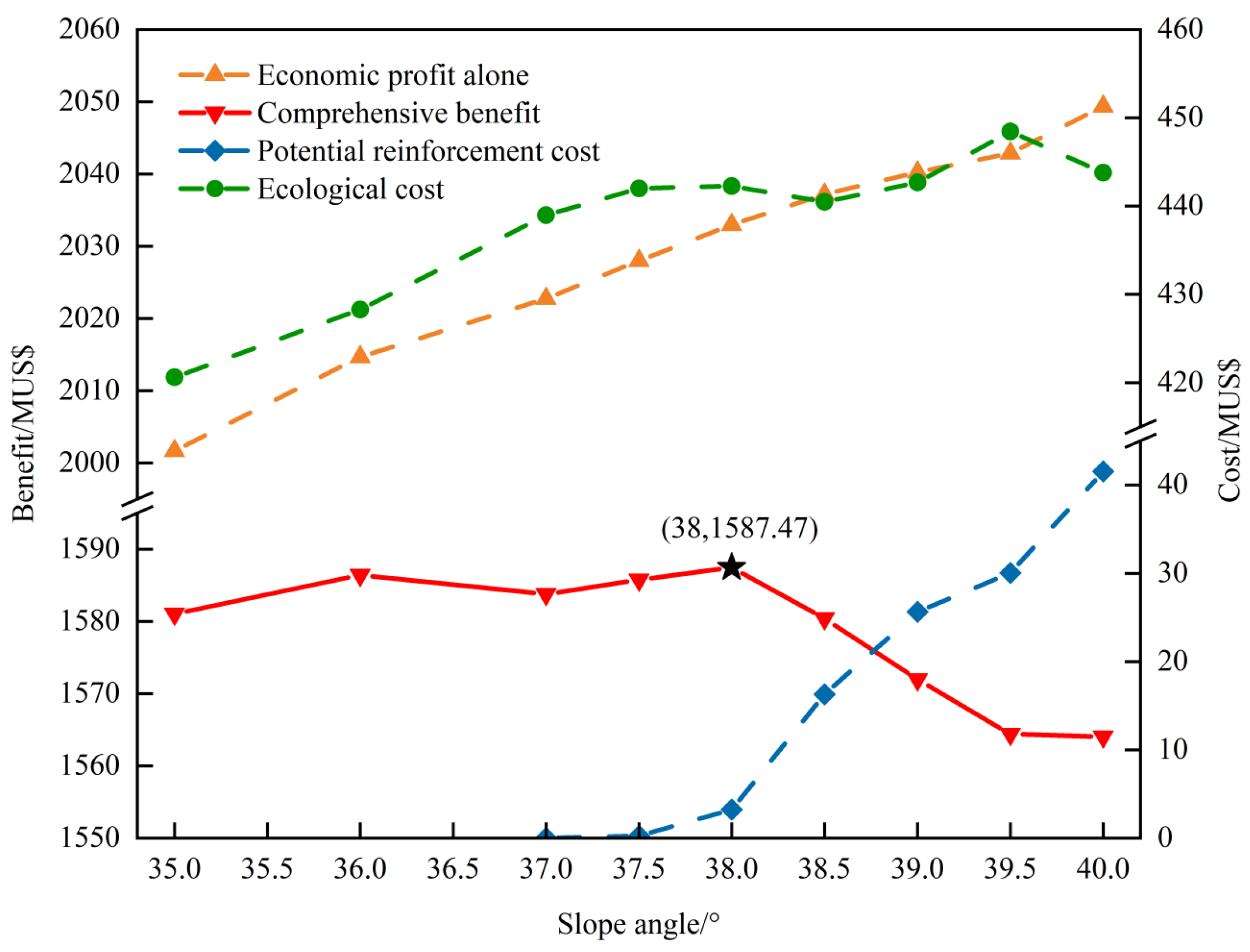

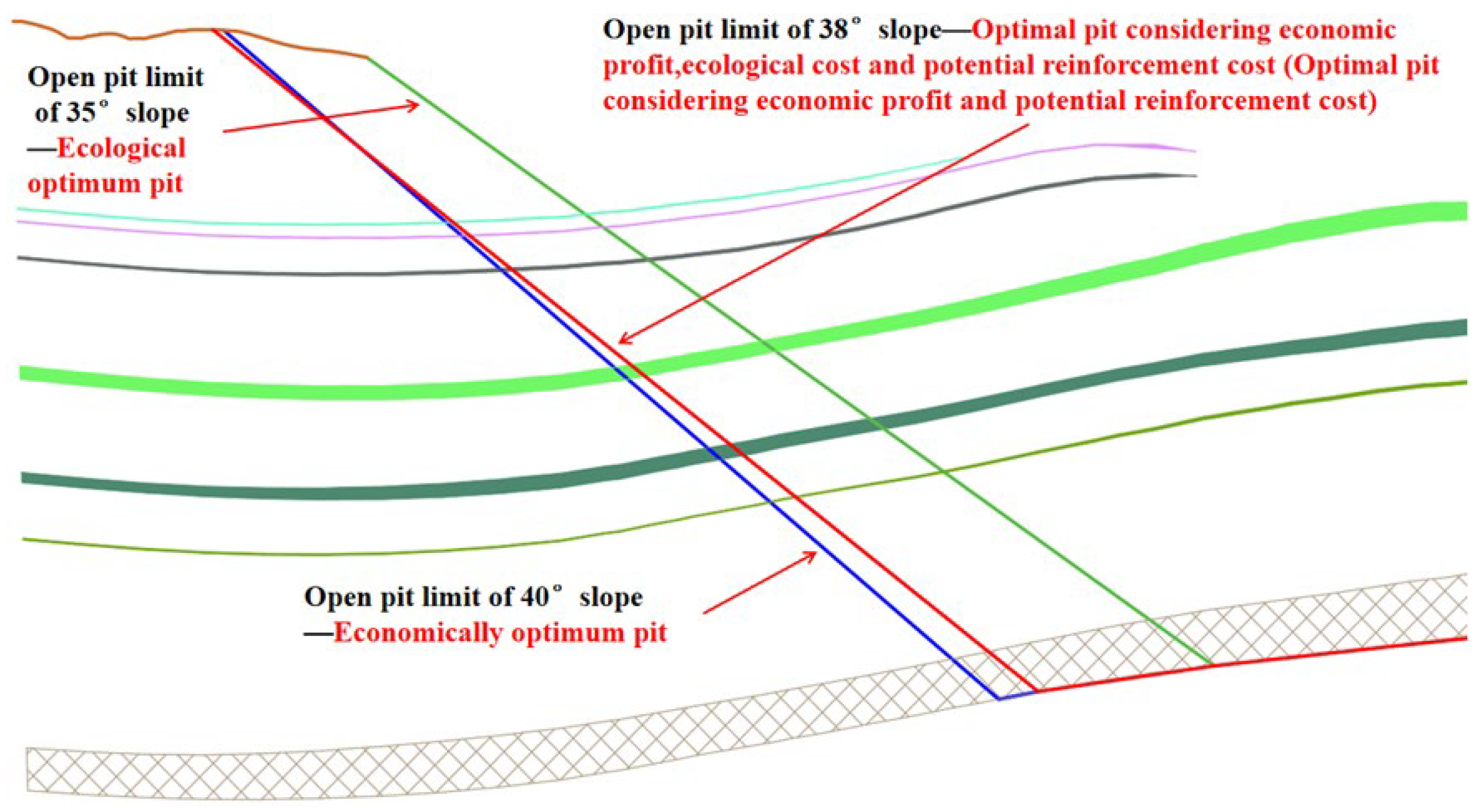

3.6. Comprehensive Benefit Analysis of Different UPLs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols or abbreviations | Meaning |

| SD | sustainable development |

| UPL | ultimate pit limit |

| surface area of the open-pit mine | |

| area occupied by ancillary facilities | |

| area taken up by waste stones and tailings | |

| volume of waste rocks in the optimized UPL | |

| height of the waste rock field | |

| morphology coefficient of the waste rock field | |

| direct economic loss | |

| land expropriation price | |

| value of water conservation | |

| area of grassland type i | |

| average rainfall in mining area | |

| proportion of runoff rainfall to the total rainfall volume in the mining area | |

| runoff reduction coefficient comparing grassland to bare land | |

| unit price of water resource | |

| cost of water purification | |

| value of soil conservation | |

| soil conservation capacity of class n grassland | |

| soil bulk density | |

| proportion of sediment deposition in reservoirs | |

| content of specific elements in the soil | |

| content of nitrogen, phosphorus, potassium, and organic matter in the fertilizer and organic matter | |

| cost incurred for the excavation per unit volume of soil | |

| cost of unit capacity | |

| prevailing market price of fertilizer and organic matter | |

| value of carbon sequestration (plant-based) | |

| value of carbon sequestration (soil-based) | |

| coefficient of carbon sequestration | |

| net primary productivity of grassland type i | |

| cost of carbon sequestration | |

| average soil depth of the grassland | |

| organic carbon density in the soil | |

| inorganic carbon density in the soil | |

| migration rate of soil pollutants | |

| conversion coefficient transforming carbon to carbon dioxide | |

| economic value of biodiversity maintaining | |

| annual species loss opportunity cost in per unit area of grassland type i | |

| value of grassland recreation | |

| unit grassland recreation value | |

| value of oxygen release | |

| coefficient for oxygen release | |

| cost of oxygen production | |

| value of air purification | |

| sulfur dioxide absorption capacity for grassland type i | |

| dust-retention capability for grassland type i | |

| treatment cost for sulfur dioxide | |

| treatment cost for dustfall | |

| value of nutrient (nitrogen and phosphorus) accumulation | |

| proportions of nitrogen and phosphorus content in the net primary productivity of grassland type i | |

| transfer coefficient from phosphorus to P2O5 | |

| prices of nitrogen fertilizer and phosphorus fertilizer | |

| exogenous ecological value loss | |

| treatment cost of production and household sewage | |

| treatment fee per unit volume sewage | |

| annual ore extraction quantity | |

| annual rock extraction quantity | |

| sewage discharge stemming from both production processes and domestic water consumption of per unit extraction | |

| treatment cost of polluted shallow groundwater | |

| adjustment coefficient | |

| infiltration coefficient of soil | |

| annual mean rainfall in the mining vicinity | |

| unit treatment cost of leaching water | |

| occupied area of mining pit and waste in the year t | |

| treatment cost of soil pollution | |

| price of soil remediation per unit volume | |

| pollutant migration rate originating from mining | |

| duration of UPL operation with a slope angle of | |

| treatment cost of solid waste | |

| unit cost for treating the i-th type of solid waste | |

| emission quantities of the i-th solid waste type from per unit stripping | |

| treatment costs of air pollution | |

| treatment cost for specific pollutants | |

| emission amount of SO2, NOX, and fume dust from per unit stripping volume | |

| production days within a year | |

| daily watering frequency | |

| watering area during each instance per day | |

| watering volume used per unit area | |

| prevailing water price in the mining community | |

| comprehensive cost for environmental treatment | |

| ecological cost model for energy consumption | |

| electricity consumption per unit mining stripping | |

| proportion of thermal power generation to total power generation | |

| standard coal consumption per kilowatt hour | |

| carbon emission coefficient of standard coal | |

| category of primary fossil energy consumed | |

| consumption of the i-th type of primary fossil energy per unit of mining stripping | |

| carbon emission coefficient of the i-th type of primary fossil energy | |

| conversion coefficient transforming carbon to carbon dioxide | |

| cost of carbon capture and sequestration | |

| reclamation cost | |

| ecological reclamation area in year t | |

| cost of reclaiming or conserving per unit area of land | |

| effective cohesion | |

| weight of soil stripe | |

| pore water pressure | |

| effective internal friction angle | |

| pore water pressure coefficient | |

| instability probability of the slope | |

| reinforcement cost | |

| engineering tasks of the i-th sub-project | |

| represents the reinforcement method adopted | |

| reinforcement range of slope | |

| type of reinforcement material used | |

| comprehensive price per unit engineering task of the i-th sub-project contained labor costs, material costs, machinery costs, business management fees, regular fees, profits, and taxes | |

| economic benefits | |

| quantity of coal mined in the UPL with a slope angle of | |

| volume of rock stripped in the UPL with a slope angle of | |

| price of raw coal | |

| unit mining cost | |

| unit rock stripping cost | |

| cumulative ecological cost | |

| production life in the UPL with a given slope angle of | |

| duration required for the ecological environment to be restored to the pre-mining state | |

| comprehensive economic benefit |

References

- Auty, R.; Warhurst, A. Sustainable development in mineral exporting economies. Resour. Policy 1993, 19, 14–29. [Google Scholar] [CrossRef]

- Mikesell, R.F. Sustainable development and mineral resources. Resour. Policy 1994, 20, 83–86. [Google Scholar] [CrossRef]

- Hilson, G.; Murck, B. Sustainable development in the mining industry: Clarifying the corporate perspective. Resour. Policy 2000, 26, 227–238. [Google Scholar] [CrossRef]

- Horowitz, L. Section 2: Mining and sustainable development. J. Clean. Prod. 2006, 14, 307–308. [Google Scholar] [CrossRef]

- Hilson, G.; Basu, A.J. Devising indicators of sustainable development for the mining and minerals industry: An analysis of critical background issues. Int. J. Sustain. Dev. World Ecol. 2003, 10, 319–331. [Google Scholar]

- Azapagic, A. Developing a framework for sustainable development indicators for the mining and minerals industry. J. Clean. Prod. 2004, 12, 639–662. [Google Scholar] [CrossRef]

- Adibi, N.; Ataee-pour, M.; Rahmanpour, M. Integration of sustainable development concepts in open pit mine design. J. Clean. Prod. 2015, 108, 1037–1049. [Google Scholar] [CrossRef]

- Amirshenava, S.; Osanloo, M. A hybrid semi-quantitative approach for impact assessment of mining activities on sustainable development indexes. J. Clean. Prod. 2019, 218, 823–834. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Rahmani, D. A five-dimensional approach to sustainability for prioritizing energy production systems using a revised GRA method: A case study. Renew. Energy 2019, 135, 345–354. [Google Scholar] [CrossRef]

- Que, S.; Awuah-Offei, K.; Demirel, A.; Wang, L.; Demirel, N.; Chen, Y. Comparative study of factors affecting public acceptance of mining projects: Evidence from USA, China and Turkey. J. Clean. Prod. 2019, 237, 117634. [Google Scholar] [CrossRef]

- Hosseinpour, M.; Osanloo, M.; Azimi, Y. Evaluation of positive and negative impacts of mining on sustainable development by a semi-quantitative method. J. Clean. Prod. 2022, 366, 132955. [Google Scholar] [CrossRef]

- Dehghani, H.; Bascompta, M.; Khajevandi, A.A.; Farnia, K.A. A Mimic Model Approach for Impact Assessment of Mining Activities on Sustainable Development Indicators. Sustainability 2023, 15, 2688. [Google Scholar] [CrossRef]

- Laurence, D. Establishing a sustainable mining operation: An overview. J. Clean. Prod. 2011, 19, 278–284. [Google Scholar] [CrossRef]

- Asr, E.T.; Kakaie, R.; Ataei, M.; Tavakoli Mohammadi, M.R. A review of studies on sustainable development in mining life cycle. J. Clean. Prod. 2019, 229, 213–231. [Google Scholar]

- Xu, X.C.; Gu, X.W.; Wang, Q.; Gao, X.; Liu, J.P.; Wang, Z.K.; Wang, X.H. Production scheduling optimization considering ecological costs for open pit metal mines. J. Clean. Prod. 2018, 180, 210–221. [Google Scholar] [CrossRef]

- Xu, X.C.; Gu, X.W.; Wang, Q.; Zhao, Y.Q.; Wang, Z.K. Open pit limit optimization considering economic profit, ecological costs and social benefits. Trans. Nonferrous Met. Soc. China 2021, 31, 3847–3861. [Google Scholar]

- Xu, X.C.; Gu, X.W.; Wang, Q.; Zhao, Y.Q.; Zhu, Z.G.; Wang, F.D.; Zhang, Z.L. Ultimate pit optimization with environmental problem for open-pit coal mine. Process Saf. Environ. Prot. 2023, 173, 366–372. [Google Scholar]

- Feng, H.; Zhou, J.; Chai, B.; Zhou, A.; Li, J.; Zhu, H.; Chen, H.; Su, D. Groundwater environmental risk assessment of abandoned coal mine in each phase of the mine life cycle: A case study of Hongshan coal mine, North China. Environ. Sci. Pollut. Res. 2020, 27, 42001–42021. [Google Scholar]

- Qi, P.; Shang, Y. Evaluation of Environmental Quality for Abandoned Coal Mine Based on Environmental Vulnerability Index. Energy Eng. 2021, 118, 727–736. [Google Scholar]

- Sun, Y.H.; Li, J.; Zhang, C.Y.; Li, F.Y.; Chen, W.; Ying, L. Environment monitoring of mining area with comprehensive mining ecological index (CMEI): A case study in Xilinhot of Inner Mongolia, China. Int. J. Sustain. Dev. World Ecol. 2023, 30, 814–825. [Google Scholar] [CrossRef]

- Marshall, A. Principles of Economics; Macmillan & Co.: London, UK; New York, NY, USA, 1890. [Google Scholar]

- Ugochukwu, U.C.; Chukwuone, N.; Jidere, C.; Ezeudu, B.; Ikpo, C.; Ozor, J. Heavy metal contamination of soil, sediment and water due to galena mining in Ebonyi State Nigeria: Economic costs of pollution based on exposure health risks. J. Environ. Manag. 2022, 321, 115864. [Google Scholar] [CrossRef]

- Badakhshan, N.; Shahriar, K.; Afraei, S.; Bakhtavar, E. Determining the environmental costs of mining projects: A comprehensive quantitative assessment. Resour. Policy 2023, 82, 103561. [Google Scholar]

- Badiozamani, M.M.; Askari-Nasab, H. Integration of reclamation and tailings management in oil sands surface mine planning. Environ. Model. Softw. 2014, 51, 45–58. [Google Scholar] [CrossRef]

- Singh, V.K.; Singh, J.K.; Kumar, A. Geotechnical study for optimizing the slope design of a deep open-pit mine, India. Bull. Eng. Geol. Environ. 2005, 64, 301–306. [Google Scholar]

- Islam, M.R.; Faruque, M.O. Optimization of slope angle and its seismic stability: A case study for the proposed open pit coalmine in Phulbari, NW Bangladesh. J. Mt. Sci. 2013, 10, 976–986. [Google Scholar]

- Ren, S.L.; Tao, Z.G.; He, M.C.; Pang, S.H.; Li, M.N.; Xu, H.T. Stability analysis of open-pit gold mine slopes and optimization of mining scheme in Inner Mongolia, China. J. Mt. Sci. 2020, 17, 2997–3011. [Google Scholar]

- Singh, V.K.; Singh, T.N. Geotechnical study of the optimum design of the Chandmari Coppermine, Rajasthan, India. Eng. Geol. 1999, 53, 47–55. [Google Scholar]

- Cai, M.; Xie, M.; Li, C. GIS-based 3D limit equilibrium analysis for design optimization of a 600 m high slope in an open pit mine. J. Univ. Sci. Technol. Beijing 2007, 14, 1–5. [Google Scholar]

- Shen, J.; Priest, S.D.; Karakus, M. Determination of Mohr–Coulomb Shear Strength Parameters from Generalized Hoek–Brown Criterion for Slope Stability Analysis. Rock Mech. Rock Eng. 2011, 45, 123–129. [Google Scholar]

- Ozbay, A.; Cabalar, A.F. FEM and LEM stability analyses of the fatal landslides at Çöllolar open-cast lignite mine in Elbistan, Turkey. Landslides 2014, 12, 155–163. [Google Scholar] [CrossRef]

- Dyson, A.P.; Tolooiyan, A. Prediction and classification for finite element slope stability analysis by random field comparison. Comput. Geotech. 2019, 109, 117–129. [Google Scholar] [CrossRef]

- Ghadrdan, M.; Dyson, A.P.; Shaghaghi, T.; Tolooiyan, A. Slope stability analysis using deterministic and probabilistic approaches for poorly defined stratigraphies. Geomech. Geophys. Geo-Energy Geo-Resour. 2020, 7, 1–17. [Google Scholar] [CrossRef]

- Kring, K.; Chatterjee, S. Uncertainty quantification of structural and geotechnical parameter by geostatistical simulations applied to a stability analysis case study with limited exploration data. Int. J. Rock Mech. Min. Sci. 2020, 125, 104157. [Google Scholar] [CrossRef]

- Shang, L.; Nguyen, H.; Bui, X.N.; Vu, T.H.; Costache, R.; Hanh, L.T.M. Toward state-of-the-art techniques in predicting and controlling slope stability in open-pit mines based on limit equilibrium analysis, radial basis function neural network, and brainstorm optimization. Acta Geotech. 2021, 17, 1295–1314. [Google Scholar] [CrossRef]

- Lu, Y.; Jin, C.; Wang, Q.; Han, T.; Li, G.; Zhong, X.; Chen, G. Combining InSAR and infrared thermography with numerical simulation to identify the unstable slope of open-pit: Qidashan case study, China. Landslides 2023, 20, 1961–1974. [Google Scholar]

- Buelga Díaz, A.; Diego Álvarez, I.; Castañón Fernández, C.; Krzemień, A.; Iglesias Rodríguez, F.J. Calculating ultimate pit limits and determining pushbacks in open-pit mining projects. Resour. Policy 2021, 72, 102058. [Google Scholar] [CrossRef]

- Jelvez, E.; Morales, N.; Ortiz, J.M. Stochastic Final Pit Limits: An Efficient Frontier Analysis under Geological Uncertainty in the Open-Pit Mining Industry. Mathematics 2021, 10, 100. [Google Scholar] [CrossRef]

- Williams, J.; Singh, J.; Kumral, M.; Ramirez Ruiseco, J. Exploring Deep Learning for Dig-Limit Optimization in Open-Pit Mines. Nat. Resour. Res. 2021, 30, 2085–2101. [Google Scholar]

- Deutsch, M.; Dağdelen, K.; Johnson, T. An Open-Source Program for Efficiently Computing Ultimate Pit Limits: MineFlow. Nat. Resour. Res. 2022, 31, 1175–1187. [Google Scholar]

- Turan, G.; Onur, A.H. Optimization of open-pit mine design and production planning with an improved floating cone algorithm. Optim. Eng. 2022, 24, 1157–1181. [Google Scholar] [CrossRef]

- Ares, G.; Castañón Fernández, C.; Álvarez, I.D. Ultimate Pit-Limit Optimization Algorithm Enhancement Using Structured Query Language. Minerals 2023, 13, 966. [Google Scholar] [CrossRef]

- Stanek, W.; Czarnowska, L.; Pikoń, K.; Bogacka, M. Thermo-ecological cost of hard coal with inclusion of the whole life cycle chain. Energy 2015, 92, 341–348. [Google Scholar]

- Fang, H.W.; Chen, Y.; Deng, X.W. A new slope optimization design based on limit curve method. J. Cent. South Univ. 2019, 26, 1856–1862. [Google Scholar]

- Altuntov, F.K.; Erkayaoğlu, M. A New Approach to Optimize Ultimate Geometry of Open Pit Mines with Variable Overall Slope Angles. Nat. Resour. Res. 2021, 30, 4047–4062. [Google Scholar]

- Wang, J.P.; Huang, D. RosenPoint: A Microsoft Excel-based program for the Rosenblueth point estimate method and an application in slope stability analysis. Comput. Geosci. 2012, 48, 239–243. [Google Scholar] [CrossRef]

- Ahmadabadi, M.; Poisel, R. Assessment of the application of point estimate methods in the probabilistic stability analysis of slopes. Comput. Geotech. 2015, 69, 540–550. [Google Scholar]

- Low, B.K. Context-Dependent Parameter Sensitivities in Rock Slope Stability. Rock Mech. Rock Eng. 2022, 55, 7445–7468. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, H.; Xiao, S.; Han, L. Study on time-varying target reliability of open-pit slope considering service life. J. Min. Saf. Eng. 2019, 36, 542–548. [Google Scholar]

- Chen, X.J.; Fang, P.P.; Chen, Q.N.; Hu, J.; Yao, K.; Liu, Y. Influence of cutterhead opening ratio on soil arching effect and face stability during tunnelling through non-uniform soils. Undergr. Space 2024, 17, 45–59. [Google Scholar] [CrossRef]

- Cheng, P.; Liu, Y.; Li, Y.P.; Yi, J.T. A large deformation finite element analysis of uplift behaviour for helical anchor in spatially variable clay. Comput. Geotech. 2023, 141, 104542. [Google Scholar] [CrossRef]

- Zevgolis, I.E.; Deliveris, A.V.; Koukouzas, N.C. Probabilistic design optimization and simplified geotechnical risk analysis for large open pit excavations. Comput. Geotech. 2018, 103, 153–164. [Google Scholar] [CrossRef]

- Peng, X.; Li, D.; Cao, Z.; Tang, X.; Zhou, C. Reliability-based design approach of rock slopes using Monte Carlo simulation. Chin. J. Rock Mech. Eng. 2016, 35, 3794–3804. [Google Scholar] [CrossRef]

- Liu, F.Y.; Yang, T.H.; Zhou, J.R.; Deng, W.X.; Yu, Q.L.; Zhang, P.H.; Cheng, G.W. Spatial Variability and Time Decay of Rock Mass Mechanical Parameters: A Landslide Study in the Dagushan Open-Pit Mine. Rock Mech. Rock Eng. 2020, 53, 3031–3053. [Google Scholar] [CrossRef]

- Zhang, H.J.; Wu, S.C.; Zhang, Z.X.; Huang, S.G. Reliability analysis of rock slopes considering the uncertainty of joint spatial distributions. Comput. Geotech. 2023, 161, 105566. [Google Scholar]

- Yashalova, N.N.; Potravny, I.M. Possibilities of applying ESG-principles and methods of climate financing in the management practice of ferrous metallurgy enterprises. Chernye Met. 2023, 5, 76–81. [Google Scholar]

| Shannon Wiener Index | (0, 1) | [1, 2) | [2, 3) | [3, 4) | [4, 5) | [5, 6) | [6, +) |

|---|---|---|---|---|---|---|---|

| Sb (USD·hm−2·a−1) | 435 | 725 | 1450 | 2900 | 4350 | 5800 | 7250 |

| Open Pit Mine Slope | Instability Probability | Reliability Index |

|---|---|---|

| Most geotechnical engineering | ≤0.1% | 3.1 |

| Normal open-pit mine slope | ≤0.01% | 3.7 |

| Rock open-pit mine slope | 0.3% | 2.86 |

| An open-pit mine slope in Peru | ≤0.3% | 2.8 |

| Dabaoshan open-pit iron mine slope | 0.084% | 3.14 |

| Qianyanshan open-pit iron mine slope | 0.004%~0.105% | 3.08~4.45 |

| Jianshan open-pit mine slope | 0.3%~1% | 2.8~2.3 |

| Yima open-pit coal mine slope | ≤0.05% | 3.29 |

| Yamansu open-pit iron mine slope | 0.037%~0.292% | 2.76~3.38 |

| Coal Price/(USD/t) | Coal Loss Thickness/m | Recovery Rate/% | Mining Cost of Rough Coal/(USD/t) | Cost of Rock Stripping/(USD/m3) | Stripping Cost of Quaternary Layer/(USD/m3) |

|---|---|---|---|---|---|

| 26 | 0.2 | 96.5 | 1.62 | 2.18 | 1.16 |

| Azimuth Range of Slope | Slope Angle |

|---|---|

| 0°~45° | 17° |

| 45°~135° | 35° |

| 135°~225° | 35° |

| 225°~315° | 35° |

| 315°~360° | 17° |

| Scheme Number | Slope Angle /° | Quantity of Coal Mining /104 * t | Stripping Rock Volume /104 * t | Profit /MUSD | Stripping Ratio /(t·t−1) | Mining Depth /m |

|---|---|---|---|---|---|---|

| 1 | 35.0 | 13,727.02 | 157,759.28 | 2001.66 | 10.11 | 397 |

| 2 | 36.0 | 13,889.91 | 160,852.05 | 2014.69 | 10.19 | 397 |

| 3 | 37.0 | 14,081.63 | 165,319.26 | 2022.76 | 10.33 | 402 |

| 4 | 37.5 | 14,148.18 | 166,592.23 | 2028.00 | 10.36 | 402 |

| 5 | 38.0 | 14,172.55 | 166,710.53 | 2032.97 | 10.35 | 402 |

| 6 | 38.5 | 14,163.53 | 165,977.78 | 2037.18 | 10.31 | 402 |

| 7 | 39.0 | 14,209.58 | 166,921.73 | 2040.26 | 10.34 | 407 |

| 8 | 39.5 | 14,302.44 | 169,232.73 | 2042.87 | 10.41 | 407 |

| 9 | 40.0 | 14,260.25 | 167,306.25 | 2049.38 | 10.32 | 407 |

| Scheme Number | Slope Angle/° | Mining Area/hm2 | Dump Area/hm2 | Other Area of Land Occupancy/hm2 | Total Area of Land Destruction/hm2 |

|---|---|---|---|---|---|

| 1 | 35 | 510.75 | 615.26 | 20.00 | 1146.01 |

| 2 | 36 | 514.98 | 627.32 | 20.00 | 1162.30 |

| 3 | 37 | 521.10 | 644.75 | 20.00 | 1185.85 |

| 4 | 37.5 | 522.36 | 649.71 | 20.00 | 1192.07 |

| 5 | 38 | 521.91 | 650.17 | 20.00 | 1192.08 |

| 6 | 38.5 | 520.20 | 647.31 | 20.00 | 1187.51 |

| 7 | 39 | 521.10 | 650.99 | 20.00 | 1192.09 |

| 8 | 39.5 | 524.97 | 660.01 | 20.00 | 1204.98 |

| 9 | 40 | 521.19 | 652.49 | 20.00 | 1193.68 |

| Parameters | Quantitative Value | Parameters | Quantitative Value | Parameters | Quantitative Value | Parameters | Quantitative Value |

|---|---|---|---|---|---|---|---|

| cz/(USD/hm2) | 55,752 | ρ/(t/m3) | 1.35 | kNi/% | 0.25 | ca1/(USD/t) | 188.6 |

| K/% | 35 | r1/% | 46 | kPi/% | 1.907 | ca2/(USD/t) | 2326.4 |

| R/% | 15 | r2/% | 15 | cgi/(USD/hm2/a) | 157 | ca3/(USD/t) | 80.88 |

| J/(mm/a) | 528.7 | r3/% | 50 | Sbi/(USD/hm2/a) | 735 | qa1/(t/a) | 49.5 |

| /(USD/m3) | 1 | r4/% | 50 | /(m3/d) | 4342 | qa2/(t/a) | 23.64 |

| L/(USD/m3) | 0.31 | Qi/(t/hm2/a) | 0.8277 | cw1/(USD/m3) | 0.8 | qa3/(t/a) | 6.88 |

| Ρ1/(USD/m3) | 1.4 | /(USD/t) | 149.25 | Cw2/(USD/m3) | 0.83 | V/(m3/m2) | 0.002 |

| Ρ2/(USD/m3) | 0.85 | h/m | 0.5 | α | 2.625 | T1/(USD/a) | 19485 |

| P31/(USD/t) | 328.36 | DSOC/(g/kg) | 2.5 | x | 3 | T2/(USD/a) | 19485 |

| P32/(USD/t) | 119.4 | DSIC/(g/kg) | 7.5 | ewt/(m3/t) | 0.0008 | ec/(kg/kWh) | 0.404 |

| P33/(USD/t) | 405 | /(USD/t) | 188.06 | λ | 0.12 | ηc/(t/t) | 0.745 |

| P34/(USD/t) | 51 | /(USD/t) | 13.6 | cst/USD/hm2 | 82610 | vc/(kcal/kg) | 7000 |

| Mi/(t/hm2/a) | 60.8 | CD/(USD/t) | 44.78 | esw1/(kg/t) | 4.676 | ηh1/(t/t) | 0.869 |

| E1/% | 0.0069 | /(t/hm2/a) | 0.0089 | esw2/(kg/t) | 0.00001 | ηh2/(t/t) | 0.854 |

| E2/% | 0.094 | /(t/hm2/a) | 0.05 | esw3/(kg/t) | 0.0038 | /(kWh/t) | 0.1 |

| E3/% | 2.28 | pN/(USD/t) | 328.36 | esw4/(kg/t) | 0.0009 | 0.8 | |

| E4/% | 0.069 | pP/(USD/t) | 119.4 | esw5/(kg/t) | 0.0275 | /(kg/t) | 0.0031 |

| qi/(t/hm2/a) | 2.875 | cr/(USD/hm2) | 59701 | /(kg/t) | 0.29 | 3.63 | |

| csw1/(USD/t) | 0.73 | csw2/(USD/t) | 145 | 3.63 | 1.5 | ||

| /(m3/d) | 0.0008 | HW/m | 200 | 1.3 | /% | 10 | |

| /d | 330 | (n/d) | 2 | /(m3/m2) | 0.002 | ||

| ea1/(kg/t) | 0.0003 | ea2/(kg/t) | 0.0001 | ea3/(kg/t) | 0.00004 |

| Density/g·cm−3 | Uniaxial Compressive Strength/MPa | Tensile Strength/MPa | Cohesion/MPa | Internal Friction Angle/° | ||

|---|---|---|---|---|---|---|

| Mudstone | Statistical number | 21 | 15 | 15 | 10 | 10 |

| Mean value | 2.61 | 7.76 | 0.46 | 0.41 | 30.08 | |

| Variance | 0.1 | 6.54 | 0.33 | 0.34 | 1.60 | |

| Coefficient of variation | 0.04 | 0.84 | 0.71 | 0.81 | 0.05 | |

| Sandstone | Statistical number | 84 | 26 | 27 | 80 | 80 |

| Mean value | 2.4 | 25.95 | 1.49 | 3.35 | 38.61 | |

| Variance | 0.1 | 10.68 | 0.84 | 1.39 | 11.47 | |

| Coefficient of variation | 0.04 | 0.41 | 0.56 | 0.41 | 0.29 |

| Slope Angle/° | Dimensions of Steel Strands | Anchoring Length/m | Row Number of Anchor Cable |

|---|---|---|---|

| 37 | 4 × 7Φ5 | 3 | 21 |

| 37.5 | 4 × 7Φ5 | 3 | 21 |

| 38 | 5 × 7Φ5 | 3 | 27 |

| 38.5 | 5 × 7Φ5 | 3 | 39 |

| 39 | 5 × 7Φ5 | 3 | 51 |

| 39.5 | 5 × 7Φ5 | 4 | 60 |

| 40 | 6 × 7Φ5 | 4 | 69 |

| 37 | 4 × 7Φ5 | 3 | 21 |

| Slope angle/° | 37 | 37.5 | 38 | 38.5 | 39 | 39.5 | 40 |

| Reinforcement cost/MUSD | 10.31 | 10.82 | 14.42 | 19.08 | 25.67 | 30.04 | 41.54 |

| Instability probability/% | 0.25 | 2.35 | 22.5 | 85.35 | 99.85 | 100 | 100 |

| Potential reinforcement cost/MUSD | 0 | 0.25 | 3.24 | 16.28 | 25.67 | 30.04 | 41.54 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Zhu, Z.; Ye, L.; Gu, X.; Wang, Q.; Zhao, Y.; Liu, S.; Zhao, Y. Ultimate Pit Limit Optimization Method with Integrated Consideration of Ecological Cost, Slope Safety and Benefits: A Case Study of Heishan Open Pit Coal Mine. Sustainability 2024, 16, 5393. https://doi.org/10.3390/su16135393

Xu X, Zhu Z, Ye L, Gu X, Wang Q, Zhao Y, Liu S, Zhao Y. Ultimate Pit Limit Optimization Method with Integrated Consideration of Ecological Cost, Slope Safety and Benefits: A Case Study of Heishan Open Pit Coal Mine. Sustainability. 2024; 16(13):5393. https://doi.org/10.3390/su16135393

Chicago/Turabian StyleXu, Xiaochuan, Zhenguo Zhu, Luqing Ye, Xiaowei Gu, Qing Wang, Yunqi Zhao, Siyi Liu, and Yuqi Zhao. 2024. "Ultimate Pit Limit Optimization Method with Integrated Consideration of Ecological Cost, Slope Safety and Benefits: A Case Study of Heishan Open Pit Coal Mine" Sustainability 16, no. 13: 5393. https://doi.org/10.3390/su16135393

APA StyleXu, X., Zhu, Z., Ye, L., Gu, X., Wang, Q., Zhao, Y., Liu, S., & Zhao, Y. (2024). Ultimate Pit Limit Optimization Method with Integrated Consideration of Ecological Cost, Slope Safety and Benefits: A Case Study of Heishan Open Pit Coal Mine. Sustainability, 16(13), 5393. https://doi.org/10.3390/su16135393