Geomechanical Response Characteristics of Different Sedimentary Hydrodynamic Cycles—Exampled by Xujiahe Formation of Upper Triassic, Western Sichuan Basin

Abstract

1. Introduction

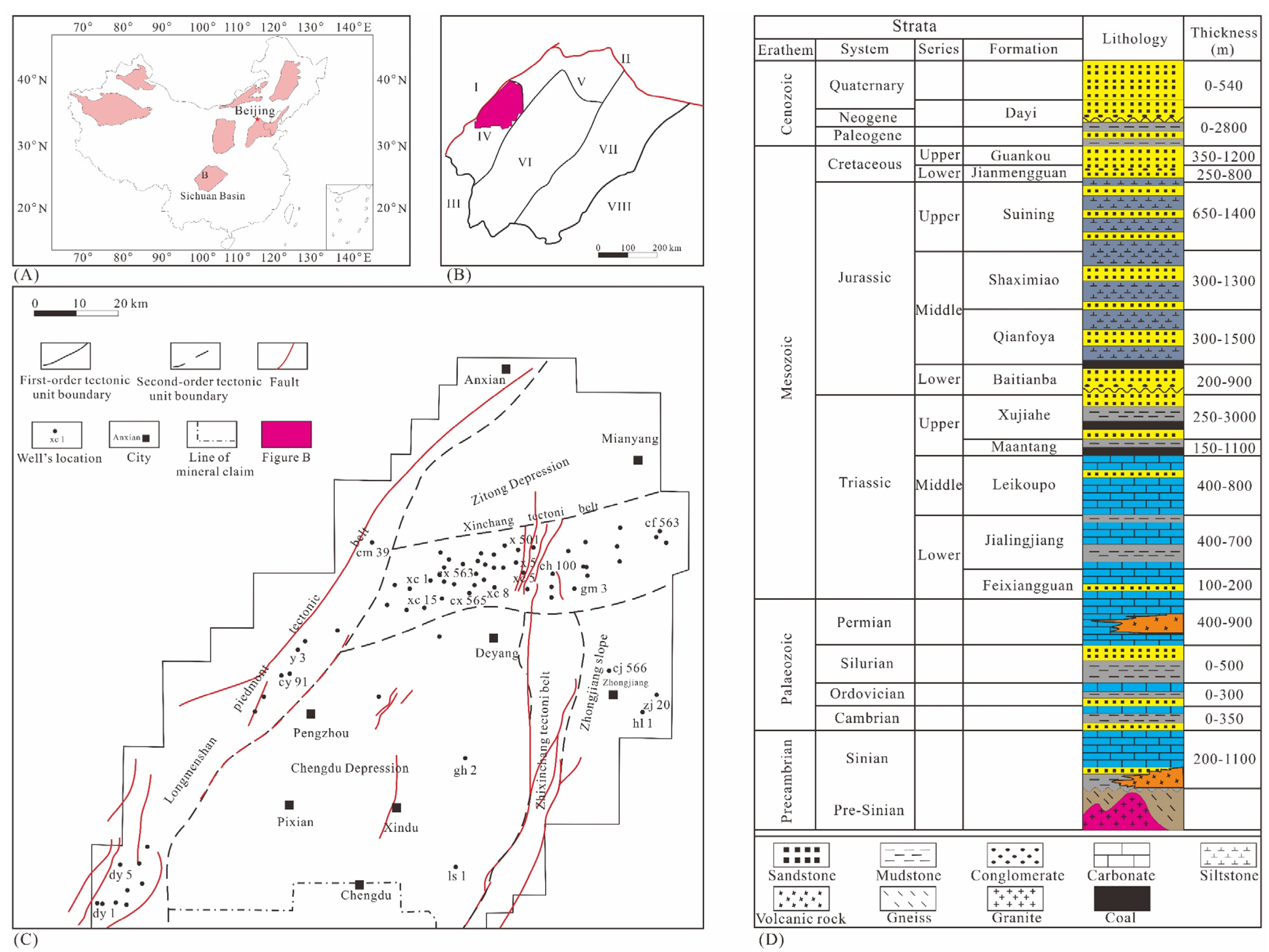

2. Geological Setting

3. Methods and Techniques

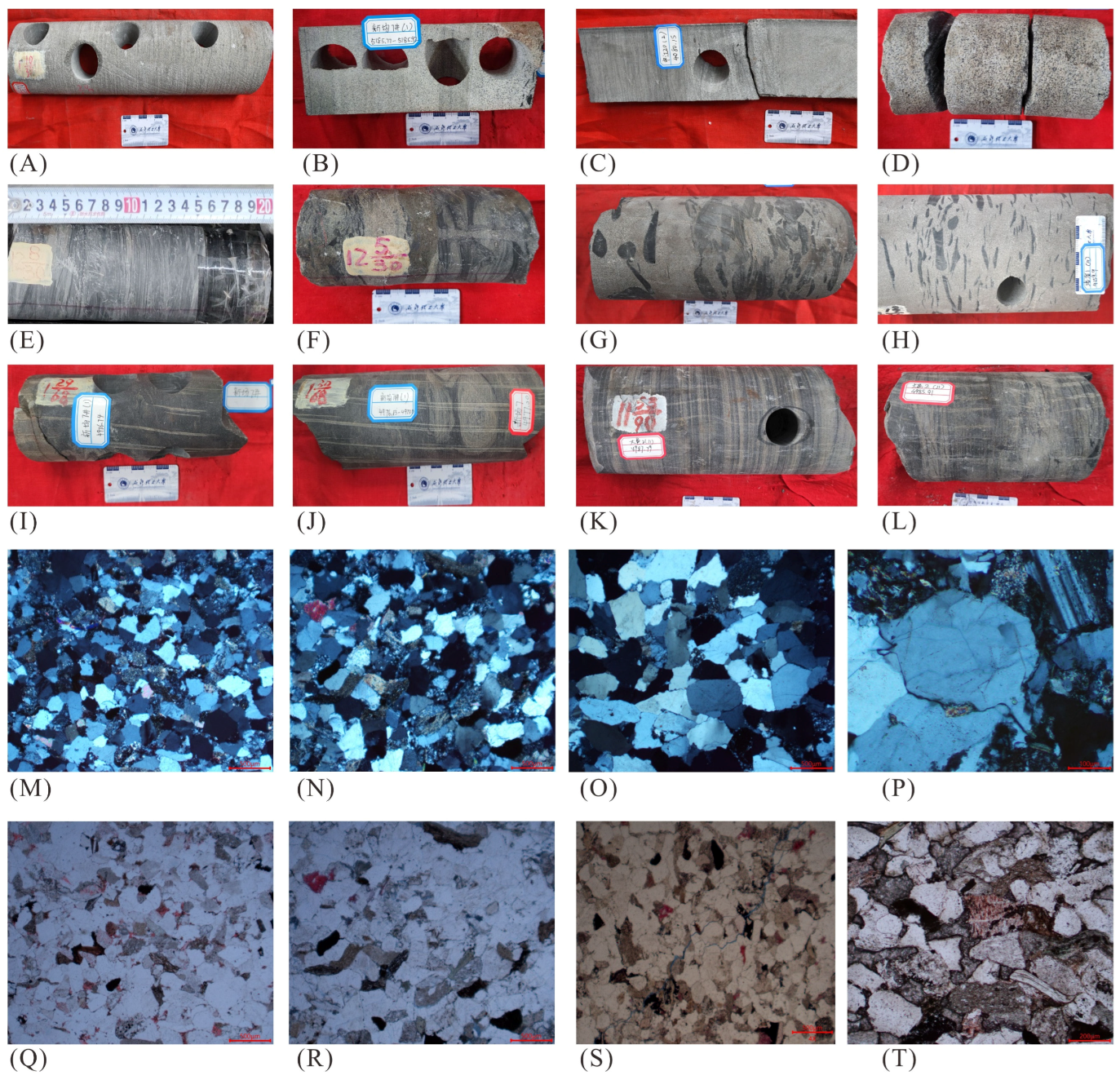

3.1. Core Observation and Sampling

3.2. Reservoir Architecture Division

3.3. Quantitative Calculation of Geomechanical Parameters

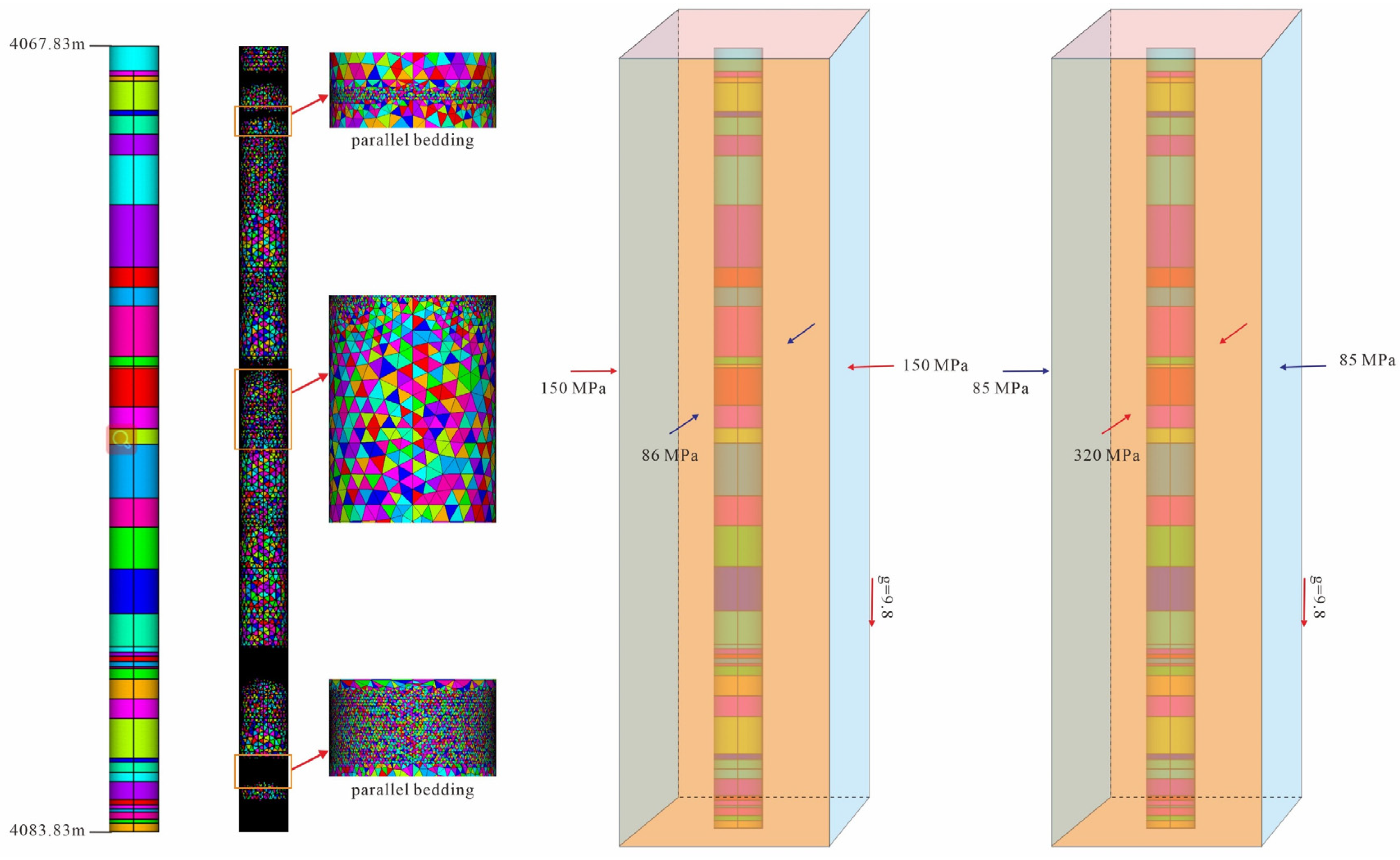

3.4. Finite Element Numerical Simulation of In Situ Stress

3.5. Quantitative Characterization of Fracture Parameters

- (1)

- Where σ3 > 0, the Coulomb–Mohr criterion was used, then the fracture’s volume density and linear density could be determined by Equations (8) and (9):where Dvf is the volume density of fracture, m2/m3; J0 refers to the required surface energy without pressure, J/m2; E shows the rock’s Young’s modulus, MPa; μ refers to the rock’s Poisson’s ratio, dimensionless; σ1, σ2, σ3 are the minimum, medium, and maximum principal stresses, respectively, MPa; b refers to the fracture aperture, m; σp is the rock rupture stress, MPa; Dlf shows the fracture linear density, /m; L1 and L3 show the characterized unit lengths along the σ1 and σ3 orientations, m; and θ is the rock rupture angle, °.

- (2)

- Where σ3 < 0, the Griffith criterion was used, which could be divided into two situations:

- σ1 + 3σ3 > 0; the criterion is shown as follows:where Dlfc shows the calculated fracture linear density, /m; σt refers to the rock’s tensile strength, MPa.

- σ1 + 3σ3 ≤ 0; according to Equation (11), the fracture volume density and linear density could be obtained.

4. Results

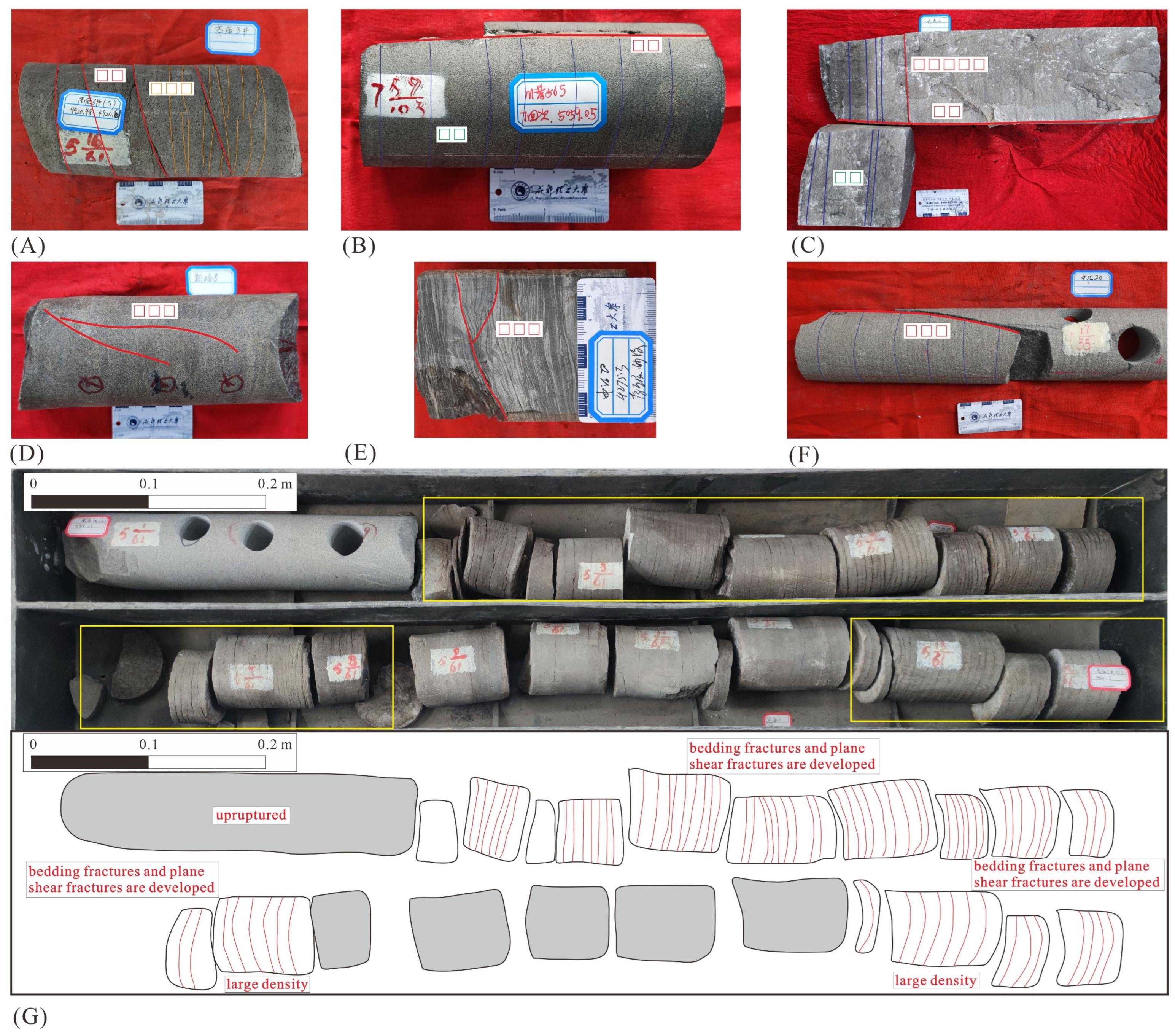

4.1. Developmental Characteristics of Bedding Plane and Structural Fractures

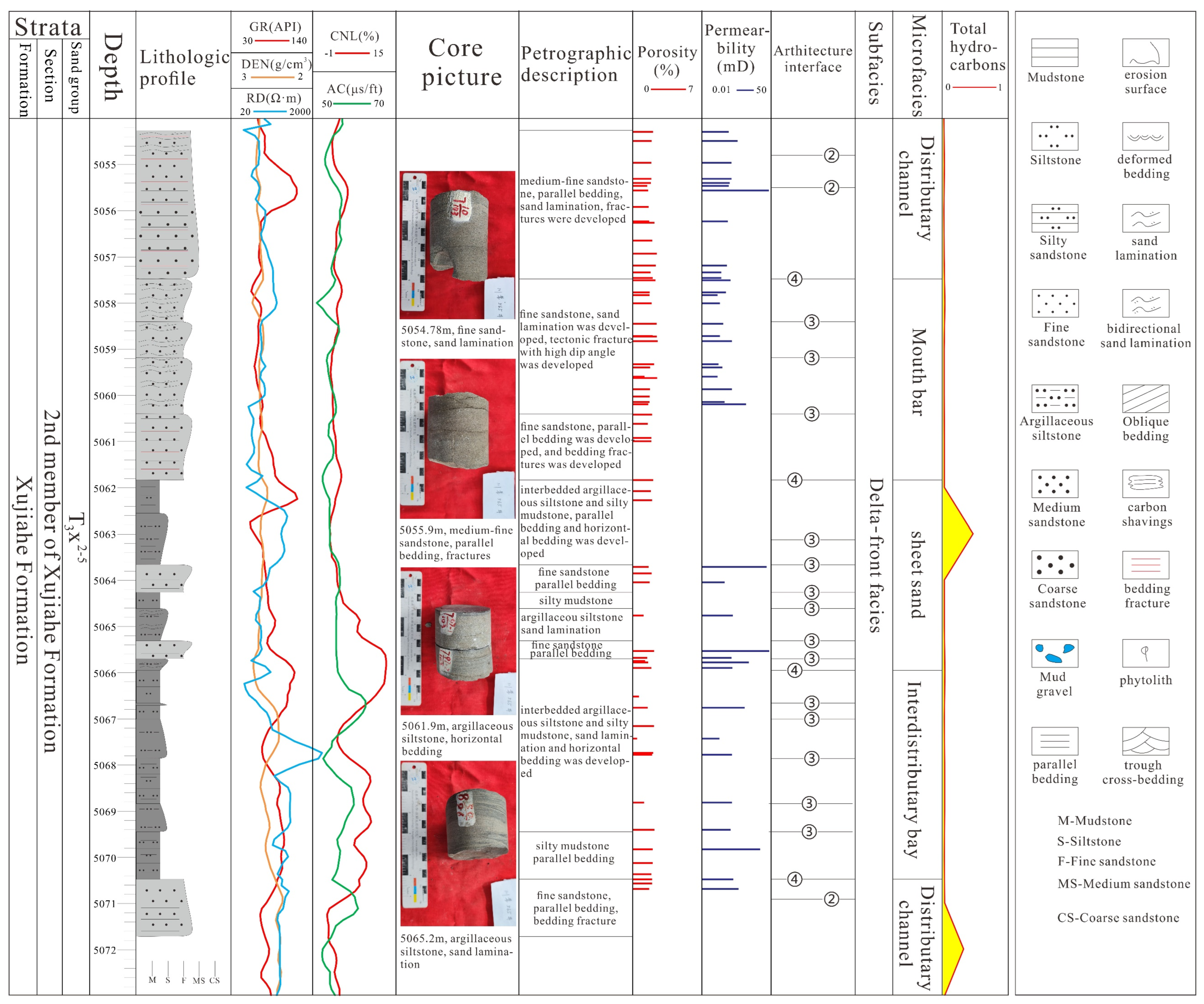

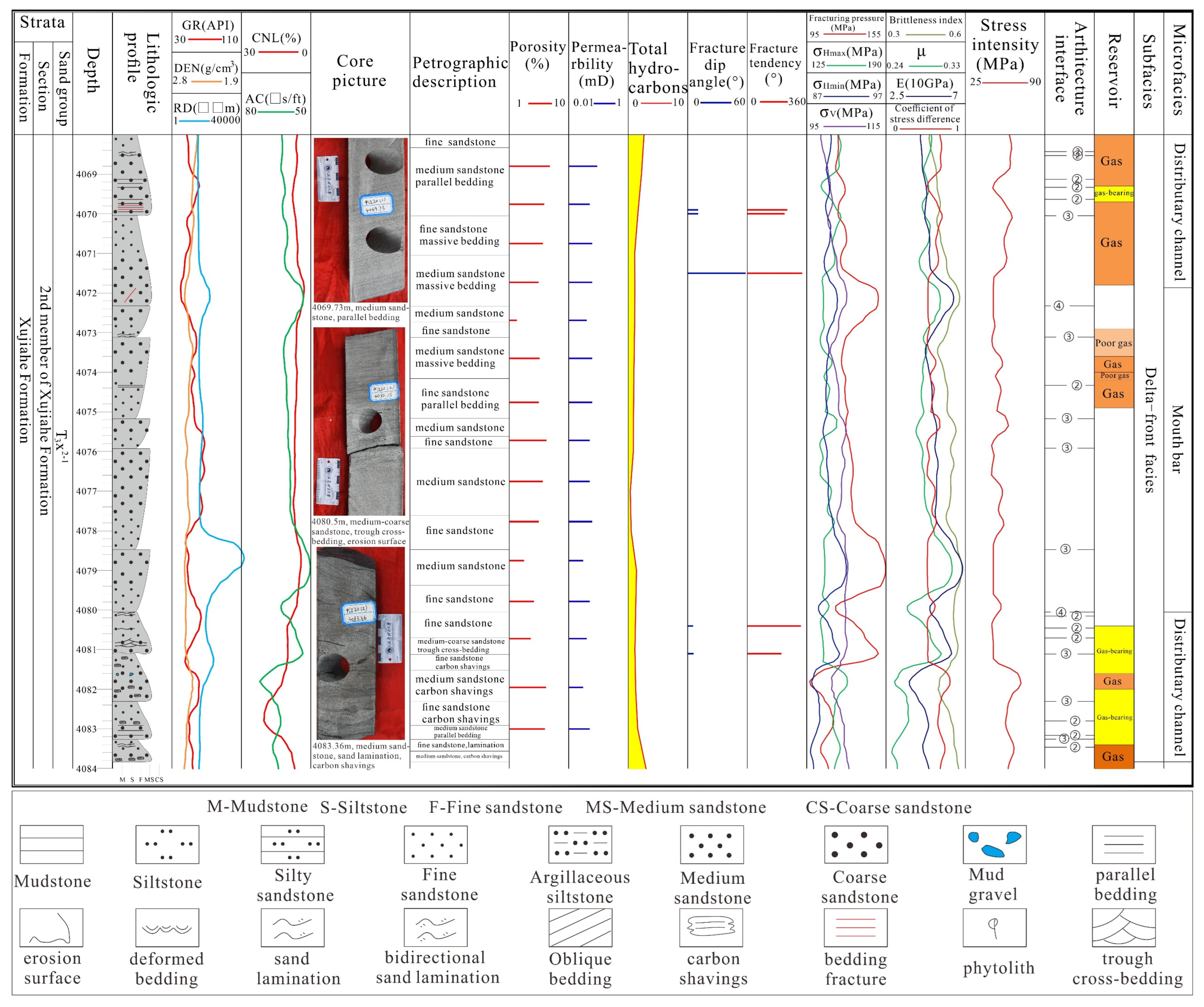

4.2. Distribution Characteristics of Reservoir Architecture

4.3. Characteristics of Geomechanical Parameters

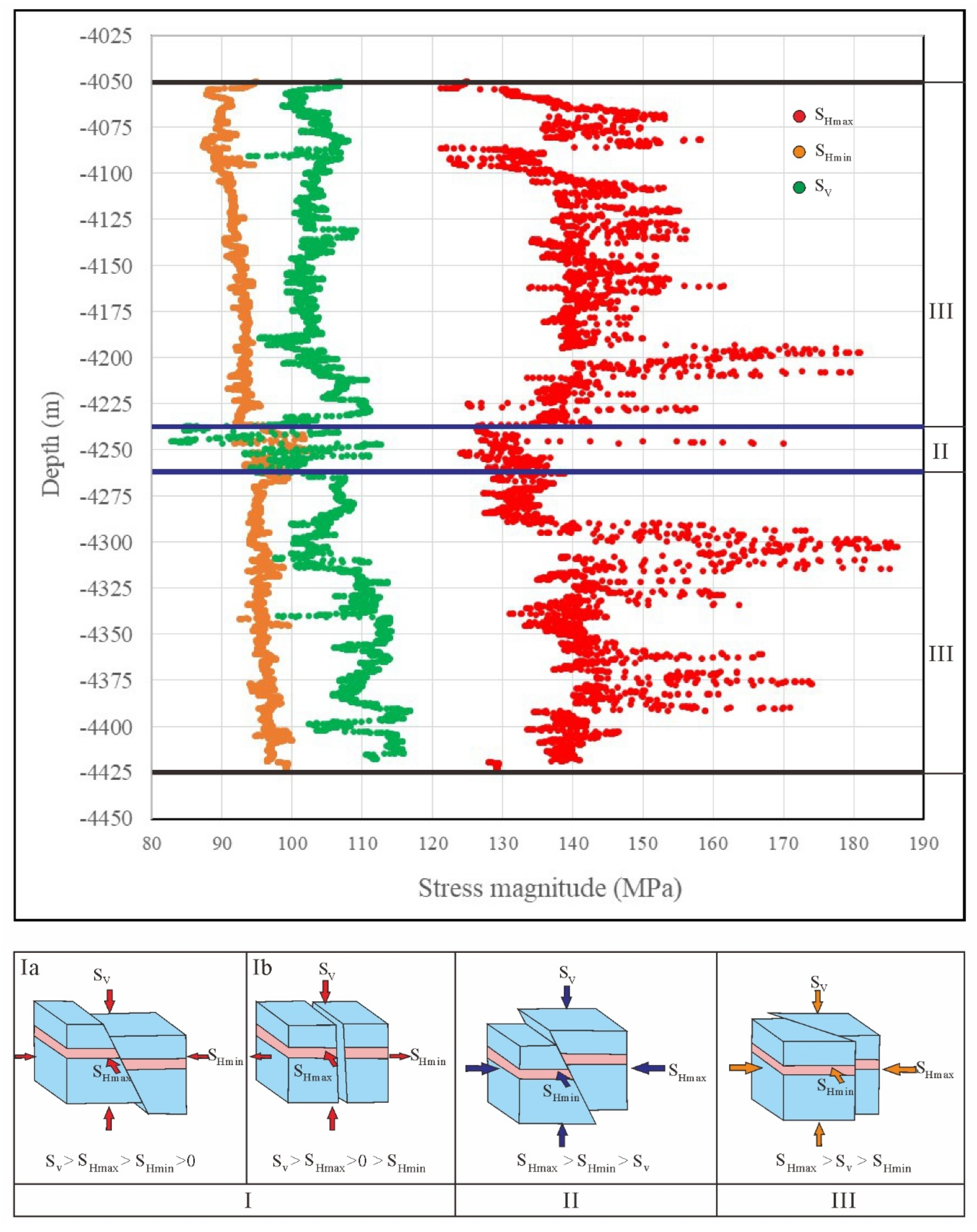

5. Discussion

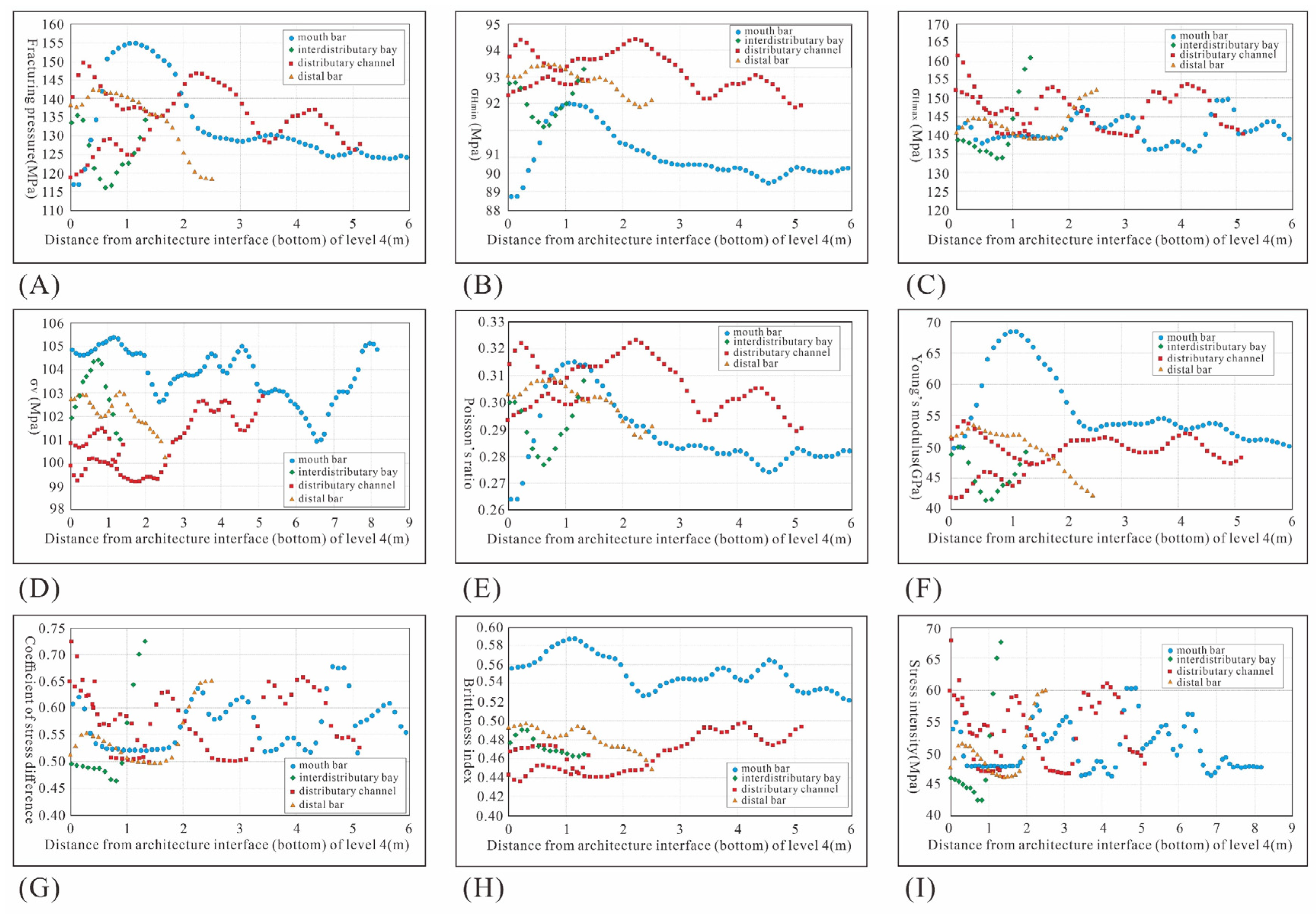

5.1. Geomechanical Response Characteristics on Reservoir Architecture Interface of Level 4

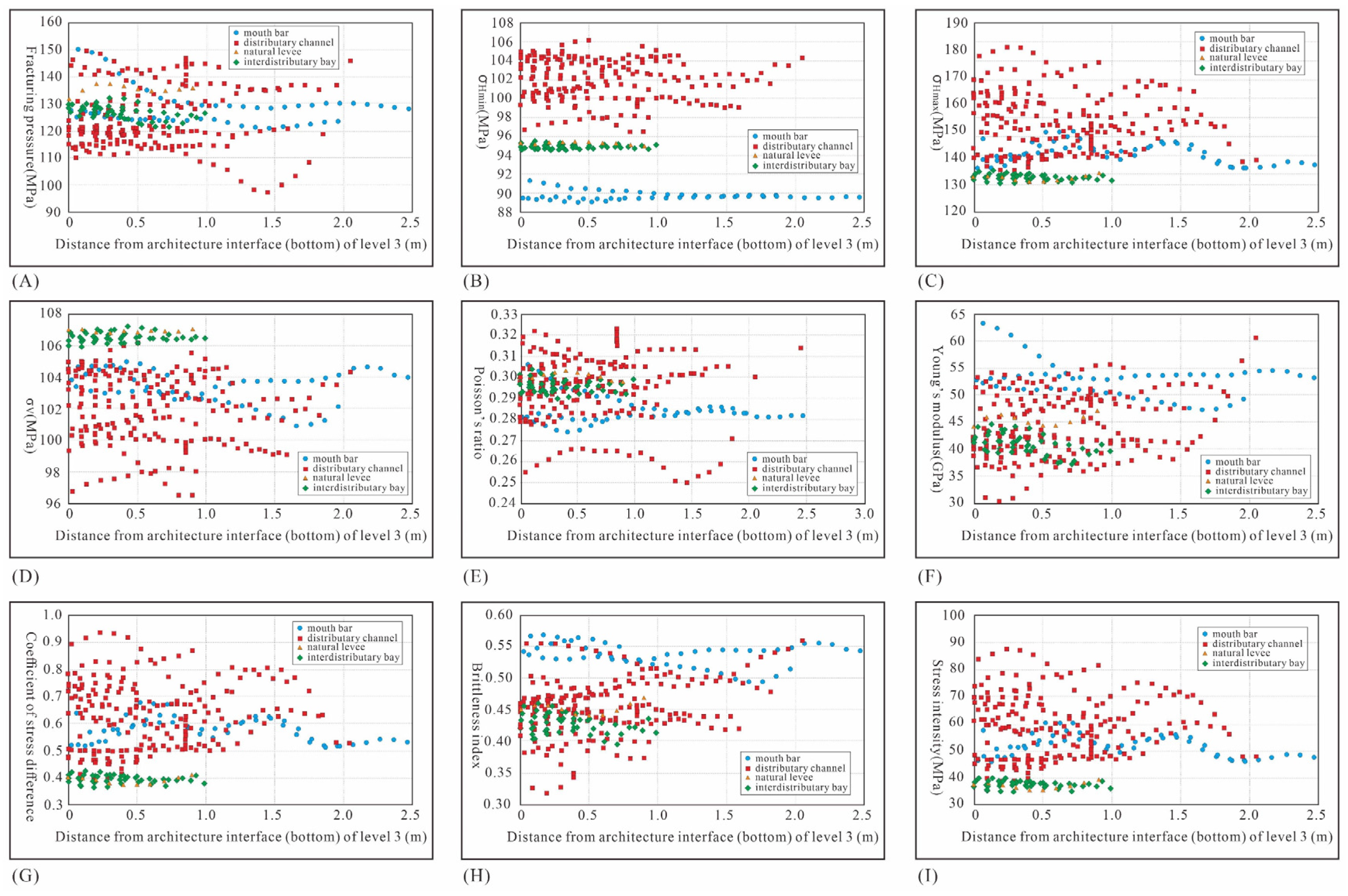

5.2. Geomechanical Response Characteristics on Reservoir Architecture Interface of Level 3

5.3. Geomechanical Response Characteristics on Reservoir Architecture Interface of Level 2

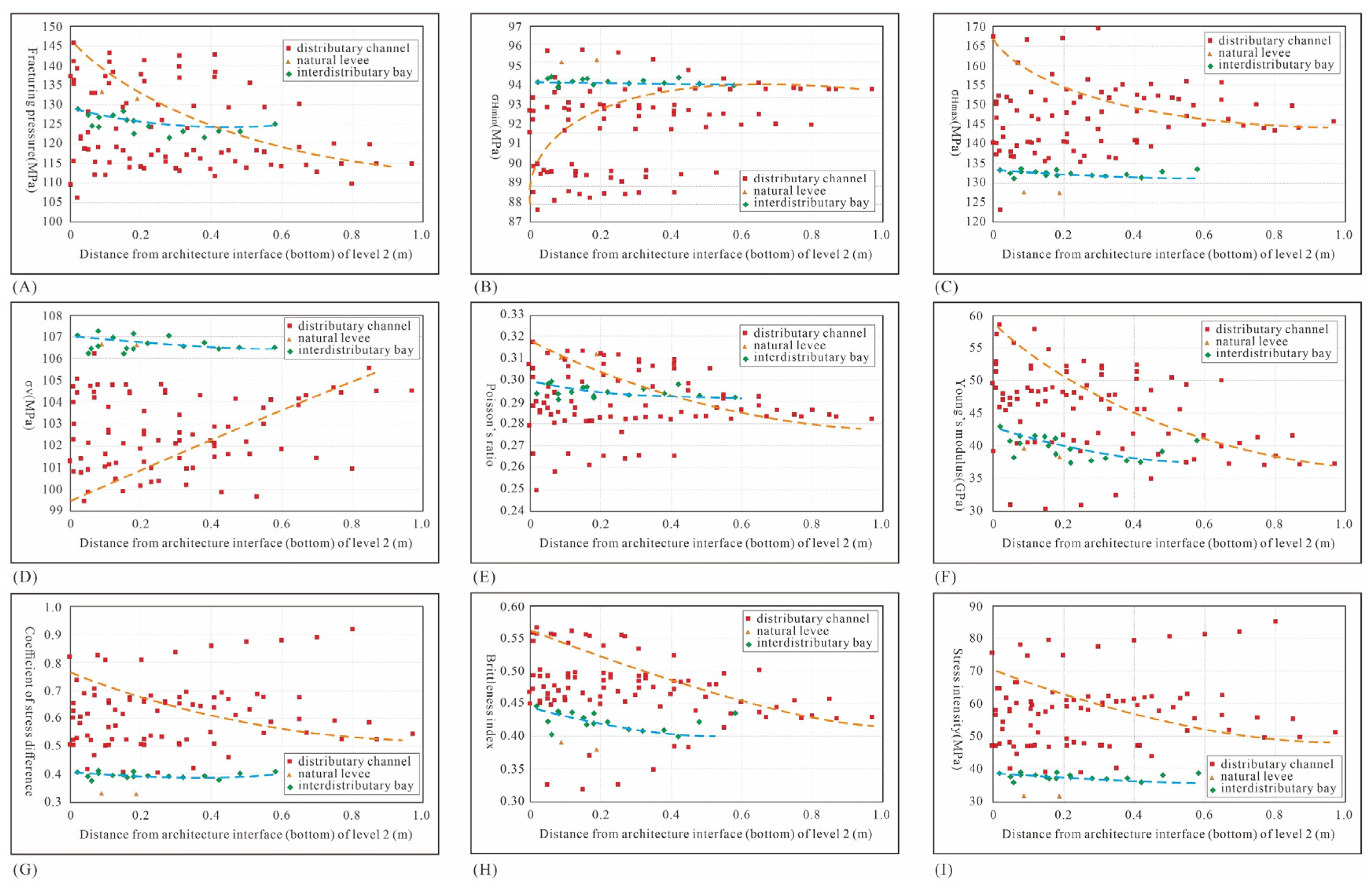

5.4. Response Characteristics of Fracture Parameters on Various Architecture Interfaces

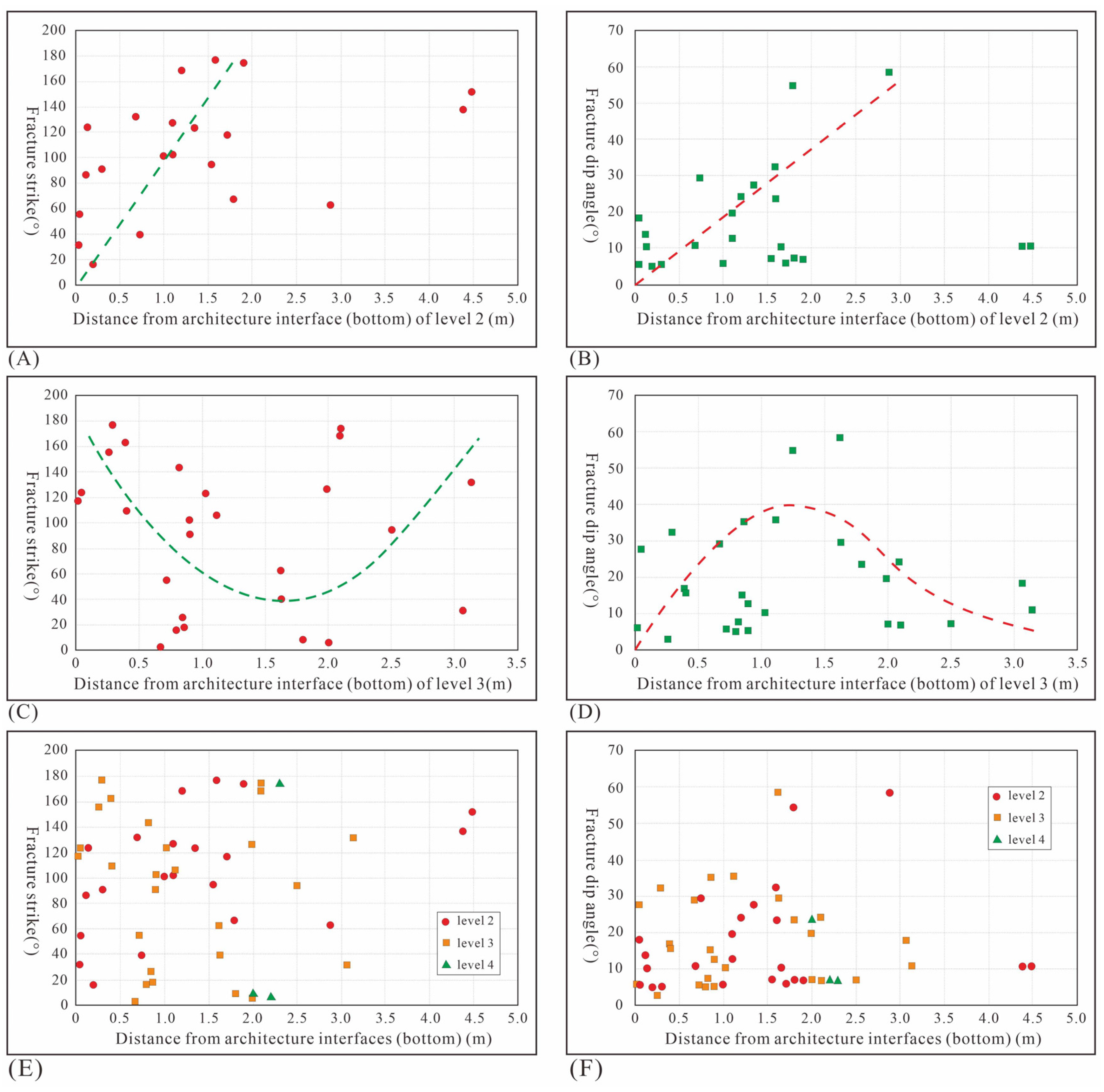

5.5. The Coupling Simulation among In Situ Stress, Fracture’s Parameter, and Reservoir Architecture Interfaces

6. Results and Conclusions

- (1)

- Young’s modulus ranged from 20 to 55 GPa, with lower values seen in specific sand groups. Poisson’s ratio was mainly between 0.28 and 0.34, with higher values observed in certain sand groups. The brittleness index varied from 0.24 to 0.53, indicating different elasticity and plasticity levels.

- (2)

- Effective distances controlled by level 4 architecture interfaces varied, affecting sedimentary hydrodynamic environments differently. Peaks and valleys shifted in geomechanical responses corresponded to changes in hydrodynamic cycles. Distances influenced by different architecture interfaces ranged from 0.6 to 2.5 m, highlighting varied environmental impacts. The Young’s modulus, Poisson’s ratio, coefficient of stress difference, brittle index, and stress intensity were key parameters in the sedimentary hydrodynamic environment.

- (3)

- Fracture characteristics were influenced by architecture interfaces, with distinct patterns seen at different levels. Fracture strike and dip angles varied based on proximity to specific interfaces, indicating strong or weak sedimentary hydrodynamic conditions. The loading stress, Young’s modulus, and Poisson’s ratio played significant roles for fracture dip and strike.

- (4)

- Three fracture face levels (I, II, III) were identified, each associated with different reservoir characteristics. Level I showed high fracture density and stress intensity, indicating good gas-bearing properties. Level II exhibited moderate fracture characteristics, while Level III displayed lower density and stress intensity, suggesting moderate gas potential.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jia, C.; Zheng, M.; Zhang, Y. Unconventional hydrocarbon resources in China and the prospect of exploration and development. Pet. Explor. Dev. 2012, 39, 129–136. [Google Scholar] [CrossRef]

- Zou, C.; Yang, Z.; Zhu, R.; Zhang, G.; Hou, L.; Wu, S.; Tao, S.; Yuan, X.; Dong, D.; Wang, Y.; et al. Progress in China’s unconventional oil & gas exploration and development and theoretical technologies. Acta Geol. Sin.-Engl. Ed. 2015, 89, 938–971. [Google Scholar]

- Guo, Y.; Pang, X.; Chen, D.; Jiang, F.; Tang, G. Progress of research on hydrocarbon accumulation of tight sand gas and several issues for concerns. Oil Gas Geol. 2013, 34, 717–724. [Google Scholar]

- Yang, H.; Zhang, R.; Yang, X.; Wang, K.; Wang, J.; Tang, Y.; Zhou, L. Characteristics and reservoir improvement effect of structural fracture in ultra-deep tight sandstone reservoir: A case study of Keshen Gasfield, Kuqa Depression, Tarim Basin. Nat. Gas Geosci. 2018, 29, 942–950. [Google Scholar]

- Olson, J.E.; Laubach, S.E.; Lander, R.H. Natural fracture characterization in tight gas sandstones: Integrating mechanics and diagenesis. AAPG Bull. 2009, 93, 1535–1549. [Google Scholar] [CrossRef]

- Ding, W.; Yin, S.; Wang, X.; Zhang, M.; Cao, X.; Liu, J. Progress in tight sandstone reservoir fractures research. Adv. Earth Sci. 2015, 30, 737–750. [Google Scholar]

- He, D.; Li, D.; Tong, X.; Wu, X. Integrated 3D hydrocarbon exploration in sedimentary basins of China. Oil Gas Geol. 2021, 42, 265–284. [Google Scholar]

- Li, W.; Liu, Z.; Hu, Z.; Jin, W.; Li, M.; Liu, J.; Xu, S.; Ma, A. Characteristics of and main factors controlling the tight sandstone reservoir fractures in the 2nd member of Xujiahe Formation in Xinchang area, Western Sichuan Depression, Sichuan Basin. Oil Gas Geol. 2021, 42, 884–897. [Google Scholar]

- Del Greco, O.; Ferrero, A.M.; Oggeri, C. Experimental and Analytical Interpretation of the Behaviour of Laboratory Tests on Composite Specimens. Int. J. Rock Mech. Min. Sci. 1993, 30, 1539–1543. [Google Scholar] [CrossRef]

- Gale, J.F.W.; Feed, R.M.; Holder, J. Natural fractures in the Barnett shale and their importance for hydraulic fracture treatments. AAPG Bull. 2007, 91, 603–622. [Google Scholar] [CrossRef]

- Dai, J.; Ni, Y.; Wu, X. Tight gas in China and its significance in exploration and exploitation. Pet. Explor. Dev. 2012, 39, 277–284. [Google Scholar] [CrossRef]

- Laubach, S.E.; Lander, R.H.; Criscenti, L.J.; Anovitz, L.M.; Urai, J.L.; Pollyea, R.M.; Hooker, J.N.; Narr, W.; Evans, M.A.; Kerisit, S.N.; et al. The role of chemistry in fracture pattern development and opportunities to advance interpretations of geological materials. Rev. Geophys. 2019, 57, 1065–1111. [Google Scholar] [CrossRef]

- Feng, J.; Zhao, L.; Wang, Y. Controlling factors for productivity of ultra-deep tight reservoirs in Keshen gas field, Kuqa depression. Acta Pet. Sin. 2020, 41, 478. [Google Scholar]

- Zhao, Z.; Tang, D.; Wang, X.; Chen, S. Discussion on main controlling factors of natural gas enrichment and high yield in tight sandstone gas reservoirs: Case study of Xujiahe Formation in Sichuan Basin. Nat. Gas Geosci. 2019, 30, 963–972. [Google Scholar]

- Long, S.; Cheng, Z.; Xu, H.; Chen, Q. Exploration domains and technological breakthrough directions of natural gas in SINOPEC exploratory areas, Sichuan Basin. Nat. Gas Geosci. 2020, 31, 1195–1203. [Google Scholar] [CrossRef]

- Zheng, H.; Liu, Z.; Xu, S.; Liu, Z.; Liu, J.; Huang, Z.; Huang, Y.; Shi, Z.; Wu, Q.; Fan, L.; et al. Progress and key research direction of tight gas exploration and development in Xujiahe Formation, Sinopec exploration areas, Sichuan Basin. Oil Gas Geol. 2021, 42, 765–783. [Google Scholar]

- Nelson, R.A. Geologic Analysis of Naturally Fractured Reservoirs; Gulf Publish Company: Houston, TX, USA, 1985. [Google Scholar]

- Gale, J.F.W.; Lander, R.H.; Reed, R.M.; Laubach, S.E. Modeling fractur porosity evolution in dolostone. J. Struct. Geol. 2010, 32, 1201–1211. [Google Scholar] [CrossRef]

- Ju, W.; You, Y.; Feng, S.; Xu, H.; Zhang, X.; Wang, S. Characteristics and genesis of bedding-parallel fractures in tight sandstone reservoirs of Chang 7 oil layer, Ordos Basin. Oil Gas Geol. 2020, 41, 596–605. [Google Scholar]

- Zeng, L.; Lyu, W.; Xu, X.; Tian, H.; Lu, S.; Zhang, M. Development characteristics, formation mechanism and hydrocarbon significance of bedding fractures in typical tight sandstone and shale. Acta Pet. Sin. 2022, 43, 180. [Google Scholar]

- Gong, L.; Su, X.; Gao, S.; Fu, X.; Jabbari, H.; Wang, X.; Liu, B.; Yue, W.; Wang, Z.; Gao, A. Characteristics and formation mechanism of natural fractures in the tight gas sandstones of Jiulongshan gas field, China. J. Pet. Sci. Eng. 2019, 175, 1112–1121. [Google Scholar] [CrossRef]

- Zeng, L.; Gong, L.; Guan, C.; Zhang, B.; Wang, Q.; Zeng, Q.; Lyu, W. Natural fractures and their contribution to tight gas conglomerate reservoirs: A case study in the northwestern Sichuan Basin, China. J. Pet. Sci. Eng. 2022, 210, 110028. [Google Scholar] [CrossRef]

- Laubach, S.E.; Eichhubl, P.; Hilgers, C.; Lander, R.H. Structural diagenesis. J. Struct. Geol. 2010, 93, 1413–1426. [Google Scholar] [CrossRef]

- Lyu, W.; Zeng, L.; Zhang, B.; Miao, F.; Lyu, P.; Dong, S. Influence of natural fractures on gas accumulation in the Upper Triassic tight gas sandstones in the northwestern Sichuan Basin, China. Mar. Pet. Geol. 2017, 83, 60–72. [Google Scholar] [CrossRef]

- Liu, G.; Zeng, L.; Zhu, R.; Gong, L.; Ostadhassan, M.; Mao, Z. Effective fractures and their contribution to the reservoirs in deep tight sandstones in the Kupa Depression, Tarim Basin, China. Mar. Pet. Geol. 2021, 124, 104824. [Google Scholar] [CrossRef]

- Swanson, S.K. Lithostratigraphic controls on bedding-plane fractures and the potential for discrete groundwater flow through a siliciclastic sandstone aquifer, southern Wisconsin. Sediment. Geol. 2007, 197, 65–78. [Google Scholar] [CrossRef]

- Smart, K.J.; Ofoegbu, G.I.; Morris, A.P.; McGinnis, R.N.; Ferrill, D.A. Geomechanical modeling of hydraulic fracturing: Why mechanical stratigraphy, stress state, and pre-existing structure matter. AAPG Bull. 2014, 98, 2237–2261. [Google Scholar] [CrossRef]

- Guo, X.; Hu, D.; Wei, X.; Li, Y. Main controlling factors on shale fractures and their influences on production capacity in Jiaoshiba area, the Sichuan Basin. Oil Gas Geol. 2016, 37, 799–808. [Google Scholar]

- Liu, D.; Zhang, C.; Luo, Q.; Zhang, Y.; Gao, Y.; Zhang, Y.; Zhu, D.; Wang, J. Development characteristics and controlling factors of natural fractures in Permian Lucaogou Formation tight reservoir in Jimsar sag, Junggar Basin. China Pet. Explor. 2017, 22, 36. [Google Scholar]

- Huang, D.; Li, B.; Ma, W.; Cen, D.; Song, Y. Effects of bedding planes on fracture behavior of sandstone under semi-circular bending test. Theor. Appl. Fract. Mech. 2020, 108, 102625. [Google Scholar] [CrossRef]

- Ismat, Z. Evolution of fracture porosity and permeability during folding by cataclastic flow: Implications for syntectonic fluid flow. Rocky Mt. Geol. 2012, 47, 133–155. [Google Scholar] [CrossRef]

- Chandler, M.R.; Meredith, P.G.; Brantut, N.; Crawford, B.R. Fracture toughness anisotropy in shale. J. Geophys. Res. Solid Earth 2016, 121, 1706–1729. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, D.; Luo, Q.; Liu, L.; Liu, D.; Yan, L.; Zhang, Y. Major factors controlling fracture development in the Middle Permian Lucaogou Formation tight oil reservoir, Junggar Basin, NW China. J. Asian Earth Sci. 2017, 146, 279–295. [Google Scholar] [CrossRef]

- Zhou, T.; Wang, H.; Li, F.; Li, Y.; Zou, Y.; Zhang, C. Numerical simulation of hydraulic fracture propagation in laminated shale reservoirs. Pet. Explor. Dev. 2020, 47, 1117–1130. [Google Scholar] [CrossRef]

- Cui, X.; Radwan, A. Coupling relationship between current in-situ stress and natural fractures of continental tight sandstone oil reservoirs. Interpretation 2022, 10, SF9–SF21. [Google Scholar] [CrossRef]

- Zhang, Y.; Zeng, L.; Lyu, W.; Sun, D.; Chen, S.; Guan, C.; Tang, L.; Shi, J.; Zhang, J. Natural fractures in tight gas sandstones: A case study of the Upper Triassic Xujiahe Formation in Xinchang gas field, Western Sichuan Basin, China. Geol. Mag. 2021, 158, 1543–1560. [Google Scholar] [CrossRef]

- Liu, Z.; Li, H.; Wu, Q.; Nan, Z.; Su, J.; Jin, W. Characteristics and application effect of logging-based fracture identification in tight sandstones: A case study of the Upper Triassic Xu 2 Member in Western Sichuan Depression, Sichuan Basin. Oil Gas Geol. 2021, 42, 981–991. [Google Scholar]

- Li, Y.; Deng, H.; He, J.; Ma, R. Reconstruction of paleo stress field after the depositional period of Leikoupo Formation in Pengzhou area, western Sichuan and its oil and gas geological significance. Acta Geol. Sin. 2022, 96, 2023007. [Google Scholar]

- Yin, J.; Gu, Z.; Li, Q. Characteristics of deep-rooted faults and their geological significances in Dachuanzhong area, Sichuan Basin. Oil Gas Geol. 2013, 34, 376–382. [Google Scholar]

- Qin, S.; Zhang, Y.; Zhao, C.; Zhou, Z. Geochemical evidence for in situ accumulation of tight gas in the Xujiahe Formation coal measures in the central Sichuan Basin, China. Int. J. Coal Geol. 2018, 196, 173–184. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, D.; Gao, X.; Wang, F.; Li, J.; Liao, W.; Wang, Z.; Xie, G. Microscopic pore structures of tight sandstone reservoirs and their diagenetic controls: A case study of the Upper Triassic Xujiahe Formation of the Western Sichuan Depression, China. Mar. Pet. Geol. 2020, 113, 104119. [Google Scholar] [CrossRef]

- Kang, D.; Tan, X.; Wang, X.; Liang, J.; Tu, L.; Wu, C. Tight gas accumulation elements and favorable zone evaluation of Xujiahe Formation in Sichuan Basin. Spec. Oil Gas Reserv. 2020, 27, 40–46. [Google Scholar]

- Miall, A.D. Architectural-element analysis: A new method of facies analysis applied to fluvial deposits. Earth-Sci. Rev. 1985, 22, 261–308. [Google Scholar] [CrossRef]

- Miall, A.D. Reconstructing the architecture and sequence stratigraphy of the preserved fluvial record as a tool for reservoir development: A reality check. AAPG Bull. 2006, 90, 989–1002. [Google Scholar] [CrossRef]

- Zhu, W.; Wu, S.; Yin, Z.; Han, T.; Wu, Y.; Liu, Y.; Feng, W.; Luo, Y.; Cao, C. Braided river delta outcrop architecture: A case study of Triassic Huangshanjie Formation in Kuche Depression, Tarim Basin, NW China. Pet. Explor. Dev. 2016, 43, 482–489. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Yuan, W.; Jiang, J.; Xie, Y.; Zhang, R.; Zhou, S.; Lou, H.; Wang, Z.; Zhang, H.; et al. Characteristics on reservoir architecture and quality of tight sandstone reservoirs: Taking Jurassic Ahe formation in Dibei area of Kuqa foreland basin as an example. J. China Univ. Min. Technol. 2021, 50, 877–892. [Google Scholar]

- Jiang, Y.; Li, M.; Wang, L.; Liu, J.; Zeng, T.; Zhao, C. Characteristics and controlling factors of tight sandstone reservoir fractures of the Xujiahe Formation in the Bazhong-Tongnanba area, Northeast Sichuan. Acta Geol. Sin. 2020, 94, 1525–1537. [Google Scholar]

- Ren, Q.; Jin, Q.; Feng, J.; Li, M. Simulation of stress fields and quantitative prediction of fractures distribution in upper Ordovician biological limestone formation within Hetianhe field, Tarim Basin, NW China. J. Pet. Sci. Eng. 2019, 173, 1236–1253. [Google Scholar] [CrossRef]

- Ren, Q.; Feng, J.; Johnston, S.; Du, H. The influence of argillaceous content in carbonate rocks on the 3D modeling and characterization of tectonic fracture parameters—Example from the Carboniferous and Ordovician formations in the Hetianhe gas field, Tarim Basin, NW China. J. Pet. Sci. Eng. 2021, 203, 108668. [Google Scholar] [CrossRef]

| Top Depth/m | Bottom Depth/m | Thickness | Lithology/Architecture | E/GPa | µ | Density/kg/m3 |

|---|---|---|---|---|---|---|

| 4067.83 | 4068.33 | 0.5 | fine sandstone | 44.75 | 0.291 | 2476 |

| 4068.33 | 4068.43 | 0.1 | medium sandstone | 45.14 | 0.290 | 2485 |

| 4068.43 | 4068.54 | 0.11 | sand wave lamination | 45.36 | 0.289 | 2494 |

| 4068.54 | 4069.13 | 0.59 | medium sandstone | 45.88 | 0.285 | 2513 |

| 4069.13 | 4069.25 | 0.12 | parallel bedding | 47.29 | 0.287 | 2530 |

| 4069.25 | 4069.63 | 0.38 | medium sandstone | 47.92 | 0.287 | 2536 |

| 4069.63 | 4070.05 | 0.42 | parallel bedding | 47.30 | 0.282 | 2537 |

| 4070.05 | 4071.05 | 1.00 | fine sandstone | 49.00 | 0.287 | 2536 |

| 4071.05 | 4072.33 | 1.28 | medium sandstone | 56.50 | 0.290 | 2604 |

| 4072.33 | 4072.73 | 0.40 | medium sandstone | 58.21 | 0.298 | 2593 |

| 4072.73 | 4073.12 | 0.39 | fine sandstone | 52.40 | 0.287 | 2577 |

| 4073.12 | 4074.16 | 1.04 | medium sandstone | 48.53 | 0.284 | 2548 |

| 4074.16 | 4074.33 | 0.17 | fine sandstone | 50.59 | 0.282 | 2575 |

| 4074.33 | 4074.38 | 0.05 | parallel bedding | 50.74 | 0.281 | 2578 |

| 4074.38 | 4075.16 | 0.78 | fine sandstone | 51.29 | 0.281 | 2582 |

| 4075.16 | 4075.62 | 0.46 | medium sandstone | 53.48 | 0.276 | 2621 |

| 4075.62 | 4075.92 | 0.30 | fine sandstone | 52.95 | 0.279 | 2608 |

| 4075.92 | 4077.02 | 1.10 | medium sandstone | 53.84 | 0.283 | 2606 |

| 4077.02 | 4077.62 | 0.60 | medium sandstone | 53.28 | 0.286 | 2587 |

| 4077.62 | 4078.47 | 0.85 | fine sandstone | 58.18 | 0.297 | 2601 |

| 4078.47 | 4079.37 | 0.90 | medium sandstone | 66.98 | 0.313 | 2630 |

| 4079.37 | 4080.05 | 0.68 | fine sandstone | 55.20 | 0.281 | 2620 |

| 4080.05 | 4080.15 | 0.10 | fine sandstone | 50.60 | 0.268 | 2622 |

| 4080.15 | 4080.25 | 0.10 | medium sandstone | 52.91 | 0.276 | 2621 |

| 4080.25 | 4080.35 | 0.10 | fine sandstone | 54.57 | 0.281 | 2620 |

| 4080.35 | 4080.45 | 0.10 | medium sandstone | 55.54 | 0.274 | 2618 |

| 4080.45 | 4080.50 | 0.05 | sand wave lamination | 56.92 | 0.288 | 2618 |

| 4080.50 | 4080.70 | 0.20 | fine sandstone | 57.73 | 0.289 | 2621 |

| 4080.70 | 4081.12 | 0.42 | medium sandstone | 60.55 | 0.296 | 2625 |

| 4081.12 | 4081.52 | 0.40 | fine sandstone | 52.85 | 0.281 | 2588 |

| 4081.52 | 4082.31 | 0.79 | medium sandstone | 40.80 | 0.257 | 2542 |

| 4082.31 | 4082.41 | 0.10 | fine sandstone | 45.56 | 0.265 | 2571 |

| 4082.41 | 4082.61 | 0.20 | medium sandstone | 47.29 | 0.265 | 2586 |

| 4082.61 | 4082.81 | 0.20 | fine sandstone | 48.54 | 0.266 | 2596 |

| 4082.81 | 4083.17 | 0.36 | parallel bedding | 48.69 | 0.261 | 2610 |

| 4083.17 | 4083.26 | 0.09 | medium sandstone | 47.33 | 0.255 | 2610 |

| 4083.26 | 4083.36 | 0.10 | fine sandstone | 46.57 | 0.252 | 2610 |

| 4083.36 | 4083.41 | 0.05 | sand wave lamination | 45.85 | 0.249 | 2609 |

| 4083.41 | 4083.56 | 0.15 | medium sandstone | 45.88 | 0.247 | 2618 |

| 4083.56 | 4083.66 | 0.10 | fine sandstone | 46.33 | 0.247 | 2624 |

| 4083.66 | 4083.83 | 0.17 | medium sandstone | 47.63 | 0.251 | 2628 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Q.; Li, L.; Cai, L.; Feng, J.; Li, M.; Wang, X. Geomechanical Response Characteristics of Different Sedimentary Hydrodynamic Cycles—Exampled by Xujiahe Formation of Upper Triassic, Western Sichuan Basin. Sustainability 2024, 16, 4304. https://doi.org/10.3390/su16104304

Ren Q, Li L, Cai L, Feng J, Li M, Wang X. Geomechanical Response Characteristics of Different Sedimentary Hydrodynamic Cycles—Exampled by Xujiahe Formation of Upper Triassic, Western Sichuan Basin. Sustainability. 2024; 16(10):4304. https://doi.org/10.3390/su16104304

Chicago/Turabian StyleRen, Qiqiang, Lifei Li, Laixing Cai, Jianwei Feng, Mengping Li, and Xingjian Wang. 2024. "Geomechanical Response Characteristics of Different Sedimentary Hydrodynamic Cycles—Exampled by Xujiahe Formation of Upper Triassic, Western Sichuan Basin" Sustainability 16, no. 10: 4304. https://doi.org/10.3390/su16104304

APA StyleRen, Q., Li, L., Cai, L., Feng, J., Li, M., & Wang, X. (2024). Geomechanical Response Characteristics of Different Sedimentary Hydrodynamic Cycles—Exampled by Xujiahe Formation of Upper Triassic, Western Sichuan Basin. Sustainability, 16(10), 4304. https://doi.org/10.3390/su16104304